Automatic molding machine for producing pulp moulded products at super small draft angle

An automatic molding machine and pulp molding technology, which is applied in the direction of textiles and papermaking, can solve the problems of reduced yield, non-parallel, high manufacturing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

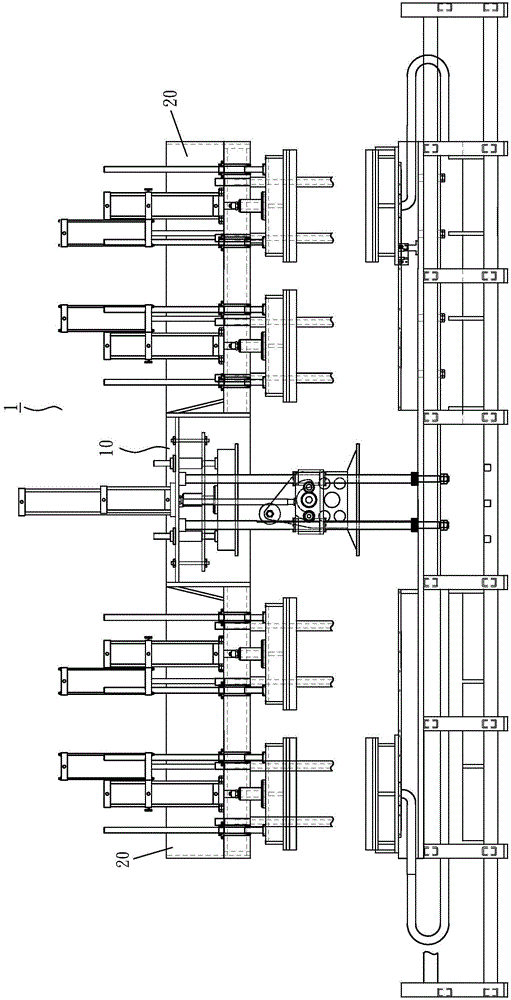

[0032] see figure 1 As shown, the embodiment of the present invention is a molding machine 1 as a whole, which is an automatic molding machine for manufacturing (molding) molded products, especially an automatic molding machine suitable for manufacturing molded products with ultra-small draft angles. The forming machine 1 has a main frame 10 and side frames 20 positioned on two sides. The main frame 10 is equipped with a structure for carrying out the process of "suction and shaping", and the side frame 20 is equipped with a The structural composition of the "hot pressing shaping" process, that is, the initial product formed after the "suction shaping" process is completed in the main frame 10, and is further sent to the right or left into the side frame The "hot pressing and shaping" process is carried out within 20 to manufacture and complete the molded product.

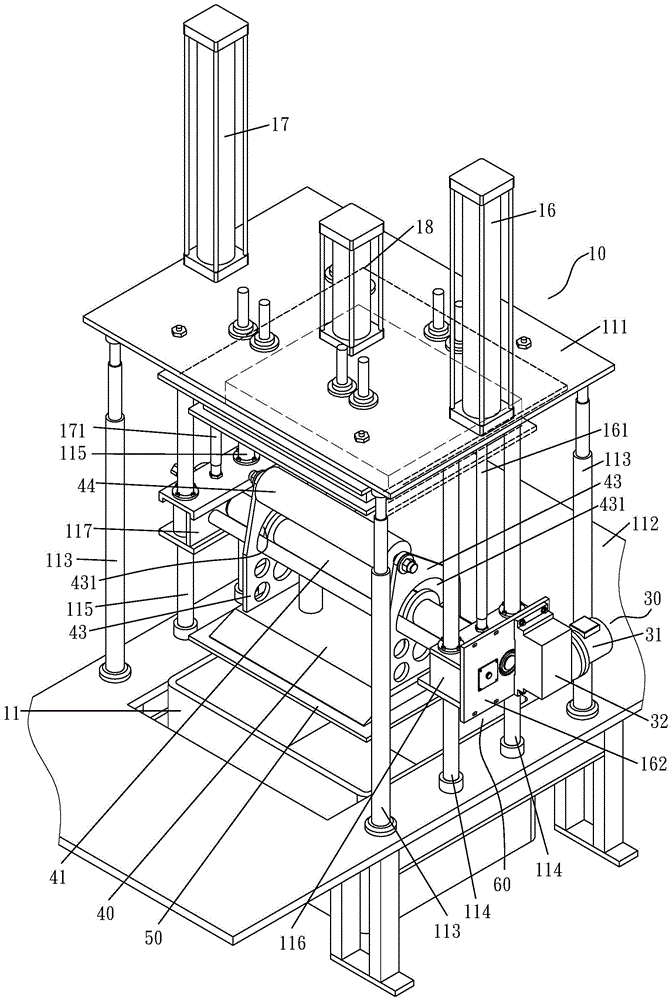

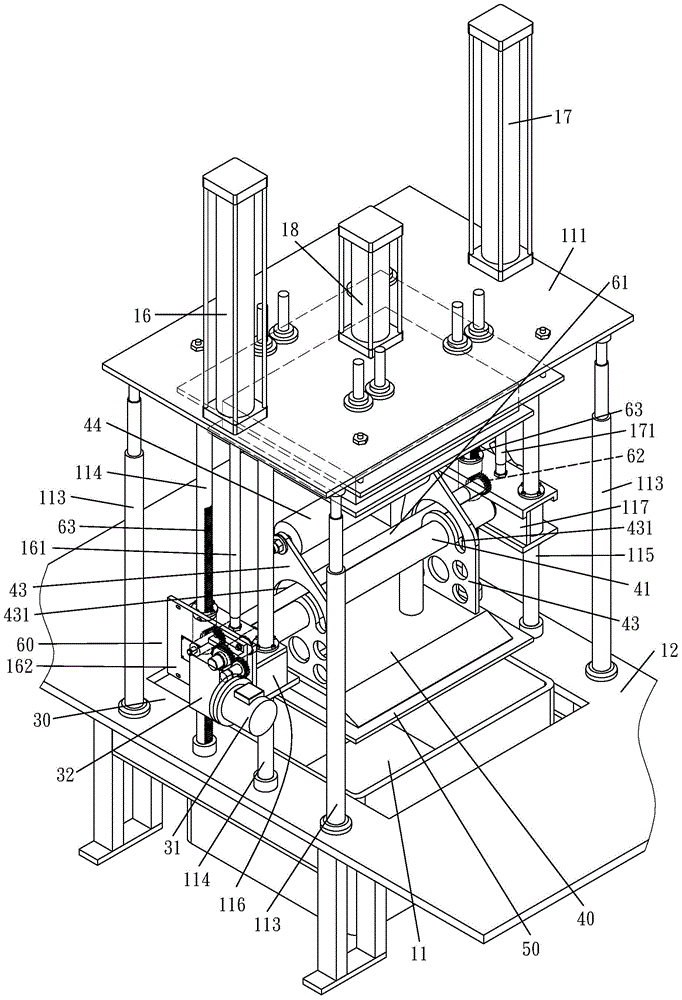

[0033] see figure 2 As shown, the main frame 10 is supported by some spacer columns 113 between a top plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com