Preparation method of coated alloy wire

A technology of alloy wire and cladding, which is applied in the field of preparation of cladding alloy wire, can solve problems such as poor passability, uneven distribution, and excessive carbide particle size, and achieve the effect of reducing hardness difference and improving elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

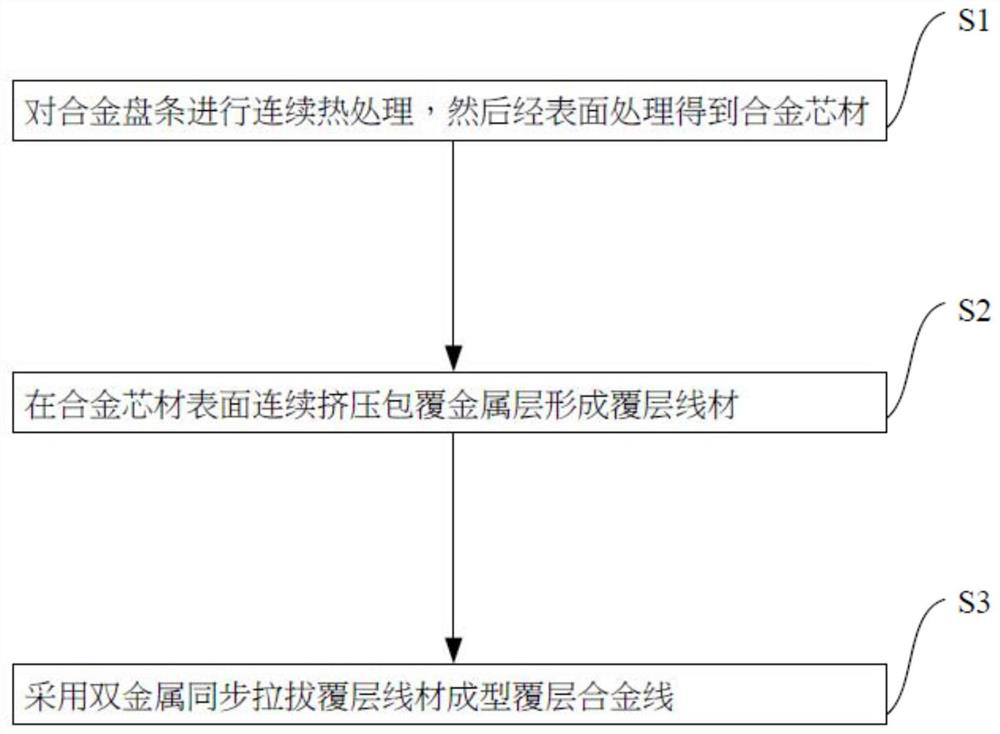

[0032] see figure 1 , the present application relates to a preparation method of clad alloy wire, comprising the following steps:

[0033] Step S1, performing continuous heat treatment on the alloy wire rod, and then obtaining the alloy core material through surface treatment; wherein, the heating temperature of the continuous heat treatment is 680-820°C, the wire speed is 1.5-5m / min, and the alloy wire rod includes Invar wire rod or One of the iron-nickel alloy wire rods.

