Patents

Literature

511results about How to "Fast packing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

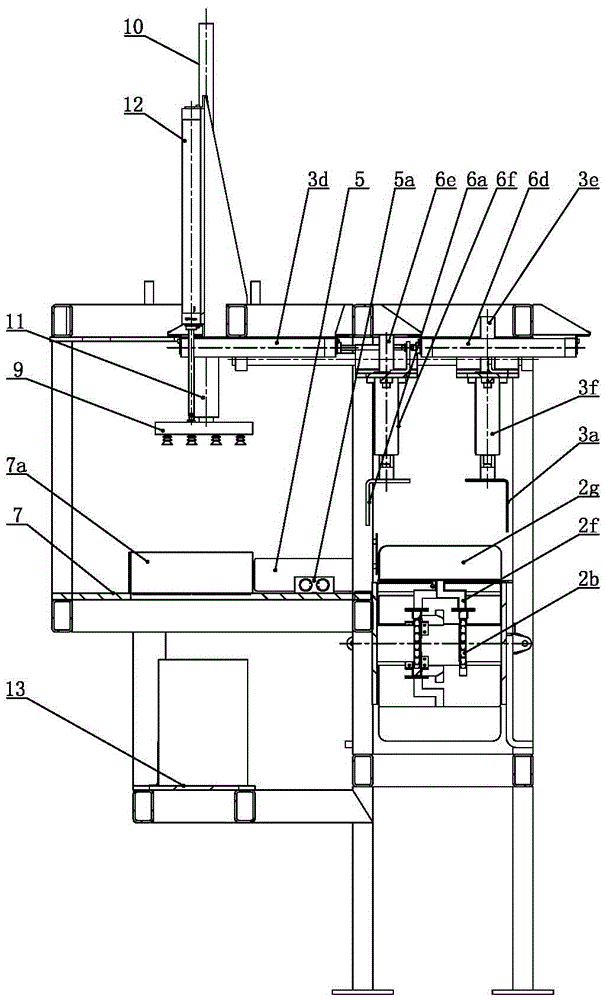

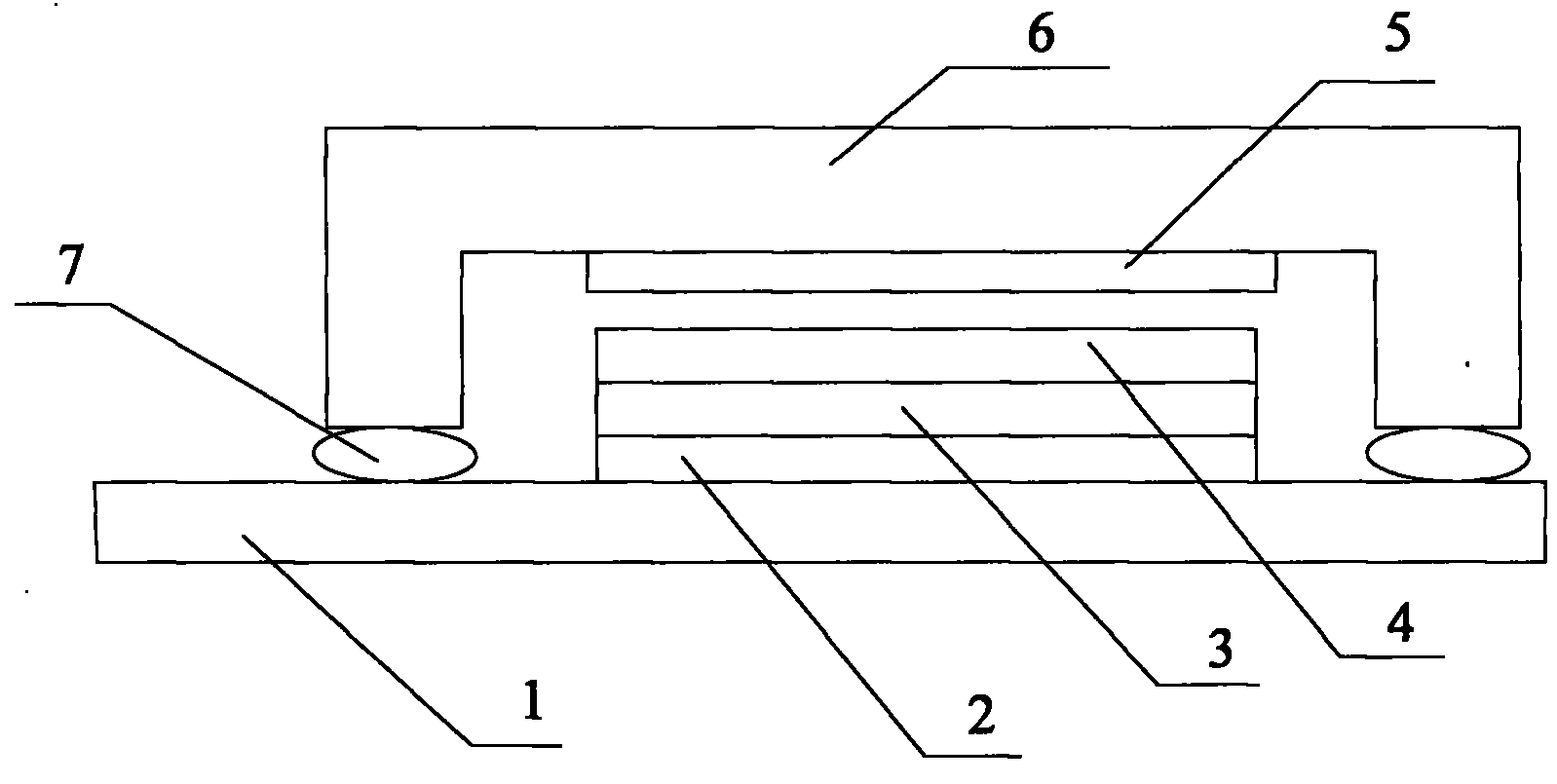

IC full-automatic method for testing brede and full-automatic holding tray type machine for testing brede

InactiveCN101244767AQuality assuranceAvoid lostSemiconductor/solid-state device testing/measurementOptically investigating flaws/contaminationElectricityControl system

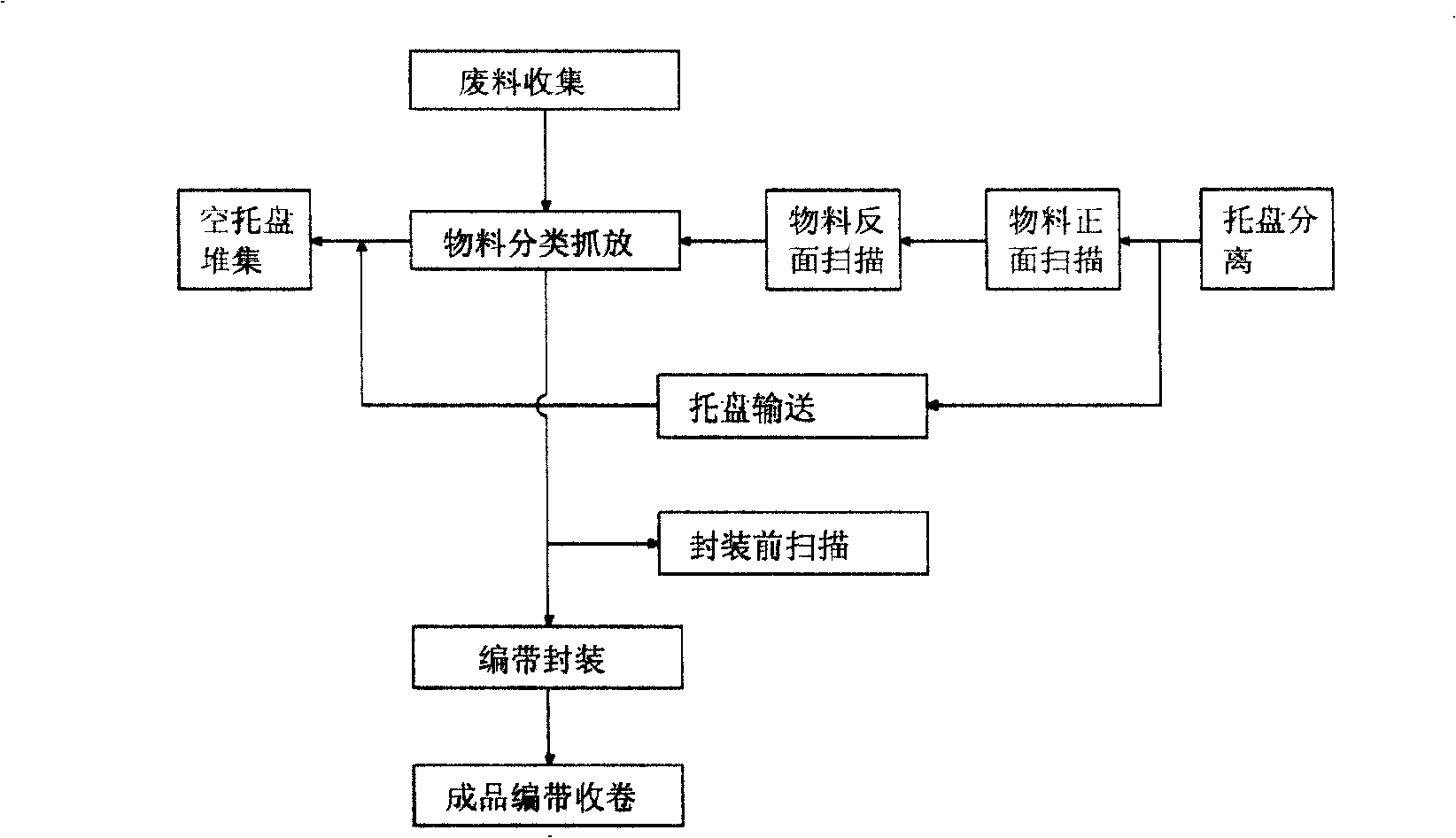

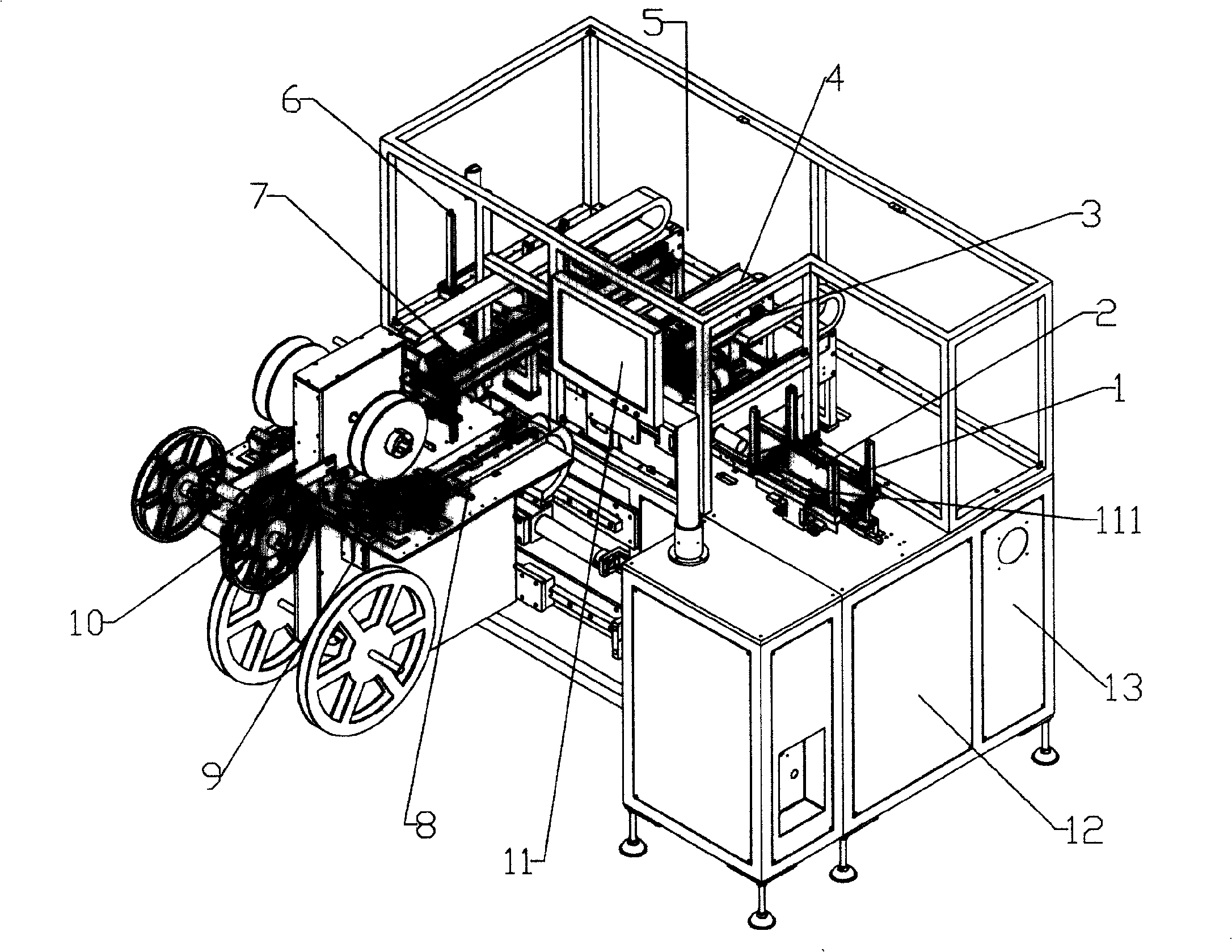

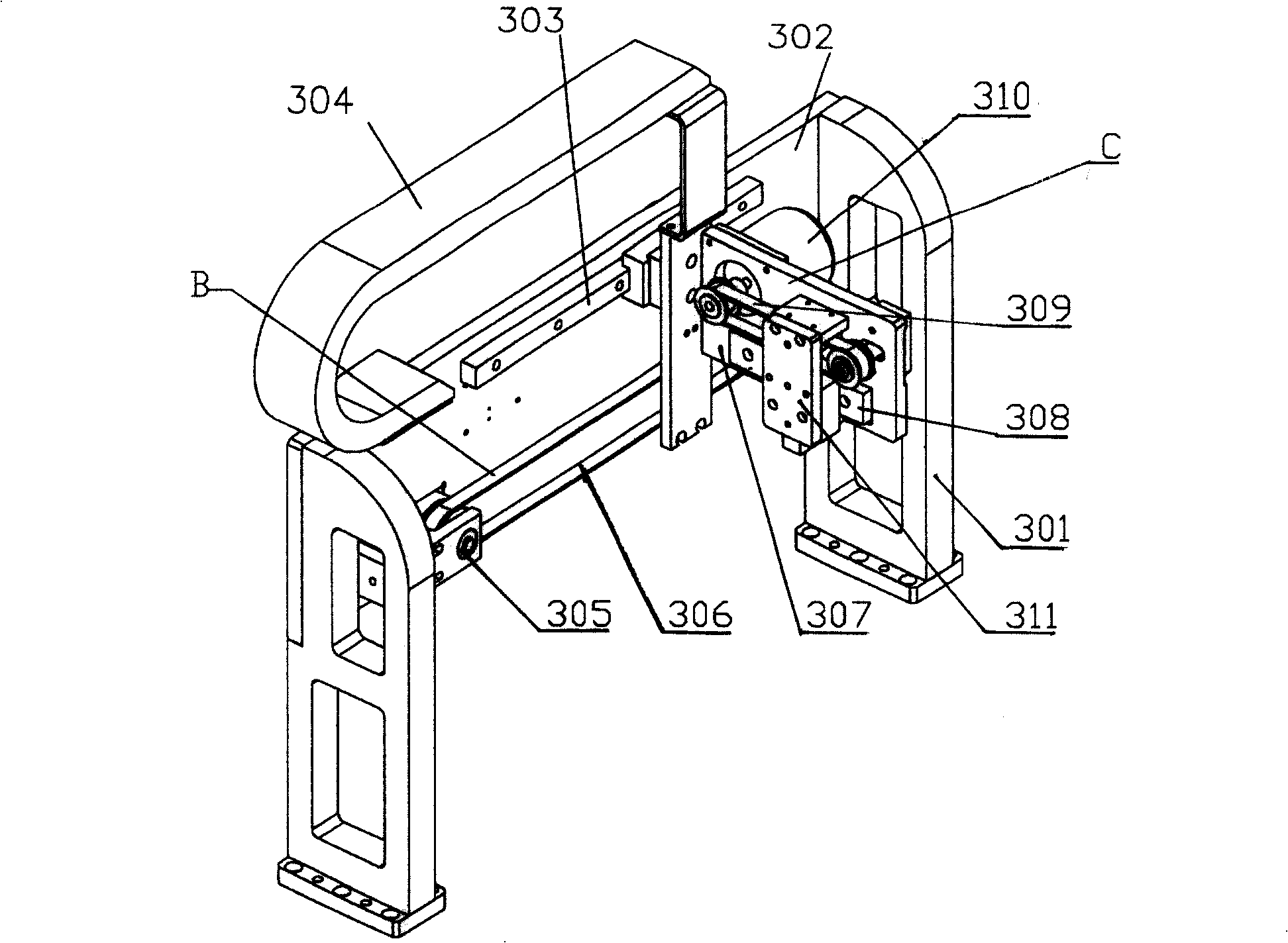

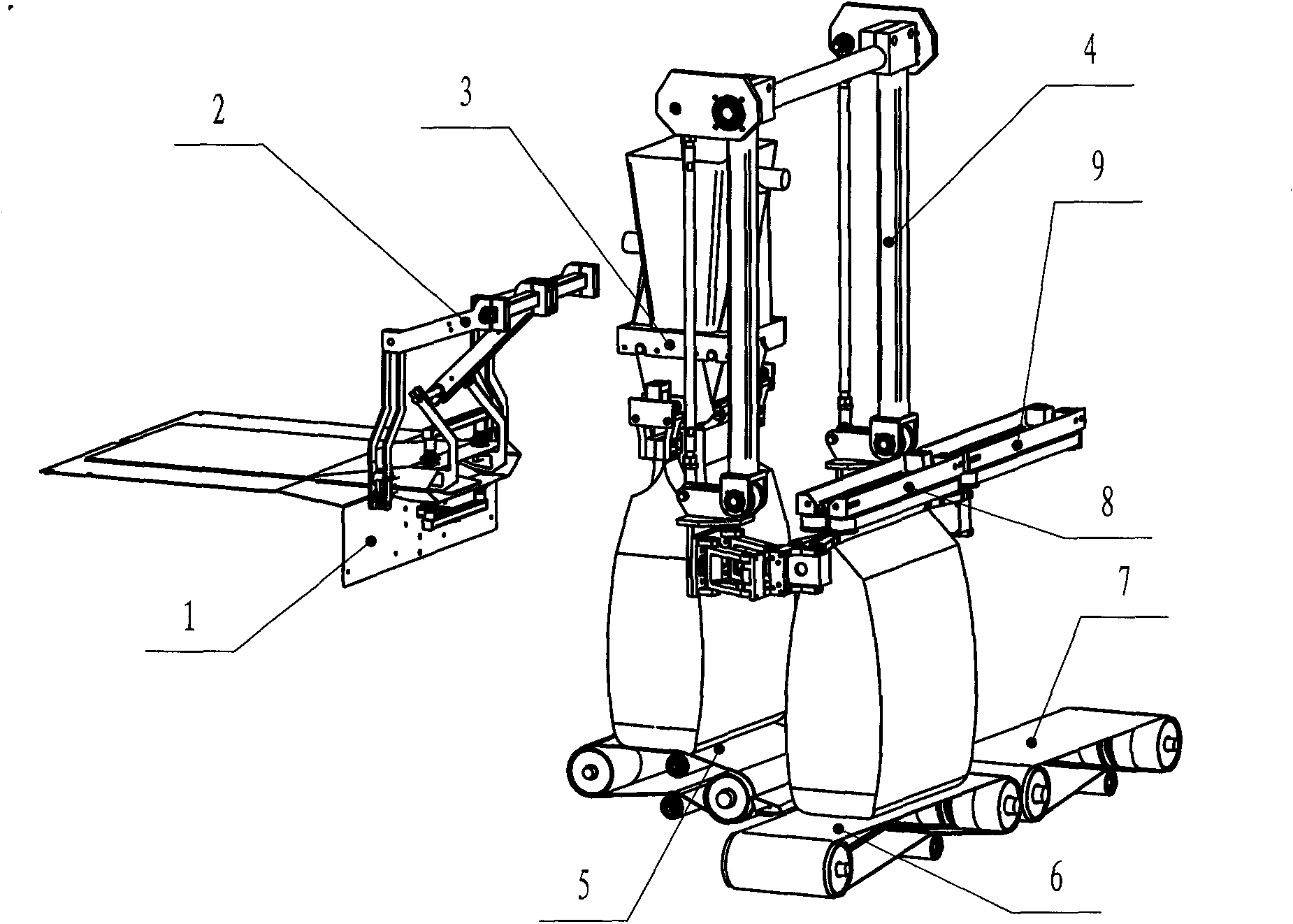

The invention discloses an IC automatic detecting braiding method and an automatic pallet type detecting braiding machine, comprising a pallet-transport device, a braiding packing device, a waste materials collecting device. A PC control system and an electrical control system as well as a pallet-separate device are arranged on the front end of the pallet transport device and an empty pallet-collect device is arranged on the back end. The braiding lead direction of the braiding packing device is vertical to the pallet-transport direction of the pallet-transport device. A face side scan device and a back side device for detecting IC as well as a catch-and-put device for catching IC from the pallet are orderly arranged in the transportation range of the pallet-transport device. The catch-and-put device is electrically connected with the PC control system and the electrical control system and is a classification catch-and-put device which can classify the ICs according to the detecting results of the face side scan device and the back side device and then send the eligible ICs to the braiding packing device and the unqualified ICs to the waste materials collecting device. The braiding machine has the advantages of good accuracy and reliability for scanning and detecting, rapid speed for braiding and packing, low composite cost and high production efficiency.

Owner:GRAND TECH SHENZHEN

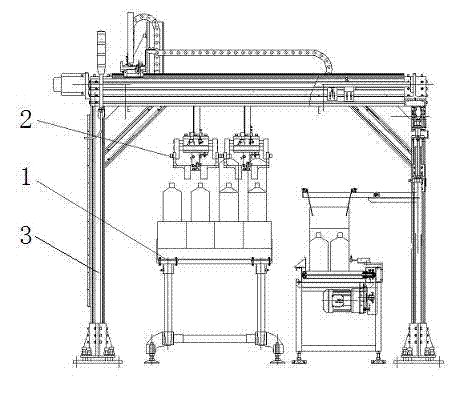

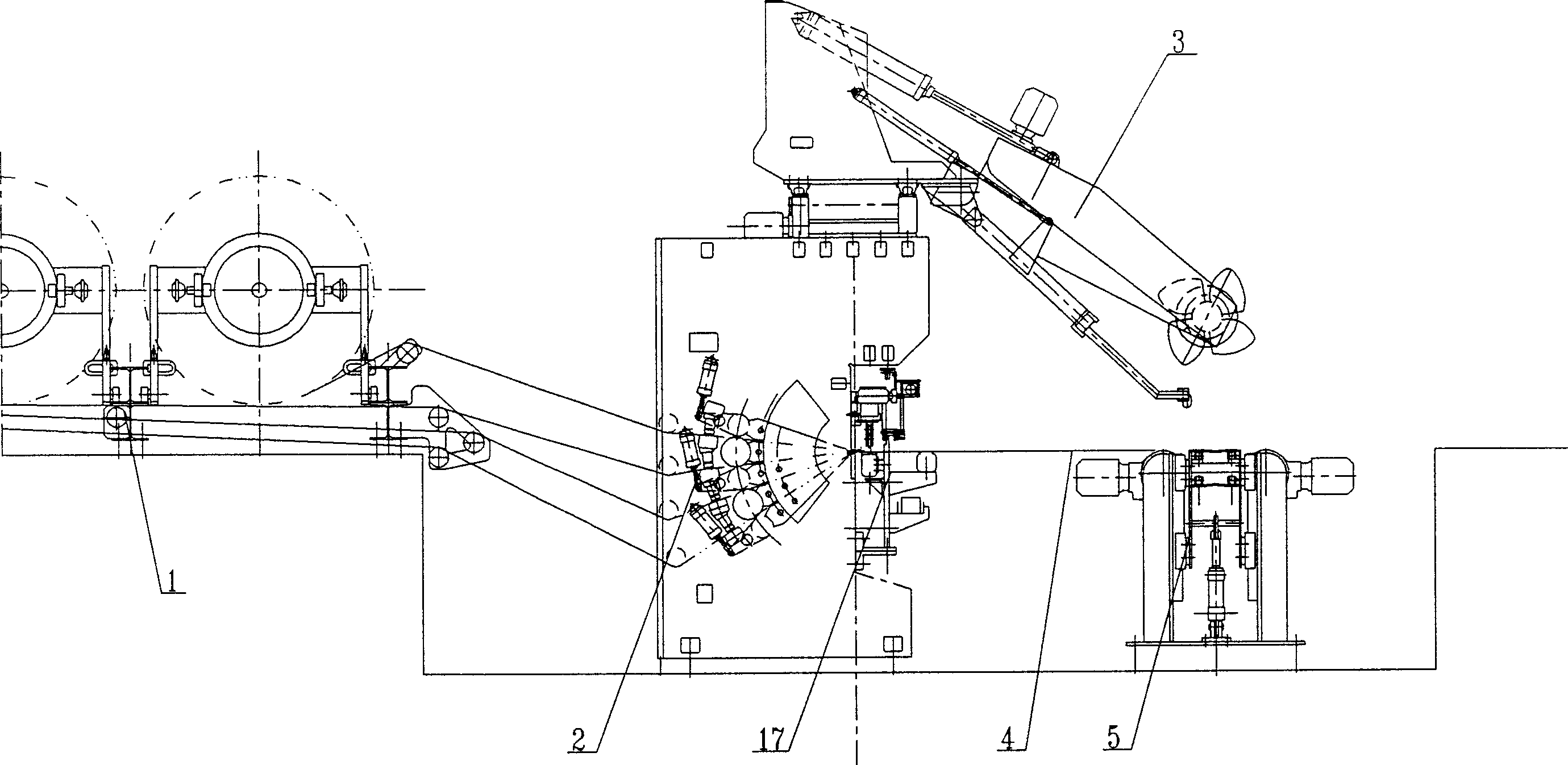

Material packaging method and device for laterally transferring full material bags

ActiveCN102275654AAvoid sliding frictionShorten the transfer distanceSolid materialFilling materialsEngineering

The invention discloses a material packing method for transversely conveying full bags, and aims to solve the problems that a full bag conveying distance is long and sliding friction exists at the bottoms of the full bags in the conventional packing method for longitudinally conveying the full bags. The packing method comprises the following steps of: (1) opening bag mouths; (2) taking empty bags; (3) sleeving the empty bags; (4) clamping the empty bags; (5) propping up contracted bag mouths; (6) filling materials in the bags; (7) grasping the full bags; (8) transversely conveying the full bags; (9) clamping the full bags; (10) outputting the full bags; and (11) conveying the full bags. By the material packing method, the material packing speed can be improved to more than 1,600 bags per hour.

Owner:HARBIN BOSHI AUTOMATION

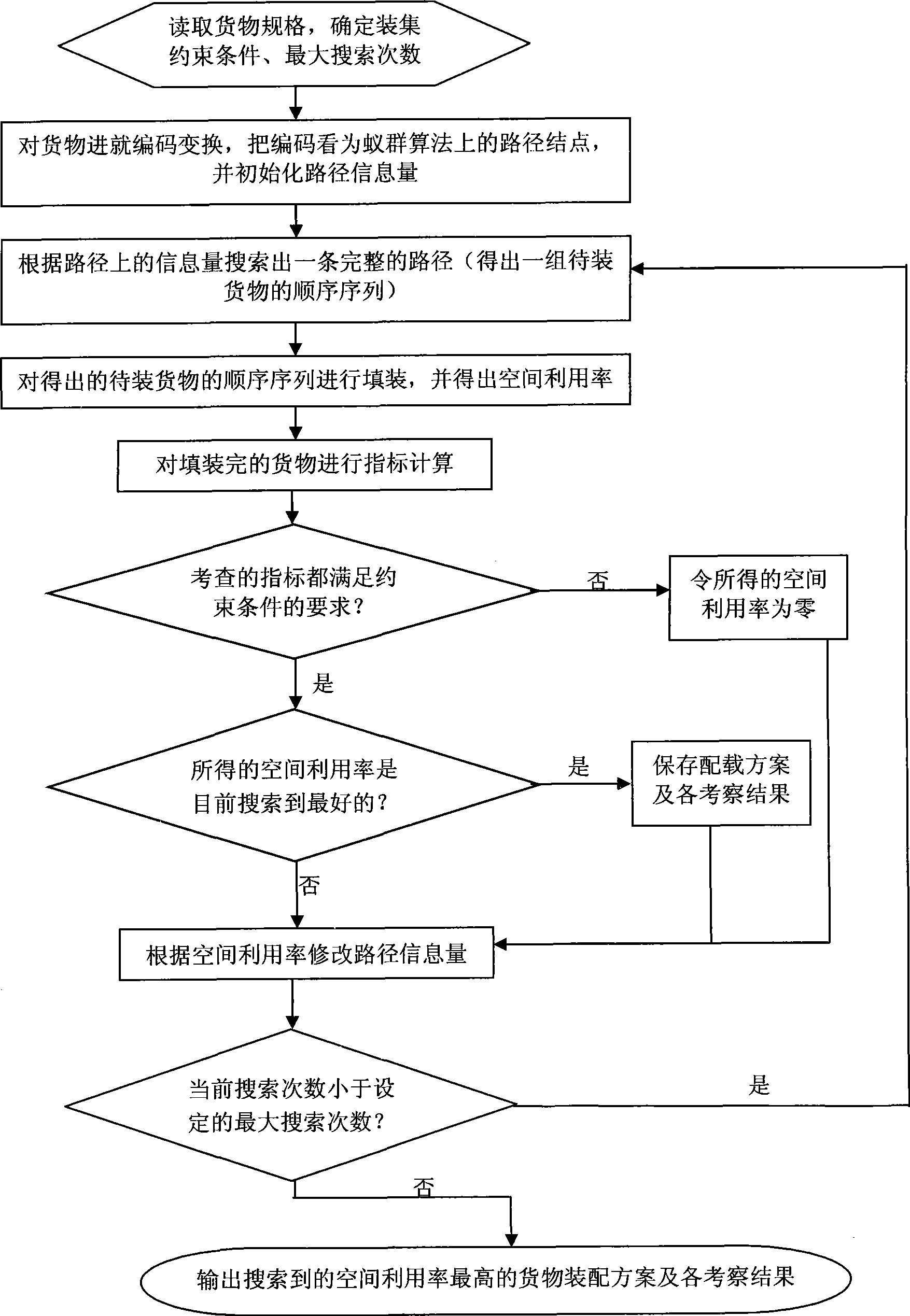

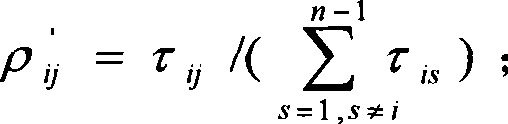

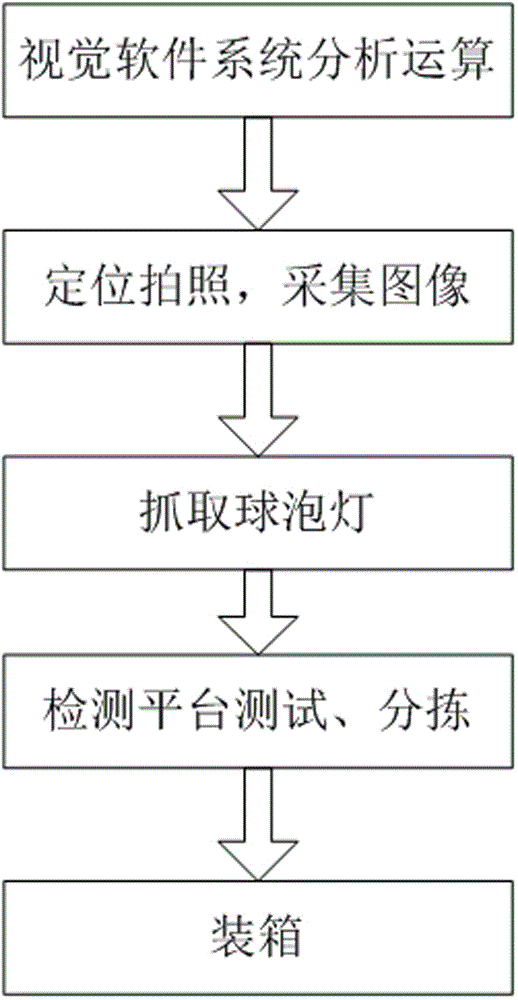

Container loading method based on ant colony algorithm

InactiveCN101381033AReduce operating costsImprove space utilizationBiological modelsLoading/unloadingLoad capacityStowage

The invention discloses a container loading method based on an ant colony algorithm. The method takes into consideration overall constraints such as the load capacity of a container, the stability of cargo placement, the convenience of loading and unloading and so on, and introduces the ant colony algorithm for a group of goods to be loaded in order to search for a stowage solution allowing for high space utilization rate. The specific proposal of the method is as follows: firstly, searching for the sequence of the goods to be loaded which allows the goods after being loaded to meet the constraints and get good space utilization rate; and secondly, loading goods according to the searched stowage solution allowing for high space utilization rate, wherein the stowage solution contains information on how goods to be placed. The container loading method of the invention has high use value.

