Exhaust manifold having improved NVH characteristics

a technology of exhaust manifold and nvh, which is applied in the direction of mechanical equipment, machines/engines, other domestic objects, etc., can solve the problems of reducing the fuel efficiency of the vehicle, affecting the performance of the exhaust manifold, so as to improve the exhaust manifold and reduce the nvh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

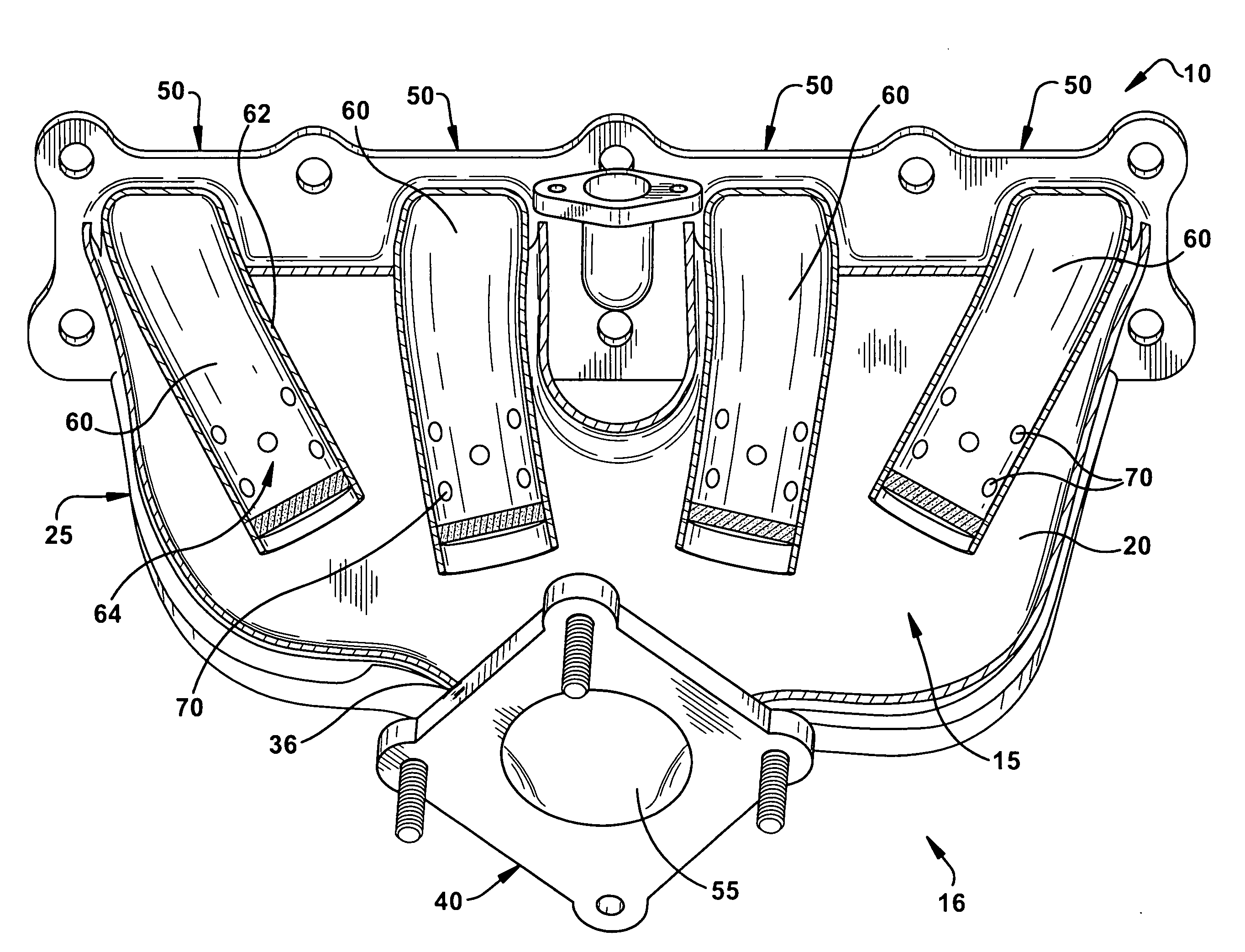

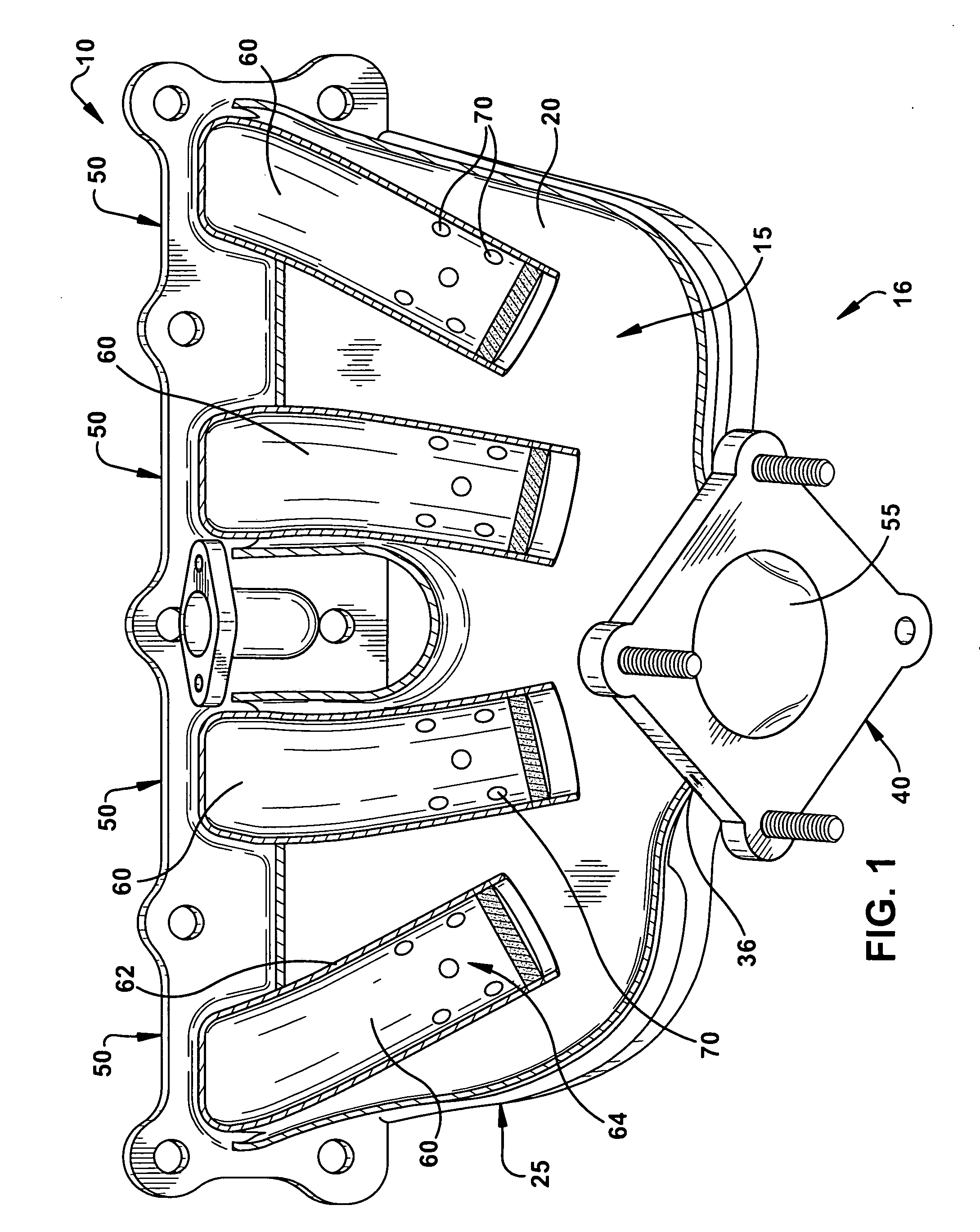

[0012]Referring now to FIG. 1, an exhaust manifold 10 is illustrated. The manifold 10 may include a lower half shell 20 and an upper half shell (not shown). The lower half shell 20 and the upper half shell may be integrally formed, attached, such as by welding or fastening, or otherwise joined together. The upper half shell and the lower half shell 20 may be joined to define a housing 25.

[0013]The housing 25 may be defined between the upper half shell and the lower half shell 20. The housing 25 may have an outlet flange 40 providing fluid communication between an interior 15 of the housing 25 and an exterior 16 of the housing 25. The outlet flange 40 may have an opening 55 permitting fluid communication between the remainder of the exhaust system and the housing 25. The outlet flange 40 may be sized and shaped for attachment to a remaining portion of the exhaust system (e.g. exhaust piping, turbocharger, etc.). The outlet flange 40 may be connected to the housing 25, such as to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com