Patents

Literature

35results about How to "Guaranteed looseness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

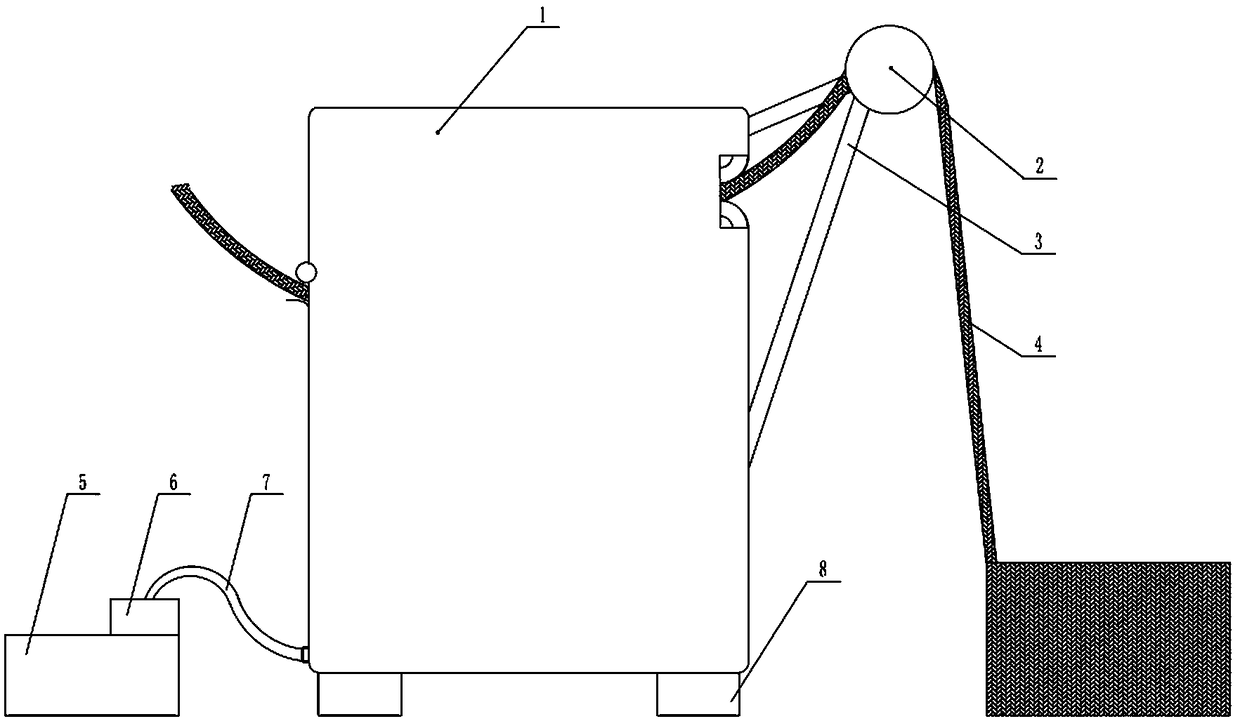

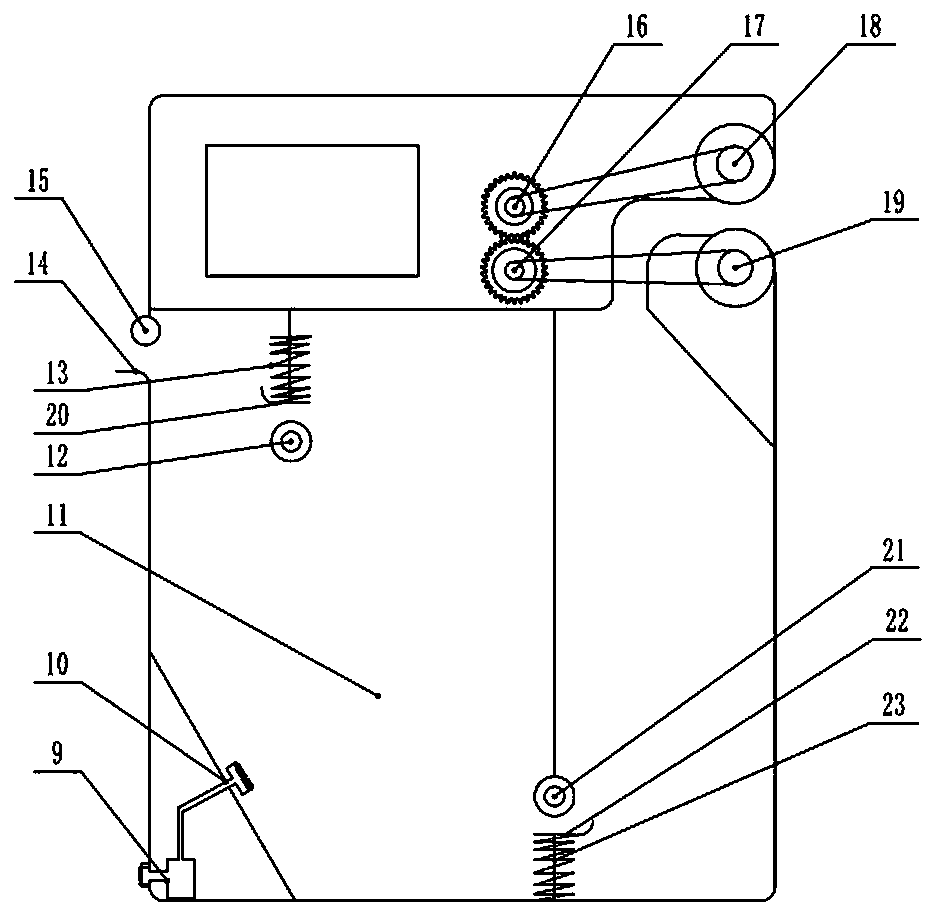

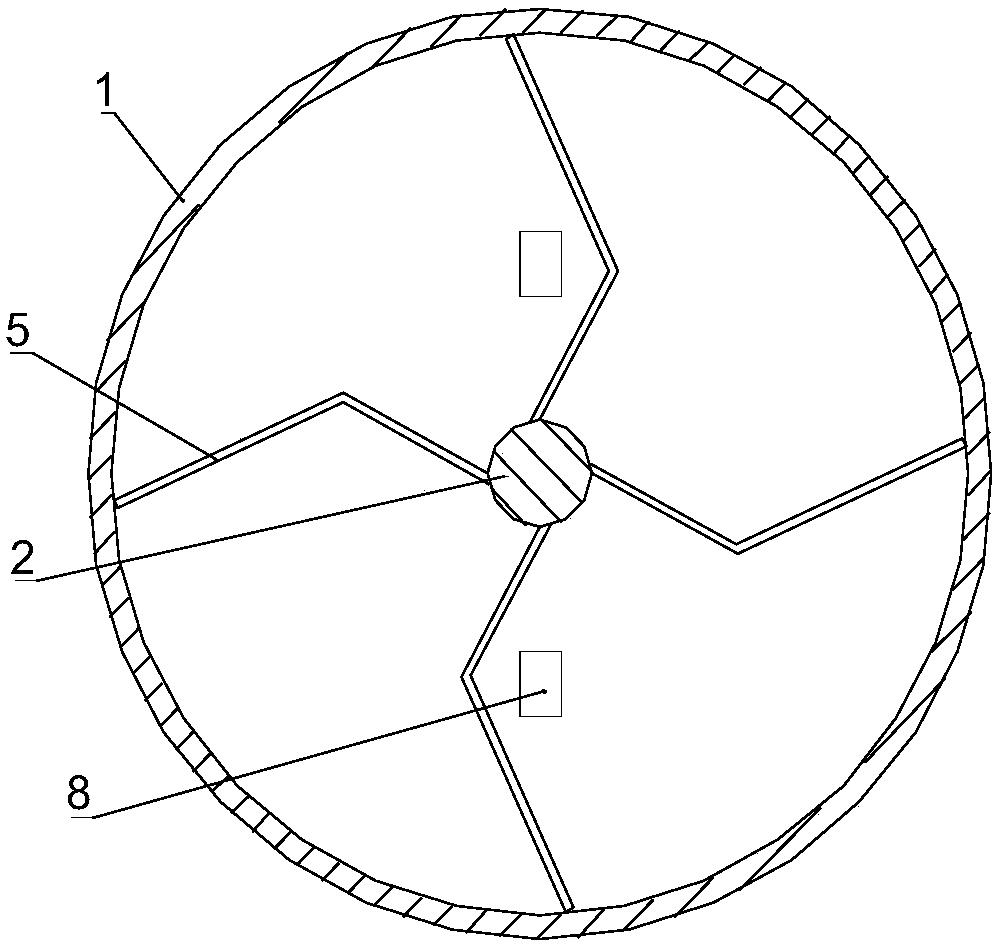

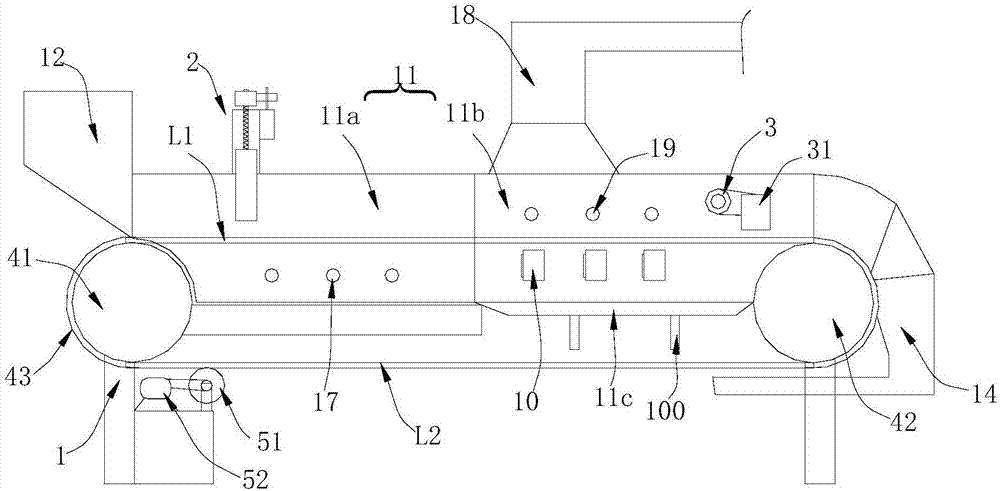

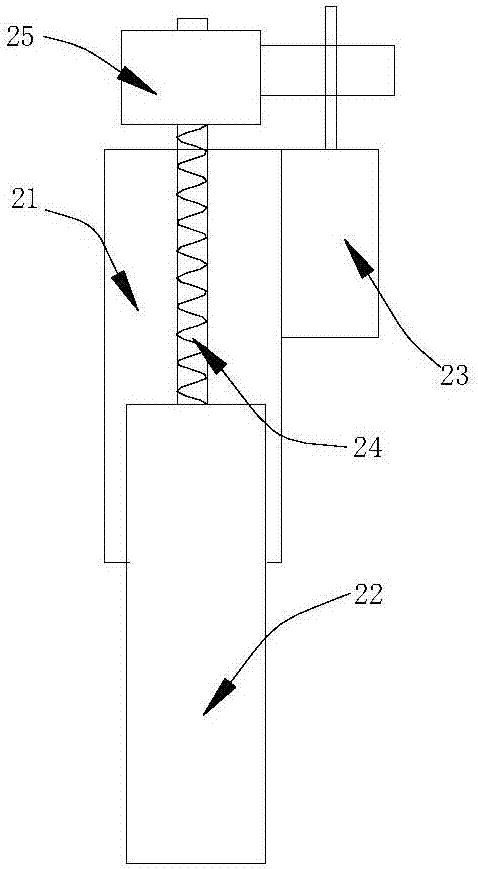

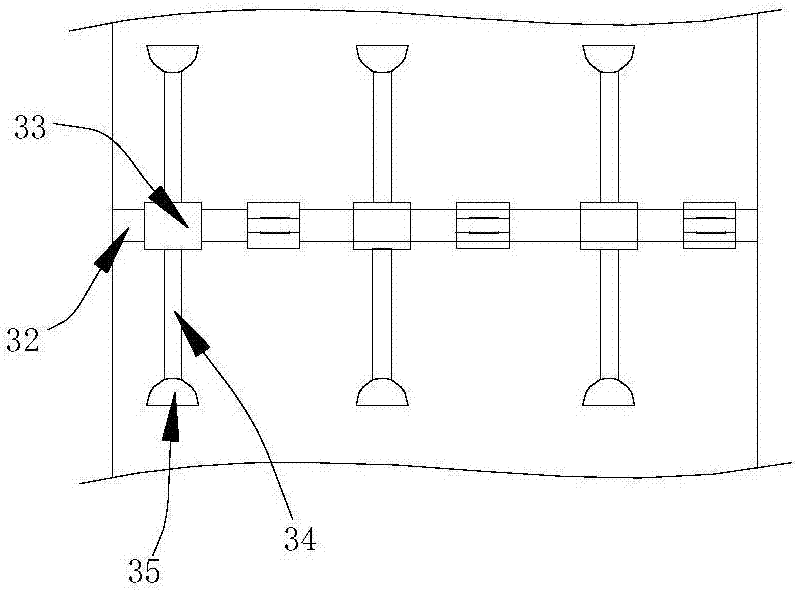

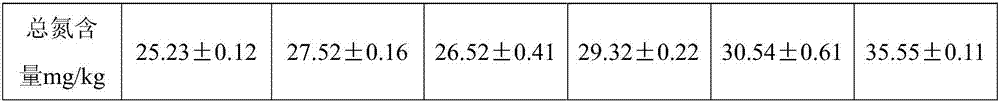

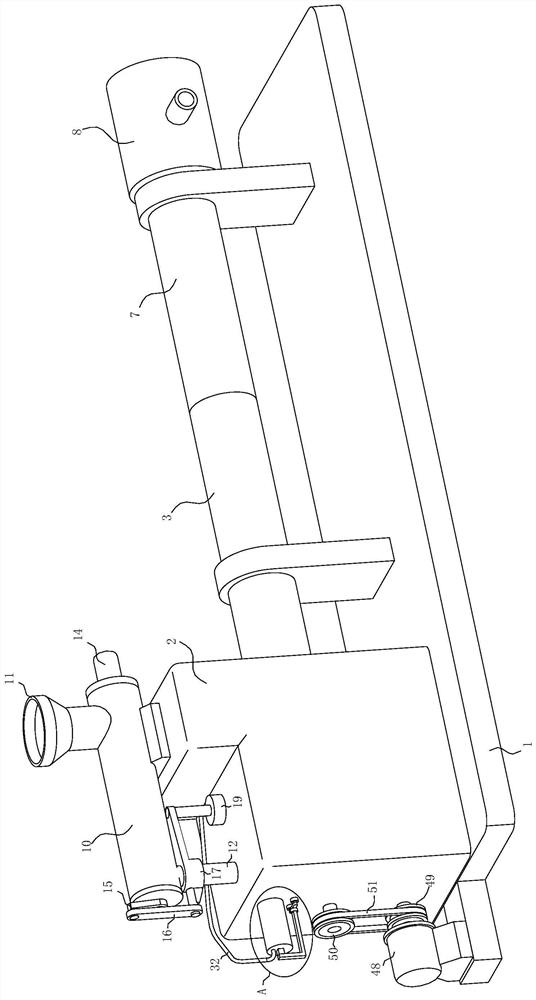

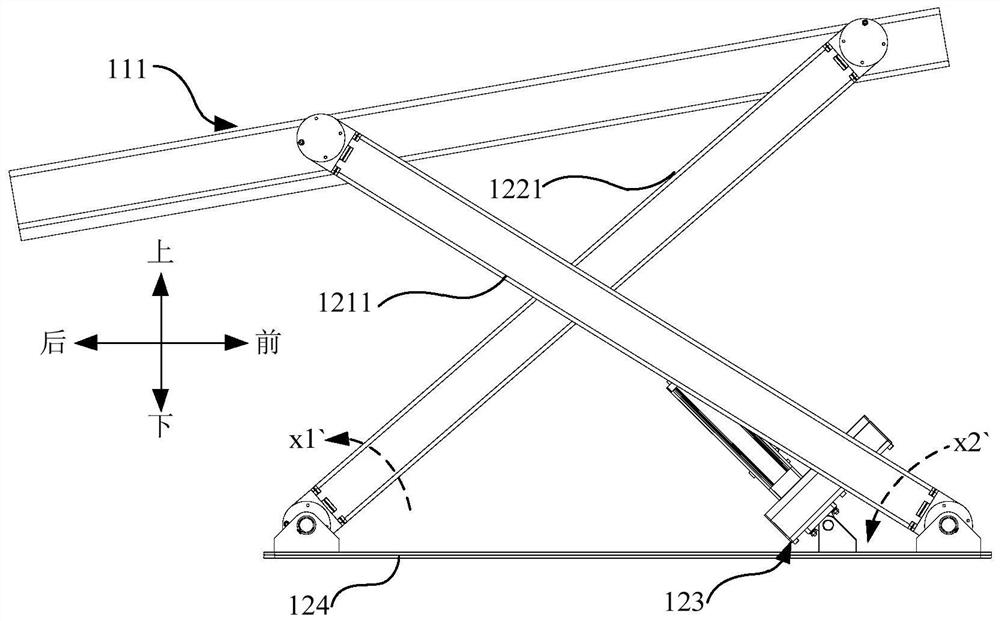

Tow flavoring device and flavoring method for flavoring cigarette filter rods

The invention discloses a tow flavoring device for flavoring cigarette filter rods, which comprises a buffer chamber and a perfuming mechanism, the wire inlet of the buffer chamber is provided with afeed driving mechanism, A thread inlet is communicated with the buffer chamber through a feeding passage, two groups of elastic guide mechanisms are arranged in the buffer chamber in the direction from the wire inlet to the wire outlet, Two sets of elastic guide mechanisms are staggered vertically, and the fragrance adding mechanism comprises a fragrance adding nozzle arranged in a buffer chamber,and the fragrance adding nozzle is arranged toward a tow between two adjacent sets of elastic guide mechanisms. The invention also discloses a tow fragrance adding method for fragrance adding of a cigarette filter rod, comprising a loose tow and a tow fragrance adding; The invention can automatically carry out uniform fragrance addition to the tow, At that same time, the buff effect of the loosetow before flavoring effectively improve the self-looseness of the tow, enhances the filtering efficiency of the formed nozzle rod, and has positive effect on reducing tar, reducing harm and stabilizing the suction resistance of cigarette. The invention can avoid the harm of harmful chemical gases caused by the burning of spices with tobacco shreds to the health of consumers, and effectively improve the self-looseness of the tow before flavoring.