Owner:JIANGSU UNIV OF SCI & TECH

Biaxially oriented polylactic acid film with improved heat seal properties

ActiveUS20100323196A1Lower heat seal initiation temperatureHeat seal rangeSynthetic resin layered productsLaminationPolybutylene adipate co-terephthalatePolylactic acid

Multi-layer biaxially oriented polylactic acid (BOPLA) film with a novel formulation improves the heat seal initiation temperature and heat seal performance of BOPLA films while maintaining good optical clarity. The film may include a core layer including polylactic acid base polymer resin, and a heat sealable layer including amorphous polylactic acid base polymer and a modifier comprising polycaprolactone or poly(butylene-adipate-co-butylene terephthalate).

Owner:TORAY PLASTICS AMERICA

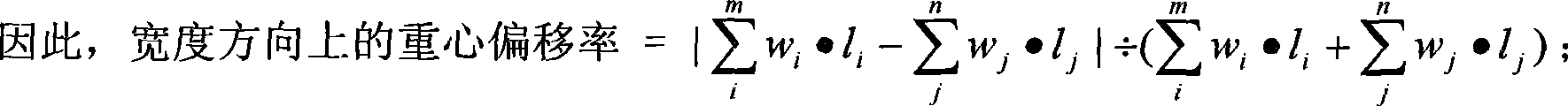

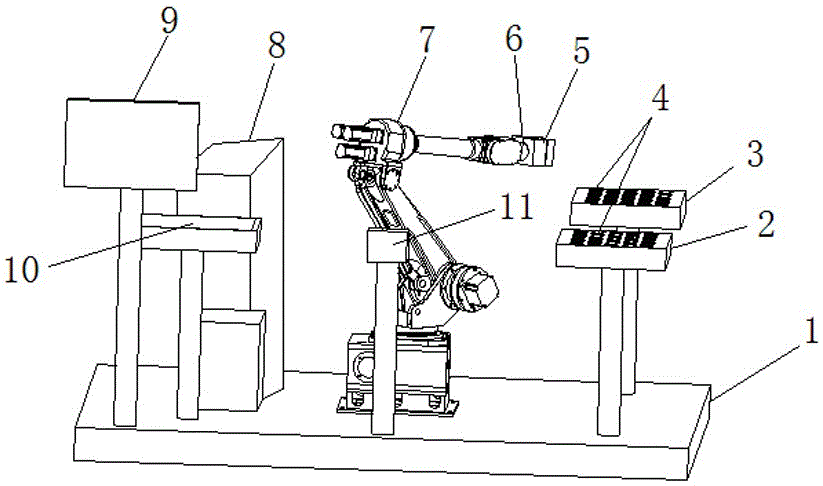

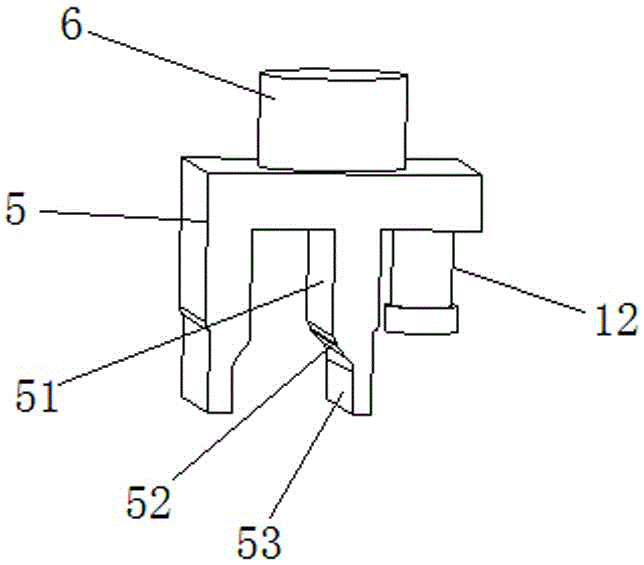

Bulb lamp sorting and packing system and method based on machine vision

ActiveCN105729472ARealize sortingSimple structureProgramme-controlled manipulatorGripping headsMachine visionSoftware system

The invention discloses a bulb lamp sorting and packing system based on machine vision. The system comprises a working platform; the working platform is provided with a robot module, a visual system module and a workpiece platform module; the robot module includes a six-axle robot, a mechanical jaw and a PLC control box; the mechanical jaw is mounted on a rotating manipulator at the end part of the six-axle robot; the workpiece platform module includes a shooting area platform, a detecting platform, a finished product box and a defective product box; the visual system module includes a 2D camera, light sources, an industrial controller all-in-one machine and a visual software system; the 2D camera is fixed on the mechanical jaw through a bracket; and multiple light sources are uniformly distributed around a shooting area. The bulb lamp sorting and packing system based on machine vision is simple in structure, high in integration degree, convenient for installation, fast in sorting speed, high in efficiency, low in cost and excellent in safety, and effectively realizes sorting and packing of bulb lamps based on machine vision.

Owner:惠州中科先进制造有限公司

Packaging process and packaging equipment for large-specification ceramic tile

ActiveCN101992864AEnsure quality stabilityRealize automatic high speedWrapper folding/bending apparatusConveyor wrappingBrickEngineering

The invention discloses a packaging process and packaging equipment for a large-specification ceramic tile. Three independent working faces are included. The centering process, the alignment patting process and the corner wrapping process of a tile stack are finished on the first working face; the prepackaging location of the tile stack is finished on the second working face by using pre-placed box packaging paper; the tile pack packaging is finished in the process of the tile stack falling to the third working face; and finally, the outlet tiles of the tile pack are conveyed on the third working face. The packaging equipment comprises three working platforms, wherein the first working platform is provided with a centering mechanism, an alignment patting mechanism and a corner picking and placing mechanism; the second working platform is provided with a vertical packaging device; and the third working platform is arranged below the second working platform and is provided with an outlet tile conveying device. The invention adopts a brand-new packaging process flow and the packaging equipment with a brand-new layout to package the large-specification ceramic tile, makes the packaging speed greatly improved under the condition of ensuring the packaging quality stability and realizes automatic high-speed corner-wrapping packaging.

Owner:KEDA INDUSTRIAL GROUP CO LTD

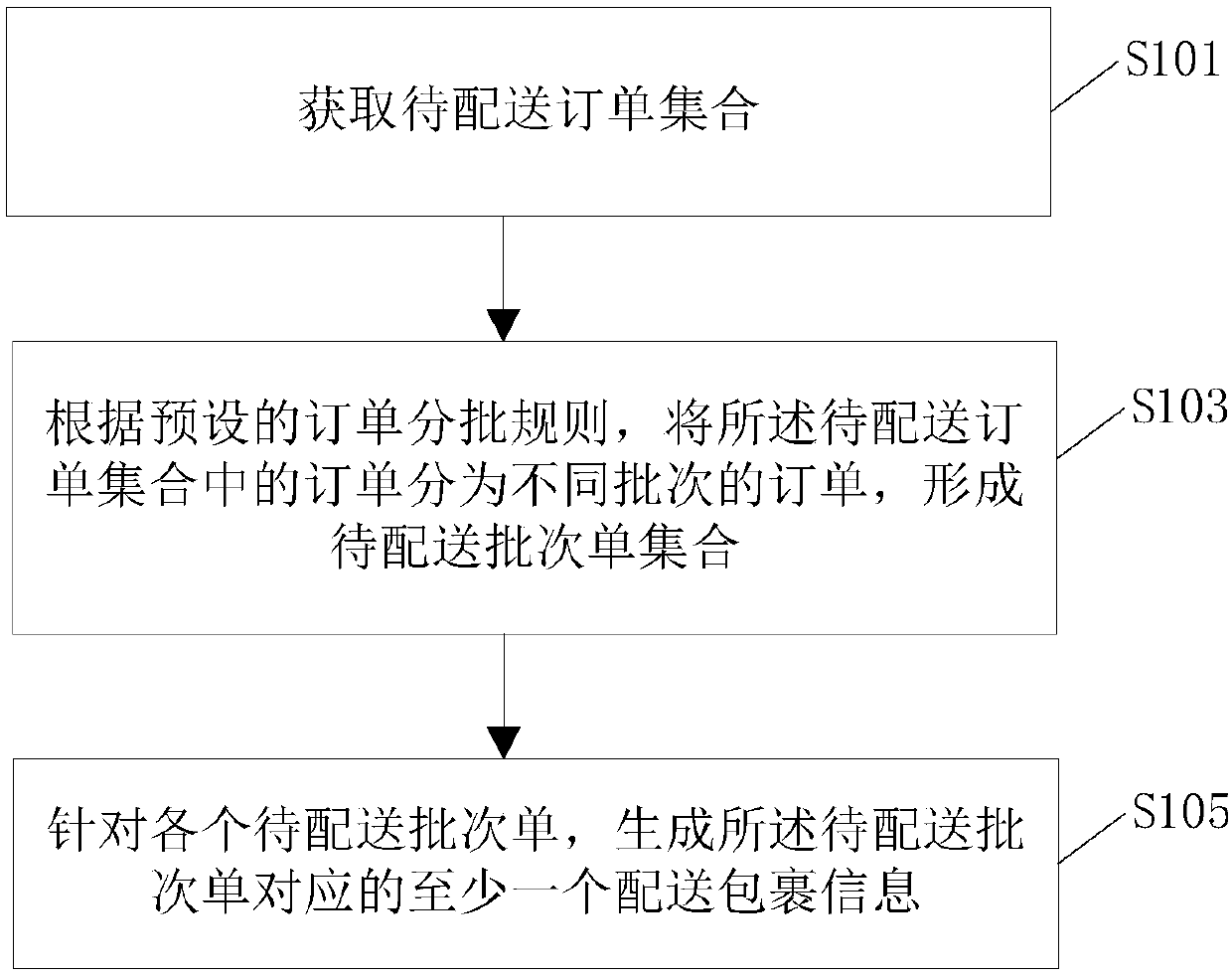

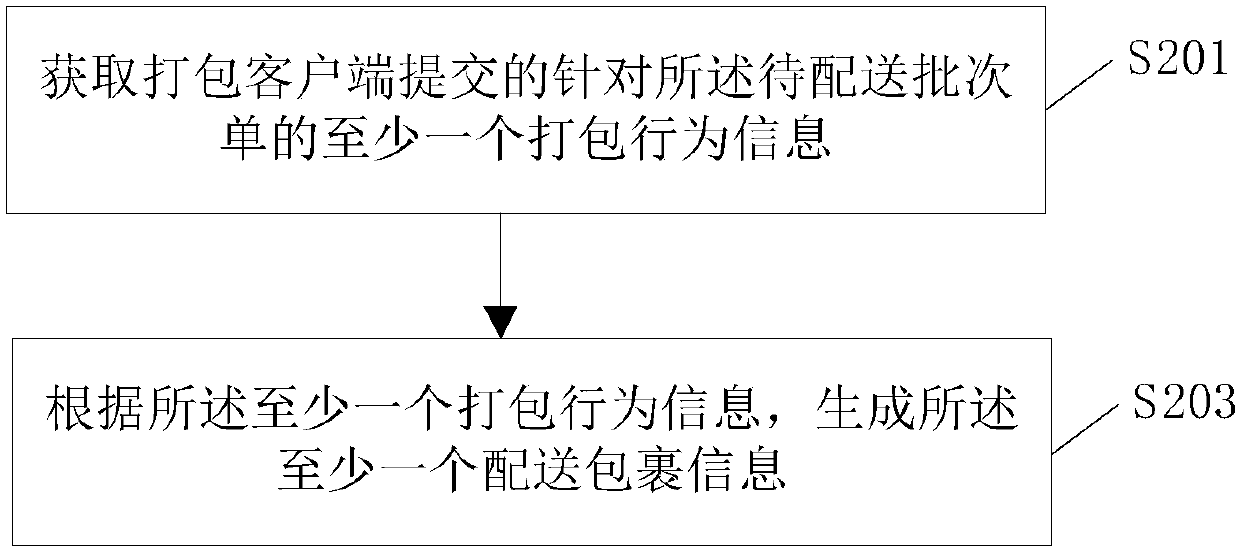

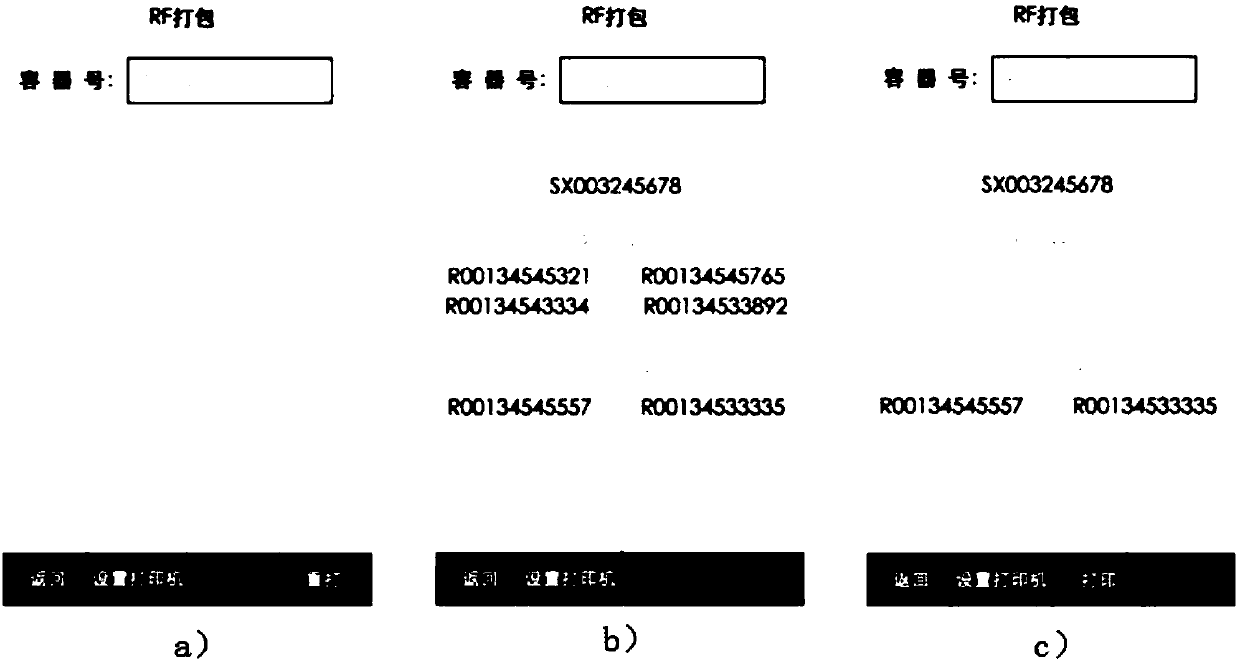

Order information processing methods and apparatus and system

This application discloses four types of order information processing methods and apparatus, an electronic device, and an order information processing system. A first order information processing method comprises the following steps: a set of orders to be delivered is obtained; according to a preset order batching rule, orders in the set of orders to be delivered are divided into different batchesof orders to form a set of batch orders to be distributed; for each batch order to be delivered, information of at least one delivery parcel corresponding to each batch order to be delivered is generated. Via the methods provided in the present application, delivery parcel information corresponding to each batch order to be delivered instead of the delivery parcel information corresponding to theorders may be generated, and one batch order to be delivered may correspond to information of one or more delivery packages, and information of one delivery package may include information of multiple commodity objects related to multiple orders; via this processing method, commodities listed in the orders can be packaged according to batches, product packaging operation for individual orders canbe prevented, and therefore speed of product packaging can be improved.

Owner:ALIBABA GRP HLDG LTD

Case packing mechanism enabling paper box to be opened in stretching mode

The invention discloses a case packing mechanism enabling a paper box to be opened in a stretching mode. The case packing mechanism is characterized by comprising four angle-shaped supporting guiding boards, the angle-shaped supporting guiding boards can be inserted into a paper box barrel and correspond to the four corners of the paper box barrel to enable the paper box barrel to be opened in a stretching mode. The upper supporting guiding board and the lower supporting guiding board at the same side are provided with a clamping seat mechanism capable of driving the upper supporting guiding board and the lower supporting guiding board to be opened and closed, and when the four angle-shaped supporting guiding boards are opened in a stretching mode in parallel, a channel for objects to be contained to pass is defined. According to the case packing mechanism, due to the fact that the four angle-shaped supporting guiding boards are used for enabling the paper box to be opened in a stretching mode and fixing the paper box, and then the channel defined when the four angle-shaped supporting guiding boards are opened in a stretching mode in parallel is used for guiding the objects to be contained in, and the objects to be contained are pushed in the paper box. The case packing mechanism can directly pack finished bricks very conveniently for the wall and floor tile industry, the case packing speed is fast, procedures are easy, the most trouble packing procedures are removed, and the production efficiency is greatly improved.

Owner:FOSHAN RUIBO CERAMICS ELECTRICAL & MECHANICAL

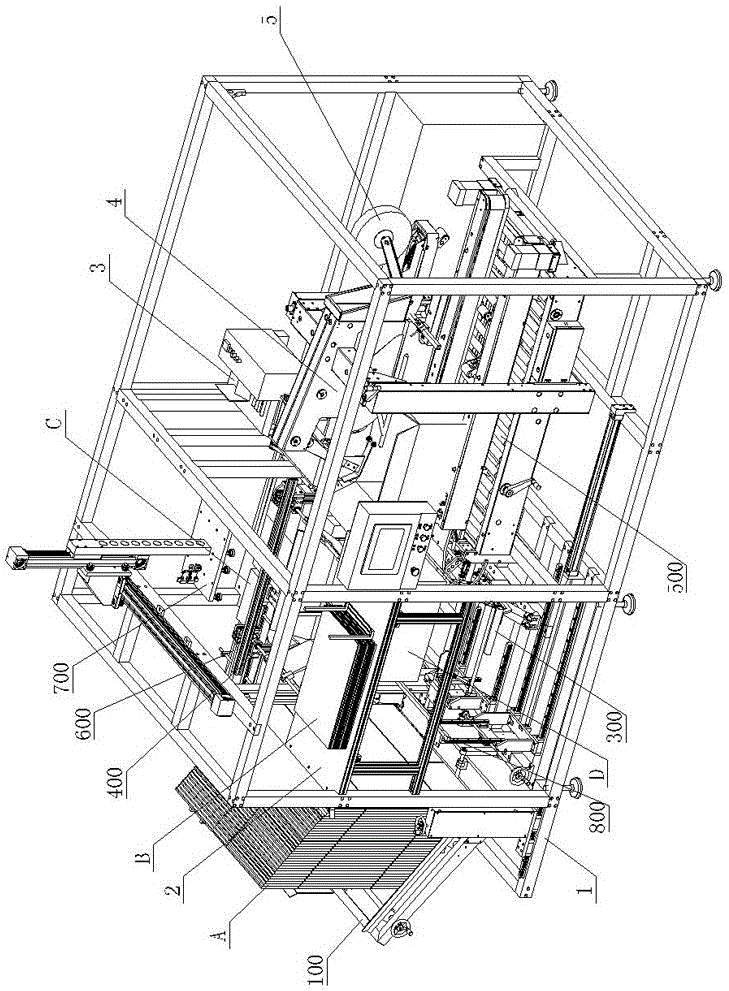

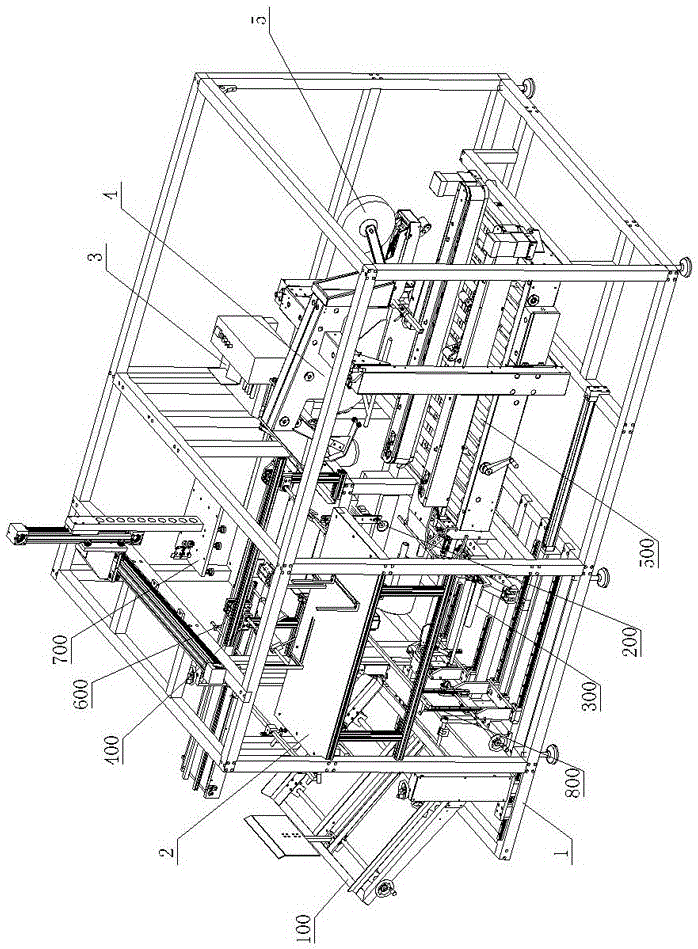

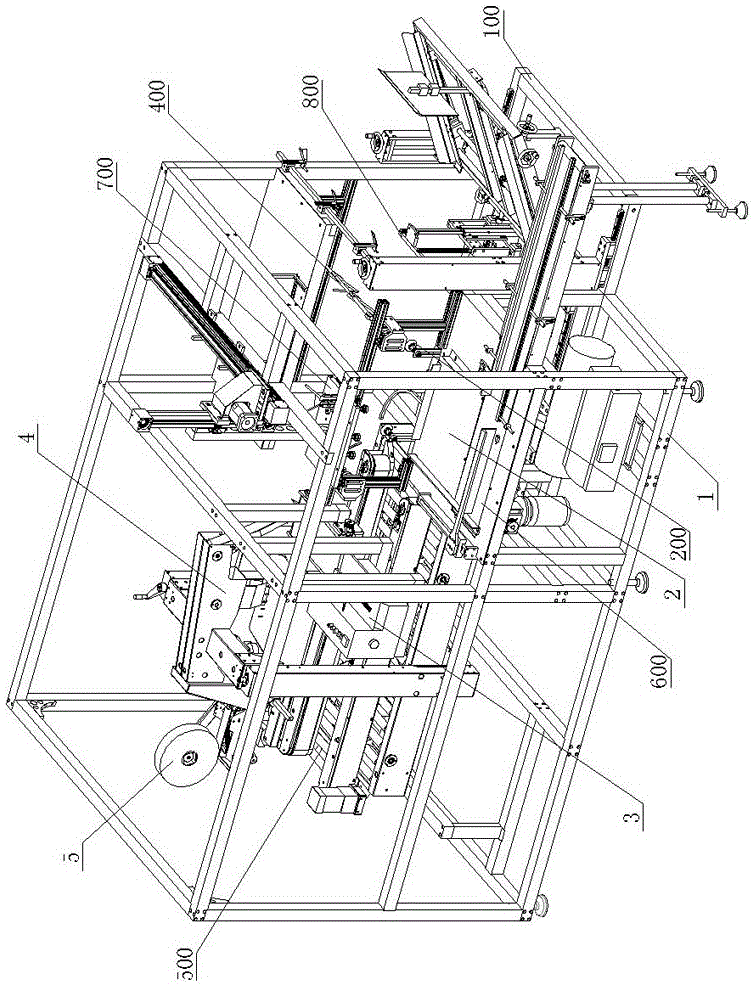

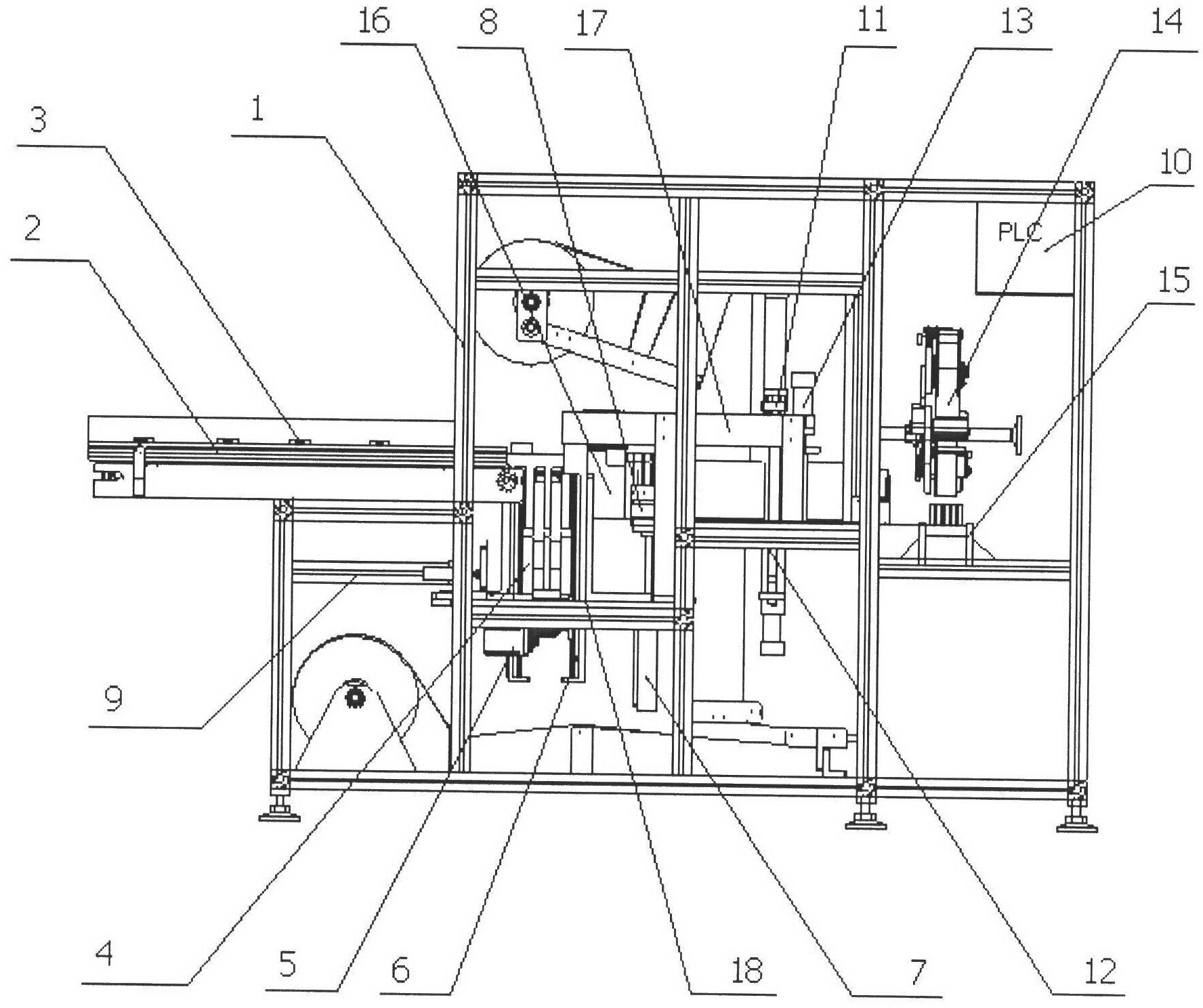

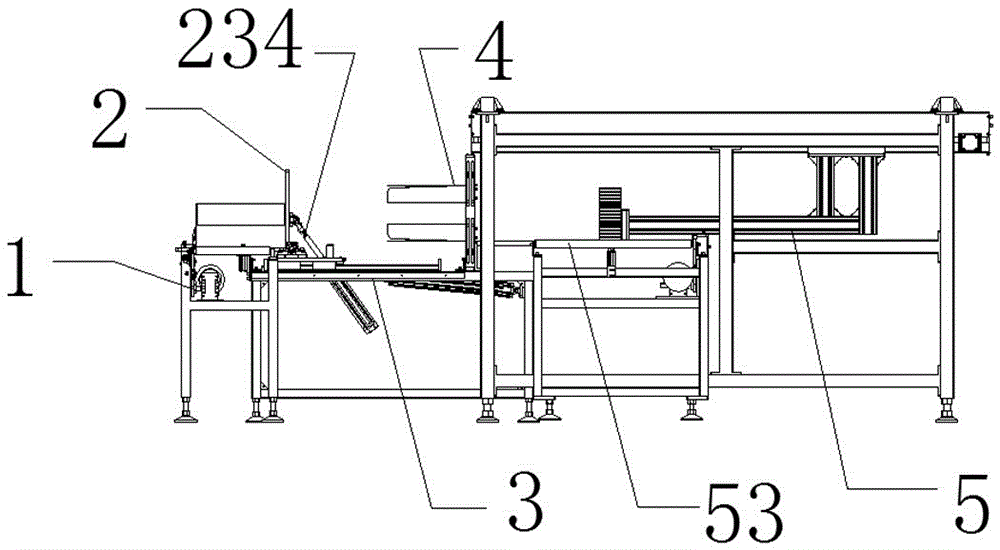

Full-automatic case packing machine

InactiveCN106672327ASimple structureFast packingWrapper twisting/gatheringDifferences sizeMechanical engineering

The invention discloses a full-automatic case packing machine which is characterized in that the full-automatic case packing machine is provided with a case packing station arranged in the center; a storage bin component, a case suction component, a tongue closing component, a tongue opening component and a case sealing platform are arranged around the case packing station; the storage bin component is located on the rear side of the case packing station; the case suction component is located on the right side of the case packing station; the tongue closing component is located at the bottom of the case packing station; the tongue opening component is located at the top of the case packing station; the case sealing platform is located on the front side of the case packing station; a partition plate stacking table and a stacking component are arranged on the left side and the right side of a place above the tongue opening component respectively; a material suction component is arranged above the partition plate stacking table and the stacking component; when the material suction component acts, a to-be-packed product and a partition plate are put in a packing case; and the case packing station is further provided with a case pushing component for pushing the packing case supported by the tongue closing component onto the case sealing platform. The full-automatic case packing machine is simple and compact in structure and wide in case packing range, full-automatic case packing is realized, the case packing speed is high, and the full-automatic case packing machine can be applied to the packing cases in difference sizes conveniently.

