Patents

Literature

123results about How to "Shorten the travel distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

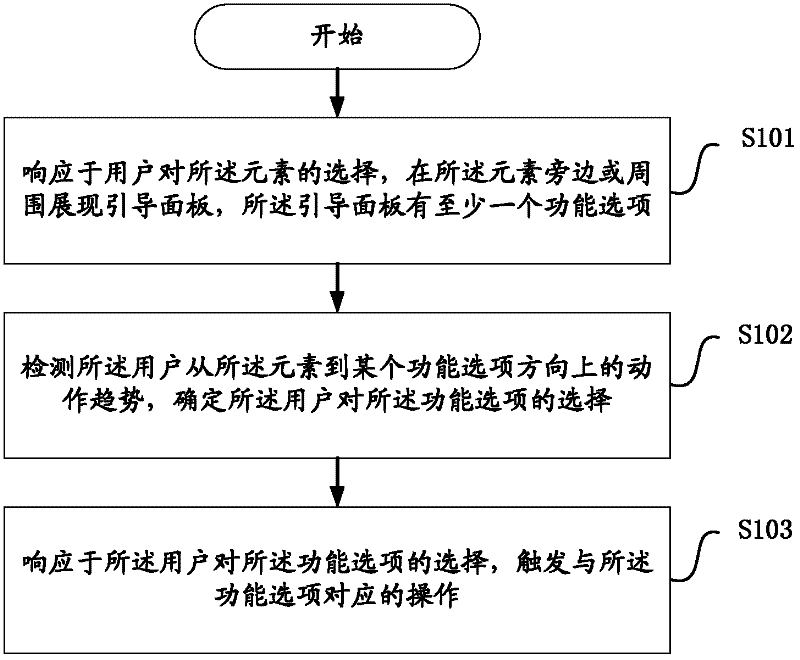

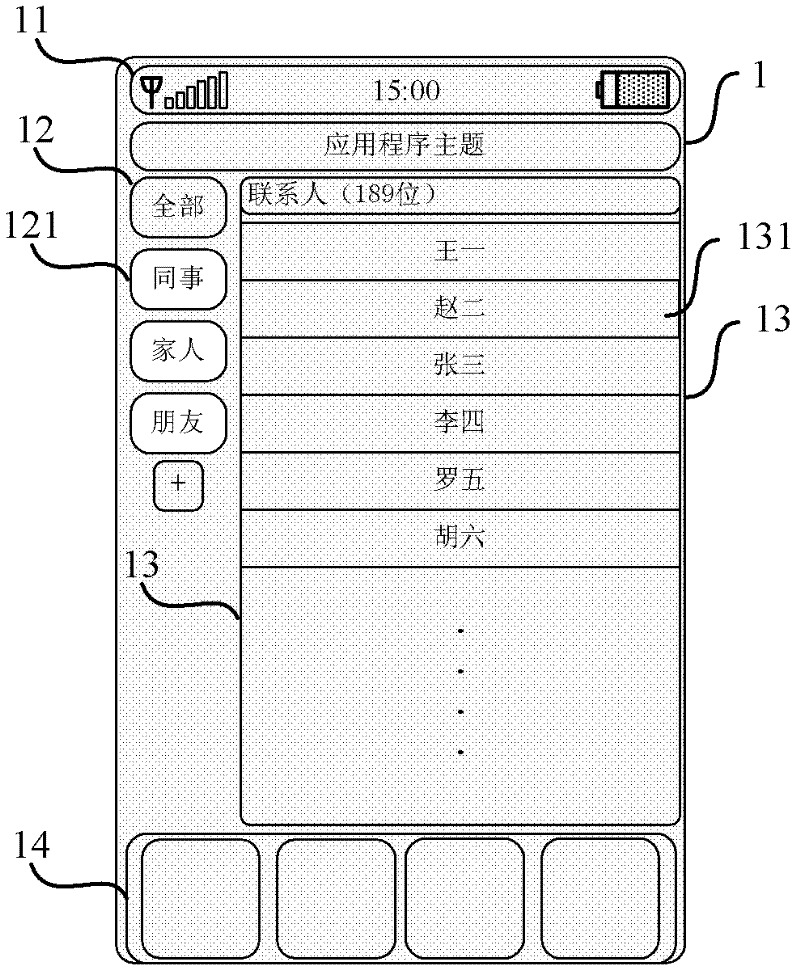

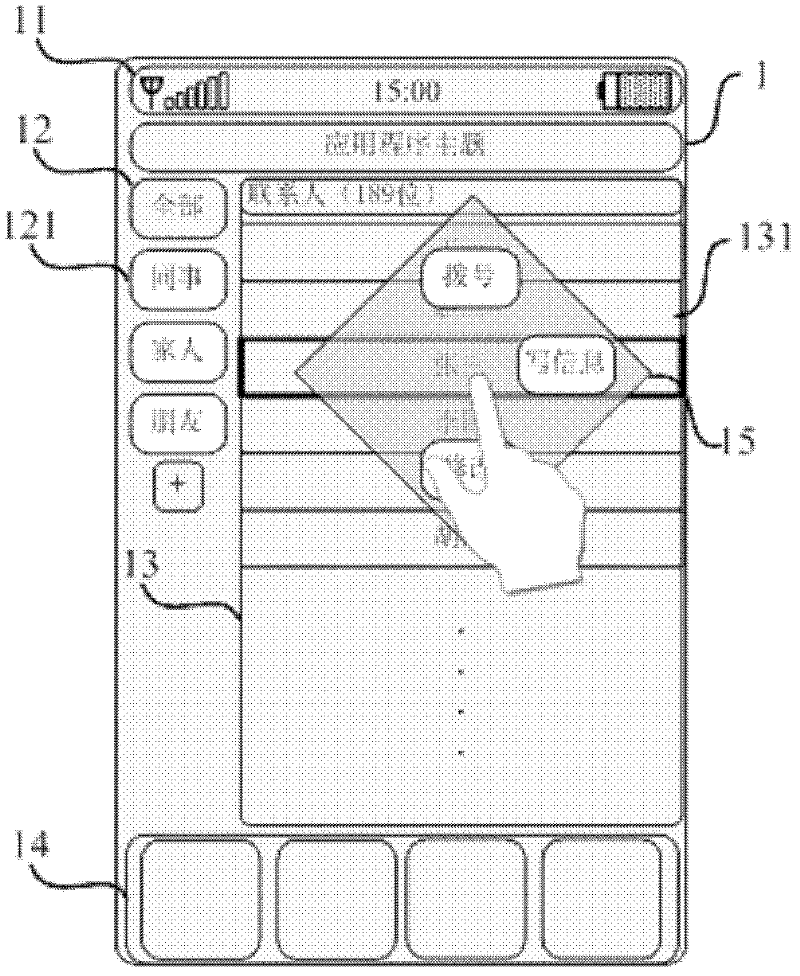

Method and system for rapid operation of elements in touch screen type mobile terminal

InactiveCN102591584AReduce redundant actionsShorten the travel distanceInput/output processes for data processingSpecific functionDisplay device

The invention provides a method for rapid operation of elements in a touch screen type mobile terminal, which includes the steps: responding to selection of a user to the elements, and displaying a guide panel beside or around the elements, wherein the guide panel at least comprises a function option; detecting the action trend of the user from the elements to a specific function option direction, and determining selection of the user to the function option; and responding to the selection of the user to the function option, and triggering operation corresponding to the function option. Correspondingly, the invention further provides a system using the method. The method and the system have the advantages that management operation on the elements can be realized by simply operating a touch screen monitor, subsequent operation for the elements can be better performed, and operating efficiency of equipment equipped with the corresponding touch screen monitor is improved.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

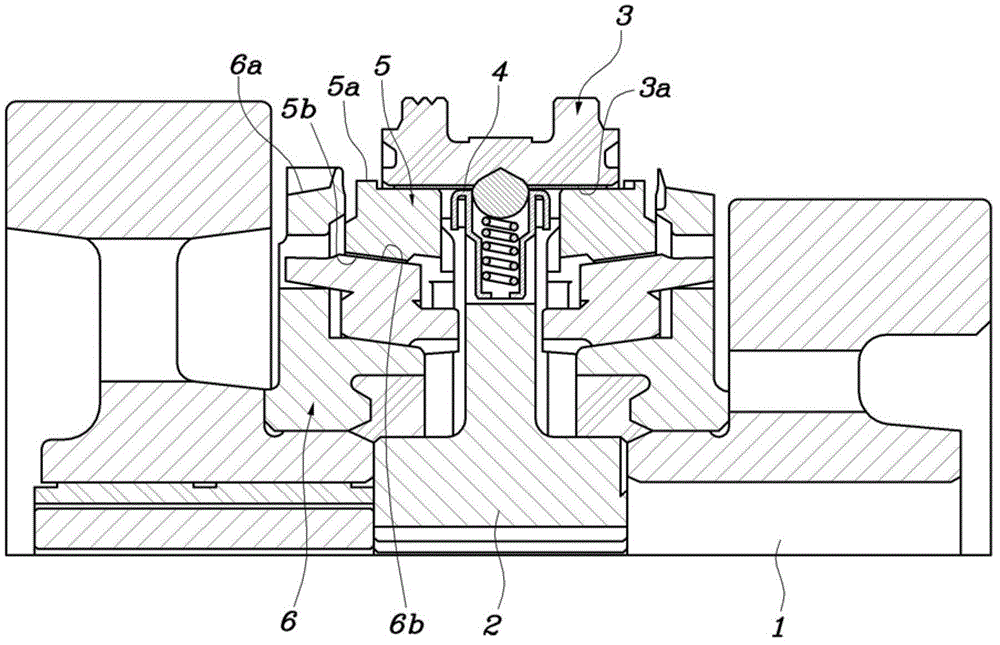

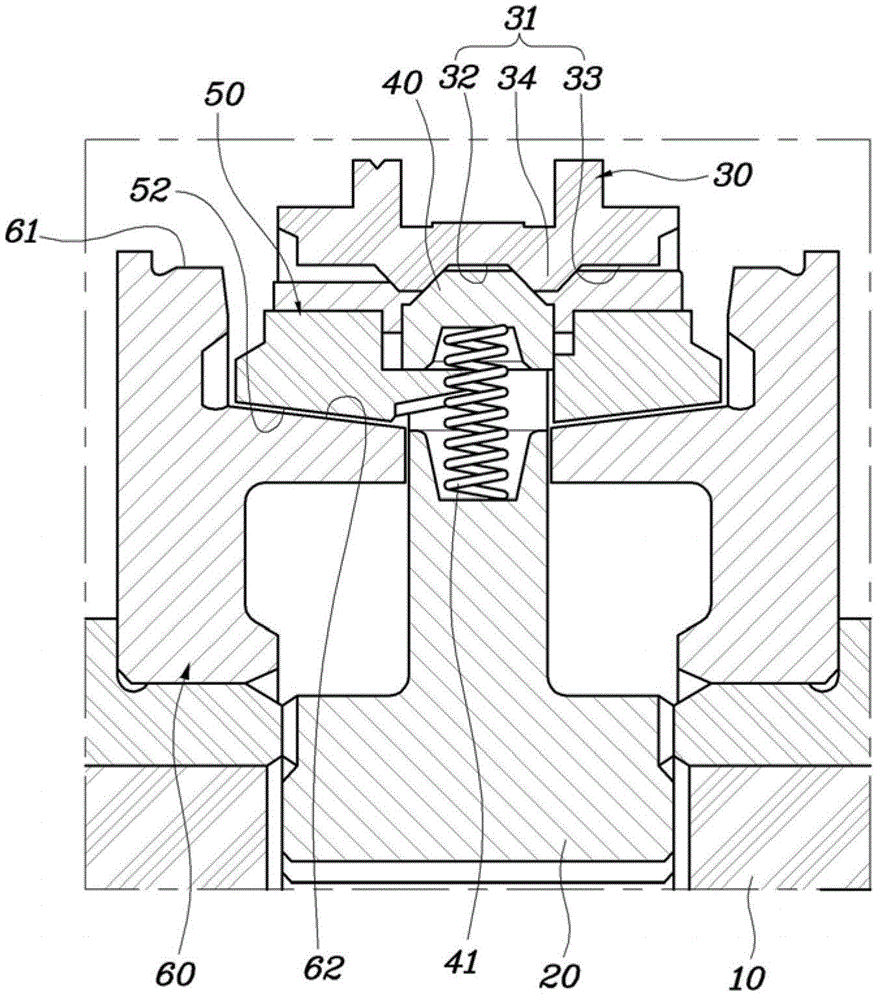

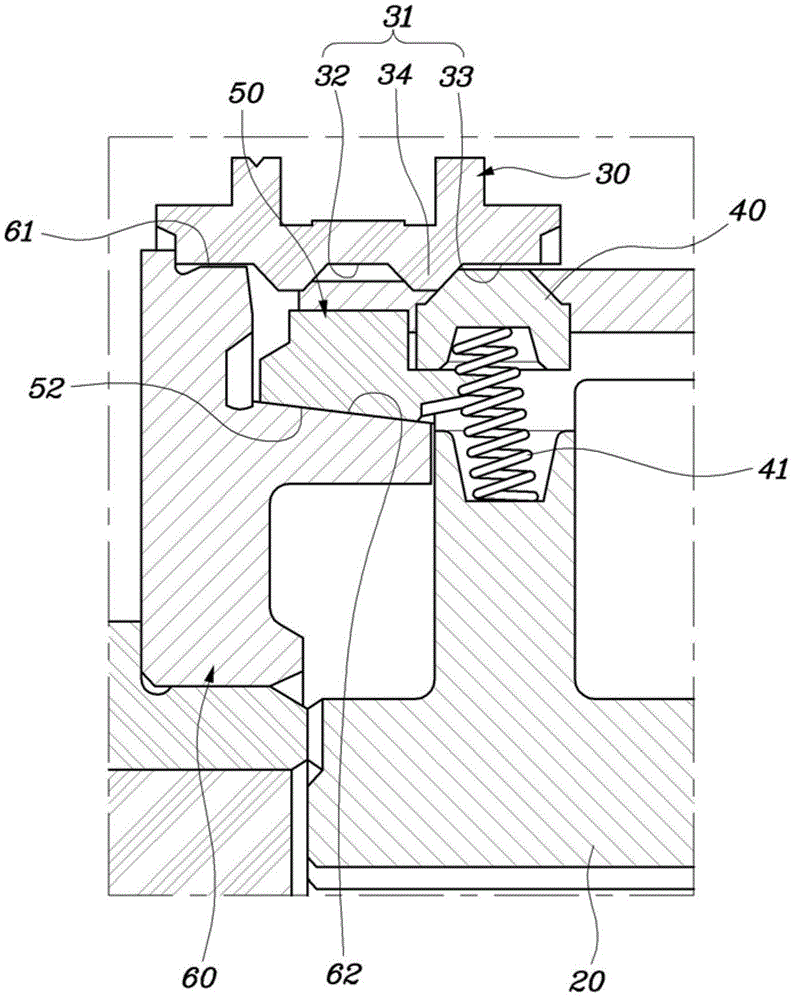

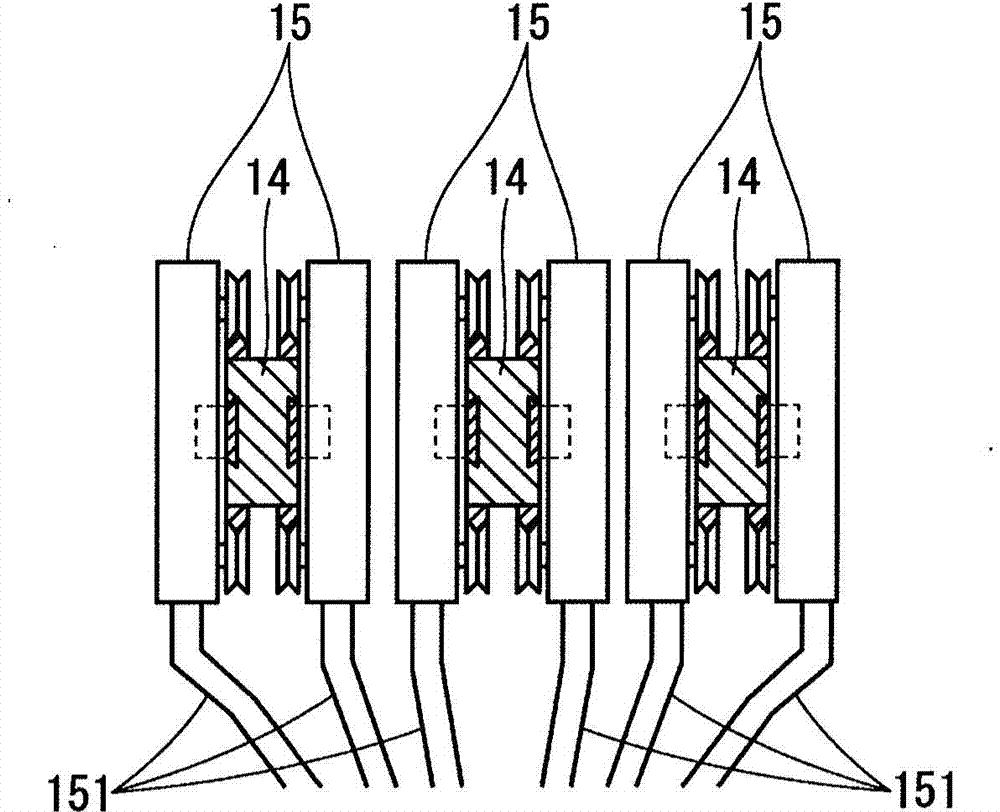

Synchronizer used for transmission

ActiveCN103912601AIncreased durabilityShorten the travel distanceMechanical actuated clutchesEngineeringGear tooth

The present invention discloses a synchronizer used for a transmission. The synchronizer comprises a sleeve having a gear-shifting gear. A synchronization key is arranged to a hub so as to protrude towards the sleeve. A synchronizer locking ring is arranged around the circumference of the hub. A transmission gear can be arranged around the synchronizer locking ring in a freely rotating way, and is provided with a clutch gear facing to the sleeve in the circumferential direction. The gear-shifting gear can have different gear teeth thicknesses based on a contact state relative to the synchronization key, so that the gear teeth thicknesses when the gear-shifting gear is contacted with the synchronization key is larger than the gear teeth thicknesses when the gear-shifting gear is not contacted with the synchronization key.

Owner:HYUNDAI MOTOR CO LTD

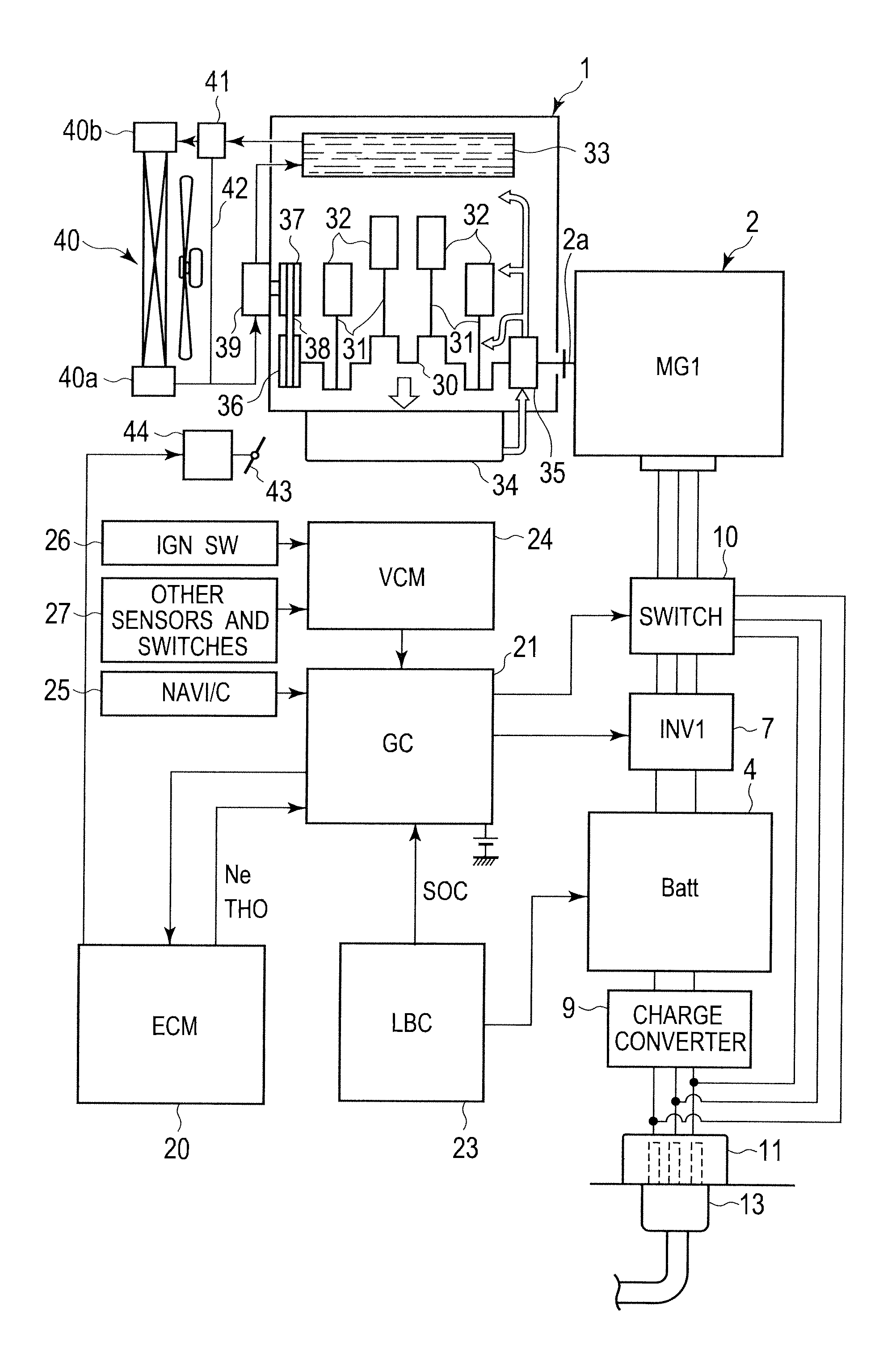

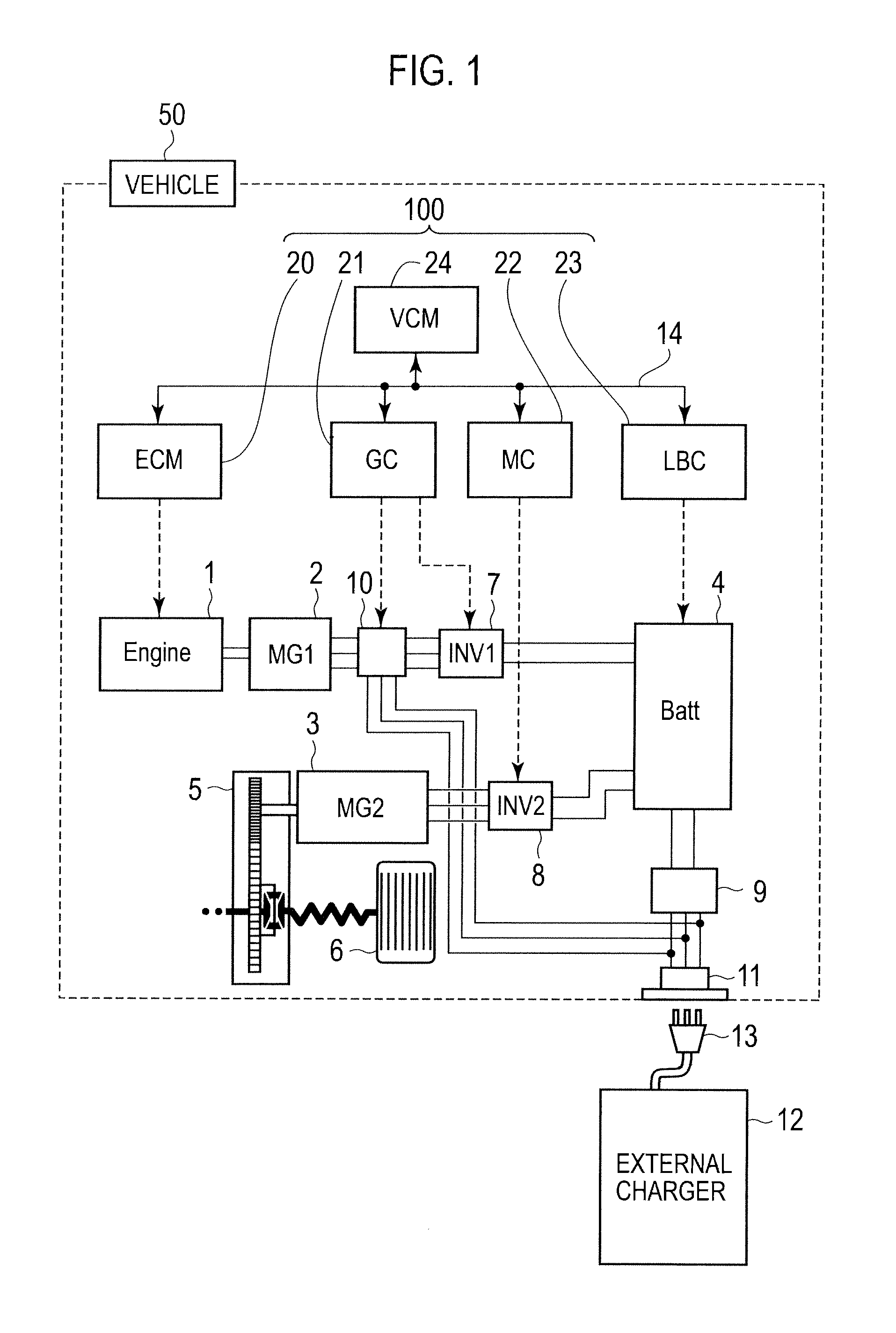

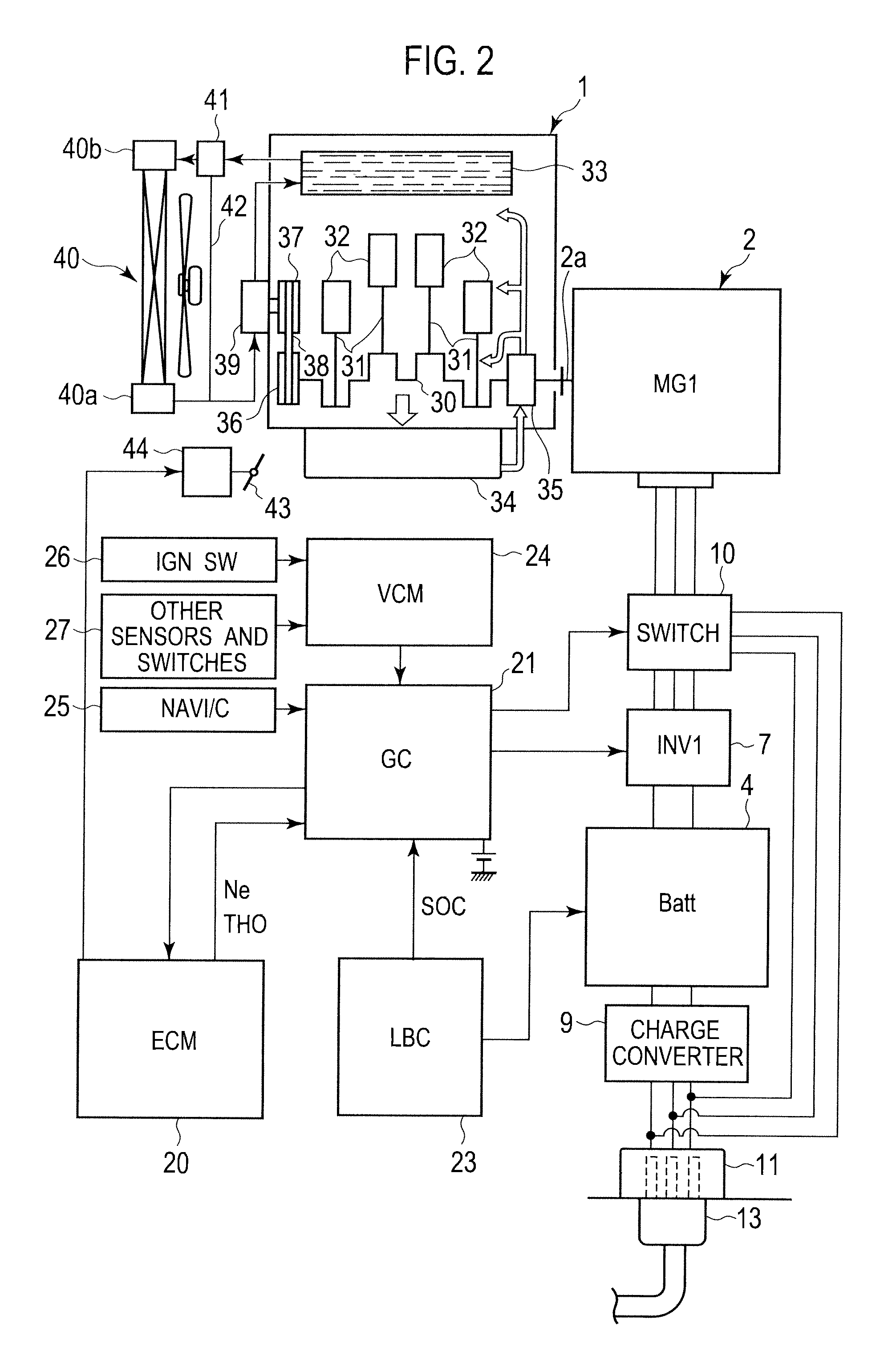

Control system of hybrid vehicle

InactiveUS20110213521A1Shorten the travel distanceDigital data processing detailsEngine controllersDriver/operatorLubrication

A control system of a hybrid vehicle, includes: an engine; a motor capable of driving the engine; an oil pump for supplying a lubricant oil to a lubrication requiring portion of the engine; and an engine lubrication controller configured to make the following operations in a case that a stop state of the engine continues for more than or equal to a certain period: when a vehicle stop condition that a driver has no intention of travel is established, supplying, by the oil pump, the lubricant oil to the lubrication requiring portion of the engine, and rotating the engine by the motor without igniting the engine, thereby implementing an engine lubrication control.

