Processing device for full-automatic chemiluminescence immunoassay analytical instrument

An automatic chemistry and luminescent immunity technology, which is applied in the field of medical inspection and analysis instruments, can solve the problems of reducing processing efficiency, inconsistent detection results, and affecting detection results, so as to achieve the effect of improving processing efficiency, reducing processing stations, and reducing waiting processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

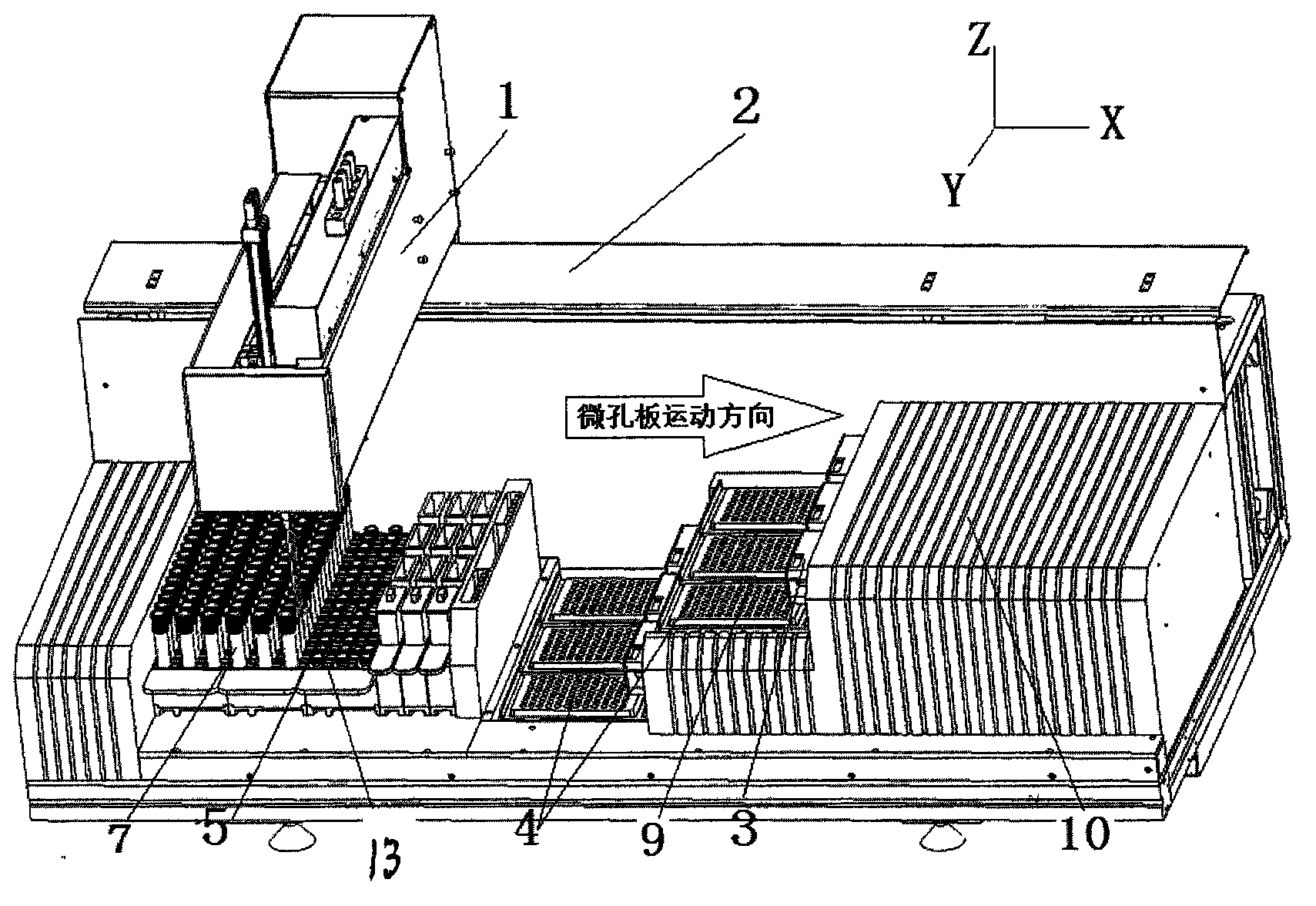

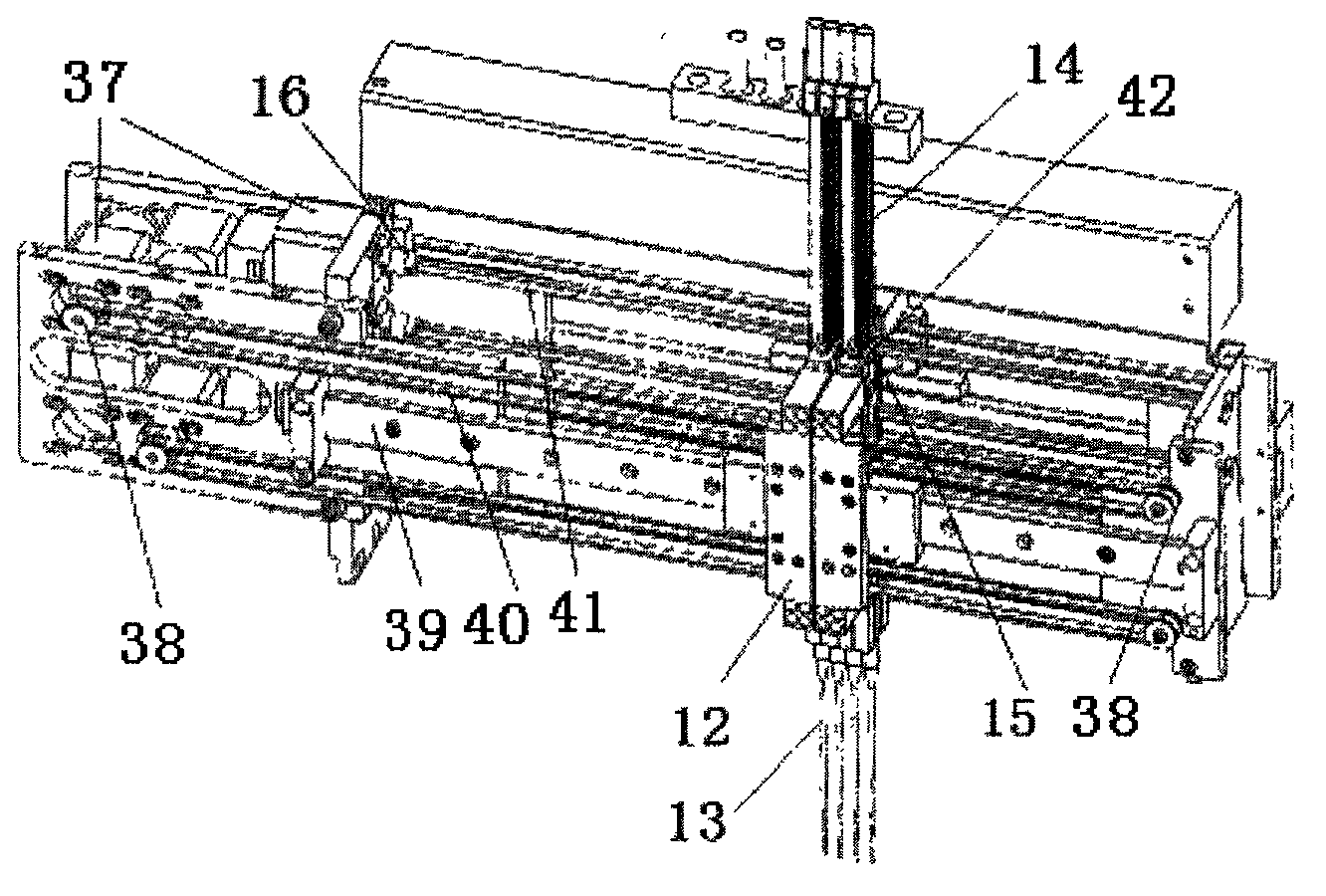

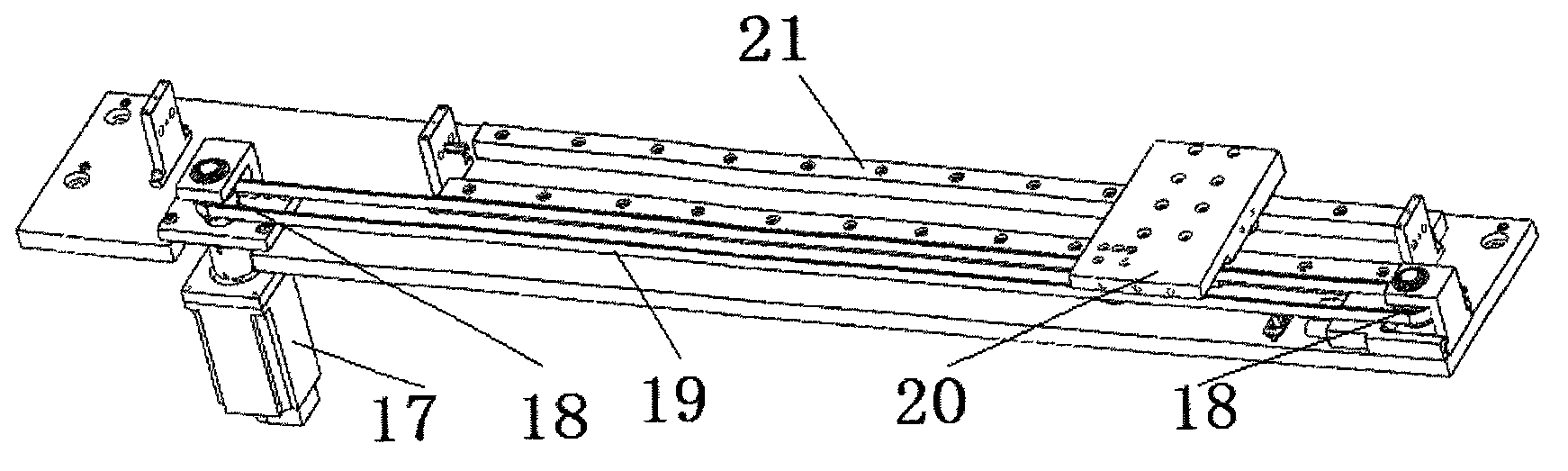

[0041] figure 1 It is a perspective view of an embodiment of a processing device for a fully automatic chemiluminescent immunoassay instrument, such as figure 1 As shown, the processing device for a fully automatic chemiluminescence immunoassay instrument as an embodiment of the present invention includes a sample loading mechanism, and the sample loading mechanism can be horizontally horizontal (ie, X direction), horizontally vertical (ie, Y direction) direction, front and rear direction), and the way of moving up and down (Z direction) is set on the bracket 2, the up and down direction (Z direction) is perpendicular to the horizontal direction (X direction), and the up and down direction (Z direction) is parallel to the horizontal longitudinal direction (Y direction) is vertical; sample area 5, in this sample area 5, is placed with sample container 7, and above-mentioned sampling mechanism can pass above the top of sample area 5, in horizontal direction (X direction), horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com