Turning-milling combination machine

A compound machine, turning and milling technology, which is applied in the direction of metal processing machinery parts, large fixed members, clamping, etc., can solve the problems of unsatisfactory processing efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

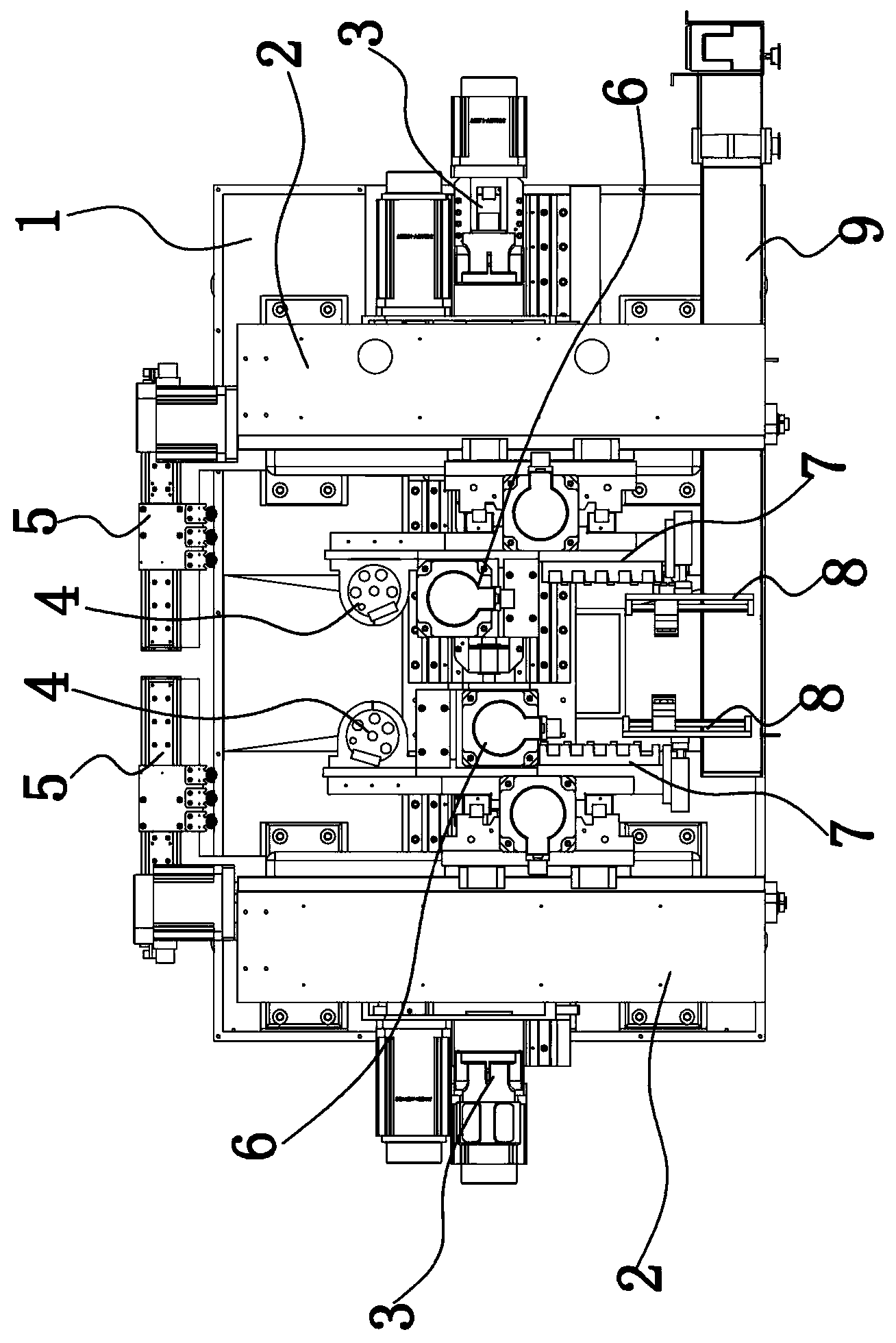

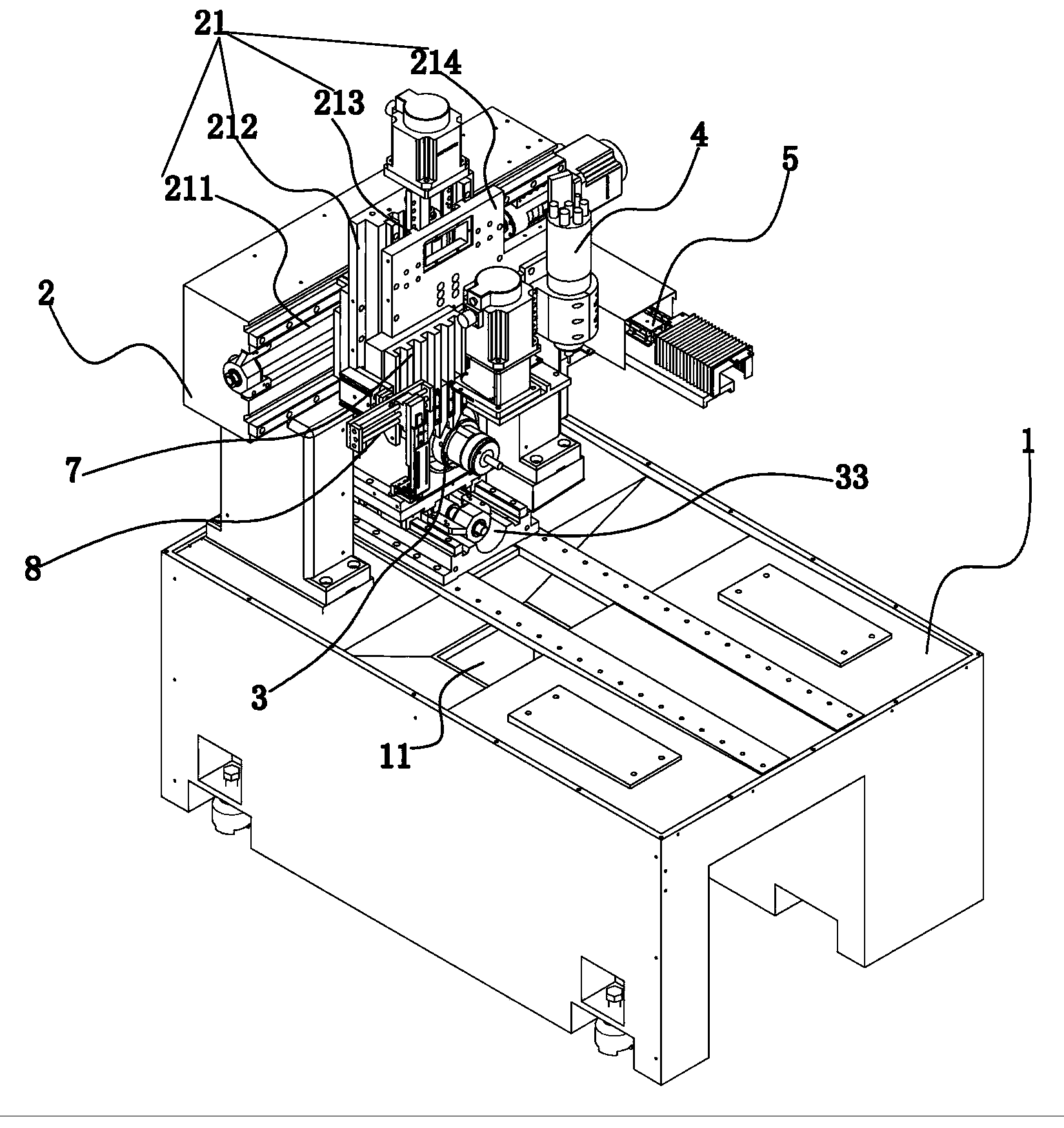

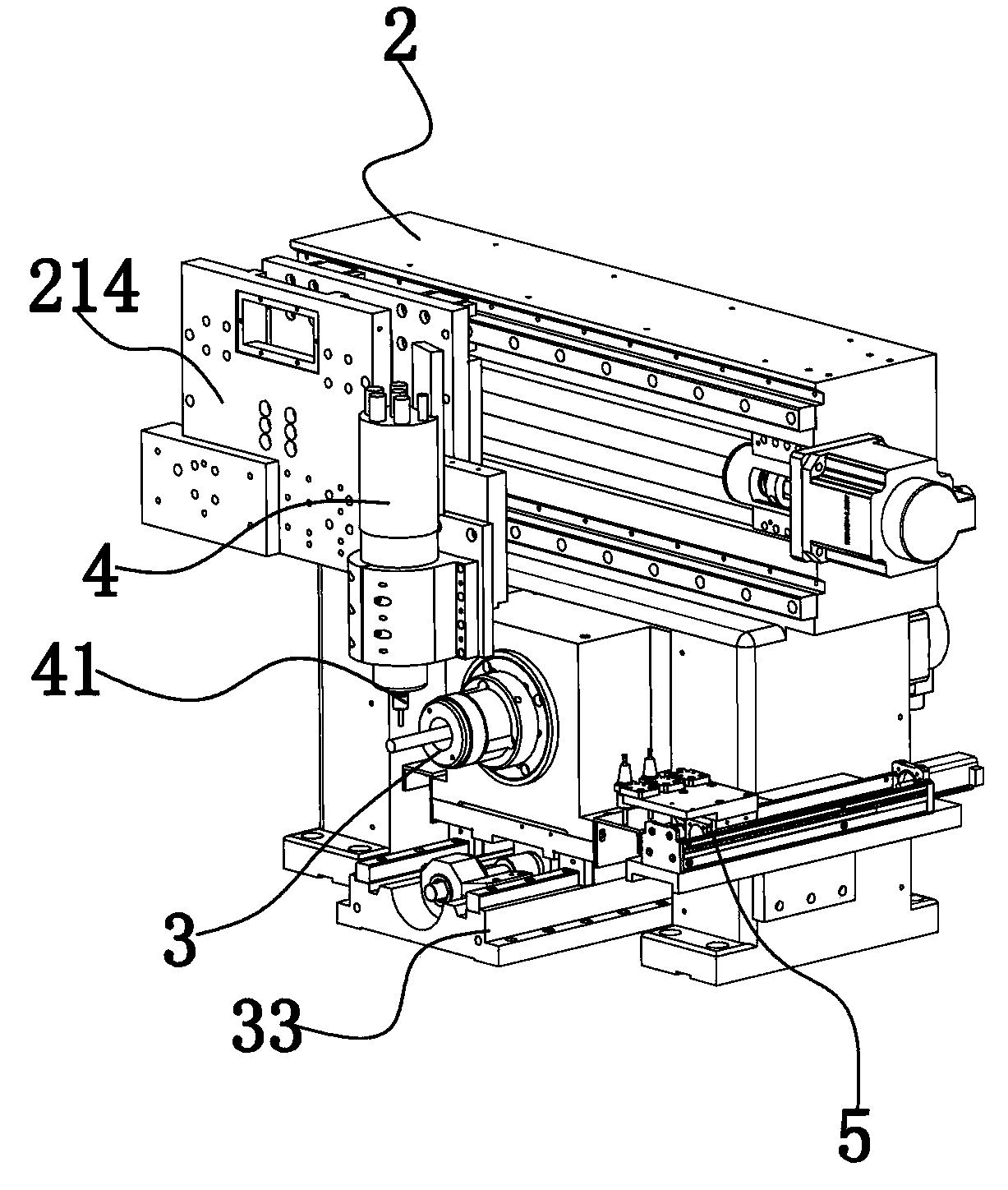

[0023] Figure 1 to Figure 8 A mill-turn machine according to an embodiment of the present invention is schematically shown.

[0024] The turning and milling compound machine includes machine base 1, gantry frame 2, horizontal spindle base 3, vertical spindle arm 4, vertical spindle arm tool changing mechanism 5, power turret 6, tool rack 7, and material receiving manipulator 8 and receiving channel 9.

[0025] Machine base 1: used to install gantry frame 2, vertical spindle arm 4, vertical spindle arm tool change mechanism 5, horizontal spindle seat 3, power turret 6, row tool holder 7, receiving manipulator 8 and receiving channel 9. The machine base 1 is provided with a drain hole 11, and the drain hole 11 is set in the middle of the upper end of the machine base 1 to drain away the water used when the turning-milling compound machine is working.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com