Owner:NISSAN MOTOR CO LTD

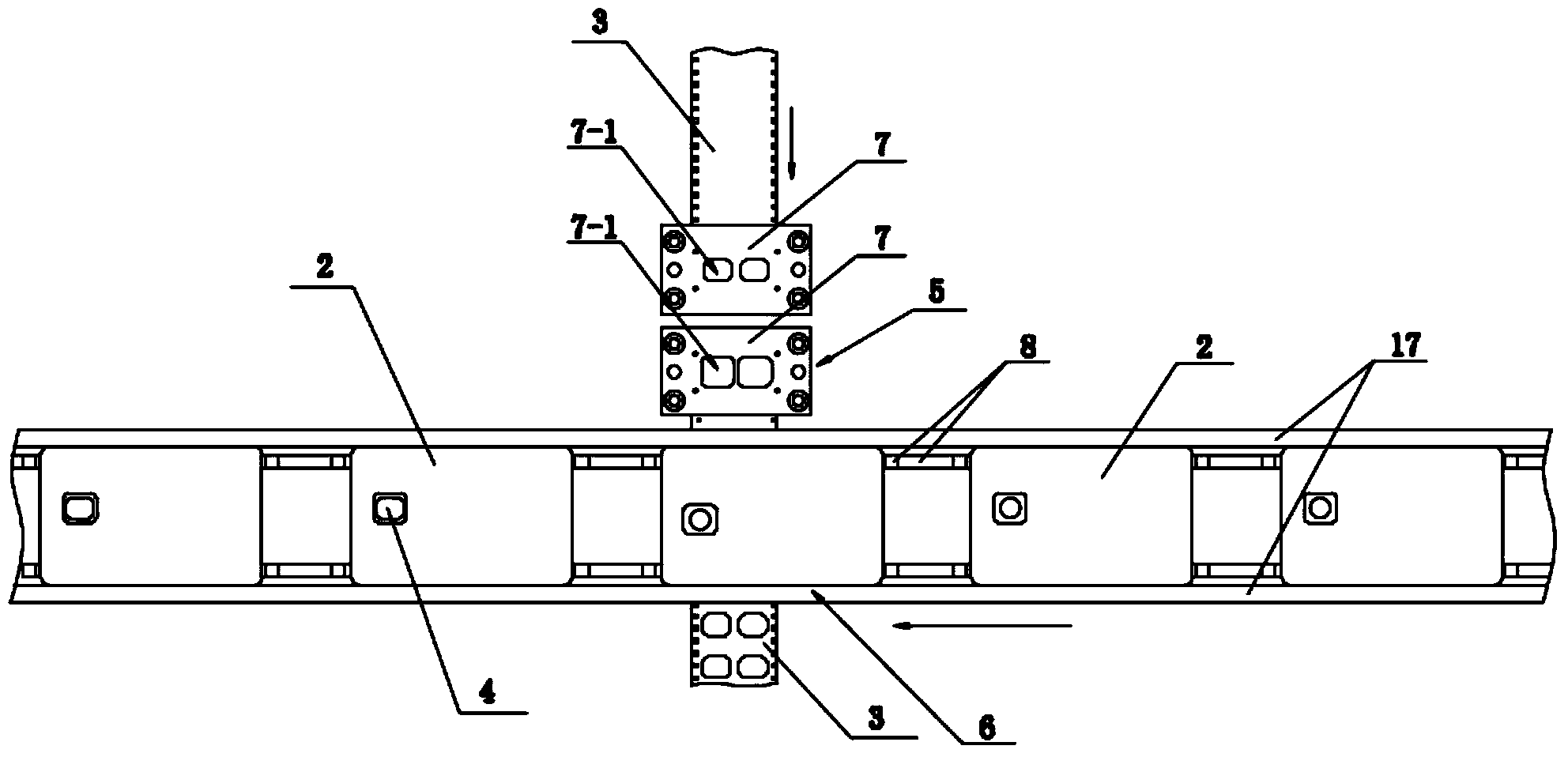

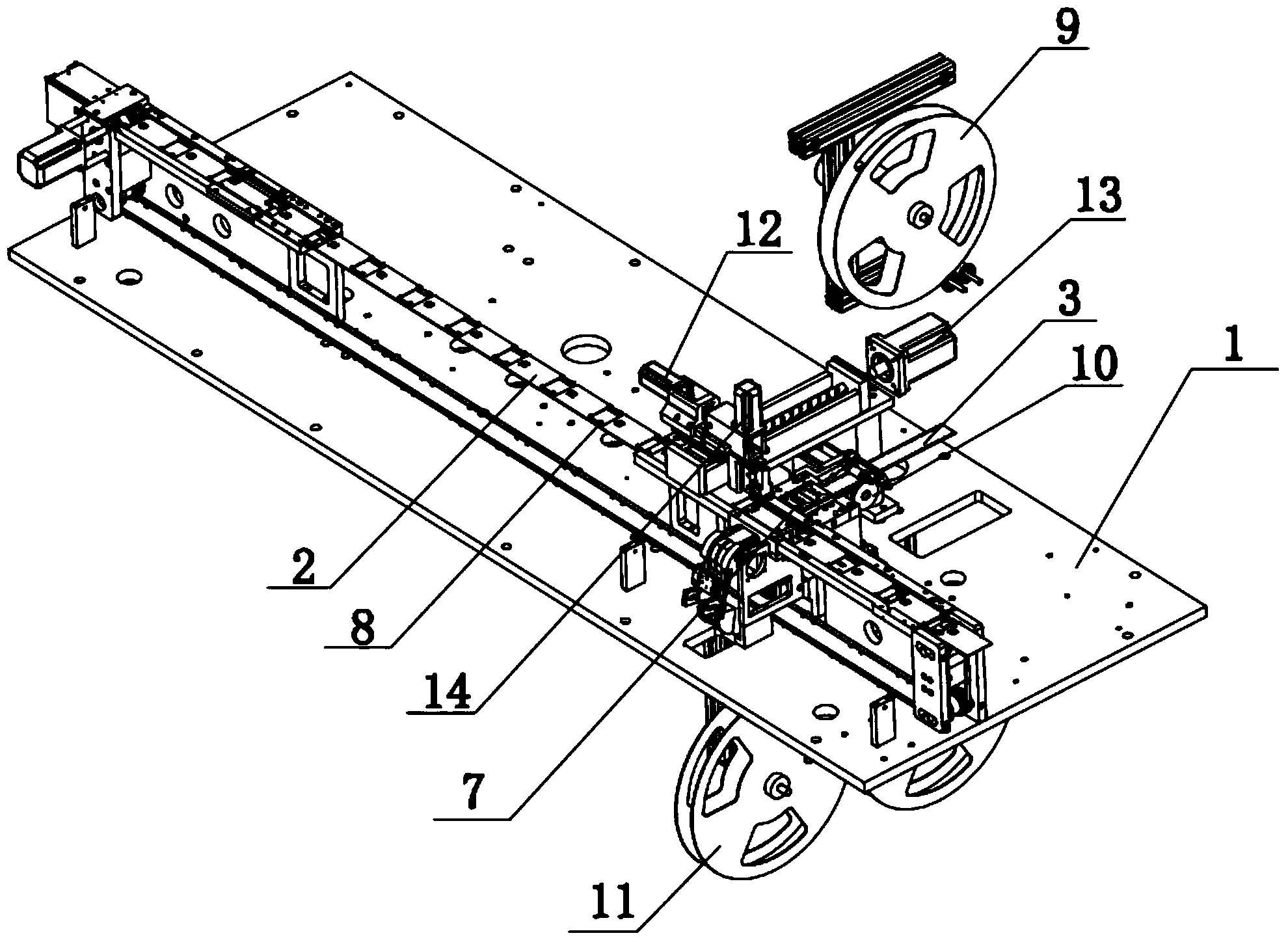

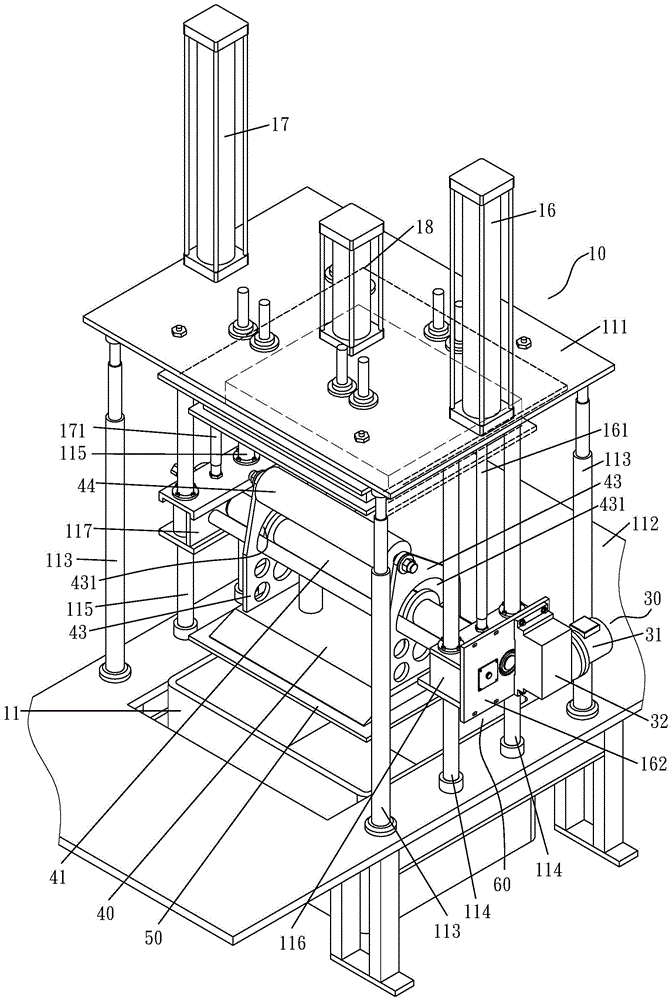

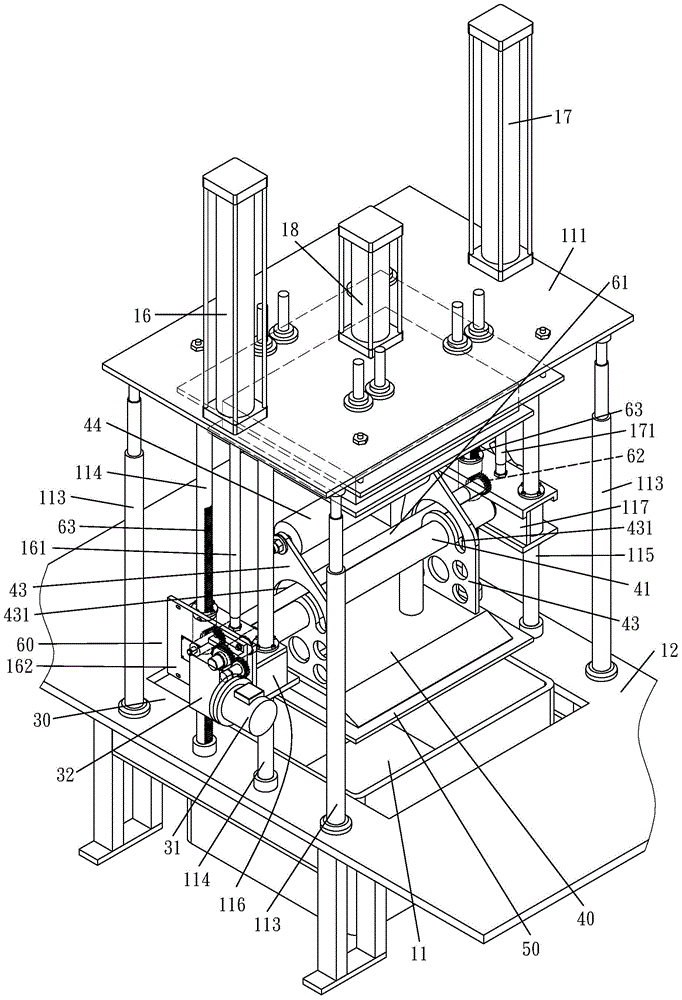

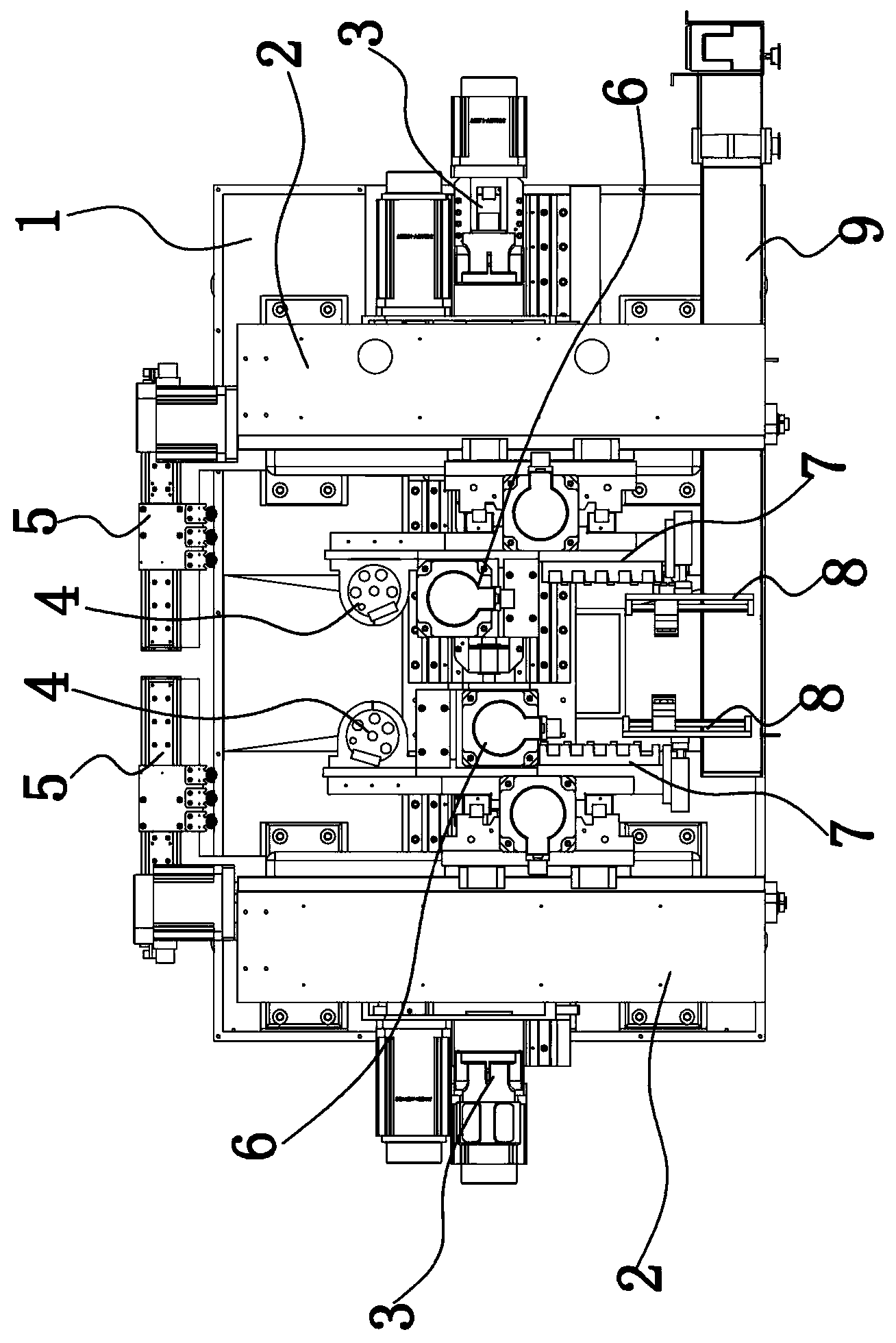

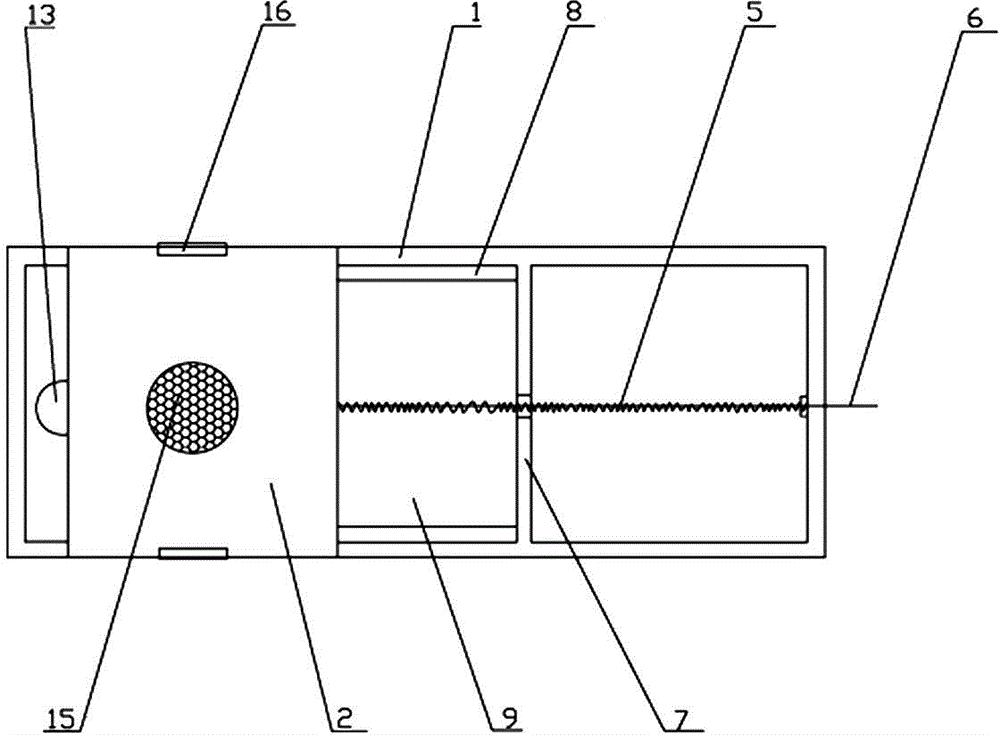

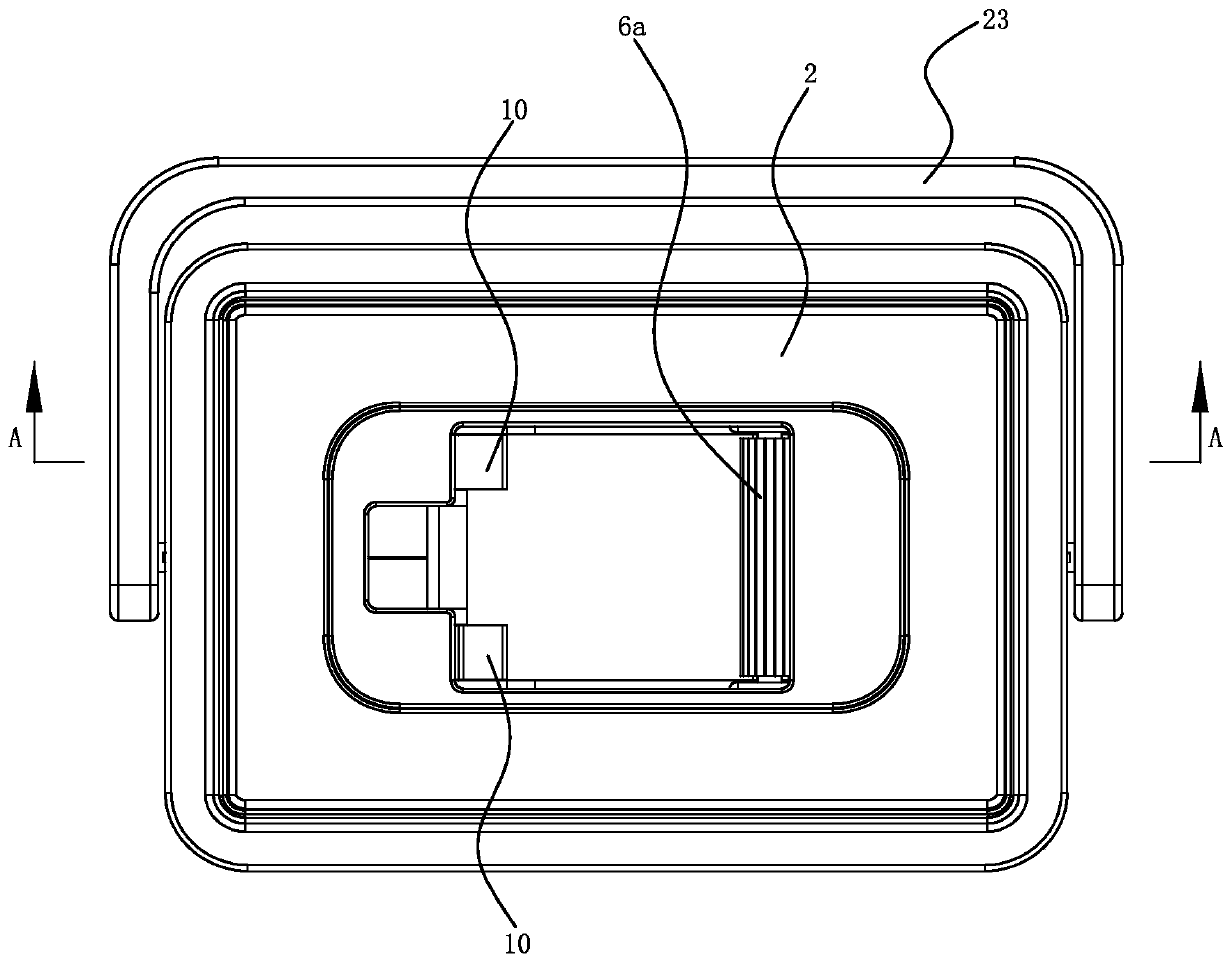

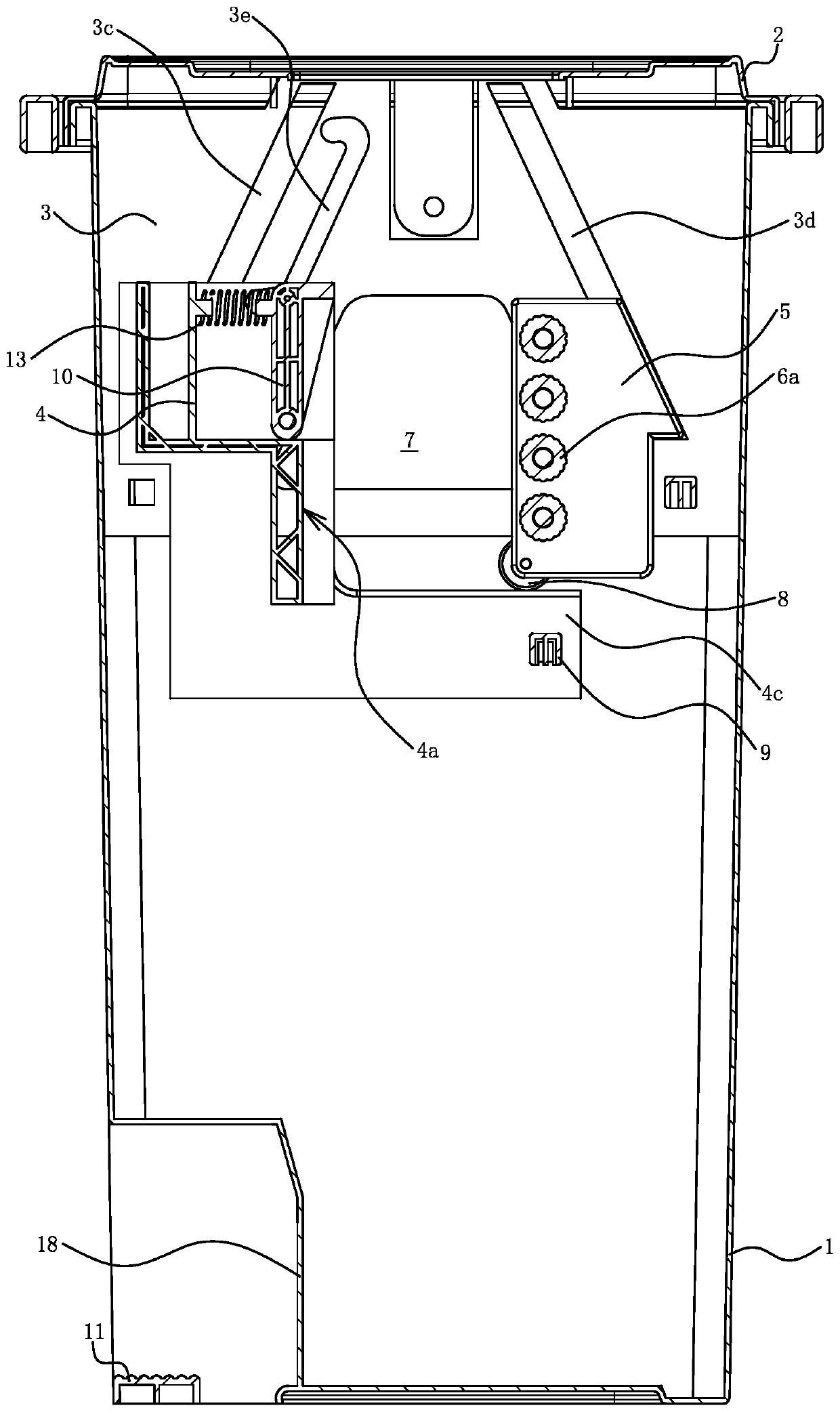

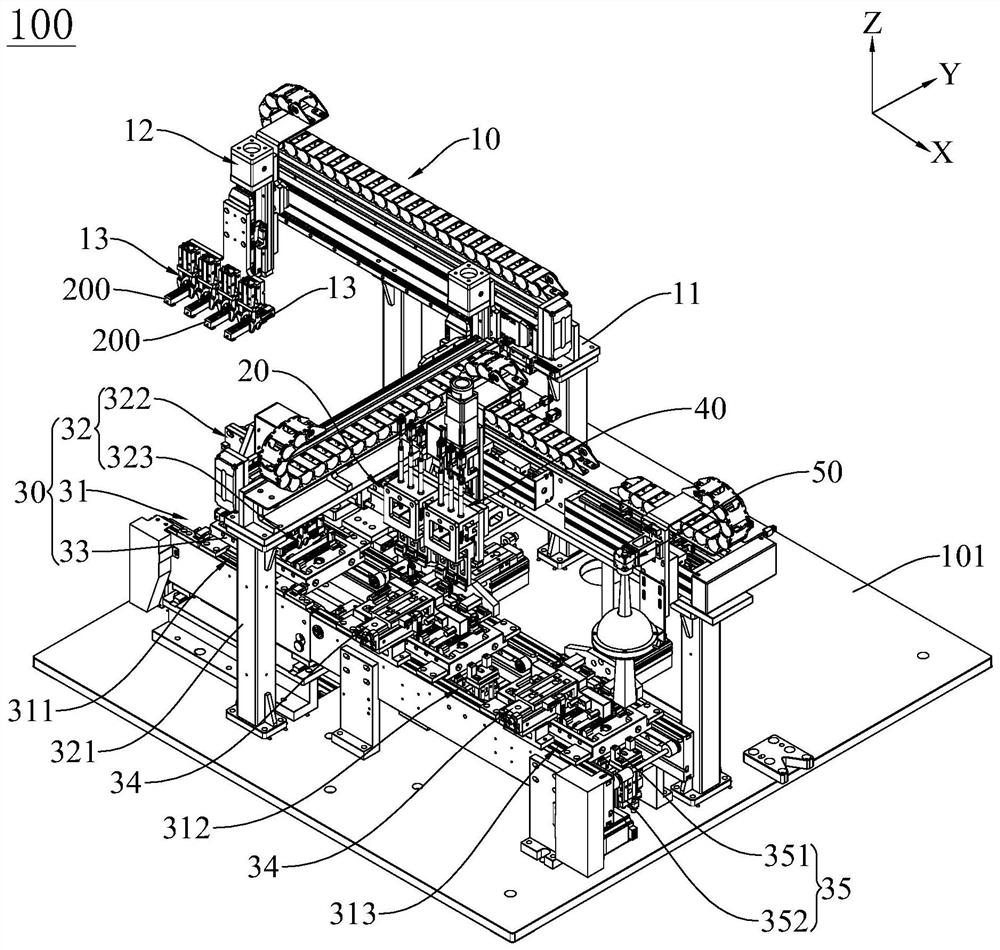

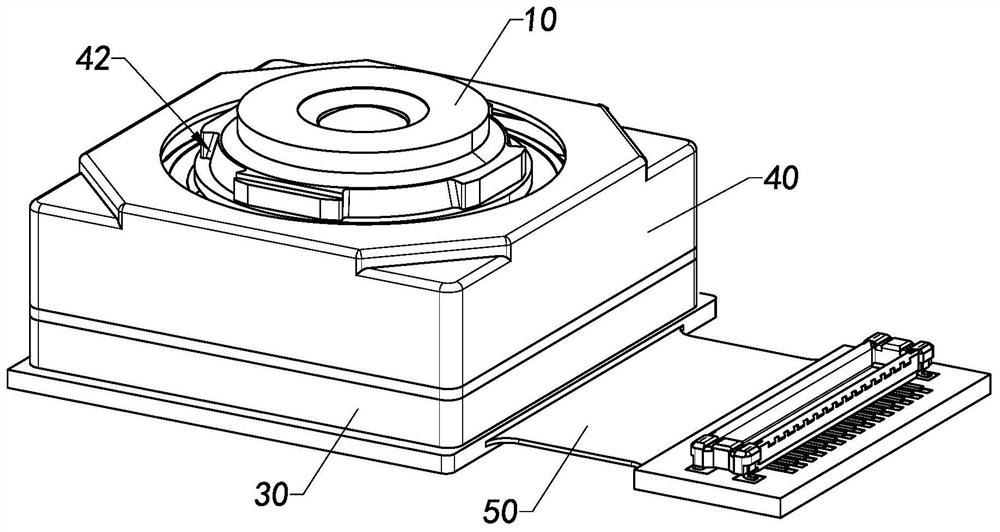

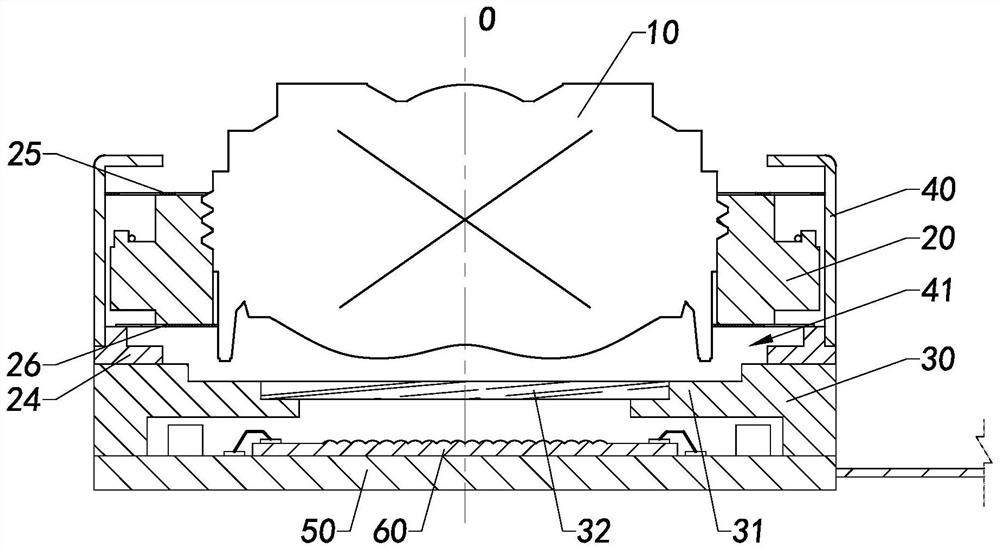

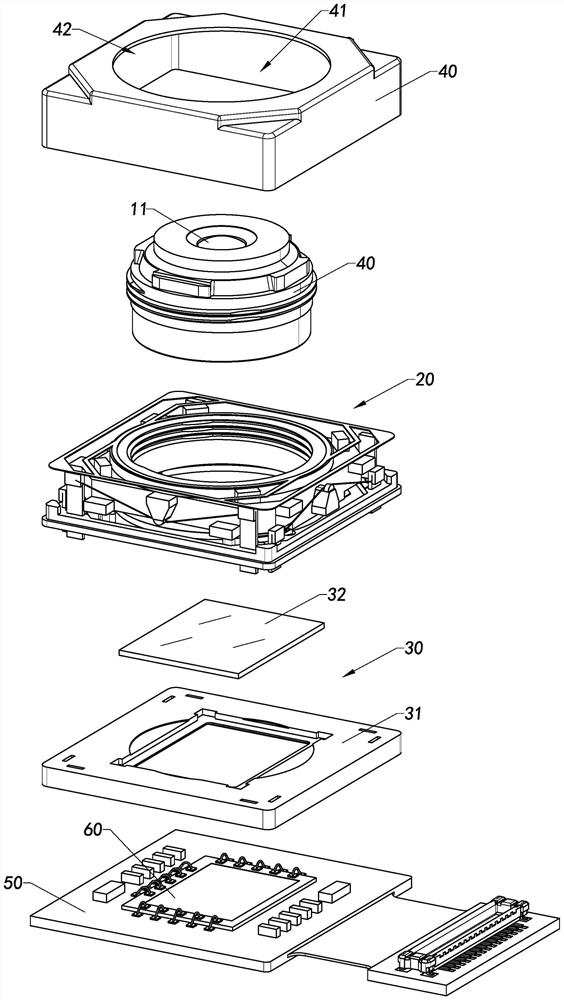

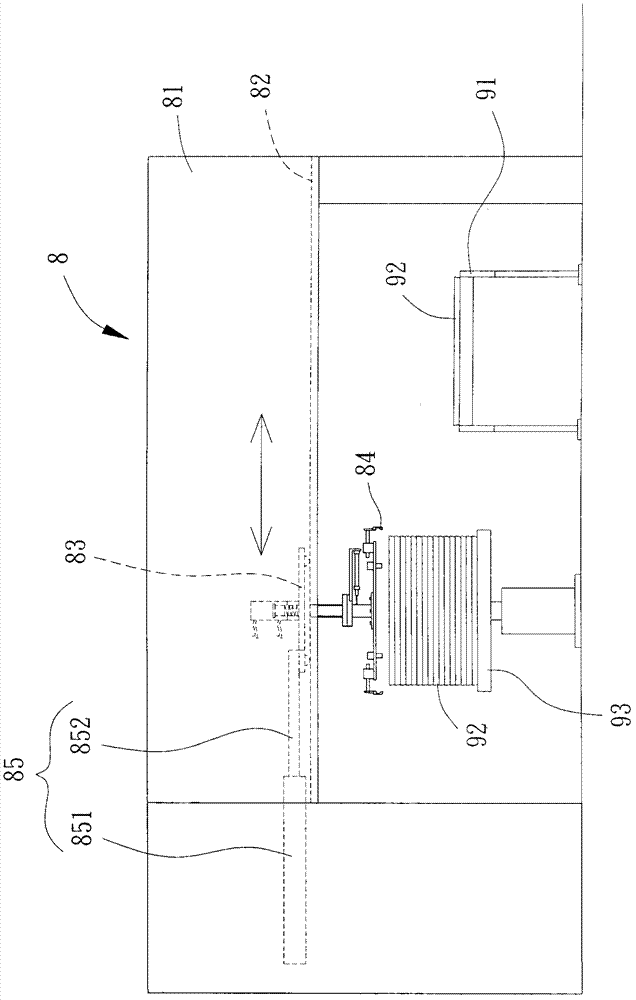

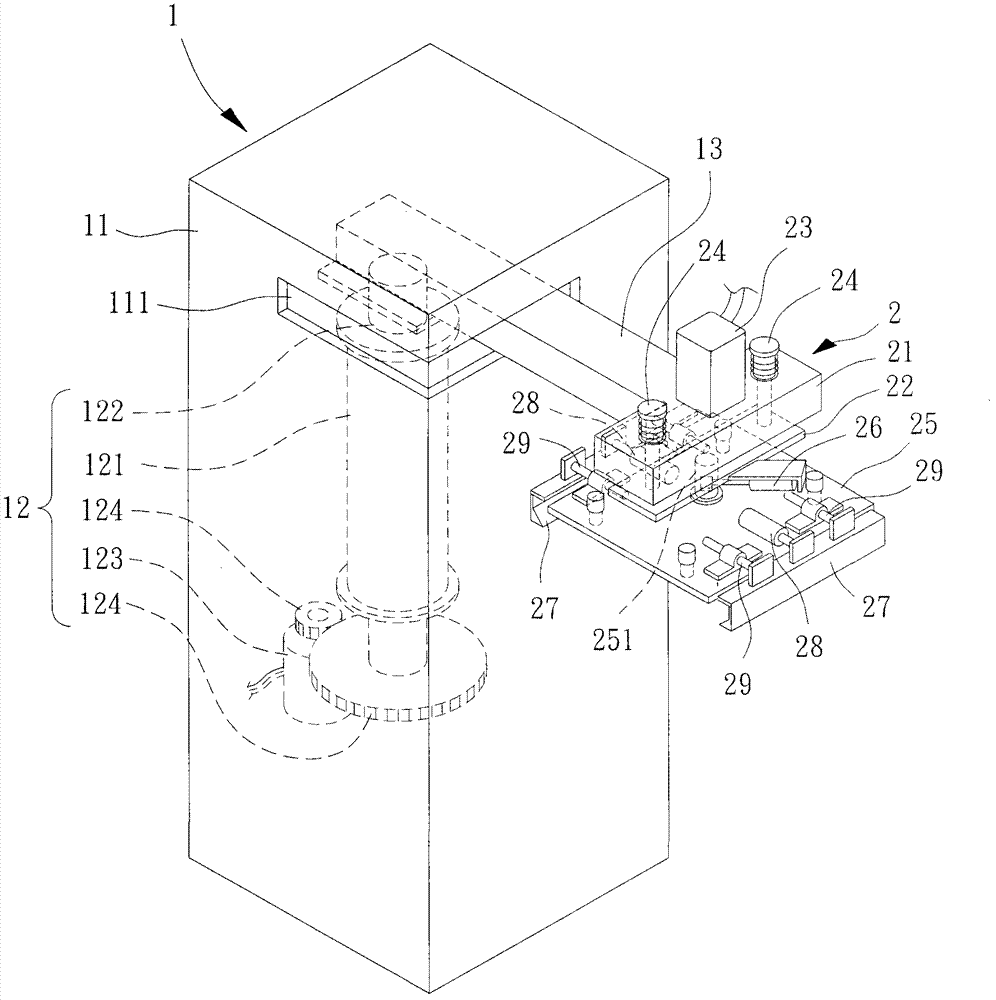

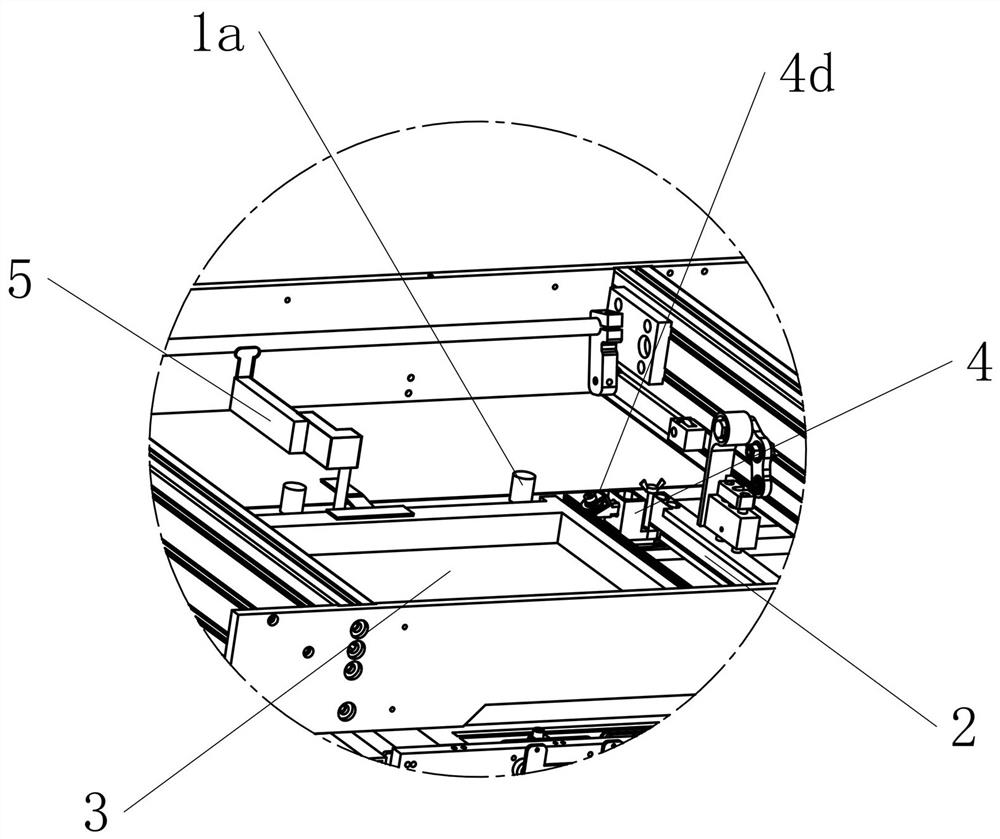

Smart card chip packaging equipment

ActiveCN104269373AShort tripFast packagingSolid-state devicesSemiconductor/solid-state device manufacturingEmbedded systemSmart card

The invention discloses smart card chip packaging equipment. The smart card chip packaging equipment comprises a working table, a card conveying device, a chip packaging device and a chip feeding device, wherein the card conveying device, the chip packaging device and the chip feeding device are arranged on the working table. The card conveying device comprises a card conveying mechanism used for intermittently conveying cards to be packaged to a packaging station one by one; the chip feeding device comprises a chip belt conveying mechanism, a blanking die and a blanking mechanism, and the chip belt conveying mechanism is used for conveying chips on a chip belt to a blanking station one by one; the chip packaging device comprises a packaging mechanism used for transferring the chips which have been blanked to the cards for packaging; the conveying direction of the chip belt conveying mechanism is perpendicular to the conveying direction of the card conveying mechanism, the chip belt penetrates through the position below the packaging station in the card conveying device, and the blanking station in the chip feeding device is arranged at the position tightly attached to the packaging station in the card conveying device. According to the smart card chip packaging equipment, the movement stroke of the chips is shortened, and the packaging speed is increased.

Owner:GUANGZHOU MINGSEN TECH CO LTD

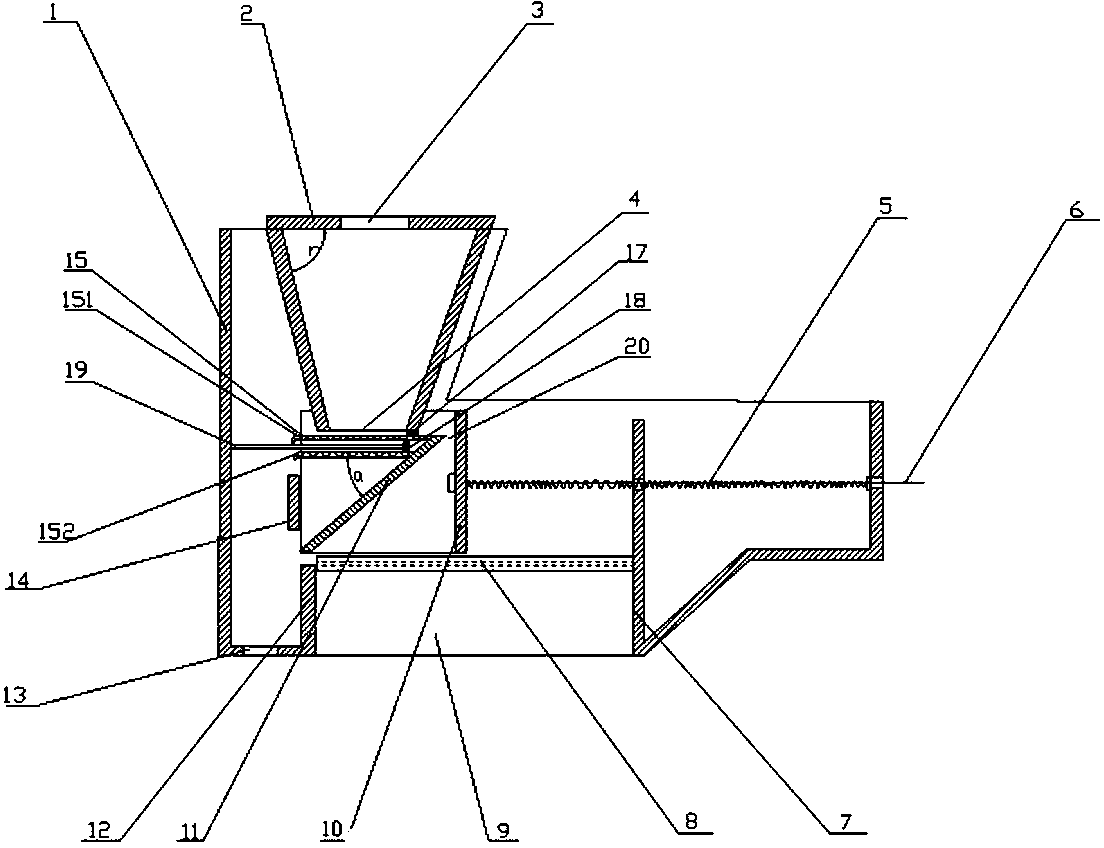

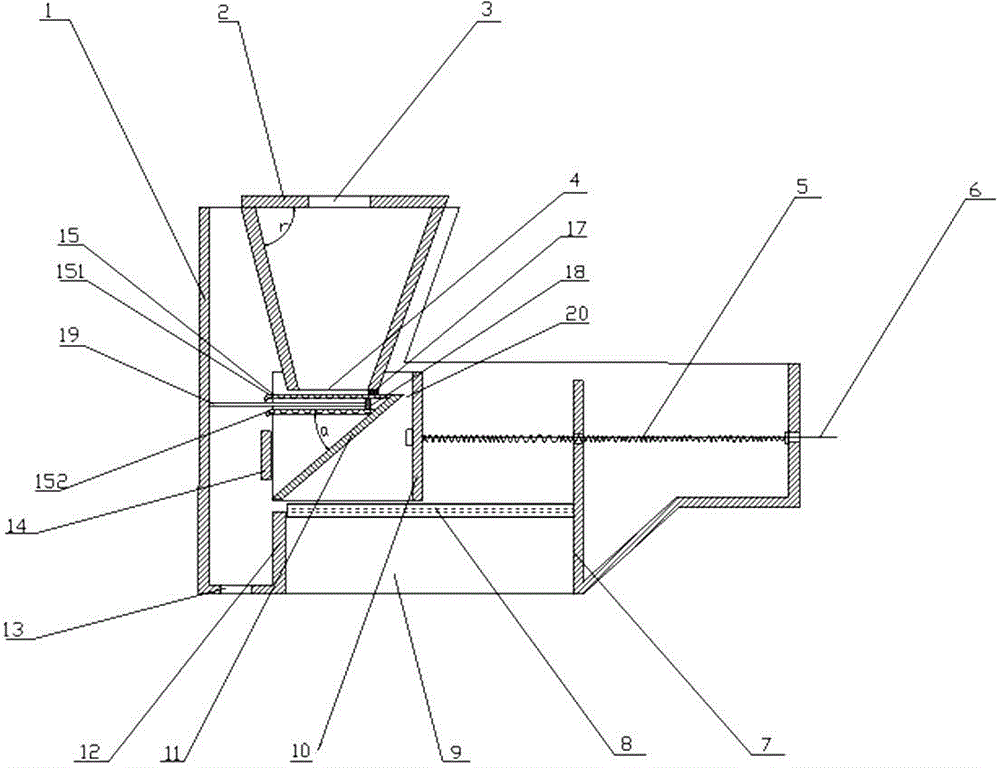

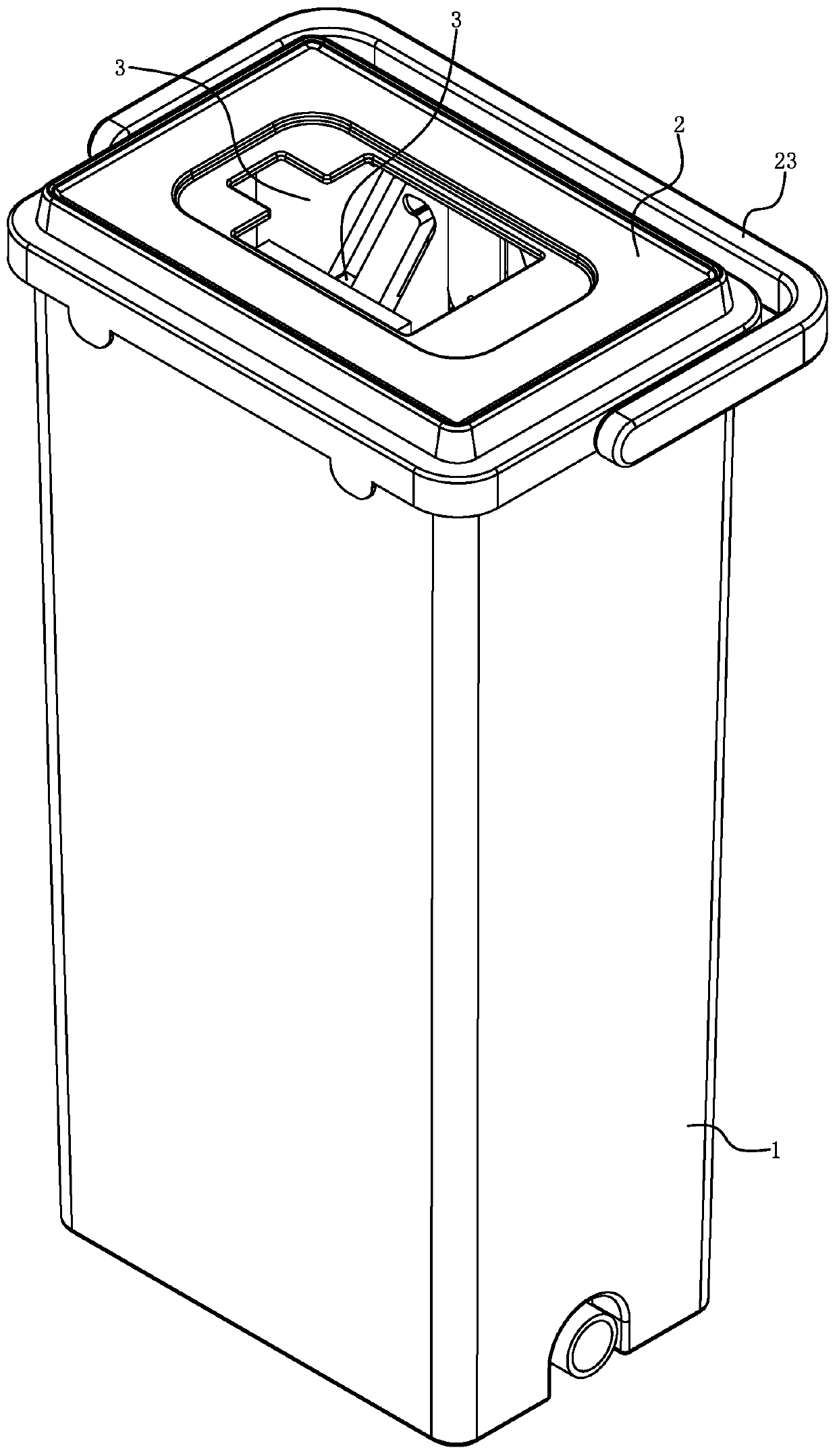

Solid-liquid separation device for kitchen waste

ActiveCN103967084AEasy to clean and maintainAvoid cloggingDomestic plumbingEnvironmental engineeringPower apparatus

