Horizontal fluidized stirring dryer of beer grains

A technology for stirring dryers and brewer's grains, which is applied in the direction of dryers, drying solid materials, drying chambers/containers, etc. It can solve the problems of high bound water content, high viscosity of brewer's grains, and easy agglomeration, so as to improve drying efficiency , improve work efficiency, and ensure the effect of looseness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

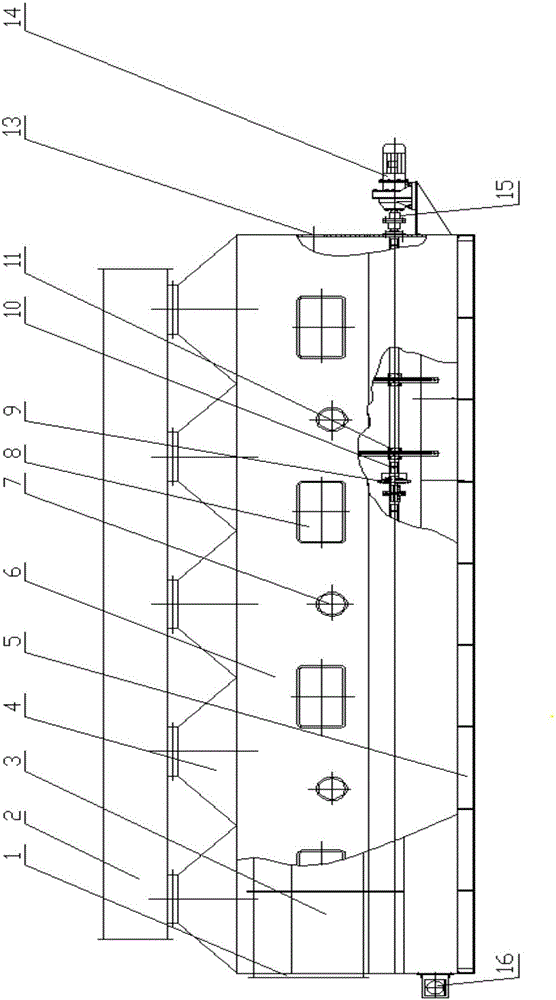

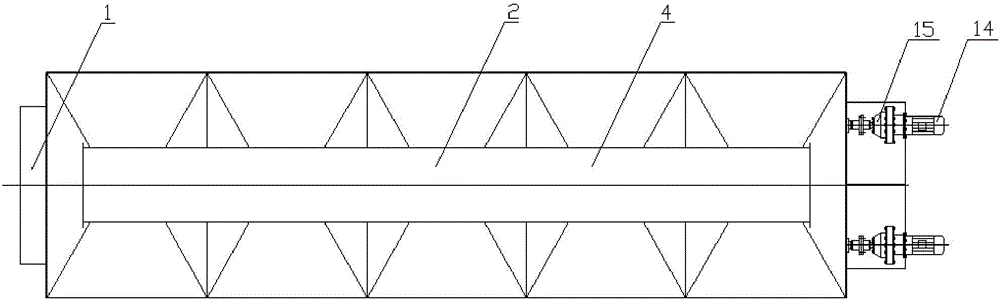

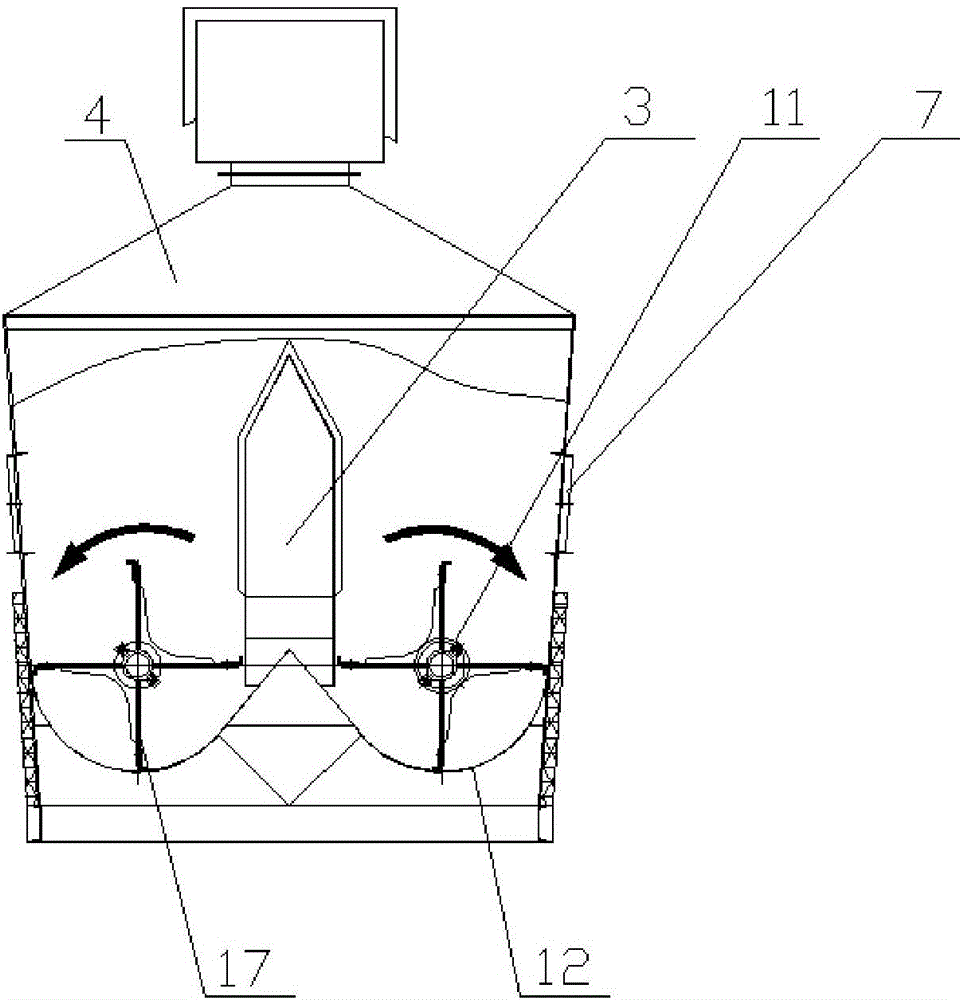

[0026] A horizontal fluidized mixing dryer for brewer's grains, including a frame 5 and a shell 6 installed on the frame. The housing is divided into two drying chambers, and the stirring shaft 10 is installed in the two drying chambers respectively. The stirring shaft is composed of multi-segment multi-segment shafts connected by a coupling 11. The stirring shaft is installed on a pair of bearings at both ends of the housing. On the seat 9, the stirring shaft is driven to rotate by the motor 14 arranged on the outside of the housing through the transmission mechanism 15. A number of stirring paddles 17 are evenly distributed on the stirring shaft, and an arc-shaped plate 12 is arranged on the inner wall of the drying chamber below the stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com