Coiling apparatus of yarn

A yarn winding machine and yarn technology, which is applied in spinning machines, textiles and papermaking, and conveying filamentous materials, etc., can solve problems such as excessive tension and disconnection of yarns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

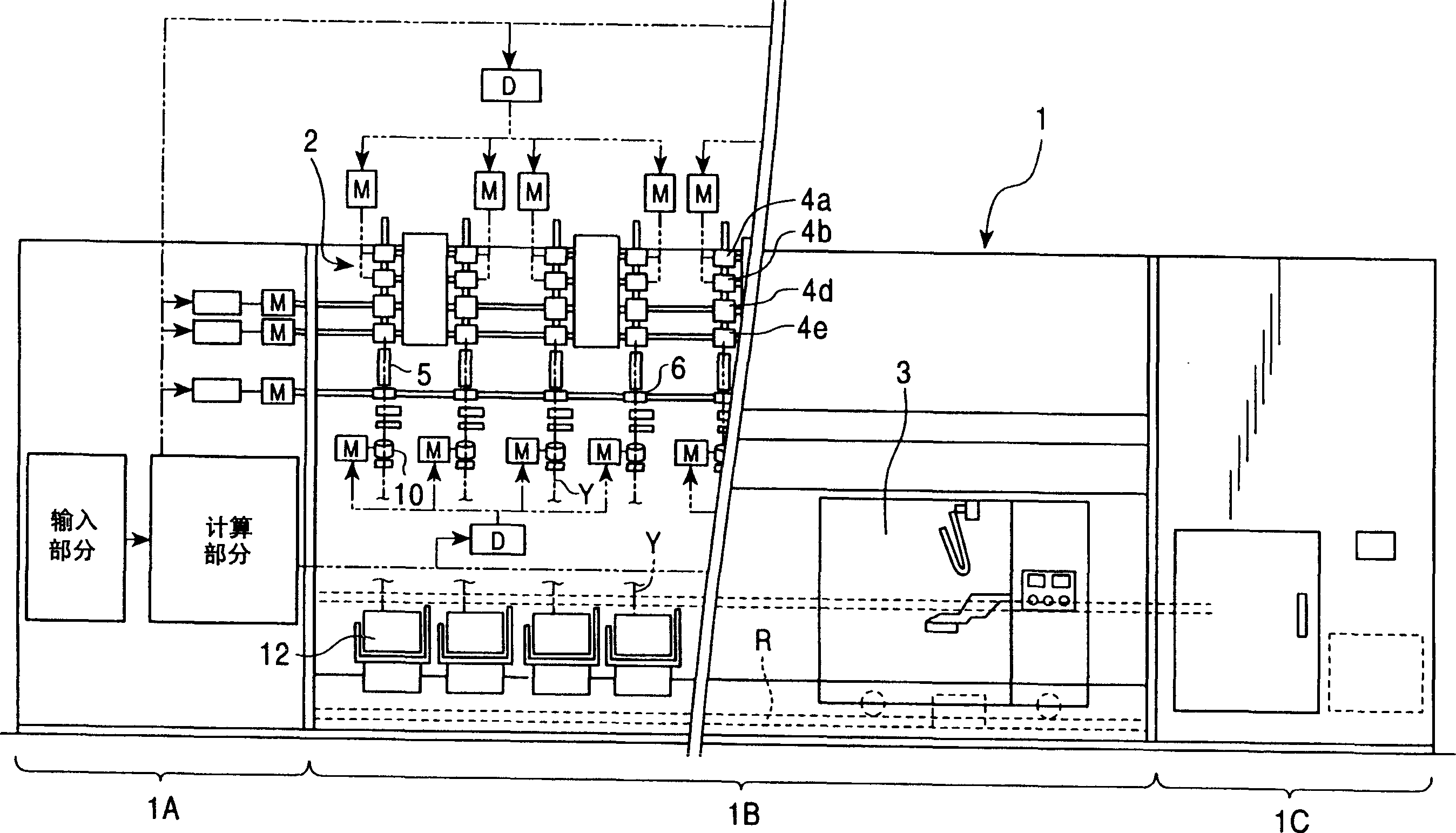

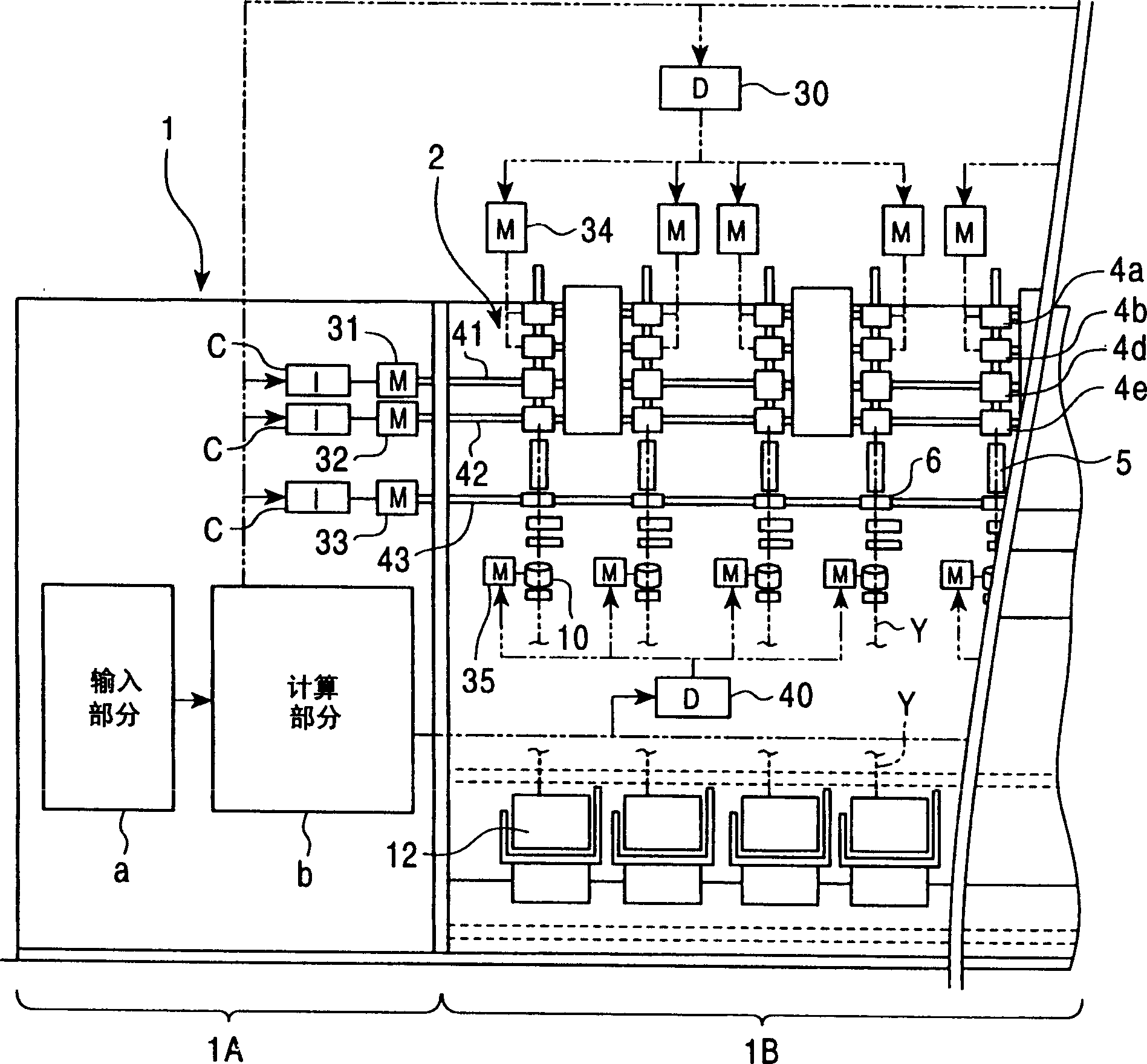

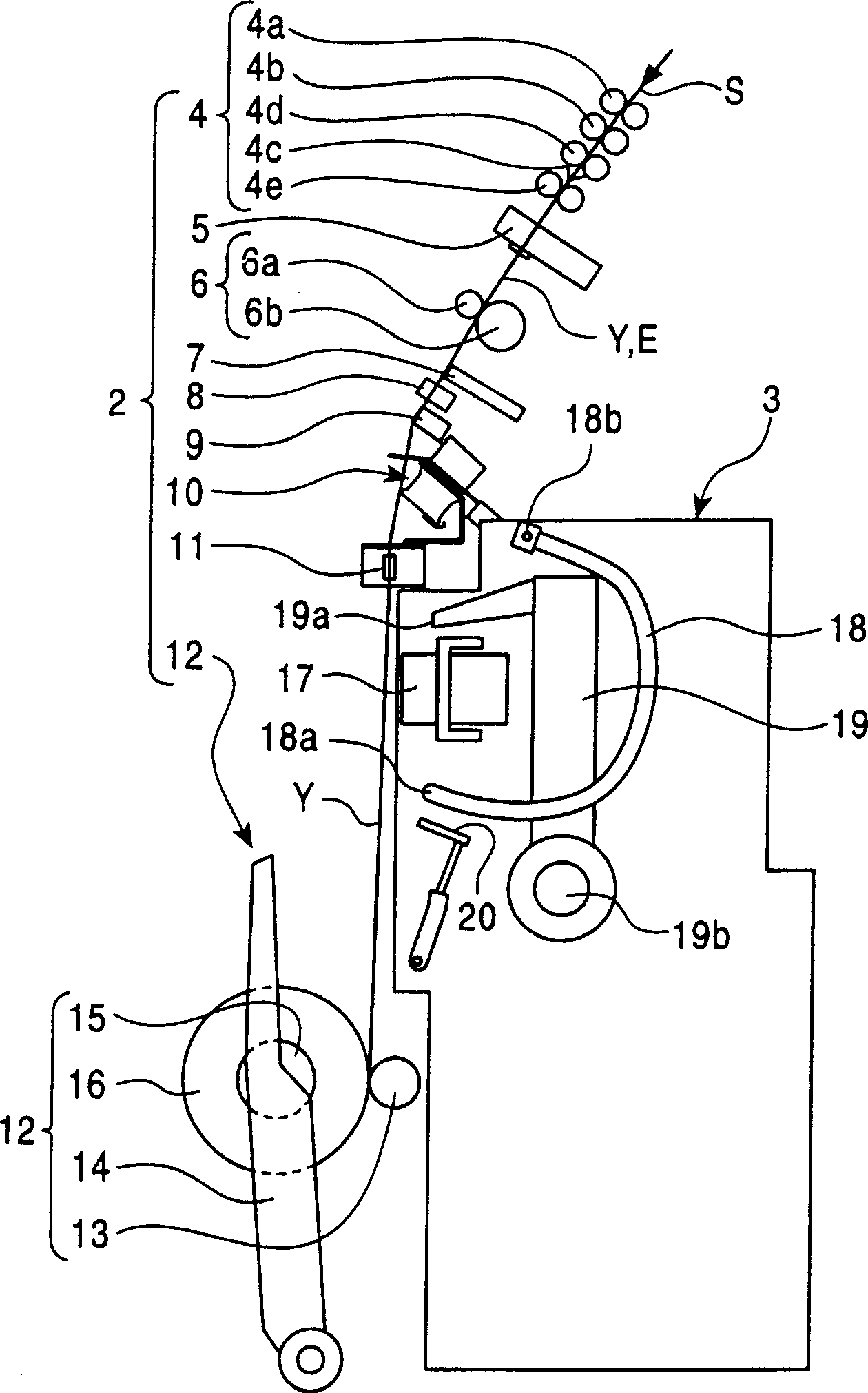

[0040] figure 1 It is a front view of an example of the spinning machine 1 used in the present invention. figure 2 is an enlarged view schematically showing a part of the internal structure of the spinning machine 1 . The spinning machine 1 is constituted by, for example, an air spinning machine. The main components of the spinning machine 1 include a control section 1A, a spinning section 1B in which a large number of spinning units 2 are arranged in line, a blower section 1C, and a work cart 3 including a yarn Splicing device (yarn splicing device), and is suitable for running freely along the track R between the spinning units 2.