Owner:CHINA TOBACCO HENAN IND

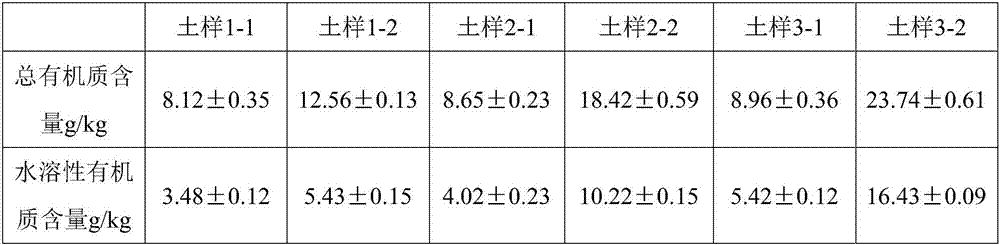

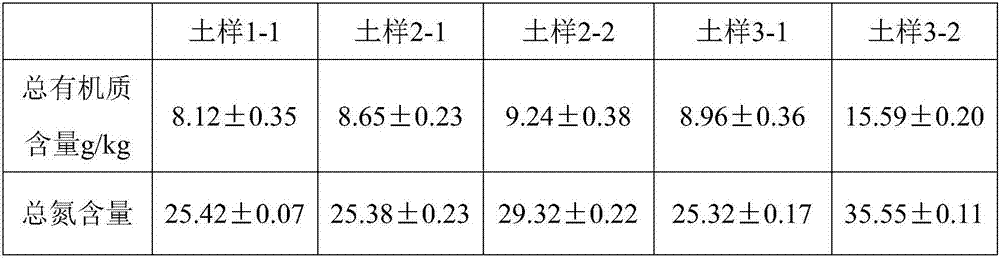

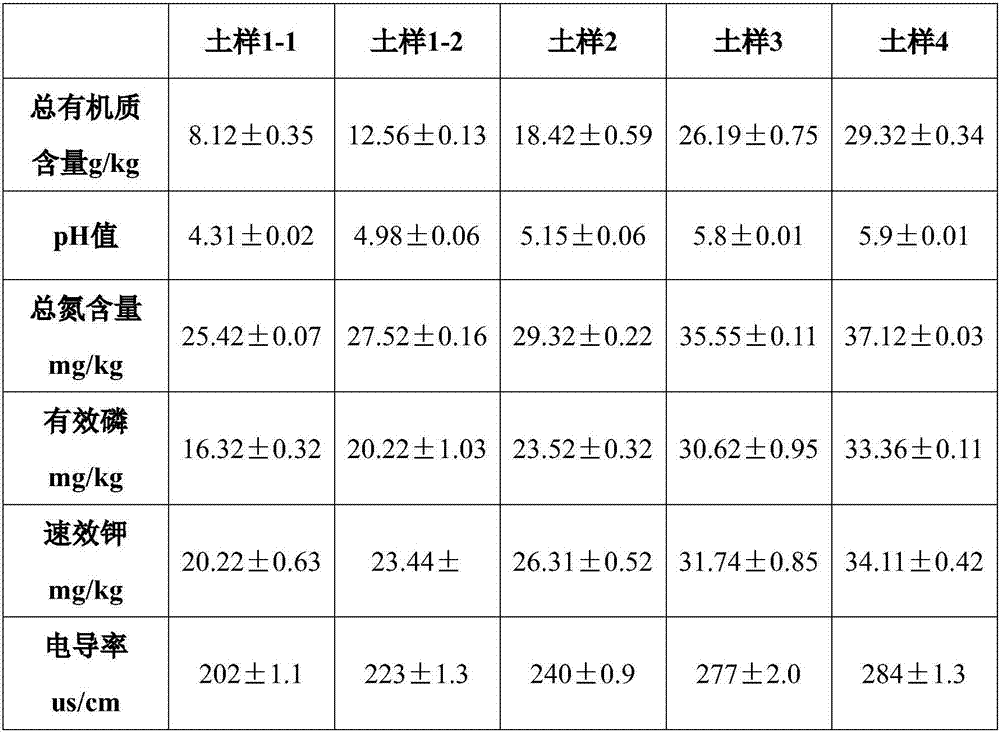

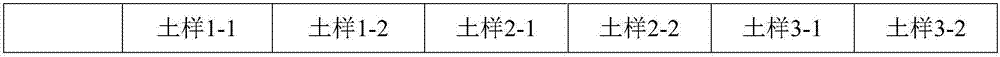

Garden building method of ecological young tea garden

InactiveCN107318568AImprove nitrogen fixation capacityImprove fertilityExcrement fertilisersCultivating equipmentsFarmyard manureFertility

The invention discloses a garden building method of an ecological young tea garden and relates to the technical field of building of ecological tea gardens. The garden building method is characterized by including the steps of 1), preparation of tea garden land; 2), fermentation of farmyard manure; 3), selection and transplantation of young tea tree seedlings; 4), management of the young tea garden. The garden building method has the advantages that the soil for the young tea garden is well improved, the soil is fertile, fertility is long and stable, building of the standardized ecological tea garden and development of tea industry is benefited, and higher market demand is met.

Owner:刘振

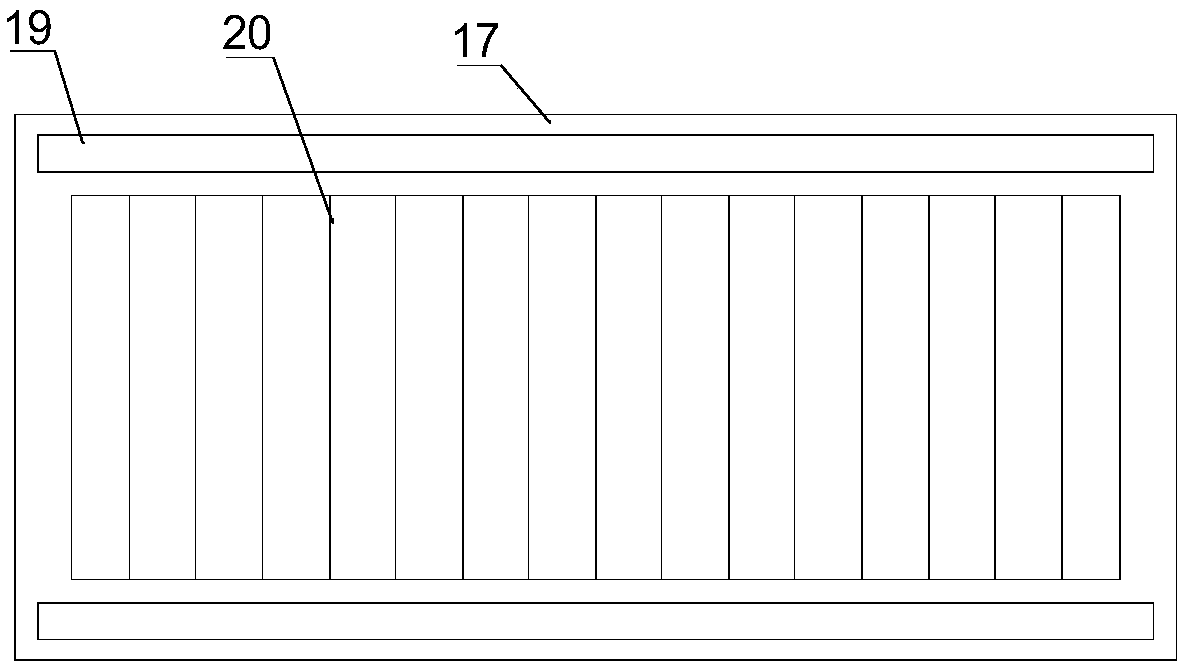

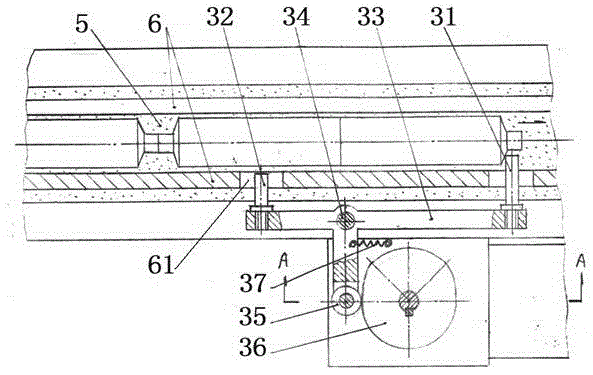

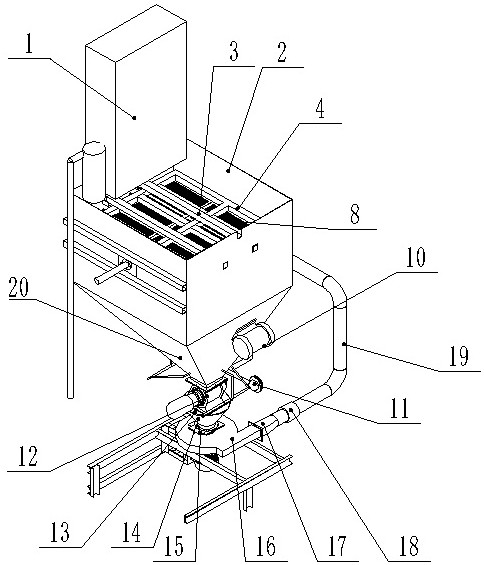

Powder material discharge transmission system for batch-type packaging machine and control method thereof

The invention relates to a powder material discharge transmission system for a batch-type packaging machine and a control method thereof. The powder material discharging transmission system comprises a powder material stirring transmission mechanism, a discharge filling transmission mechanism, a discharge driving stepping motor and a discharge stepping motor driver. The discharge filling transmission mechanism adopts a discharge filling storage pump, so that the discharge filling time is greatly shortened, and the general packaging speed is increased; by the powder material stirring transmission mechanism, the loose degree of powder materials in a powder material storage bin can be effectively guaranteed, a system controller finishes the operation of pulling bags to feed paper and transverse and longitudinal sealing, and automatically drives the discharge filling storage pump to execute discharge filling operation on the stored powder materials, and in the operating process, the next bag of the required powder materials is stored in the powder material storage bin in the discharge filling storage pump. By the cycle, the discharge filling execution time is greatly shortened, and the discharge filling speed is effectively increased.

Owner:TIANJIN POLYTECHNIC UNIV +4

Device for preventing locking by mistake for financial service equipment

ActiveCN109611865ASolve the problem of clumpingGuaranteed loosenessIncinerator apparatusElectrical and Electronics engineering

The invention discloses a device for preventing locking by mistake for financial service equipment. The device comprises a handle, a safe box lock tongue, a lock stopping door strip, a spring piece, acoded lock and a pickproof door strip, wherein the spring piece is installed under the safe box lock tongue; the pickproof door strip is welded to a corresponding position in a safe box; the handle,the safe box lock tongue, the lock stopping door strip, the spring piece and the coded lock are all installed on a box door of the safe box; the lock stopping door strip is installed under the safe box lock tongue and is connected with the spring piece; the safe box lock tongue is installed on the inner side of the box door of the safe box and has a preset distance from the inner side of the box door; and the upper end and the lower end of the safe box lock tongue are slidably connected with an upper limiting block and a lower limiting block which are installed on the box door. According to the device for preventing locking by mistake for the financial service equipment, the left moving position and the right moving position of the safe box lock tongue can be restricted automatically through the action of a combination of the lock stopping door strip and the spring piece and the pickproof door strip, and a function of preventing locking by mistake is realized.

Owner:甸石(上海)环保科技有限公司

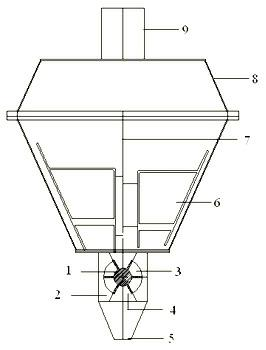

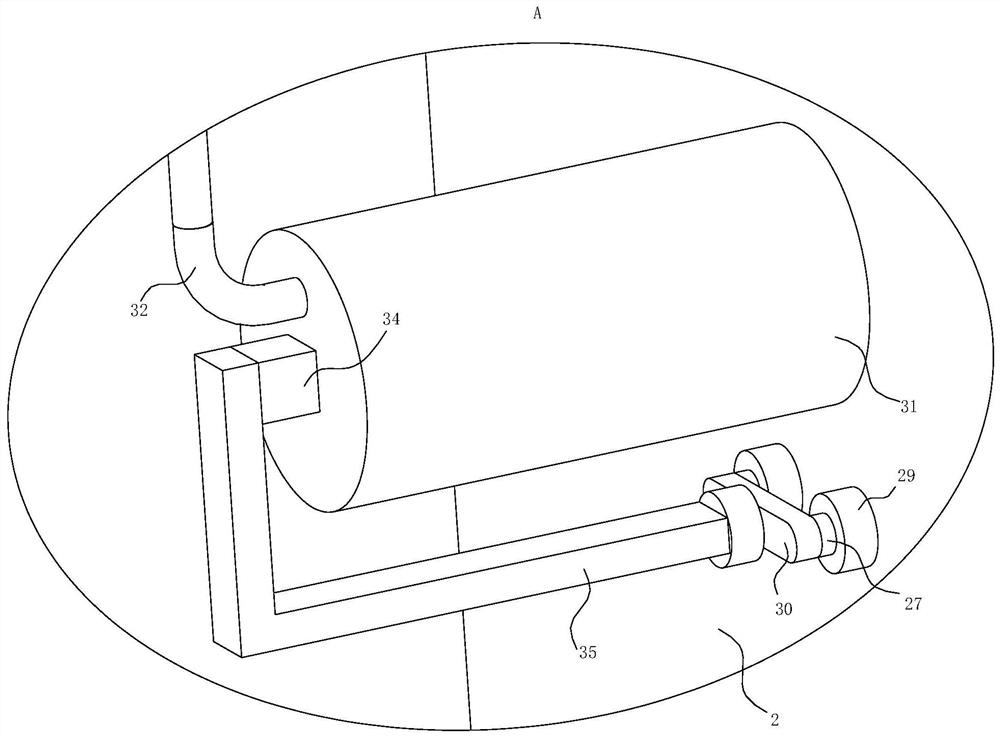

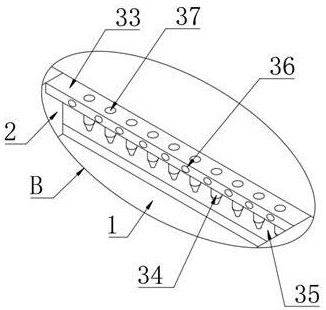

Concrete bridge face aggregate laying device

InactiveCN107587433AGuaranteed uniformityGuaranteed loosenessBridge structural detailsBridge erection/assemblyStructural engineeringConstruction aggregate

The invention discloses a concrete bridge face aggregate laying device which comprises a moving material box. A first grinding protrusion at the lower portion of a bending plate and a second grindingprotrusion on the lower side wall body of the moving material box are used for rubbing so that bonding spheres in concrete aggregate are ground to be flat and are scattered, and a discharging port canbe hardly blocked by the concrete aggregate. When the concrete aggregate falls from the area between discharging plates, the concrete aggregates is impacted by a transverse steel wire to form an evenand loosened state. In the falling process of the concrete aggregate, the concrete aggregate is subjected to the third time of impacting through a vertical steel wire, and therefore uniformity and looseness of the concrete aggregate during falling are ensured. Due to the fact that a first spiral blade and a second spiral blade are opposite in spiral direction, the concrete aggregate flows from top to bottom through the first spiral blade, the concrete aggregate moves from bottom to top through the second spiral blade, cyclic circulation of the concrete aggregate is formed, and a very good homogenizing effect is achieved on the concrete aggregate.

Owner:龙里县逸轩生产力促进中心

Method for preparing aromatic bacterial dried fermented soybeans

InactiveCN104757440AGuaranteed loosenessImprove integrityClimate change adaptationFood preparationNutrientWater content

The invention relates to a method for preparing aromatic bacterial dried fermented soybeans. The method is characterized by comprising the following steps: (1) washing selected soybeans, drying in air or drying by baking; (2) stir-frying the soybeans dried in air or dried by baking; (3) crushing the stir-fried soybeans into crude granules; (4) soaking the crushed soybeans into boiled water with the amount which is 3 times weight of the soybeans for 2 hours; (5) fishing out the soybeans swollen by soaking, draining the water and steaming the soybeans in a steamer; (6) cooling the soybeans cooled out of the steamer to 35-40 DEG C, inoculating fermentation strains, blending uniformly, and fermenting; (7) adding mashed garlic, mashed ginger, chili powder and refined salt into fermented soybeans; and (8) drying the soybeans added with accessories in air or by baking till the content of the water of the soybeans is within 15-20%, thus obtaining the aromatic bacterial dried fermented soybeans. The fermented soybeans produced by adopting the method are fulvous, thick and permanent in aroma, good in mouthfeel and rich in nutrient, do not need to be preserved with high salinity, and have the characteristics of simplicity in preparation, high safety and low cost.

