A kind of preparation method of modified asparagus fiber

A technology of asparagus fiber and asparagus, which is applied in the field of textile materials, can solve the problems of not much mechanical performance of asparagus fiber, improvement of spinnability and functionality, limited degumming rate of asparagus, etc. Achieve the effects of improving spinnability, improving handle and softness, and improving structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

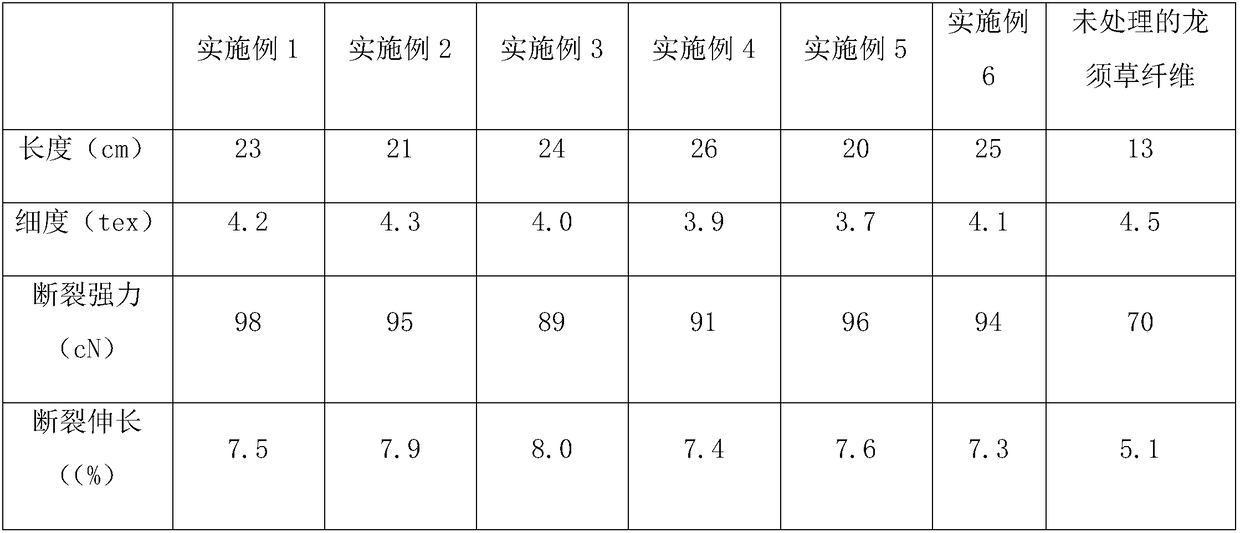

Examples

Embodiment 1

[0027] (1) Using fresh asparagus with high maturity as raw material, let it dry naturally until the water content is 8.5%, remove impurities by mechanical beating, soak in deionized water, and ultrasonically remove impurities and soften for 60-90min under 200W power to obtain the pre-treated Processed asparagus.

[0028] (2) Immerse the pretreated asparagus asparagus prepared in step (1) in the degumming solution, heat and ultrasonically treat it at 45°C and 200W power for 30min, take it out and wash it fully, and obtain degummed asparagus asparagus with a residual glue rate of 15% The grass fiber, wherein the components in the degumming solution, by weight, include: 30 parts of sodium hydroxide, 10 parts of potassium dihydrogen phosphate, and 60 parts of deionized water.

[0029] (3) Immerse the degummed asparagus fiber prepared in step (2) in 2 g / L acetic anhydride mixed with glacial acetic acid solution, raise the temperature to 50° C. Fully washed with water and dried to ...

Embodiment 2

[0032] (1) Using fresh asparagus with high maturity as raw material, let it dry naturally until the water content is 8.8%, remove impurities by mechanical beating, soak in deionized water, and ultrasonically remove impurities and soften for 90 minutes at a power of 250W to obtain pretreated Asparagus.

[0033] (2) Immerse the pretreated asparagus asparagus prepared in step (1) in the degumming solution, heat and ultrasonically treat it at 50°C and 200W power for 60min, take it out and wash it fully, and obtain degummed asparagus asparagus with a residual glue rate of 18% The grass fiber, wherein the components in the degumming solution, by weight, include: 50 parts of sodium hydroxide, 30 parts of potassium dihydrogen phosphate, and 80 parts of deionized water.

[0034] (3) Immerse the degummed asparagus fiber prepared in step (2) in 5 g / L acetic anhydride mixed with glacial acetic acid solution, raise the temperature to 50° C. Fully washed with water and dried to obtain acet...

Embodiment 3

[0037] (1) Use fresh asparagus with high maturity as raw material, let it dry naturally until the water content is 8.6%, remove impurities by mechanical beating, soak in deionized water, and ultrasonically remove impurities and soften for 70 minutes under 220W power to obtain pretreated Asparagus.

[0038] (2) Immerse the pretreated Asparagus japonica prepared in step (1) in the degumming solution, heat and ultrasonically treat it at 47°C and 200W power for 40min, take it out and wash it fully, and obtain the degummed asparagus asparagus with a residual glue rate of 16%. The grass fiber, wherein the components in the degumming solution, by weight, include: 20 parts of sodium hydroxide, 15 parts of potassium dihydrogen phosphate, and 70 parts of deionized water.

[0039] (3) Immerse the degummed asparagus fiber prepared in step (2) in 3 g / L acetic anhydride mixed with glacial acetic acid solution, raise the temperature to 50°C and keep warm for acetic acid esterification for 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com