[0041] The control section 1A controls the operation of the drive motors 31, 32, 33 for the drive shafts 41, 42, 43, the operation of the motors 34, 35 for the respective spinning units 2, the operation of the winding device 12, etc., among which The driving shafts 41, 42, 43 apply a driving force to all the spinning units 2 constituting the ...

no. 2 example

[0079] In the yarn slack eliminating device 10 according to the present invention, the upstream side yarn guide member 23 of the slack eliminating roller 21 may be fixed, and the downstream side yarn guide member 36 may be movable, such as Figure 19 shown. However, in view of the aforementioned configuration in which the upstream-side yarn guide member 23 is closer to the yarn defect detector 9 than the downstream-side yarn guide member 23, if it is satisfied that the yarn Y is removed from the yarn defect detector 9 just before the slack is eliminated condition, the upstream side yarn guide member 23 is preferably pushed forward to bend the yarn Y in the process of removing the yarn from the yarn defect detector 9 . This operation reduces the movement stroke compared to the operation in which the downstream-side yarn guide member 36 is reciprocated, and can prevent the member from protruding excessively.

[0080] However, instead of the operation of the yarn defect detector...

no. 3 example

[0082] Embodiments of the present invention are not limited to the above aspects. In the above description, the present invention is applied to a spinning machine having a plurality of spinning units. However, the present invention is also applicable to single-spindle type spinning machines. In the first embodiment described above, the yarn splicing device 17 is mounted on the work trolley 3 and this single yarn splicing device 17 performs the yarn splicing operation on all the spinning units 2 . However, a configuration in which the yarn splicing device 17 is provided for each spinning unit 2 may also be employed. In this case, the work cart 3 can be omitted. On the contrary, the yarn slack eliminating device 10 may be installed on the work cart 3 so that the single yarn slack eliminating device 10 can perform the yarn slack eliminating operation on all the spinning units. Also, in the examples described above, the present invention is used in a spinning machine designed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com