Mop wiping object water-squeezing device and mop cleaning bucket

The technology of mop cleaning bucket and water squeezing device is applied in the field of mop, mop wiper squeezing device and mop cleaning bucket, which can solve the problems of large volume and high manufacturing cost, shorten the moving stroke, improve the service life, and ensure the water squeezing. The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

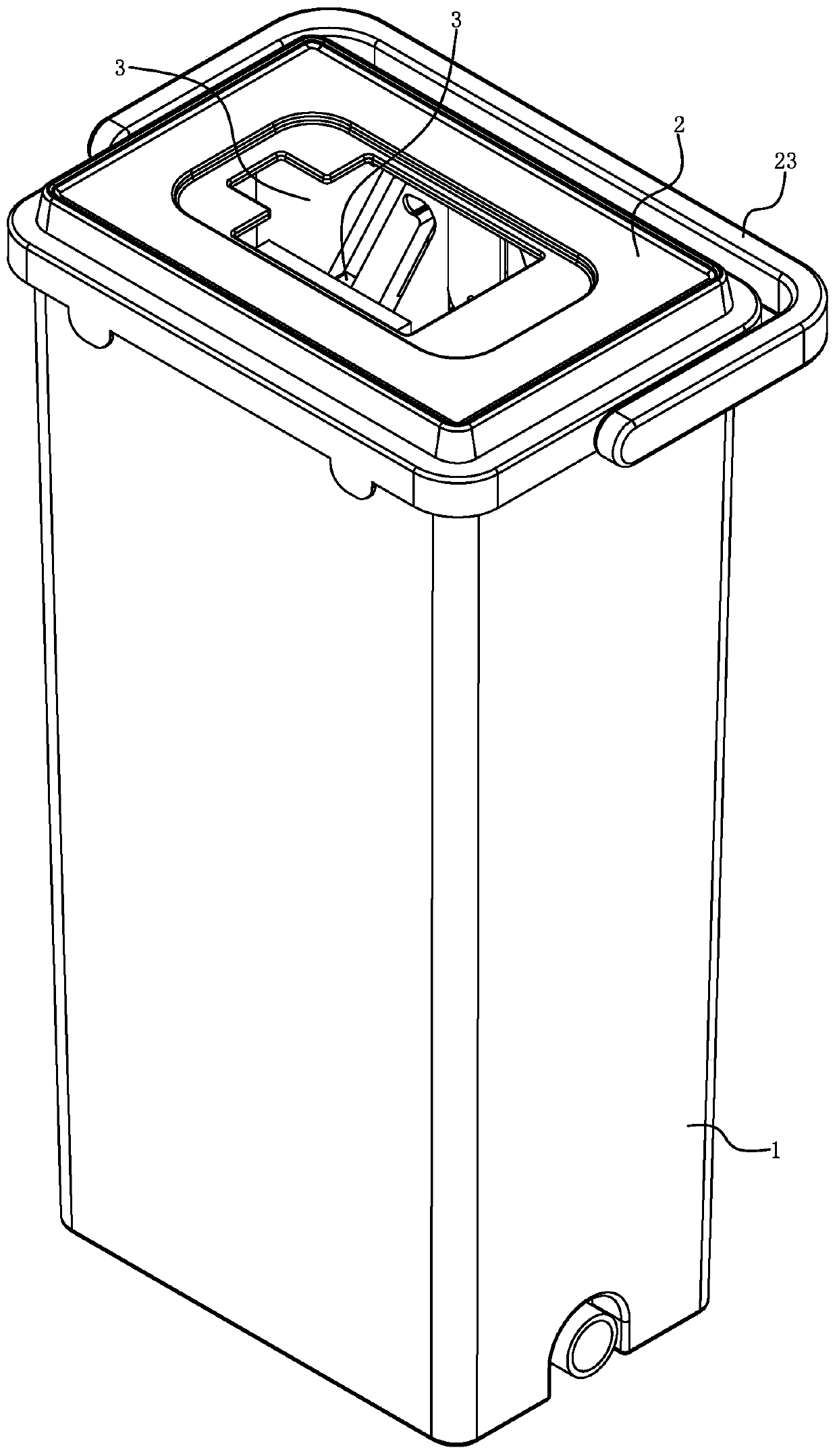

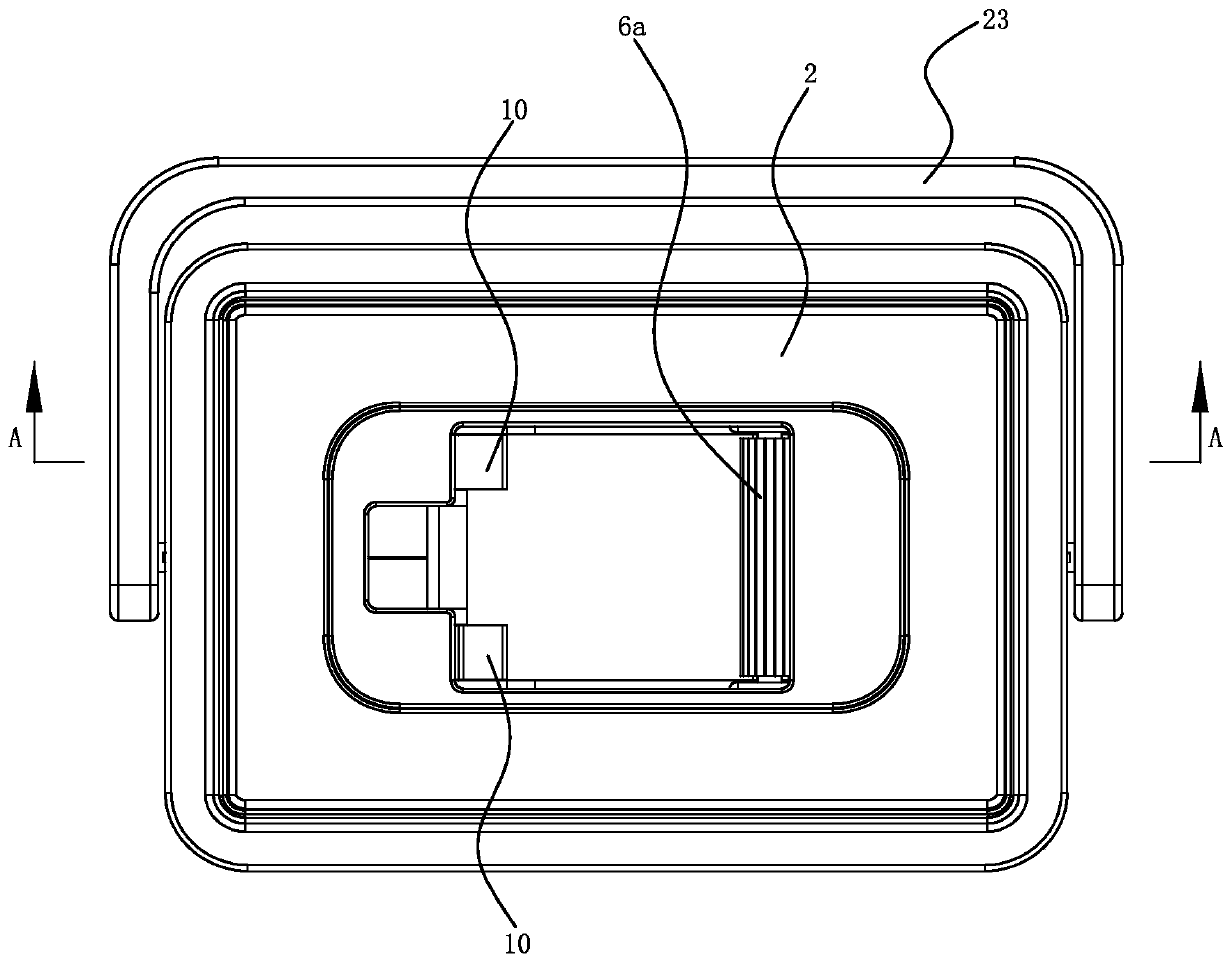

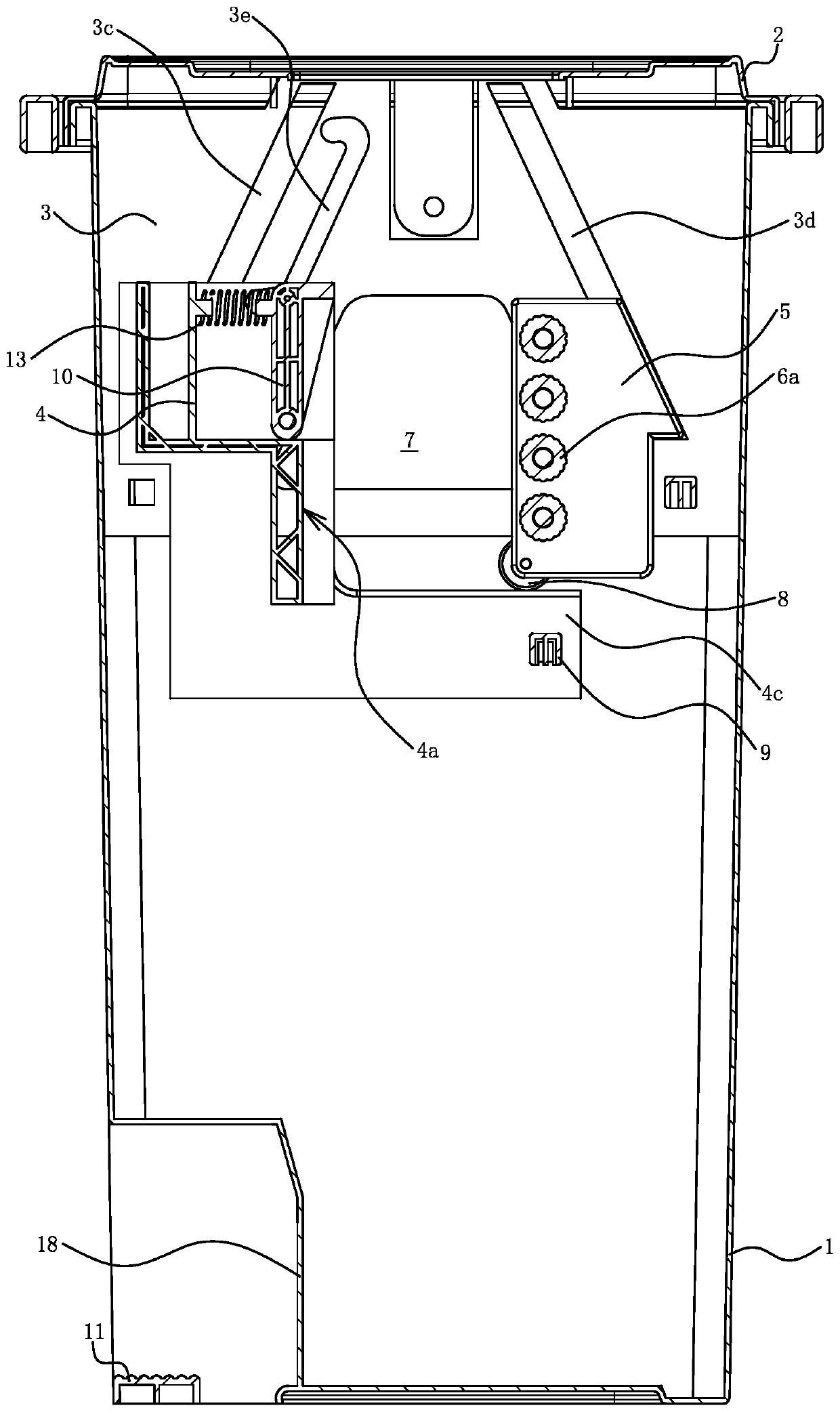

[0033] Embodiment one: if Figure 1 to Figure 11 As shown, the mop cleaning bucket includes a bucket body 1, a bucket cover 2 and a water squeezing device for mop wipes.

[0034] Such as Figure 4 As shown, the mop wiper water squeezing device includes a bracket 3, a second slider 5 and a first slider 4 with a relying surface 4a, and the second slider 5 is installed with a support