A solid-liquid separation device for kitchen waste belongs to the technical field of life appliances and comprises a shell, a drainage body and a separator, wherein a water outlet, a residue outlet and a partition board are arranged on the shell; the partition board is arranged between the water outlet and the residue outlet, the residue outlet is connected with a waste residue barrel by a pipe, the drainage body is arranged at the upper end of the shell, a liquid inlet is arranged at the upper end of the drainage body and is communicated with a downcomer of a basin, a liquid outlet is arranged at the lower end of the drainage body, a horizontal slide rail is arranged at the upper end of the residue outlet along the inner wall of the shell, the separator is arranged between the liquid outlet and the horizontal slide rail, and the separator can slide along the horizontal slide rail. The solid-liquid separation device for kitchen waste is simple, practical and convenient to mount, does not need a power device, saves energy and is friendly to the environment and efficient. The solid-liquid separation device can perform quick and effective solid-liquid separation on residue waste in the basin of a kitchen, is convenient to clean and maintain, provides convenience for life of people and is easy to popularize and use.

Owner:陆全东

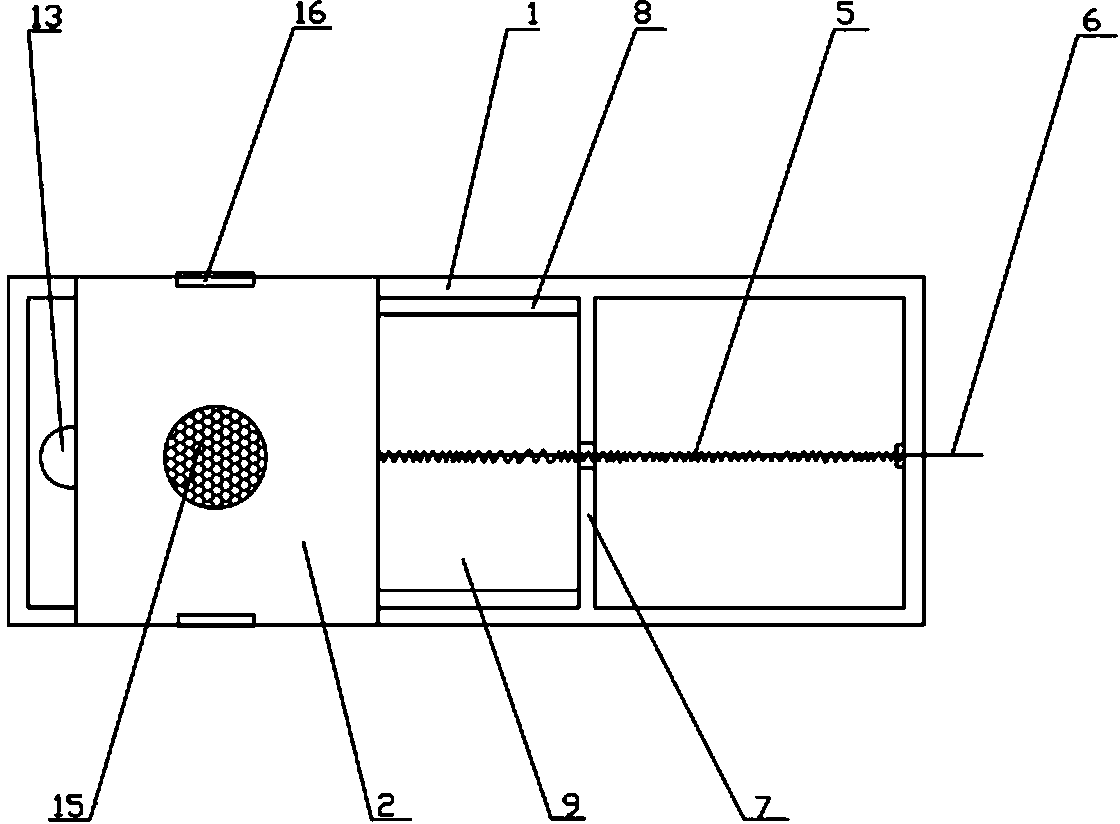

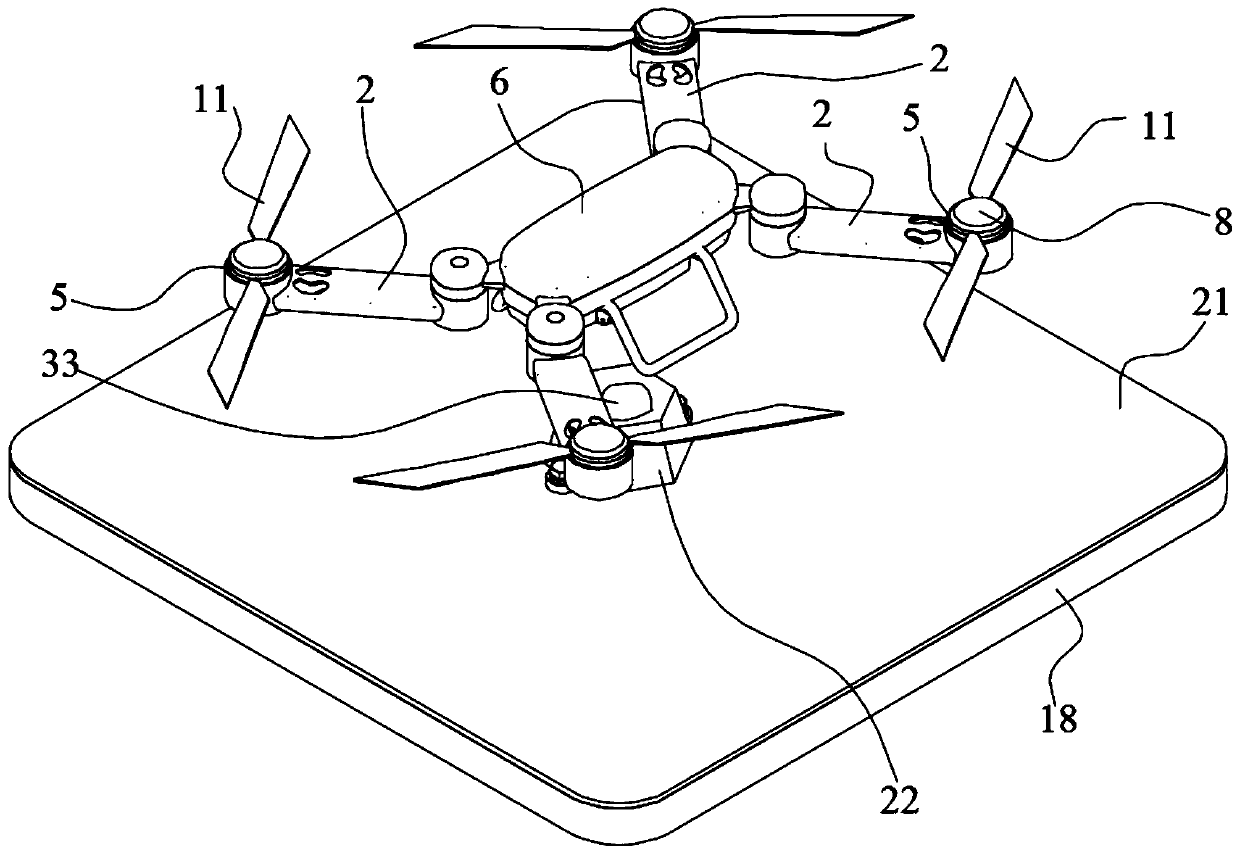

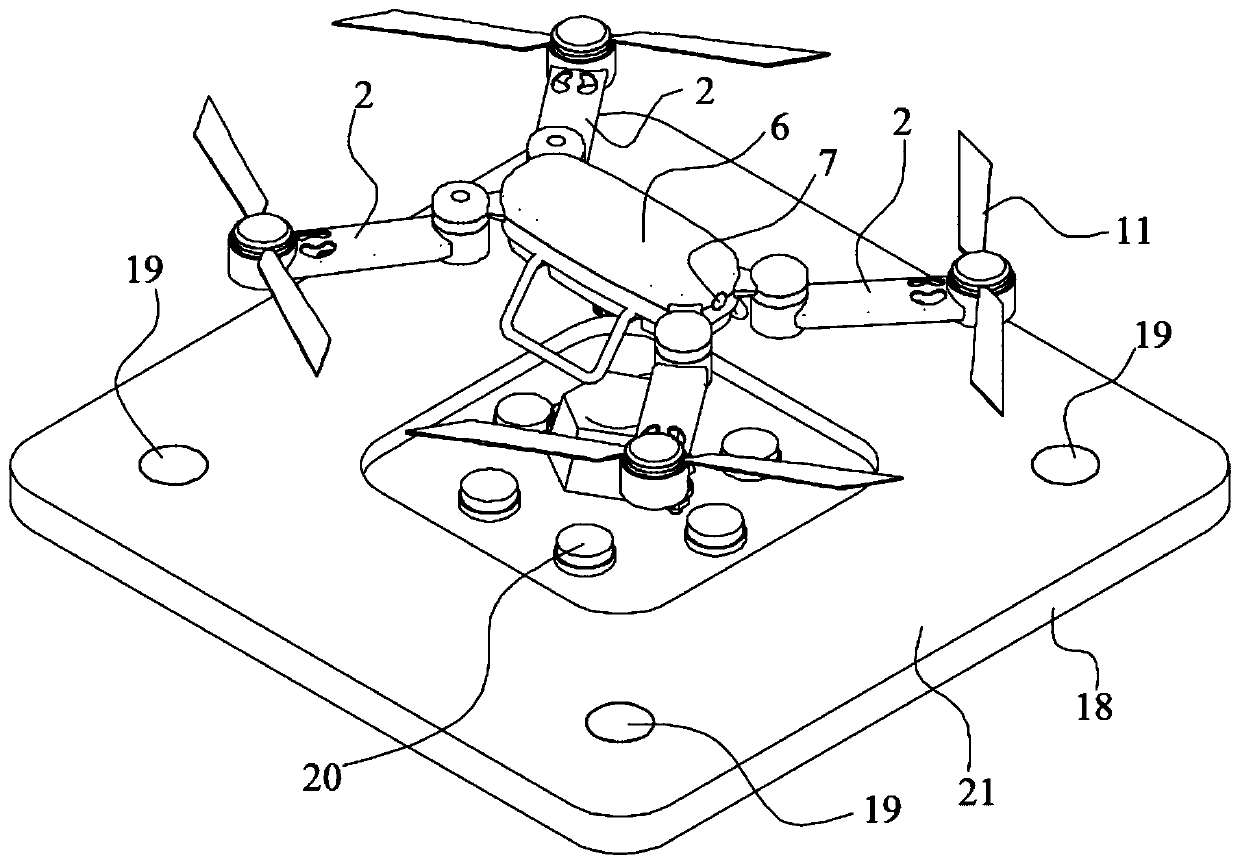

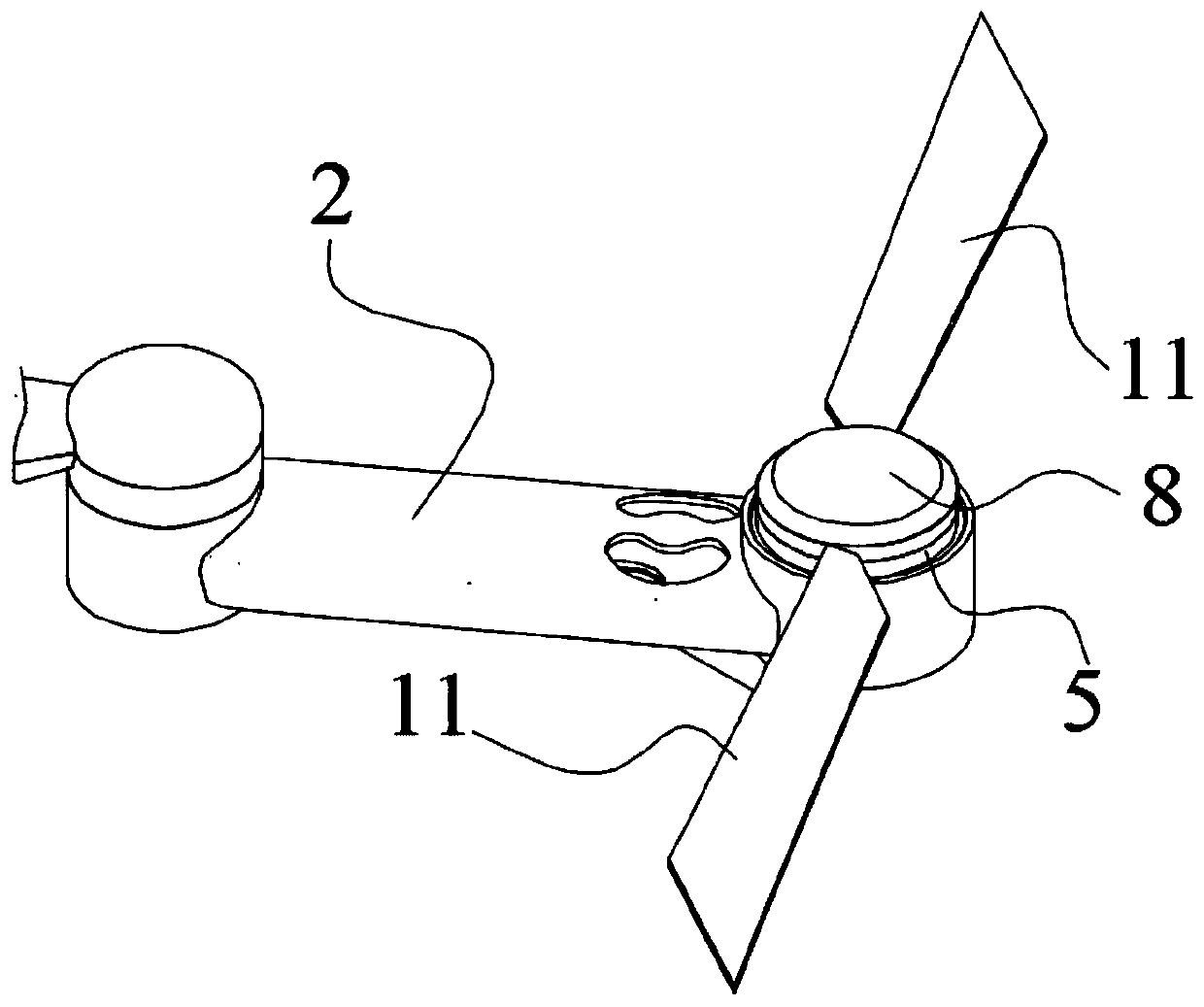

Vehicle-mounted multi-rotor unmanned aerial vehicle charger

InactiveCN109808530AReduced docking accuracyIncrease profitFuselage framesCharging stationsIn vehicleDrive motor

The invention discloses a vehicle-mounted multi-rotor unmanned aerial vehicle charger which comprises an unmanned aerial vehicle body and a charging platform, wherein the charging platform comprises acharging base and a charging table arranged on the charging base; a charging slot is formed at the top of the charging table; a charging connector A is arranged in the charging slot; a charging butting device is arranged at the bottom of the unmanned aerial vehicle body and comprises a folding charging rod and an undercarriage; a charging connector B corresponding to the charging connector A in the charging slot is formed at the lower end of the charging rod; the unmanned aerial vehicle body comprises an upper housing and a lower housing; a containing slot is formed at the bottom of the lowerhousing; the charging rod is mounted in the containing slot through a rotating shaft; and the lower housing is further internally provided with a driving motor for driving the rotating shaft to rotate so as to retract the charging rod. The charger is applicable to large- and medium-sized multi-rotor unmanned aerial vehicles for line patrol, shortens a required movement distance of the unmanned aerial vehicles during charging and accelerates the patrol. The charger is quick and stable in charging butting operation, strong in operability and convenient to use.