Owner:YANGTZE UNIVERSITY

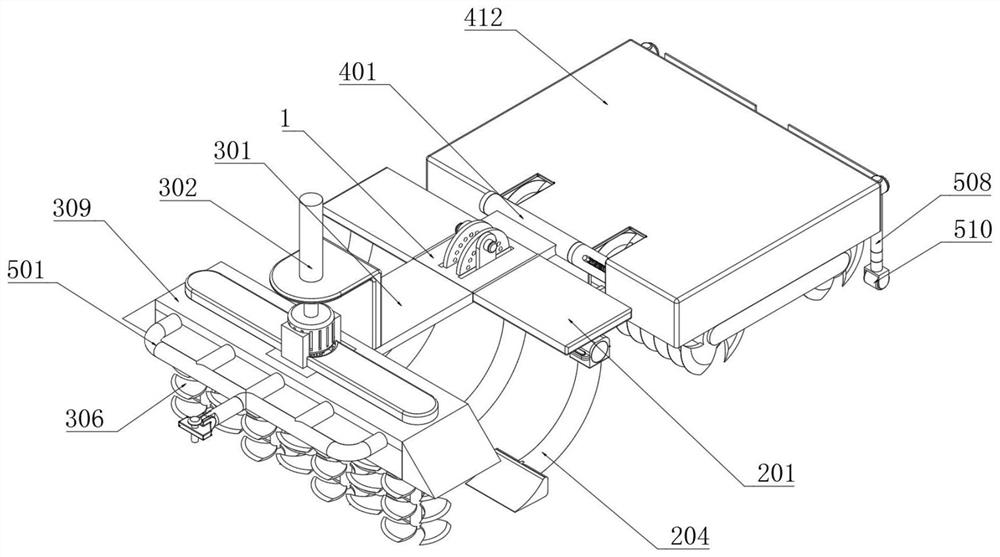

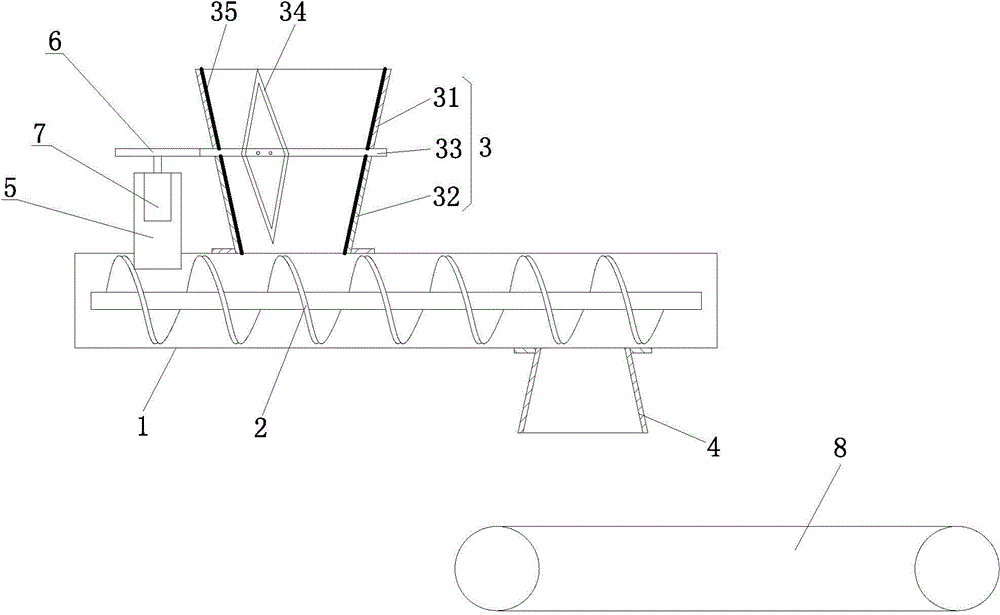

Deep scarification combined land preparation machine for straw crushing, mixing and returning to field

PendingCN113207331AScientific and reasonable structureEasy to useSpadesPloughsAgricultural scienceAgricultural engineering

Owner:HEILONGJIANG AGRI ECONOMY VOCATIONAL COLLEGE

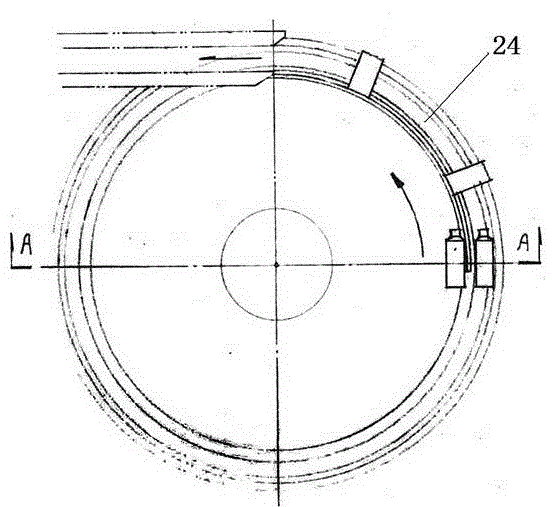

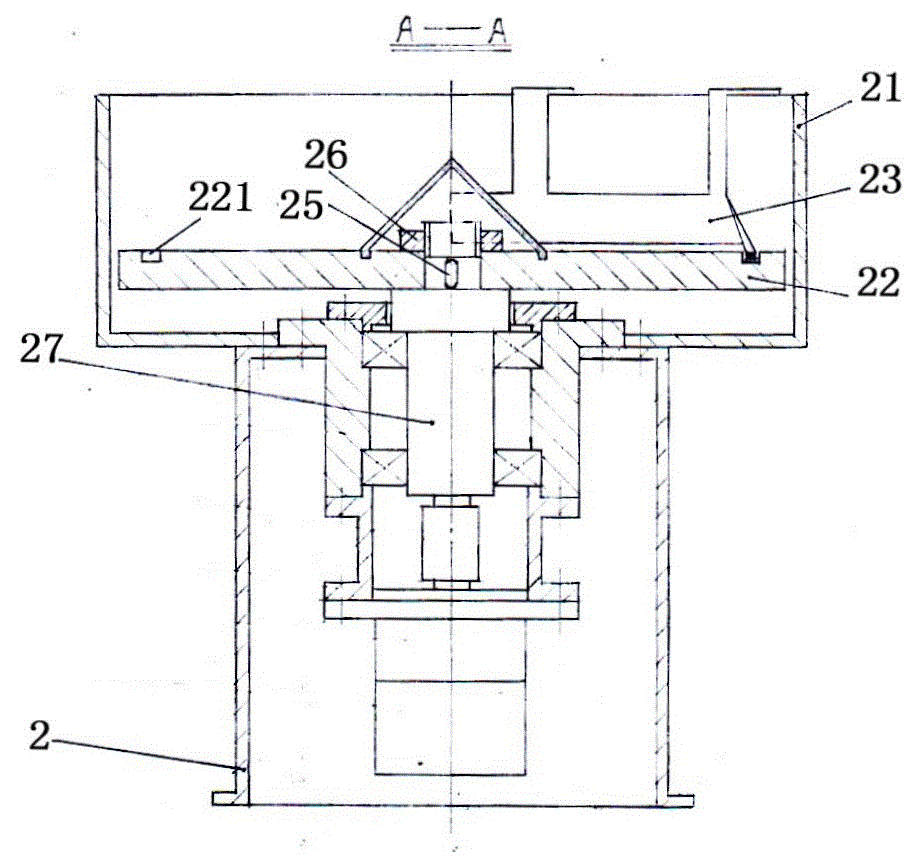

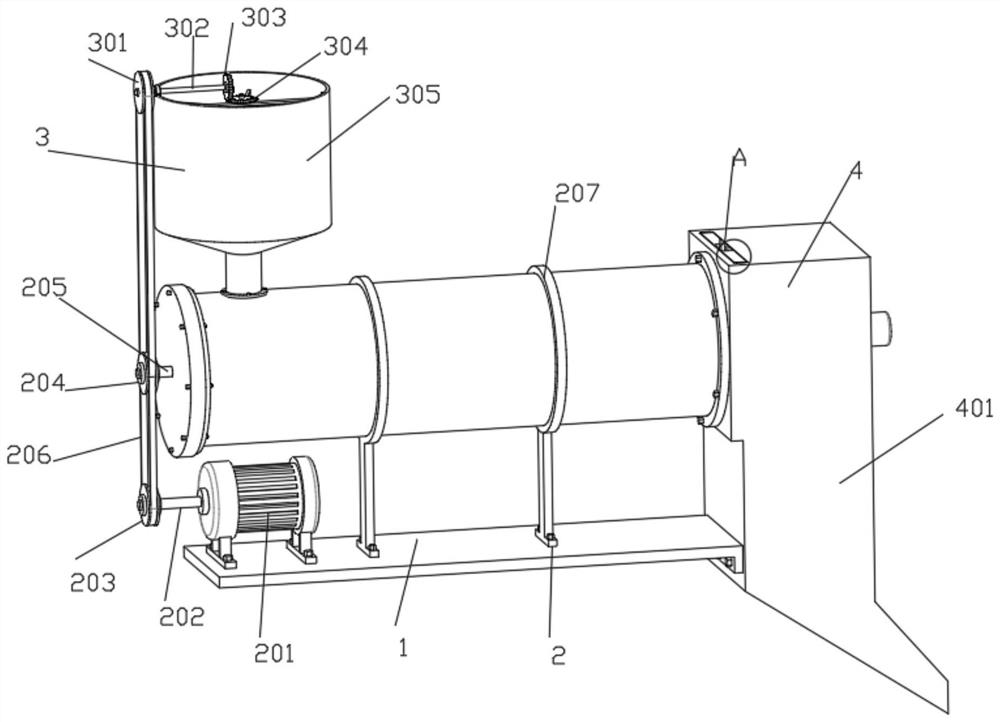

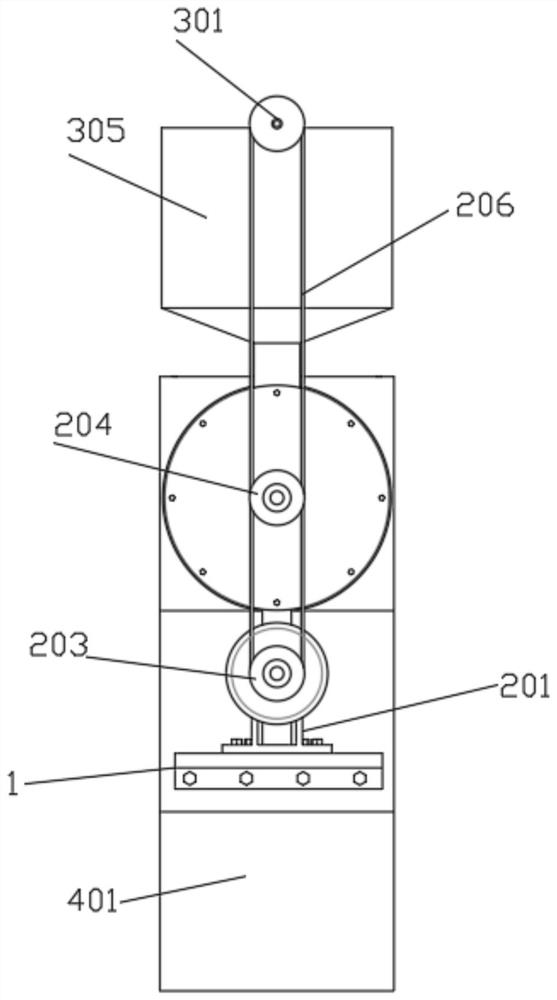

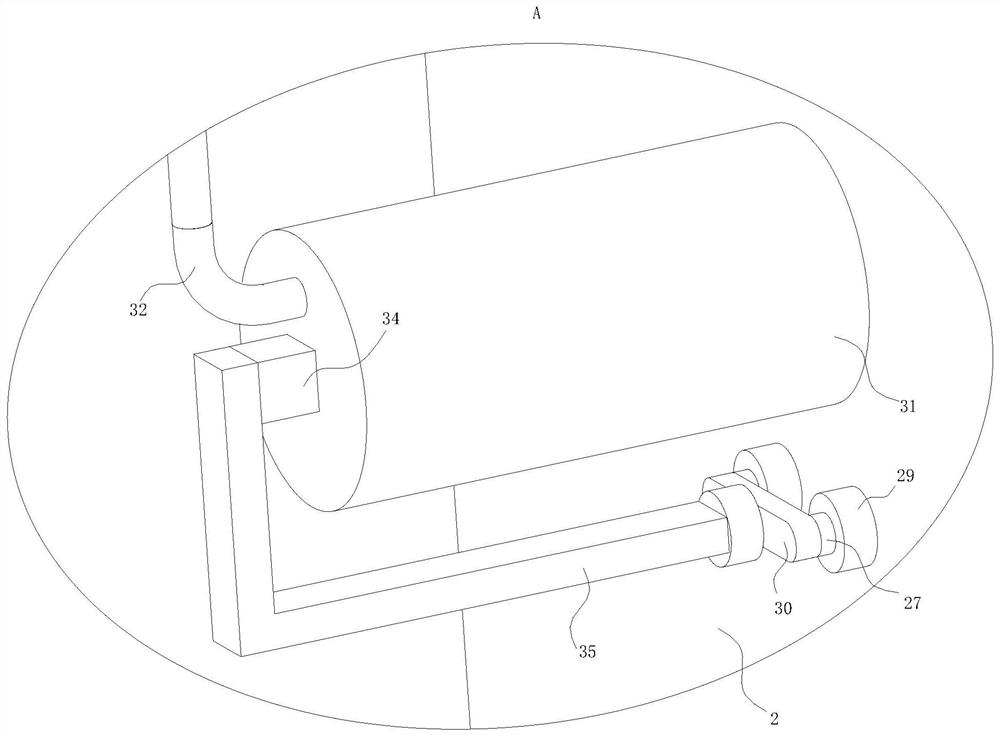

Automatic bottle sorting machine

The invention relates to an automatic bottle sorting machine. The automatic bottle sorting machine is characterized by comprising a gravity type feeding machine (1), the lower portion of the gravity type feeding machine (1) is connected with a diversion type centrifugal material ordering machine (2) with the rear portion connected with a multi-gear discharging mechanism (3), and the rear portion of the multi-gear discharging mechanism (3) is connected with a u-turn mechanism (4). The automatic bottle sorting machine is compact in layout, stable and reliable in work, free of noise, free of damaging workpieces and efficient in running.