Owner:浙江春余机械有限公司

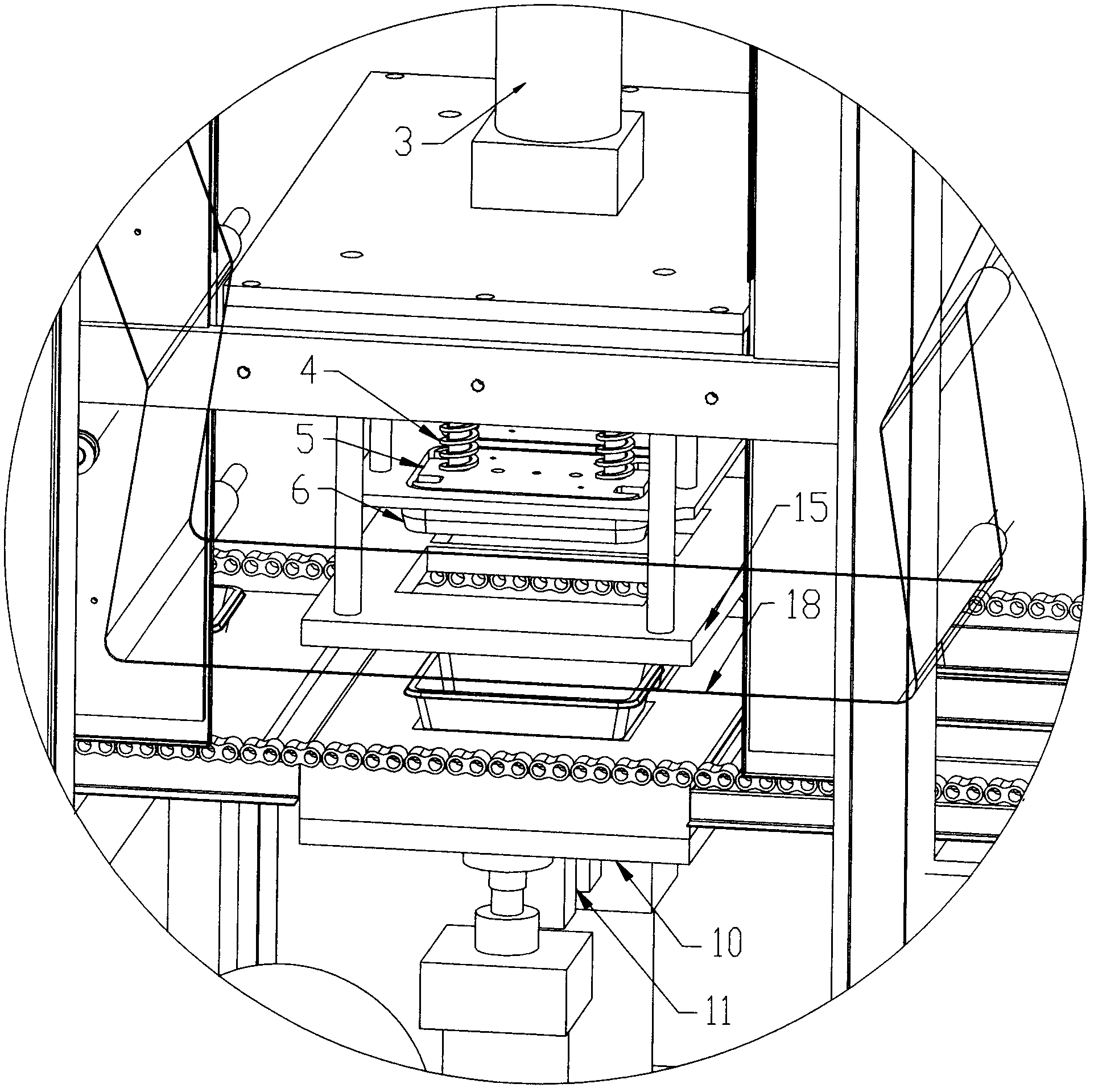

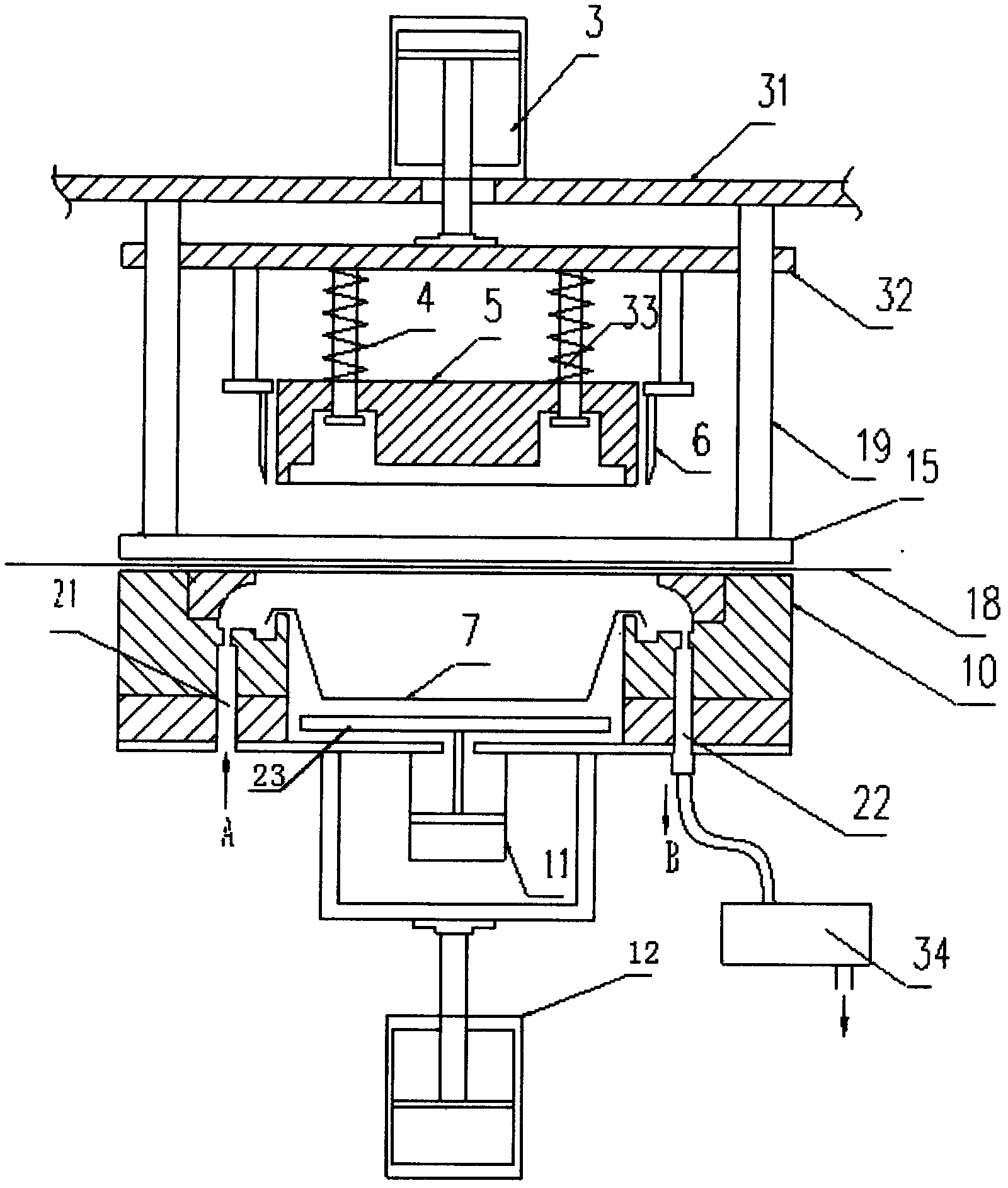

Pulse sterilization continuous box type modified atmosphere packaging machine

InactiveCN103419960ASimple structureCompact structurePackage sterilisationPackaging by pressurising/gasifyingControl systemEngineering

The invention discloses a pulse sterilization continuous box type modified atmosphere packaging machine. The modified atmosphere packaging machine comprises a transmission system, a packaging system and a film sealing system and further comprises a control system, wherein the transmission system, the packaging system and the film sealing system are installed on a rack, a sterilization system is installed at the front end of the transmission system, and the packaging system comprises a film sealing device, a gas replacement device, a hot-sealing device and a cutting device. With the method, the modified atmosphere packaging machine is simple in structure, capable of performing continuous sterilization and continuous and automatic modified atmosphere packaging on products through a small number of work stations, high in packaging speed and capable of achieving the high gas replacement rate and the high gas mixing accuracy.