Owner:WUHAN UNIV OF TECH

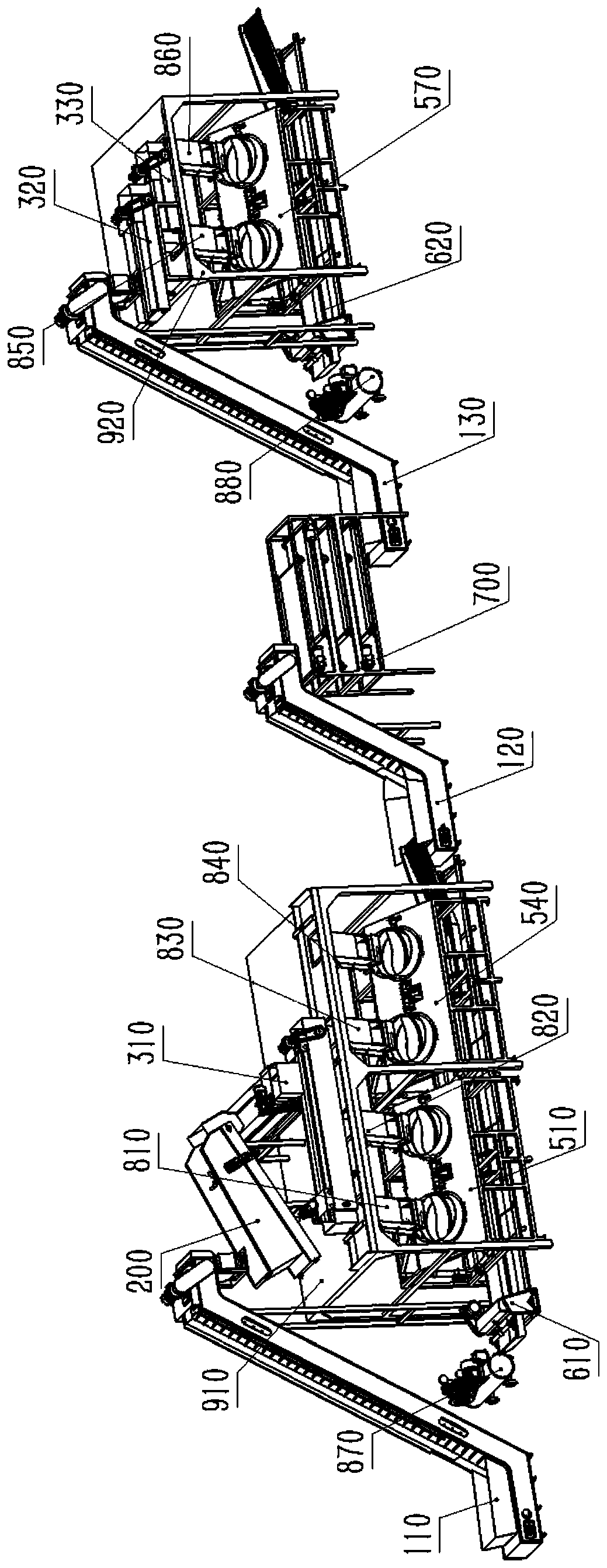

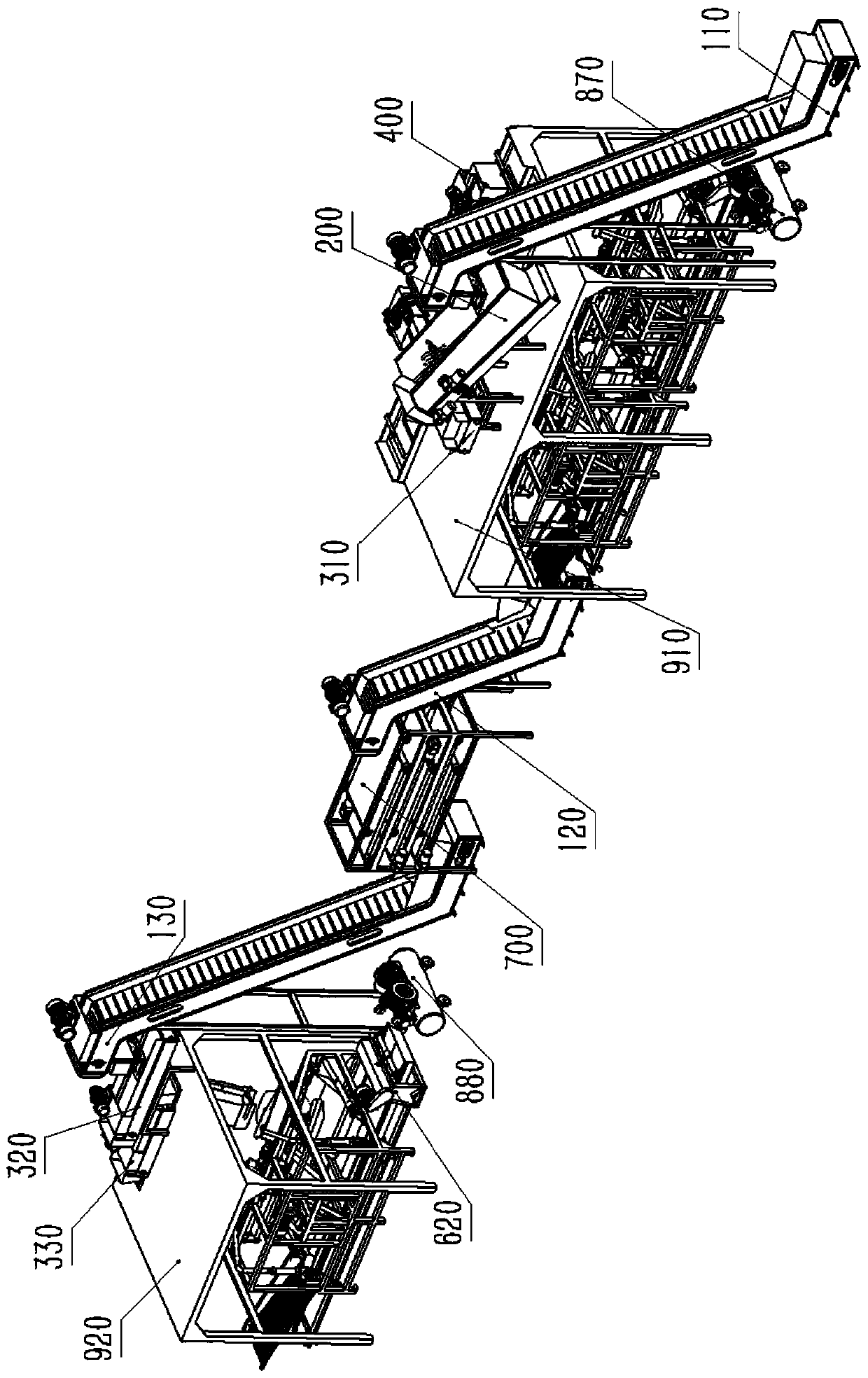

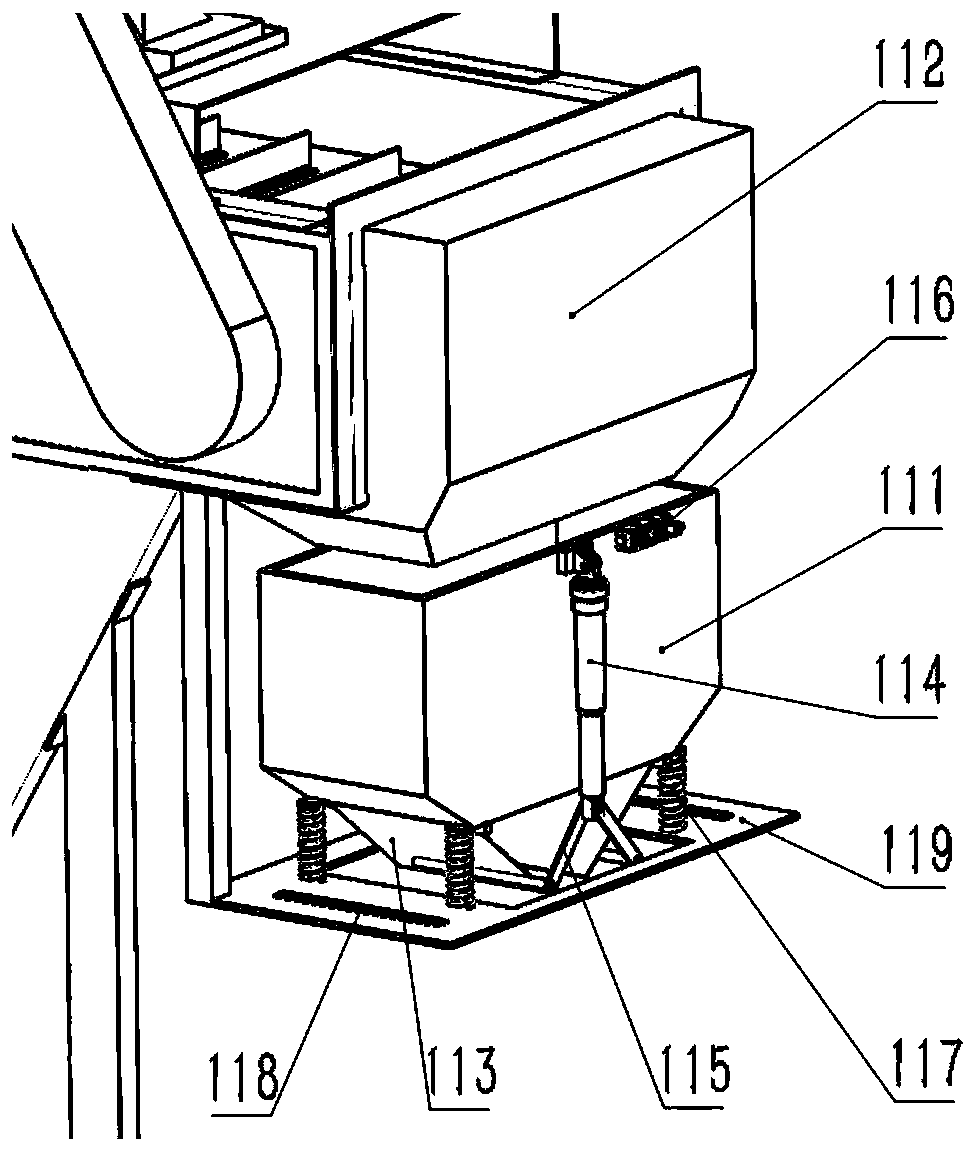

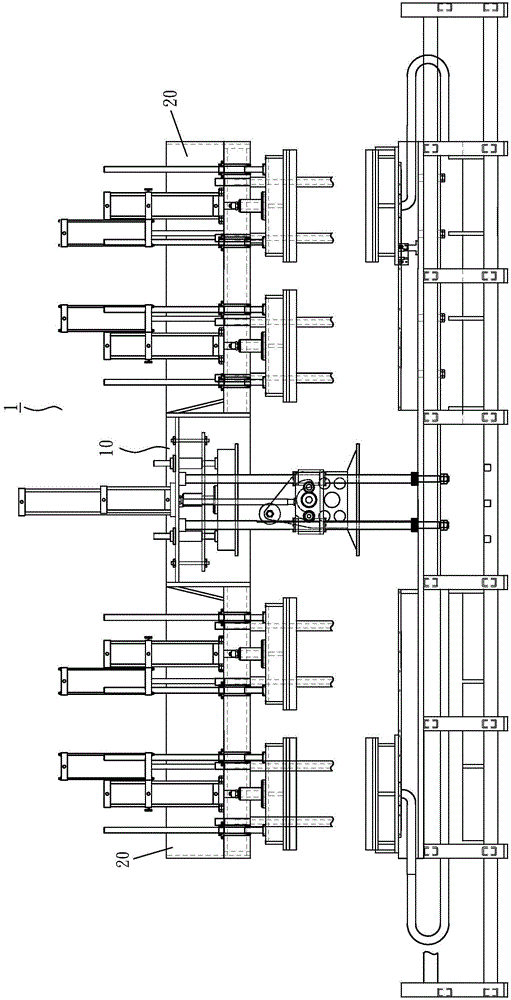

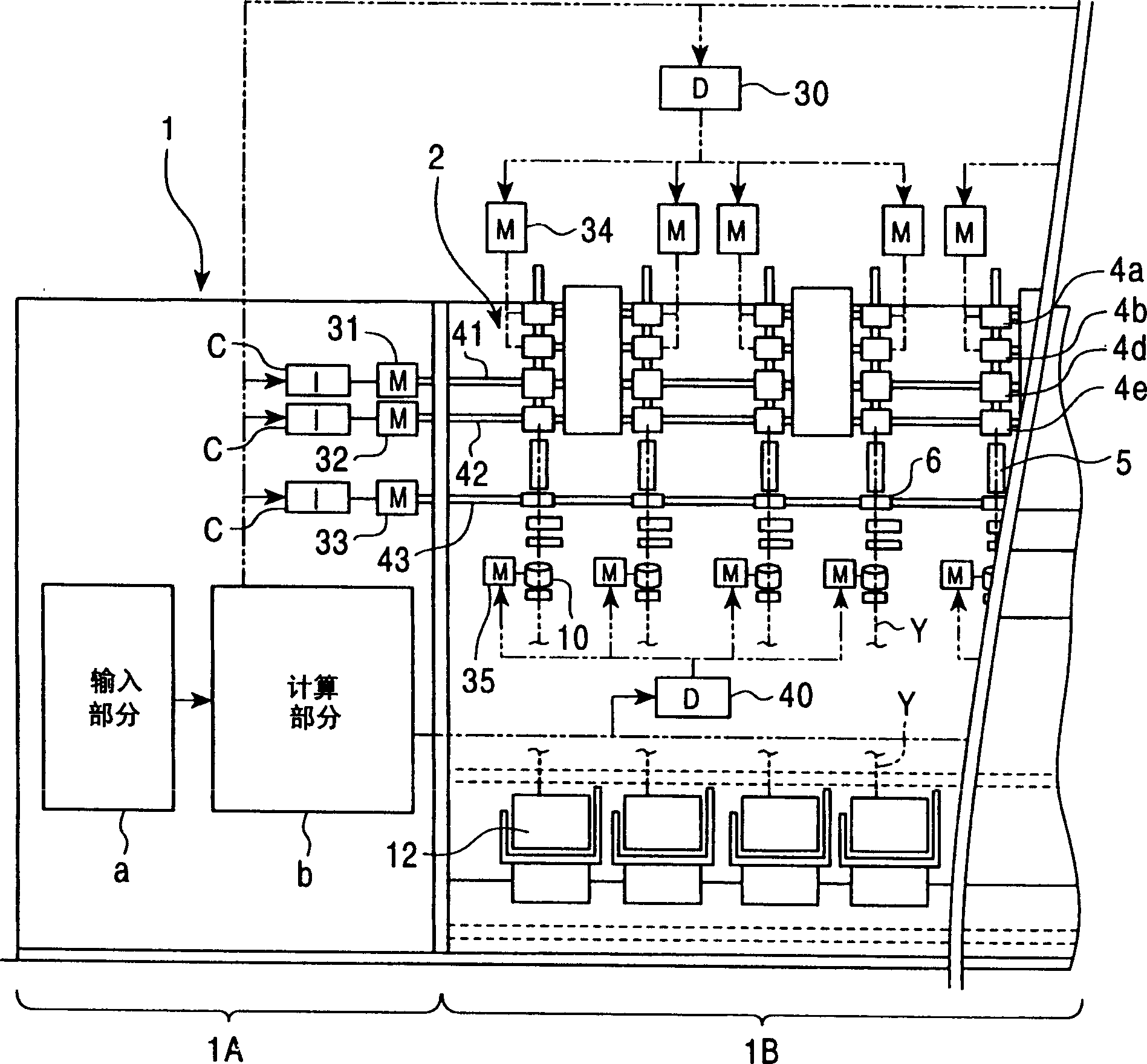

Bead tea continuous forming system based on automatic feeding and control method thereof

ActiveCN109733903AImprove qualityGuaranteed qualityWeighing apparatus using elastically-deformable membersWeighing apparatus with automatic feed/dischargeEngineeringMaterial distribution

The invention relates to a bead tea continuous forming system based on automatic feeding and a control method thereof. The system comprises a PLC control unit, an initial frying unit, a spreading andcooling unit and a refrying unit, a vertical lifting machine, a weighing mechanism, a material distribution mechanism and a vibration type conveyor are arranged on the initial frying unit and the refrying unit, so that automatic feedingg, automatic pan-frying are realized, the continuous making of the pearl tea production is realized, and the production efficiency and the quality of the pearl teaare greatly improved. The control method comprises a primary frying feeding link, a primary frying link, a spreading and cooling link, a refrying and feeding link and a re-frying link control process.According to the control method, the automation degree of the forming system is higher.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Technology for simultaneously preparing metallic magnesium and calcium carbide through carbothermal method

The invention discloses a technology for simultaneously preparing metallic magnesium and calcium carbide through a carbothermal method and belongs to the field of metallic magnesium smelting. The technology comprises the preparation steps that firstly, a magnesium oxide, a calcium oxide, a carbonaceous reducing agent and a fluorite catalyst are prepared according to the weight ratio of components; secondly, the prepared materials are mixed uniformly and then placed into a ball grinding mill with a screen to be ground and screened, and materials with different finenesses are obtained; thirdly, the screened materials are mixed uniformly and then sent into a high-pressure double-roller ball press machine to be pressed into balls and dried; and fourthly, the balls are placed into a vacuum reactor, the vacuum reactor is vacuumized, and metallic magnesium steam and the calcium carbide are produced under a certain pressure and a certain pressure. By utilizing the magnesium oxide and the calcium oxide, the magnesium and the calcium carbide can be produced simultaneously, energy sources are saved, environmental pollution is reduced, and the raw material utilization rate is increased greatly.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

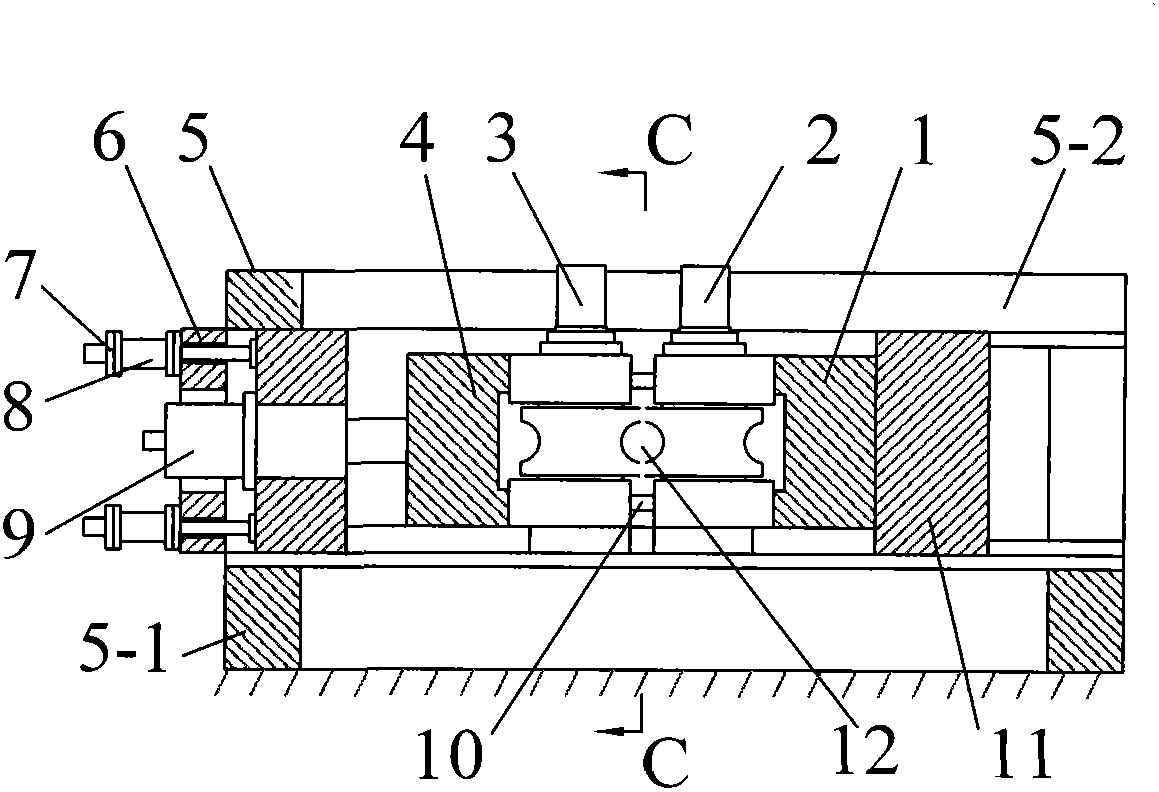

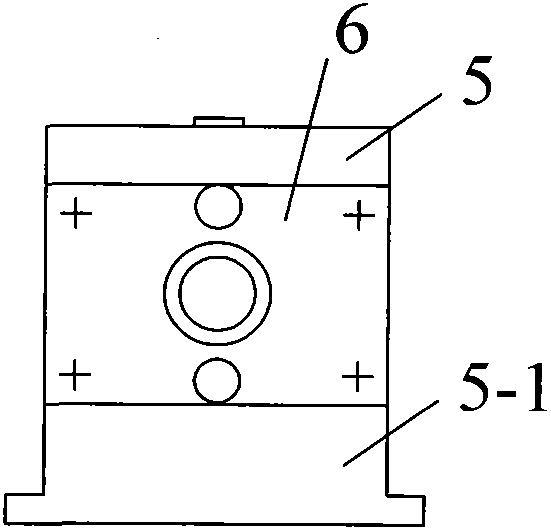

Two roller upright rolling mill

ActiveCN102581011AThe position of the center of the roll gap remains unchangedLess investmentMetal rolling stand detailsMetal rolling arrangementsStrip millRolling mill

The invention relates to a two roller upright rolling mill, which comprises a rolling mill base, a rolling mill rack, two upright mill rollers (3, 2) and a mill roller clearance regulating mechanism, wherein the two upright mill rollers (3, 2) are arranged inside the rolling mill rack in parallel; the rolling mill base (5) comprises an upright end plate (5-1) and horizontal transverse beams (5-2) which are connected with four angles of the upright end plate (5-1) respectively; the horizontal transverse beams (5-2) are vertical to the upright end plate and extend towards the same direction; the rolling mill base is a floating type rack (11) which is embedded among the four horizontal transverse beams of the rolling mill base; the mill roller clearance regulating mechanism is arranged at the transmission side or the operation side of the rolling mill; and a roller gap centering mechanism is also arranged at the same side with the mill roller clearance regulating mechanism. While the two mill rollers are subjected to clearance regulation, the roller gap between the two mill rollers is centered automatically; the device is simple and convenient to operate and maintain; and the rollers can be exchanged conveniently and rapidly.

Owner:BEIJING JINGCHENG RUIXINCHANGCAI ENG TECH

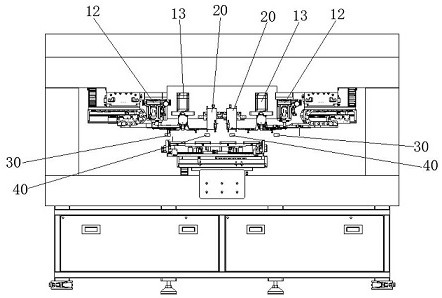

Automatic molding machine for producing pulp moulded products at super small draft angle

ActiveCN104928995AShorten the travel distanceReduce production man-hoursTextiles and paperMan-hourEngineering

The present invention discloses an automatic molding machine for producing pulp moulded products at a super small draft angle, being configured as such that when an overturn means is performing the action of overturning, a centralizing gear of a centralizing means supportively assists in the ascending or descending synchronous movements along a centralizing rack on a centralizing shaft rod so as to enable all shafts to ascend or descend to a defined position in a synchronous and parallel manner, when a pulp absorbing die is conducting up and down movement or overturning movement, due to the supportive assistance between the centralizing gear and the centralizing rack, which will facilitate the realization of a complete and correct die locking as the pulp absorbing die is driven ascended for die locking with an extrusion die, or is driven descended for die locking with a moving die. At the same time, the extrusion die has a descending stroke controlled by a power cylinder body so as to conduct die locking with the ascending pulp absorbing die, which will reduce the move stroke of the pulp die, reduce manufacturing man-hour and manpower, decrease manufacturing cost, and improve qualification rate and excellent quality rate and product competitiveness.

Owner:CHANGZHOU CHENGXIN ENVIRONMENTAL PROTECTION TECH CO LTD

Flat knitting machine having looping press sheet and control method thereof

ActiveCN103668760AAvoid Interfering ActionsGrasp the state of interferenceFlat-bed knitting machinesYarnEngineering

The present invention provides a flat knitting machine having a looping press sheet and a control method thereof, capable of simply confirming poor condition occuring at a front end of a cam follower, capable of reliably preventing the cam follower from being used all the time in the case of the poor condition. When a base end portion of the cam follower is switched from a set position to a reset position, in the state that a reset position sensor detects that the base end portion of the cam follower has been switched to the reset position, only when a recover state detection unit detects that the front end of the cam follower is not recovered to the reset position, occurrence the poor condition of the front end of the cam follower is judged. If the judgement and retreat of a cam carrier to the outside of a knitting width of knitted fabric are performed simultaneously, it is judged that the cam follower is interferenced with a yarn feeding port of a yarn guide device, then an interference avoiding action which enables move stroke of the cam carrier to be prolonged to a position where the cam follower and the yarn feeding port of the yarn guide device are not interferenced is performed, and then the cam carrier is inverted.

Owner:SHIMA SEIKI MFG LTD

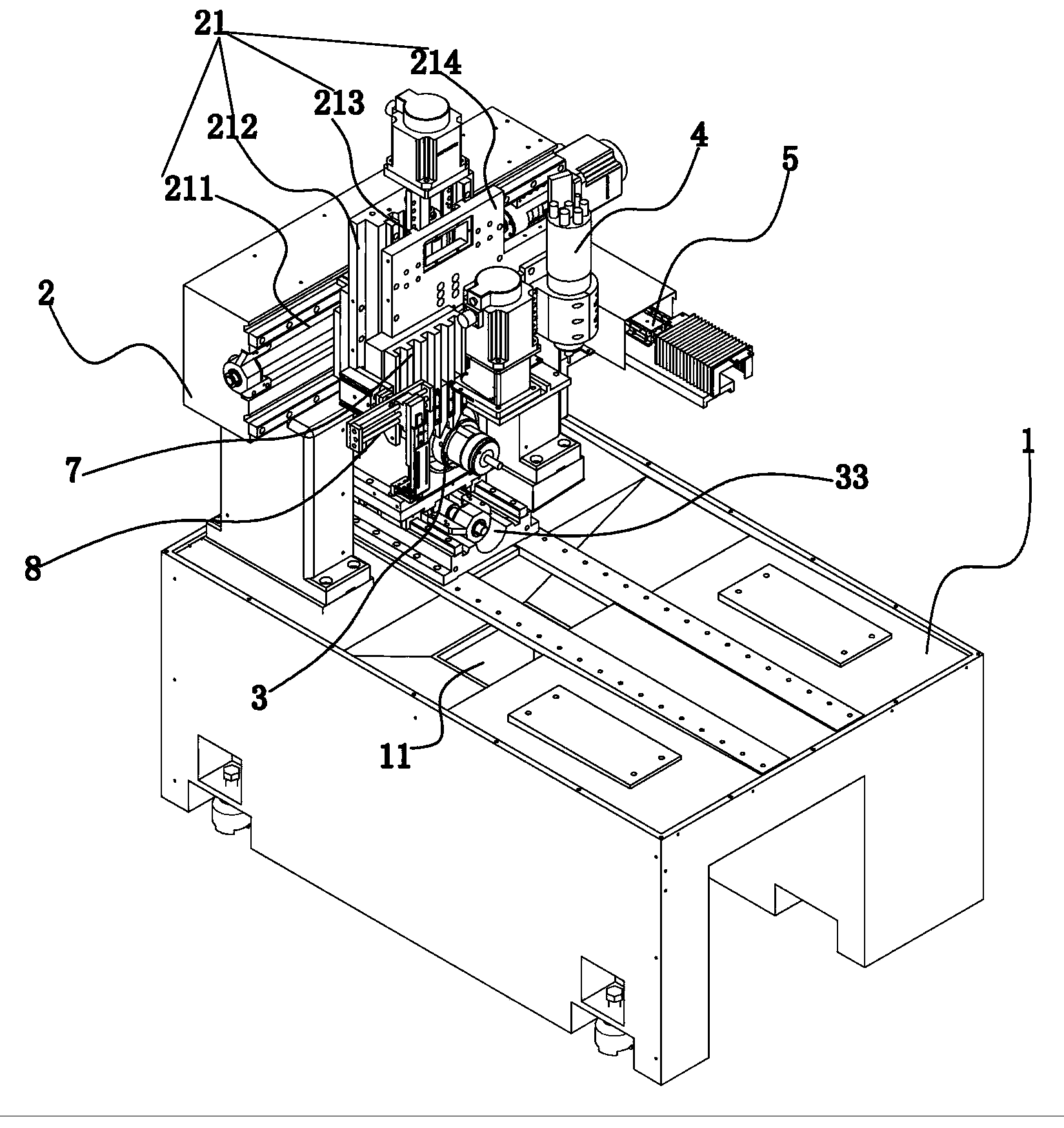

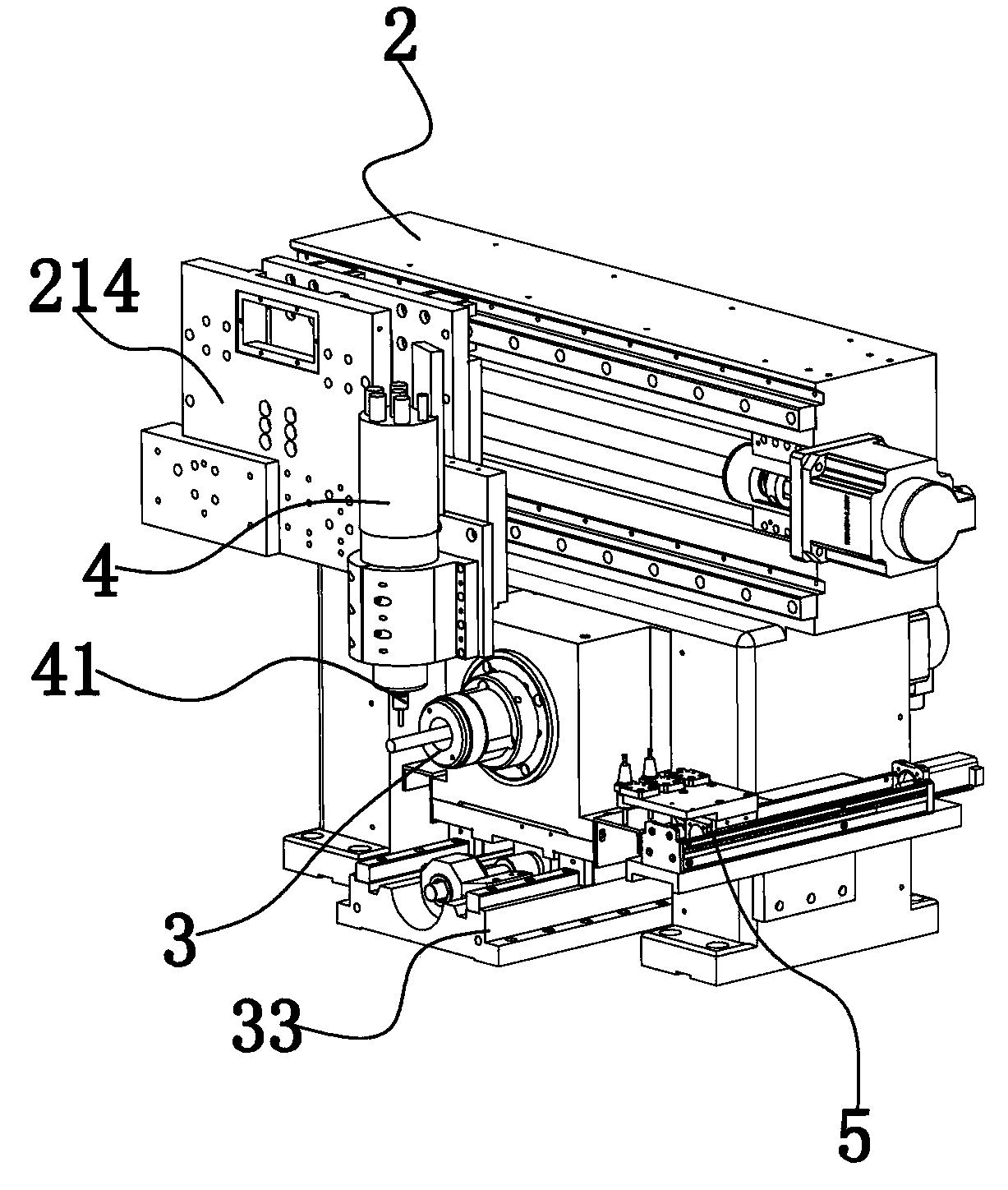

Turning-milling combination machine

InactiveCN103817529AShorten the travel distanceStable processingAutomatic workpiece supply/removalOther manufacturing equipments/toolsVertical planeTower

The invention discloses a turning-milling combination machine and belongs to the field of turning-milling machining. The turning-milling combination machine comprises a portal frame, a horizontal main shaft base, a vertical main shaft arm, a power tool tower and a row tool rest. The horizontal main shaft base is arranged in a gantry of the portal frame in a penetrating mode. A transmission mechanism is arranged on the portal frame. The vertical main shaft arm, the power tool tower and the row tool rest are arranged on the transmission mechanism, so that vertical plane moving of the vertical main shaft arm, the power tool tower and the row tool rest is achieved, and a workpiece is machined. The turning-milling combination machine is high in machining efficiency and stable in performance.

