Induction heating quenching and tempering system

An induction heating and quenching and tempering technology, which is applied in the direction of improving process efficiency and energy efficiency, can solve the problems of easy deformation and large hardness difference between core and surface, so as to achieve less cooling and no deformation of the workpiece, small hardness difference between core and surface, and improve The effect of uniformity and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

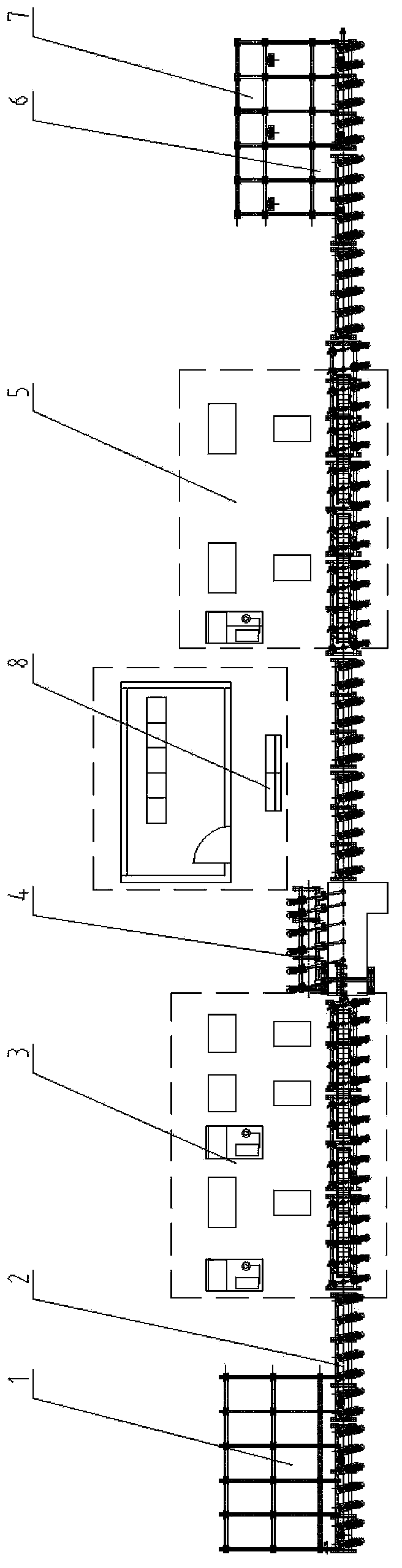

[0026] Such as figure 1 As shown, the induction heating quenching and tempering system of the present invention is suitable for quenching and tempering heat treatment of automobile rack blanks and connecting rod rods. It includes a feeding mechanism 1, an adjustable conveying system 2, an induction quenching heating unit 3, an adjustable spray ring type quenching cooling mechanism 4, an induction tempering heating unit 5, a chain cooling bed 6, an outlet Material mechanism 7 and an electric control system 8 are formed. The adjustable conveying system is used for several workpieces to be transported forward and backward while rotating, and the electrical control system is used for controlling the induction heating conditioning system.

[0027] Wherein, the adjustable conveying system 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com