Detection machine

A technology of inspection machine and visual inspection device, which is applied in the field of inspection machines, can solve problems such as numerous procedures, difficult assembly, and difficult assembly, and achieve the effect of compact structure of the whole machine, reduced moving stroke, and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

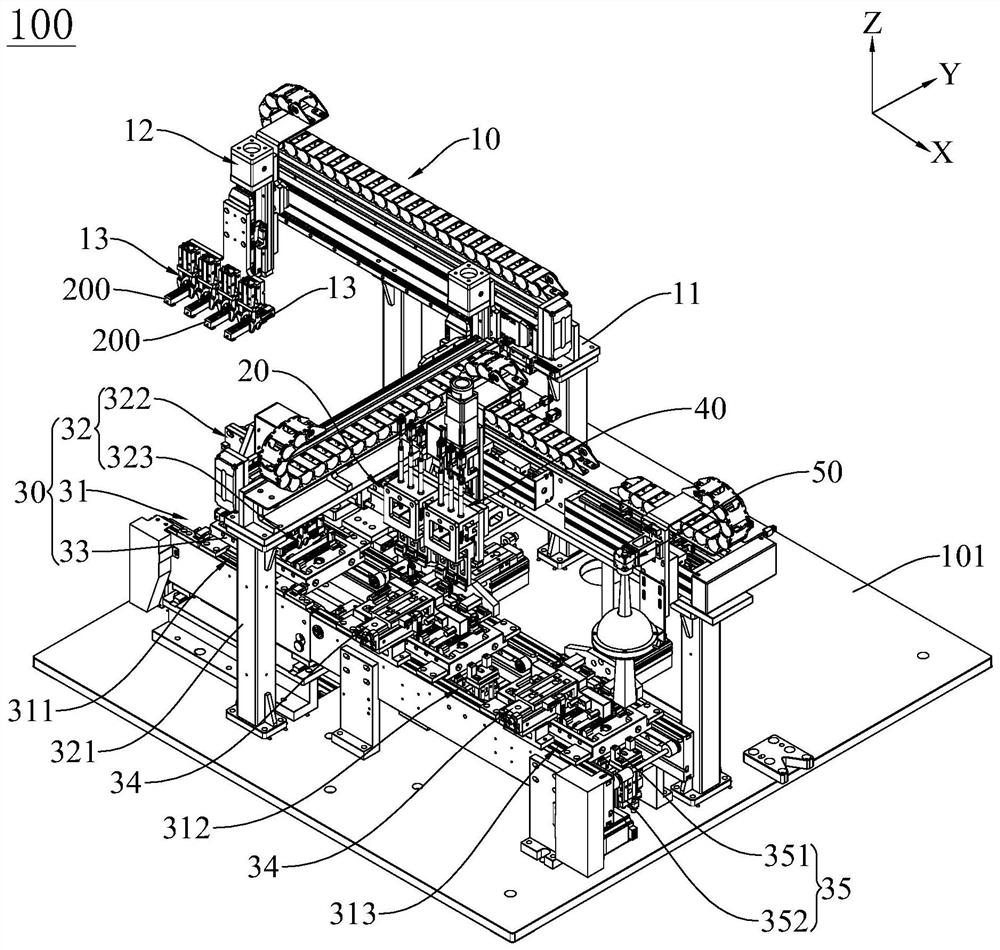

[0025] In order to describe the content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in combination with the embodiments and accompanying drawings.