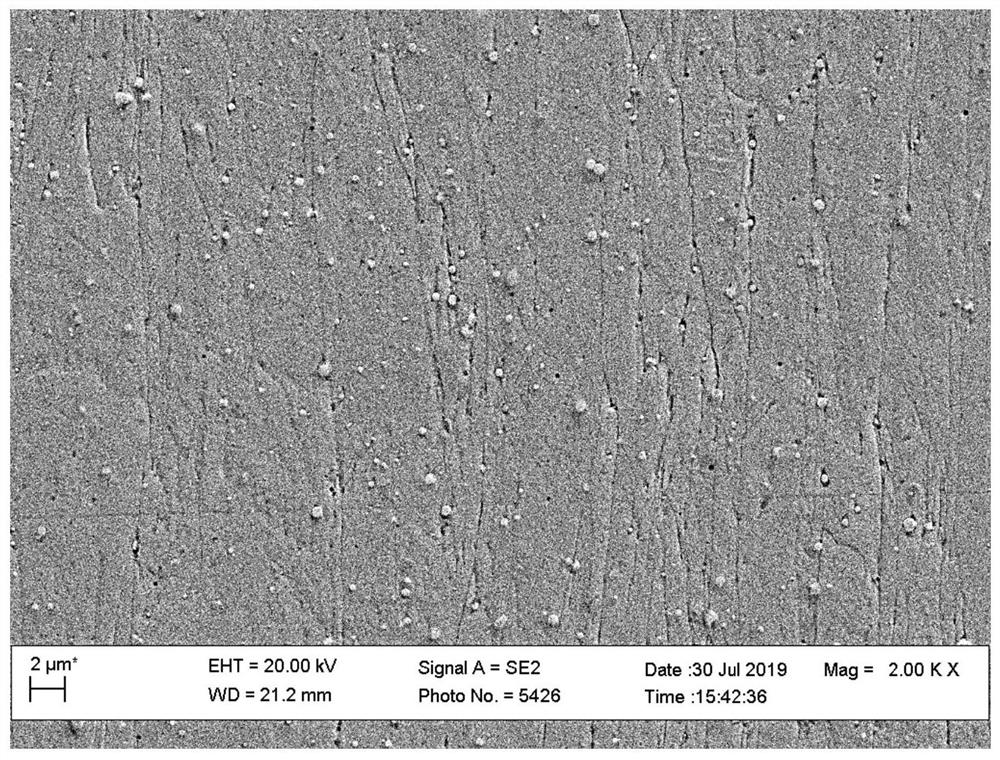

[0034] The main components of existing invar wire rods or iron-nickel alloy wire rods are Ni, Mo, V, Cr, C and other main chemical elements, and the structure, tensile strength, and linear expansion of invar materials are optimized by adjusting the chemical composition ratio. coefficient. In general Invar wire rod or iron-nickel alloy wire rod (such as 4J36, 4J38, etc.), the mass fraction of V element is between 0.4% and 1.2%, the mass fraction of Mo element is between 0.5% and 2.8%, and the mass fractio...

Embodiment 1

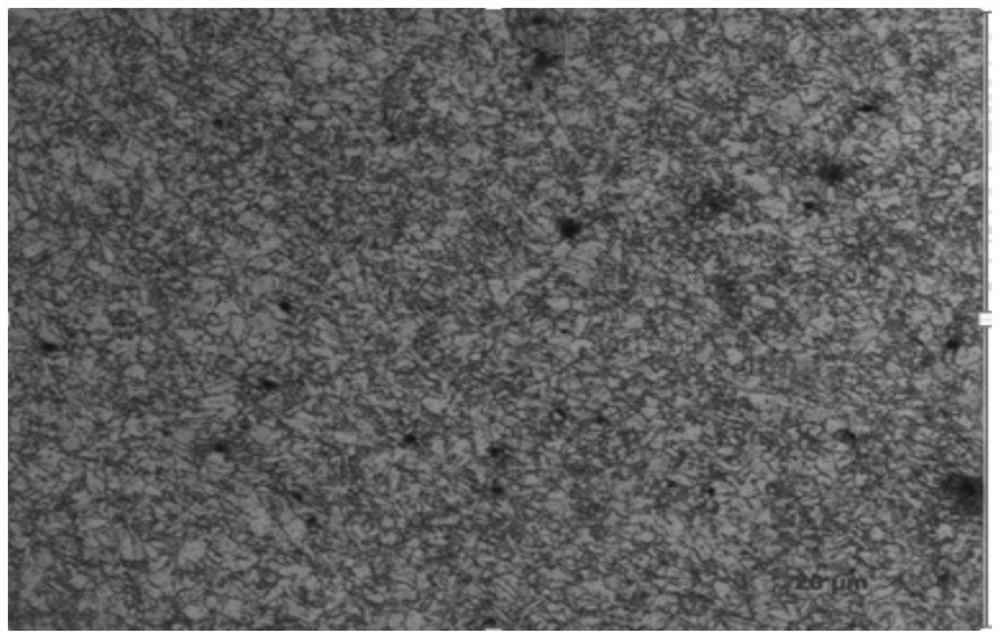

[0072] Invar wire rods with a diameter of 4.0 mm were sequentially processed on-line in a natural gas continuous heat treatment furnace, on-line abrasive belt polishing, and on-line 5 MPa high-pressure water washing to obtain Invar core materials. Among them, the heating temperature of the heat treatment furnace is 700°C, the running speed of the Invar wire rod is 3.6m / min, the strength of the Invar wire rod after treatment is 1120MPa, and the elongation is 12.2%; the mesh number of the abrasive belt is 120, and the rotation coefficient of the abrasive belt is is 0.6.

[0073]A uniformly coated aluminum layer is formed on the surface of the Invar core material by continuous extrusion cladding technology, and the cladding wire is formed. Wherein, the cladding temperature is 420° C., the cladding speed is 130 m / min, and the diameter of the cladding wire is 4.50 mm.

[0074] Calcium stearate was used as the lubricant to carry out 6-pass bimetal synchronous drawing on the coated ...

Embodiment 2

[0076] The 4J36 iron-nickel alloy wire rod with a diameter of 4.4mm was sequentially processed on-line in a natural gas continuous heat treatment furnace, on-line abrasive belt polishing and on-line 10MPa high-pressure water washing to obtain an iron-nickel alloy core material. Among them, the heating temperature of the heat treatment furnace is 720°C, the running speed of the iron-nickel alloy wire rod is 3.3m / min, the strength of the iron-nickel alloy wire rod after treatment is 1100MPa, and the elongation is 11.4%; the mesh number of the abrasive belt is 120, the belt rotation coefficient is 0.7.

[0077] A uniformly coated aluminum alloy layer is formed on the surface of the iron-nickel alloy core material by continuous extrusion cladding technology, and the cladding wire is formed. Wherein, the cladding temperature is 430° C., the cladding speed is 130 m / min, and the diameter of the cladding wire is 4.95 mm.

[0078] Sodium stearate was used as lubricant to carry out 6-p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com