Owner:东莞市美迈士机械科技有限公司

Kitchen garbage solid-liquid separation device

ActiveCN103967084BEasy to clean and maintainAvoid cloggingDomestic plumbingEnvironmental engineeringPower apparatus

A solid-liquid separation device for kitchen waste belongs to the technical field of life appliances and comprises a shell, a drainage body and a separator, wherein a water outlet, a residue outlet and a partition board are arranged on the shell; the partition board is arranged between the water outlet and the residue outlet, the residue outlet is connected with a waste residue barrel by a pipe, the drainage body is arranged at the upper end of the shell, a liquid inlet is arranged at the upper end of the drainage body and is communicated with a downcomer of a basin, a liquid outlet is arranged at the lower end of the drainage body, a horizontal slide rail is arranged at the upper end of the residue outlet along the inner wall of the shell, the separator is arranged between the liquid outlet and the horizontal slide rail, and the separator can slide along the horizontal slide rail. The solid-liquid separation device for kitchen waste is simple, practical and convenient to mount, does not need a power device, saves energy and is friendly to the environment and efficient. The solid-liquid separation device can perform quick and effective solid-liquid separation on residue waste in the basin of a kitchen, is convenient to clean and maintain, provides convenience for life of people and is easy to popularize and use.

Owner:陆全东

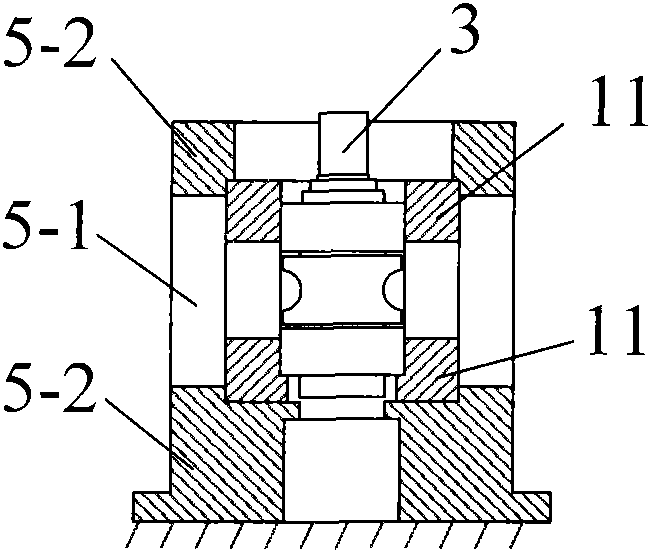

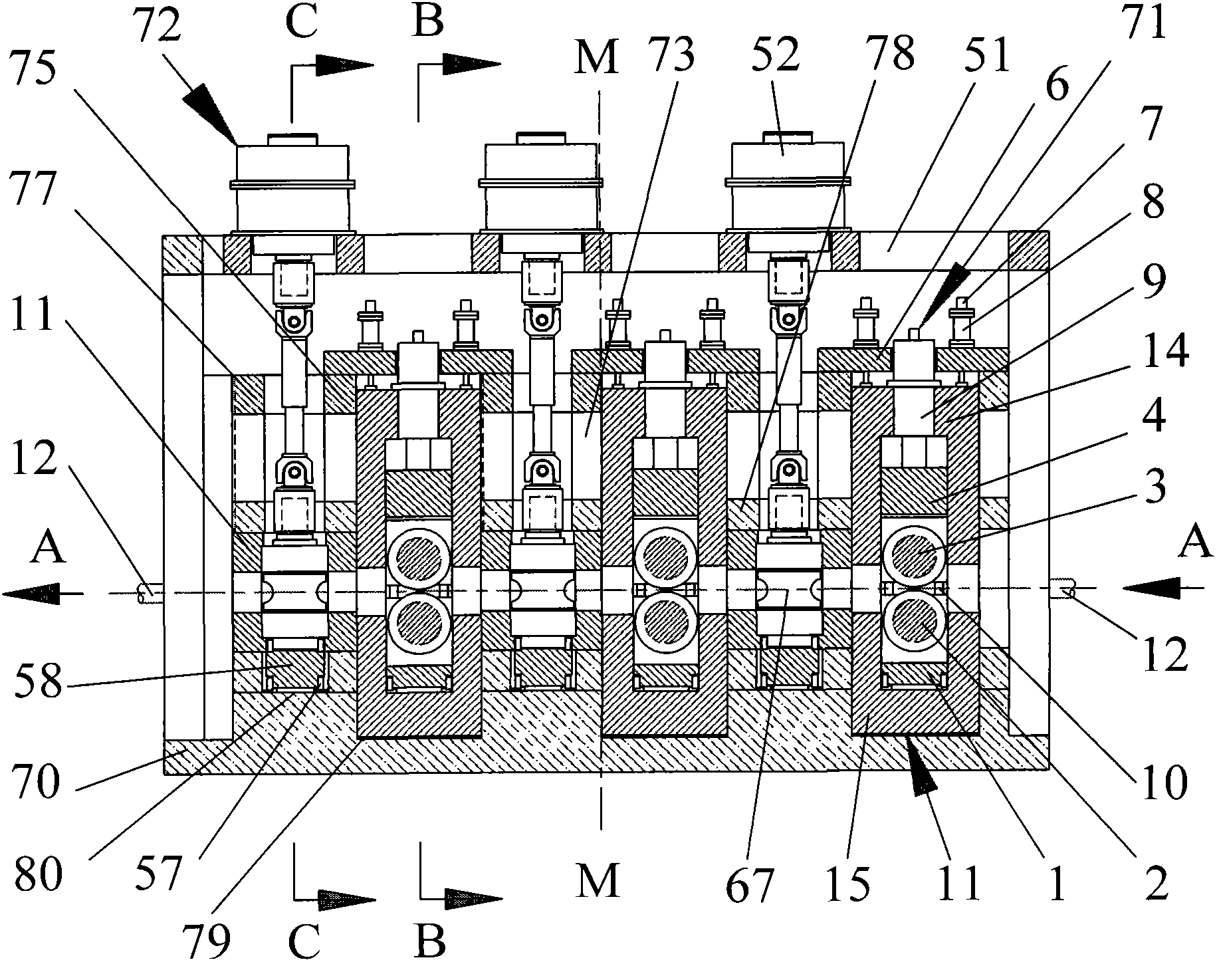

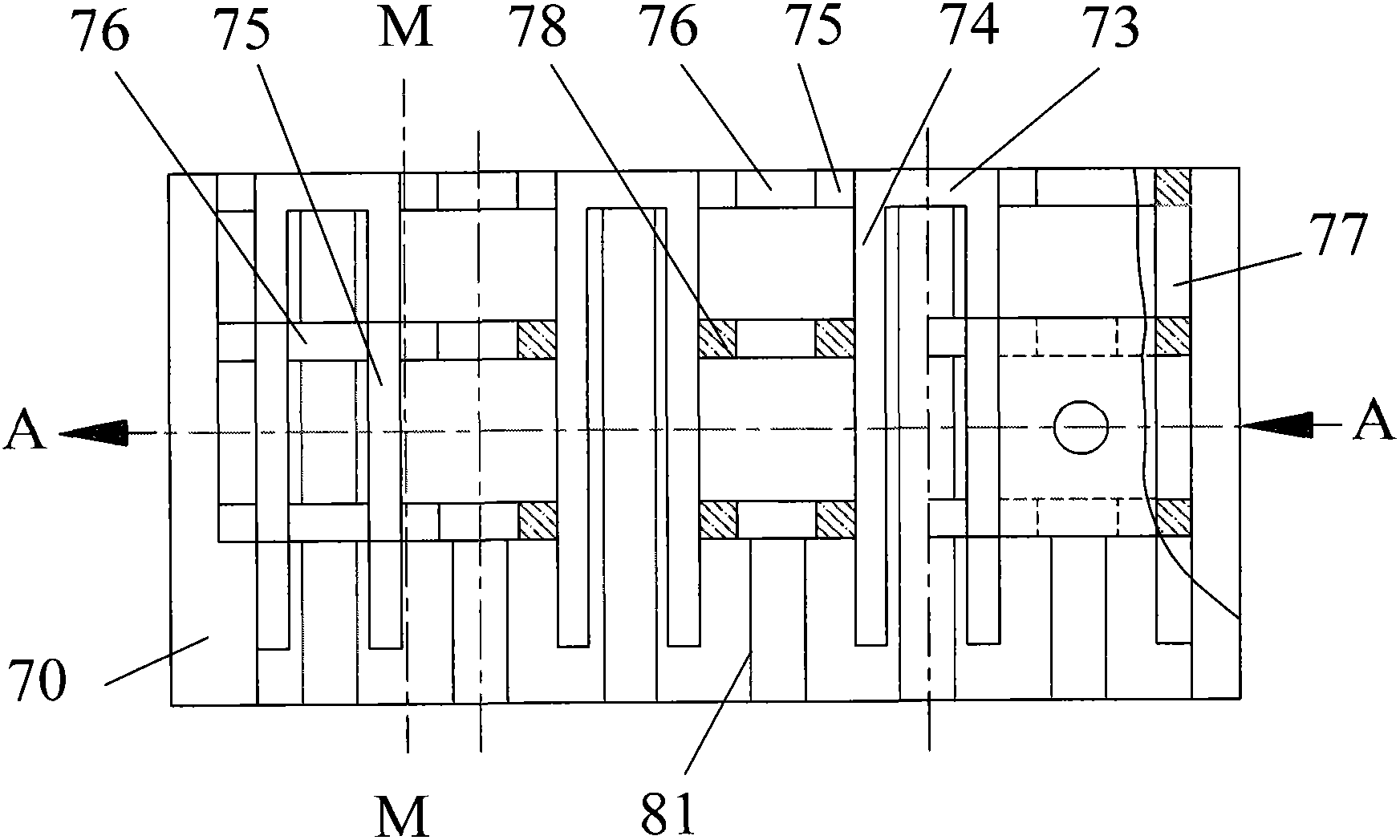

Combined two-roller continuous mill

ActiveCN102581012AReduce length dimensionReduce the length of the out-of-tolerance segmentMetal rolling stand detailsMetal rolling arrangementsEngineeringMechanical engineering

The invention relates to a combined two-roller continuous mill, which comprises at least one horizontal rolling assembly (71), at least one vertical rolling assembly (72) and a roll changing mechanism, wherein rolling assembly frames are alternately and continuously attached along a rolling line (A-A) and are arranged on a base 5 in 90 degrees; each rolling assembly (71) comprises a floating frame (11) which is embedded in the rolling assembly frame; two rollers and a roller bearing seat are arranged in the floating frame; a roller gap adjusting mechanism is arranged on an upper roller bearing seat (4) or on an end plate (14) of the floating frame (11) corresponding to a roller bearing seat(65) at the transmission side; and a roller gap centering mechanism which is arranged on a movable top cover (6) is further added. The rolling assembly frames are compactly arranged in a gapless way, when the gap between two rollers is adjusted by the roller gap adjusting mechanism and the roller gap centering mechanism, the gap between the two rollers is automatically centered; and the continuous mill is high in operating rate.

Owner:BEIJING JINGCHENG RUIXINCHANGCAI ENG TECH

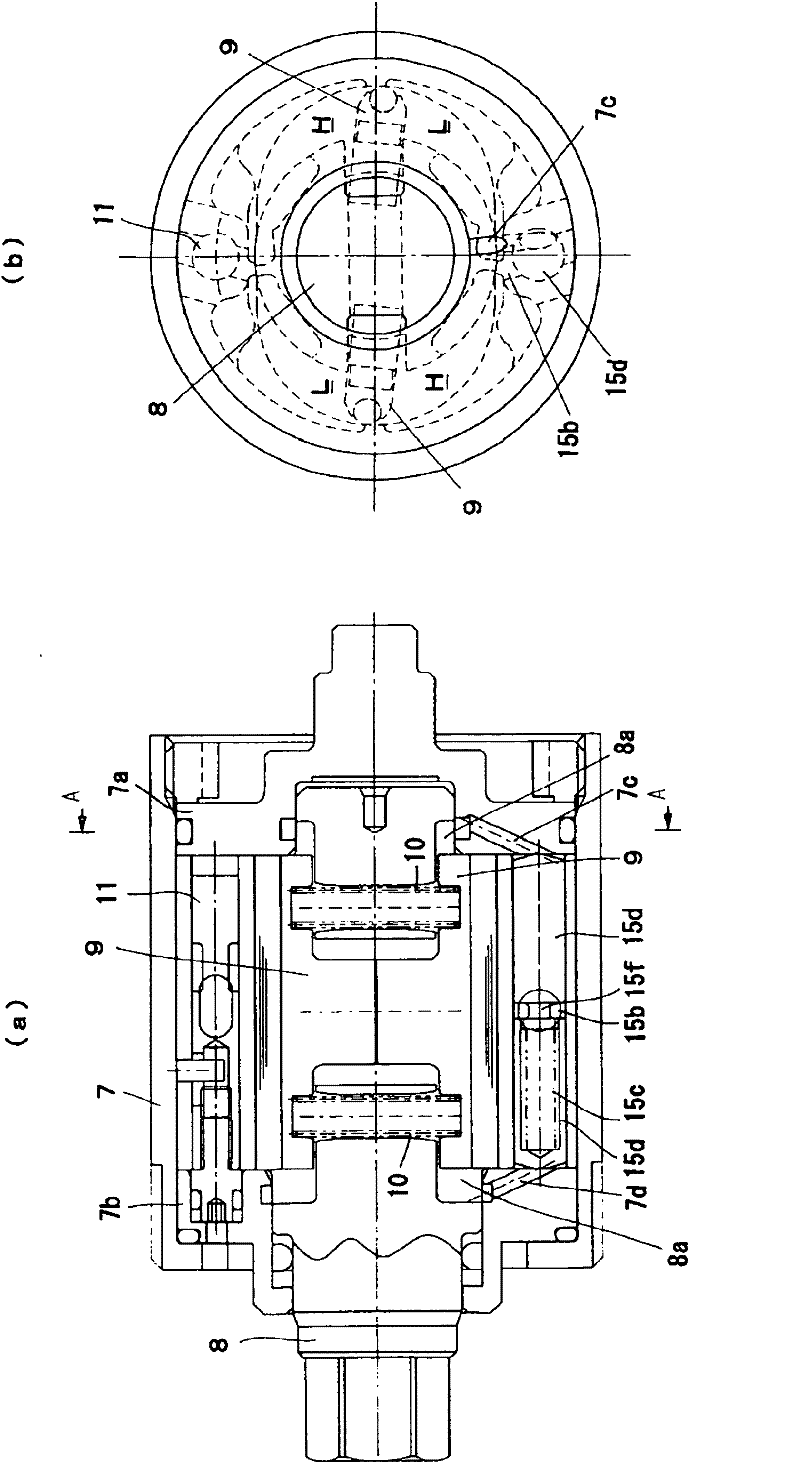

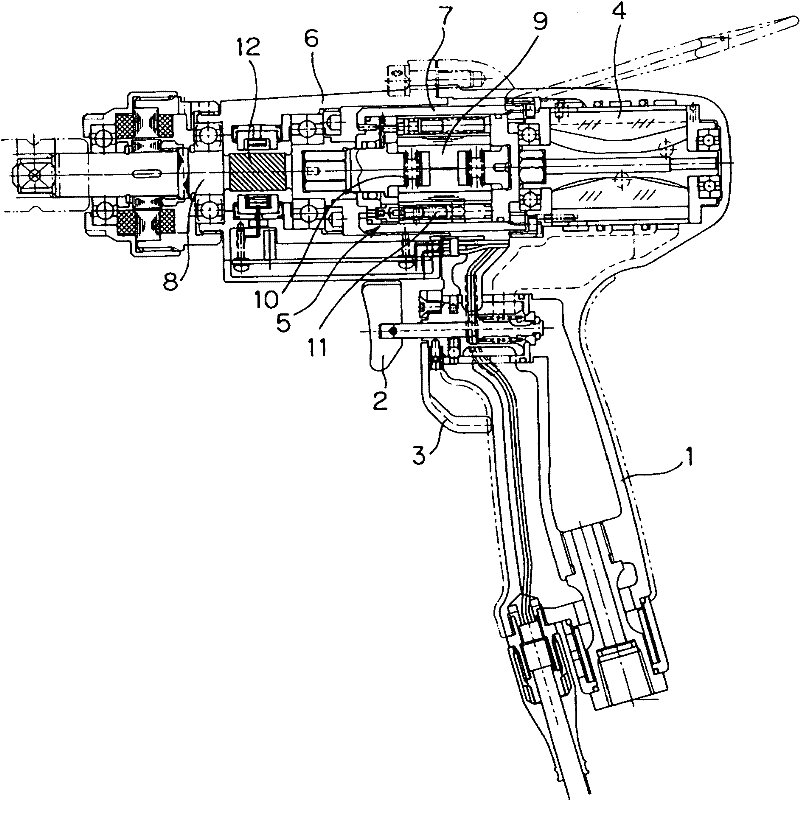

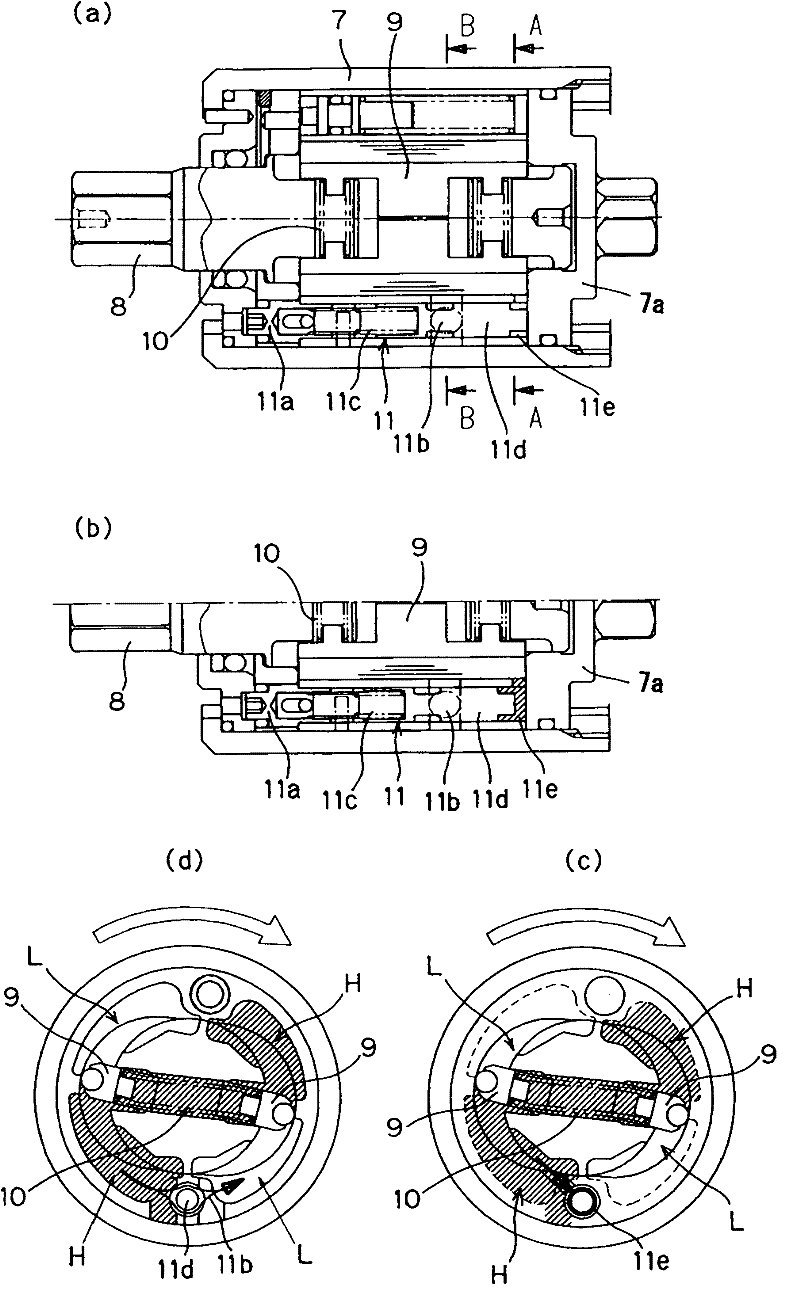

Impact torque adjusting device of hydraulic torque wrench

InactiveCN102398243AShorten the production cycleHigh precisionSpannersWrenchesWorking fluidEngineering

To present a impact torque adjusting device of a hydraulic torque wrench capable of enhancing the precision of the magnitude of the impact torque generated by the impact torque generating device of the hydraulic torque wrench, shortening the generation period of impact toques, and enhancing the durability of the impact torque generating device of the hydraulic torque wrench, when rotating in two directions, that is, in normal rotation (when tightening) and in reverse rotation (when loosening). The present invention provides a working fluid path (11b) for communicating with the inside of a liner (7) serving as a high-pressure chamber (H) and a low-pressure chamber (L) at the time of generation of a impact torque is formed, and a valve body (11d) biased in a direction of releasing the working fluid path (11b) is disposed in the working fluid chamber, and at the rear back side of the valve body (11d), an oil chamber (15e) is formed to communicate with a blade insertion part (8a) of a main shaft (8) by way of fluid paths (7c, 7d) formed in liner lids (7a, 7b), and thereby the working fluid path (11b) is narrowed depending on an elevation of the pressure of the working fluid in the blade insertion part (8a) of the main shaft (8) elevating along with an elevation of the working fluid in the high-pressure chamber (H).