that is opposite to the relying surface 4a of the first slider 4. There is a water squeezing work area 7 where the mop cleaning head 14 can be placed between the water squeezing piece and the relying surface 4 a of the first slider 4 .

[0035] The water squeezing device for mop wipes is located in the bucket body 1. The bracket 3 includes two side plates 3a and one or more first support rods 3b. The two side plates 3a are arranged in parallel, and the first support rods 3b are located on the two side plates. 3a, the two ends of the first support rod 3b are respectively inserted into the two side p...

Embodiment 2

[0052] Embodiment 2: The structure and principle of this embodiment are basically the same as those of Embodiment 1. The basic similarities will not be described redundantly, and only the differences will be described. The differences lie in: between the second slider 5 and the bracket 3 A second spring is provided, under the elastic force of the second spring, the second sliding block 5 can be automatically inclined and slide downward to realize automatic reset.

Embodiment 3

[0053] Embodiment 3: The structure and principle of this embodiment are basically the same as those of Embodiment 1 and Embodiment 2. The basic similarities will not be redundantly described, and only the differences will be described. The difference lies in: the mop wiper squeezing device The bracket 3 can be directly installed on the wall, or on the mop bar 15 of the mop in which the bracket 3 of the mop wiper water squeezing device is installed, the mop wiper water squeezing device can slide axially relative to the mop bar 15, so the first sliding The moving direction of the block 4 and the second sliding block 5 relative to the horizontal plane is not necessarily inclined upward, but will be changed adaptively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com