Cooling structure for integrated horizontal cold rice steaming machine

A technology of cooling structure and cold rice, which is applied in the preparation of alcoholic beverages and other directions, can solve the problems of inability to meet production requirements, insufficient looseness of rice, and poor cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The preferred embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

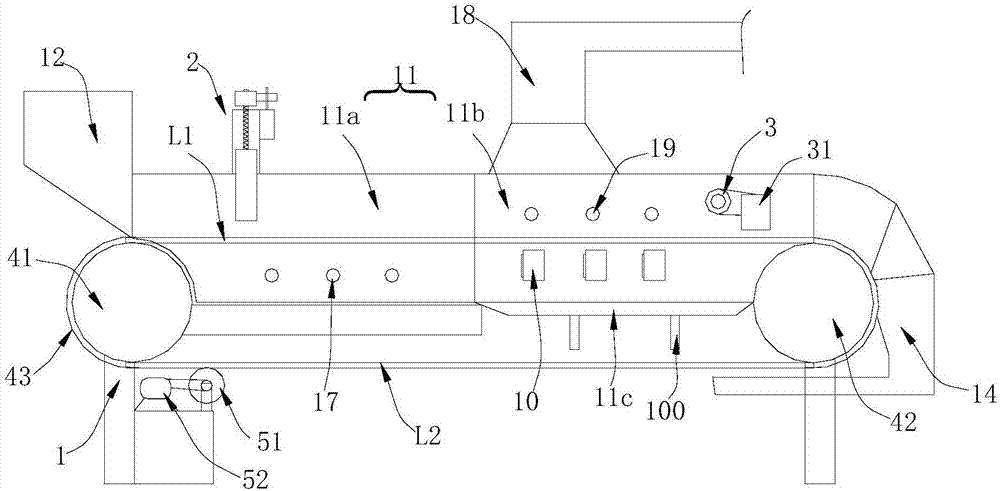

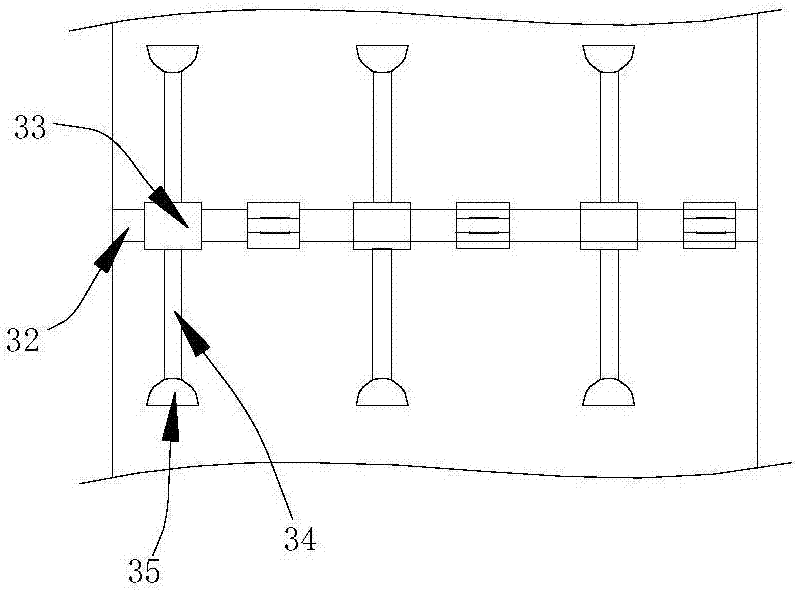

[0011] Such as Figure 1~3 The shown integrated horizontal rice steaming and cooling unit includes a cabinet 1 and a conveying mechanism.

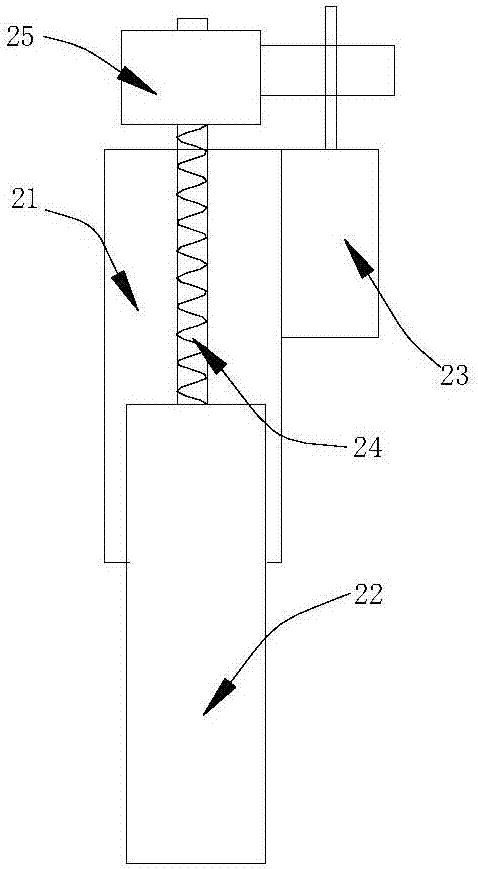

[0012] The inside of the cabinet 1 is provided with a linear box chamber 11, the top of the front end of the cabinet 1 is provided with a feed port 12 communicating with the linear cabinet chamber 11, and the cabinet 1 above the feed port 12 is provided with a feed slope, and the feed port A flow valve device 2 is provided at 12, and the flow valve device 2 includes a gantry 21 fixed on the side wall of the linear chamber 11, a valve plate 22 slidingly arranged on the gantry 21, and an adjustment device for driving the valve plate 22 to move longitudinally. Motor 23. The upper end of the valve plate 22 is connected with a screw 24 , and the output end of the adjustment motor 23 is driven and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com