Owner:URYU SEISAKU

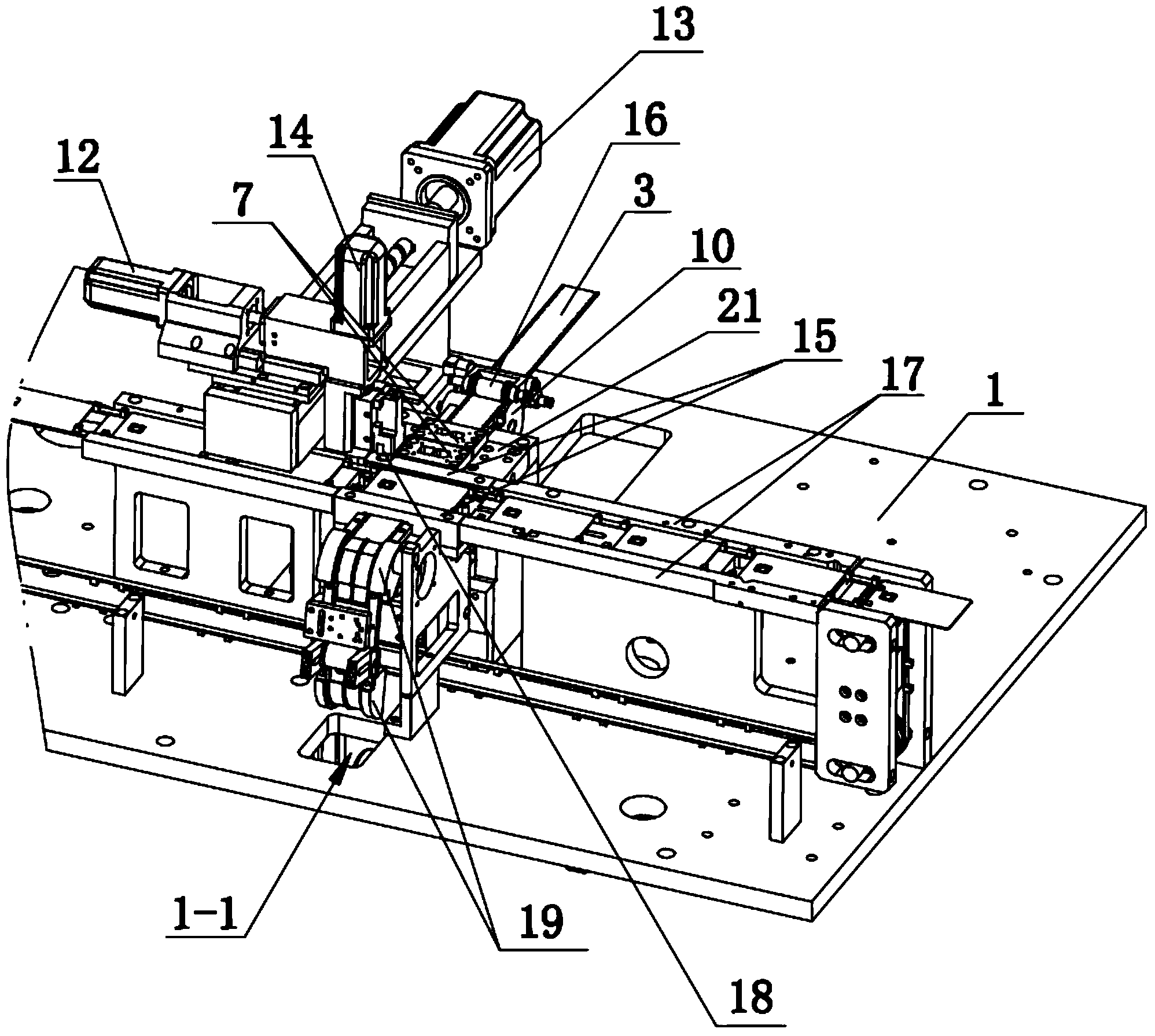

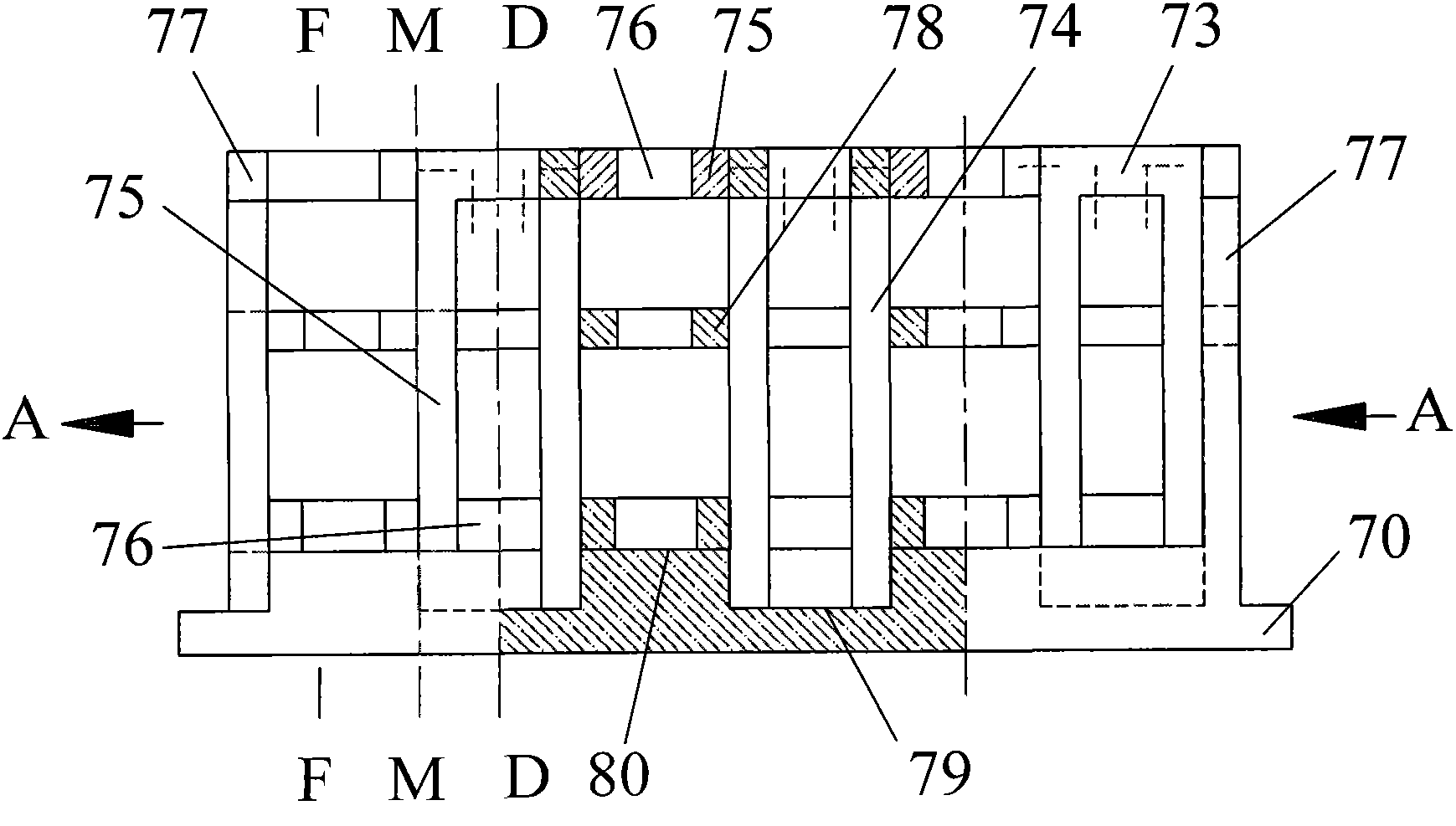

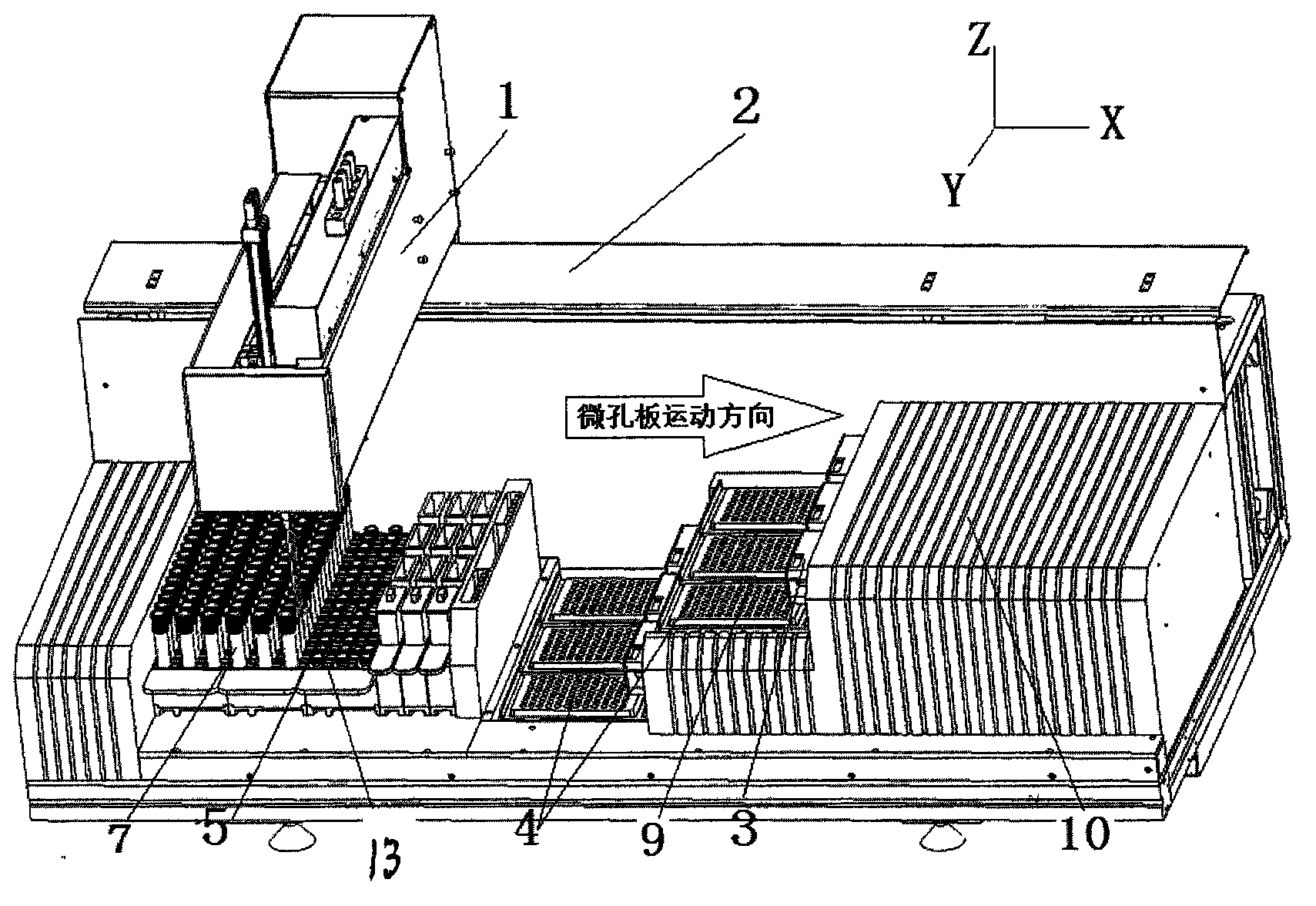

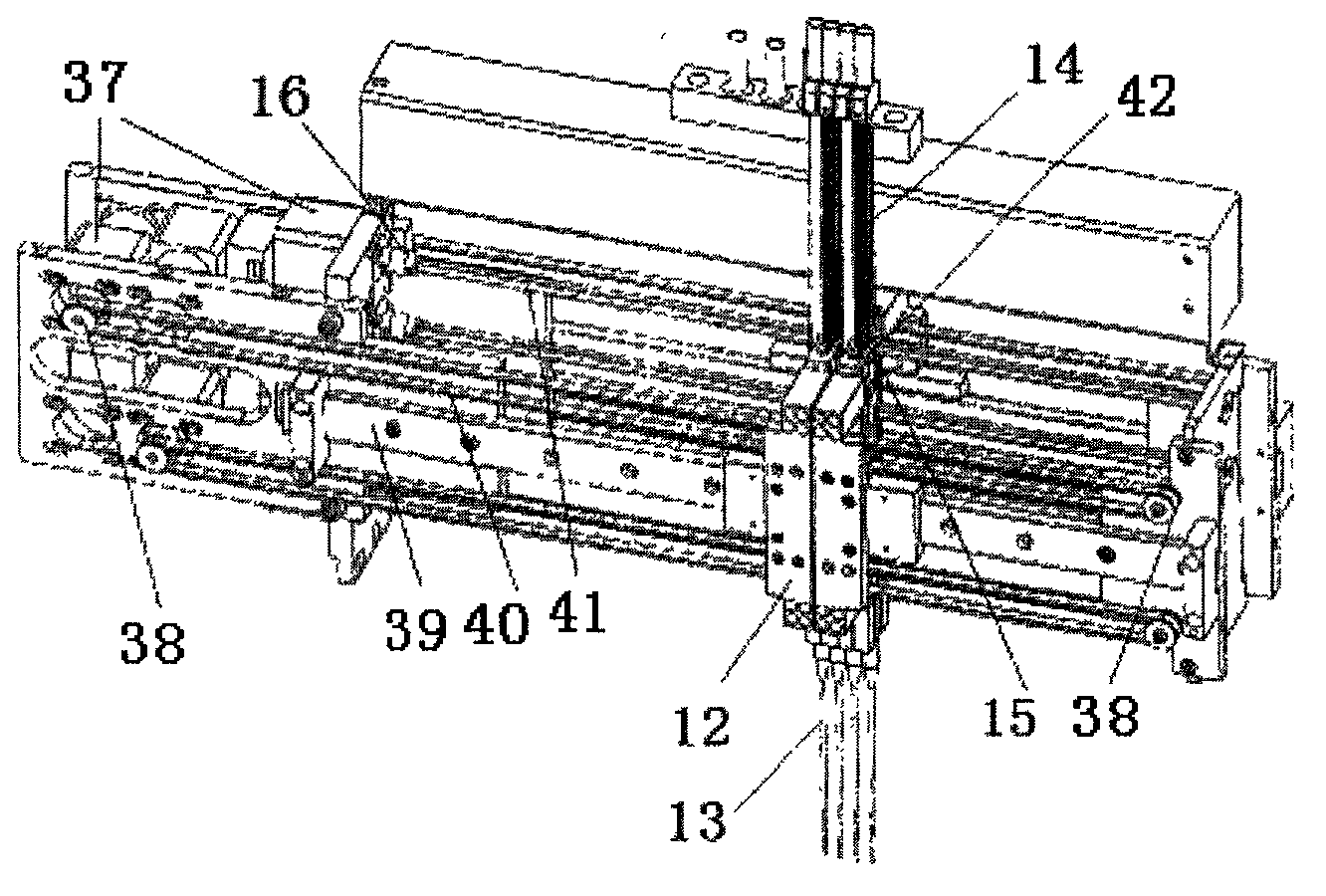

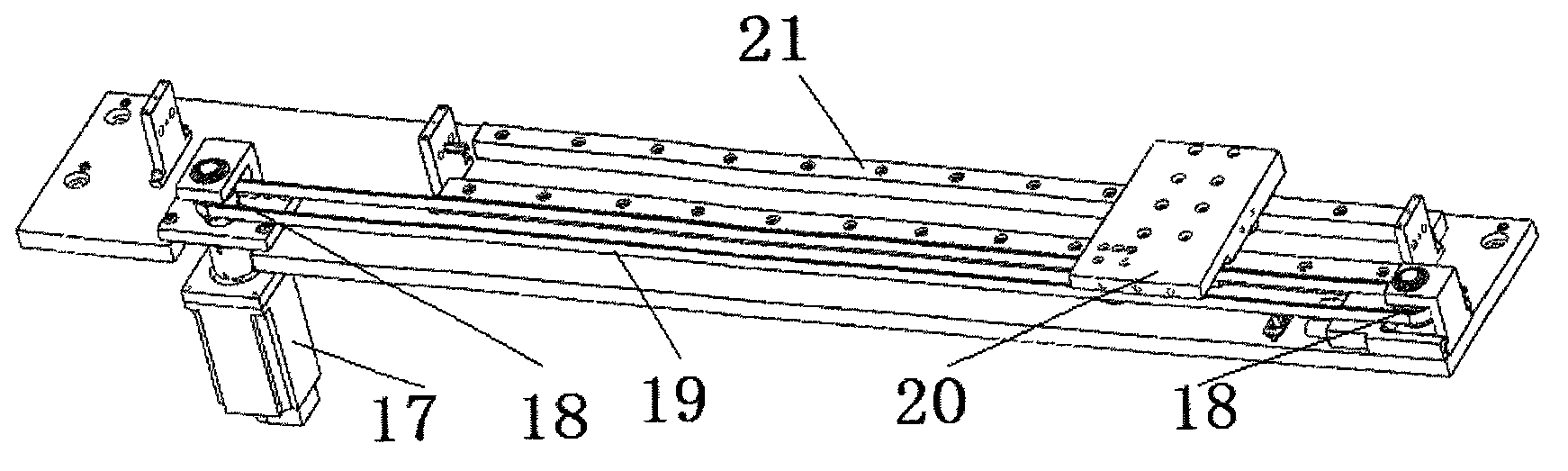

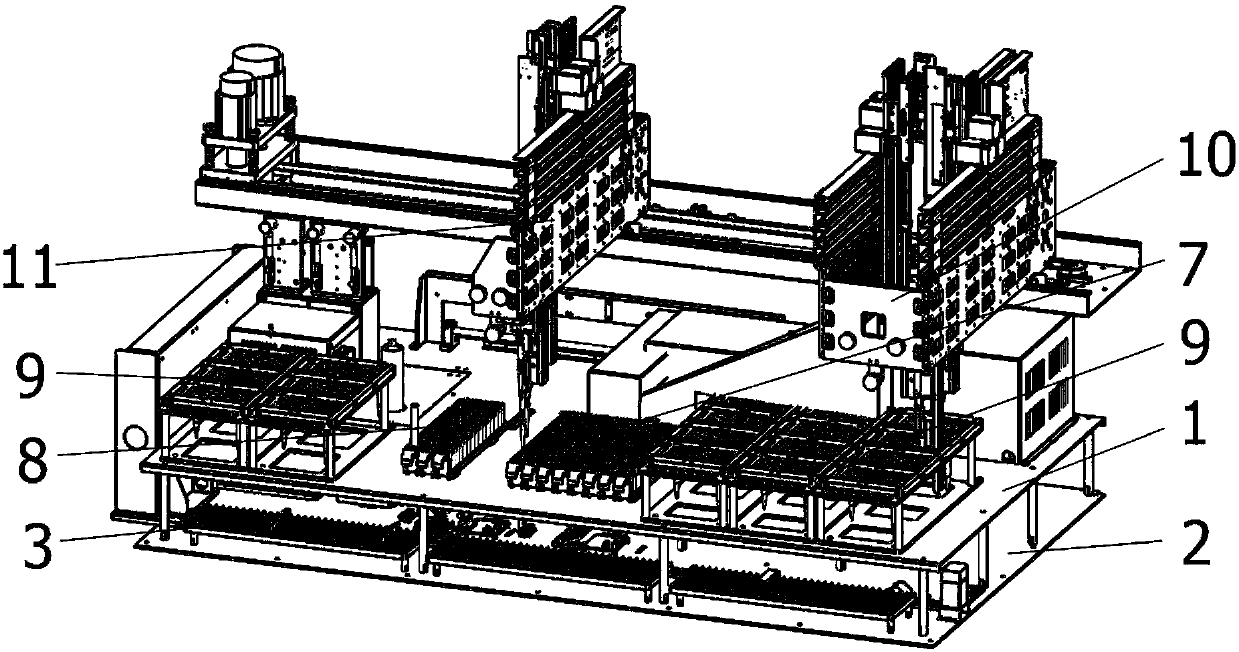

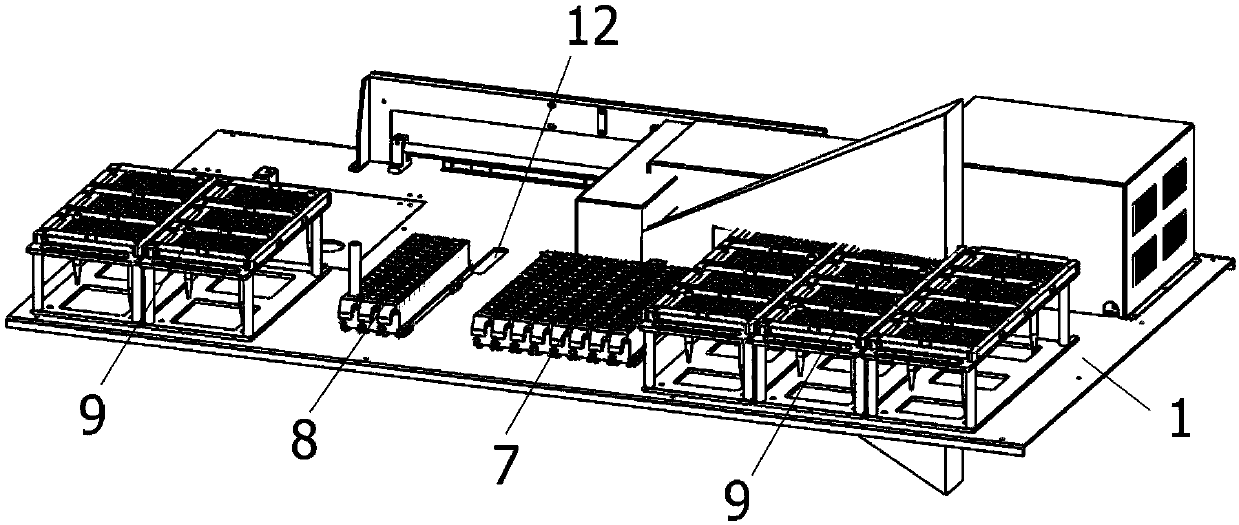

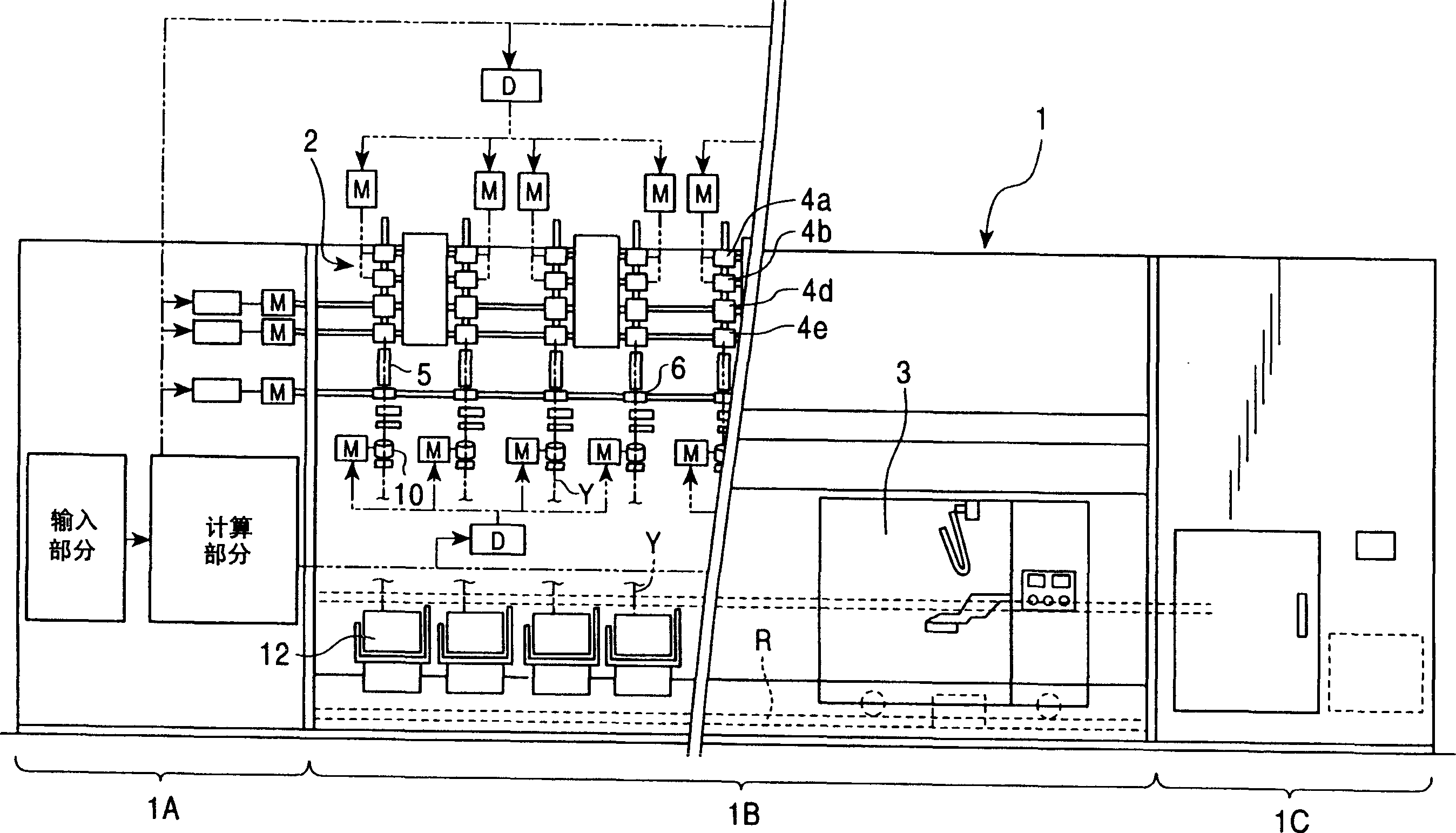

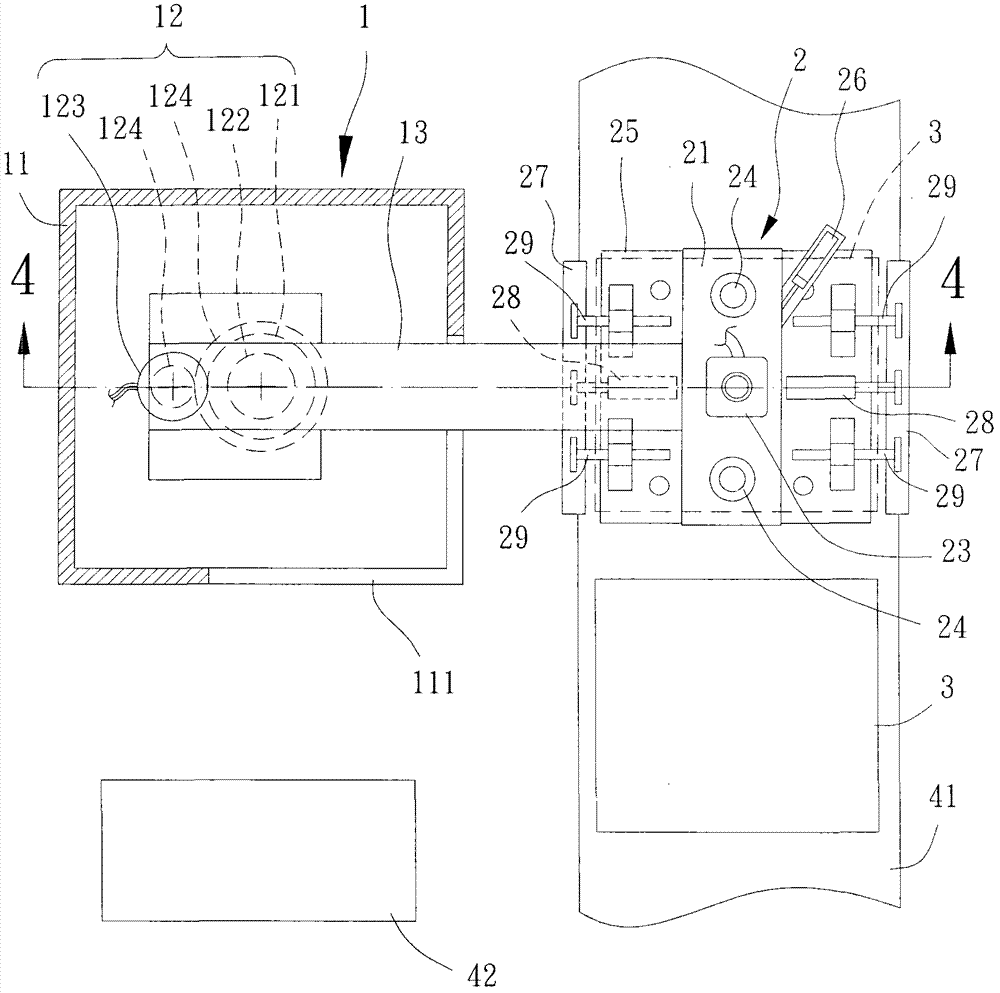

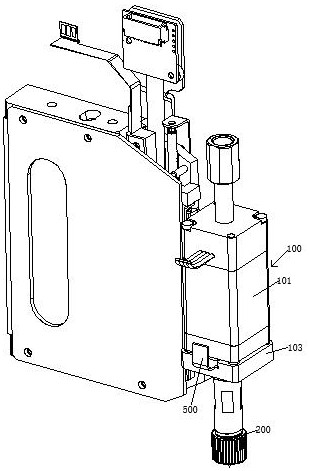

Processing device for full-automatic chemiluminescence immunoassay analytical instrument

InactiveCN103197085AShorten the travel distanceImprove processing efficiencyMaterial analysisMicrowell PlateChemiluminescence immunoassay

The invention provides a processing device for a full-automatic chemiluminescence immunoassay analytical instrument, which is capable of improving the efficiency from sample injection to incubation. The device comprises a sample injection mechanism, a sample region (5), a micropore plate region (4), an incubation region (10) and a cleaning head (3), wherein the sample injection mechanism is arranged in a manner of moving along the horizontal longitudinal-transverse and up-down directions; a sample container (7) is arranged in the sample region (5), and the sample injection mechanism samples in the sample region (5) through the movements along the horizontal longitudinal-transverse and up-down directions; a micropore plate (9) is put in the micropore plate region (4), the sample injection mechanism sucking a sample injects the sample in the micropore plate (9) through the movements along the horizontal longitudinal-transverse and up-down directions; the incubation region (10) is arranged to be adjacent to the micropore plate region (4) in a manner that the micropore plate (9) injected with the sample immediately enters the incubation region (10) to incubate; and the cleaning head (3) is arranged above the micropore plate region (4) in a manner of cleaning the micropore plate (9) returning to the micropore plate region (4) after incubation through the up-own movements.

Owner:北京源诚科仪生物技术有限公司

Mop wiping object water-squeezing device and mop cleaning bucket

The invention provides a mop wiping object water-squeezing device and a mop cleaning bucket, and belongs to the technical field of sweeping. With the mop wiping object water-squeezing device and the mop cleaning bucket, the problem that the existing mop cleaning head is forcefully stuffed into a rubbing sleeve, and thus the cleaning head is easily damaged is solved. The mop wiping object water-squeezing device comprises a bracket, a first slider and a second slider, and a water squeezing part is mounted on the second slider; and the first slider and the bracket are connected through a first guide structure, and the second slider and the bracket are connected through a second guide structure. The first slider and the second slider are connected through a linking strucutre, so that the watersqueezing part moves towards the direction close to the first slider, then the space between the water squeezing part and the leaning face of the first slider is narrowed, and thus the speed is obviously improved. During the water-squeezing work, the first slider and the water squeezing part clamp the cleaning head, the cleaning head is then moved so that the water squeezing part carries out water squeezing on a wiping object, therefore, the phenomenon that the cleaning head is forcefully stuffed between the first slider and the water squeezing part is avoided, and further, the service life of the cleaning head is prolonged.

Owner:胡国云

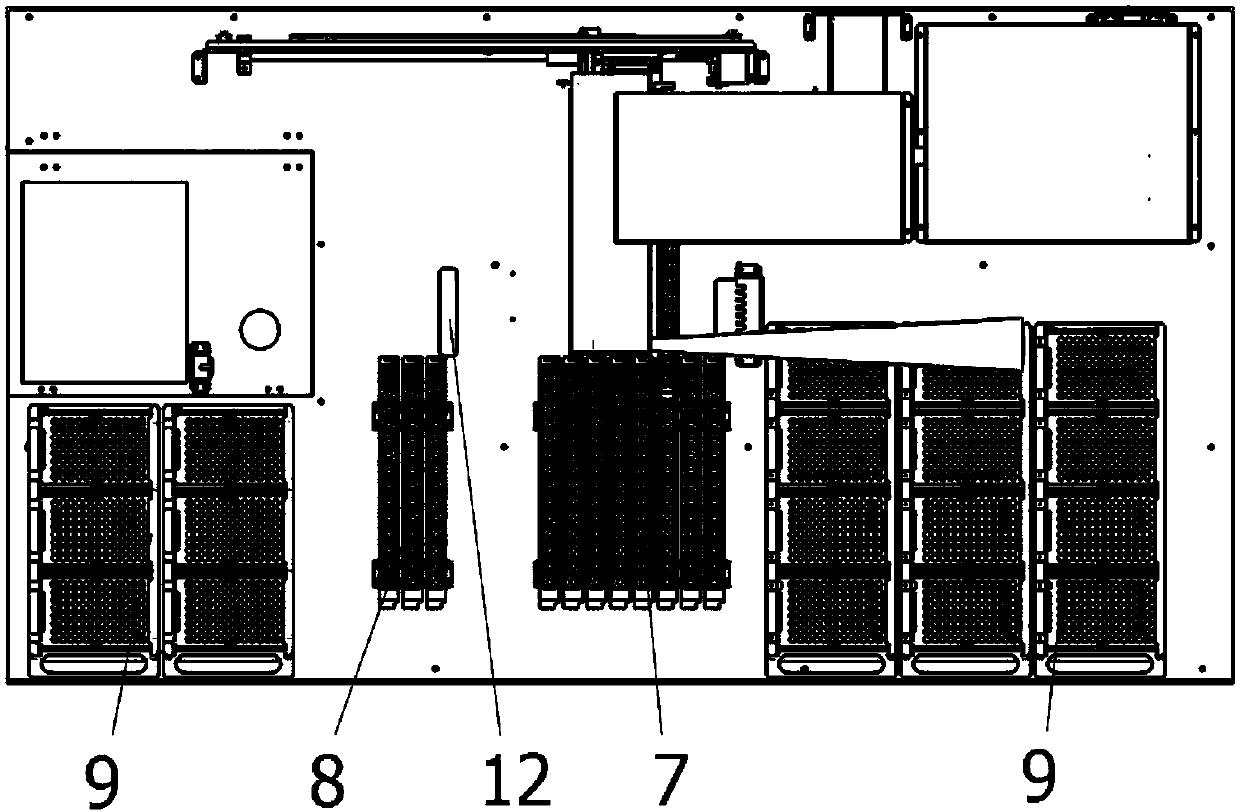

Fully-automatic chemiluminescence immunoassay analyzer

A fully-automatic chemiluminescence immunoassay analyzer provided by the invention includes: a frame including a supporting frame, and a first workbench and a second workbench which are arranged in the vertical direction of the supporting frame in a layered manner and communicate with each other; a functional station group and a cuvette storage area which are respectively arranged on the second workbench, wherein the functional station group includes an incubating area, a cleaning area and a detecting area; a liquid taking station group arranged on the first workbench and including a sample area, a reagent area and a tip storage area for storing pipette tips; a control system; and a delivery mechanism arranged on the frame, wherein the delivery mechanism allows a sample from the sample area and a reagent from the reagent area to be mixed in a cuvette under the control of the control system in order to obtain a substance to be detected, and sequentially delivers the substance to be detected to the incubating area, the cleaning area and the detecting area. The fully-automatic chemiluminescence immunoassay analyzer can overcome the defects of large occupied land and low efficiency offully-automatic chemiluminescence immunoassay analyzers in the prior art, and has the advantages of small occupied land and high efficiency.