Owner:沈滢

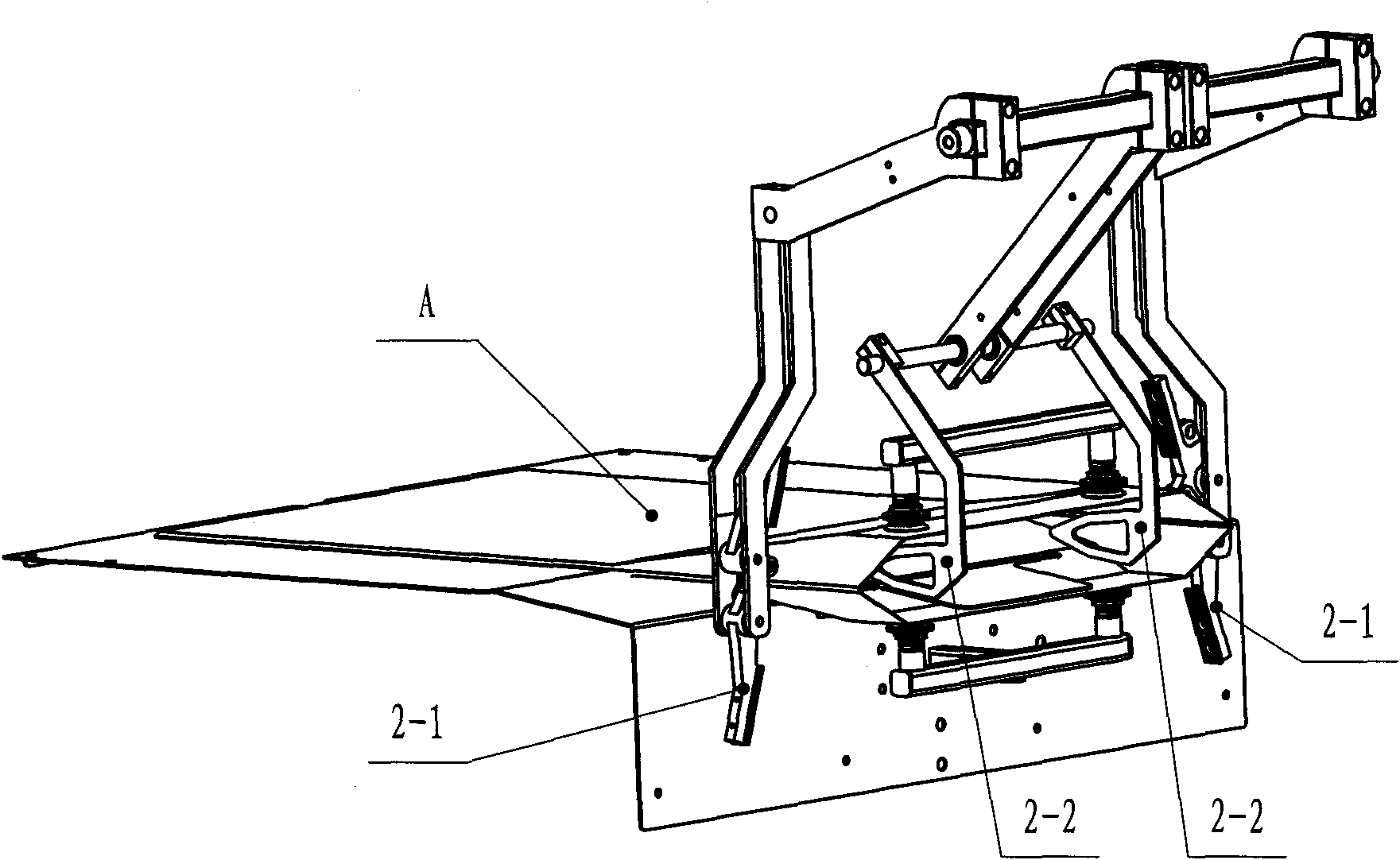

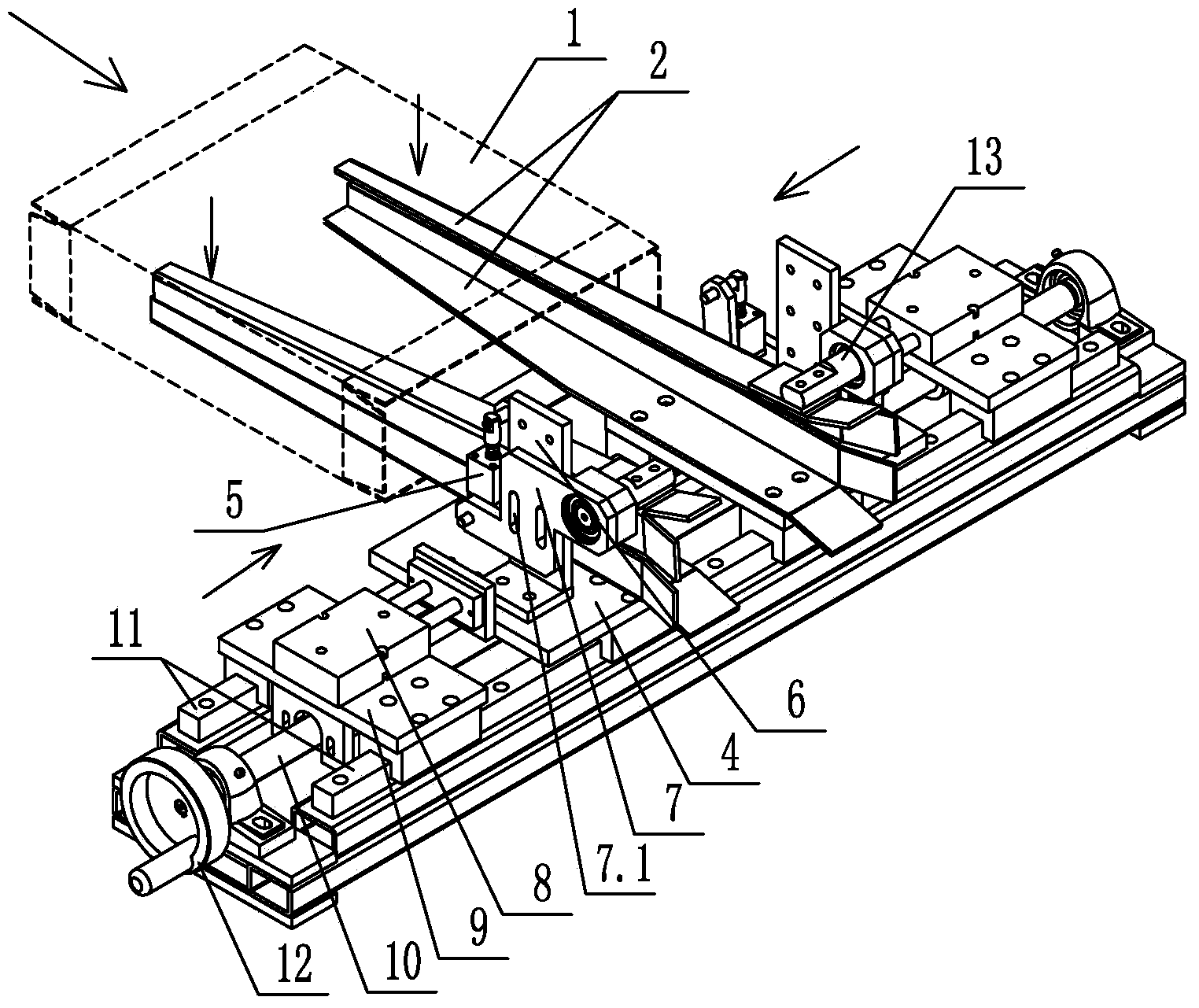

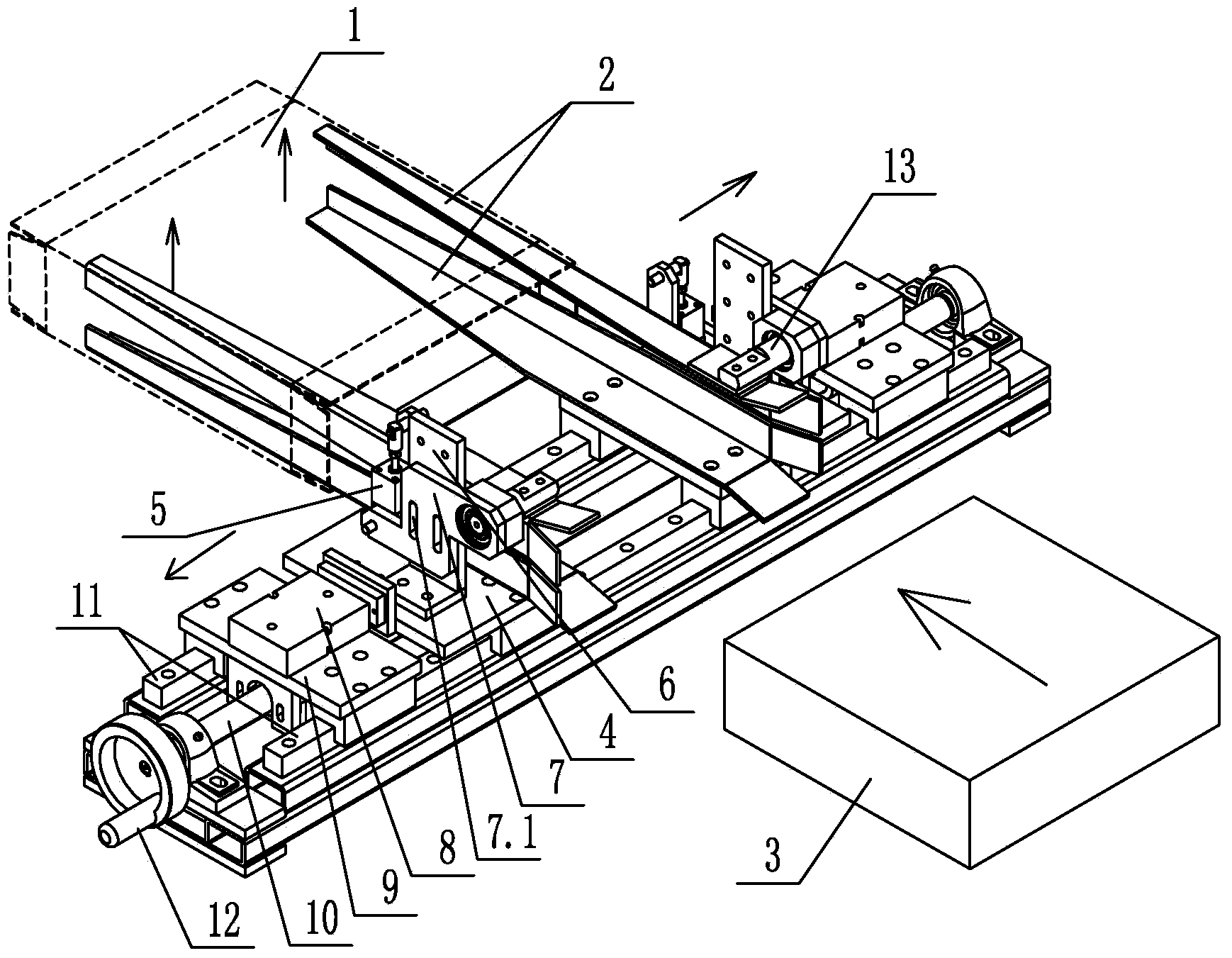

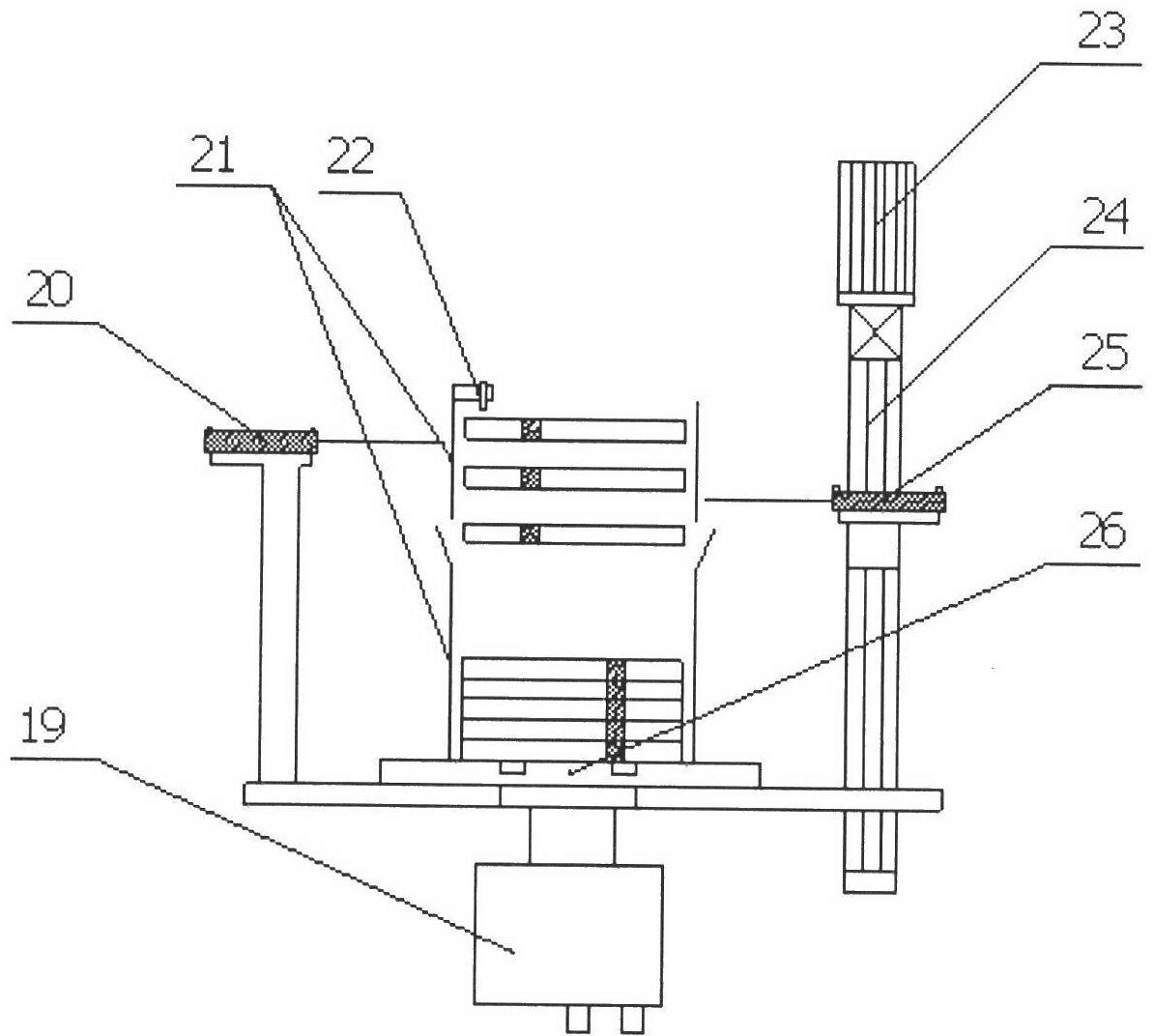

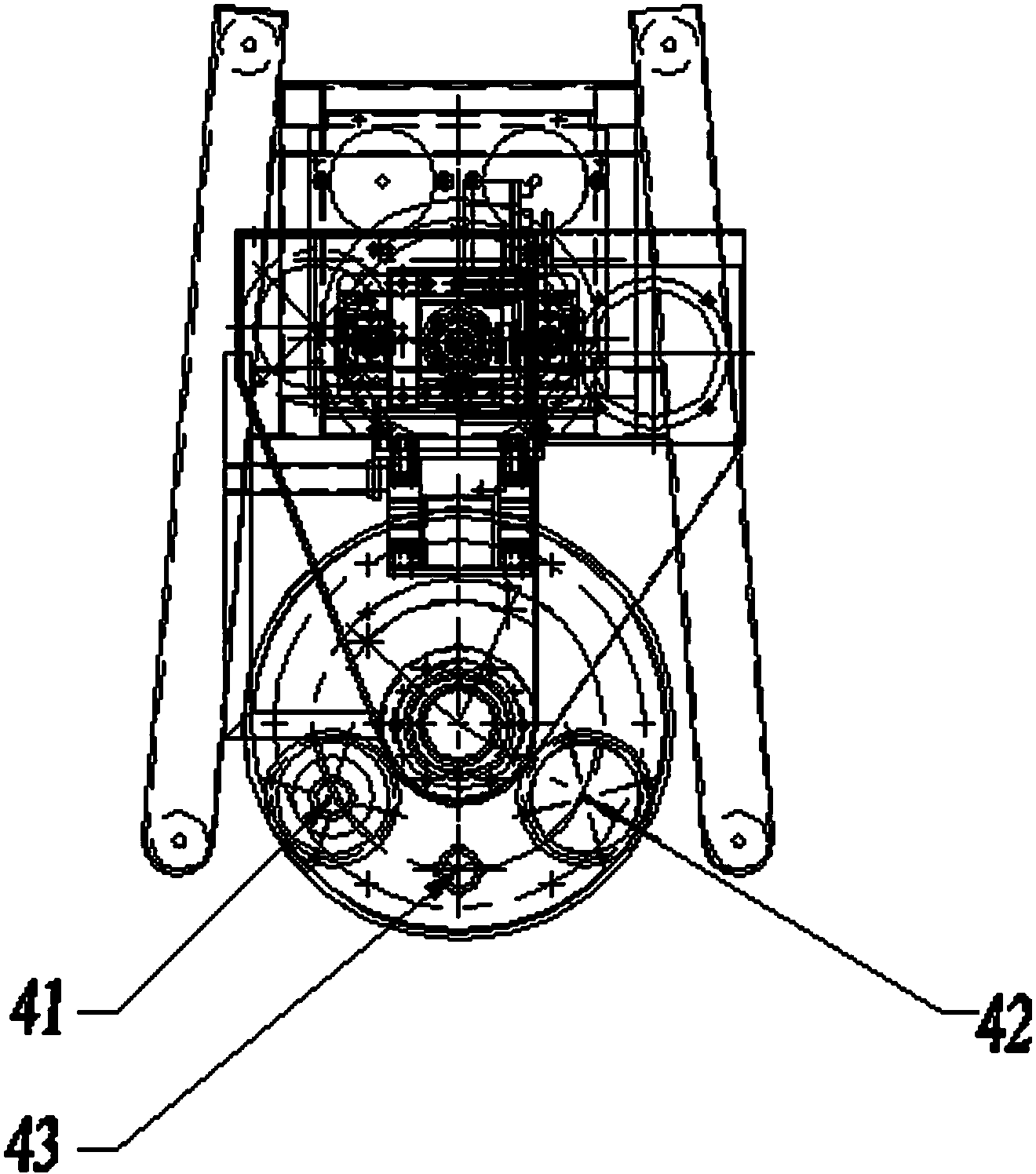

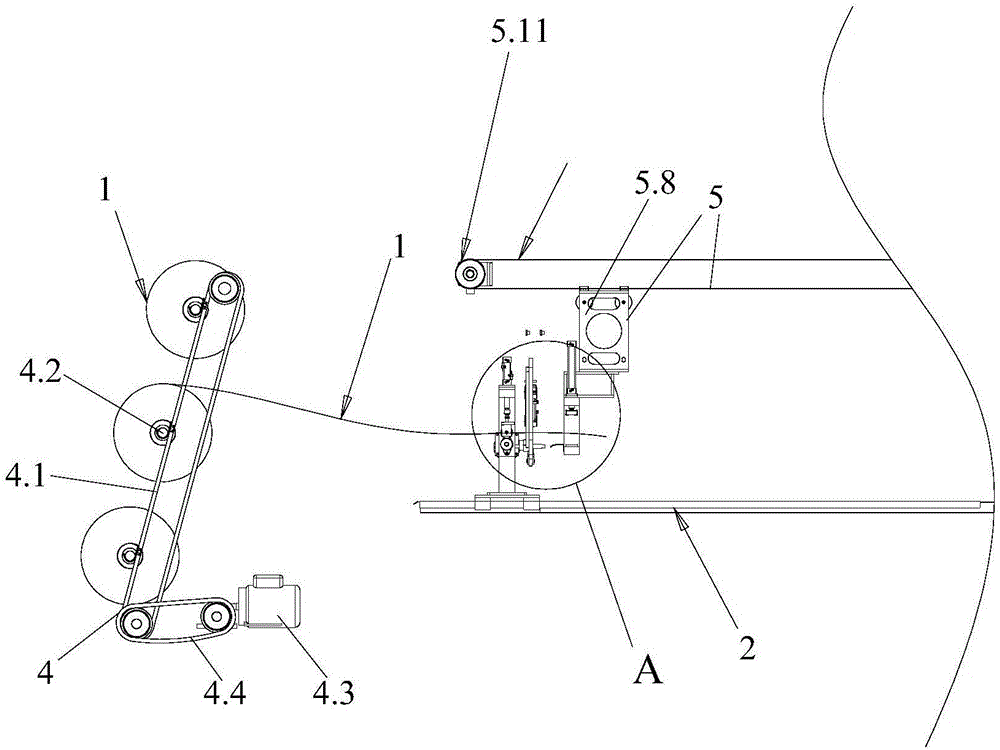

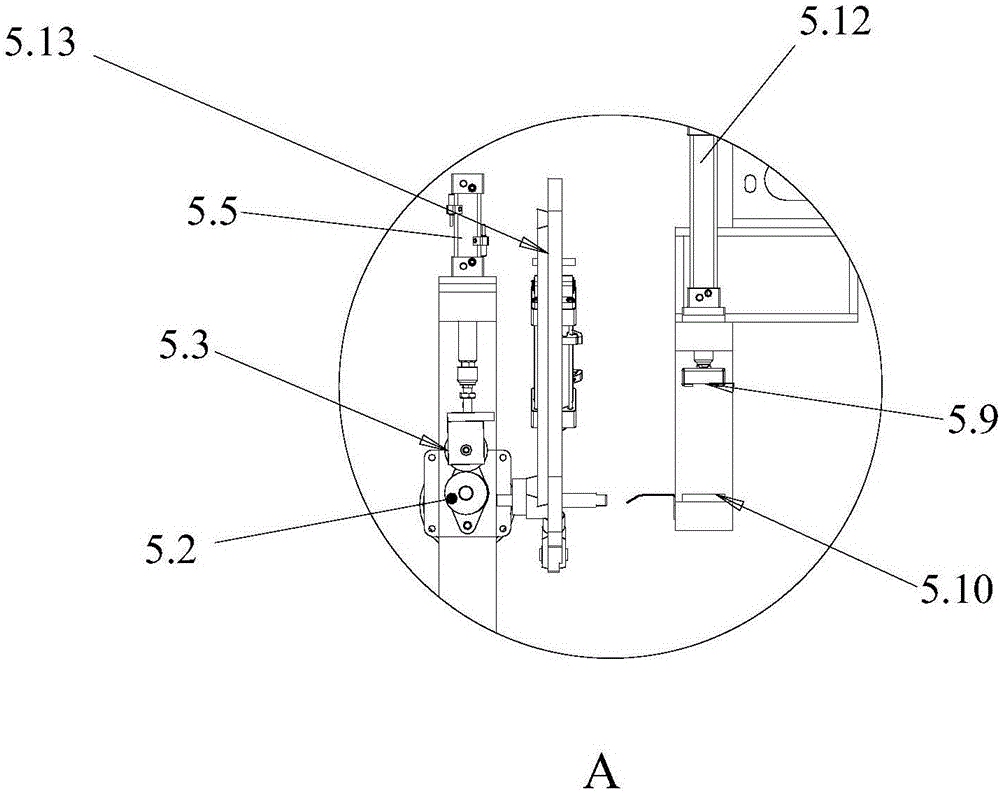

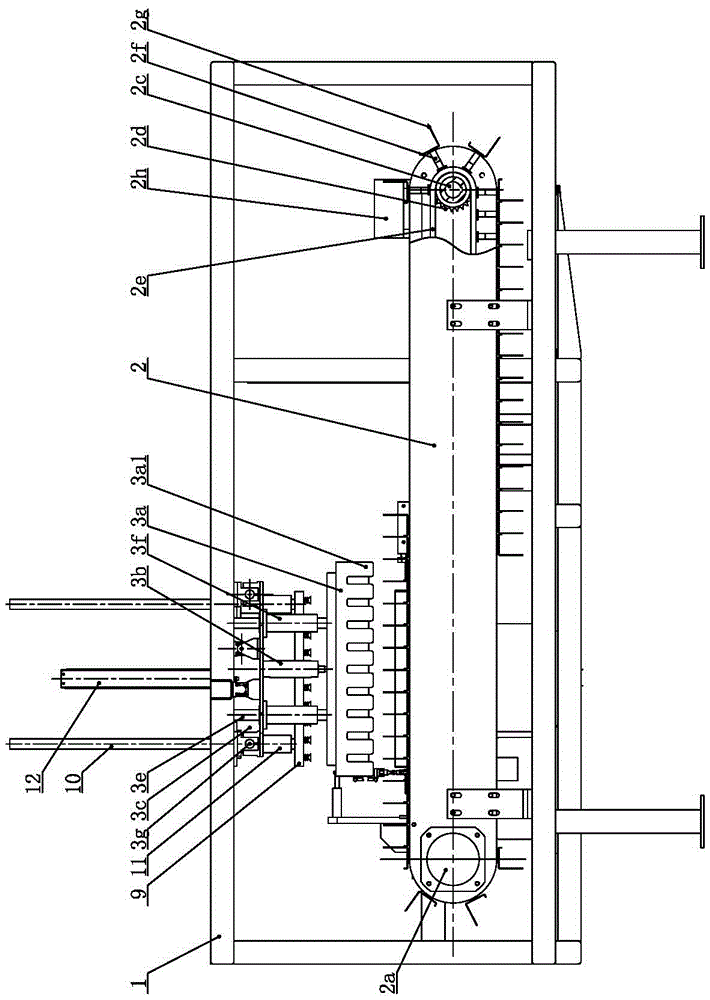

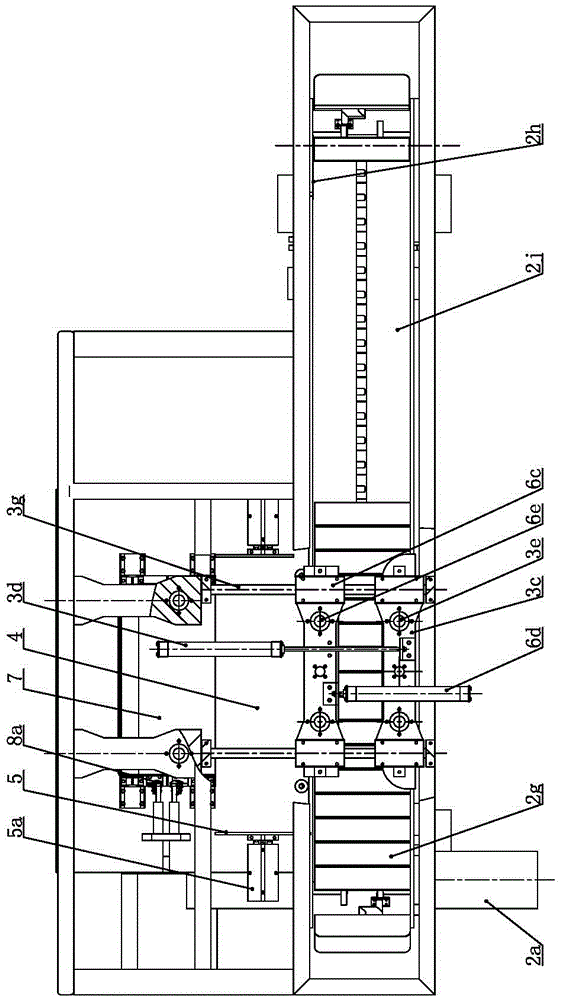

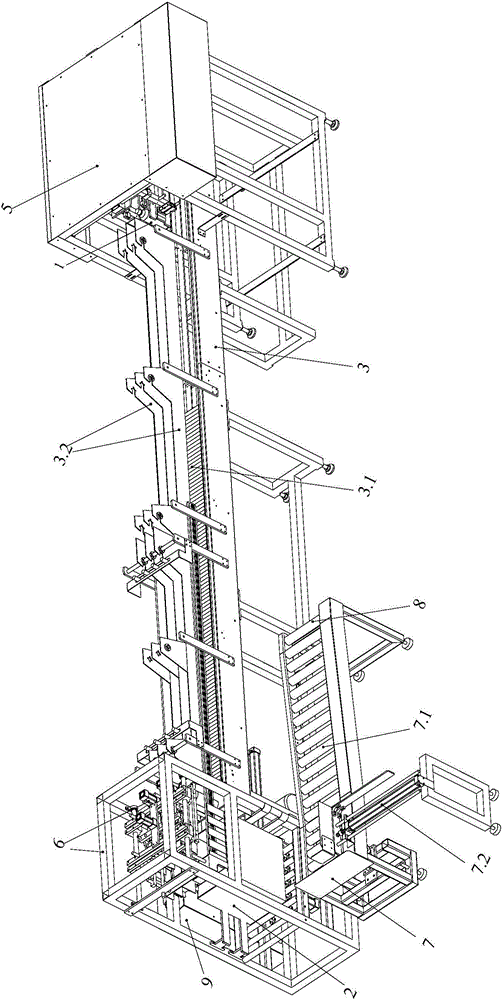

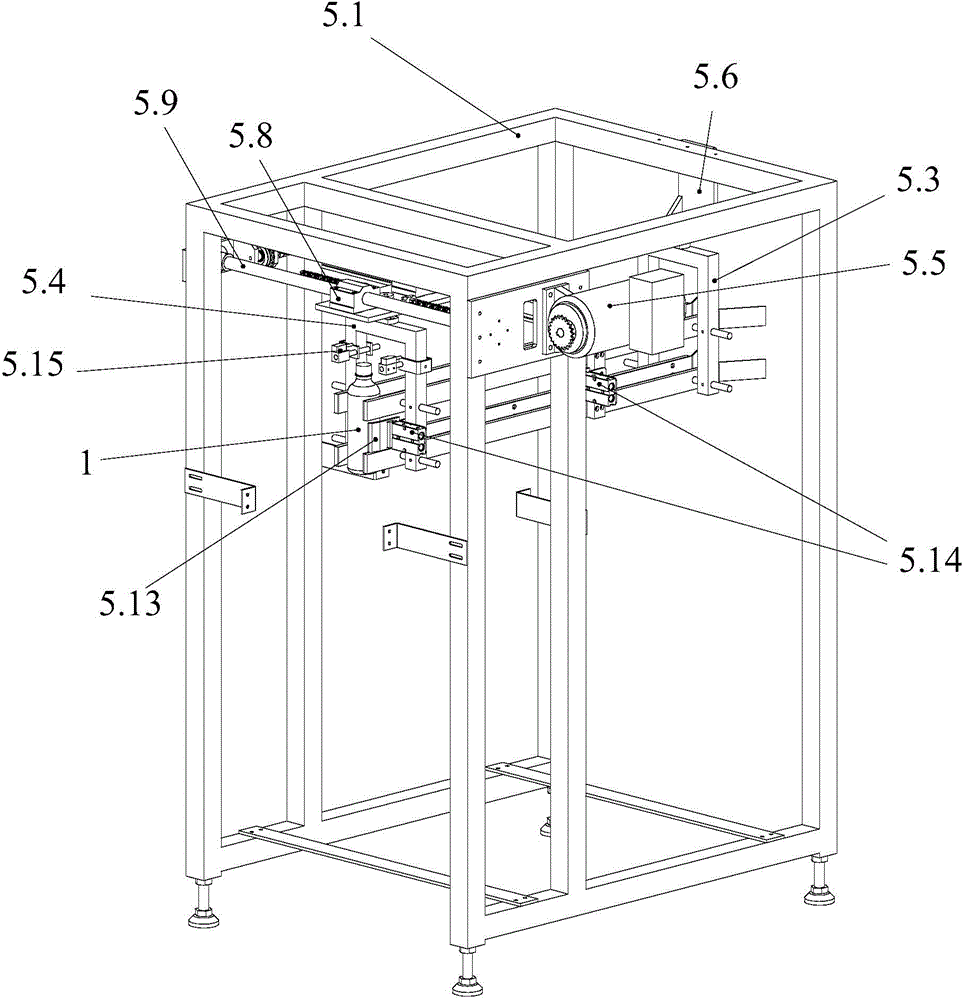

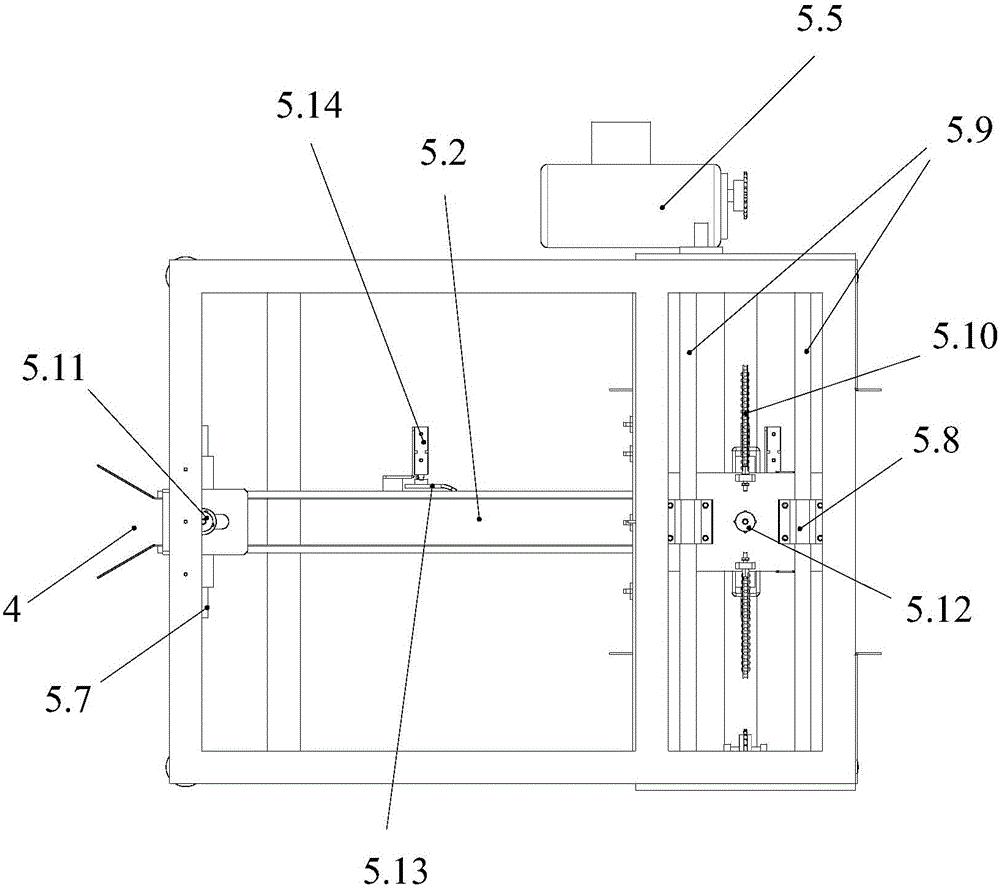

Automatic binning method and automatic binning mechanical arm

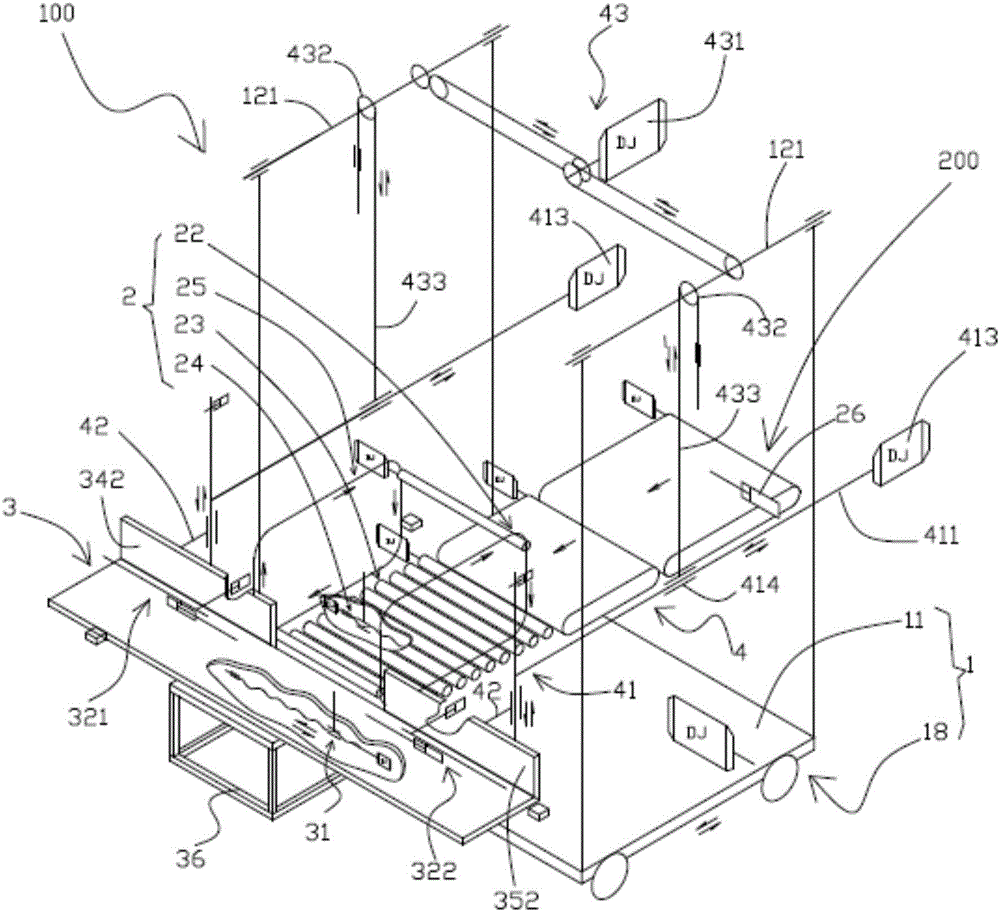

ActiveCN106144624ASave human effortFast packingStacking articlesDe-stacking articlesManipulatorMovement system

The invention discloses an automatic binning method. The automatic binning method includes the following steps that standardizing bins enter a tray of the automatic binning mechanical arm one by one; the standardizing bins entering the tray are transversely pushed leftwards or rightwards one by one until the tray is full of the standardizing bins in the transverse direction; when the tray is full of the standardizing bins in the transverse direction, just two or more standardizing bins can be contained; and the tray is moved, and of the multiple standardizing bins fully arranged on the tray in the transverse direction wholly drop to the stacking position. The invention further discloses the automatic binning mechanical arm. The automatic binning mechanical arm comprises a machine frame, a conveying device, the tray and a movement system which work in a matched manner under control of an PLC system; a travelling crane is installed on a base of the machine frame, the conveying device is arranged in the machine frame, the tray which is full of two or more standardizing bins in the transverse direction is arranged in front of the conveying device, and the tray is connected to the movement system capable of driving the tray to move up and down and front and back; and the mechanical arm is further provided with a distribution device and a bin dropping device, manual work is completely replaced, the binning speed is high, and manpower is saved.

