Full-automatic vertical filling vacuum packing machine

A vacuum packaging machine, fully automatic technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of lack of packaging continuity, slow packaging speed, lack of continuity, etc., to achieve simple structure, fast packaging speed, use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] specific implementation plan

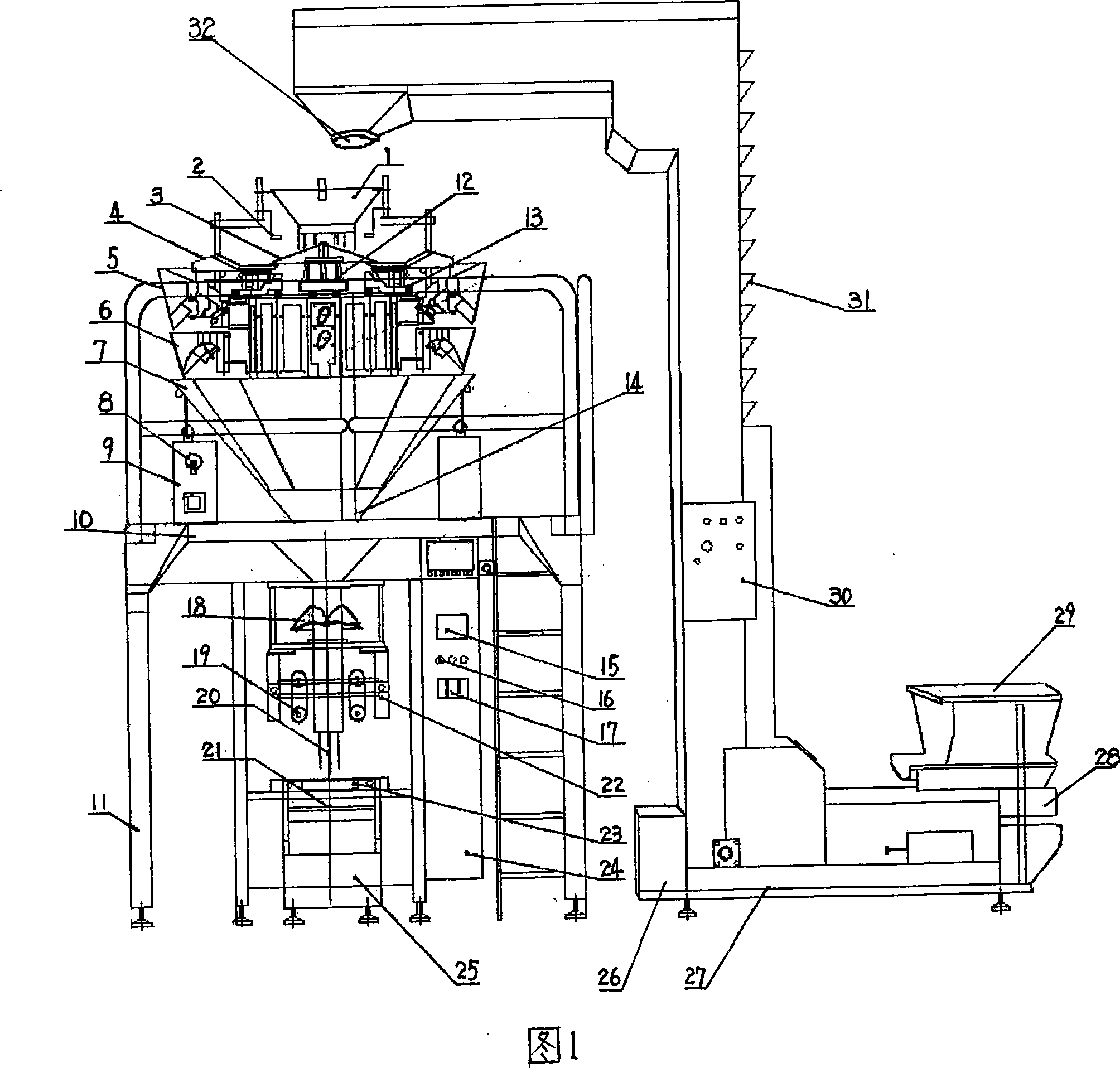

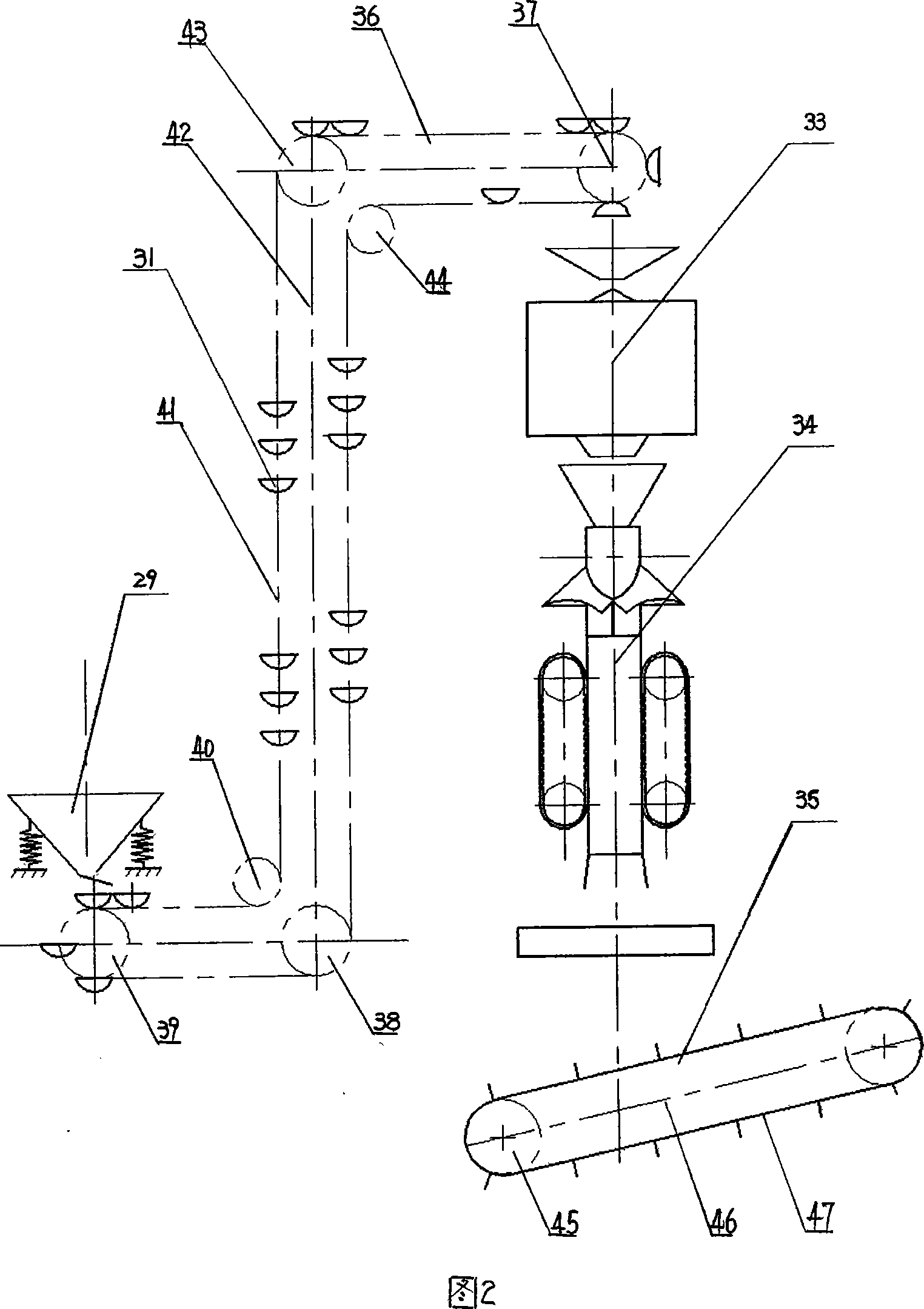

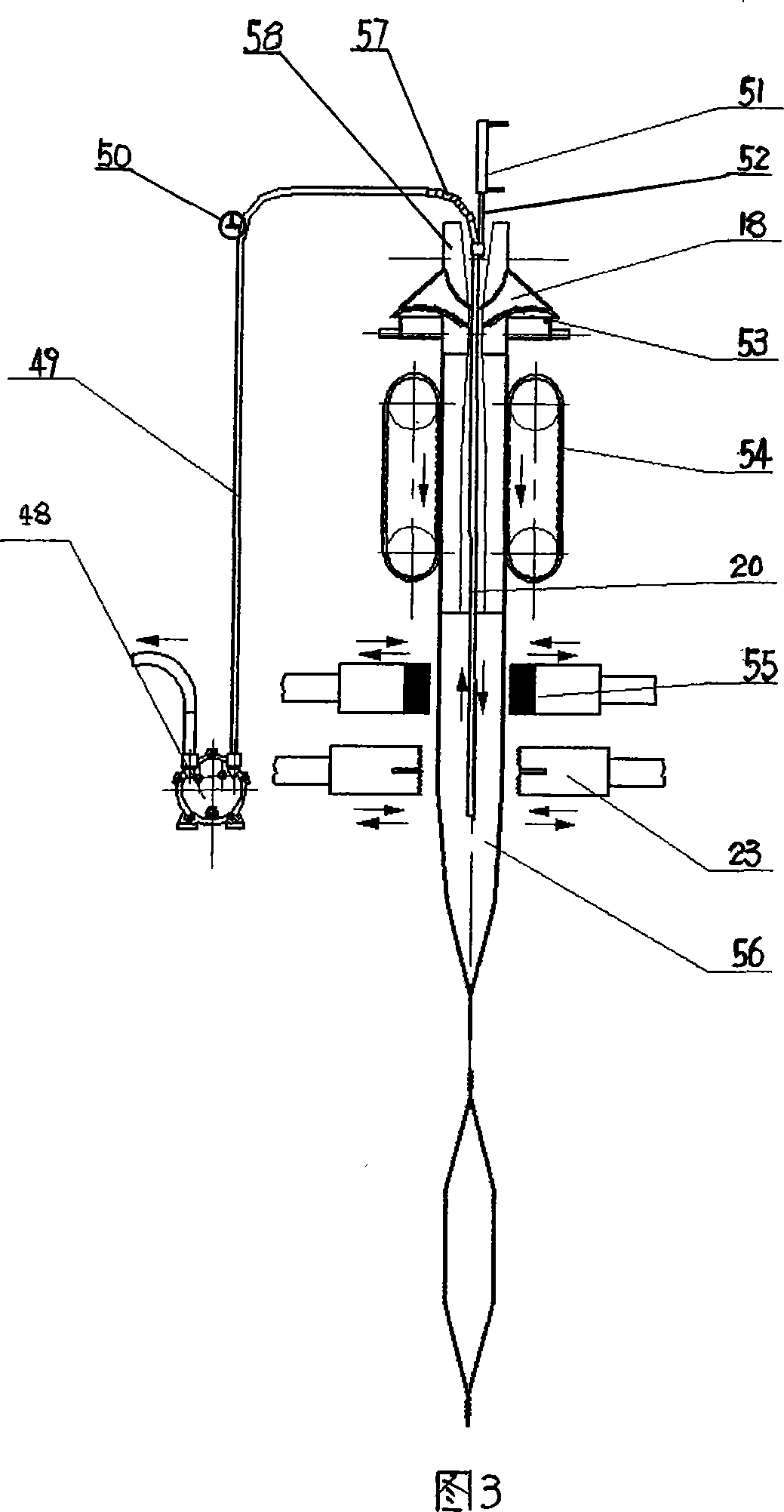

[0011] As shown in Figures 1-2, a fully automatic vertical filling vacuum packaging machine is mainly composed of a lifting feeding device 36, an electronic weighing device 33, an automatic vacuum packaging device 34 and a conveying device 35, wherein:

[0012] Elevate the feeding device, the discharge port 32 of the elevating feeding device is located at the upper end of the storage hopper 1 of the electronic weighing device, the elevating feeding device is in a Z shape, the top of one end of the bottom frame 27 is provided with a material hopper 29, the lower end of the material hopper Establish the vibrating feeder 28, the outlet of the material hopper communicates with the feed hopper 31 on the transmission belt 41, the upper and lower ends of the frame 42 are provided with driving wheels 38, 43 driven by the hoisting motor 26, and the frame parallel to the driving wheels is provided with Driven wheel 39,37, two turning wheels 40,44 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com