Smart card chip packaging equipment

A technology for smart card chips and packaging equipment, applied in transportation and packaging, conveyor objects, electrical components, etc., can solve the problems of affecting packaging speed, packaging speed is not high enough, affecting chip position accuracy, etc., to improve position accuracy, improve packaging Speed, the effect of improving packaging accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

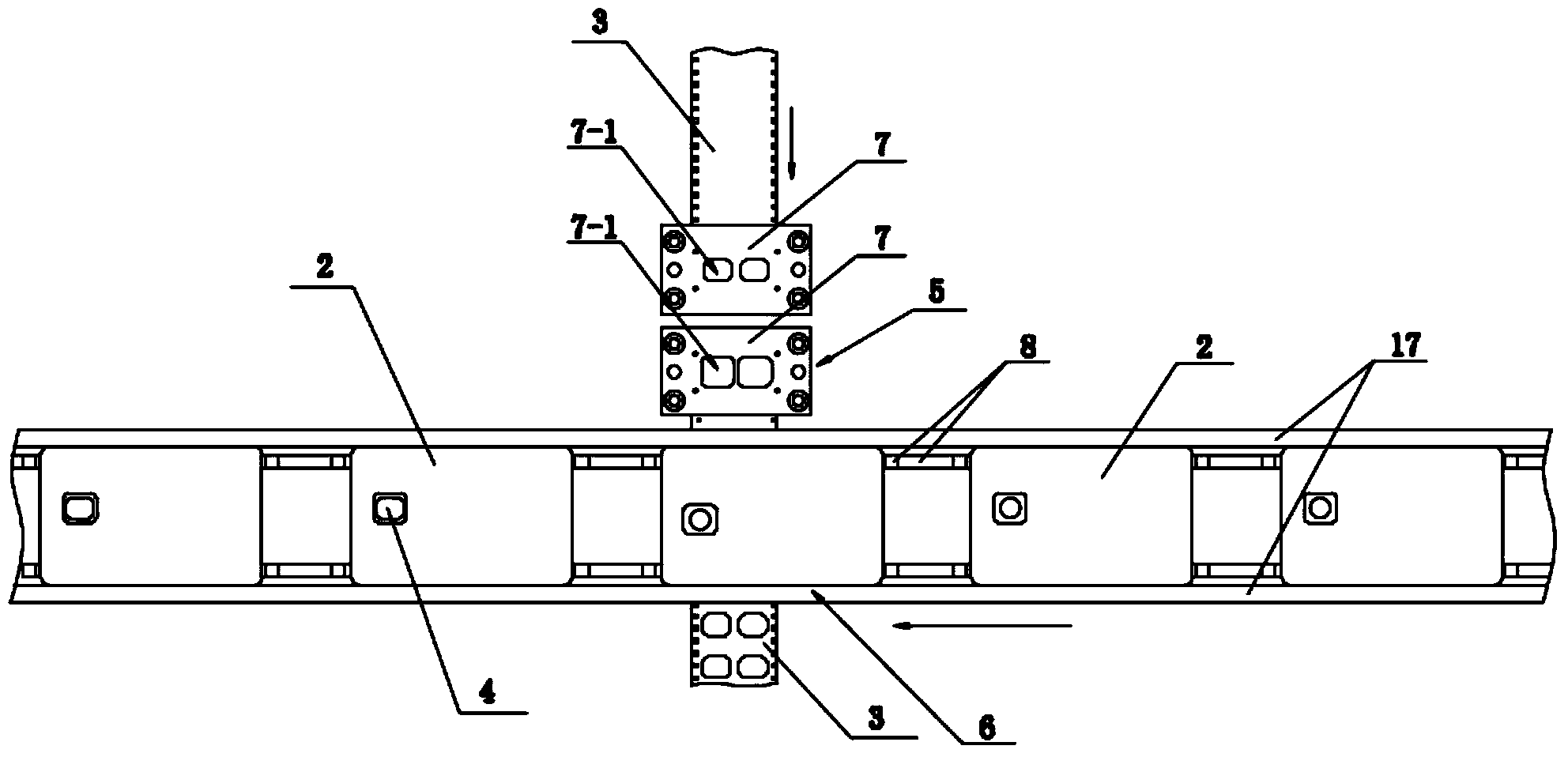

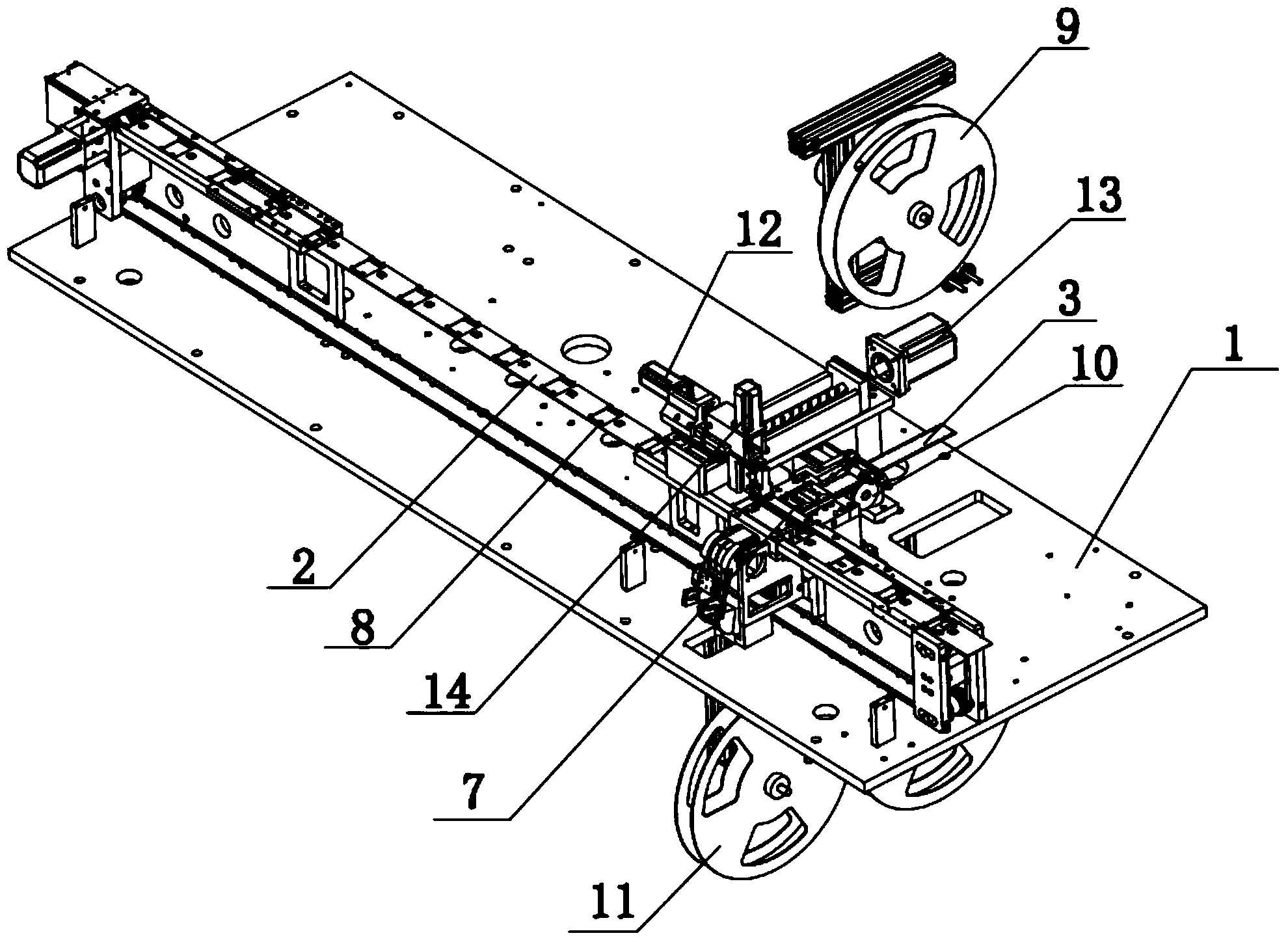

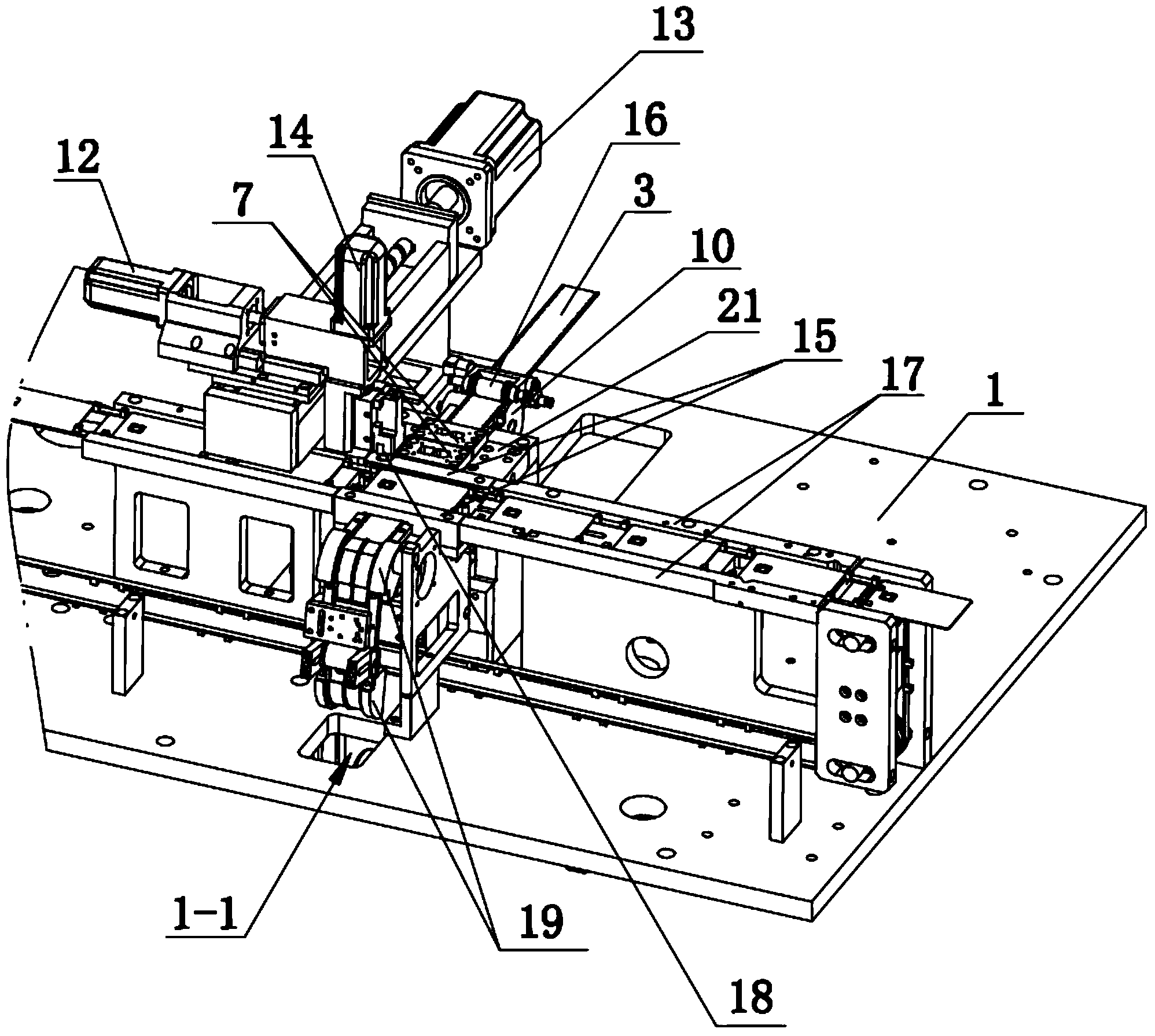

[0033] see Figure 1 to Figure 5 , The smart card chip packaging equipment of the present invention includes a workbench 1 and a card conveying device, a chip packaging device and a chip supply device arranged on the workbench 1 .

[0034] see Figure 1 to Figure 5 , the card conveying device includes a card conveying mechanism that conveys the cards 2 to be packaged to the packaging station 6 one by one in an intermittent conveying manner, and the card conveying includes a card conveying guide rail, a conveying belt 8 and a conveying motor, wherein the Conveyor belt 8 is circular structure, totally two, is provided with on each conveyer belt 8 and is used for pushing card 2 to move, and two conveyer belts 8 pushes card 2 to convey forward intermittently during work. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com