Automatic binning method and automatic binning mechanical arm

A technology of automatic packing and manipulator, applied in transportation and packaging, stacking of objects, de-stacking of objects, etc., can solve the problems of heavy labor and low work efficiency, and achieve fast packing speed, high efficiency and saving. human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

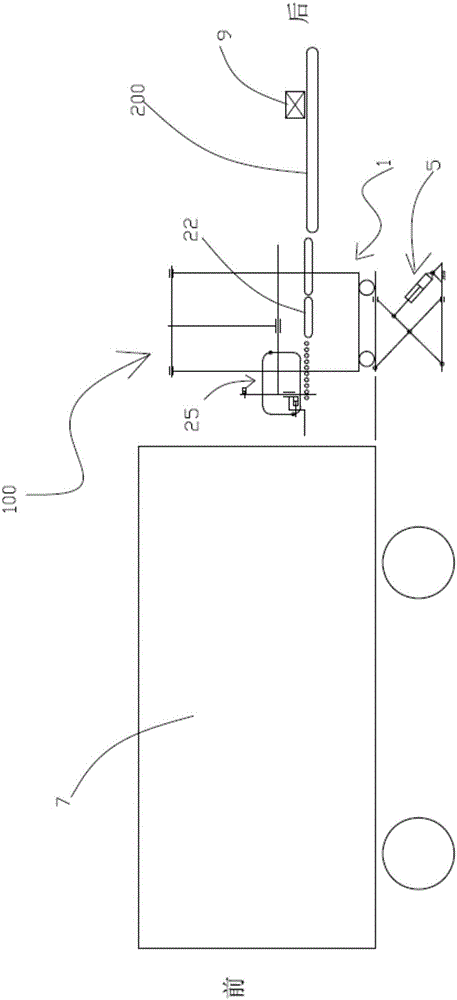

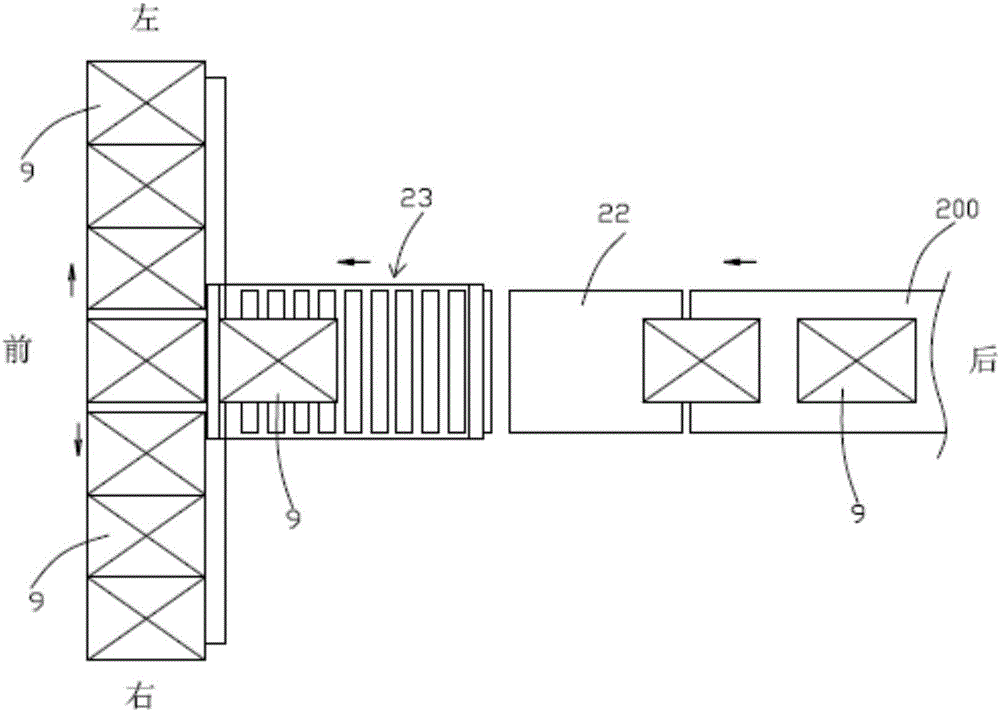

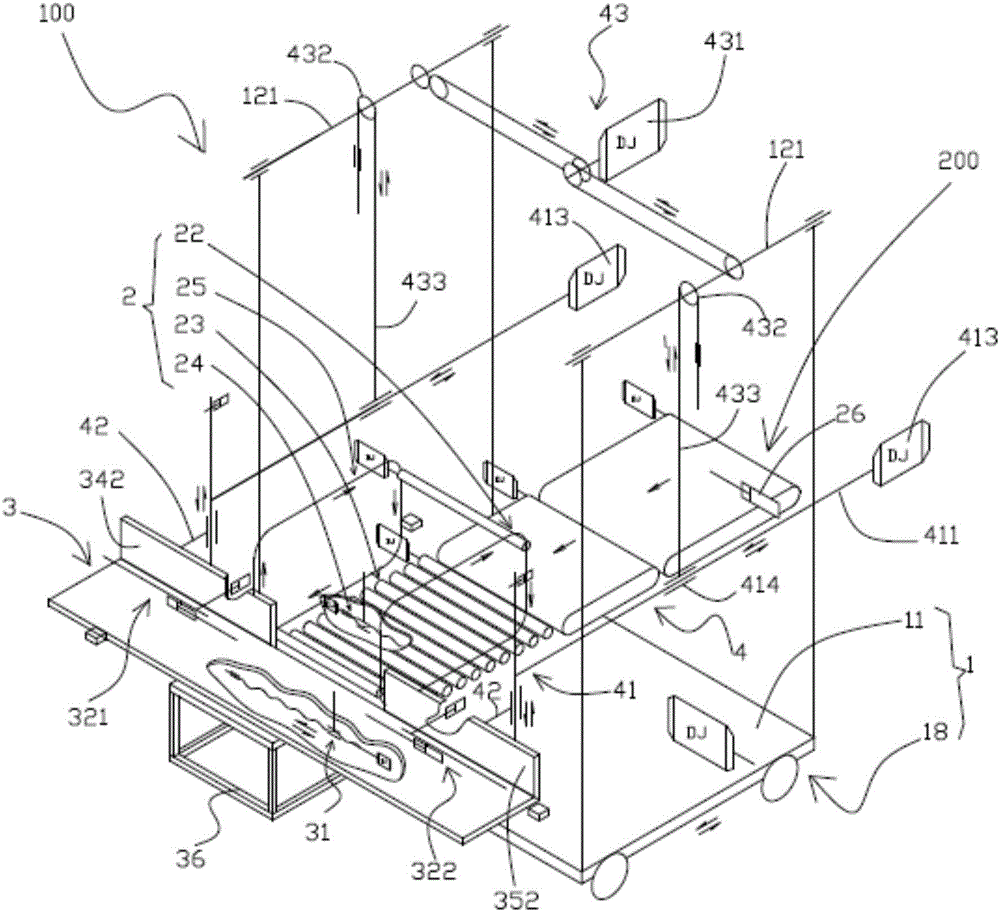

[0060] For the convenience of description, such as figure 1 , figure 2 Shown in Chinese characters is reference, and the direction that standard box 9 advances is defined as the front, and left and right shown in the diagram are left and right. Define between the front and back walls of the standard case 9 as the length of the standard case 9, define between the left and right sides of the standard case 9 as the width of the standard case 9, and the centerline of the standard case 9 can divide the standard case 9 into two parts that are left and right equal; The width between the front and back of the tray 3 is defined as the width of the tray 3, and the length between the left and right ends of the tray 3 is defined as the length of the tray 3. The center line of the tray 3 can divide the tray 3 into two equal left and right parts.

[0061] Such as figure 1 , image 3 , Figure 4 As shown, an automatic packing manipulator 100 includes a frame 1 with a driving device 18 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com