Generator with lubricating grease self-transposition bearing

A generator and grease technology, applied in the direction of lubricating oil input, bearing components, shafts and bearings, etc., can solve the problems of grease deterioration, bearing wear, difficulty in determining the time of grease deterioration, etc., to avoid deterioration and prolong use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

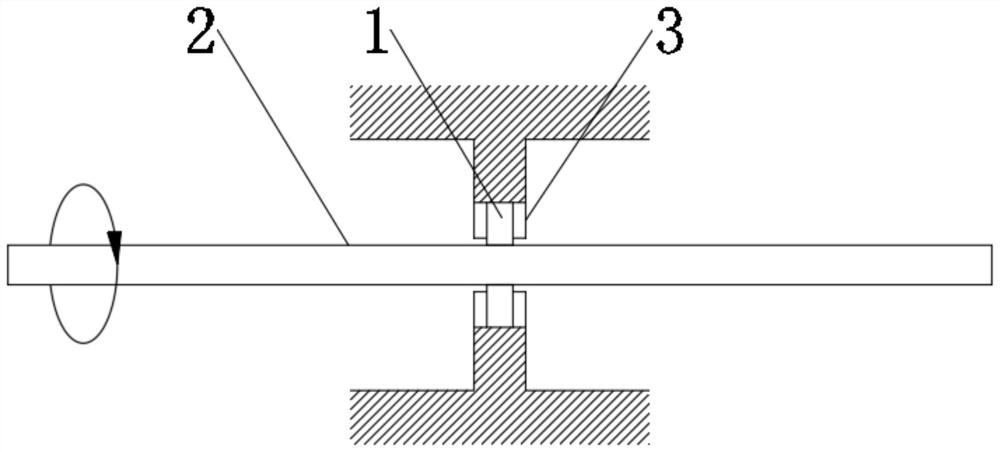

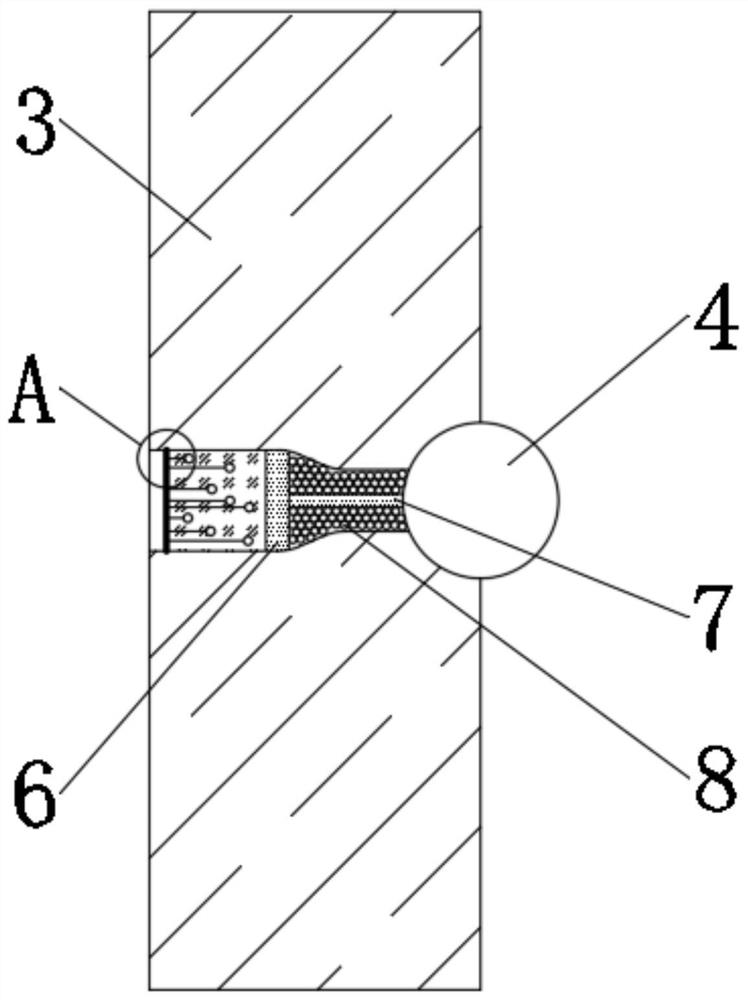

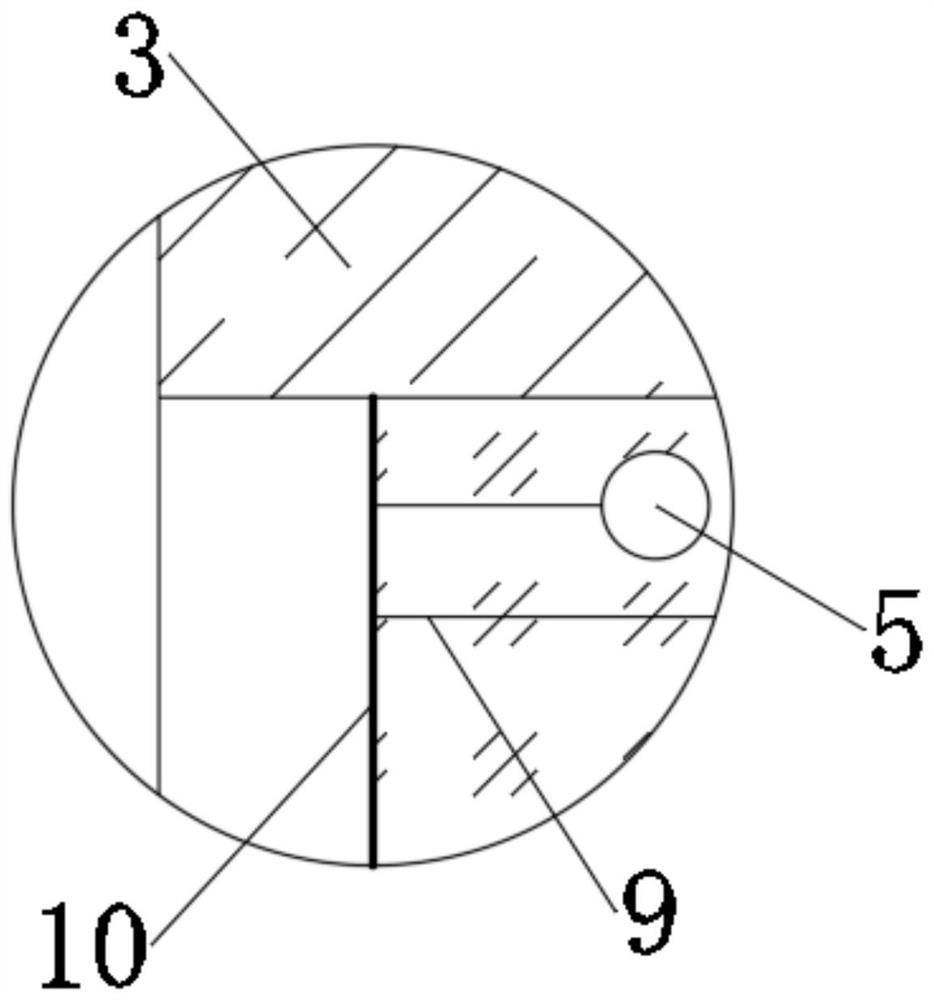

[0042] see Figure 1-2 , a generator with grease self-transfer bearings, including a generator bearing 1 and a generator shaft 2, grease changing rings 3 are installed at both ends of the generator bearing 1, and the grease changing ring 3 is far away from the generator bearing 1 One end is inlaid with a thermal dynamic magnetic ball 4, and a grease change hole corresponding to the thermal dynamic magnetic ball 4 is opened on the grease change ring 3, and a matching grease pushing block 6 is slidingly connected to the middle side of the grease changing hole, and the grease pushing block 6 is inlaid with a repelling magnet, and one end of the fat pushing block 6 close to the thermal moving magnetic ball 4 is connected with a heat conduction rod 7, and the space surrounded by the pushing fat block 6 and the thermal moving magnetic ball 4 is filled with a plurality of thermal insulation capsules 8. When the grease block 6 pushes the grease to transpose, the heat conducting rod 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com