Owner:贾立璋

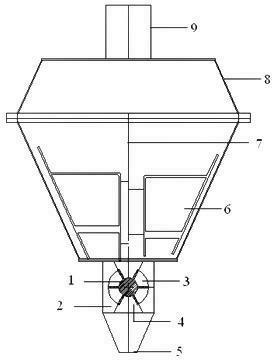

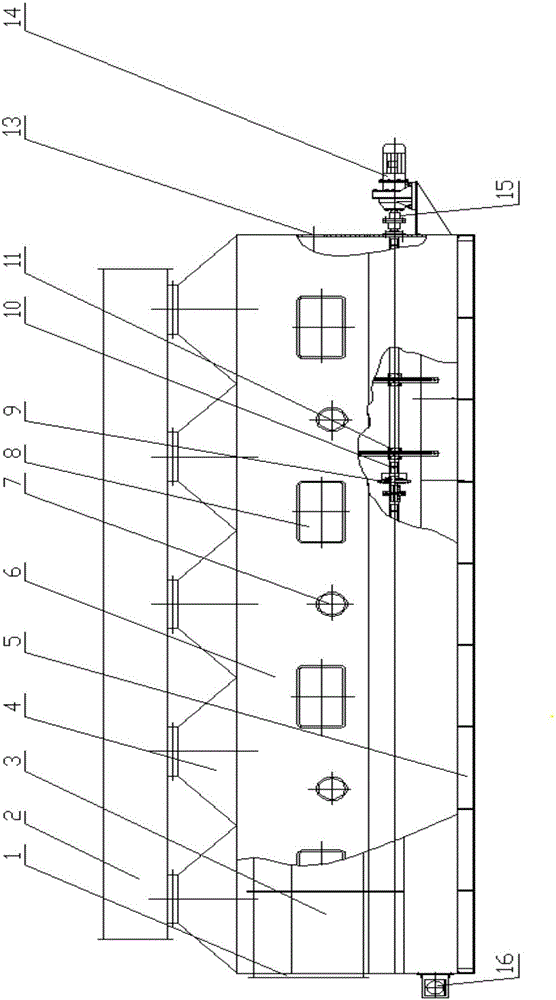

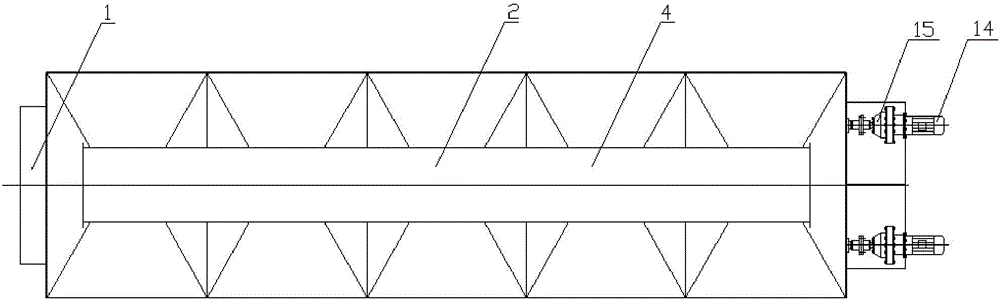

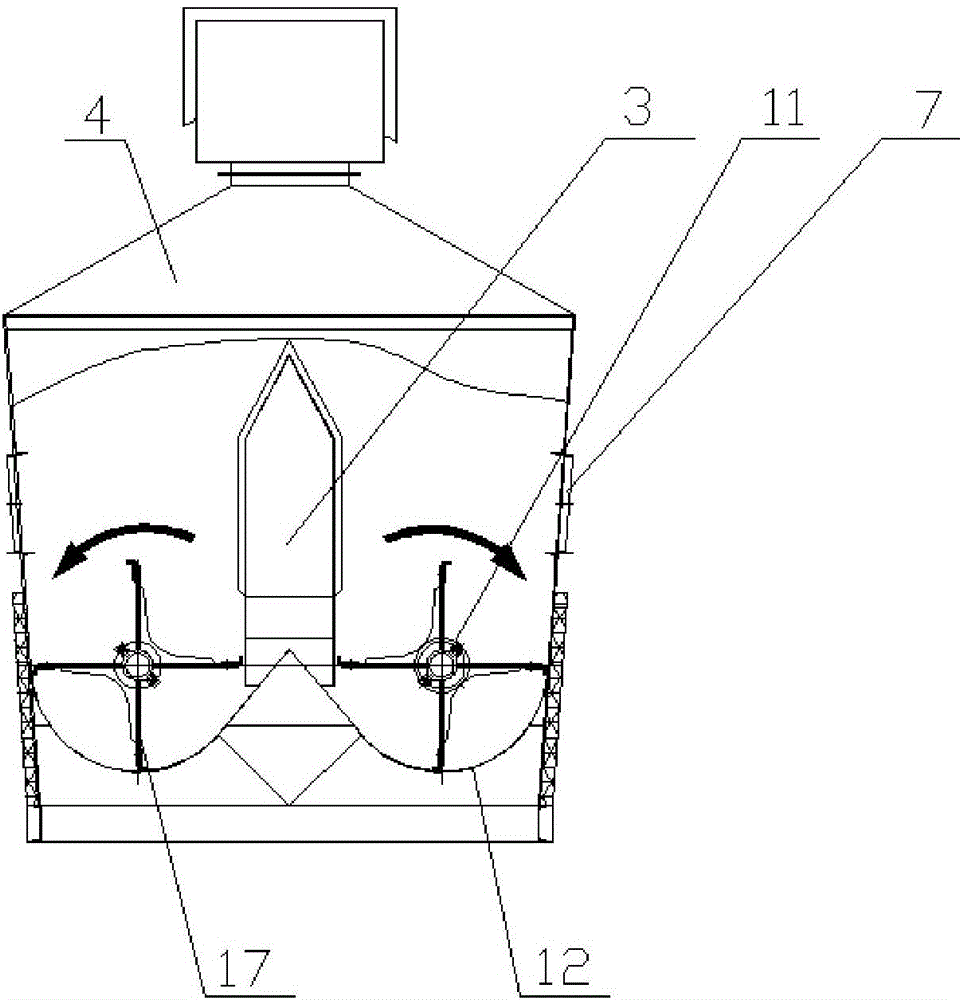

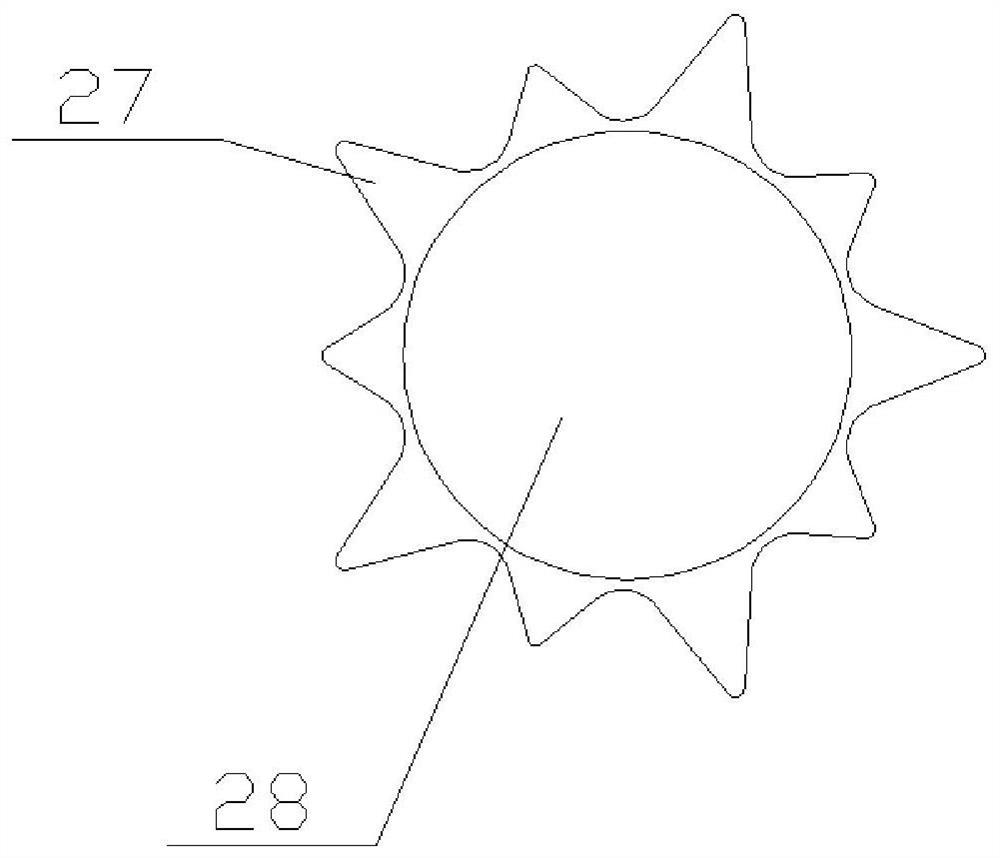

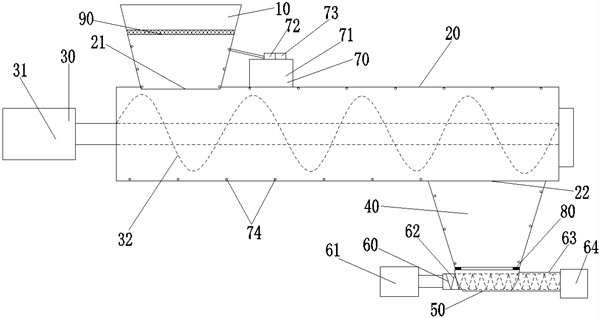

Horizontal fluidized stirring dryer of beer grains

InactiveCN106766685AHave a crushing effectGuaranteed loosenessDrying solid materials with heatDrying gas arrangementsPulp and paper industry

The invention relates to a horizontal fluidized stirring dryer of beer grains. The horizontal fluidized stirring dryer of the beer grains comprises a machine frame and a housing installed on the machine frame. The central position in the housing is provided with a blast channel. The blast channel divides the housing to two drying chambers. A stirring shaft is respectively installed in each of two drying chambers. The stirring shafts are installed on a pair of bearing seats at two ends of the housing. The stirring shafts are driven to be rotated by a motor installed at the exterior of the housing through a transmission mechanism. A plurality of stirring blades is uniformly distributed on the stirring shafts. An arc plate is installed on the inner wall of the drying chambers below the stirring shafts. One end of each of two drying chamber housings is provided with a material inlet, and the other end of the housing is provided with a material outlet and an air inlet. The upper part of the housing is provided with an air inducing pipe. The end part of the blast channel is communicated with the air inlet. The bottom of the blast channel is provided with an air guiding plate. The top of the housing is provided with an air inducing cover. The structure design of the horizontal fluidized stirring dryer of the beer grains is scientific and reasonable. The material is stirred to be fluidized state by the stirring blades, and the thick beer grains are crushed, so the loose degree of the beer grains is guaranteed, the drying efficiency is improved, and the integrated drying treatment of the bear grains is realized.

Owner:宁波沪港食品机械制造有限公司

Method for crushing and solidifying cohesive soil by spraying high-pressure liquid-gas mixed fluid

ActiveCN112227127AWell mixedMoisture content is easy to controlRoadwaysSoil preservationLand acquisitionSoil science

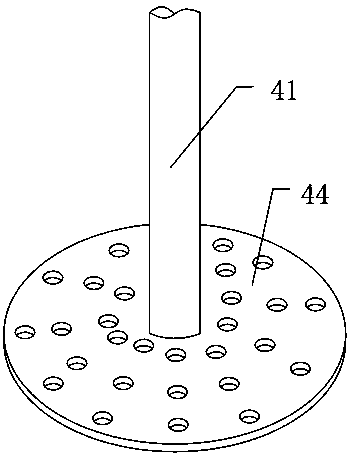

The invention discloses a method for crushing and solidifying cohesive soil by spraying a high-pressure liquid-gas mixed fluid. The method comprises the following steps: detecting the characteristicsof cohesive soil on a construction site, including detection of the water content and the clay particle content, then pre-burying a pipeline into the cohesive soil, and starting to prepare liquid-gasmixed fluid; then, applying the pressure on the liquid-gas mixed fluid, after pressing is finished, conveying the high-pressure liquid-gas mixed fluid into the cohesive soil at a certain burial depththrough a pipeline and spraying the fluid into the cohesive soil through spraying devices such as a spraying head, applying the shearing force to a soil body, cutting and crushing the soil body, and in the cutting and crushing process of the soil body through the high-pressure spraying mixed fluid, fully mixing a curing agent solution in the mixed fluid with the soil body broken particles to ensure that the soil body broken particles react with the soil body, so that the soil body is cured. According to the method, the soil body can be maintained in situ, land occupation or land acquisition isnot needed, and the method is efficient and environment-friendly.

Owner:HEBEI ROAD & BRIDGE GROUP +1

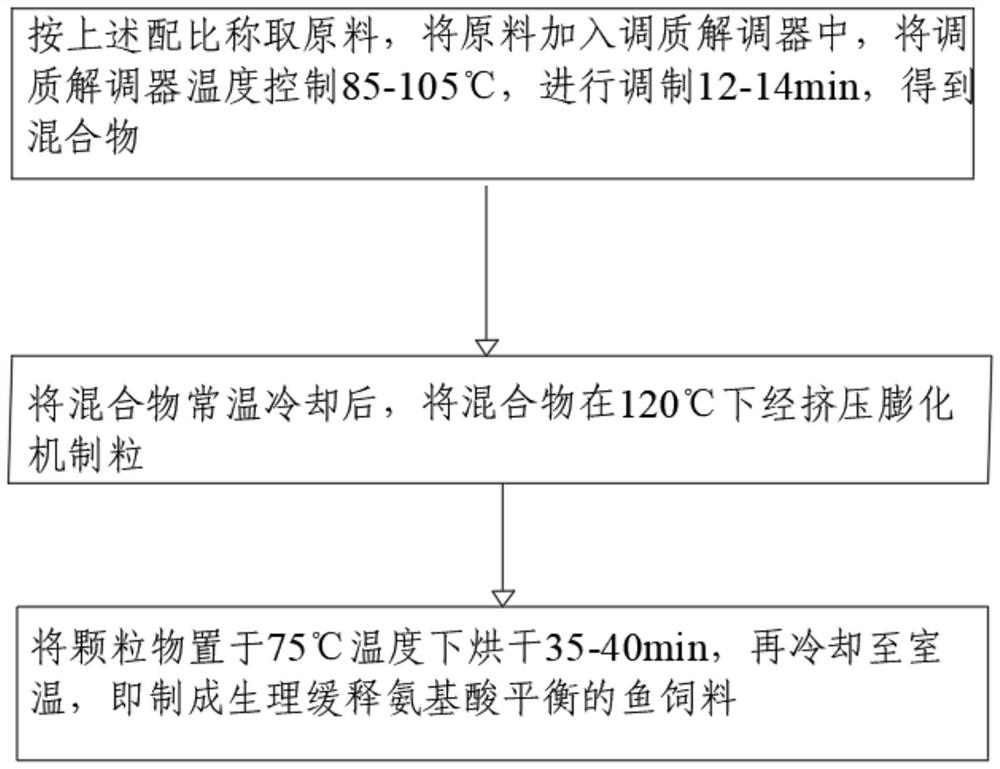

Physiologically sustained-release amino acid-balanced feed for tilapia mossambica

InactiveCN113115872AGuaranteed loosenessConducive to flowFeeding-stuffLighting and heating apparatusProtein proteinSOYBEAN SEED OIL

The present invention discloses a physiologically sustained-release amino acid-balanced feed for tilapia mossambica and relates to the field of feeds. The physiologically sustained-release amino acid-balanced feed for tilapia mossambica comprises the following components in parts by weight: 35-42 parts of petroprotein liquid, 3.6-10.4 parts of soybean oil, 33-58 parts of starch, 1.3-3.2 parts of compound vitamins, 1-2.5 parts of compound mineral salts, 0.1-0.5 part of resveratrol, 3.5-4.5 parts of carboxymethyl cellulose, 1.2-2.4 parts of glycine and 0.3-2.3 parts of arginine. The petroprotein liquid, glycine and arginine are added into the raw materials, such that a problem of unbalanced amino acid of a single protein source is solved, protein efficiency of the feed is improved, digestion and absorption of tilapia mossambica are facilitated, a growth cycle of tilapia mossambica is shortened, economic benefits are improved, meanwhile, ammonia nitrogen emission and water environment pollution are reduced, and in addition, a preparation method is simple and conductive for rapid production of enterprises.

Owner:福建大昌盛饲料有限公司

Conveying device for disinfectant production

InactiveCN112373814AImprove uniformityConvenient whereaboutsLarge containersLoading/unloadingProcess engineeringCaking

The invention relates to the technical field of conveying devices, in particular to a conveying device for disinfectant production. The conveying device comprises a mounting rack, a grinding structure, a conveying structure, a discharging structure, a screening structure and an adjusting structure. Through the grinding structure, the placed powdery disinfectant can be ground and the caked disinfectant can be crushed, so that the disinfectant keeps a powdery structure and is convenient to convey and package, the ground powdery disinfectant can be further screened and refined through the screening structure, the uniformity of the powdery disinfectant is improved, and the transportation is convenient; the powdery disinfectant can be conveyed through the conveying structure, blocking of the disinfectant in the conveying process is avoided, uniform conveying and packaging are facilitated, the powdery disinfectant can be quantitatively discharged through the discharging structure, and therefore it is guaranteed that the packaging amount of each time is approximately the same; and the packaging amount of the powdery disinfectant can be changed through the adjusting structure, and packaging of different specifications is facilitated.

Owner:台州智子科技有限公司

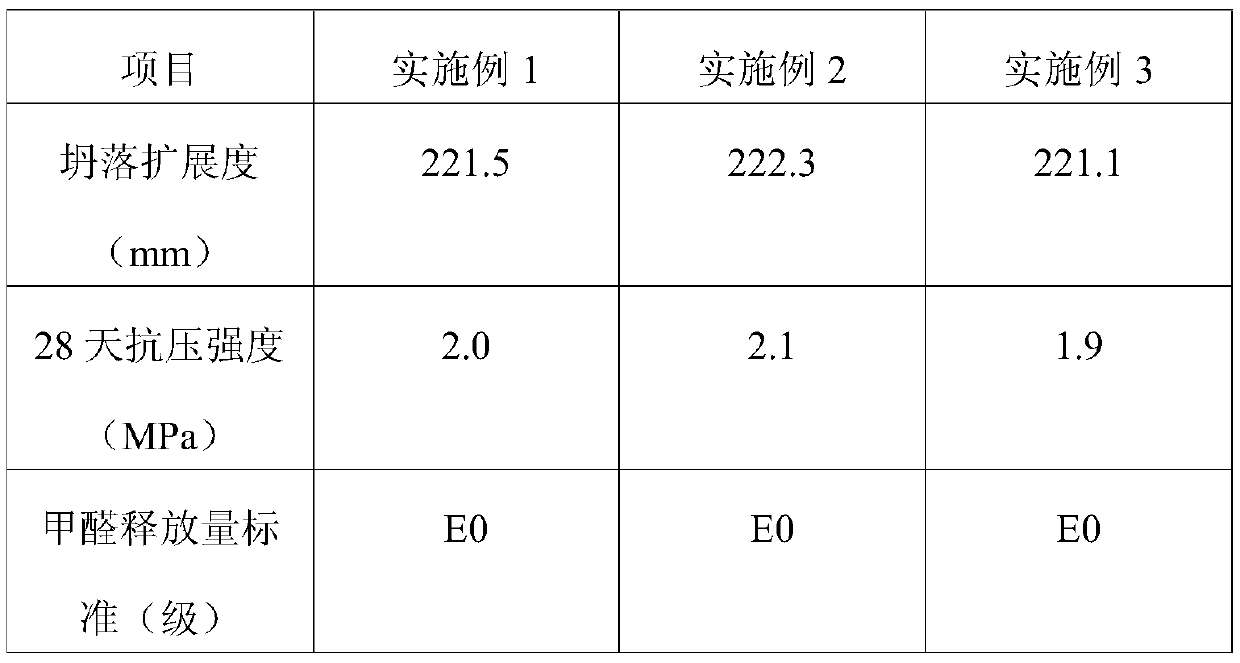

Method for preparing green and environmentally-friendly building material from building wastes

InactiveCN110092637AIntrinsic Quality GuaranteeImprove inner qualityEnvironmental resistancePolyphenol

The invention provides a method for preparing a green and environmentally-friendly building material from building wastes, and relates to the technical field of building materials. The method comprises the following steps: (1) pretreatment of the building wastes, (2) mixing, (3) calcination, and (4) mixing. Building waste recycled fine aggregates are obtained after pretreatment, and are mixed withfly ash, diatomaceous earth, tea polyphenol, chopped glass fibers and an antifreeze agent, and the obtained mixture is subjected to a series of treatments to obtain the building material with the characteristics of high compressive strength, good wear resistance, greenness, environmental protection and low cost, etc. The method can solve the problem of environmental pollution caused by the building wastes.