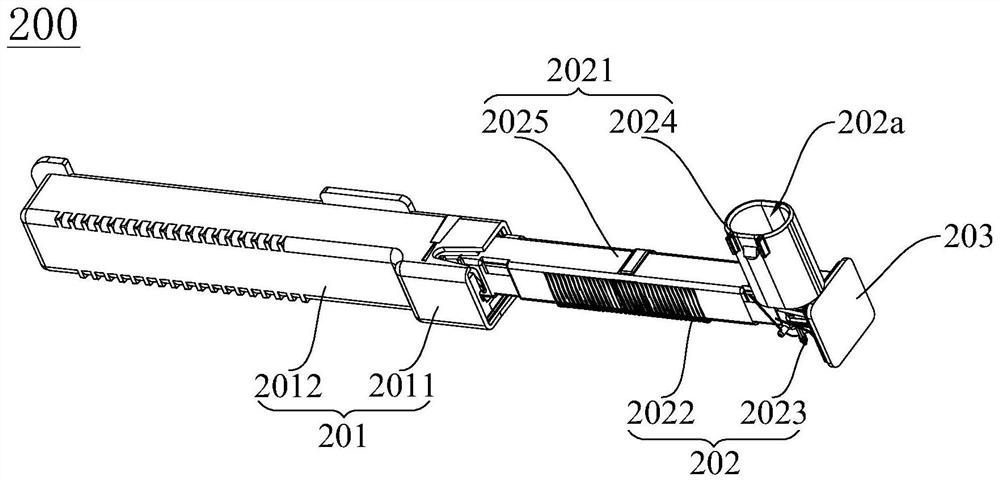

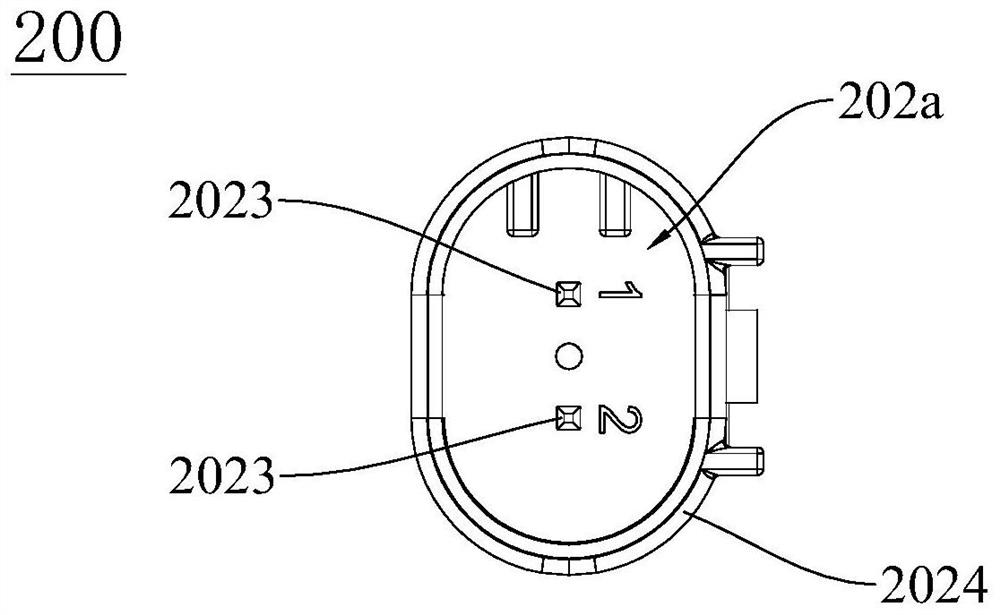

[0026] see first figure 1 and figure 2 , The present invention relates to a filter 200, which includes a housing 201, a sealing ring assembled in the housing 201, a magnetic core 202, an end cover 203 and other components. Specifically, the shell 201 is cylindrical and roughly in the shape of an "L". The magnetic core 202 includes a skeleton 2021, a central stem mounted on the skeleton 2021, a coil 2022 wound on the central stem, and a coil 2022 mounted on the skeleton 2021. The two PIN needles 2023 in the groove 202a are arranged, and the two PIN needles 2023 are also connected with the coil 2022 . Wherein, the skeleton 2021 is roughly in the shape of an "L", and the placement groove 202a is arranged at the short side 2024 of the skeleton 2021. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com