Owner:杨晖伟

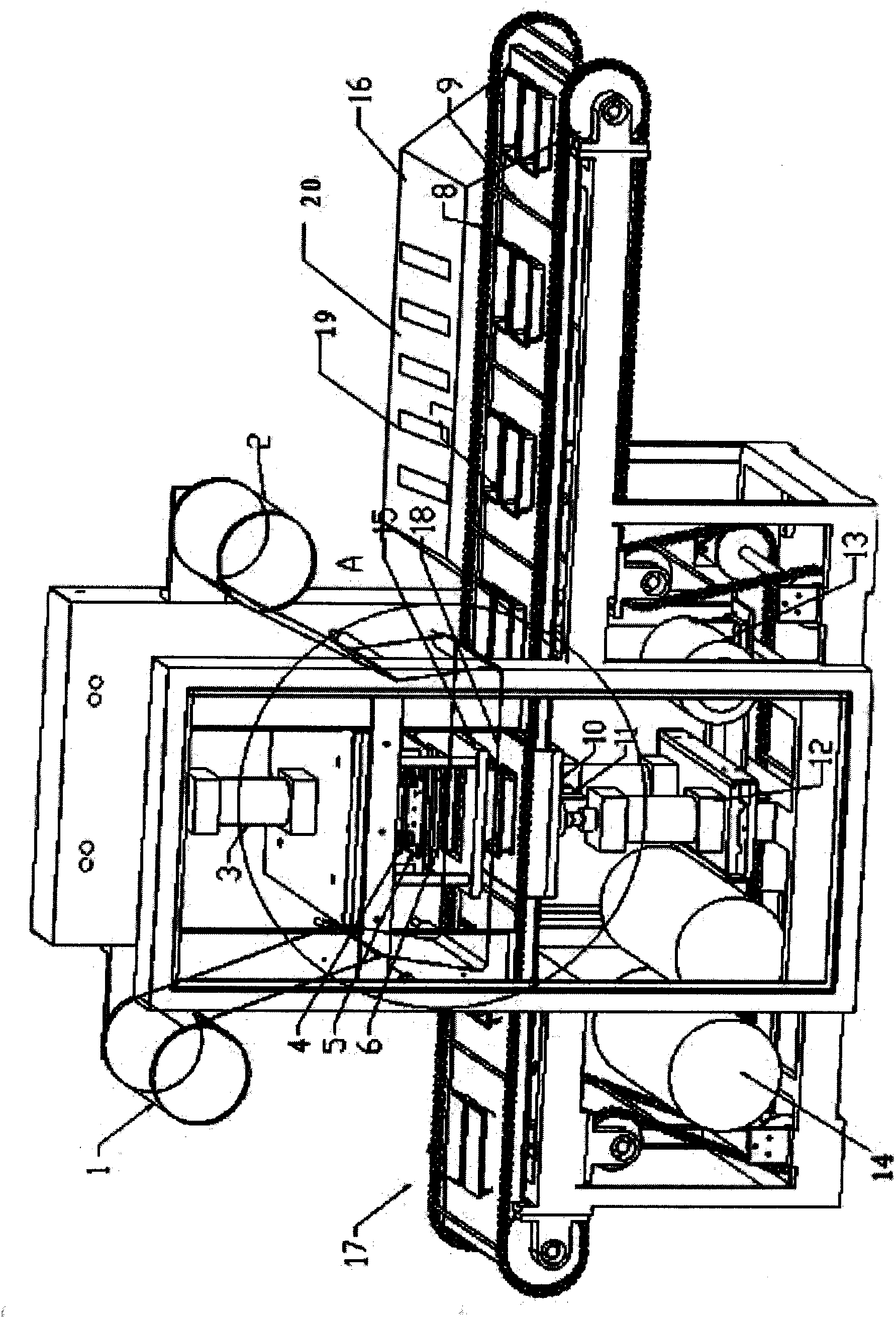

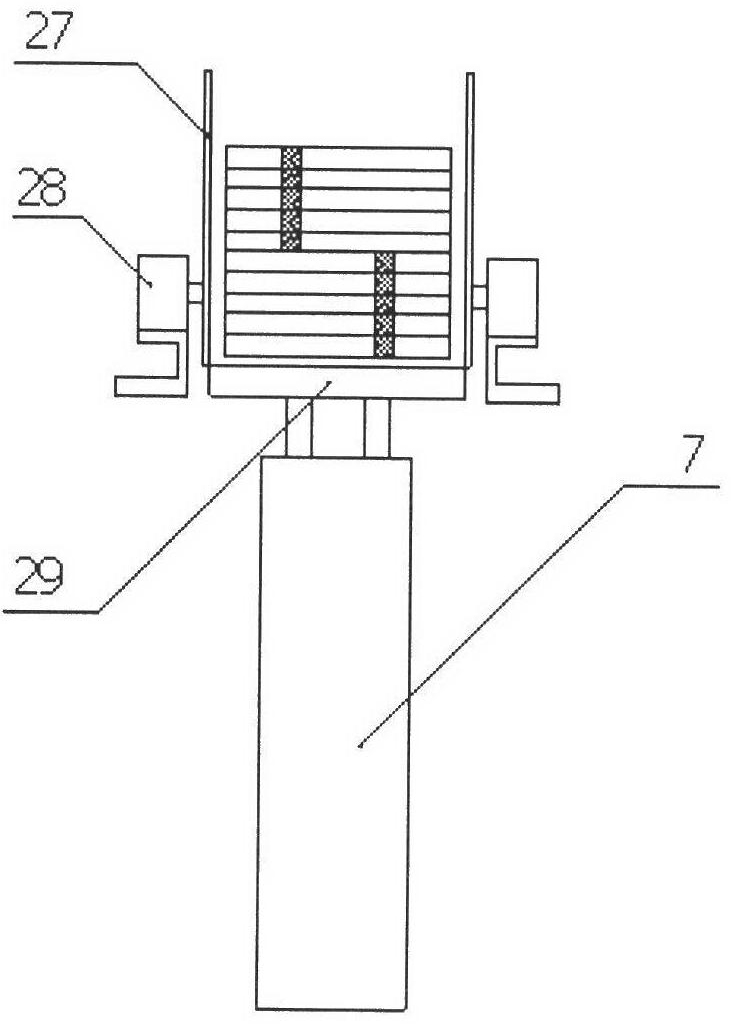

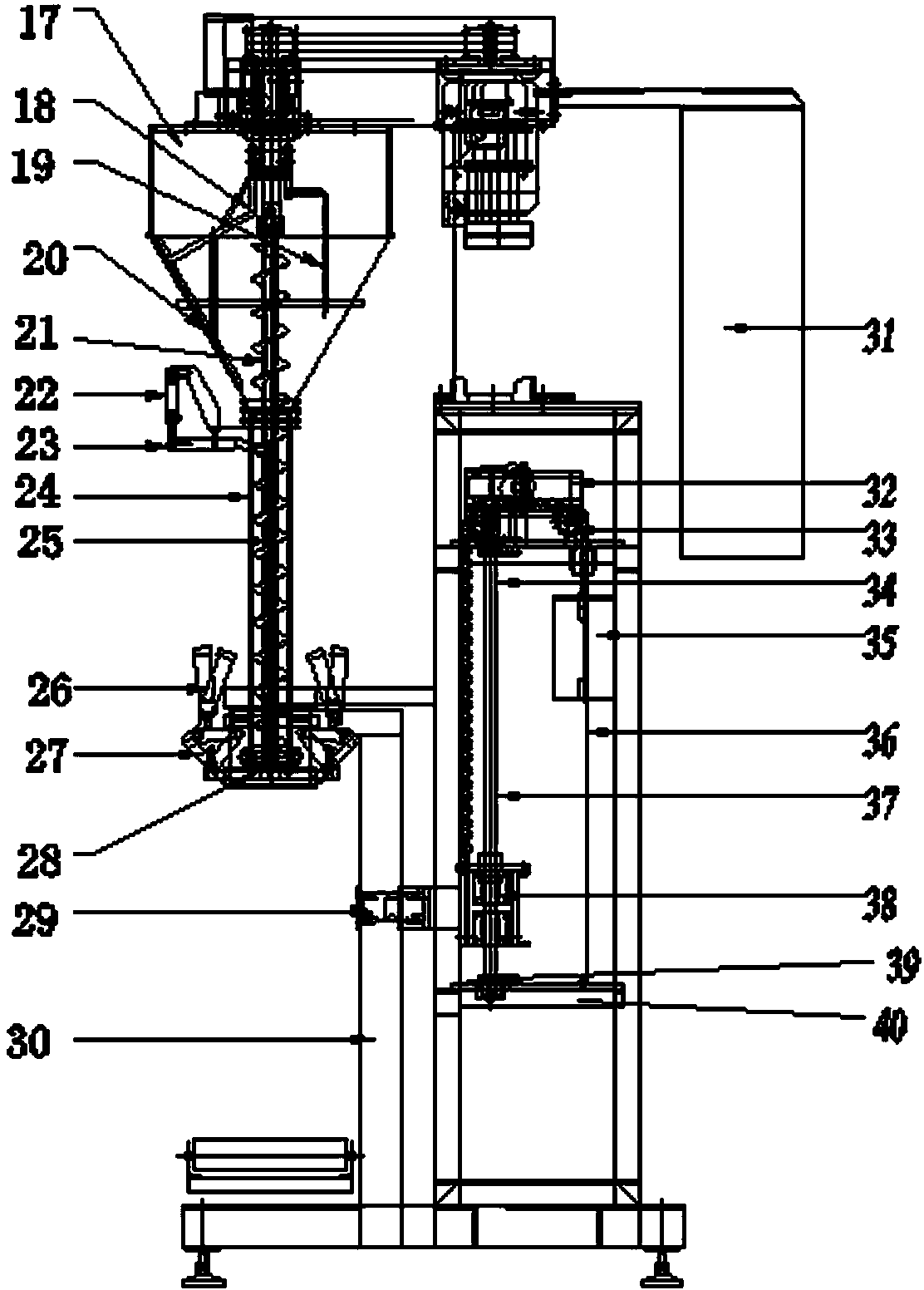

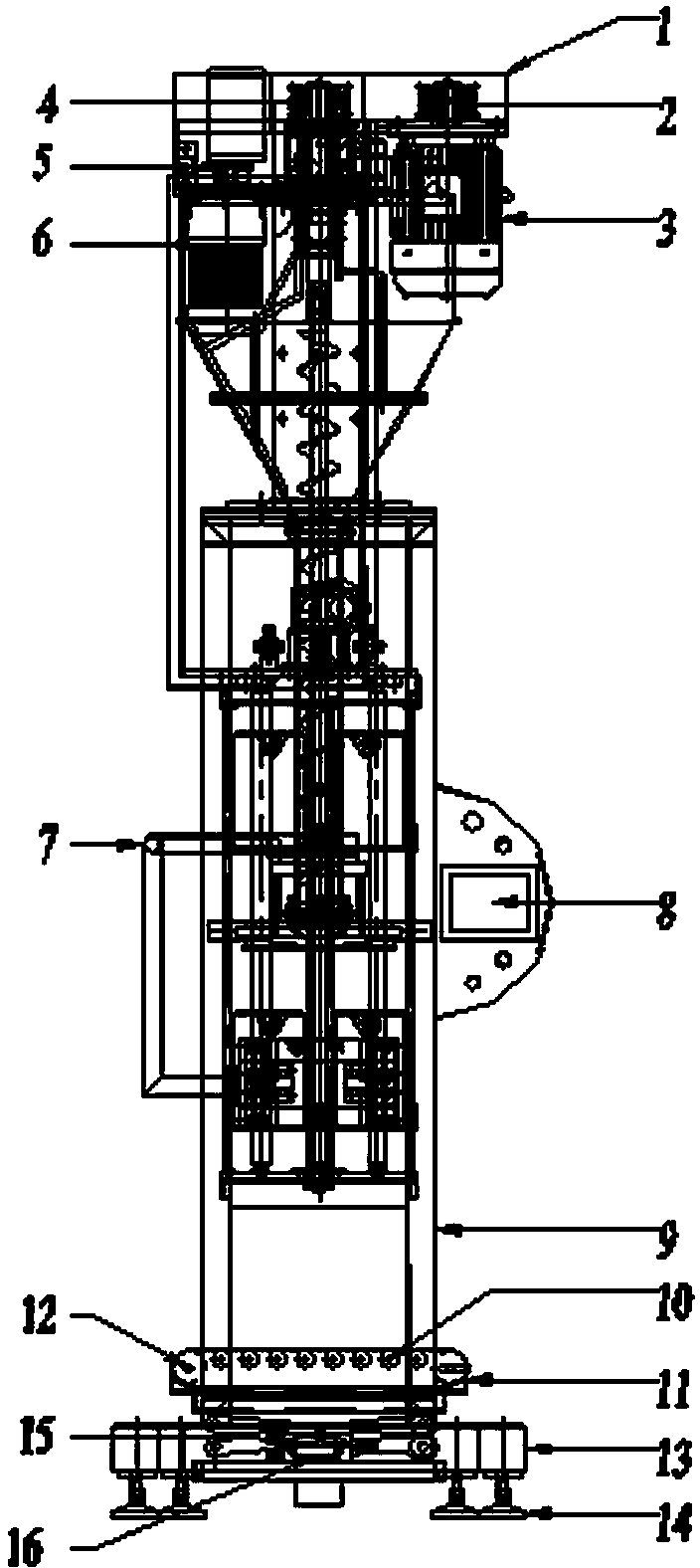

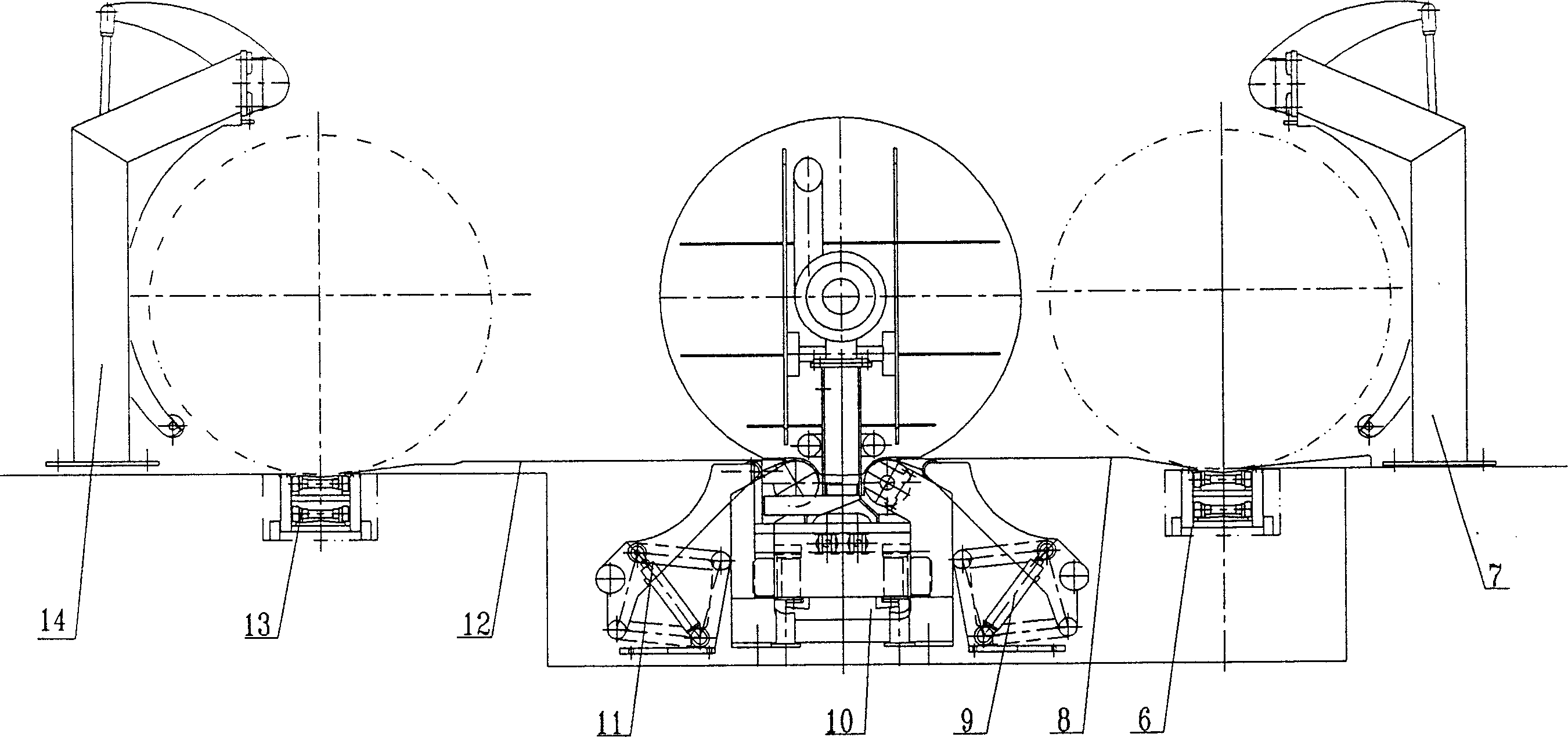

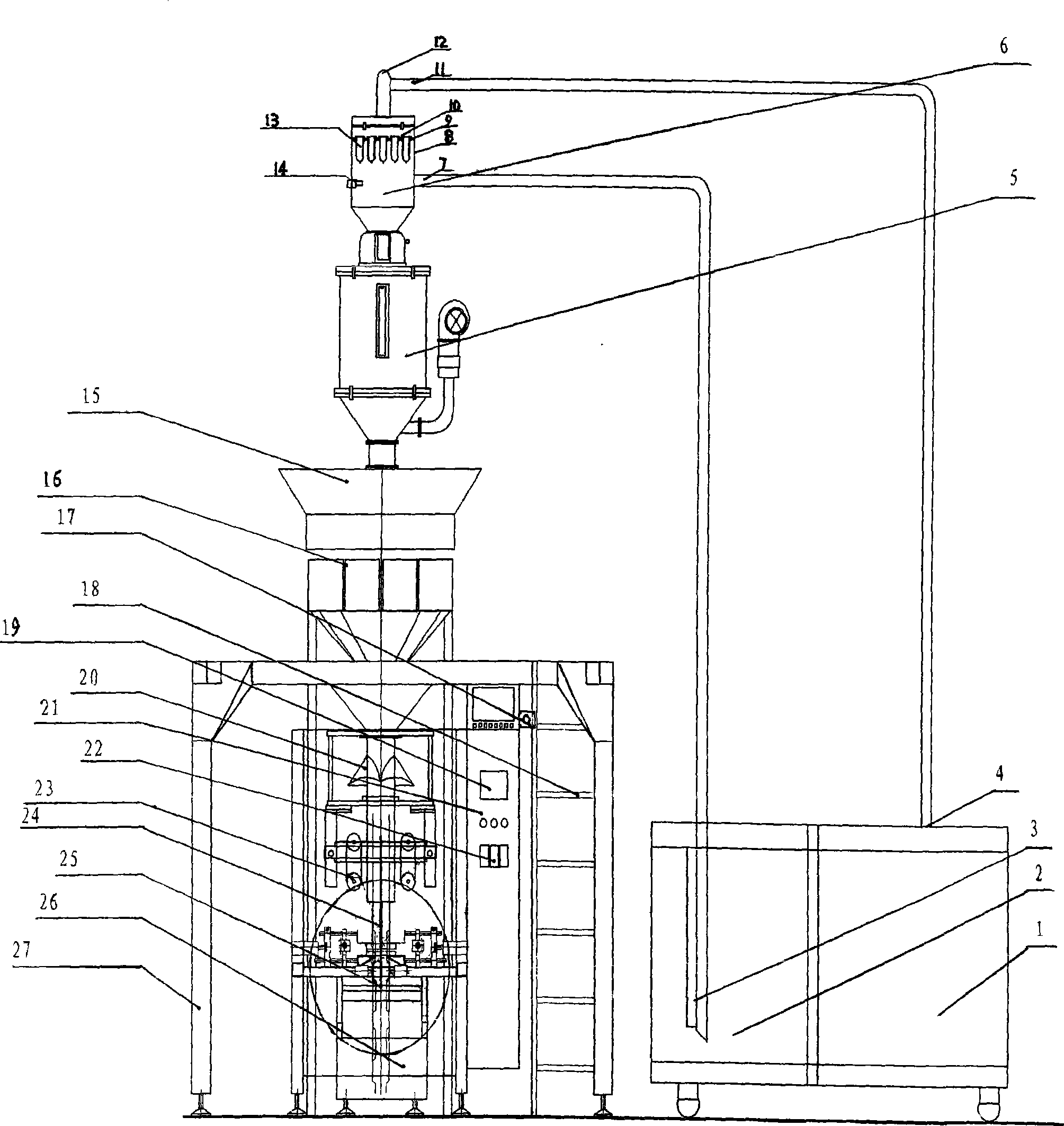

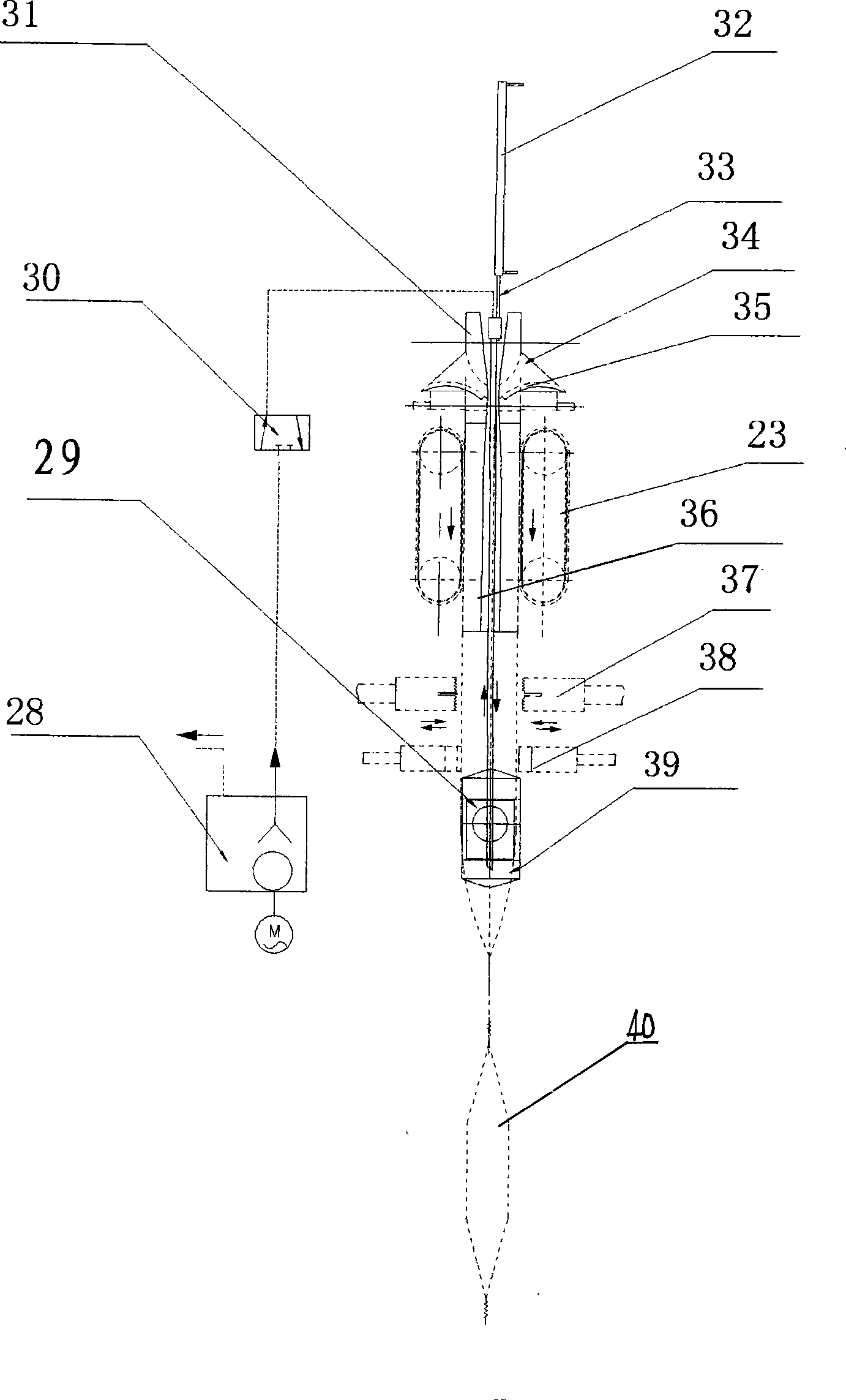

Full-automatic vertical filling vacuum packing machine

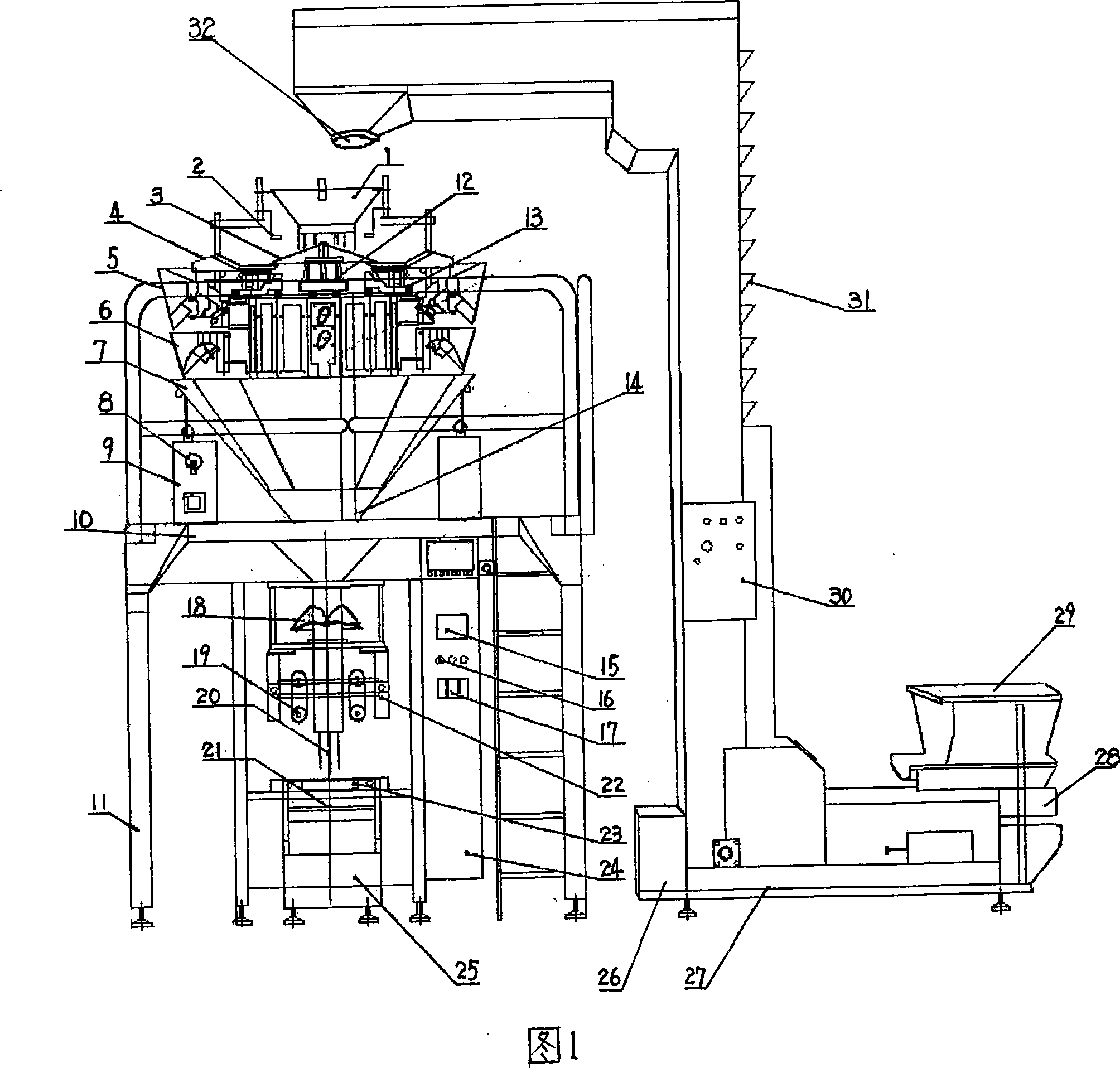

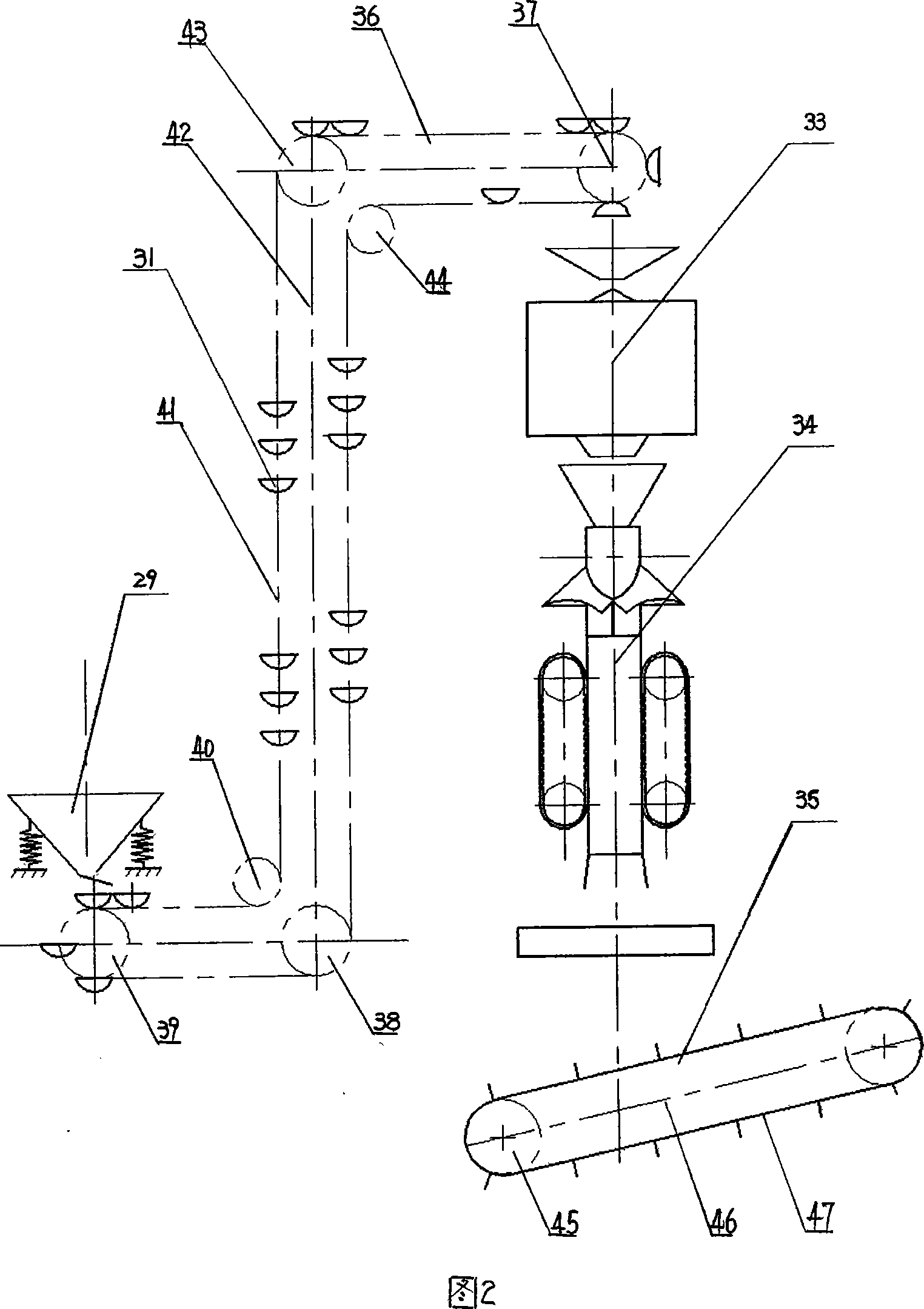

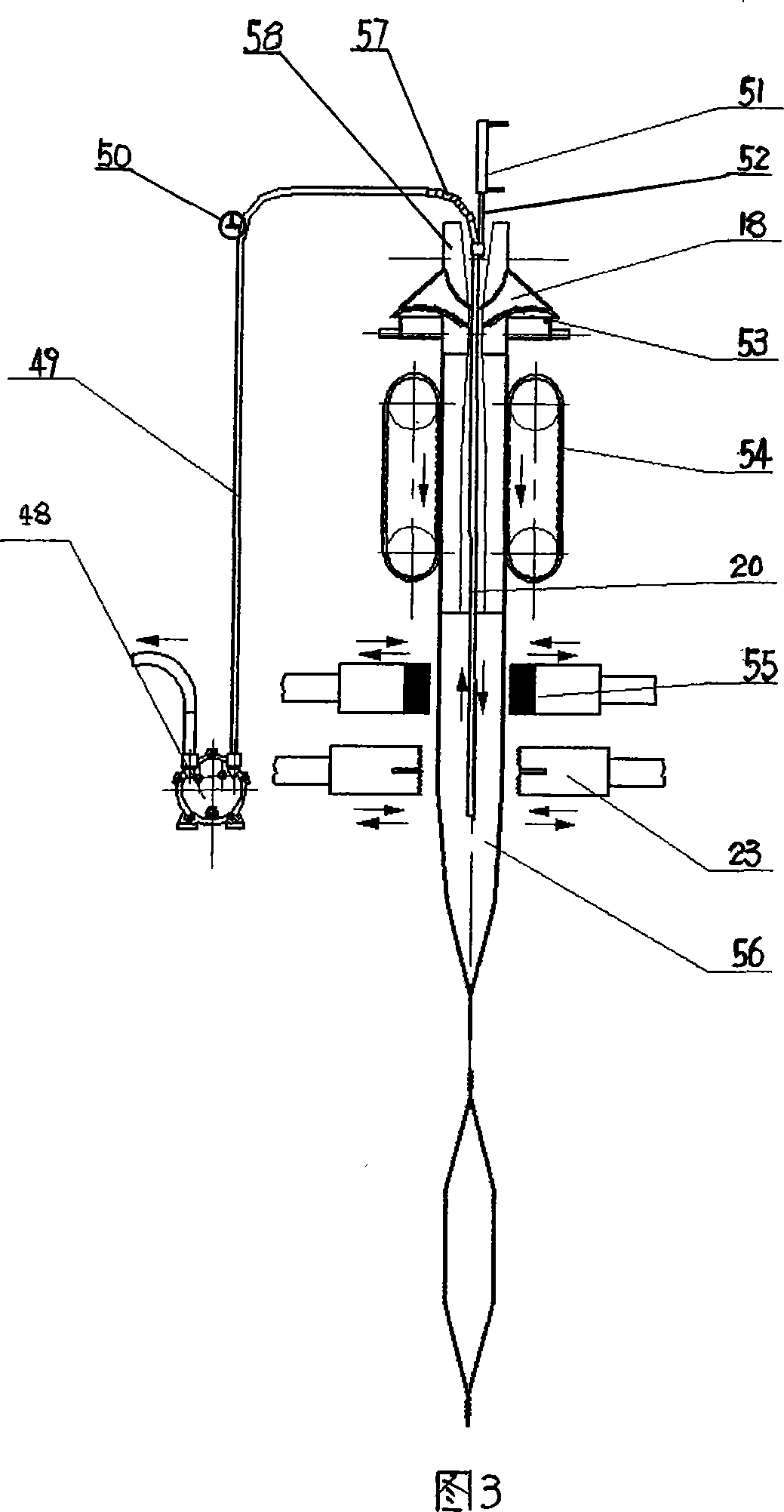

InactiveCN101168387AFast packingImprove packaging efficiencyPackaging by pressurising/gasifyingWrapper twisting/gatheringVacuum pumpPlunger

An automatic upright-type filling and vacuum packing machine, mainly consists of a lifting and feeding device (36), an electrical weigh device (33), an automatic vacuum suction packing device (34) and a conveyor (35), wherein the output port of the lifting and feeding device (36) is at the upside of the storing hopper (1), the lifting and feeding device (36) is in Z-shape structure, a hopper (29) is placed at one side of the support base (27), on the upper of the support base (27). The downside of the hopper (29) is provided with a vibrating feeder (28). The automatic vacuum suction packing device (34) comprises a vacuum pump (48), conduit (49), electromagnet valve (50), extension tube (57), vacuum suction pipe (20), cylinder (51) and plunger (52). The invention can realize a series of packing process and finish the whole packing process without the help of operator; it has the advantage of safe, sanitary, and rapid package, and also high efficiency.

