Impact torque adjusting device of hydraulic torque wrench

A torque wrench and torque adjustment technology, applied in the directions of wrenches, wrenches, screwdrivers, etc., can solve the problems of large impact torque impact torque error, applied load pressure on the sealing part, and long impact torque generation cycle, etc. Accuracy, the effect of reducing the travel stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

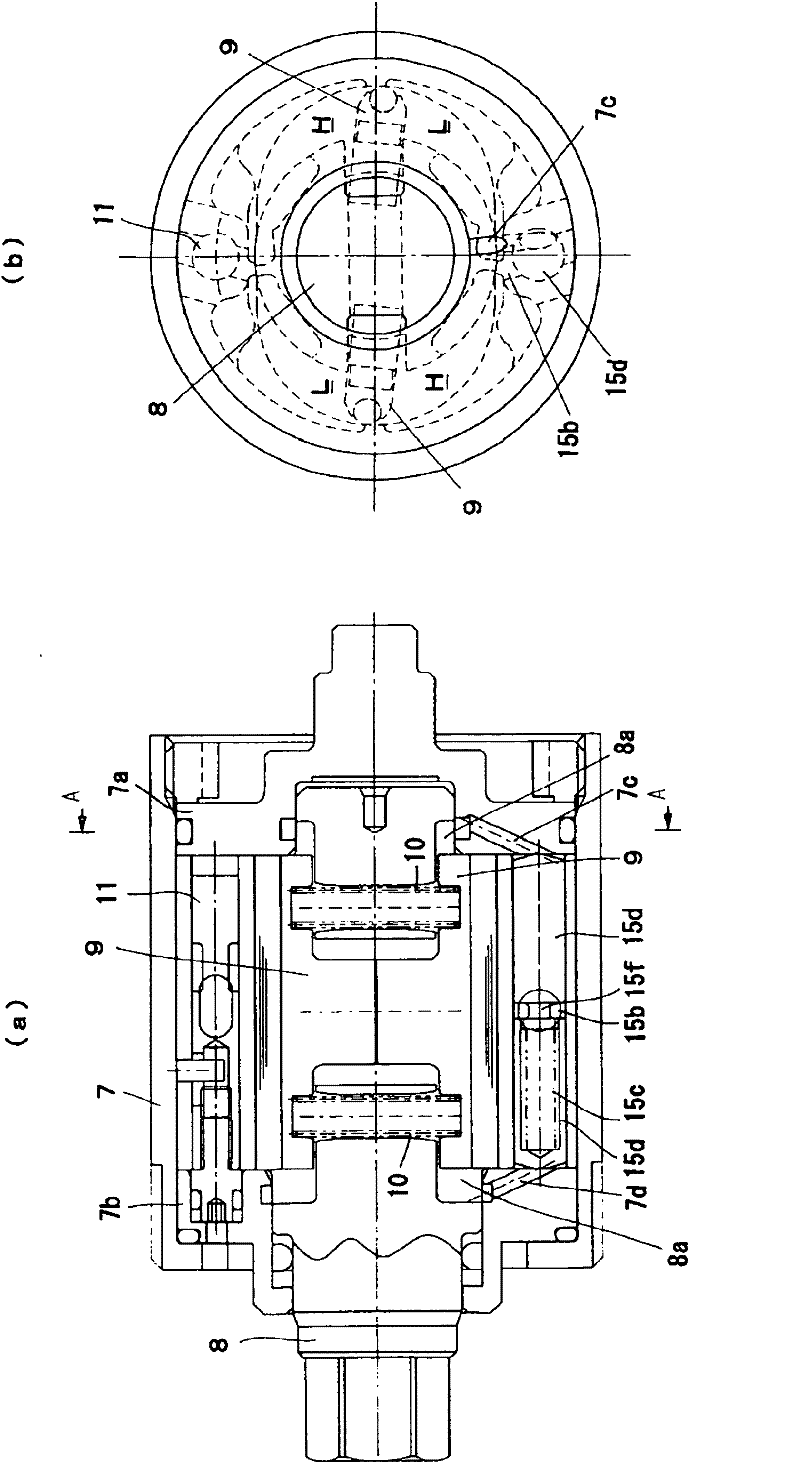

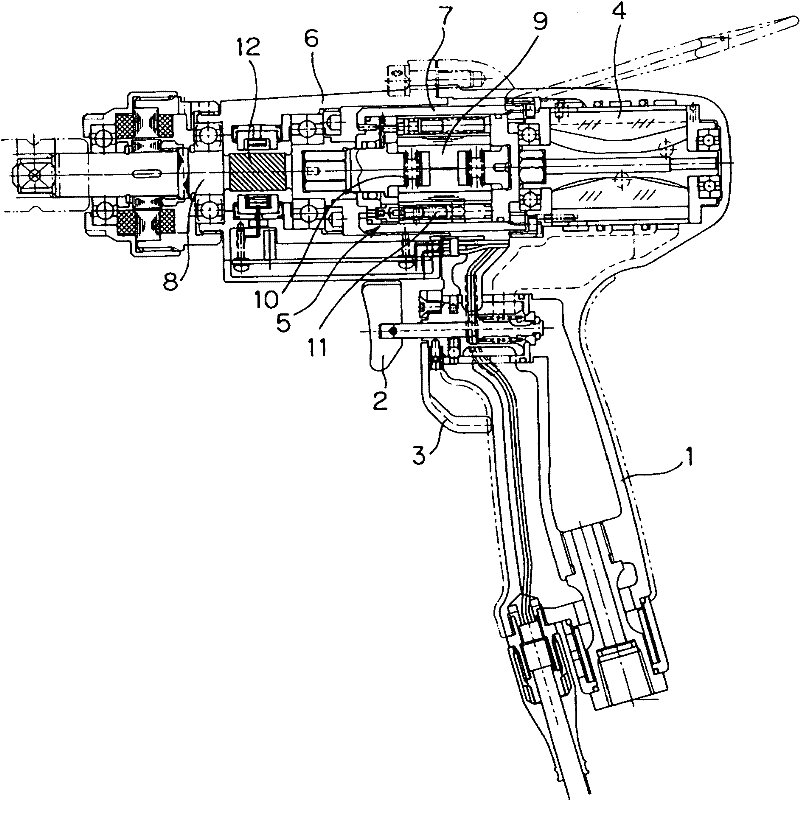

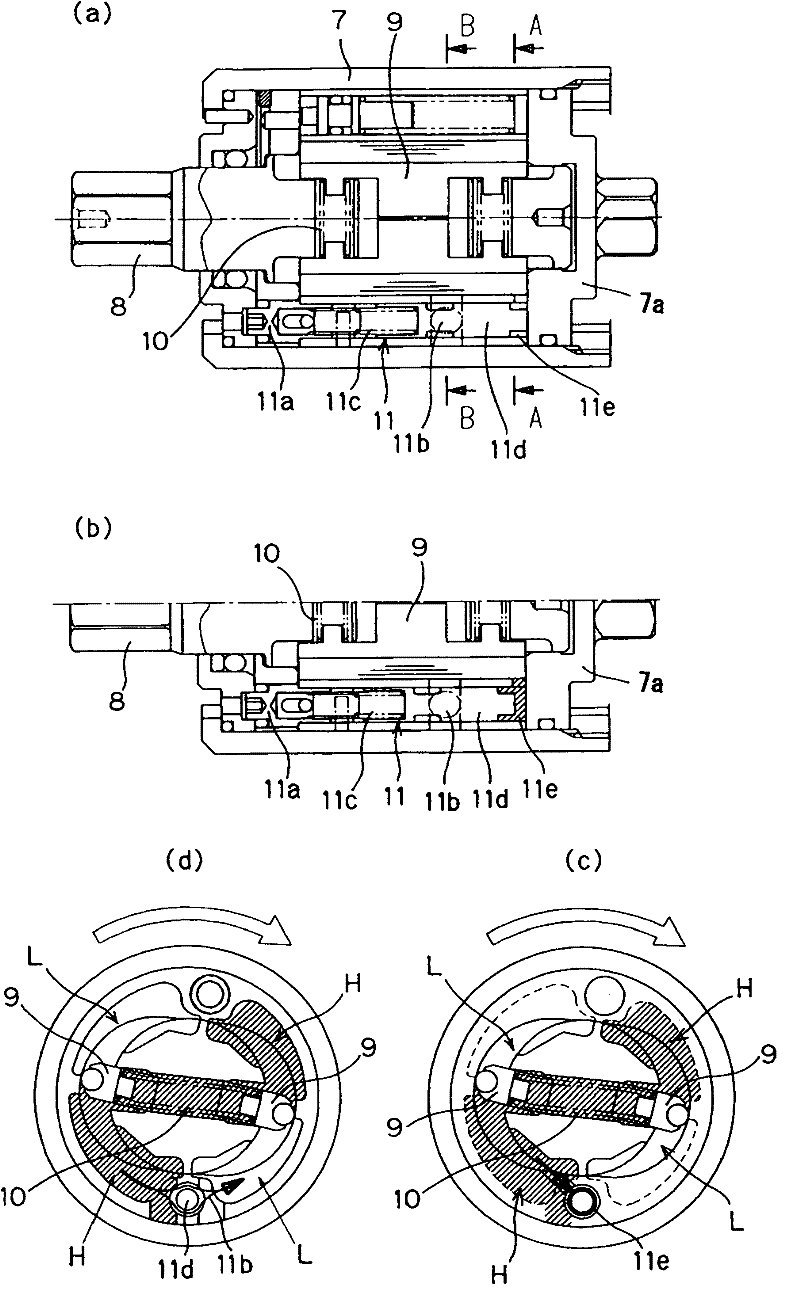

[0060] Next, an embodiment of an impact torque adjusting device for a hydraulic torque wrench according to the present invention will be described with reference to the drawings.

[0061] figure 1 It shows an embodiment of the impact torque adjusting device of the hydraulic torque wrench of the present invention (overall view omitted).

[0062] The hydraulic torque wrench 1 of the present embodiment controls the driving of the rotor 4 by the output of the torque detection mechanism such as the magnetostrictive torque detection mechanism 12 of the above-mentioned first reference example instead of the control of the drive of the rotor 4, and the above-mentioned second to second Three Reference Examples, Patent Document 1 and Figure 8 The disclosed conventional hydraulic torque wrench is similarly equipped with a release valve B in the output adjustment mechanism 11, and when the tightening action progresses, when the pressure (impact torque) of the working oil in the high pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com