Owner:广西理工职业技术学校

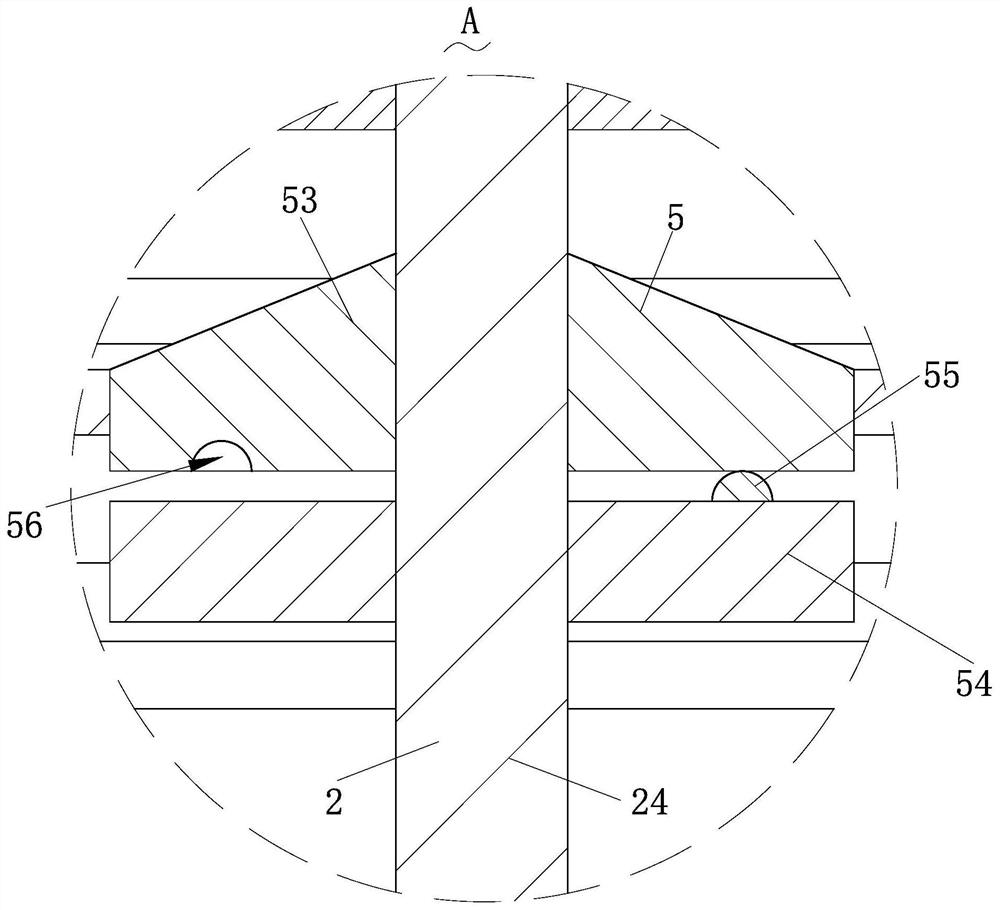

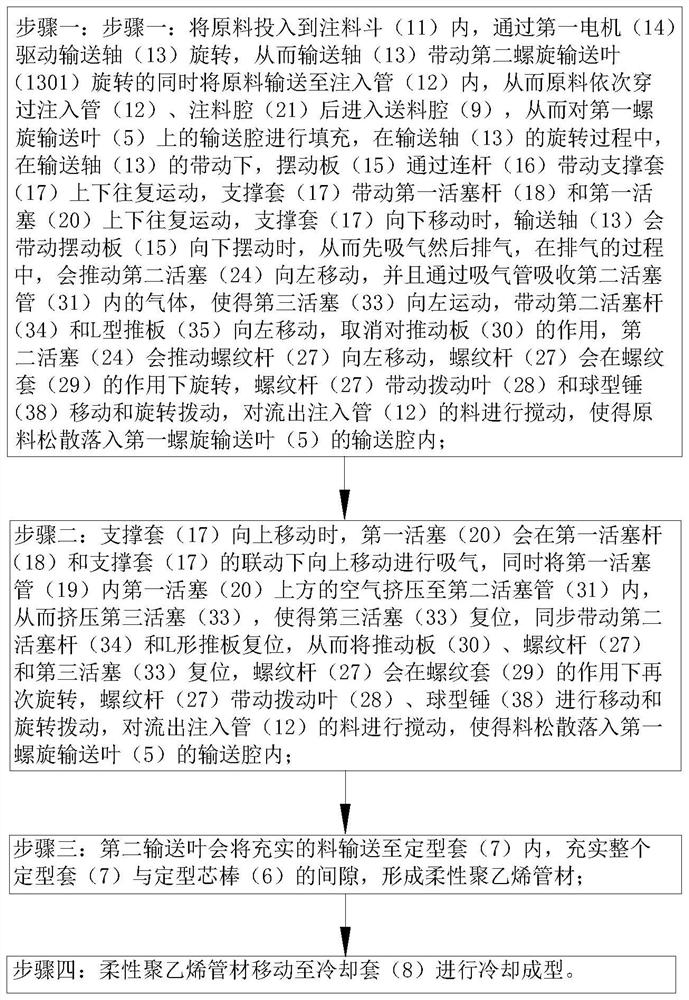

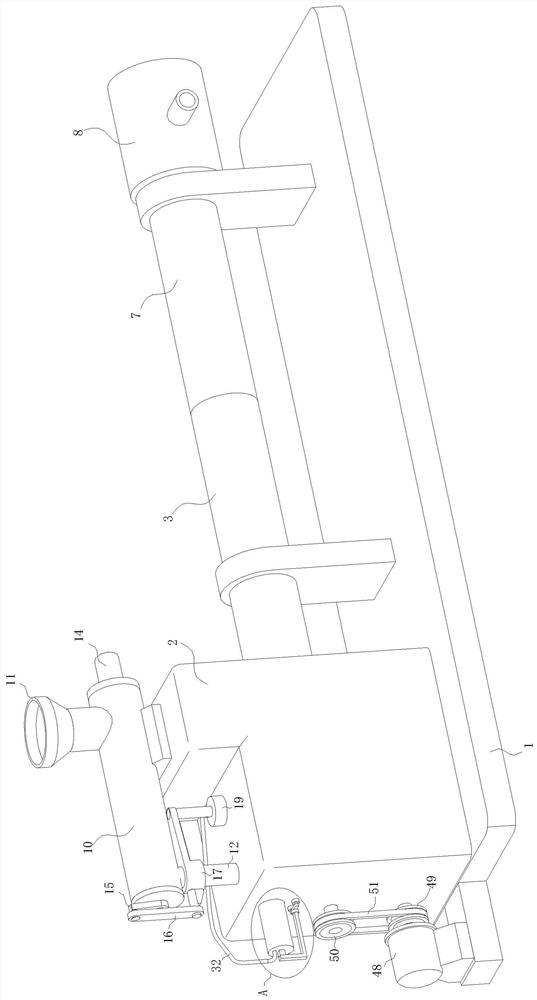

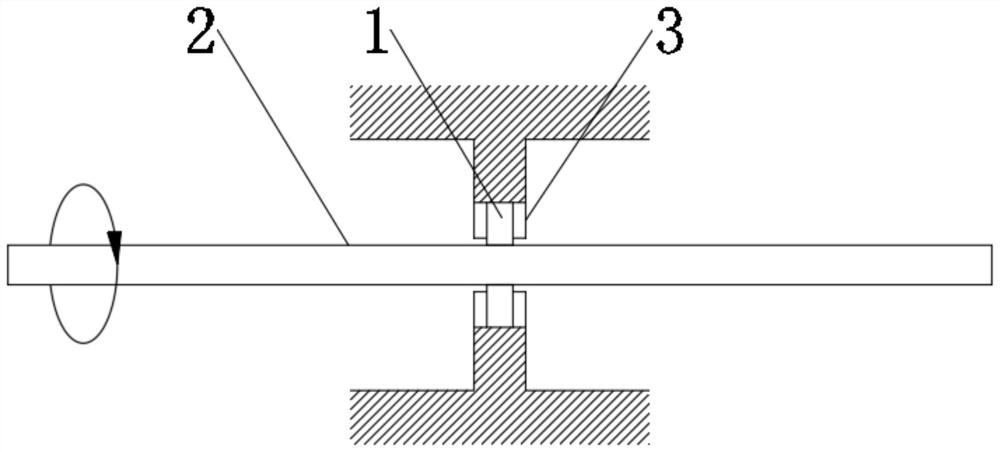

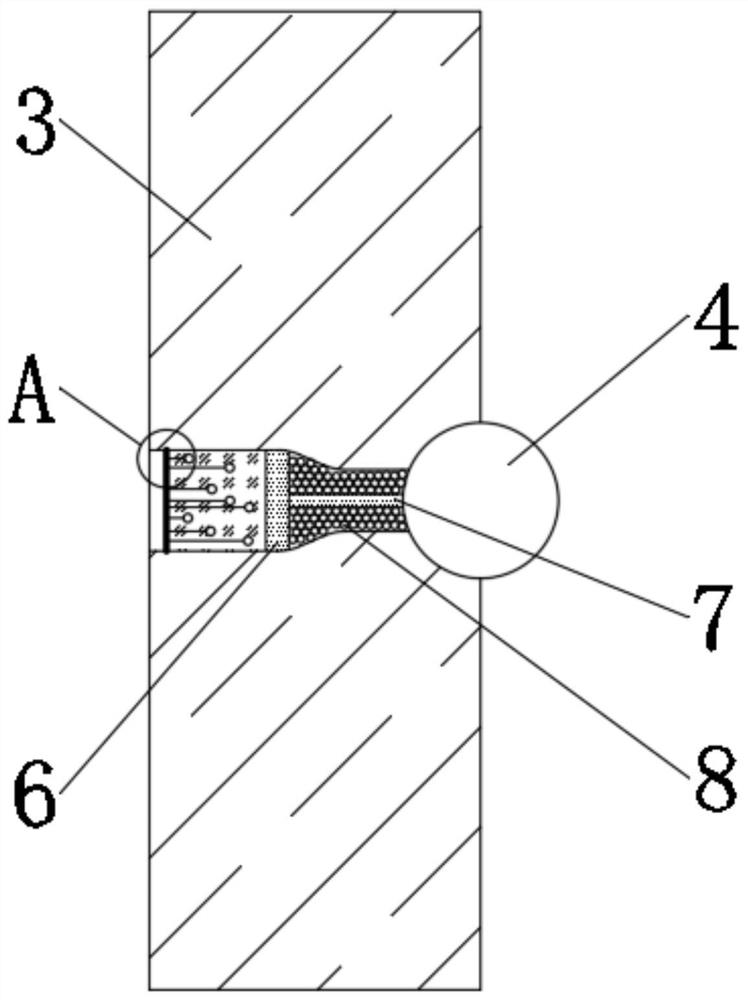

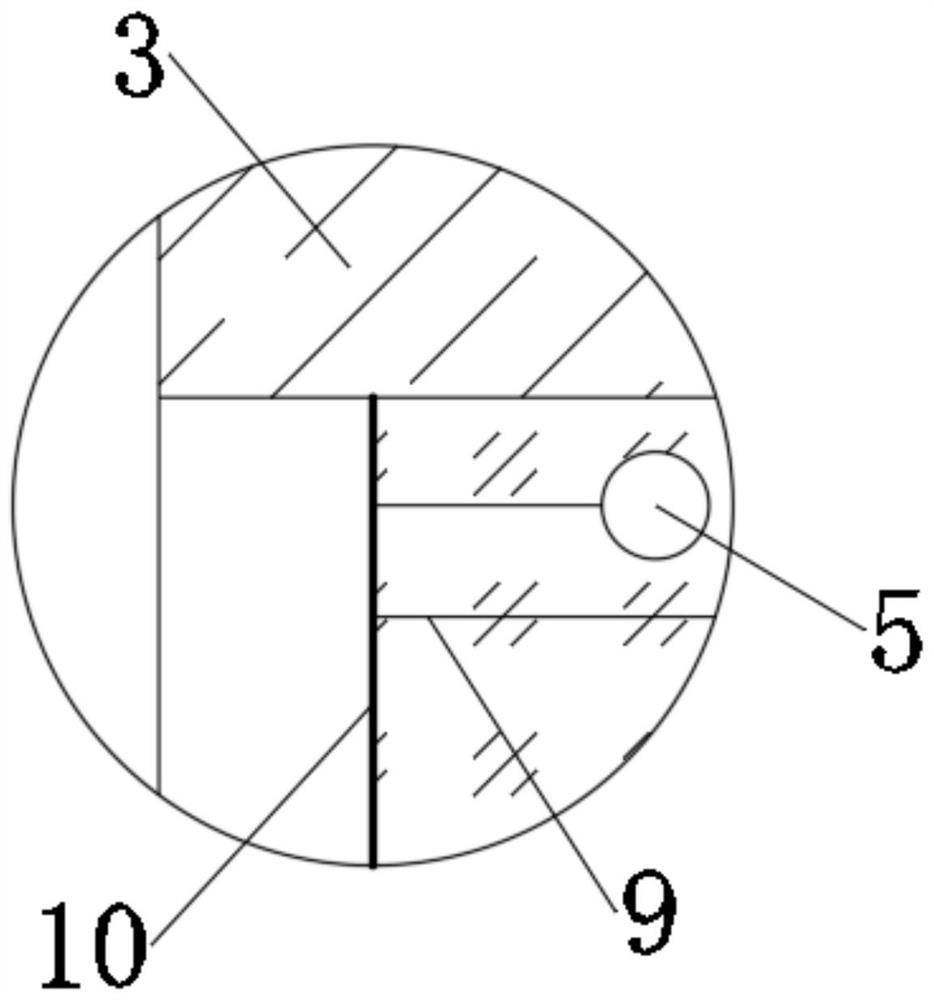

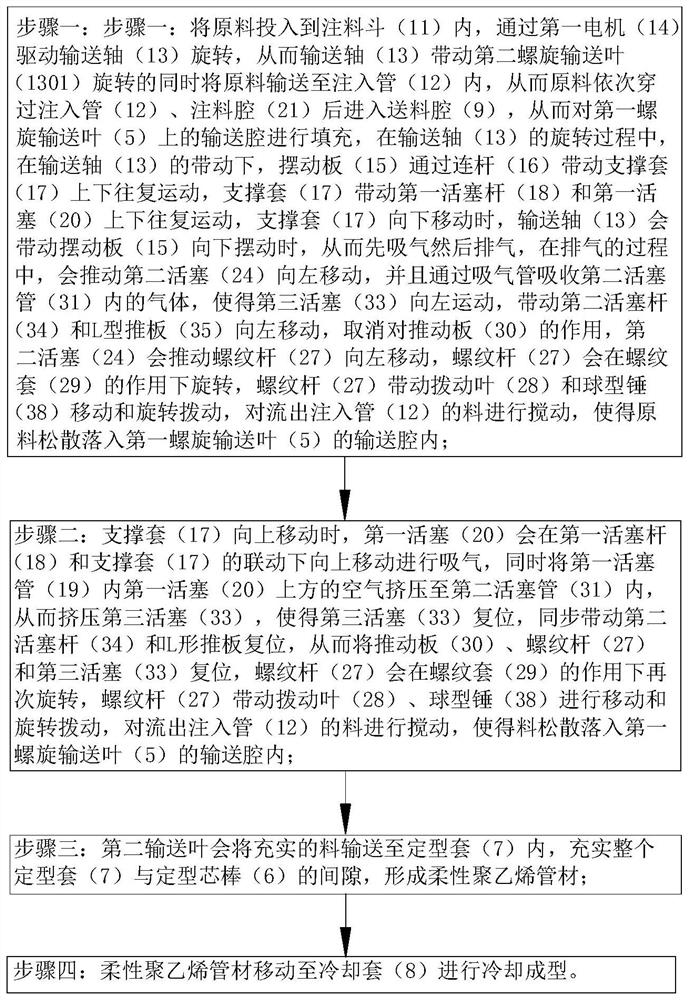

Ultra-high molecular weight polyethylene pipe forming system and process

The invention discloses an ultra-high molecular weight polyethylene pipe forming system and process, and belongs to the technical field of ultra-high molecular weight polyethylene pipe forming. The ultra-high molecular weight polyethylene pipe forming system comprises a base, a hopper base, a machine barrel, a feeding shaft, a shaping core rod, a shaping sleeve and a cooling sleeve, the hopper base is fixedly connected to the left side of the top of the base, and a feeding cavity is formed in the hopper base. The machine barrel fixedly communicates with the right side of the hopper base and communicates with the feeding cavity. According to the ultra-high molecular weight polyethylene pipe forming system and process, materials flowing out of an injection pipe are stirred, so that the materials loosen and fall into a conveying cavity of a first spiral conveying blade, in the exhaust process, when a first piston moves to not seal an air injection pipe, continuously exhausted air can be injected into an annular spray head to vibrate the materials accumulated below, the conveying cavity of the first spiral conveying blade is filled with the materials as much as possible, a second spiral conveying blade can convey the filled materials into the shaping sleeve, a gap between the whole shaping sleeve and the shaping core rod is filled, and the machining quality of formed pipes is guaranteed.

Owner:东营市东达机械制造有限责任公司

Cooling structure for integrated horizontal cold rice steaming machine

PendingCN107502512AImprove cooling effectGuaranteed loosenessAlcoholic beverage preparationEngineeringSteel belt

The invention relates to the field of wine brewing equipment and provides a cooling structure for an integrated horizontal cold rice steaming machine. The cooling structure comprises a chassis, wherein a linear chamber is arranged in the chassis; the linear chamber is divided into a steaming area and a cooling area; an air exhaust pipe is connected with the upper end of the chassis in the cooling area; a cold water pipeline and a cold air pipeline are connected with a side wall of the chassis in the cooling area; an inner end part of the cold water pipeline is located in the linear chamber and a nozzle is arranged on the inner end part; the nozzle is located above a process path of a conveying steel belt; an air cooling motor is connected with an outer end part of the cold air pipeline; the inner end part of the cold air pipeline is located under the process path of the conveying steel belt; an area under the process path of the conveying steel belt in the cooling area of the linear chamber is arranged as a water collecting area; a water draining pipe is connected with the lower end of the chassis in the cooling area; the upper end part of the water draining pipe is connected with the water collecting area. The cooling structure is capable of quickly cooling the steamed rice, guaranteeing the losing degree of the rice and promoting the wine brewing quality in the next stage.

Owner:浙江德清莫干山酒业有限公司

Soil improvement method of ecological tea garden

InactiveCN107318294AGuaranteed loosenessImprove nitrogen fixation capacitySoil-working methodsOrganic fertilizerGreen manure

The invention discloses a soil improvement method of an ecological tea garden and relates to the technical field of ecological tea garden establishment. The soil improvement method is characterized by including the steps of 1), land selection; 2), land regulation; 3), planting of leguminous green manure; 4), application of weathering coal; 5), application of organic fertilizer containing rhizobium; 6), adjustment of soil aid and alkali in the tea garden. The soil improvement method has the advantages that soil is well improved via placement and cultivation application of the weathering coal and planting of the leguminous green manure, the soil is fertile, fertility is long and stable, the soil is loosen, construction of the standardized ecological tea garden and development of tea industry are benefited, and higher market demand is met.

Owner:刘振

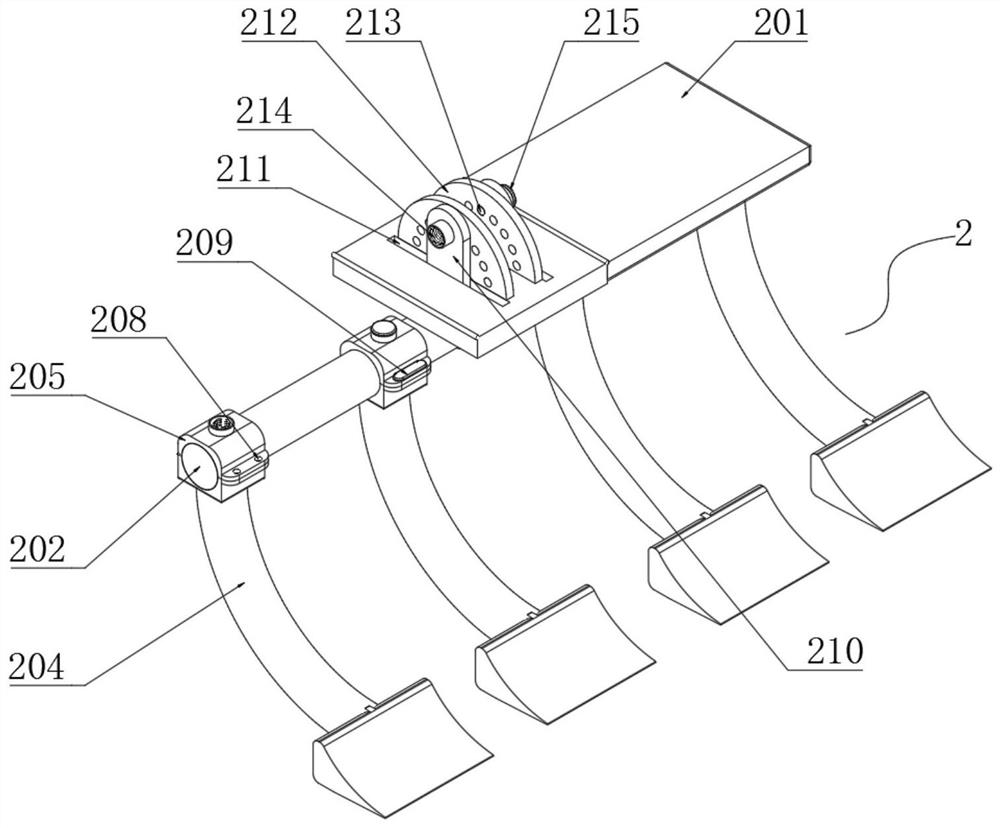

Ploughshare device being of counteroffensive structure

The invention discloses a ploughshare device being of a counteroffensive structure. The ploughshare device being of the counteroffensive structure comprises a plough body (1), wherein the plough body (1) is integrally divided into three parts of structural design; two sides of a plough surface are provided with flexional moving wing devices (2); the middle of the plough surface is provided with a central control device (3) connected with a counteroffensive area (4); the area is of a loop bar structure; during running, multiple induction piece devices (5) detect data, and then transmit the data to the central control device (3); the central control device (3) adjusts the penetration extent and the counteroffensive trend of the plough surface according to a soil texture state, drag data and the like, and makes a corresponding prompt; a promoting device (6) is arranged; the way of prompting information is a voice or the display by LED (light-emitting diode) lamplight; the counteroffensive area (4) is designed in a triangular mode; the middle of the counteroffensive area is provided with an elastic component (7), so as to facilitate counteroffensive work; the structural design is unique; the counteroffensive work is carried out by utilizing the plough surface and the triangular mode; the looseness of soil is guaranteed; meanwhile, the intelligent monitoring is carried out; the work efficiency is effectively improved; the operation is simple; the practicability is strong.