Owner:彭智松

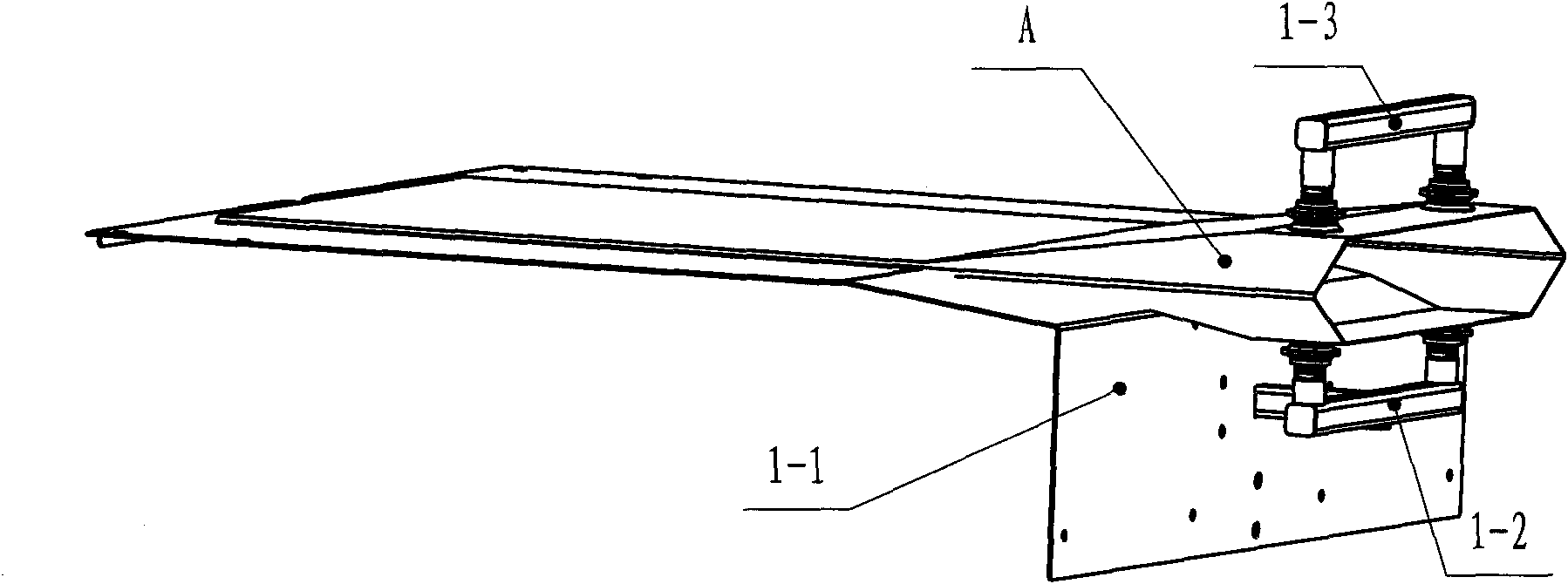

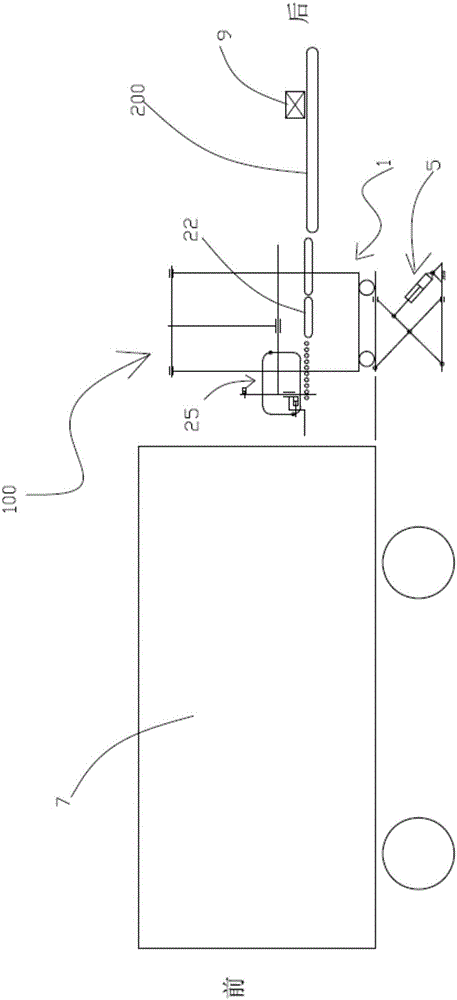

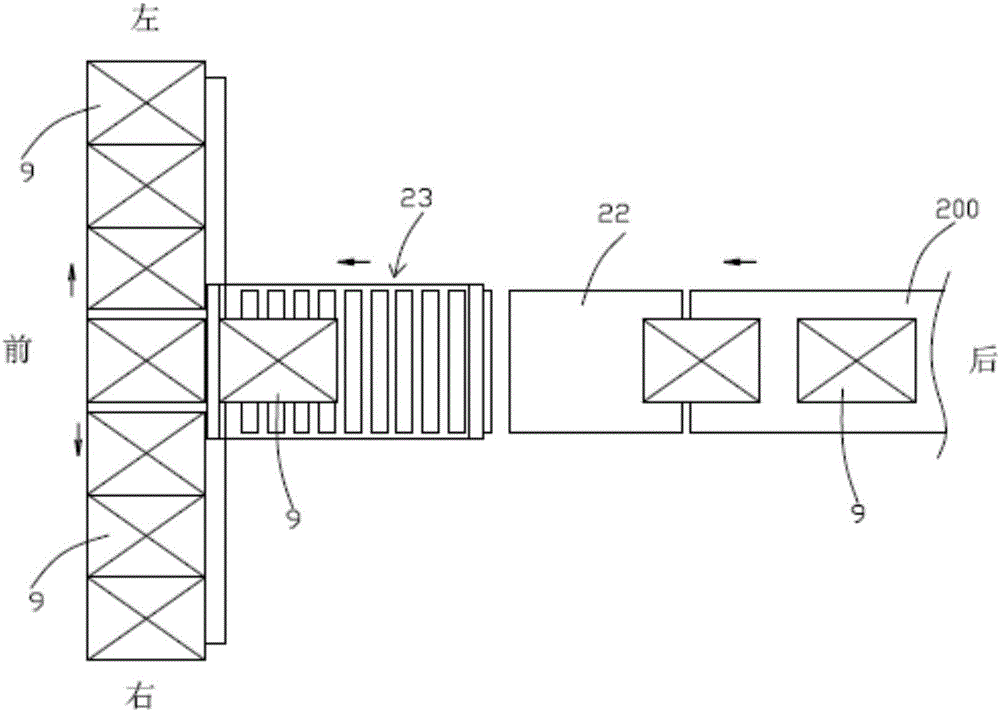

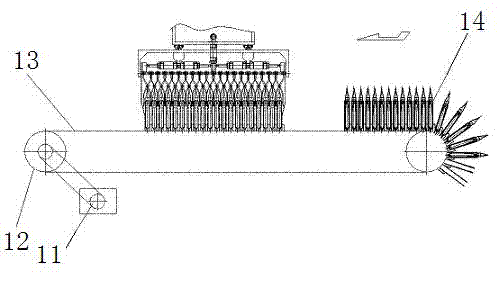

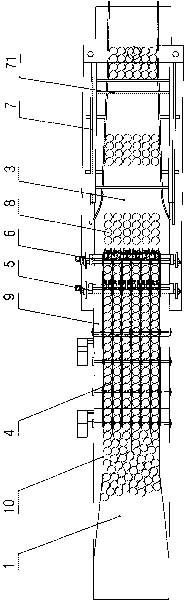

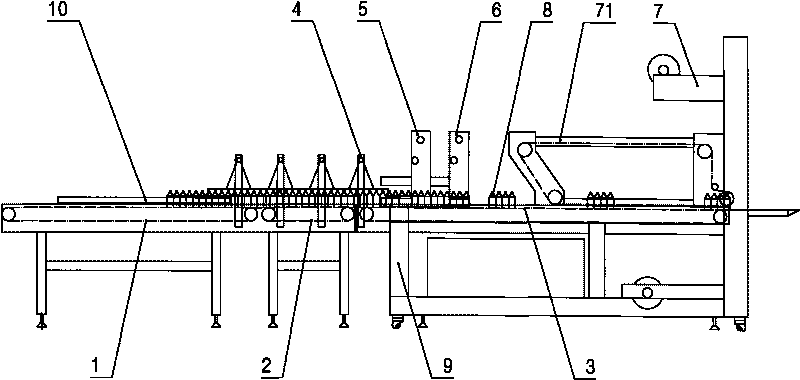

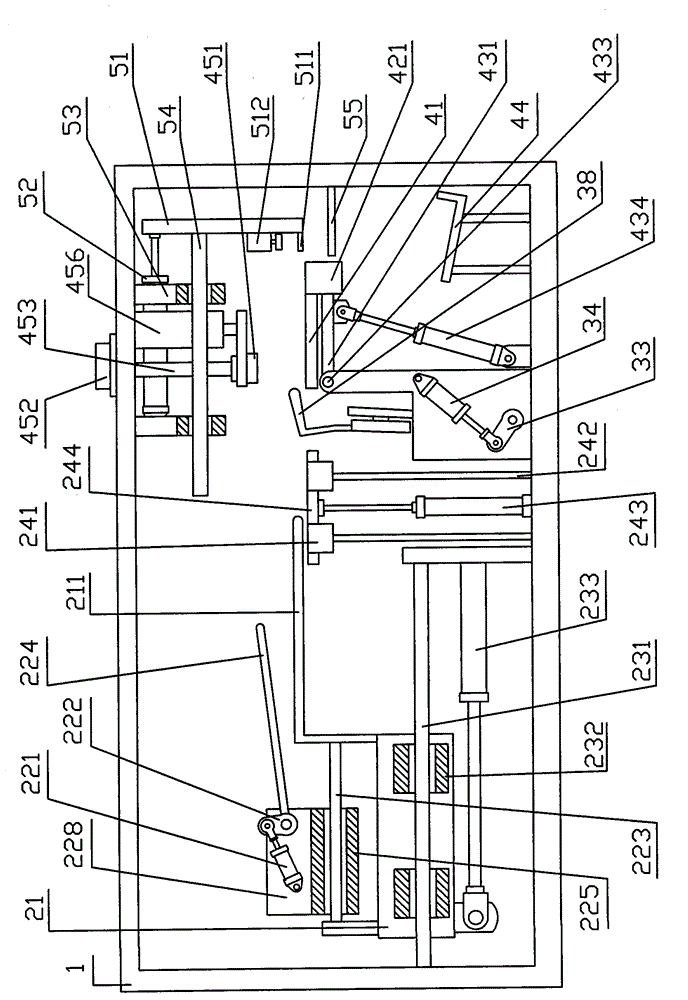

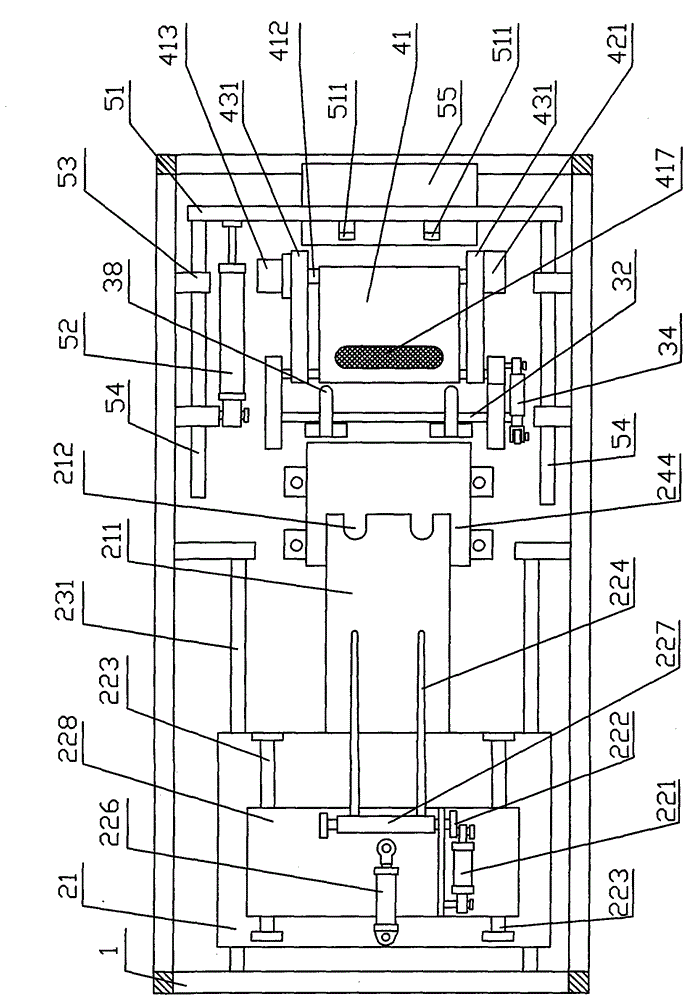

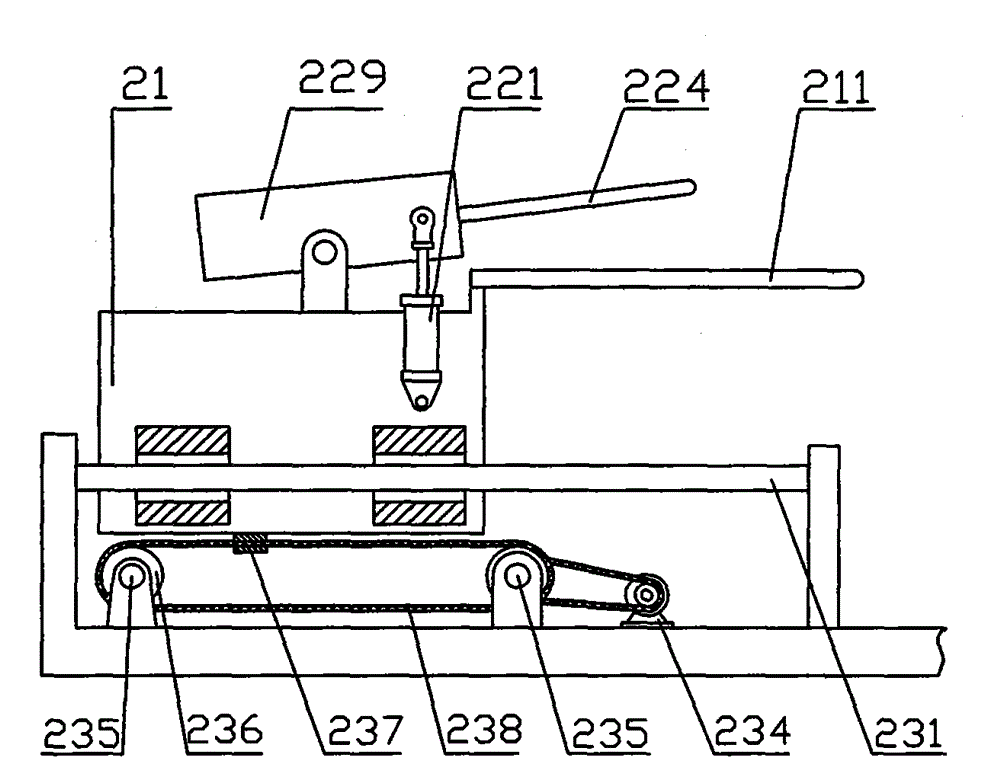

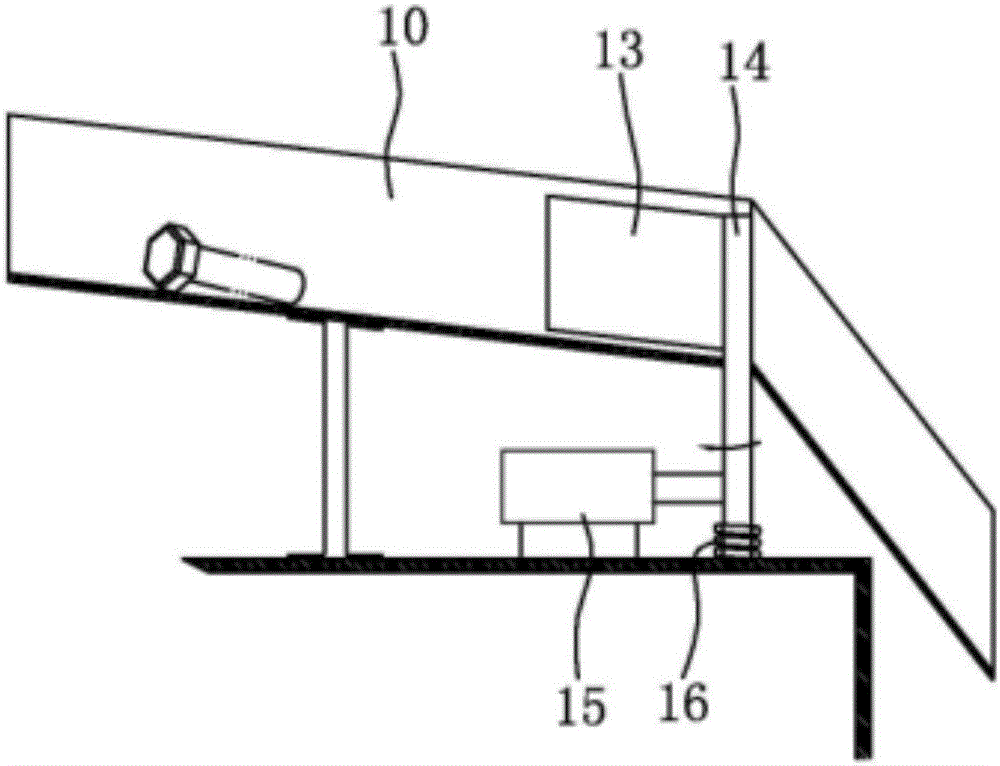

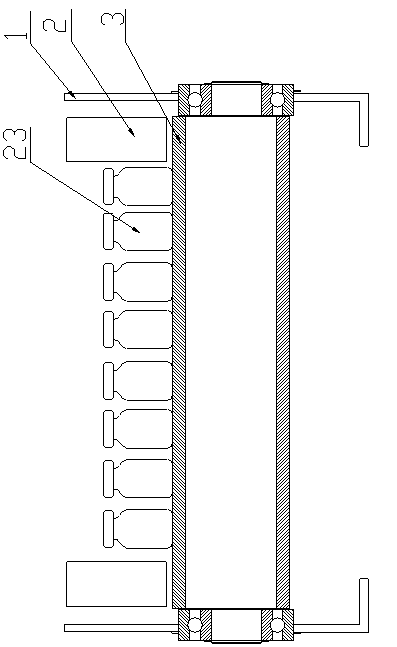

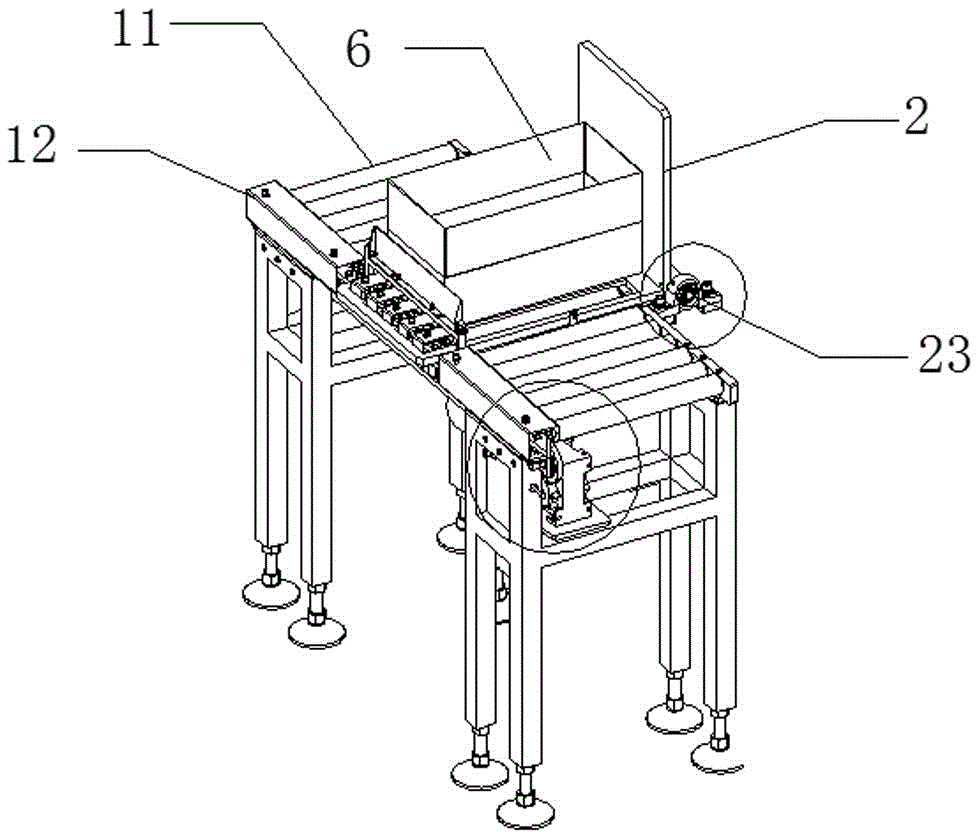

Vertical bag boxing machine

InactiveCN102556386AImprove gripLow bag drop rateIndividual articlesAgricultural engineeringSprocket

The invention discloses a vertical bag boxing machine, which comprises a vertical bag mechanism (1), a grasping mechanism (2) and a frame body (3), wherein the grasping mechanism (2) is arranged on the frame body (3); the vertical bag mechanism (1) is connected on the grasping mechanism (2); the vertical bag mechanism (1) is composed of a servo motor (11), a drive chain wheel (12), a chain (13) and a groove plate (14); the servo motor (11) is connected on the drive chain wheel (12); the chain (13) is arranged on the drive chain wheel (12); the groove plate (14) is fixed on the chain (13); thegrasping mechanism (2) is composed of a lateral face inserting mechanism (21), a hand grip mechanism (22) and a bag spacing control mechanism (23); and the hand grip mechanism (22) and the bag spacing control mechanism (23) are respectively arranged at two sides of the lateral face inserting mechanism (21). The vertical bag boxing machine is stable to grasp, low in bag falling rate and fast in boxing speed, cause no damage to soft bags in a grasping process and can realize full-automatic grasping and boxing of bags.

Owner:DALIAN JIALIN EQUIP MFG

Envelope type thin film packaging machine

The invention discloses an envelope type thin film packaging machine, which can improve the stability and the packaging speed. The envelope type thin film packaging machine comprises a rack, a conveying device, a sub-packaging device and an envelope sealing and cutting device, the conveying device, the sub-packaging device and the envelope sealing and cutting device are arranged on the rack, wherein the conveying device comprises a front conveying belt and a rear conveying belt which are arranged linearly and are combined with each other, the sub-packaging device is arranged above the rear conveying belt and comprises two gate opening and closing mechanisms and an alignment channel, the two gate opening and closing mechanisms cross over the rack, the alignment channel is arranged between the two gate opening and closing mechanisms, each gate opening and closing mechanism is provided with an opening and closing gate corresponding to a corridor; and a bottle distributing device which ismatched up with the alignment channel is arranged on the front conveying belt. The invention prevents the interference between conveying and sub-packaging, and improves the stability and the packaging speed of the whole device.

Owner:ZHANGJIAGANG DESHUN MACHINERY

Plastic bag packing machine

The invention discloses a plastic bag packing machine which is used for packing plastic bags. The plastic bag packing machine comprises a rack, a folding loading device, a supporting plate swing mechanism, a clamping output device and a mechanical arm conveying device, and is characterized in that the rack is provided with a swing type bag fetching and mouth opening device. The swing type bag fetching and mouth opening device is composed of a suction plate, a swing device, a lifting mechanism, a bag storage plate and a mouth opening mechanism, the swing device is connected with the suction plate and mounted on a bracket of the lifting mechanism, the suction plate can ascend and descend along with the bracket and swing front and back at the bracket under driving of the lifting mechanism and a swing device, the suction plate descends for a certain distance and then swings backwards and sucks packing bags in the bag storage plate, the packing bags are sucked when the suction plate ascends, swings and rotates to an initial position, the bottom layers of the packing bags are fixed to the suction plate, and the mouth opening mechanism sucks the upper layers of the packing bags to form openings. The plastic bag packing machine is compact in structure, high in efficiency and capable of carrying out packing by using common packing bags.

Owner:王秀来

Full-automatic film banknote bundling machine

ActiveCN102582869AFast packingRealize automatic palletizingPaper article packagingPackaging automatic controlControl systemProgrammable logic controller

The invention discloses a full-automatic film banknote bundling machine, which is mainly used for alignment packaging of printed matters such as banknotes, bank documents, bills and the like, and comprises a feed conveying mechanism, a stacking and steering mechanism, a primary pushing mechanism, an arranging and ejecting mechanism, a secondary pushing mechanism, a heat sealing mechanism, a discharging mechanism, a labeling mechanism and a PLC (programmable logic controller) control system. The running principle of the full-automatic film banknote bundling machine includes the steps: firstly, automatically conveying, stacking and counting banknotes in a single bundle, steering the banknotes for 180 degrees, and pushing the banknotes in ten bundles into the arranging and ejecting mechanism for arrangement and ejection by the aid of the primary pushing mechanism; then, pushing the banknotes in ten bundles into the heat sealing mechanism for heat sealing and bundling by the secondary pushing mechanism; and finally, after bundling is completed, utilizing the discharging mechanism to push banknote bundles onto a discharge conveying mechanism, and then labeling, namely, the whole process including counting, stacking, steering, arranging, bundling and labeling is completed. The full-automatic film banknote bundling machine has the advantages that the full-automatic film banknote bundling machine is high in automation level, stable in performance and high in cost performance, operating efficiency is improved and packaging material cost is reduced by the aid of the bundling mode, and the full-automatic film banknote bundling machine has extremely high professional popularization value.

Owner:合肥哈工龙延智能装备有限公司

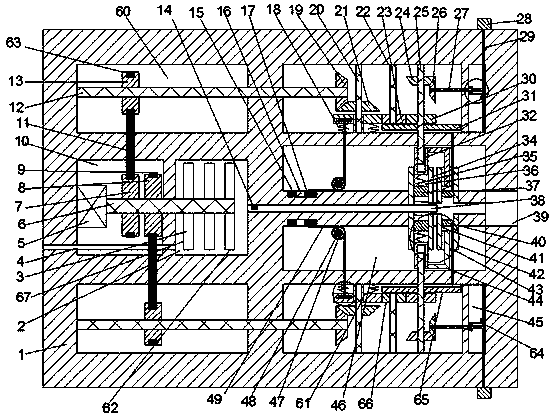

Novel ultrafine-powder packing machine

The invention discloses a novel ultrafine-powder packing machine, and relates to packaging equipment. A machine frame and a lifting column are arranged on a machine frame base, a weighing sensor is arranged on the lifting column, a clamping mechanism is further arranged at the upper end of the lifting column and is connected with a clamping air cylinder, a material stop valve and a dust removal pipeline, the material stop valve is further connected with a screw material cup, a filling screw is arranged inside a discharging hopper, a stirring motor is arranged inside a feeding hopper, a driven synchronous pulley is arranged above the feeding hopper, the driven synchronous pulley is connected with a driving synchronous pulley through a belt, and the driving synchronous pulley is connected with the filling motor. A lifting servo motor is arranged inside the machine frame and connected with a guide rod. The novel ultrafine-powder packing machine is high in production efficiency, and reasonable in design, has the functions of automatic quantification, automatic filling, automatic adjustment of metering errors and the like, is high in packing speed, is high in precision by the adoption of spiral discharging, and solves the problem that dust flies upward in a packing and filling process of ultrafine powder and materials having a great amount of dust.

Owner:SHANGHAI LUDA PACKING MACHINERY CO LTD

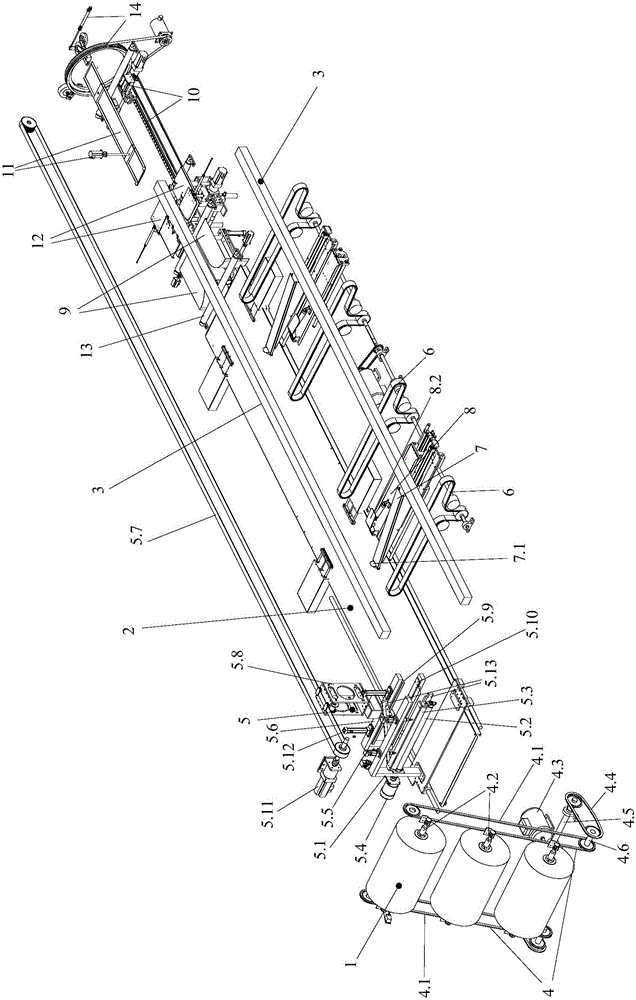

Section bar automatic packaging equipment

ActiveCN106218968AIncrease productivitySolve the low degree of automationWrapper folding/bending apparatusWrappingReciprocating motionUltimate tensile strength

The invention provides section bar automatic packaging equipment. The section bar automatic packaging equipment comprises a packaging paper feeding mechanism, a section feeding mechanism, a vertical folding mechanism, horizontal folding mechanisms, a packaging mechanism, a clamping and feeding mechanism, a pushing mechanism and a control mechanism, wherein the packaging paper feeding mechanism is used for lifting, pulling out and shearing and paving packaging paper on a platform; the section feeding mechanism is used for transferring and locating a section bar in the middle part of the platform where the packaging paper is paved; the vertical folding mechanism is used for adjusting the side edge separation distance of the packaging paper and bending the side edge of the packaging paper paved on the platform; the horizontal folding mechanisms are used for adjusting the side edge separation distance of the packaging paper and bending the side edge of the packaging paper paved on the platform and then horizontally folding the upper part of the side edge of the packaging paper, so that the packaging paper wrap the end surface of the section bar; the packaging mechanism is used for winding and sealing the packaging paper which wraps the section bar; the clamping and feeding mechanism is used for a reciprocating motion to transfer the section bar wrapped by the packaging paper to the packaging mechanism; and the pushing mechanism is used for compacting the opening of the packaging paper which wraps the end surface of the section bar. The section bar automatic packaging equipment provided by the invention can solve the problems that the efficiency is low and the labor intensity is great due to a manual operation, so that the packaging efficiency and quality of the section bar are improved.

Owner:佛山市嘉荣智能机械有限公司

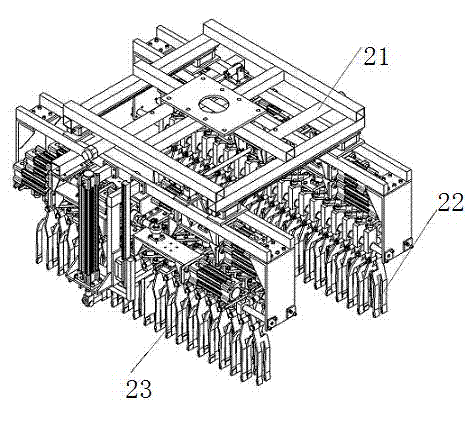

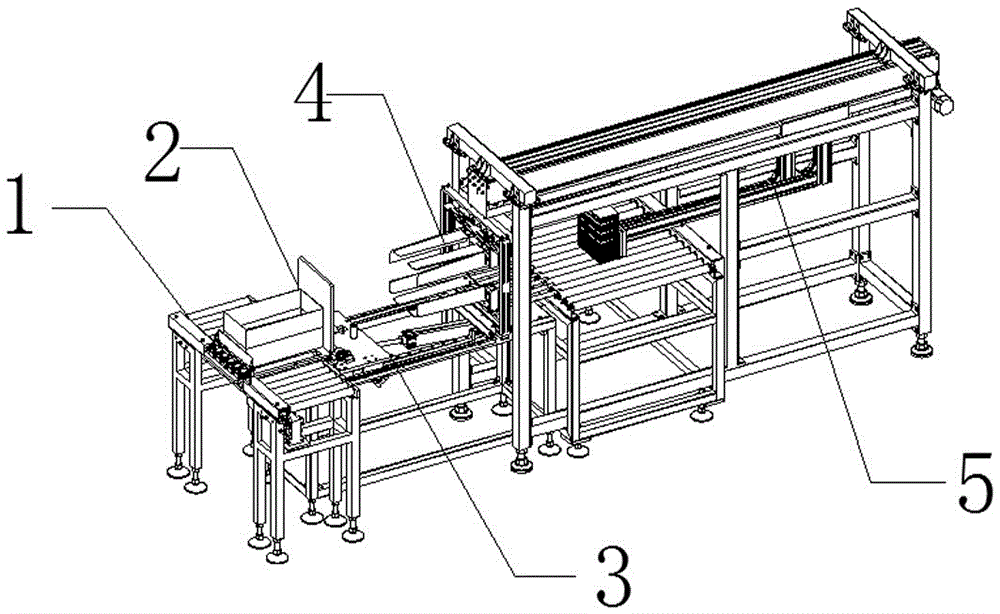

Automatic marshalling and binning device and binning method of small packaging boxes

ActiveCN105667878ARealize fully automatic operationImprove packaging efficiencyPackaging automatic controlIndividual articlesEngineeringUltimate tensile strength

The invention relates to an automatic marshalling and binning device and a binning method of small packaging boxes. A marshalling conveyor for marshalling the small packaging boxes is arranged on the right side of an equipment frame; a sorting platform is arranged on the left side of a discharging station of the marshalling conveyor; a binning platform is arranged on the left side of the sorting platform; a discharging mechanism for horizontally moving the small packaging boxes to the sorting platform is arranged above the discharging station of the marshalling conveyor; box clamping mechanisms for clamping the small packaging boxes are arranged on the front side and the rear side of the sorting platform; and a box moving mechanism for horizontally moving the small packaging boxes to the binning platform is arranged above the sorting platform. The small packaging boxes are firstly fed and marshaled and then are moved to the discharging station; and the small packaging boxes are discharged to the sorting platform by the discharging mechanism and then are clamped by clamping plates, the small packaging boxes are pushed to a binning supporting plate by the box moving mechanism, and the small packaging boxes are sucked by a suction cup assembly and downwards contained in a large packaging box. The device and method are low in human cost and labor intensity and high in automation degree.

Owner:YANGZHOU SINO-EU IND ROBOT CO LTD

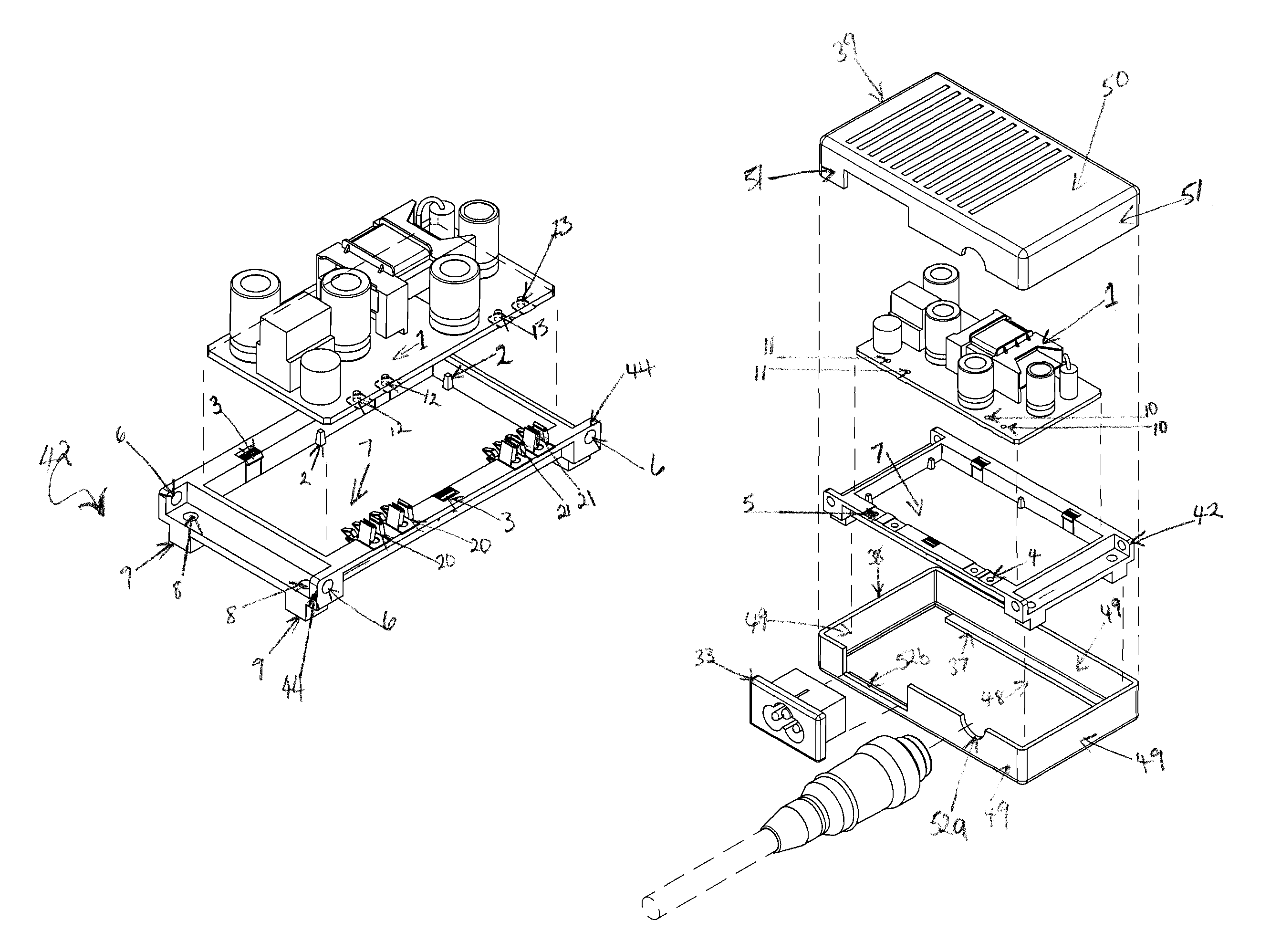

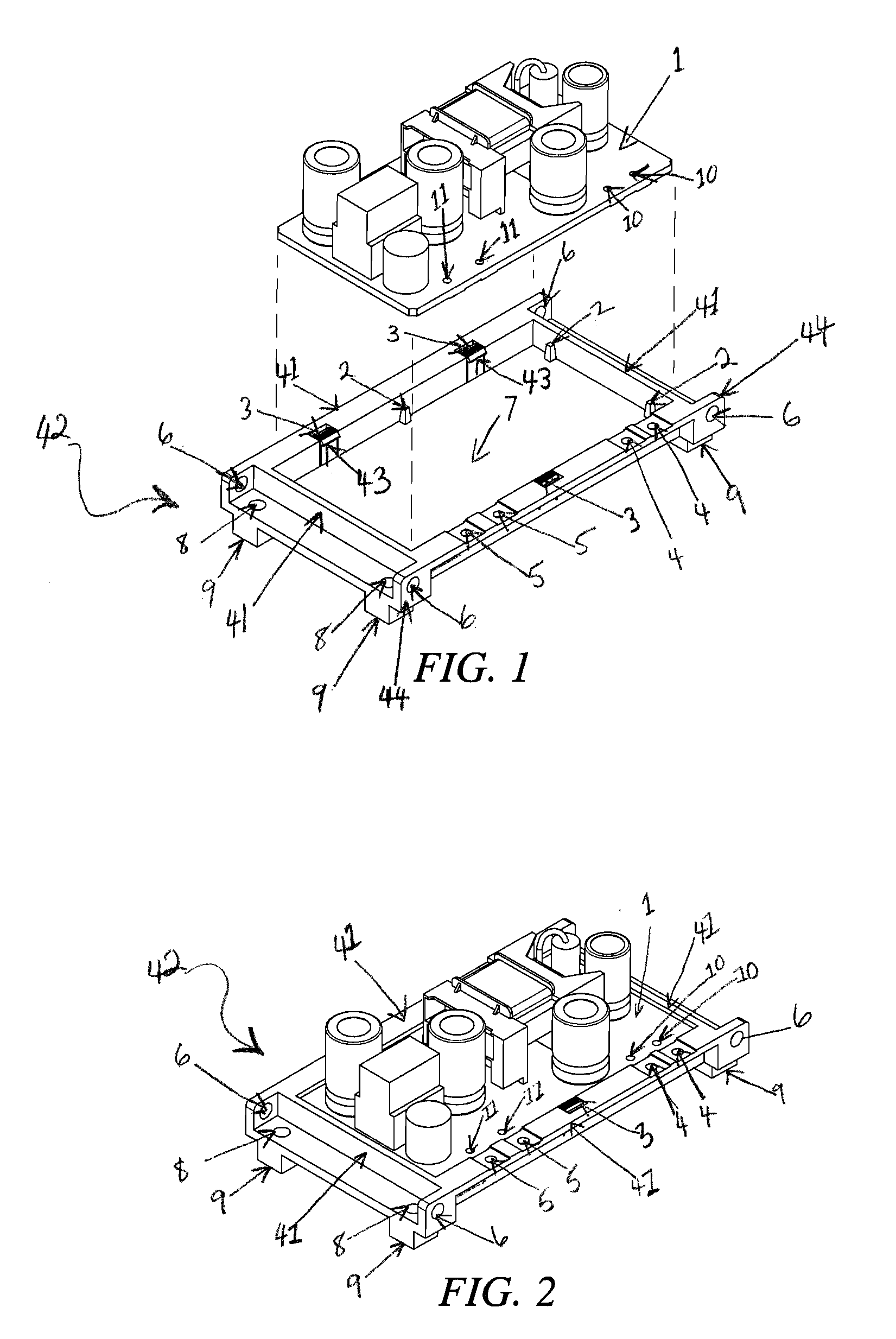

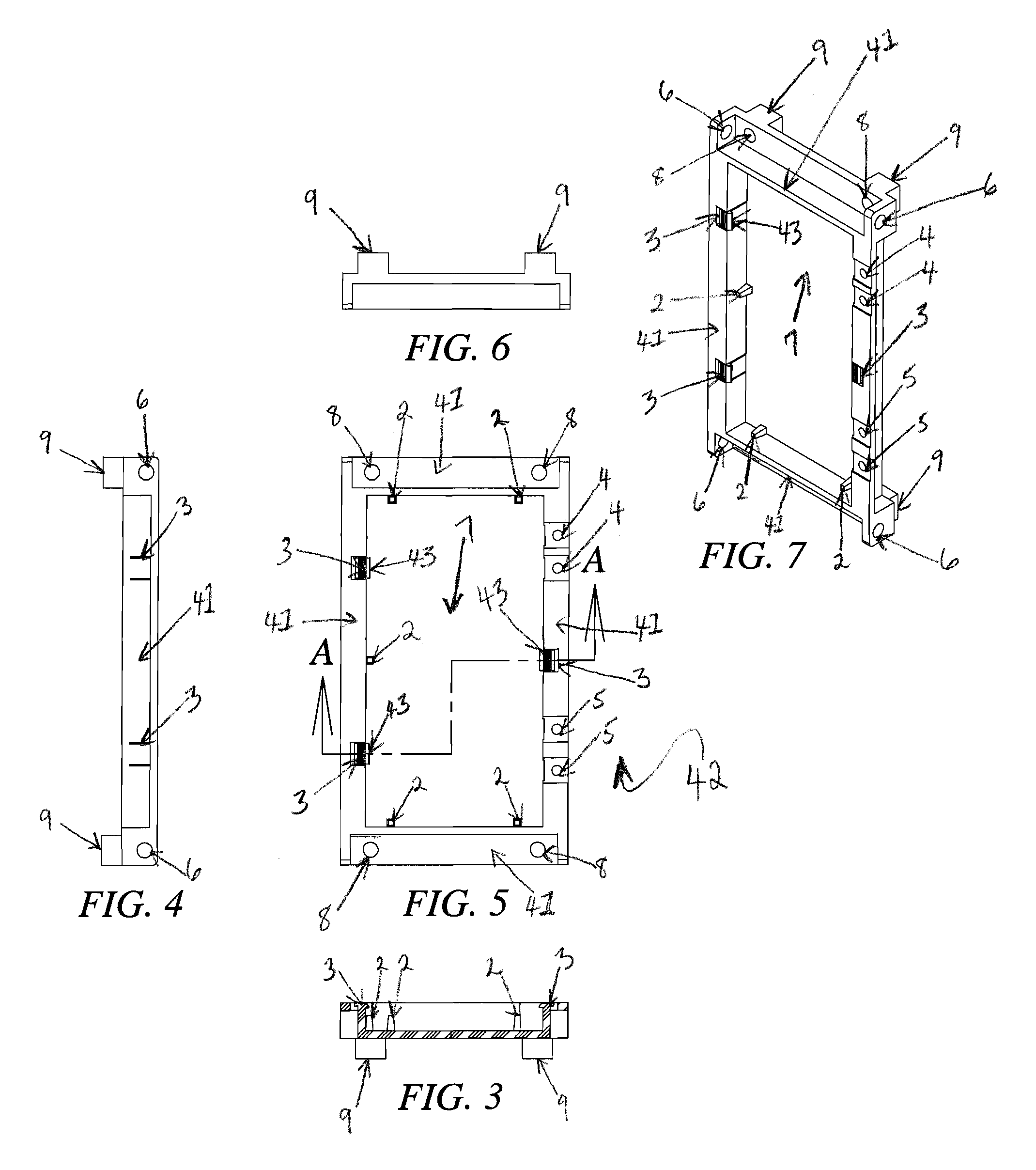

Power conversion device frame packaging apparatus and methods

InactiveUS7940532B2Increase flexibilityFast packingConversion constructional detailsPrinted circuit aspectsProduction lineCommon framework

The present invention relates, generally, to electrical power conversion devices and to the universal packaging of those devices for a wide range of applications yielding cost efficient inventory management of product lines consisting of a group of power conversion devices each with minor variations. More specifically, the present invention relates to a universal mounting frame for receiving a printed circuit board in a switch mode power supply. The universal frame is adapted for receiving an open frame or printed circuit board and securing the open frame within a plurality of known packaging configurations. To this end, only a single size printed circuit board is necessary for any type of switch mode power supply configurations, thereby, reducing costs associated with manufacture and testing.

