High strength steel plate and method for production thereof

a technology of steel plate and high strength, applied in the field of steel plate, can solve the problems of deformation of toughness and hic resistance, inability to achieve sufficient strength, etc., and achieve the effects of high strength, excellent hic resistance, and low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

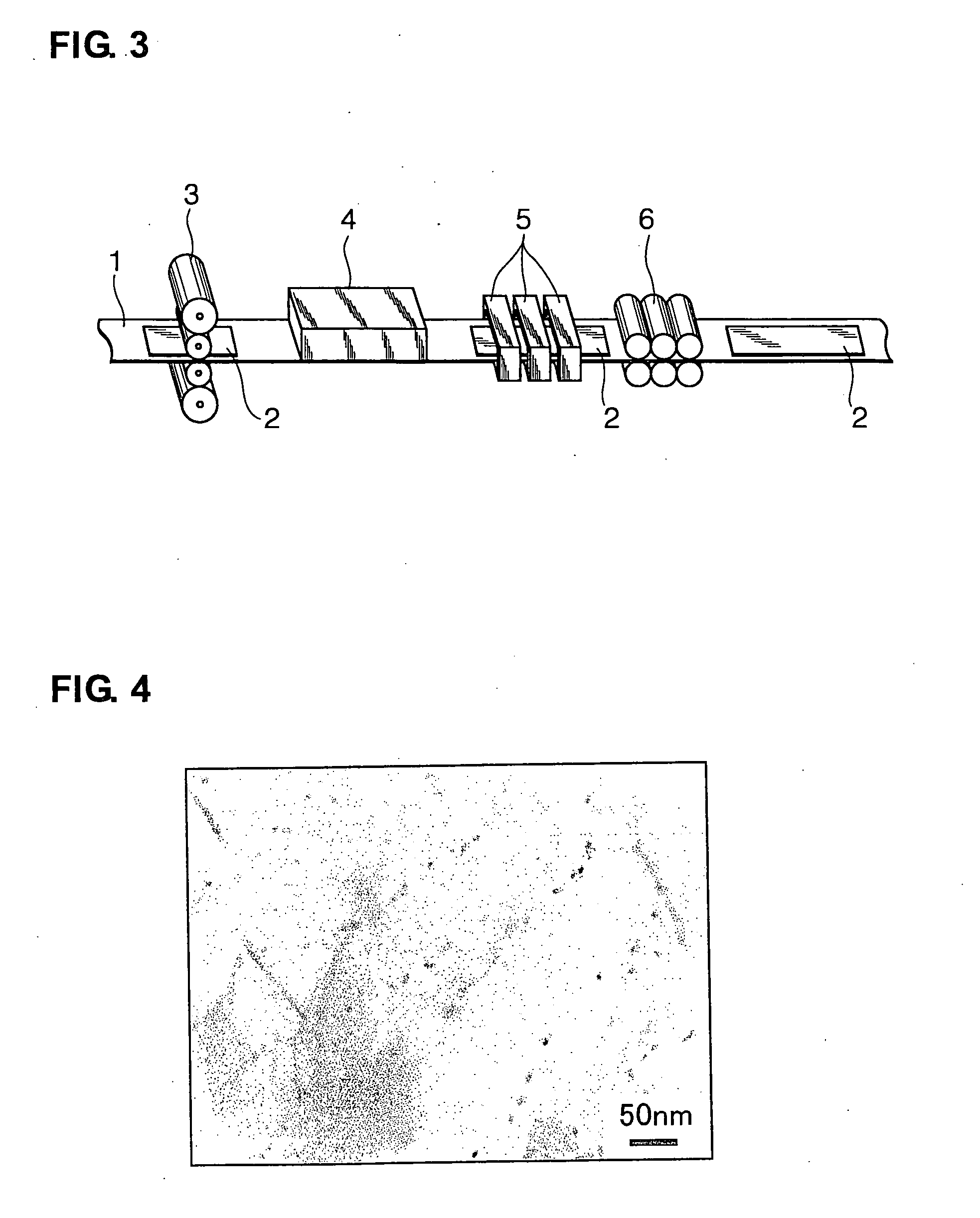

[0041] To obtain both excellent HIC resistance and high strength, the inventors of the present invention studied microstructure of steel, and found that a two phase microstructure of ferrite and bainite is the most effective. That is, for improving HIC resistance, the ferrite is effective, and for improving strength, the bainite is effective. The two phase microstructure of ferrite and bainite, which is generally used in high strength steels, is a mixed microstructure of soft ferrite and hard bainite. That kind of microstructure tends to accumulate hydrogen atoms at the interface between ferrite and bainite, and the interface acts as a route for propagating crack, thus degrading HIC resistance. The inventors of the present invention, however, found that both high strength and excellent HIC resistance are attained by adjusting the strength of ferrite and that of bainite to control the difference in hardness therebetween to a specific range. Furthermore, the inventors of the present i...