Owner:ANQING HONGYU IND PROD DESIGN

Generator with lubricating grease self-transposition bearing

InactiveCN113251295ARealize repeated transpositionAchieve effective repositioningThermal insulationLubricant transferThermodynamicsChange positions

The invention discloses a generator with a lubricating grease self-transposition bearing, and belongs to the technical field of generators. The heat generated in the working process of a generator rotating shaft can be absorbed by mounting grease exchange rings at the left end and the right end of the generator bearing to trigger the magnetic field action of thermodynamic magnetic balls on the grease exchange rings, then grease pushing blocks are repelled to push lubricating grease to change positions, the deformation action of cooling inner balls in the lubricating grease is triggered in the position changing process, the substance dissolution phenomenon occurs in the cooling inner balls along with the deformation of the cooling inner balls, and the situation that a large amount of heat is absorbed occurs, so that the position-changed lubricating grease is effectively cooled, then the lubricating grease in the generator bearing is replaced, the process is repeated, repeated transposition of the lubricating grease can be achieved, the low temperature is kept all the time, the situation that the lubricating grease is in a high-temperature state for a long time and deteriorates is effectively avoided, the generator bearing is effectively protected, and meanwhile the service life of the lubricating grease is prolonged.

Owner:向琳

A UHMWPE pipe forming system and forming process

ActiveCN112372974BGuarantee processing qualityEasily brokenTubular articlesEngineeringHigh molecular mass

The invention discloses an ultra-high molecular weight polyethylene pipe forming system and a forming process in the technical field of ultra-high molecular weight polyethylene pipe forming, including a base, a hopper seat, a barrel, a feeding shaft, a shaping mandrel, a shaping sleeve and a cooling jacket The hopper seat is fixedly connected to the left side of the top of the base, and a feeding chamber is opened inside the hopper seat, and the barrel is fixedly connected to the right side of the hopper seat and communicates with the feeding chamber. The present invention stirs the material flowing out of the injection pipe so that the material loosely falls into the conveying chamber of the first screw conveying leaf, and in the process of exhausting, when the first piston moves to the point where the gas injection pipe is not sealed, the gas that continues to be discharged It will be injected into the annular nozzle, and the material accumulated below will be vibrated with gas, so that the material can be filled in the conveying cavity of the first screw conveying leaf as far as possible, and the second conveying leaf will convey the sufficient material into the shaping sleeve to enrich the entire shaping sleeve The gap with the shaped mandrel ensures the processing quality of the formed pipe.

Owner:东营市东达机械制造有限责任公司

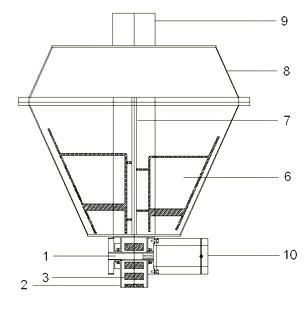

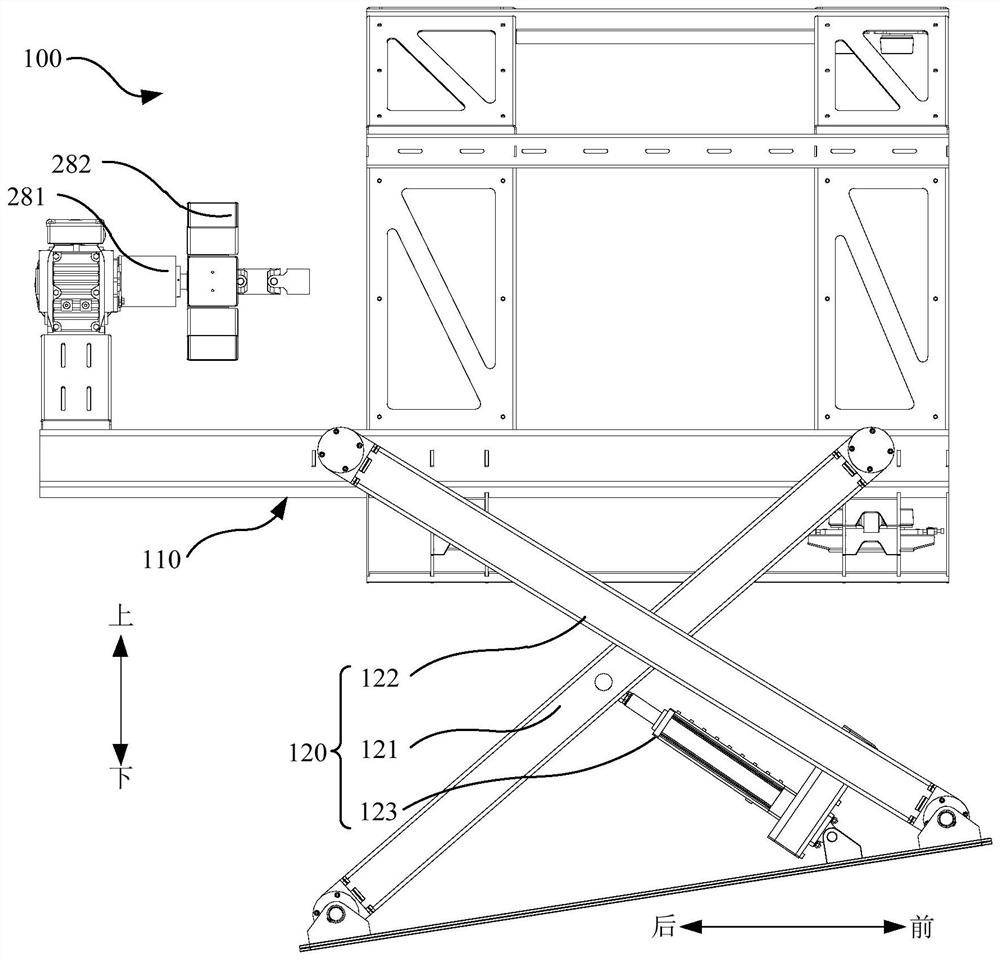

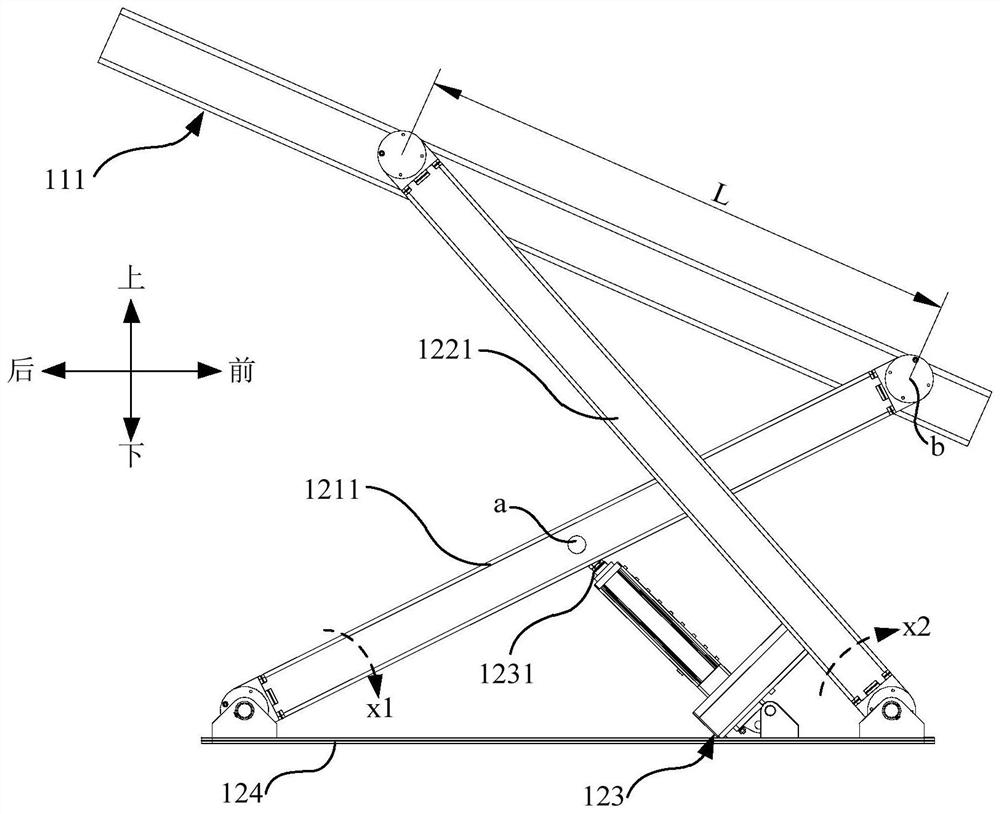

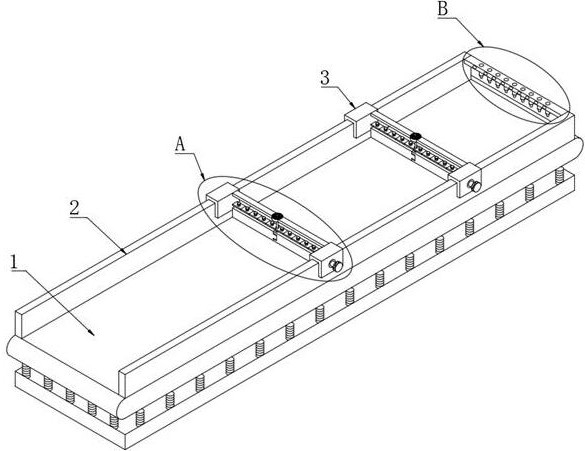

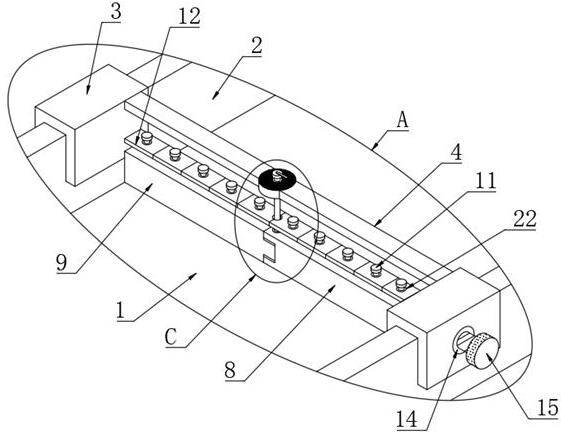

Molding powder feeding equipment

InactiveCN104139934AGuaranteed stabilityGuaranteed loosenessLarge containersConveyor partsPlastic materialsEngineering

The invention discloses molding powder feeding equipment which comprises a spiral feeding device, wherein the spiral feeding device comprises a spiral delivery pipe, a spiral delivery rod in the spiral delivery pipe, a feeding opening in the upper end of one side of the spiral delivery pipe, and a discharge opening in the lower end of the other side of the spiral delivery pipe, wherein the feeding opening is provided with a feeding hopper, the discharge opening is provided with a discharge hopper, the feeding hopper comprises an upper feeding hopper and a lower feeding hopper which are connected by a gear ring, the inner hole diameter of the gear ring is identical to the inner diameters of the connecting ends of the upper feeding hopper and the lower feeding hopper, a scraper knife is fixed on the inner hole wall of the gear ring, a U-shaped support is fixed on the spiral delivery pipe, two side surfaces of the U-shaped support are fixed together with the spiral delivery pipe, a driving gear meshed with the gear ring is fixed on the top surface of the U-shaped support, and the driving gear is driven by a decelerating driving mechanism at the inner side of the U-shaped support. The equipment has a simple structure, guarantees that plastic materials fall off from the discharge hopper constantly, lowers the labor intensity of workers, and improves the working efficiency.

Owner:NINGGUO NINGSHENG RUBBER PROD

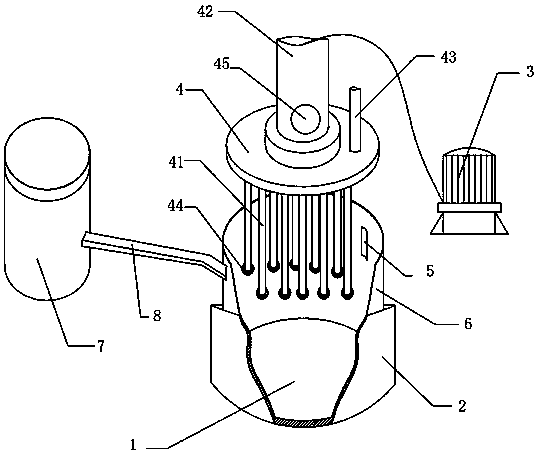

Production equipment for smoke-extinguishing glass sand

The invention relates to the field of manufacturing equipment of smoke suppressing glass sand and particularly relates to manufacturing equipment of smoke suppressing glass sand. The manufacturing equipment comprises a glass crusher, a paraffin wrapper and a motor. The glass crusher is connected to a conveyer belt, the other end of the conveyer belt is connected to the paraffin wrapper, the paraffin wrapper comprises a smelter and a hollow heating layer located on the bottom surface of the smelter, a top cover is arranged on the smelter, the upper portion of the top cover is connected to a condensing pipe, the lower portion of the top cover is connected to a plurality of stirring rods which are different in length, screens are fixedly arranged at the bottoms of the stirring rods, the top cover is connected to a driving shaft, the driving shaft is connected to the motor, a feed inlet of paraffin is formed in the driving shaft, and the feed inlet extends into the smelter downward along the driving shaft. According to the manufacturing equipment provided by the invention, coarse glass sand is prepared by using leftovers of glass, so that raw materials are saved; furthermore, a step of preparing glass at a high temperature is further cancelled, so that the preparation cost is lowered. The paraffin glass sand manufactured by the equipment forms cakes during smoke suppression, so that the cakes are only be cleaned if the paraffin glass sand is cleaned, and the manufacturing equipment is simple to operate.