Owner:PEI GENESIS

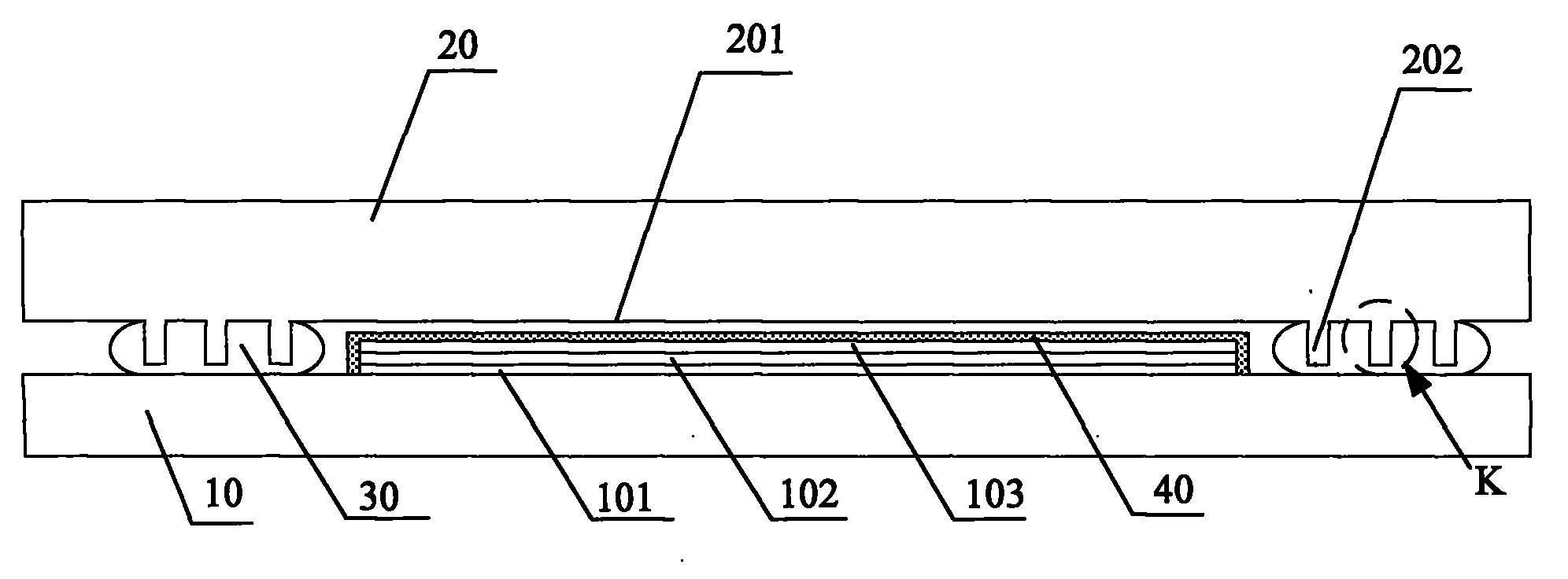

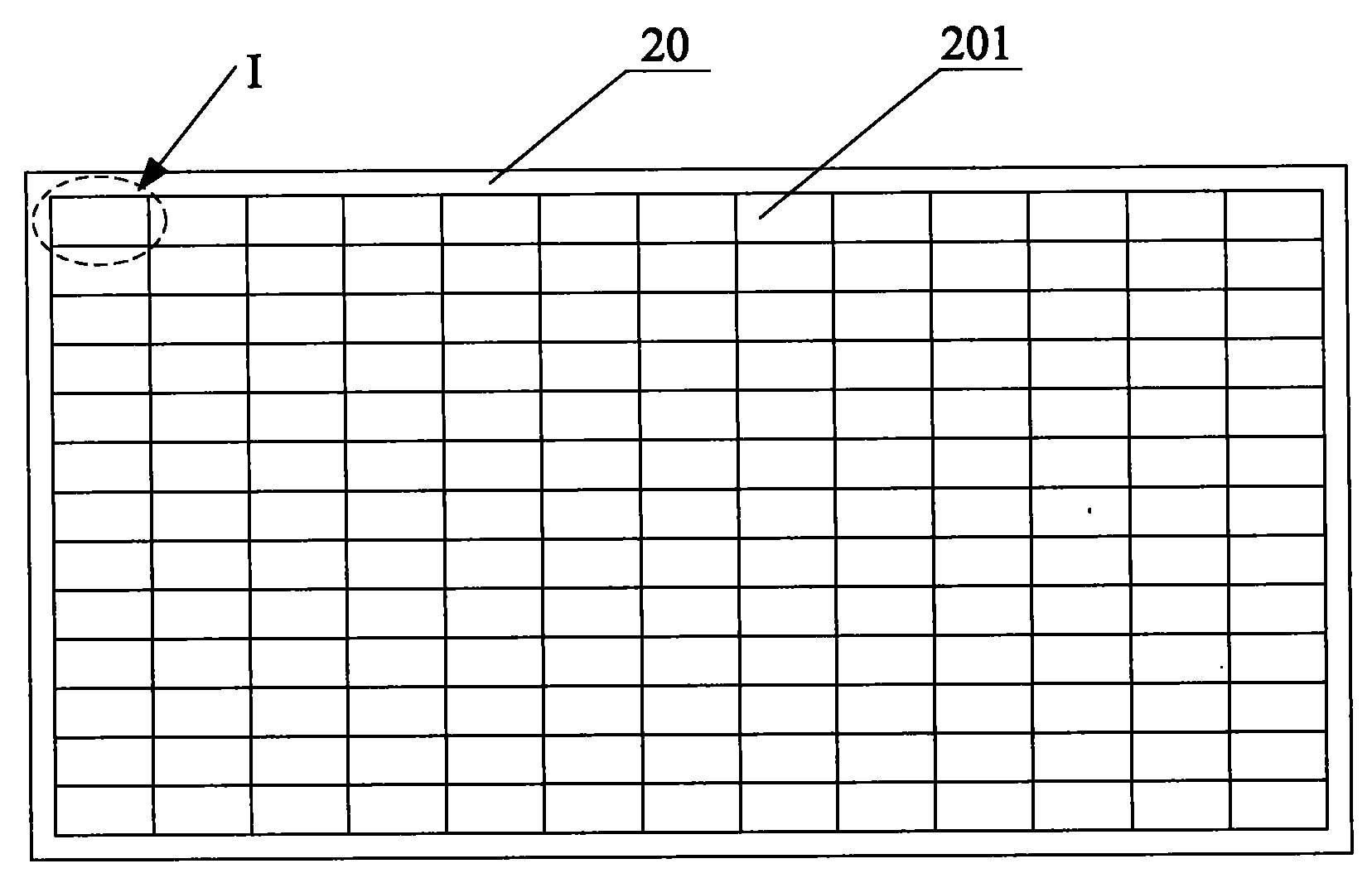

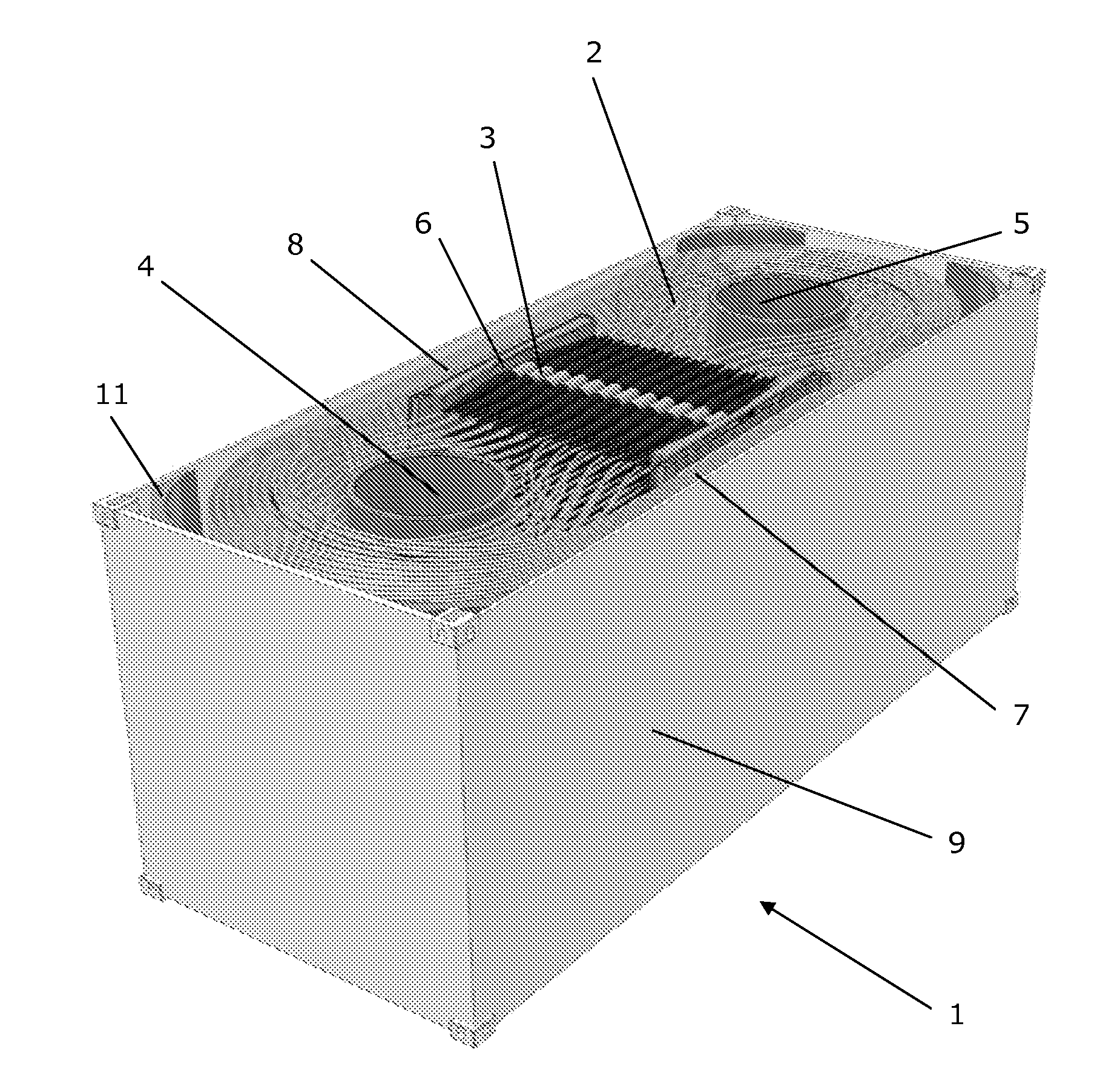

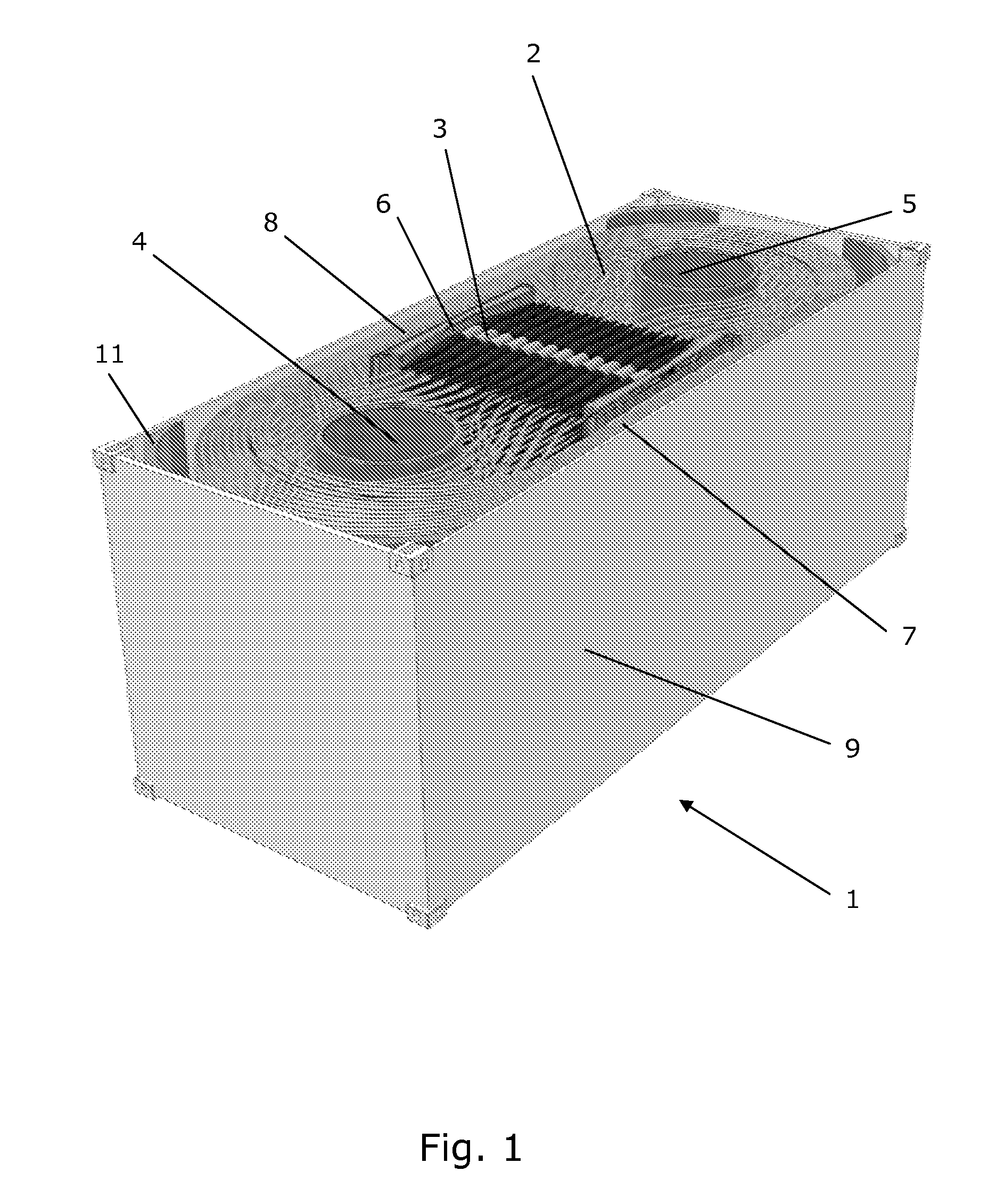

Packaging method for organic light-emitting diode display

InactiveCN101867023AReduce distanceEnhanced ability to block water vapor and oxygen infiltrationSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceAdhesive

The invention discloses a packaging method for an organic light-emitting diode (OLED) display. A rear cover of the organic light-emitting diode display also comprises at least one ring of continuous bumps surrounding the light emitting region at the periphery of the light emitting region; and a water-absorbing protection layer covers the surface of each pixel display region of a substrate. The method comprises the following steps of: coating a packaging adhesive at the periphery of the light emitting region of the rear cover, wherein the packaging adhesive surrounds the light emitting region and completely covers the at least one ring of bumps surrounding the light emitting region; aligning and pressing the rear cover coated with the packaging adhesive and the substrate; and curing the packaging adhesive. By using the rear cover provided with bumps at the periphery of the light emitting region, the required adhesive strength between the rear cover and the substrate can be ensured, the distance between the rear cover and the substrate can be greatly reduced, and the capability of the OLED of preventing the penetration of vapor and oxygen can be enhanced; and the vapor penetrated into the OLED can be adsorbed by further covering a transparent water-absorbing protection layer on the pixel display region, so that the organic functional layer is protected.