Owner:厦门市波生生物技术有限公司 +1

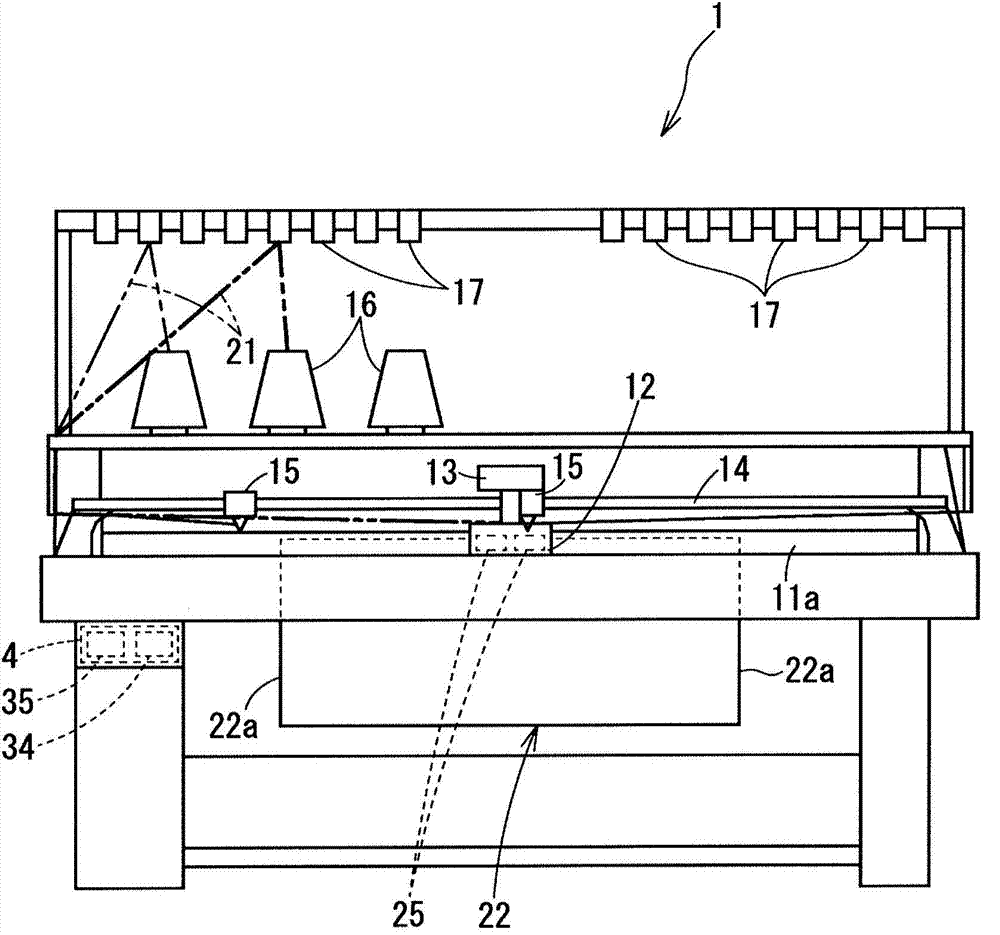

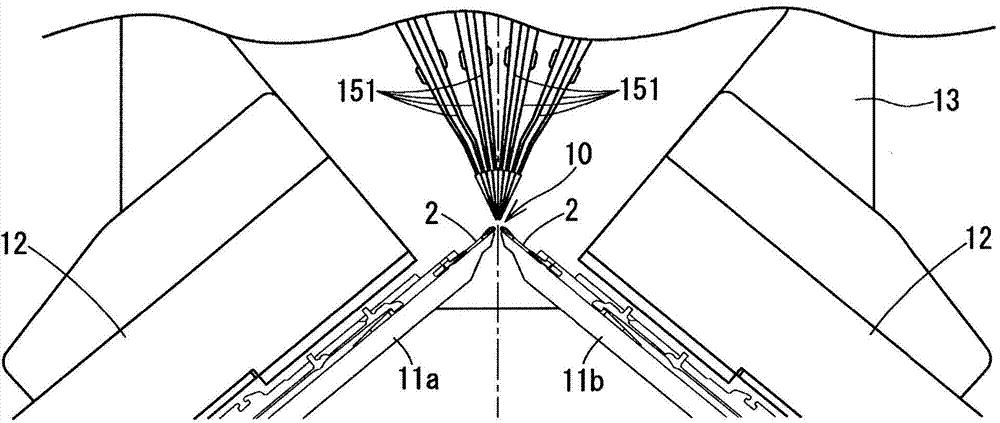

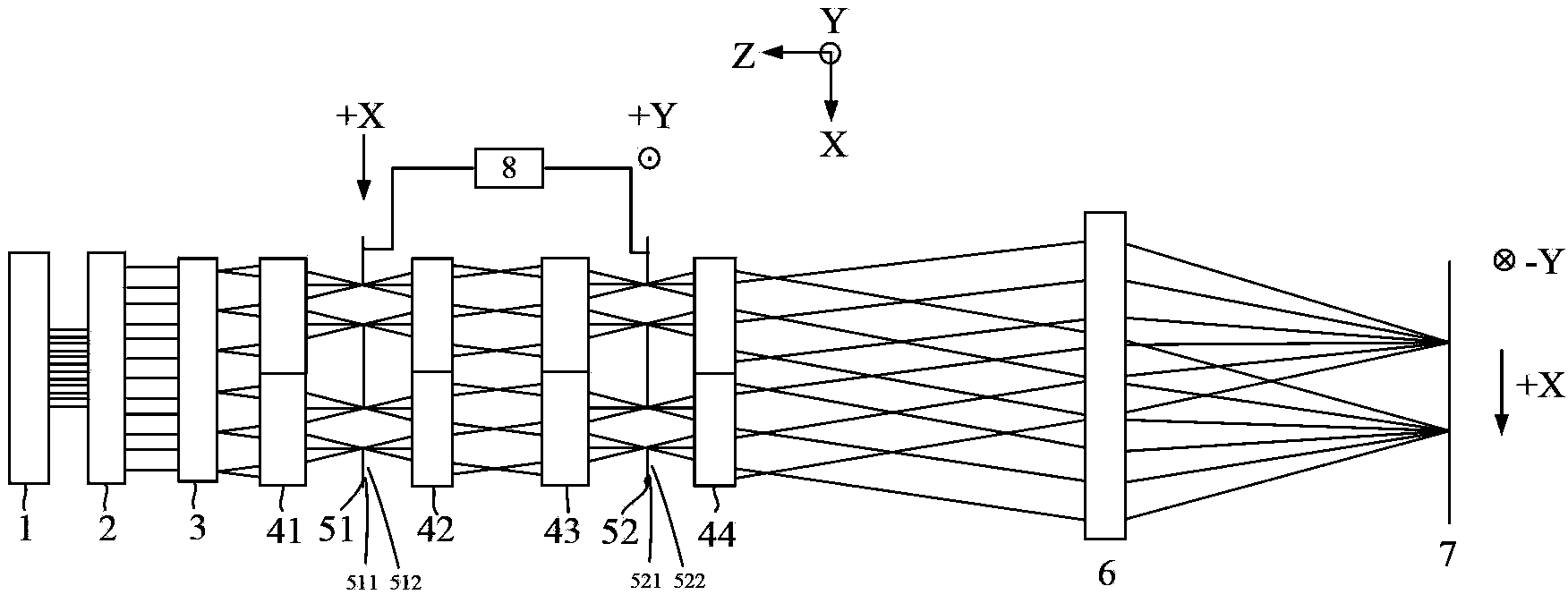

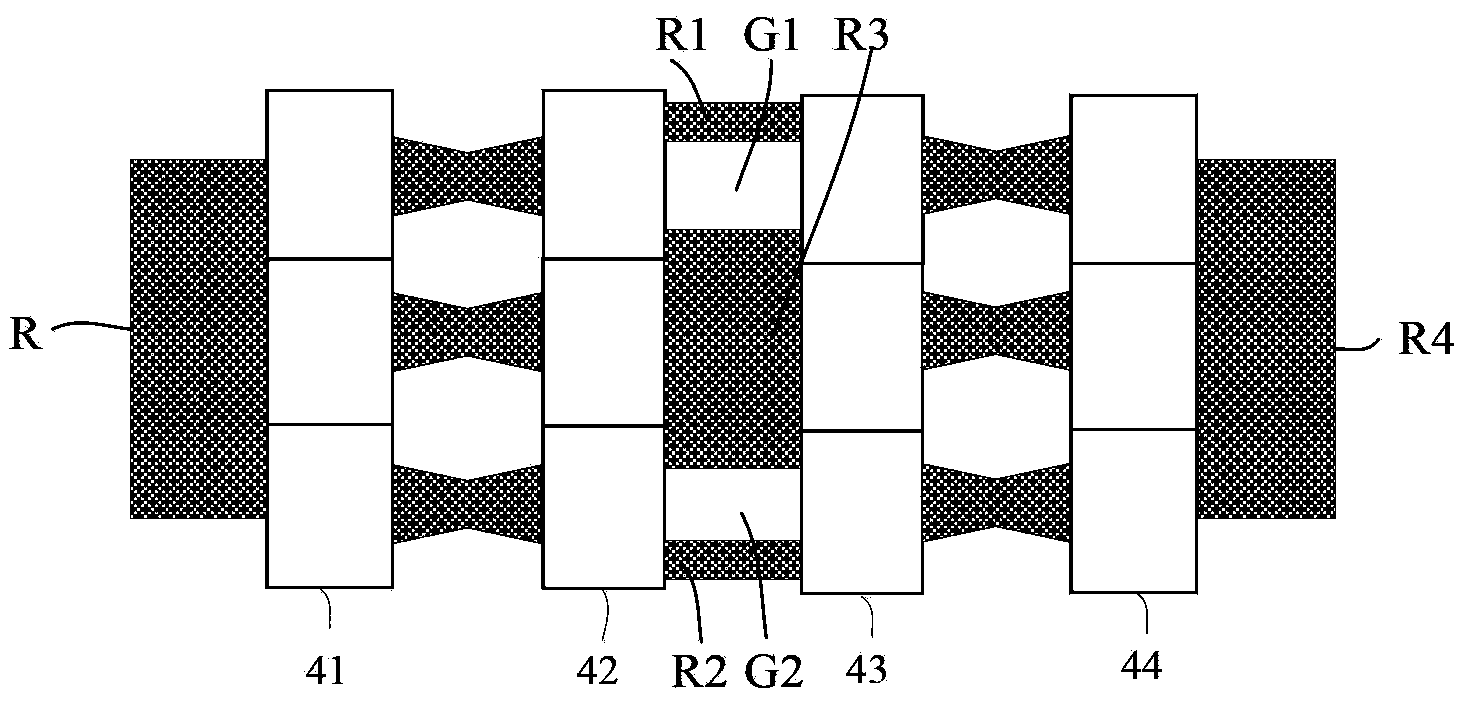

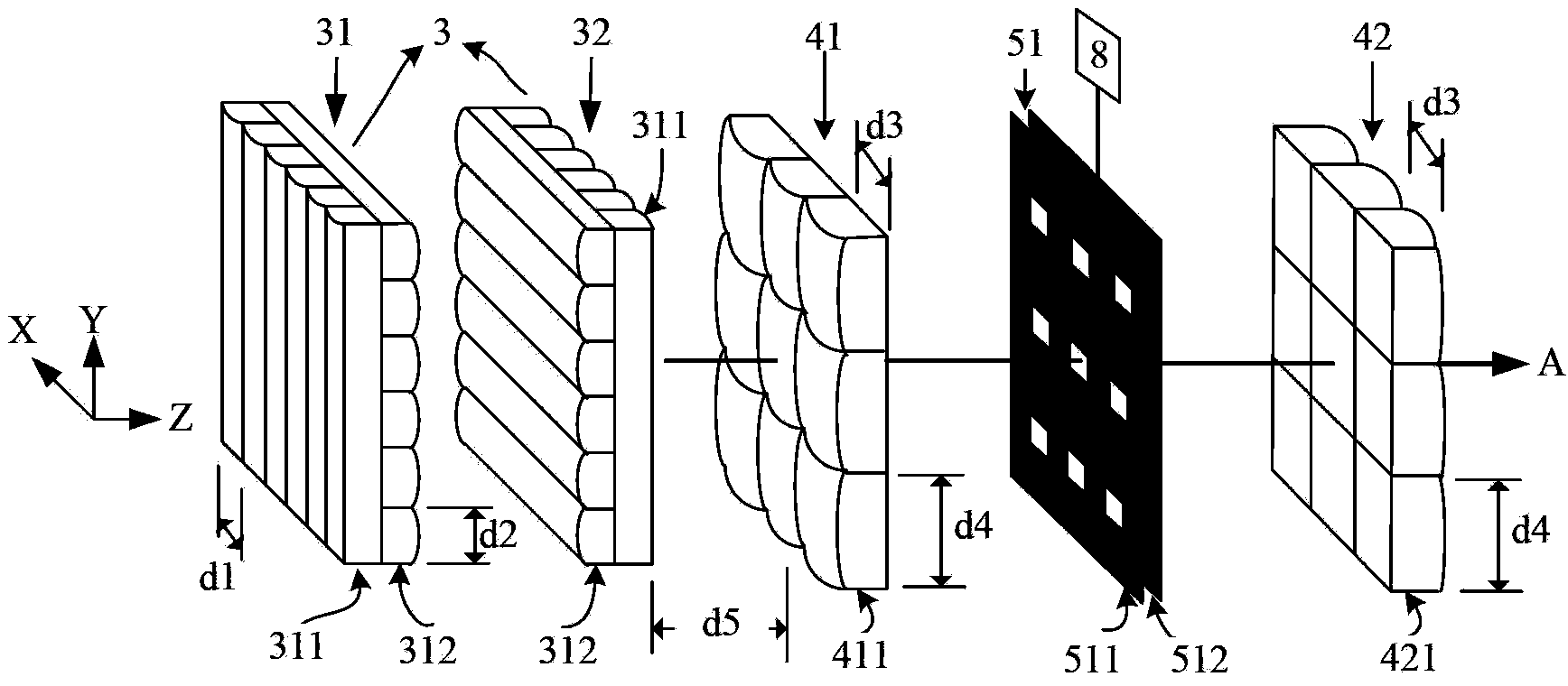

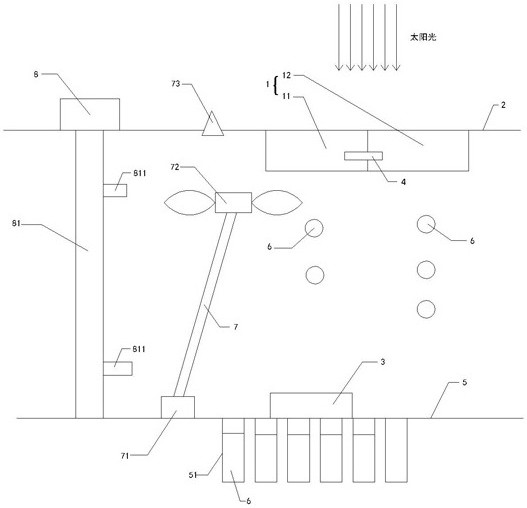

Illuminating system of step scanning projection mask aligner

ActiveCN103412465AImprove uniformityEasy to processPhotomechanical exposure apparatusMicrolithography exposure apparatusPupil shapeLight beam

The invention relates to an illuminating system of a step scanning projection mask aligner. Along the beam propagation direction, the illuminating system comprises a light source, a pupil shaping unit, a viewing field defining unit, a first lens array, a first slit array, a second lens array, a third lens array, a second slit array, a fourth lens array, a collecting lens and a scanning driving unit. According to the illuminating system, the requirements on lens processing, slit scanning speed and slit scanning precision are reduced and can be easily realized.

Owner:BEIJING GUOWANG OPTICAL TECH CO LTD

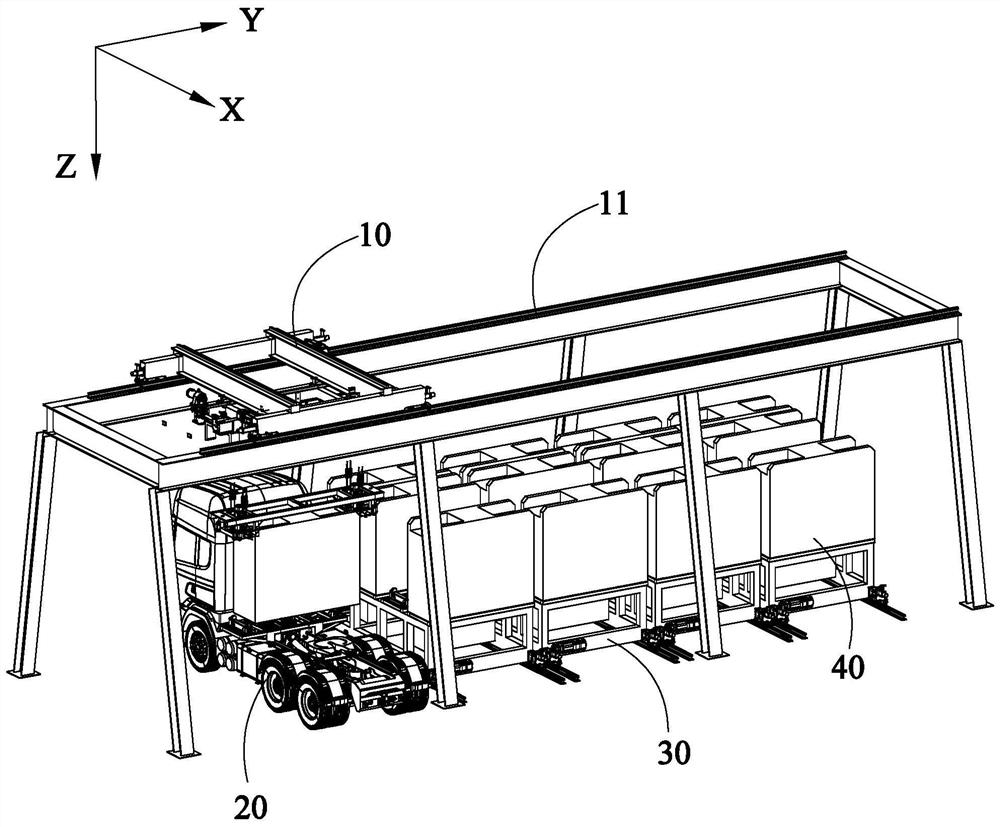

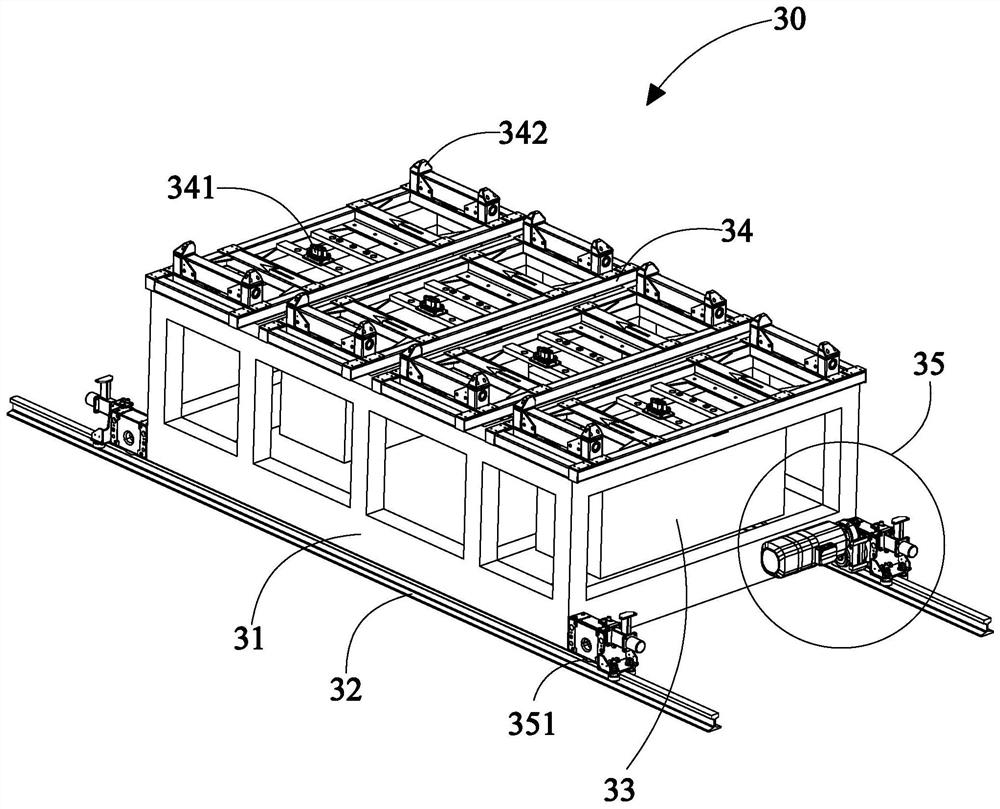

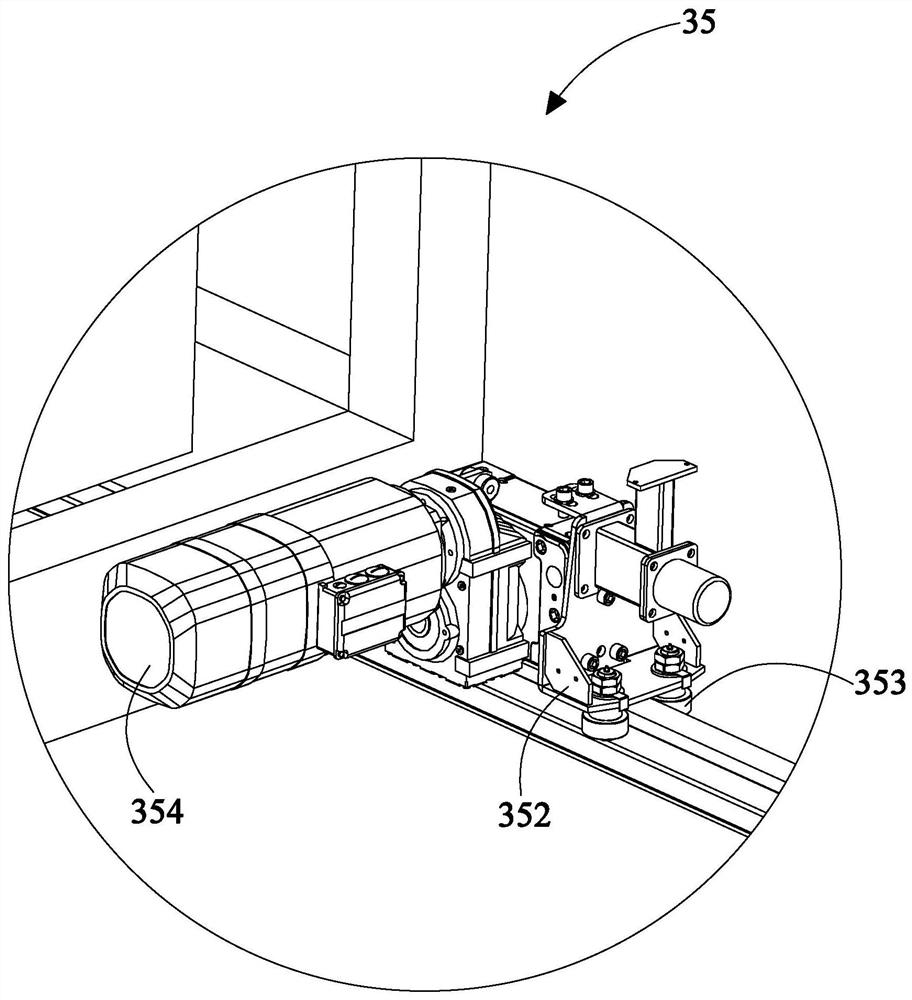

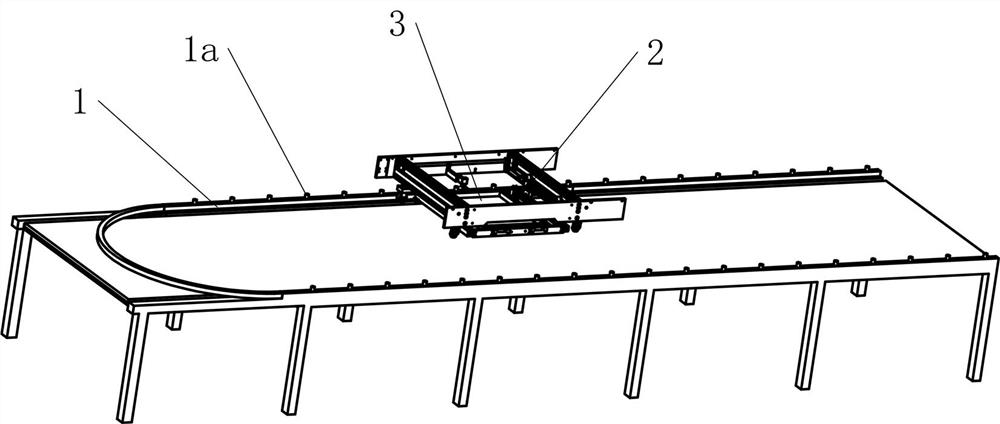

Charging system and method

InactiveCN112776656AShorten the travel distanceMove quicklyCharging stationsVehicular energy storageControl theoryMechanical engineering

The invention relates to a charging system and method. The system comprises a side moving platform which comprises a platform frame, wherein the platform frame is used for moving in a first direction, and is used for bearing a battery box and driving the whole battery box to move in the first direction; and the hoisting mechanism comprises a moving frame and a grabbing mechanism, the moving frame is movably arranged above the side moving platform in the second direction, and the grabbing mechanism is movably connected to the moving frame in the vertical direction and used for grabbing the battery box and moving along with the moving frame in the second direction so as to replace the battery box for a vehicle. According to the charging and battery replacing system, the target battery box is moved to the position below the grabbing mechanism to be grabbed through overall lateral movement of the platform frame where the target battery box of the lateral movement platform is located, other platform frames overall laterally move to form a moving channel for the target battery box, rapid movement of the target battery box is achieved, and therefore battery replacing efficiency can be improved.

Owner:SHENZHEN JINGZHI MACHINE

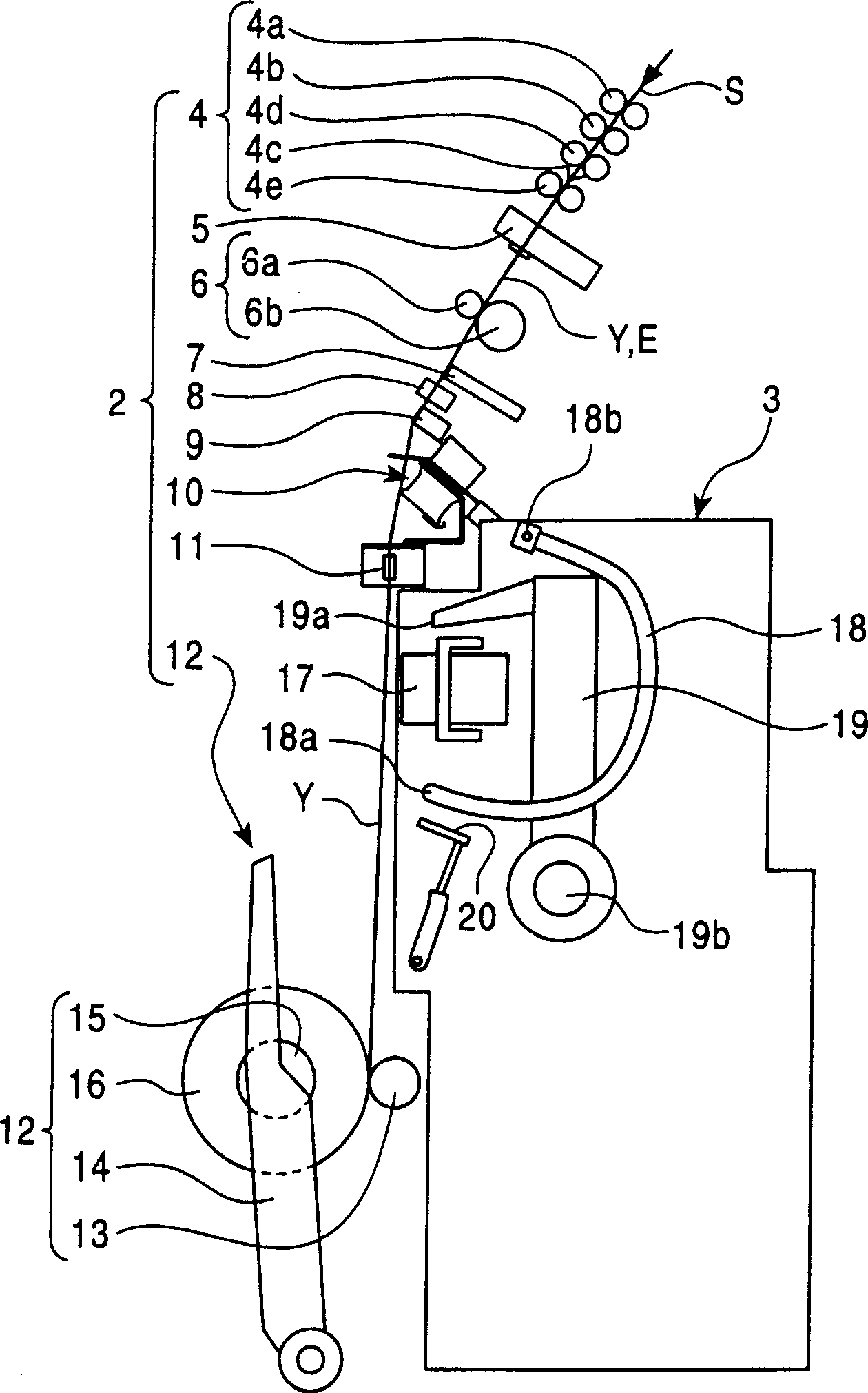

Coiling apparatus of yarn

InactiveCN1530309AReduce tensionEasy to controlPiercing arrangementsFilament handlingShortest distanceYarn tension

The present invention prevents a yarn from being excessively tensed and broken owing to an increase in yarn tension when the yarn is wound around a slack eliminating roller during a yarn splicing operation. A yarn threading member is arranged at a position where it can engage with a yarn on the shortest yarn path between an upstream side guide and a downstream side guide arranged upstream and downstream, respectively, of a slack eliminating roller. The upstream side guide constitutes yarn moving means for moving the yarn from the shortest yarn path to a yarn path on which the yarn does not engage with the yarn threading member. If a yarn splicing operation is to be performed, then before the start of the operation, the yarn moving means holds the yarn away from the yarn path corresponding to the shortest distance and at a position at which the yarn does not engage with the yarn threading member. Then, immediately before the yarn splicing operation, the yarn is moved to the position of the yarn path corresponding to the shortest distance and is then engaged with the yarn threading member. Accordingly, the direction of the operation of engaging the yarn with the yarn threading member does not involve an increase in yarn tension. Therefore, the yarn can be reliably prevented from being excessively tensed and broken.

Owner:MURATA MASCH LTD

Detection machine

PendingCN112284315AImprove detection efficiencyHigh degree of automationUsing optical meansConveyor partsComputer hardwareEngineering

The invention discloses a detection machine. The detection machine comprises a feeding device, a conveying device, a steering device, a height detection device and a visual detection device, wherein the feeding device and the conveying device are arranged in parallel at intervals, the steering device is arranged between the feeding device and the conveying device, and the height detection device and the visual detection device are erected above the conveying device and sequentially arranged in the conveying direction of the conveying device. The feeding device is used for transferring a filterto the steering device, the steering device can clamp the filter and rotate the filter by a certain angle, so that the end, provided with a PIN, of the filter is rotated to be placed upwards, and theconveying device is used for conveying the filter with the PIN facing upwards at the steering device. The height detection device is used for detecting the assembling height of the PIN of the warp-passing filter, and the visual detection device is used for detecting the assembling position of the PIN of the warp-passing filter. The machine is high in automation degree, and can realize automatic line production for detecting the assembly of the PIN of the magnetic core in the filter.

Owner:DONGGUAN WORLD PRECISION MACHINERY

Imaging device, SMA driving equipment, manufacturing method of SMA driving equipment and driving method of SMA driving equipment

PendingCN111629125AQuick responseMaximum stroke halvedTelevision system detailsColor television detailsControl engineeringDriving mode

The invention provides a camera device, SMA driving equipment, a manufacturing method of the SMA driving equipment and a driving method of the SMA driving equipment. The camera device comprises at least one circuit board, a photosensitive chip, at least one lens, a lens base and at least one SMA driving equipment. The SMA driving equipment further comprises a lens carrier, at least one uplink driver and at least one downlink driver. The lens carrier is connected to the uplink driver in a driving manner. The uplink driver supports the lens carrier upwards in a thermal driving manner, and lifting the lens carrier to move upwards, wherein the lens carrier is drivingly connected to the downlink driver, wherein the downlink driver pulls the lens carrier downwards in a thermal driving mode and pulls the lens carrier to move downwards, the lens is arranged on the lens carrier of the SMA driving equipment, and the SMA driving equipment drives the lens to move up and down.

Owner:NINGBO SUNNY OPOTECH CO LTD

Ocean system carbon neutralization method

InactiveCN114041414AAvoid switchingShorten the travel distanceBioreactor/fermenter combinationsBiological substance pretreatmentsSeaweed farmingEnvironmental engineering

The invention discloses an ocean system carbon neutralization method. A seaweed culture area is arranged on the sea surface; a burying robot and a capturing robot are arranged in the ocean; the capturing robot captures seaweeds in the seaweed culture area and then throws the captured seaweeds to the seabed; the burying robot is used for burying the seaweeds thrown by the capturing robot below the seabed at the seabed, so that the seaweeds are in an anoxic environment. Seaweed cultivation is carried out in the seaweed culture area, light above the sea surface permeates seawater to irradiate the seaweeds, so that water-soluble carbon dioxide is converted into organic matters by the seaweeds to grow and proliferate, inorganic carbon is transferred into the seaweeds from the seawater and exists in the form of organic carbon, and thus carbon in the sea is enriched to the seaweed culture area. The capturing robot captures and collects the seaweed in the seaweed culture area and puts the seaweed into the seabed, the burying robot buries the seaweed, organic carbon in the seaweed is transferred to the position below the seabed, and therefore the carbon in the seaweed is separated from ocean carbon circulation, and the purpose of carbon neutralization is achieved.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

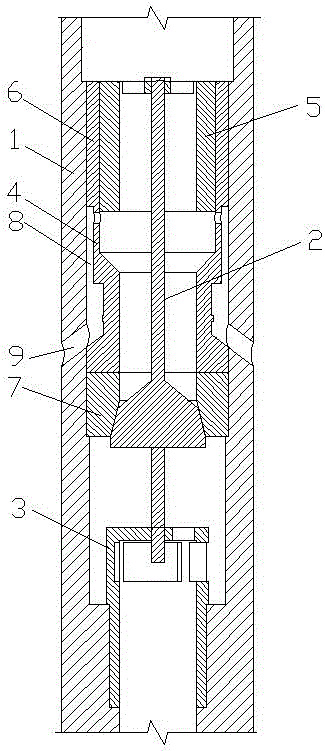

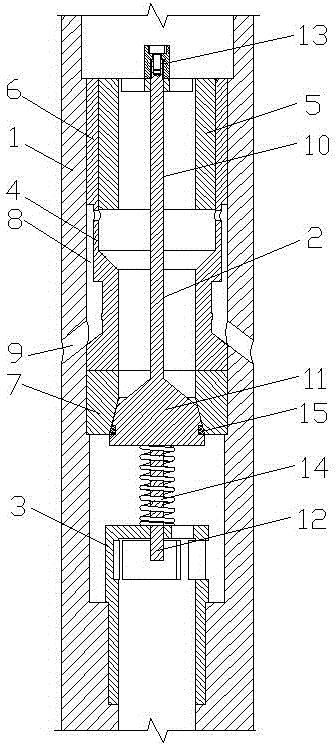

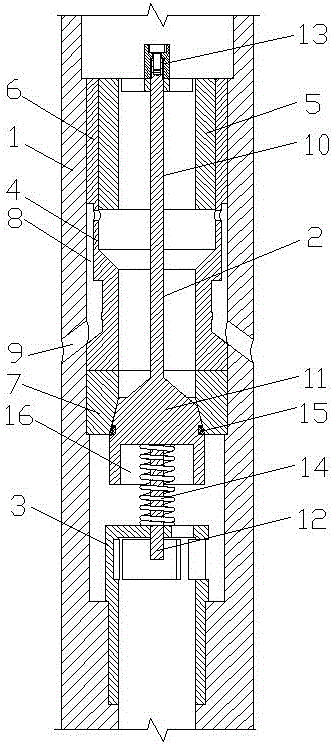

Backpressure valve capable of achieving automatic slurry injecting

The invention discloses a backpressure valve capable of achieving automatic slurry injecting, and belongs to the technical field of drilling equipment. The backpressure valve comprises a valve body, a valve element and a support base and a valve base which are arranged in the valve body, wherein the support base is located under the valve base. The backpressure valve is characterized in that a piston is arranged in the valve body and arranged on the valve element in a sleeving mode, the valve base comprises an upper valve base body and a lower valve base body, the upper valve base body is located between the piston and the valve body, a slurry reflux tank hole is formed in the upper valve base body and communicated with an inner cavity of the valve body, and a slurry reflux hole is formed in the valve body and communicated with the slurry reflux tank hole. According to the backpressure valve, due to the fact that slurry in a well can be automatically injected into a drill pipe and does not need to be injected into the drill pipe by connecting a slurry injection device to the drill pipe whenever a part of the drill pipe is put down, the work amount is greatly decreased, the slurry injecting cost is effectively reduced, the condition that the slurry in the well is reversely sprayed into the drill pipe through an inner cavity of the valve body is effectively prevented, and then well drilling safety is guaranteed.

