A kind of solid crystal method and crystal solid machine

A die-bonding machine and die-bonding technology, which is applied in the fields of electric solid-state devices, semiconductor/solid-state device manufacturing, semiconductor devices, etc. Shortened travel stroke and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

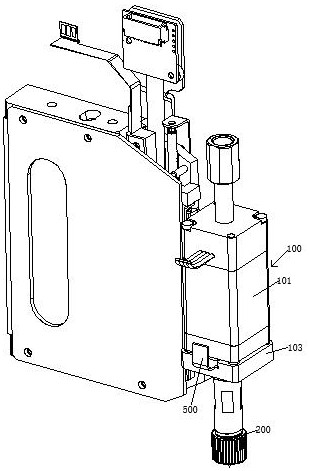

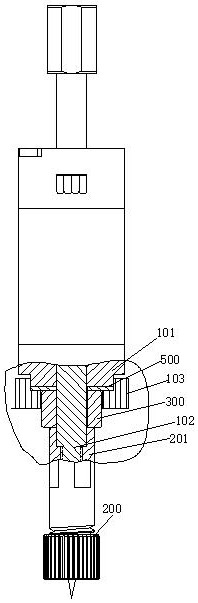

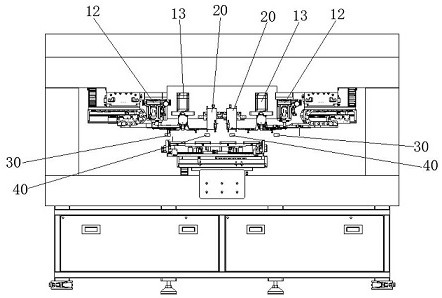

[0029] like figure 1 , 4 , 5, 6, and 7, the present invention discloses a crystal bonding machine, comprising a swing arm mechanism and a linear crystal bonding mechanism, the swing arm mechanism comprising a swing arm 10, a swing arm driving mechanism 13, and the swing arm driving The mechanism 13 is used to drive the swing arm 10 to swing. The swing arm suction nozzle is installed on the swing arm 10; The die-bonding head drive mechanism 21 is used to drive the linear die-bonding head 20 to move; when the swing arm 10 swings to the crystal picking position, push the wafer on the blue film to the swing arm suction nozzle through the thimble 12; When the swing arm 10 swings to the transfer position and the linear die bonding head 20 moves linearly to the transfer position, the die bonding nozzle 200 of the linear die bonding head 20 sucks the wafer on the swing arm suction nozzle; When the linear die bonding head 20 linearly moves to the die bonding position, the die bonding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com