Owner:CHONGQING XINGYUAN GLASSWARE CO LTD

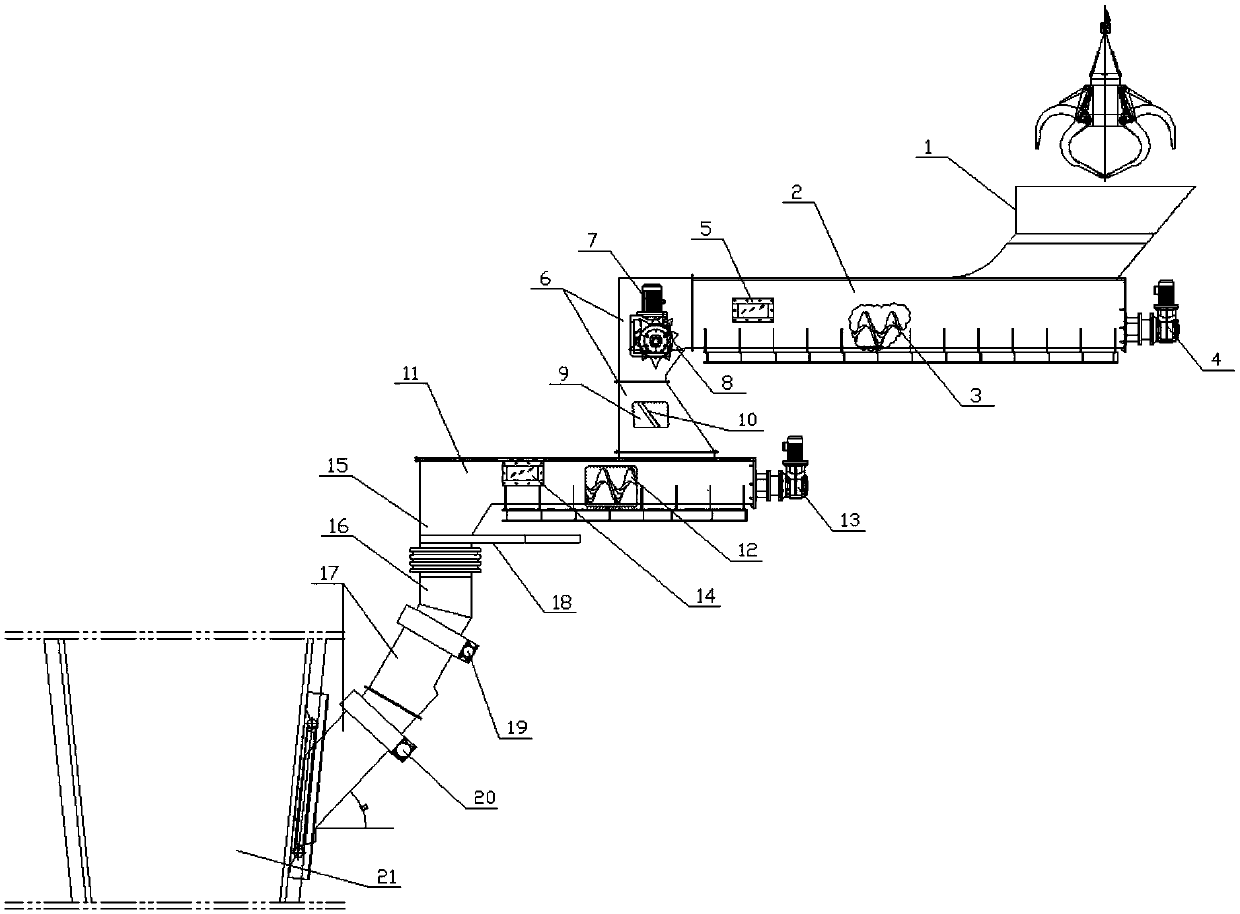

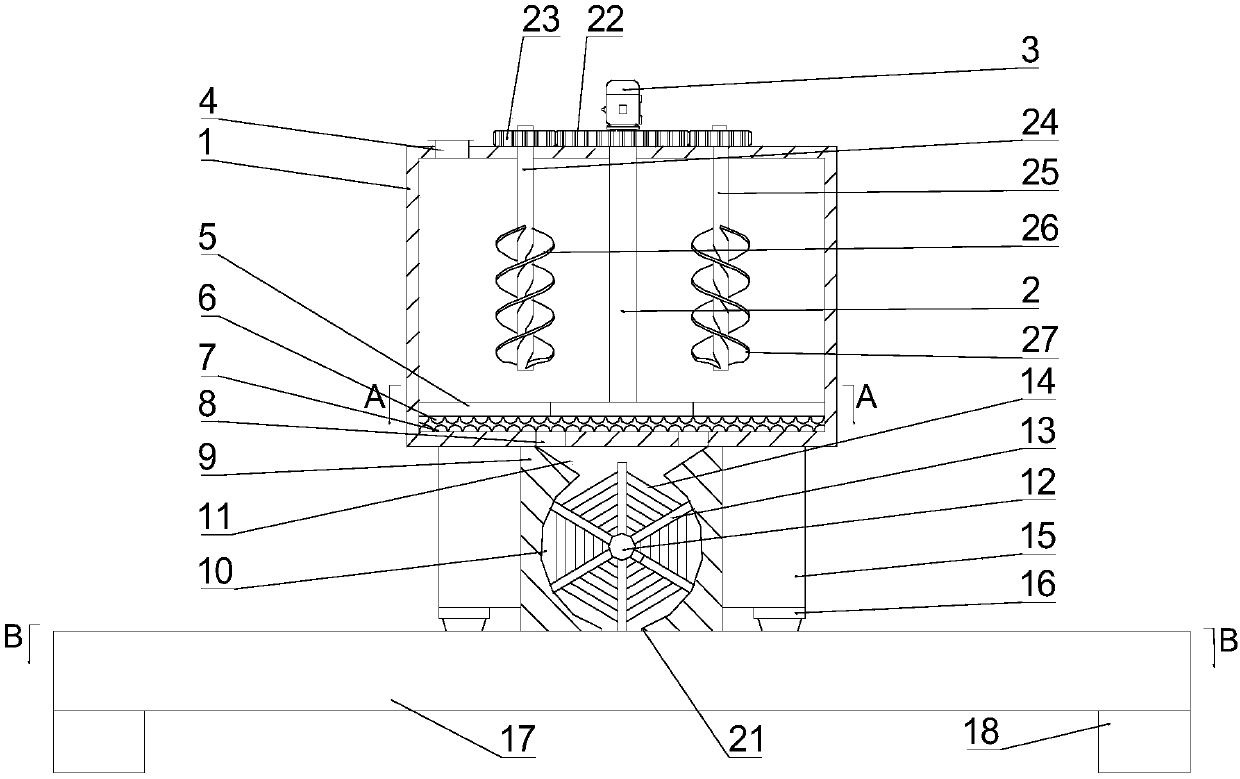

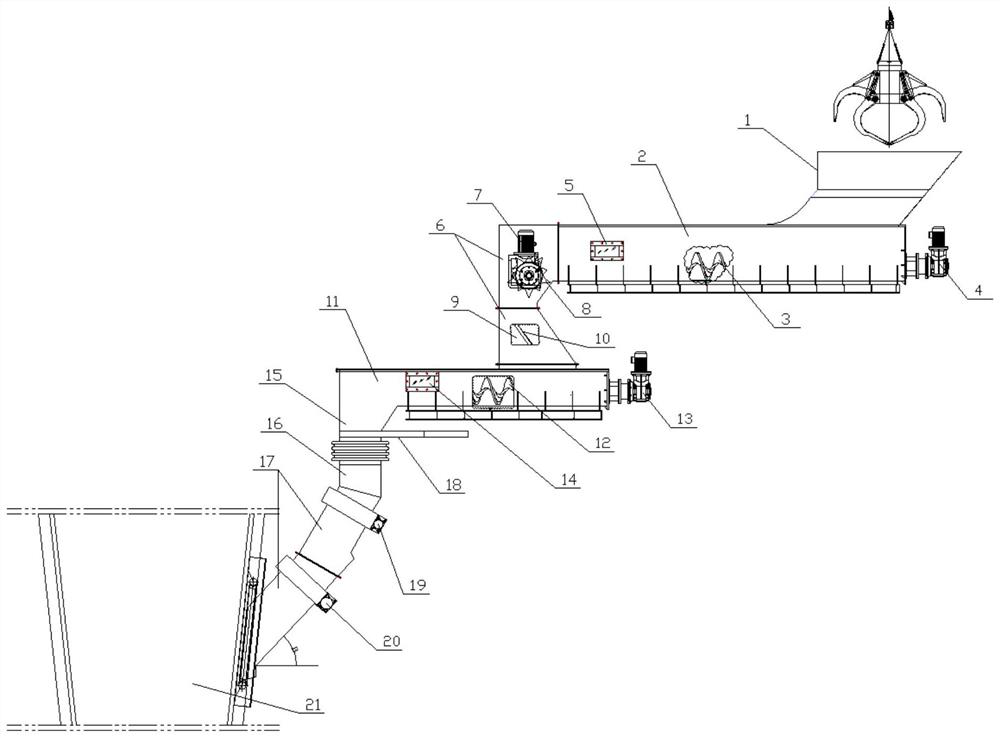

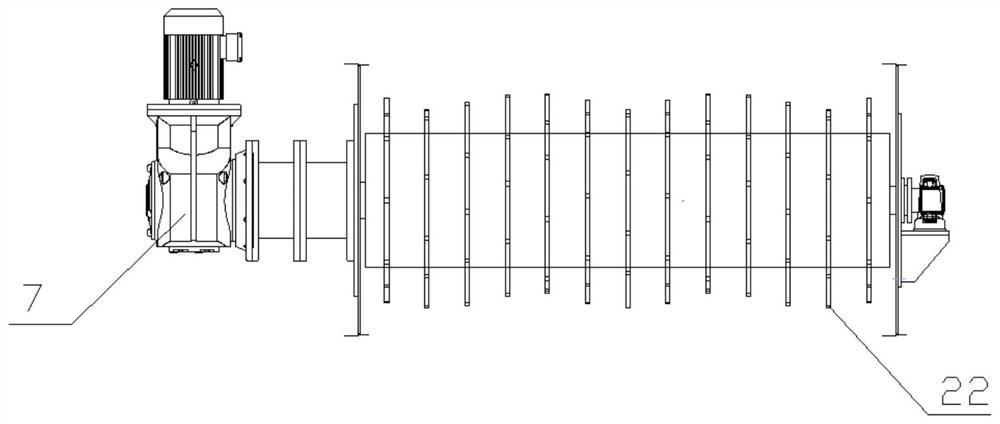

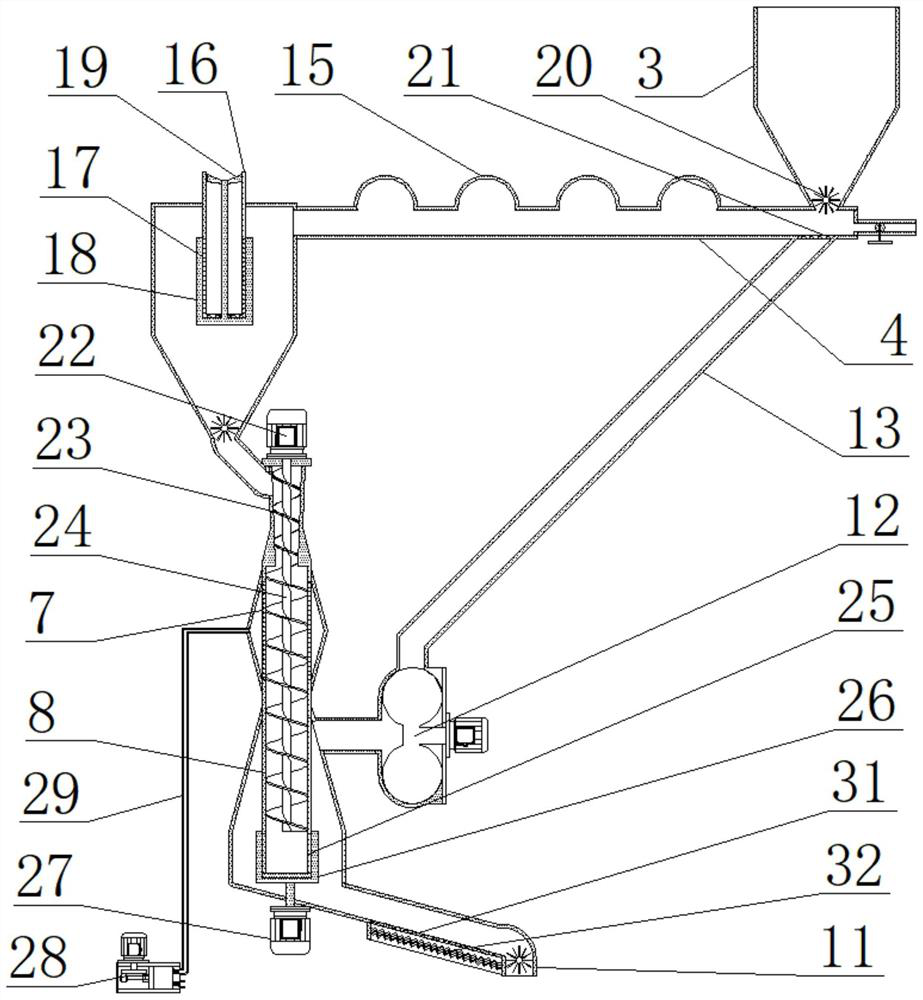

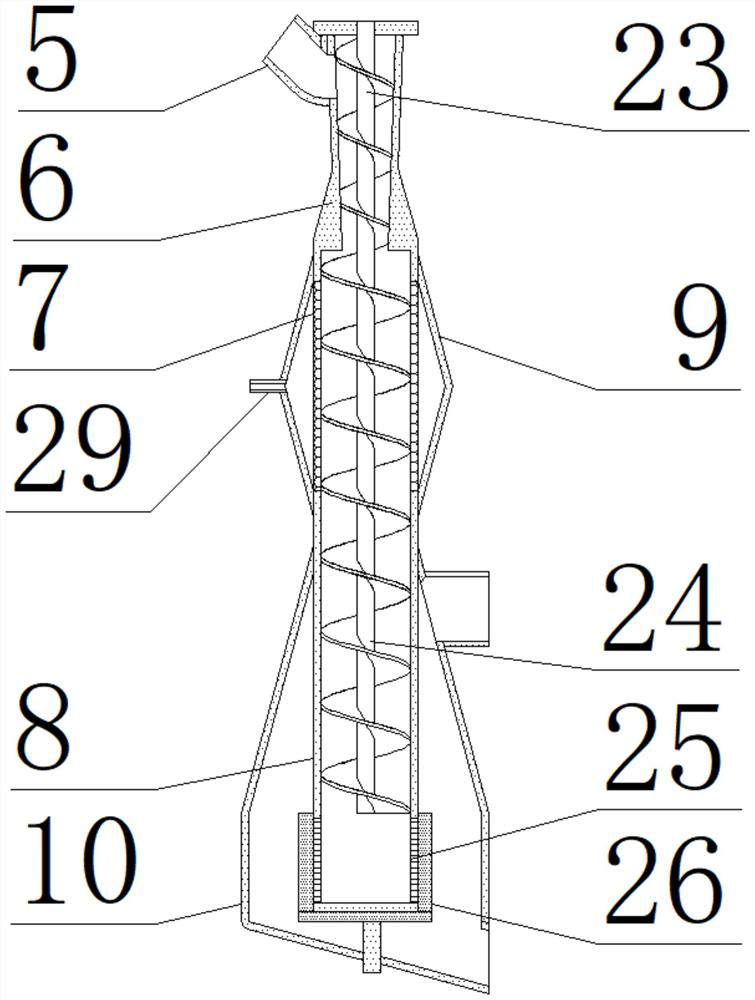

Spiral feeding system in front of circulating fluidized bed garbage incinerator

ActiveCN109611865BSolve the problem of clumpingGuaranteed loosenessIncinerator apparatusFlue gasFluidized bed

Owner:甸石(上海)环保科技有限公司

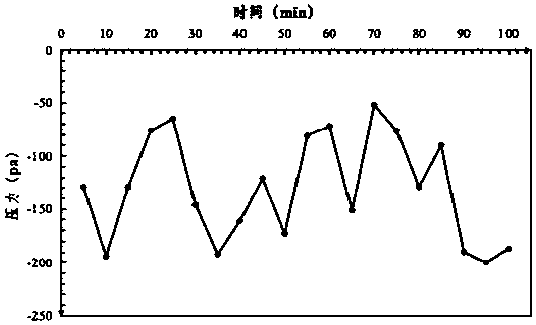

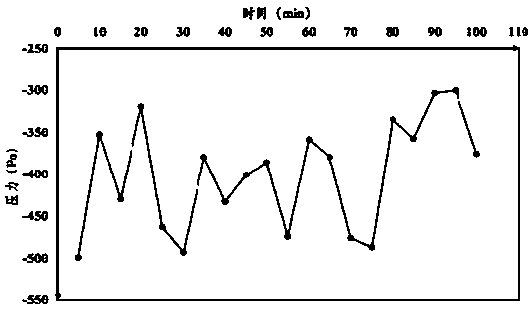

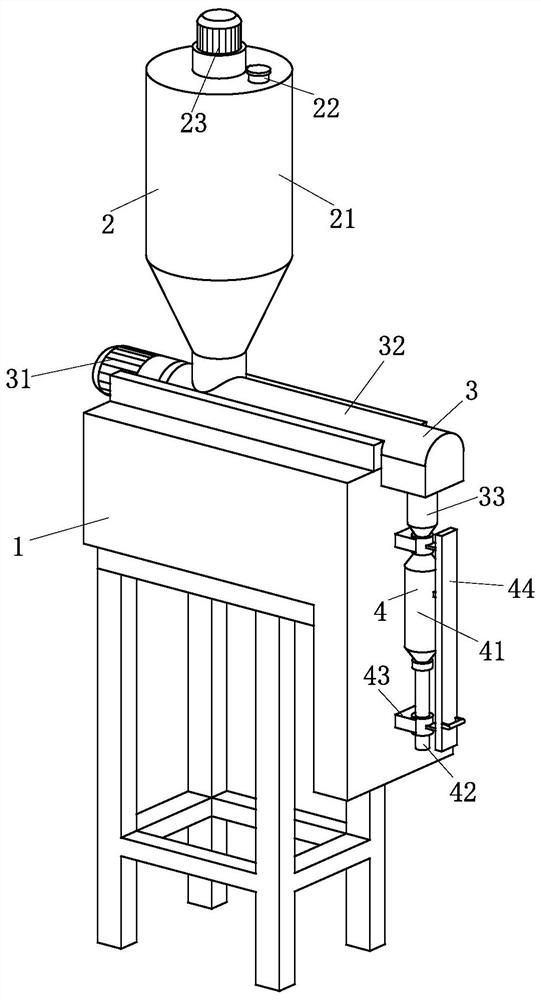

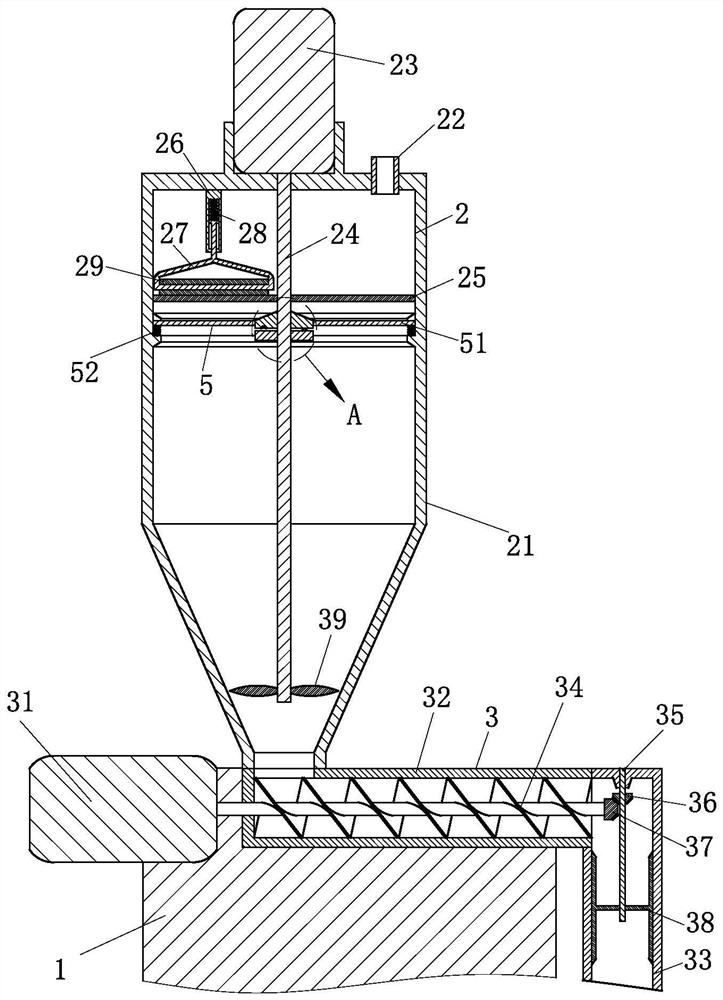

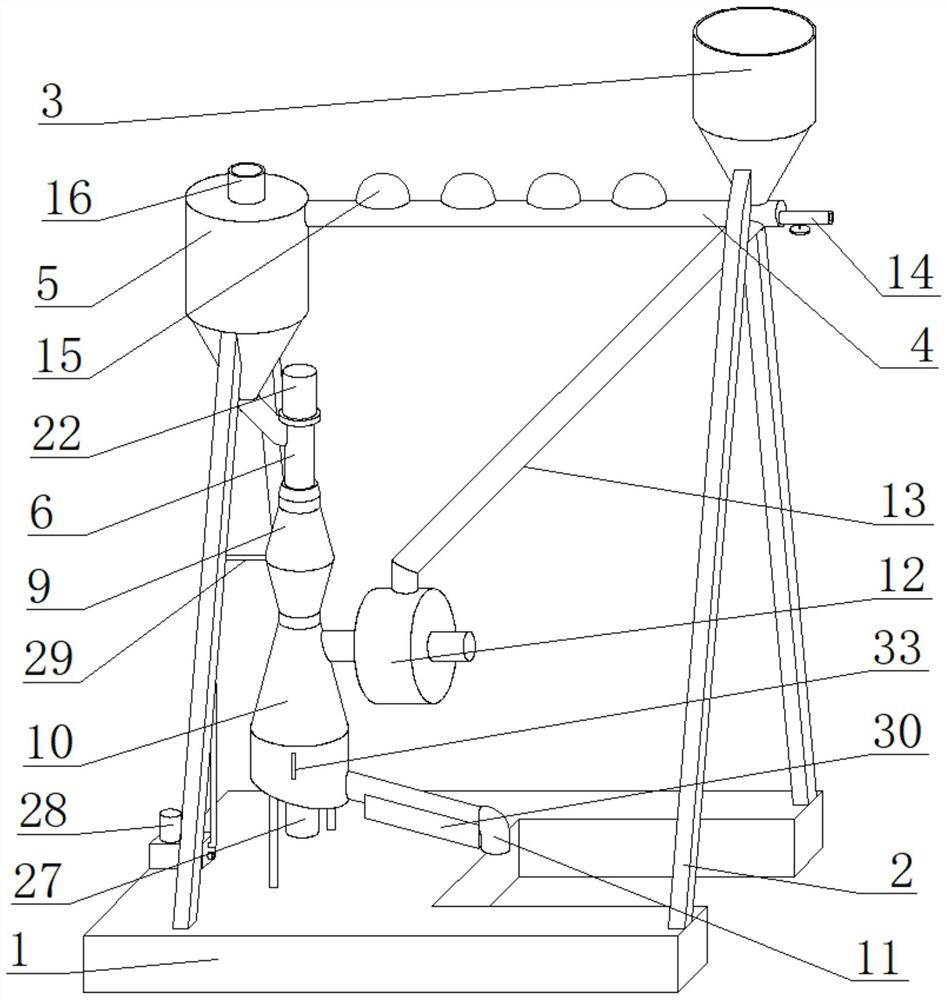

Negative-pressure quantitative powdery material adding system

PendingCN112960405AReduce wasteGuaranteed loosenessBulk conveyorsLoading/unloadingEngineeringMechanical engineering

The invention relates to the technical field of powdery material conveying, in particular to a negative-pressure quantitative powdery material adding system which solves the problem of uniform and quantitative feeding of powdery materials. The negative-pressure quantitative powdery material adding system comprises a material bin, a discharging hopper, a discharging device, a receiving device, a negative-pressure fan and a feeding pipeline which are sequentially connected. A mesh screen is arranged on the material bin. A powder batcher is arranged in the discharging device, a steel wire mesh is arranged between an upper end opening of the receiving device and the discharging device, an air adjusting valve is arranged between a lower end opening of the receiving device and the negative pressure fan, a connecting frame is arranged at the bottom of the discharging device, and a plurality of notches for installing the connecting frame are formed in the side wall of the upper end opening of the receiving device. Dispersed feeding of quantitative materials is achieved. And good development prospects are achieved in the technical field of powdery material conveying.