Owner:CHENGDU ZHUOXIN IND

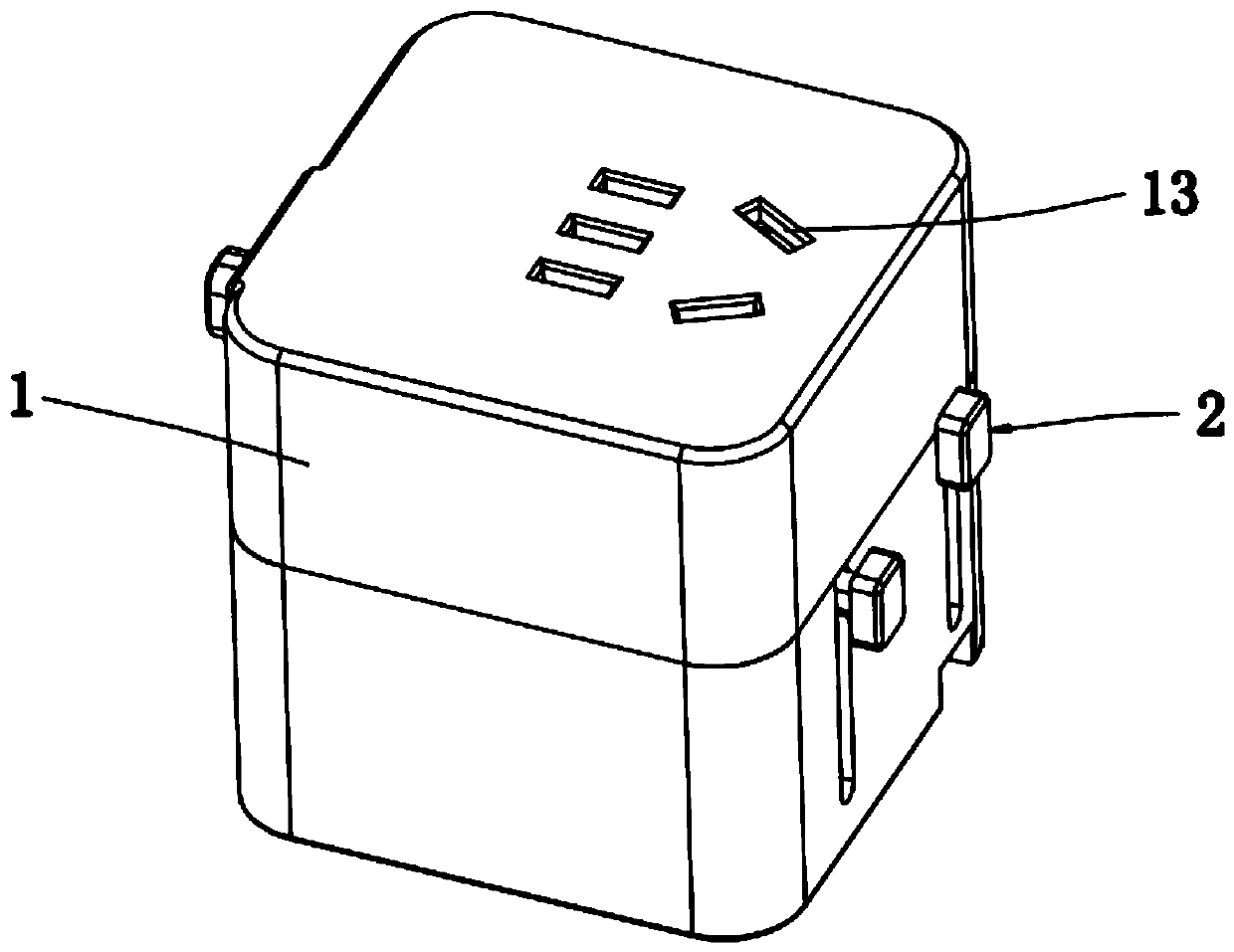

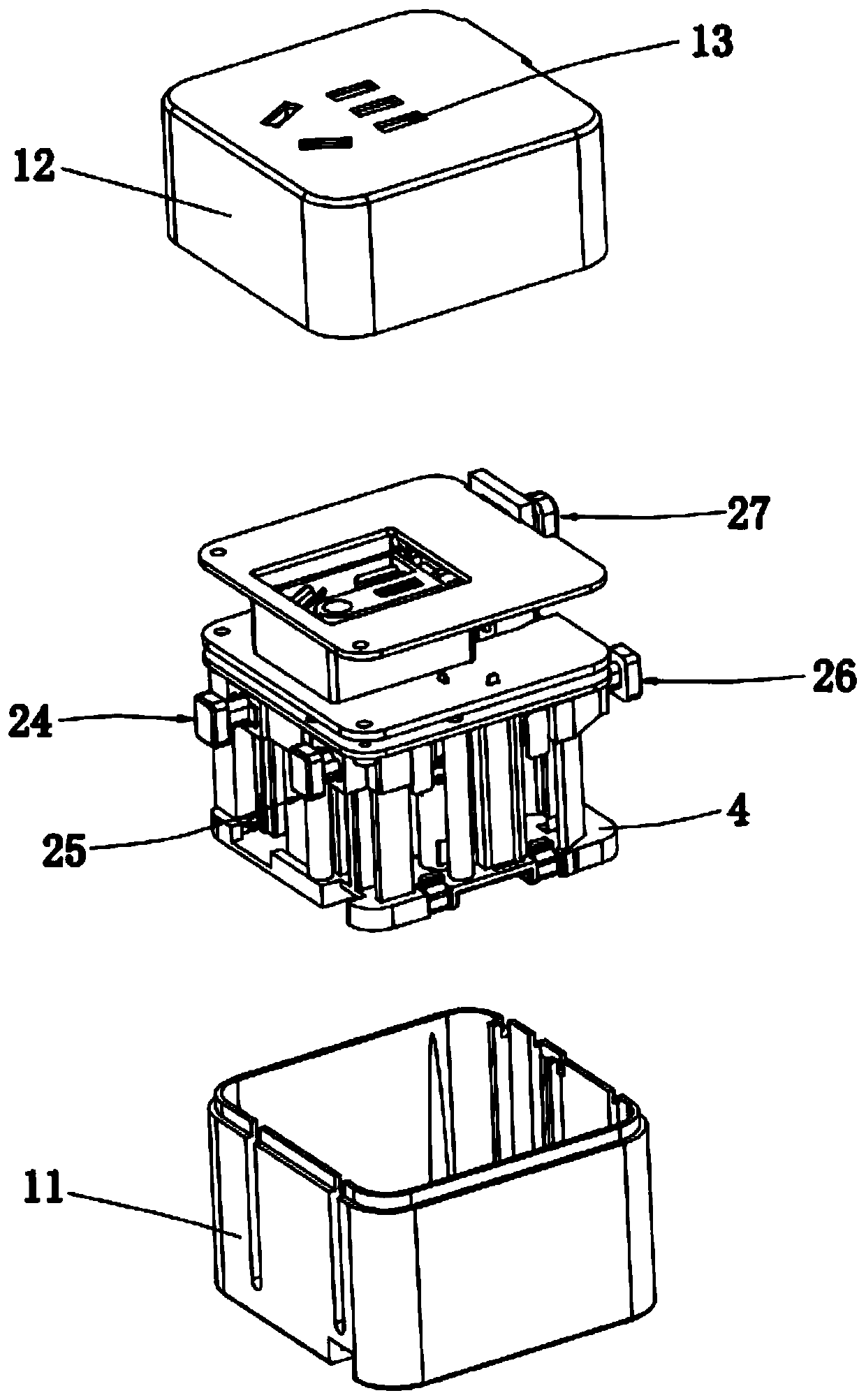

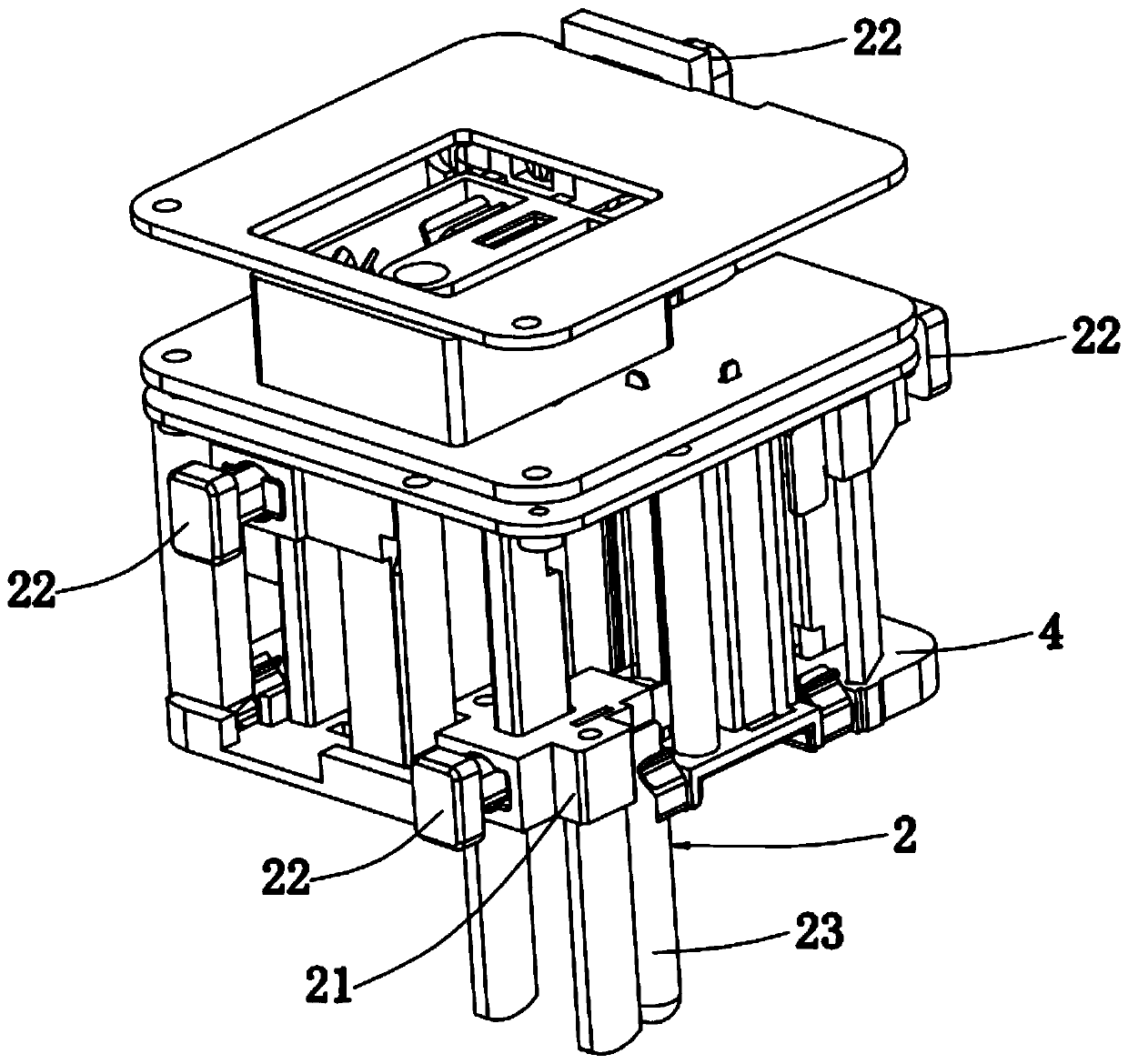

Multinational converter

PendingCN110190454AImprove securityShorten the travel distanceCoupling device detailsSelf lockingElectric shock

The invention is suitable for the field of converters, and provides a multinational converter. The multinational converter comprises: a shell; a plurality of bolt components which can stretch in the up-and-down direction of the shell and can be accommodated in the shell or extend out relative to the shell; and a plurality of self-locking plates arranged in the shell in the telescopic direction ofthe bolt components, wherein the self-locking plates are arranged adjacent to each other and can move in the left and right direction of the shell, when one of the bolt components extends out relativeto the shell, the bolt component pushes the corresponding self-locking plate to move so as to keep off the bolt component, and the bolt component simultaneously drives the rest of the self-locking plates to move so that the rest of self-locking plates respectively resist the extension of the rest bolt components relative to the shell. According to the multinational converter, the plurality of self-locking plates are arranged, when one of the bolt components is used, the bolt component can drive the other self-locking plates to move and block the other bolt components, so that potential safetyhazards of electric shock of a user due to the fact that the other bolt components extend out of the shell are avoided, and the multinational converter is good in safety performance.

Owner:BULL GRP CO LTD

Metal product stacker

InactiveCN102815541AShorten the travel distanceShorten the timeStacking articlesEngineeringClosest relatives

A metal product stacker, comprises: a table having a drive device which is connected to a first end of a swing arm, and the drive device drives the swing arm to rotate at an angle and reset; and a gripping device having a fixing member, the fixing member is provided on a second end of the swing arm. A lift member is liftablely provided below the fixing member. A rotary member is rotatably disposed below the lift member, and the rotary member has two grip members which can open and close relative to each other. The metal product stacker of the present invention, the drive device drives the swing arm to rotate at an angle, enabling the second end of the gripping device to repeatedly move, and thus shortening the moving distance of the gripping device, reducing the time consumed by the moving distance of the gripping device, and improving stacking efficiency.

Owner:TAI WEI MACHINE

Screen frame positioning system suitable for treadmill printing machine

PendingCN112937087AReduce noiseImprove stabilityScreen printersTextile printerMechanical engineering

The invention aims to provide a screen frame positioning system suitable for a treadmill printing machine, on the basis that an internal program controls the main walking process of the printing machine, a positioning structure enabling a printing screen frame to abut against and be attached to a positioning column located on a guide rail is arranged, and accurate positioning of the printing screen frame is achieved; an identification or induction detection device does not need to be added, so that the manufacturing cost is lowered; according to the positioning system, positioning of the printing screen frame is more stable and reliable, and the situation that when the position of the screen frame is controlled only through an internal program, the printing quality of a product is reduced due to introduction of external interference factors or continuously accumulated errors is effectively avoided; and meanwhile, collision impact generated by the positioning mode can be effectively relieved through a vibration reduction reset spring arranged in the system, and the working stability and durability of equipment are improved.

Owner:浙江彩诺数码科技有限公司

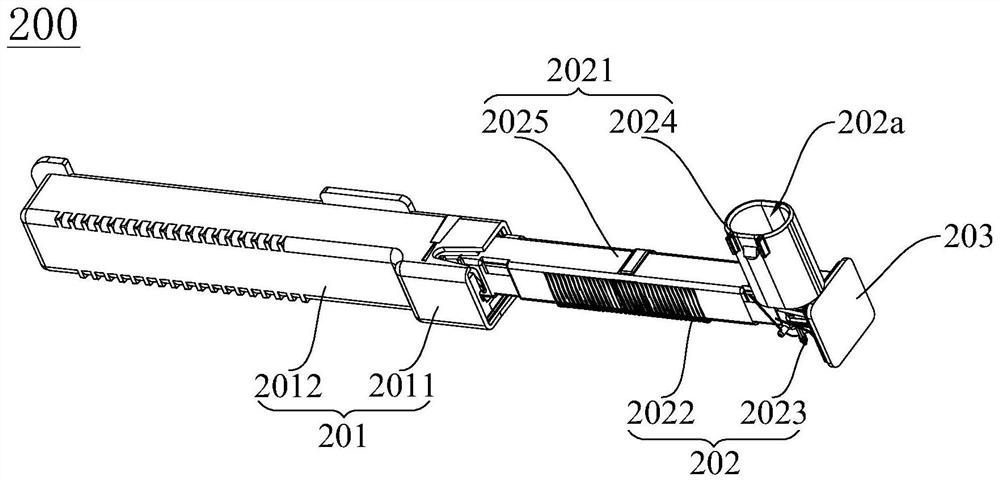

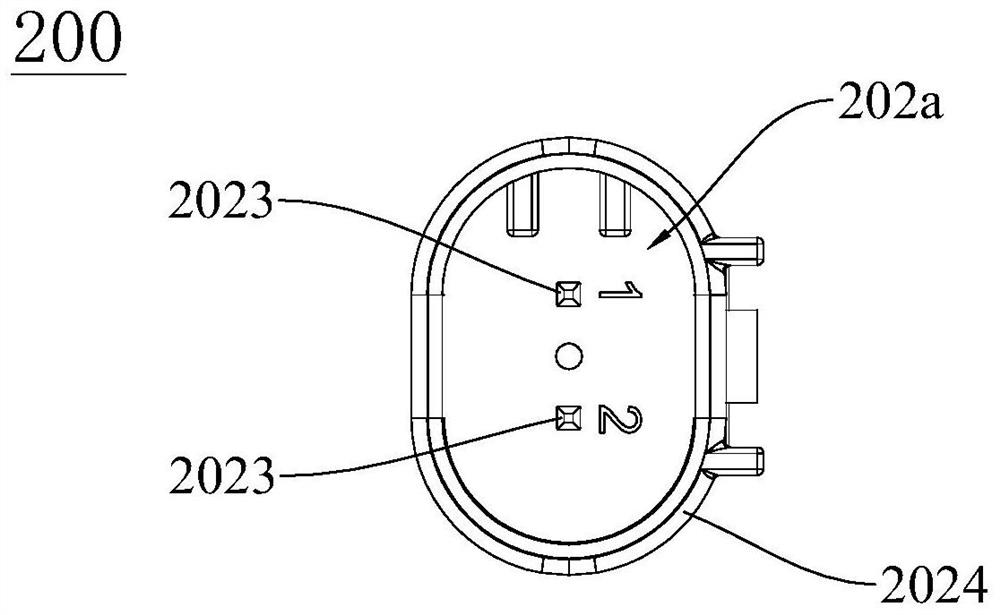

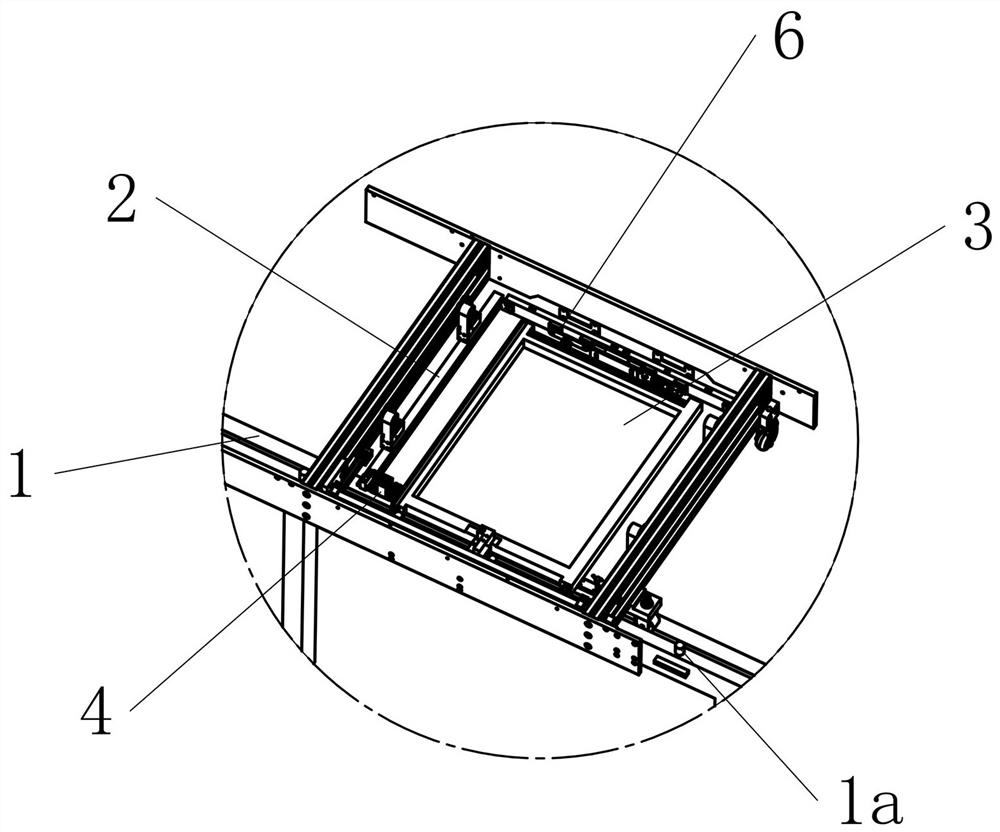

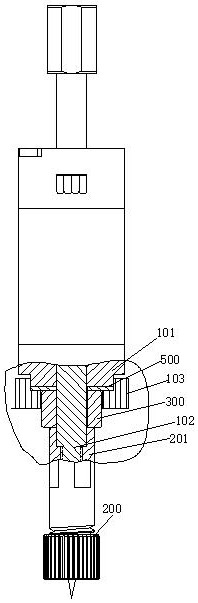

A kind of solid crystal method and crystal solid machine

ActiveCN113571429BShorten the travel distanceFast handlingPrinted circuit assemblingSolid-state devicesEngineeringWafer bonding

The invention provides a crystal bonding method and a crystal bonding machine. The crystal bonding method includes: a crystal extraction step: controlling the swing arm to swing to the crystal extraction position, pushing the wafer on the blue film onto the swing arm suction nozzle through a thimble, Then the swing arm swings to the transfer position; movement control step: control the linear movement of the linear die bonding head to the transfer position; transfer step: when both the swing arm suction nozzle and the linear die bonding head are at the transfer position, control the die bonding The nozzle picks up the wafer on the suction nozzle of the swing arm; the die bonding step: firstly control the linear die bonding head to move to the die bonding position in a straight line, and then control the die bonding nozzle of the linear die bonding head to bond the die to the circuit board. The beneficial effects of the present invention are: the present invention makes a relay on the crystal element at the transfer position through the swing arm suction nozzle and the linear die bonding head, shortens the moving stroke of the linear die bonding head, and adopts the die bonding method and die bonding method of the present invention The crystal machine can not only fix larger circuit boards, but also greatly improve the handling speed of wafers, resulting in higher efficiency.

Owner:SHEN ZHEN TALUER TECH CO LTD

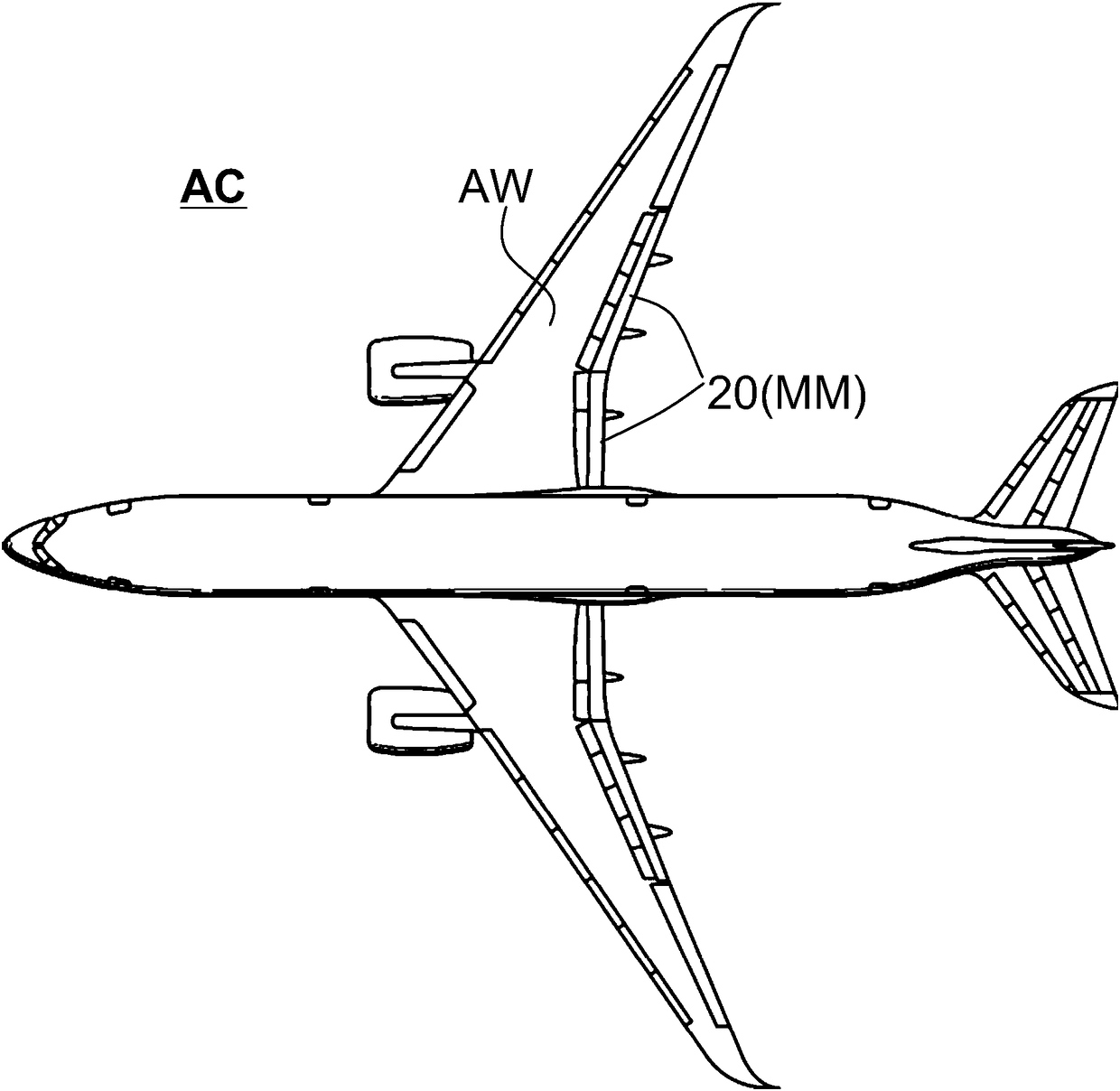

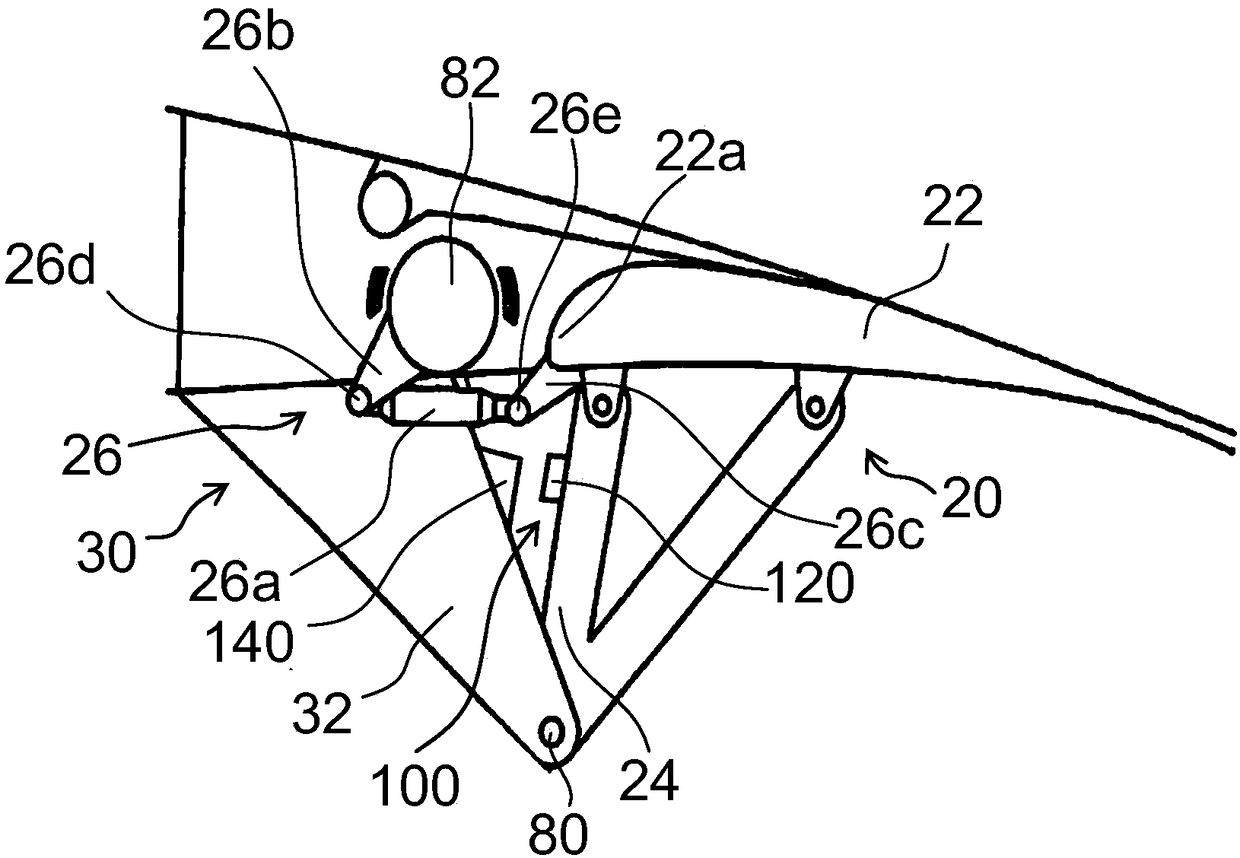

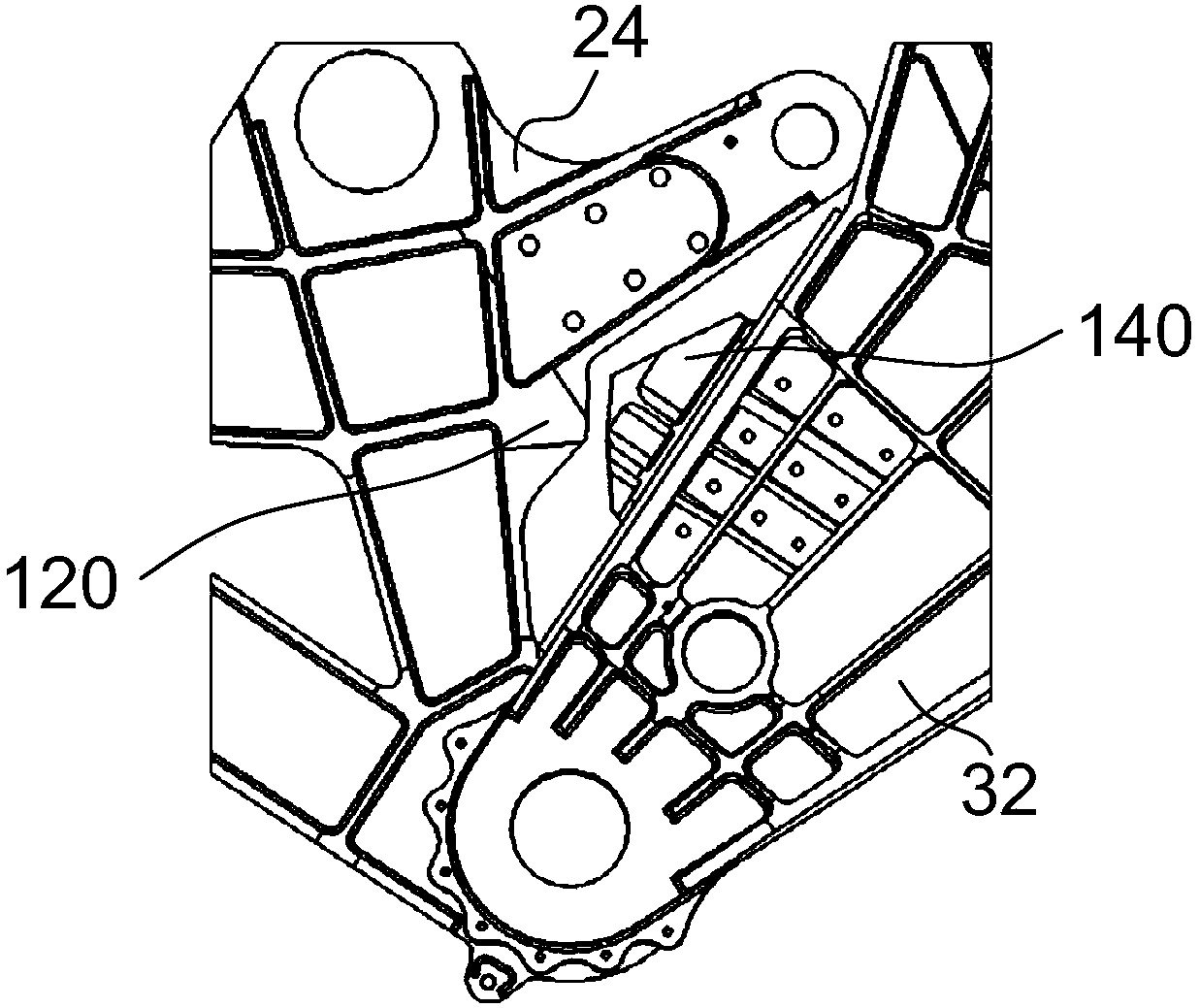

Detent device, moving mechanism and aircraft

PendingCN108082505AWell formedSimply and reliably formSpringsAircraft stabilisationRange of motionDetent

Owner:AIRBUS BEIJING ENG CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com