Envelope type thin film packaging machine

A film packaging and filming technology, applied in packaging, wrapping paper, packaging bottles, etc., can solve problems such as poor stability, slow packaging speed, and packaging machine work disorder, so as to improve stability, facilitate quick adjustment, and increase packaging speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

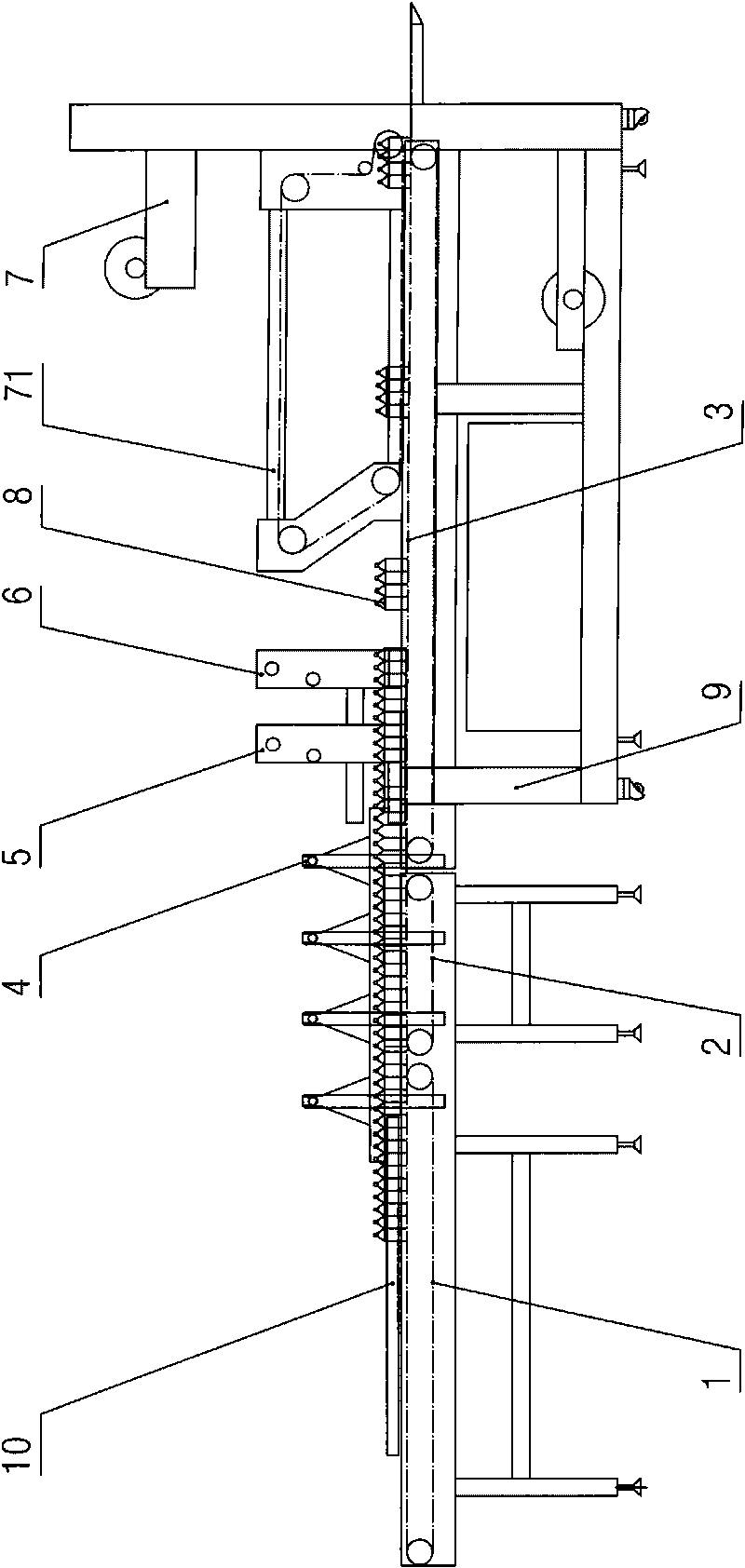

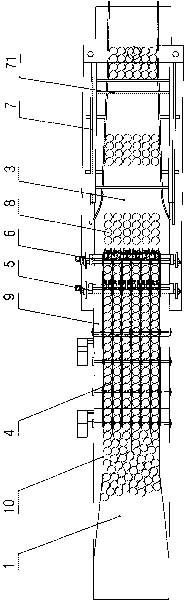

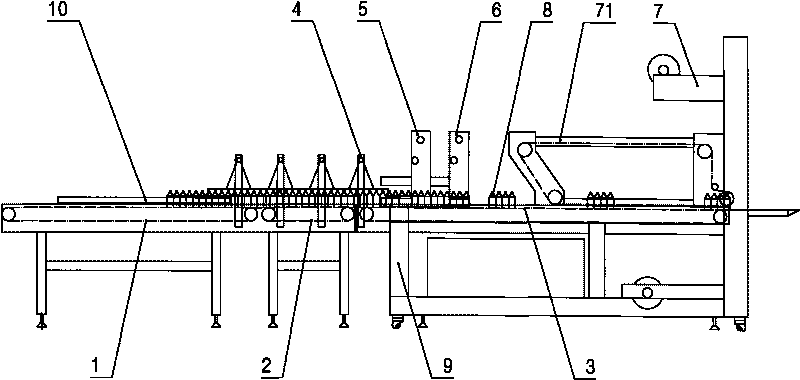

[0011] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] Such as figure 1 , figure 2 As shown, the mantle film packaging machine of the present invention includes: a frame 9 and a conveying device, a subpackaging device and a film sealing and cutting device 7 arranged on the frame 9 in sequence, and the conveying device includes: a linear The front and rear conveyor belts 1 and 2 are arranged and joined together. The subpackaging device 5 is located above the rear conveyor belt 2. Its structure includes: two sets of gate opening and closing mechanisms spanning the frame 9, that is, the front gate The opening and closing mechanism 5 and the rear gate opening and closing mechanism 6 are provided with six full-line channels between the front gate opening and closing mechanism 5 and the rear gate opening and closing mechanism 6, and the front and rear gate opening and closing mechanisms 5 and 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com