second embodiment

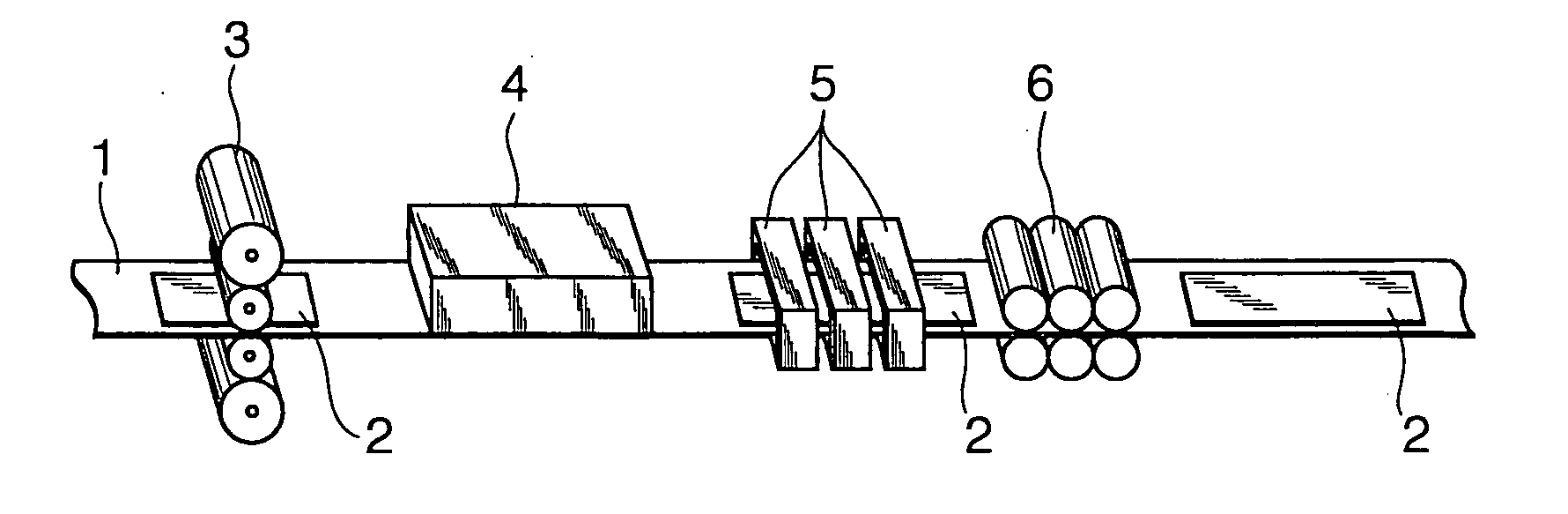

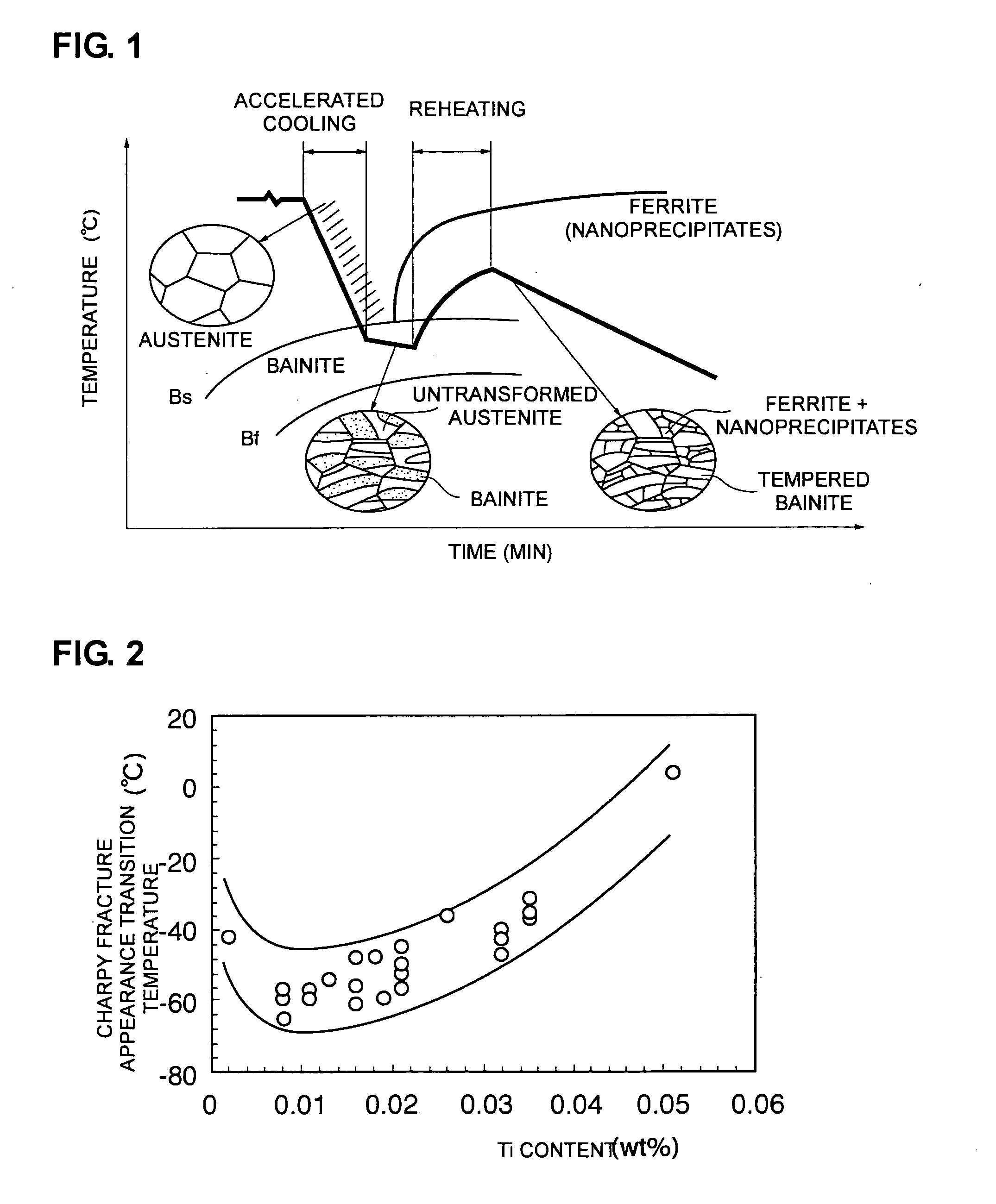

[0081] To obtain both excellent HIC resistance and high strength, the inventors of the present invention studied in detail microstructure of steel and method for manufacturing thereof, and found that it is the most effective to form a two phase microstructure of ferrite and bainite for attaining both high strength and excellent HIC resistance, and to reduce the difference in strength between ferrite and bainite, and that manufacturing process including accelerated cooling after hot rolling followed by reheating induces strengthening of ferrite which was a soft phase by fine precipitates containing Ti, Mo, and the like, and the softening of bainite which was a hard phase, thus obtaining the two phase microstructure with small difference in strength therebetween. It was concretely found that desired microstructure is obtained firstly by accelerated cooling the steel plate after hot rolling to form a two phase microstructure of untransformed austenite and bainite, and then by reheating...

third embodiment

[0132] In the second embodiment, the inventors of the present invention found that both HIC resistance and high strength are available even if a part or whole of Mo is substituted by W.

[0133] High strength steel plate for line pipe according to the third embodiment will be described in detail in the following.

[0134] First, precipitates dispersed in ferrite according to the third embodiment will be discussed.

[0135] In the steel plate according to the third embodiment, ferrite is strengthened by dispersed precipitates containing basically Mo, W, and Ti, or W and Ti in ferrite, and the difference in strength between ferrite and bainite is decreased, thus giving excellent HIC resistance. Since the precipitates are extremely fine, they do not give influence on HIC resistance. Mo, W, and Ti are the elements of forming carbides in steel, and strengthening by precipitating MoC, WC, and TiC is well known in the related art. In the third embodiment, however, strength increase is attained o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com