Owner:XINXIANG HUARUI POWER SUPPLY MATERIAL

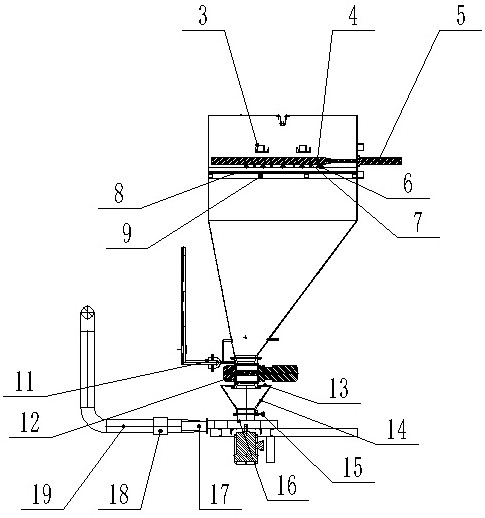

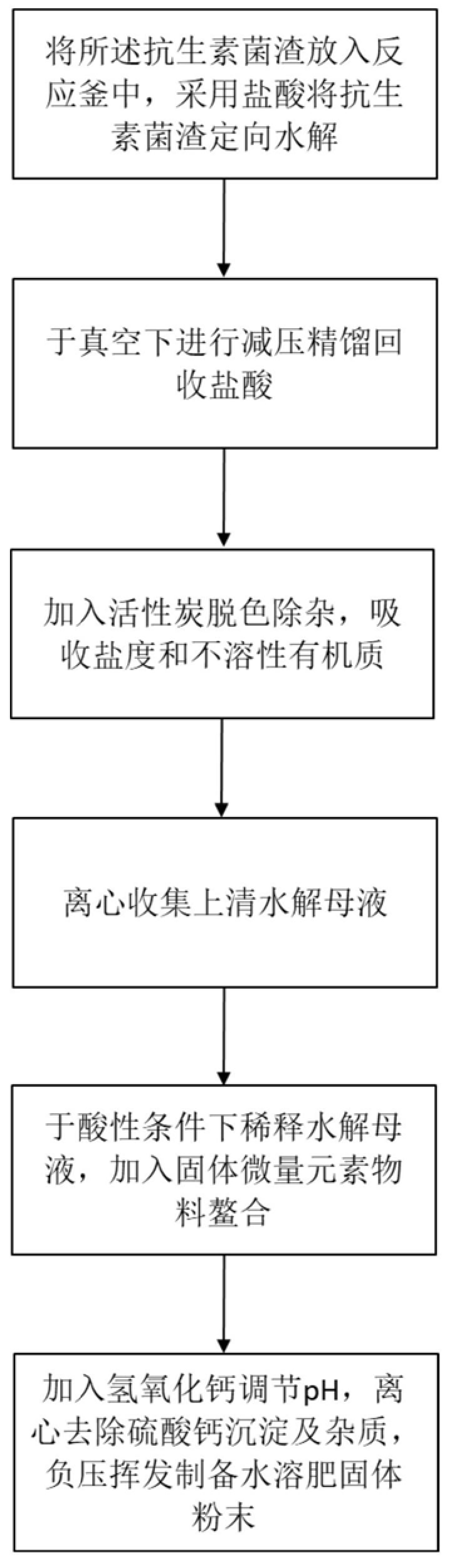

Multi-element composite water-soluble fertilizer solid powder prepared from antibiotic mushroom dregs and method and application thereof

InactiveCN111440022AHigh recovery rateResidue reductionCalcareous fertilisersSolid/semi-solid fertilisersFertilizerNutrient

The invention discloses multi-element composite water-soluble fertilizer solid powder prepared from antibiotic mushroom dregs and a method and application thereof. The method comprises the steps: putting the antibiotic mushroom dregs into a reaction kettle, and using hydrochloric acid for directional hydrolysis of the antibiotic mushroom dregs; carrying out reduced pressure distillation under vacuum to recover hydrochloric acid; adding activated carbon for decoloration and impurity removal, and absorbing salinity and insoluble organic matter; centrifugally collecting supernatant hydrolysis mother liquor; diluting the hydrolysis mother liquor under an acidic condition, and adding a solid trace element material for chelating; and adding calcium hydroxide to adjust the pH value, centrifugingto remove calcium sulfate precipitate and impurities, and volatilizing under negative pressure to prepare water-soluble fertilizer solid powder. The prepared multi-element water-soluble fertilizer solid powder can be applied to gardening, fruits and vegetables, farmlands, forests or urban landscaping lands and can degrade and remove residual antibiotics in the antibiotic fungi residues, avoid large fertilizer efficiency loss and unreasonable nutrition proportion in the degradation and removal process, improve the recovery efficiency of amino acids and reduce the loss of phytostimulant-like nutrient substances.

Owner:TONGJI UNIV

Organic fertilizer granulation equipment capable of avoiding generation of chippings and caking

PendingCN113750908AGuaranteed firmnessIntegrity guaranteedManure dryingDrying gas arrangementsAgricultural engineeringOrganic fertilizer

The invention provides organic fertilizer granulation equipment capable of avoiding generation of chippings and caking. The organic fertilizer granulation equipment comprises a base, a support and a hopper, a transverse pipe is welded at the bottom of the hopper, a cyclone cylinder is welded at one end of the transverse pipe, a sleeve is welded at the bottom of the cyclone cylinder, a filter cylinder I is welded at the bottom of the sleeve, and an inner cylinder is welded at the bottom of the filter cylinder I; and the outer side of the filter cylinder I is sleeved with a clamping cover, an outer cylinder is welded to the outer side of the inner cylinder, and an outlet pipe is welded to the bottom of one side of the outer cylinder. According to the organic fertilizer granulation equipment capable of avoiding chippings and caking, the situation that organic fertilizer particles are expanded and scattered due to internal air expansion can be prevented, the completeness of the organic fertilizer particles is guaranteed, organic fertilizer chippings are prevented from occurring, the organic fertilizer is prevented from being adhered together during storage, the subsequent uniform fertilization operation of the organic fertilizer is facilitated, chippings, peculiar smell and water vapor can be absorbed by utilizing the organic fertilizer, the consumption of the water vapor is reduced, the air environment safety is guaranteed, and the equipment is suitable for granulation of the organic fertilizer.

Owner:周建伟

Tobacco feeding mechanism

PendingCN114515013AImprove heat transfer performanceGuaranteed loosenessTobacco preparationFinal product manufactureAgricultural engineeringBiology

The invention provides a tobacco feeding mechanism which comprises a heating roller, a feeding mechanism and a feeding mechanism. The nozzle is arranged on the discharging cover; the feed liquid box is used for containing process water, feed liquid or spices; the liquid driving device is communicated with the nozzle and the feed liquid box, and the liquid driving device is suitable for driving the process water, the feed liquid or the spice in the feed liquid box and conveying the process water, the feed liquid or the spice into the nozzle; the air compression device is communicated with the nozzle through a compressed air pipeline, compressed air is discharged into the nozzle from the compressed air pipeline, and the process water, the feed liquid or the perfume in the nozzle is driven by the compressed air to be sprayed into the discharging cover through the nozzle. The heating, humidifying, charging and perfuming all-in-one machine is achieved, tobacco baking is achieved through the heating roller, the looseness of the tobacco is guaranteed, and the tobacco is not prone to adhering to the roller wall. And a high-temperature steam structure does not need to be additionally arranged, so that the product structure is simpler, and the whole product is relatively compact and small and can be better applied to places such as laboratories.

Owner:QINHUANGDAO TOBACCO MACHINERY

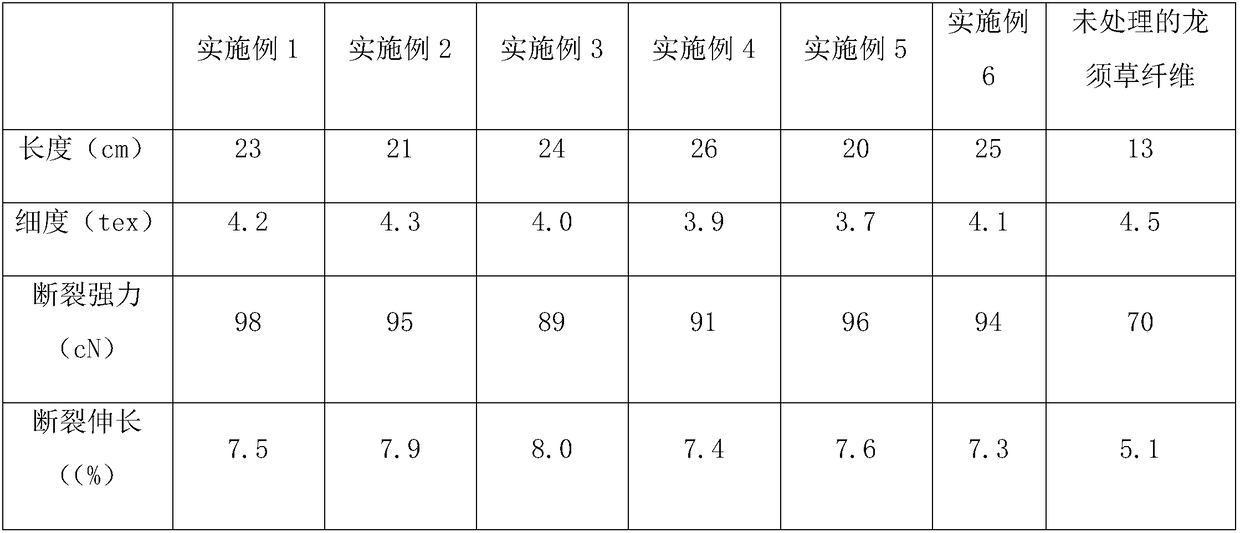

A kind of preparation method of modified asparagus fiber

ActiveCN105862140BImprove permeabilityImprove solubilityFibre treatment to obtain bast fibreFiberAcetic anhydride

Owner:TAIZHOU LAI & KE INTELLIGENT TECH CO LTD

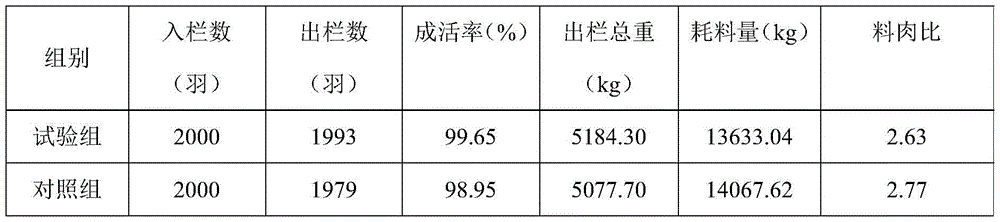

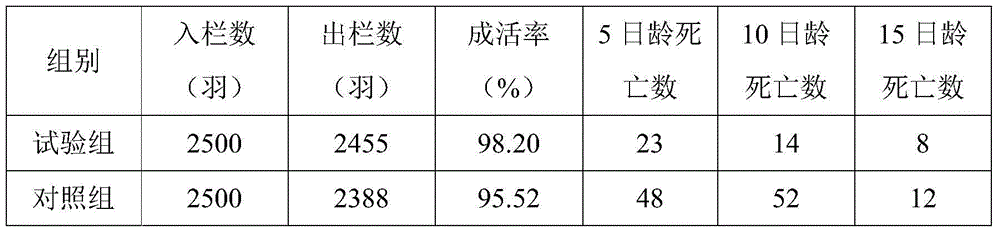

Micro-ecological bedding material for raising aquatic birds and preparation method thereof

ActiveCN105766694AReduce moisture contentOvercome the problems of low waste disposal capacity and easy compactionBird housingsDecompositionMicrobial agent

The invention relates to a micro-ecological bedding material for raising aquatic birds. The bedding material is a two-component bedding material, is divided into two dosage forms, namely A and B and is a biomass material high in lignin content; the bedding material is formed by laying the dosage form A and the dosage form B after a microbial preparation is inoculated in two treatment modes. According to the micro-ecological bedding material for raising aquatic birds and the preparation method thereof, the biomass material high in lignin content is treated with a microbial agent, then the biomass material is used as the aquatic bird bedding material, the problems that an existing bedding material is low in waste treatment capability and prone to hardening are solved, by means of the bedding material, the carbon dioxide content in an environment can be remarkably lower than that obtained by using other fermented bedding materials, meanwhile, the bedding material is obviously loose, and excrement decomposition capability is great.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

Powder grinding aid adding device

PendingCN113772343AAvoid stickingGuaranteed loosenessLarge containersControl devices for conveyorsSpiral bladeControl system

The invention discloses a powder grinding aid adding device which comprises a hopper, a stock bin and a spiral conveying mechanism. A first feeding port and a first discharging port are formed in the stock bin, and the hopper is connected with the stock bin through the first feeding port. The spiral conveying mechanism comprises a first driving motor and a spiral blade, and the spiral blade is driven by the first driving motor to rotate in the stock bin. The device further comprises a buffering hopper, a buffering stock bin, a double-screw discharging device, an air cannon device and a control system, and the stock bin is connected with the buffering hopper through the first discharging port. The buffering stock bin is arranged at the bottom of the buffering hopper. The air cannon device comprises an air cannon body, an electromagnetic valve, an air cannon controller and a plurality of nozzles. The nozzles are dispersedly arranged in the hopper, the stock bin and the buffering hopper. The powder grinding aid adding device can effectively avoid the adhesion phenomenon of the powder grinding aid on different parts, shutdown maintenance is avoided, discharging is stable, and the performance consistency of cement products is high.

Owner:唐山冀东水泥外加剂有限责任公司 +2

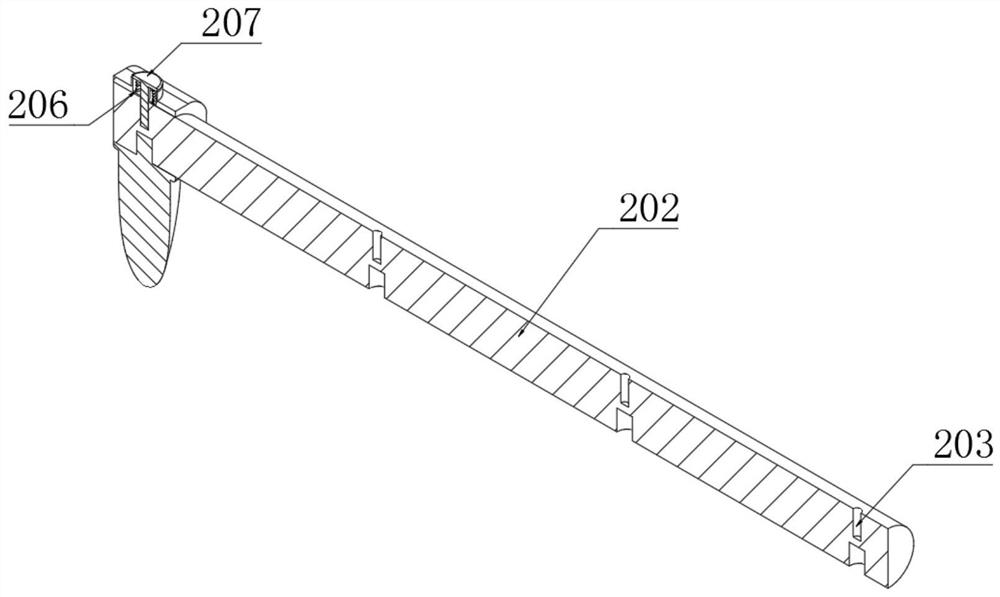

Silk production line embedded in flexible diversion conveying process structure

ActiveCN111758989BImprove loosenessIncrease flexibilityTobacco preparationControl devices for conveyorsClassical mechanicsMechanical engineering

The invention discloses a silk-making special line embedded in a flexible diversion conveying process structure, which belongs to the technical field of tobacco machinery. The silk-making special line embedded flexible flow diversion conveying process structure includes a vibrating tank main body, a side plate, a deck, a connecting plate, a bearing plate, a first bearing, a first rotating shaft, a first flow guide bar, and a second flow guide bar , the second bearing, the second rotating shaft, the lifting seat, the corrugated telescopic plate and the support plate. The present invention can adjust the position of the first guide bar and the second guide bar from left to right according to the discharge requirement of the shredded tobacco pile at the discharge port, and can also adjust the material resistance height through the lifting seat, which is flexible. Changeable, the three adjustments cooperate with each other to achieve the best loosening effect of shredded tobacco.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com