Owner:TRULY SEMICON

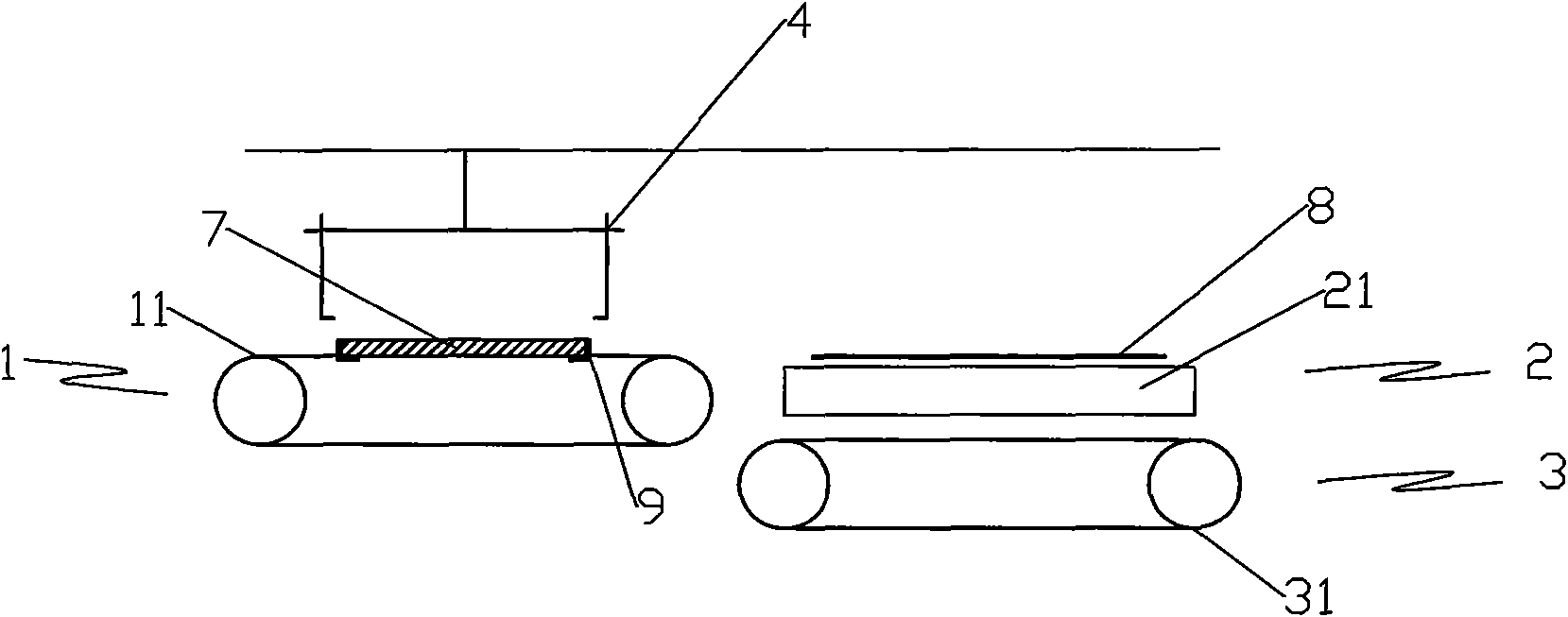

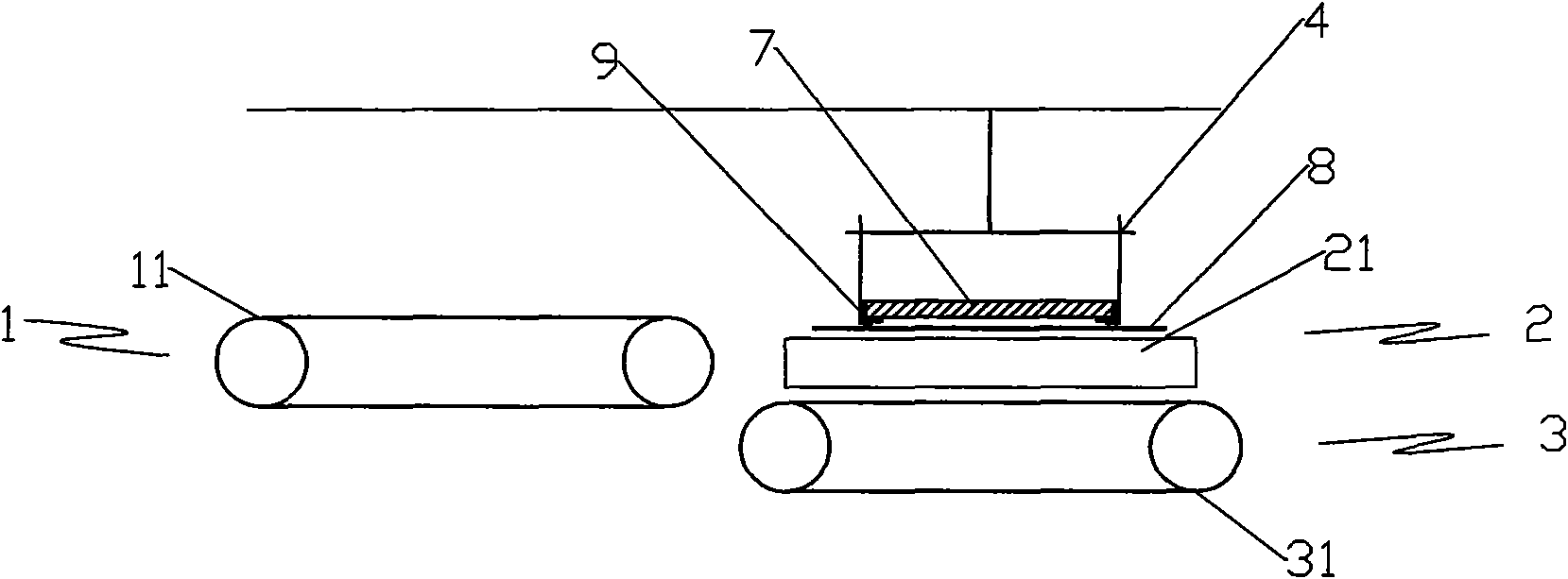

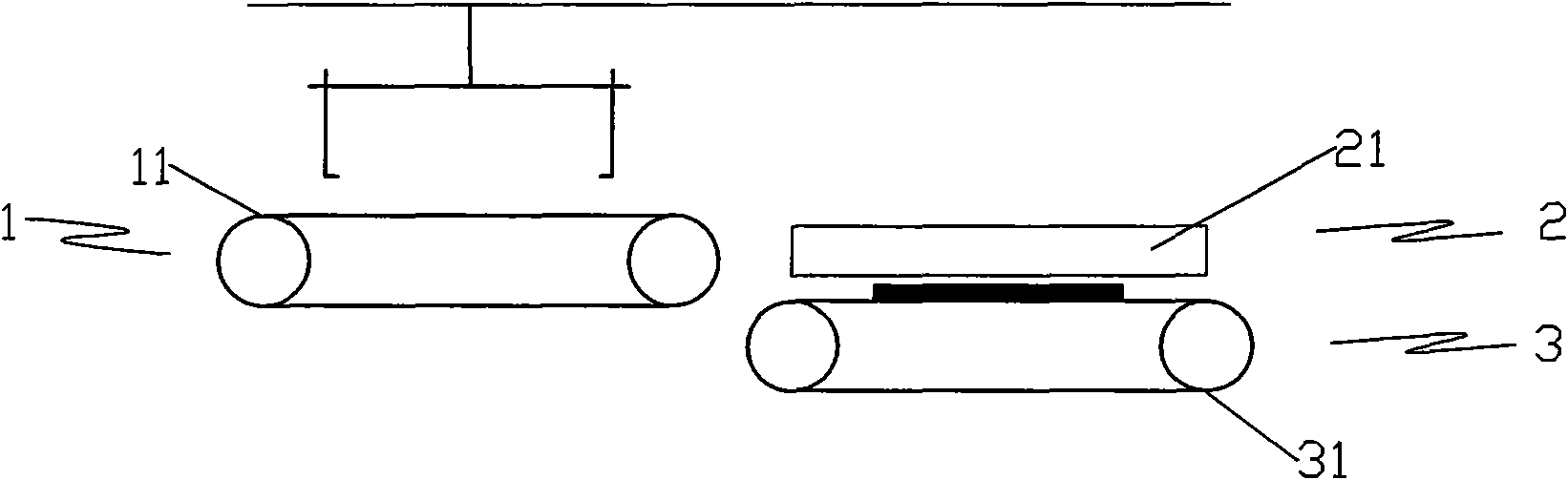

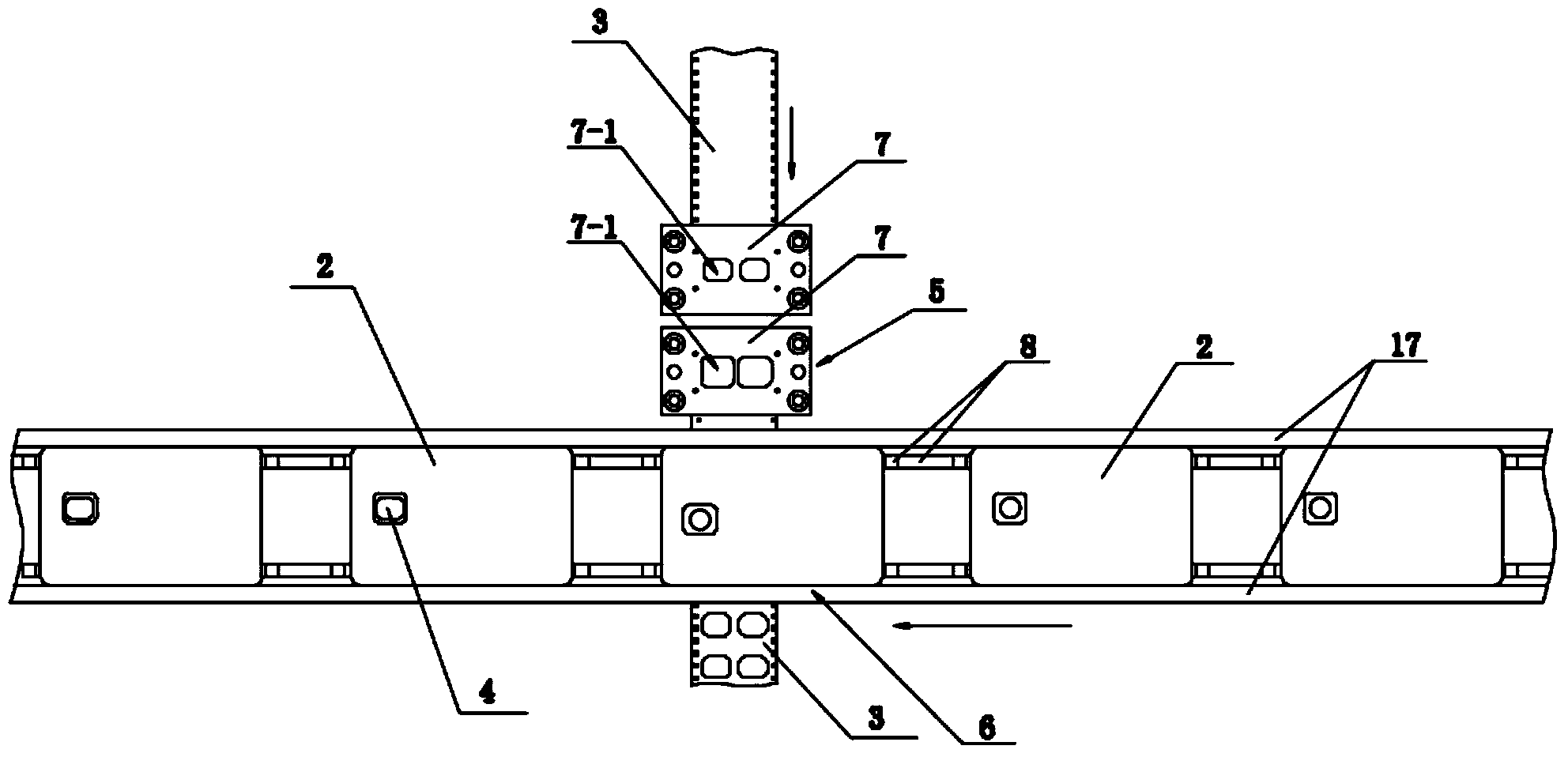

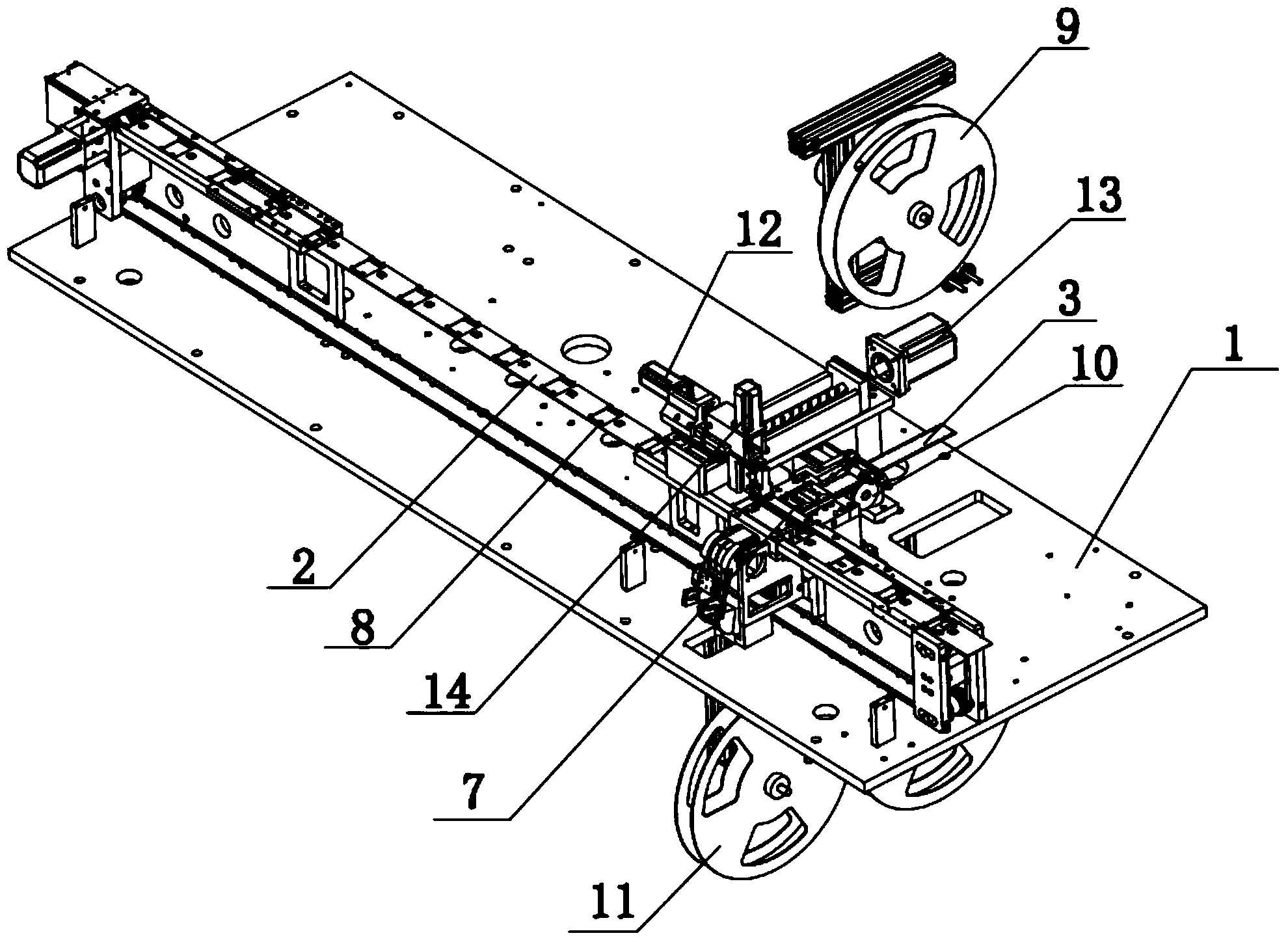

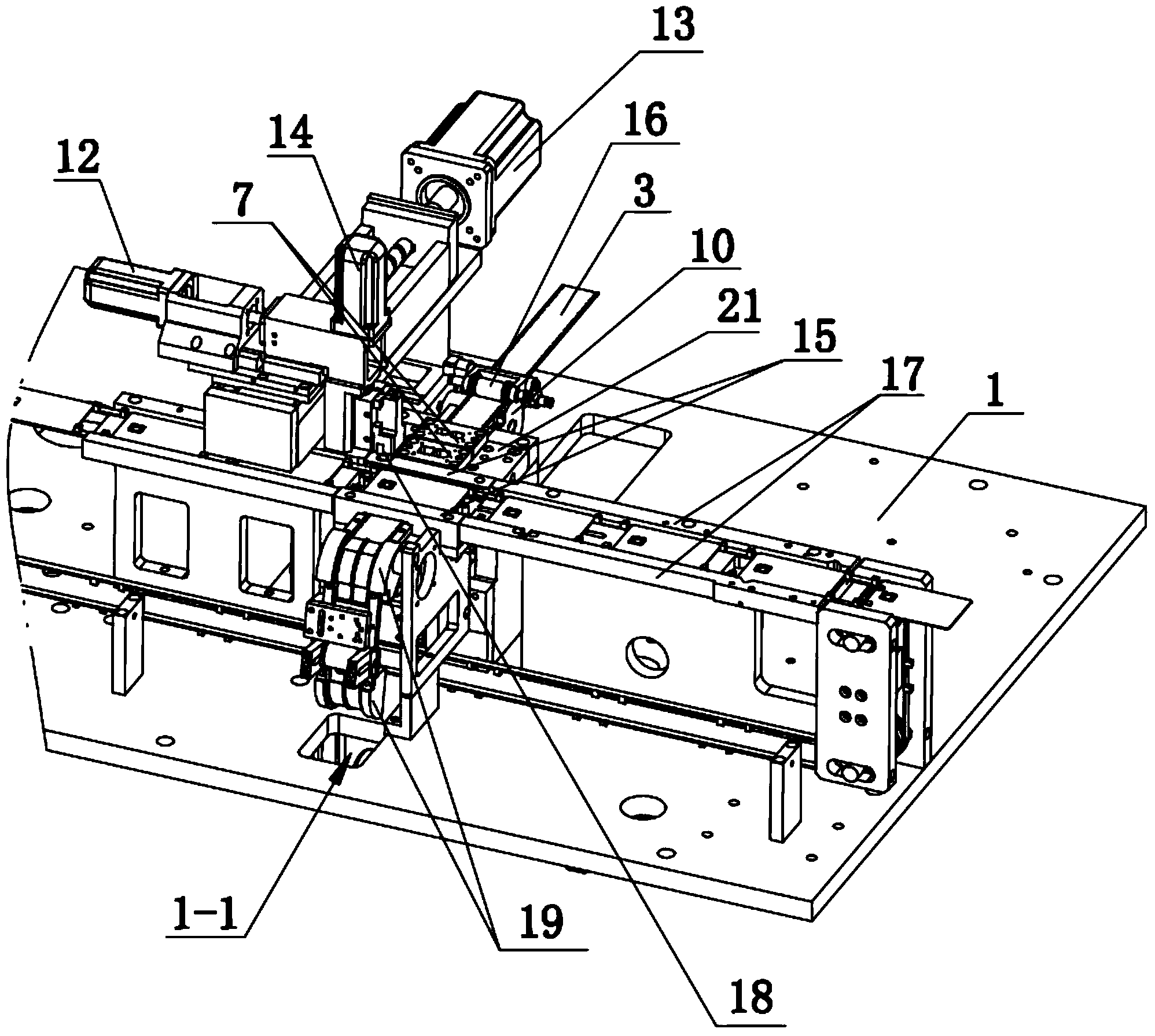

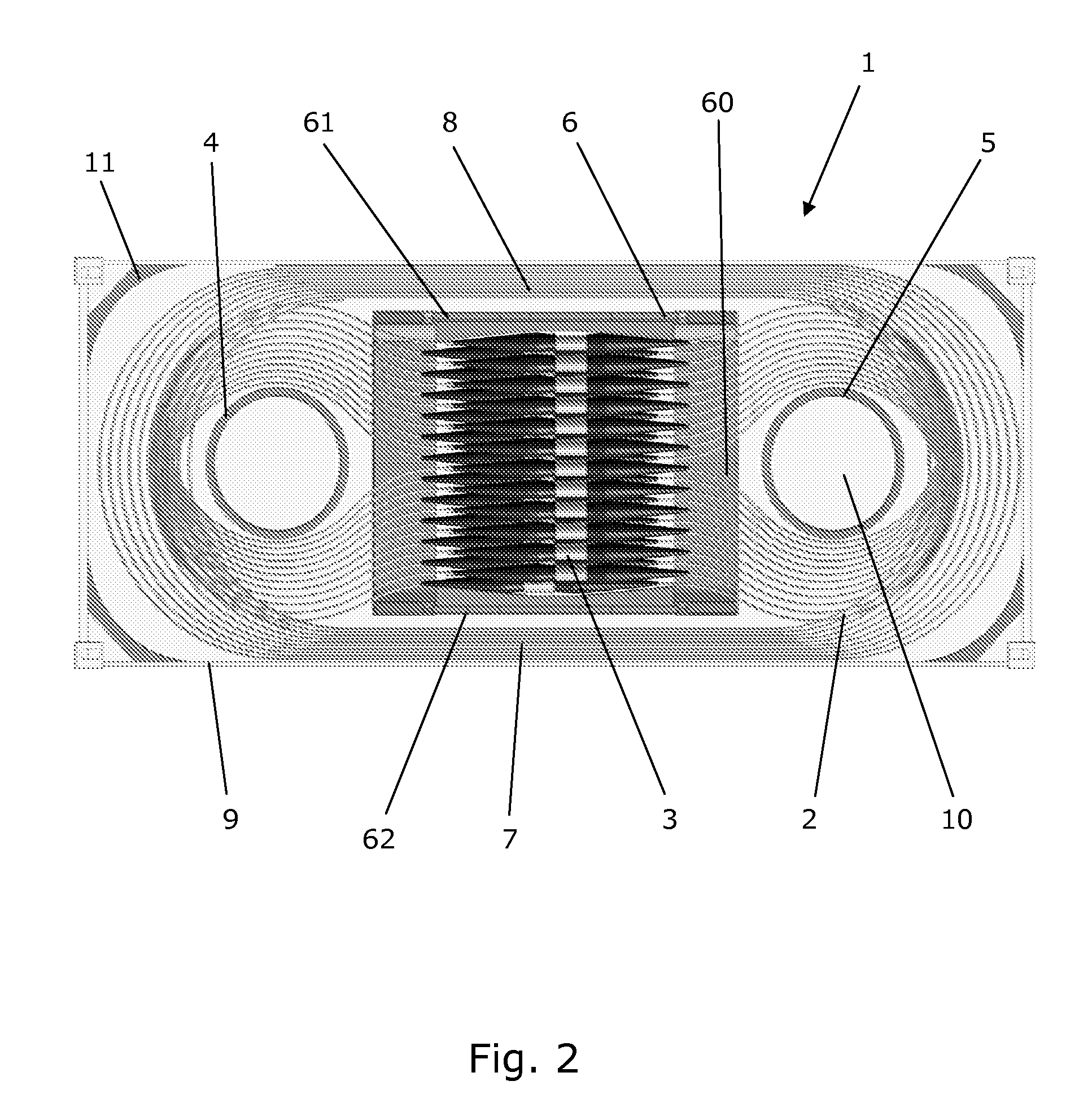

Smart card chip packaging equipment

ActiveCN104269373AShort tripFast packagingSolid-state devicesSemiconductor/solid-state device manufacturingEmbedded systemSmart card

The invention discloses smart card chip packaging equipment. The smart card chip packaging equipment comprises a working table, a card conveying device, a chip packaging device and a chip feeding device, wherein the card conveying device, the chip packaging device and the chip feeding device are arranged on the working table. The card conveying device comprises a card conveying mechanism used for intermittently conveying cards to be packaged to a packaging station one by one; the chip feeding device comprises a chip belt conveying mechanism, a blanking die and a blanking mechanism, and the chip belt conveying mechanism is used for conveying chips on a chip belt to a blanking station one by one; the chip packaging device comprises a packaging mechanism used for transferring the chips which have been blanked to the cards for packaging; the conveying direction of the chip belt conveying mechanism is perpendicular to the conveying direction of the card conveying mechanism, the chip belt penetrates through the position below the packaging station in the card conveying device, and the blanking station in the chip feeding device is arranged at the position tightly attached to the packaging station in the card conveying device. According to the smart card chip packaging equipment, the movement stroke of the chips is shortened, and the packaging speed is increased.

Owner:GUANGZHOU MINGSEN TECH CO LTD

Container system for seismic cable and stations

ActiveUS20100074048A1Different configurationUnnecessary loadPipe laying and repairContainers for annular articlesEngineering

Owner:OPTOPLAN

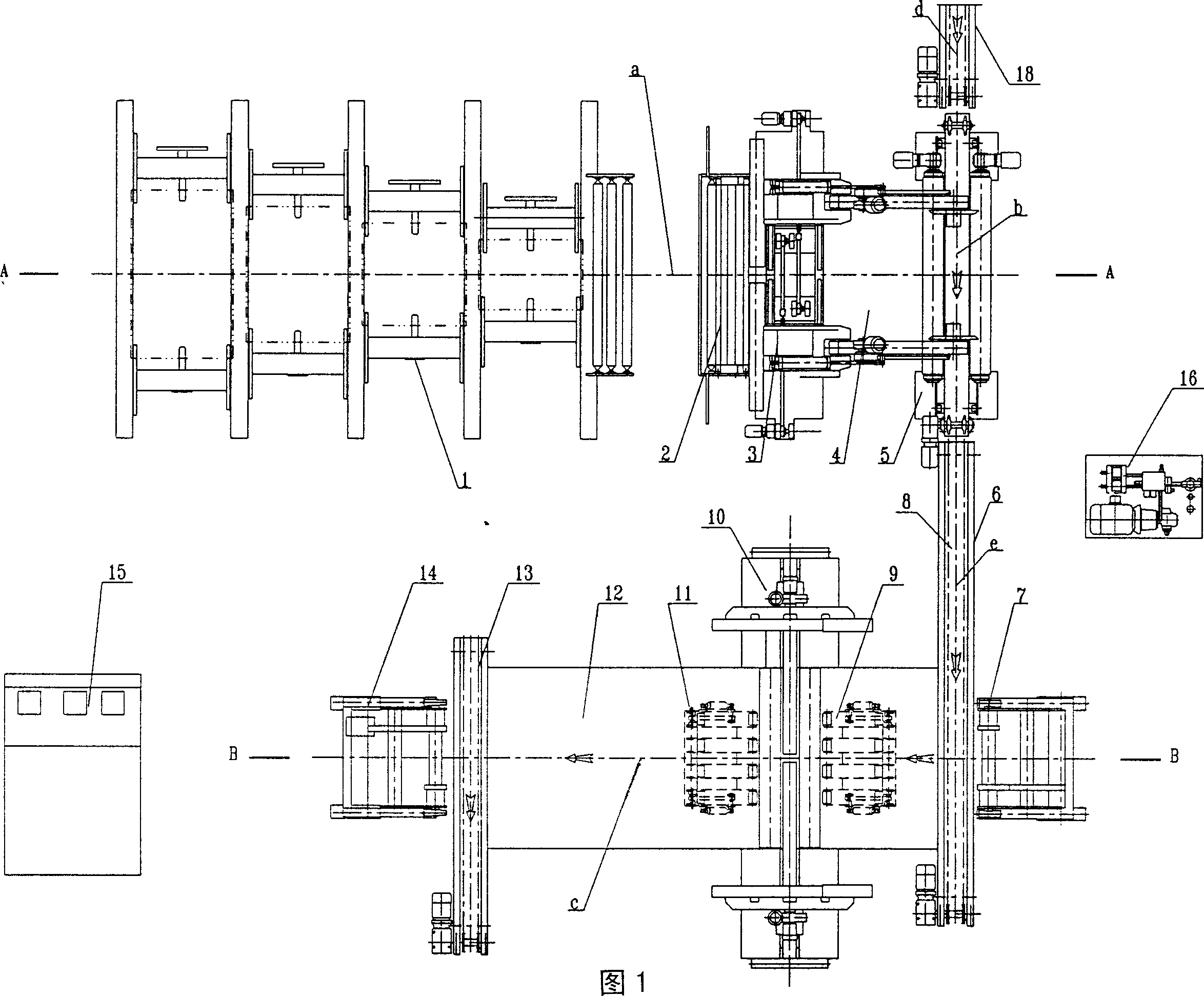

Fully automatic double-workplace paper roll packing method and packing machine

InactiveCN1421359AShorten the timeImprove work efficiencyPaper article packagingPackaging automatic controlPaper sheetFully automatic

The fully automatic double-station paper roll packing method features the separated paper roll hemming station set in the paper roll conveyer and hot pressing station with one paper roll conveyer in between. The separated setting realizes continuous packing and raises the work efficiency greatly. The packing machine features the paper roll conveyer between the two stations. The paper roll conveyer consists of elevator and conveyer.

Owner:长沙长泰智能装备有限公司

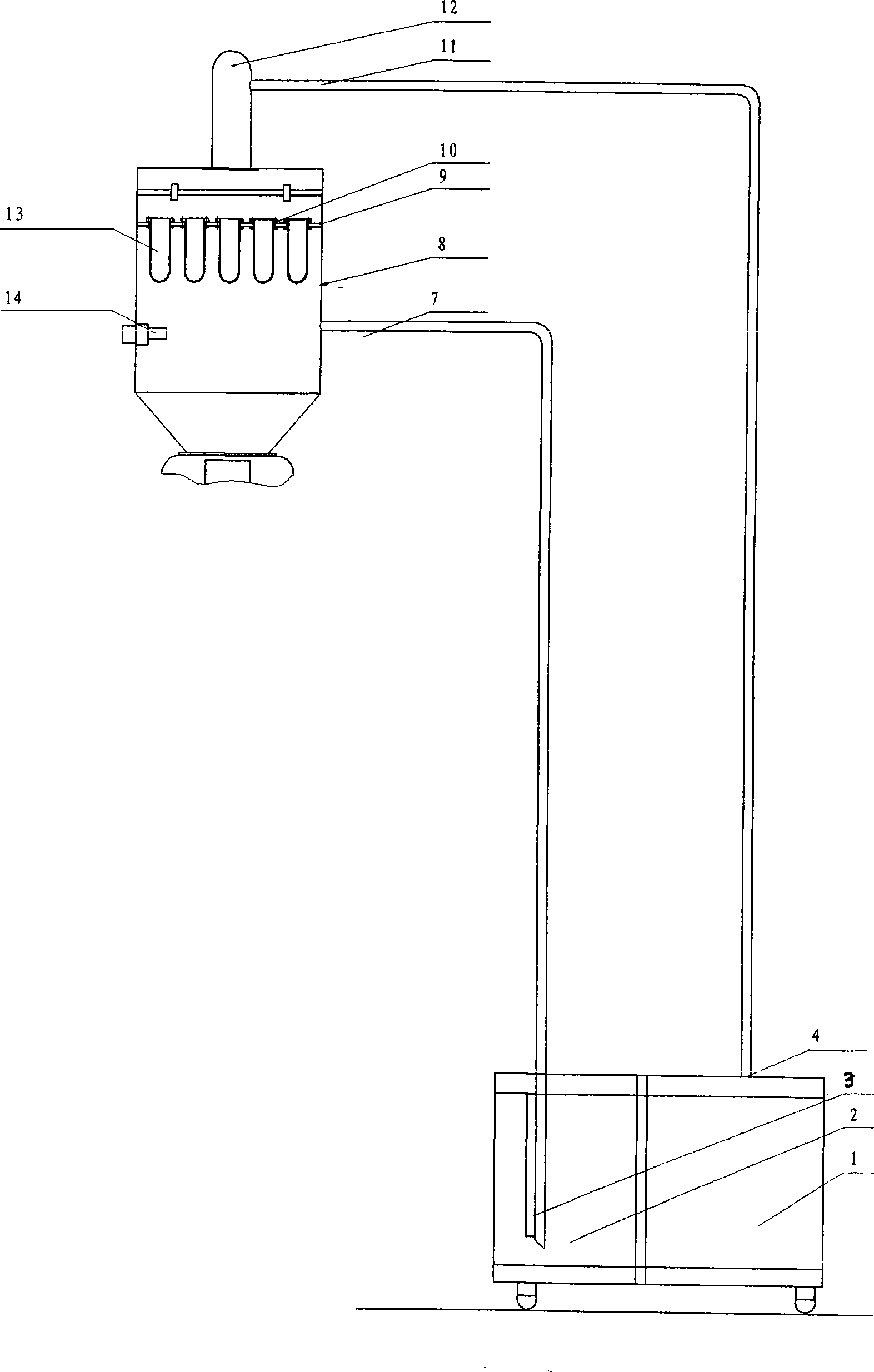

Intelligent full-automatic vacuum tea packing machine

InactiveCN101503119AFast packingFast packaging efficiencyPackaging by pressurising/gasifyingWrapper twisting/gatheringAir filterEngineering

The invention belongs to a packing machine which comprises a vacuum feeding and drying device and an automatic vacuum packing device; wherein, the vacuum feeding and drying device mainly consists of a material absorbing machine, a charging basket, a material absorbing gun, an exhaust opening, an exhaust duct, a vacuum pipe, a vacuum tank, a material absorbing pipe, an air filter, a material position sensor and a drier; the automatic vacuum packing device includes a gusseted device and a package boxlike integer type device, wherein, the gusseted device is positioned at the two sides of a horizontal sealing module and a sealing block, and the package boxlike integer type device is arranged at the lower end of the sealing block. The packing machine can complete the whole tea packing process for once in a state of unmanned operation, can meet the requirements of sealing and keeping out of the sun, the air and the moisture, and can form the shape of tea packing according to the needs, so that the package of tea is exquisite, beautiful, safe and sanitary, the packing speed is high, and the packing quality is good.

Owner:彭智松

Packaging bag vacuum sealing quick packing device

ActiveCN110304299ASimple structureEasy to operatePackaging by pressurising/gasifyingEngineeringElectrical and Electronics engineering

The invention discloses a packaging bag vacuum sealing quick packing device. The packaging bag vacuum sealing quick packing device mainly comprises a machine shell, the machine shell is internally provided with two sealing cavities, two first transmission cavities and two second transmission cavities, the machine shell is internally provided with a driving cavity and a pumping cavity, the drivingcavity is internally provided with a driving mechanism, the pumping cavity is internally provided with a pumping mechanism, the upper and lower two second transmission cavities are internally providedwith transmission mechanisms, and the upper and lower two sealing cavities are internally provided with clamping and sealing mechanisms for fixing and sealing a packaging bag. When the device works,after air in the packaging bag is completely pumped away, the device can instantly conduct hot sealing treatment on the packaging bag; after sealing of the packaging bag is completed, the device can automatically release the packaging bag and stop a power supply of a heating part, and one time of vacuum sealing treatment is completed; and while packaging bag vacuum sealing quick packing integration is achieved, the packaging speed is increased, and power is saved.

Owner:汕头市恒一机械有限公司

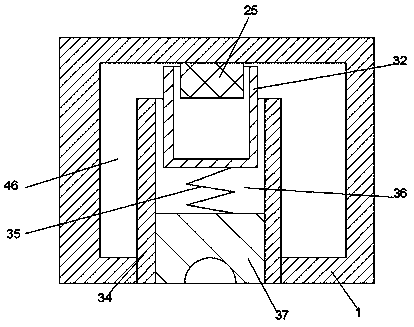

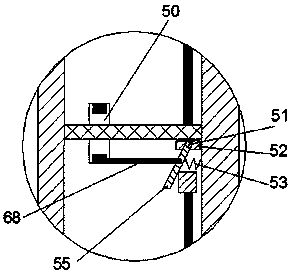

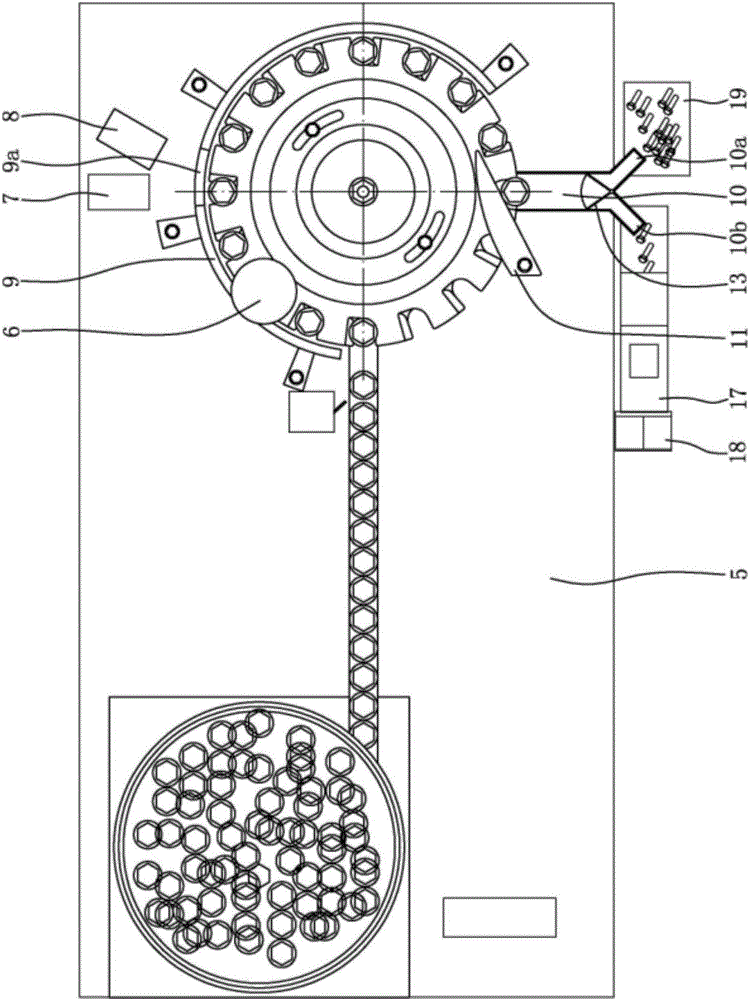

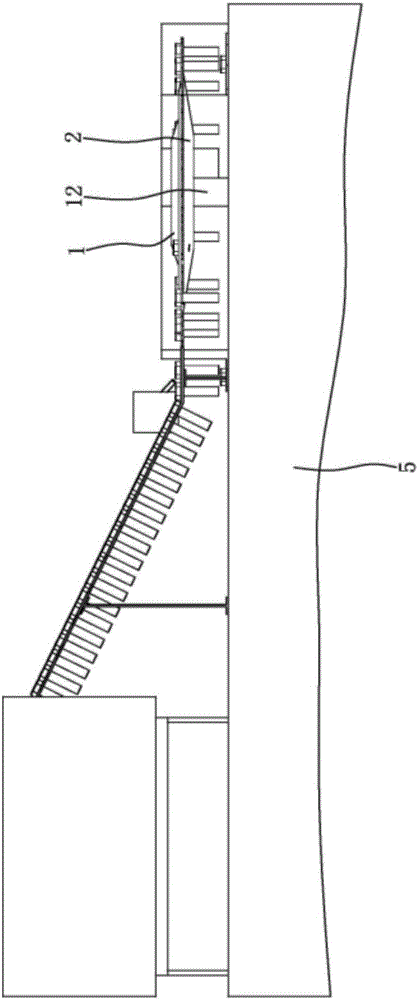

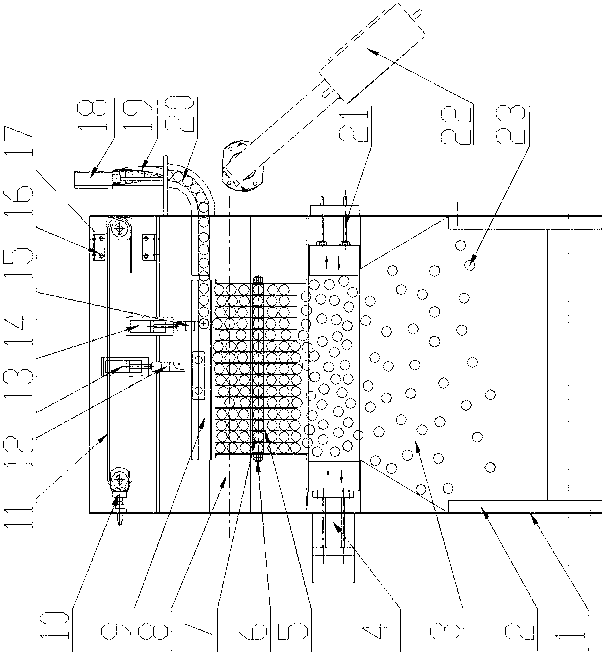

Indexing and subpackaging mechanism used for standard fastening part detection

InactiveCN107176421AThe working process is simple and fastHigh degree of automationControl devices for conveyorsOptically investigating flaws/contaminationCcd cameraComputer science

The invention discloses an indexing and subcontracting mechanism for standard fastener detection. An indexing turntable is arranged above a machine table (5), and a first CCD camera is arranged above the edge of the indexing turntable ( 6), the second CCD camera (7) and the third CCD camera (8) are set next to the indexing turntable, and there is an anti-falling baffle (9) around the periphery of the indexing turntable. A slideway (10) is also provided next to it, and the outlet end of the slideway (10) is bifurcated to form a first distribution channel (10a) and a second distribution channel (10b). There is a first parts box (16), and a parts wrapper (17) with a counter is arranged beside the first parts box (16). The invention can be used to detect various standard fasteners, and can automatically sort and pack parts by category through a sorting and packaging mechanism while preventing the standard fasteners from falling off.

Owner:肇庆市端州区麒诺机械科技有限公司

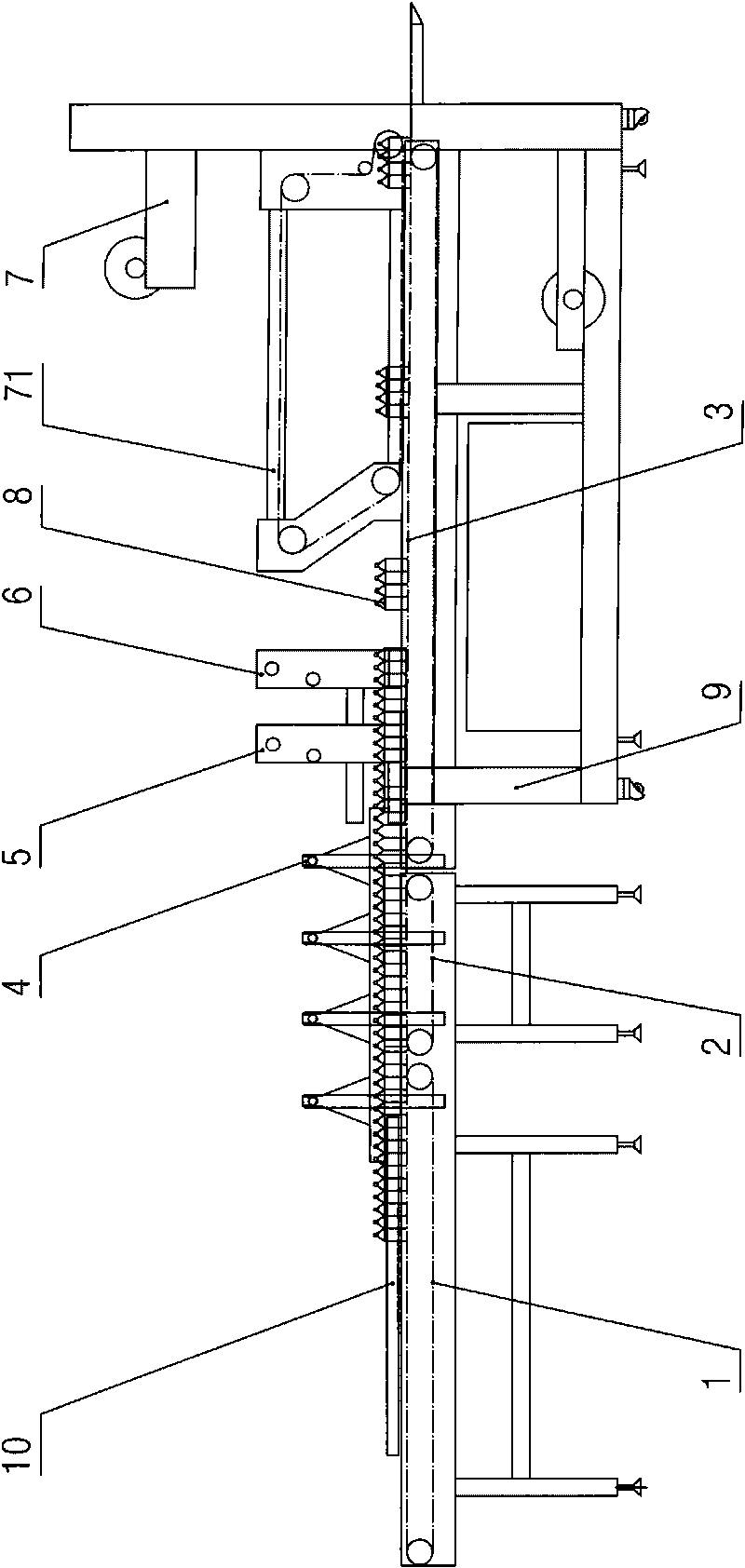

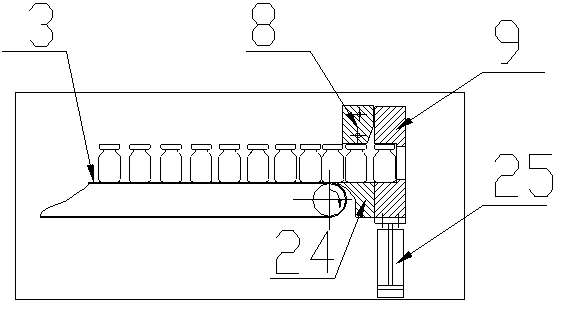

Automatic support filling device for penicillin bottles

The invention relates to a support filling mechanism, in particular to an automatic support filling device for penicillin bottles. The device comprises a horizontal feeding mechanism, a bottle separation mechanism, a bottle pulling mechanism, a spiral track and a storage apparatus. The horizontal feeding mechanism comprises a delivery belt and tracks, wherein the tracks are arranged on two sides of the delivery belt, and wall plates are arranged on the rack on the two outer sides of the tracks. The bottle separation mechanism is composed of separation plates which are arranged in parallel and at equal intervals at the tail end of the delivery belt. The device is controlled through a programmable logic controller (PLC) and a human-computer interface touch screen, so that the automation degree is high, operation staff are few in a whole packing process, the labor intensity requirement is low, connection positions are tight, the operation is stable, the device is safe and reliable, bottles cannot be blocked and broken easily, labels on the penicillin bottles cannot be abraded, the packing quality is high, the packing speed is fast, the production efficiency is high, and integrated support separation and filling is achieved.

Owner:ZHENGZHOU SHUNYI TECH CO LTD

Automatic bottled product encasing device

ActiveCN104443499AHigh speedImprove efficiencyPackaging automatic controlPackaging bottlesMechanical engineeringFast speed

The invention provides an automatic bottled product encasing device. The automatic bottled product encasing device comprises a bottled product conveying mechanism, a shunting mechanism, an encasing mechanism, a box conveying mechanism and a controller. The bottled product conveying mechanism is provided with M conveying channels and used for arranging bottled products according to the preset number of rows / columns of the bottled products needing to be arranged in a box and guiding and conveying the bottled products. One end of the shunting mechanism is connected with a device inlet, the other end of the shunting mechanism is movably connected with the M conveying channels, and the shunting mechanism is used for movably shunting and guiding the bottled products conveyed from the single device inlet into the M conveying channels of the bottled product conveying mechanism. The encasing mechanism is connected with an outlet of the bottled product conveying mechanism and used for arranging the bottled products according to the preset number of rows / columns of the bottled products needing to be arranged in the box, after an array is formed, the whole array of the bottled products fall and are arranged in the box capable of being lifted. The box conveying mechanism is arranged on one side of the encasing mechanism. The encasing device is simple in structure, high in encasing speed and encasing stability, and capable of improving bottled product encasing efficiency and accuracy.

Owner:佛山市嘉荣智能机械有限公司

Tile cartonning device and application process

The invention discloses a tile cartonning device, which comprises a rack body, and is characterized in that a carton conveying rack, a carton placing rack, a carton driving mechanism, a carton erecting device and a tile pushing mechanism are sequentially arranged on the rack body from left to right. The tile cartonning device provided by the invention has the characteristics of reasonable and scientific structure design, reliability in operation, high cartonning efficiency, high cartonning quality and the like.

Owner:JINJIANG CITY CHAOJUN MACHINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com