Packaging process and packaging equipment for large-specification ceramic tile

A packaging technology and packaging equipment technology, applied in packaging paper bending devices, packaging, transportation packaging and other directions, can solve the problems of conveying speed limitation, different working speeds, stop waiting, etc., to achieve improved packaging speed, automatic high-speed wrapping angle The effect of packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

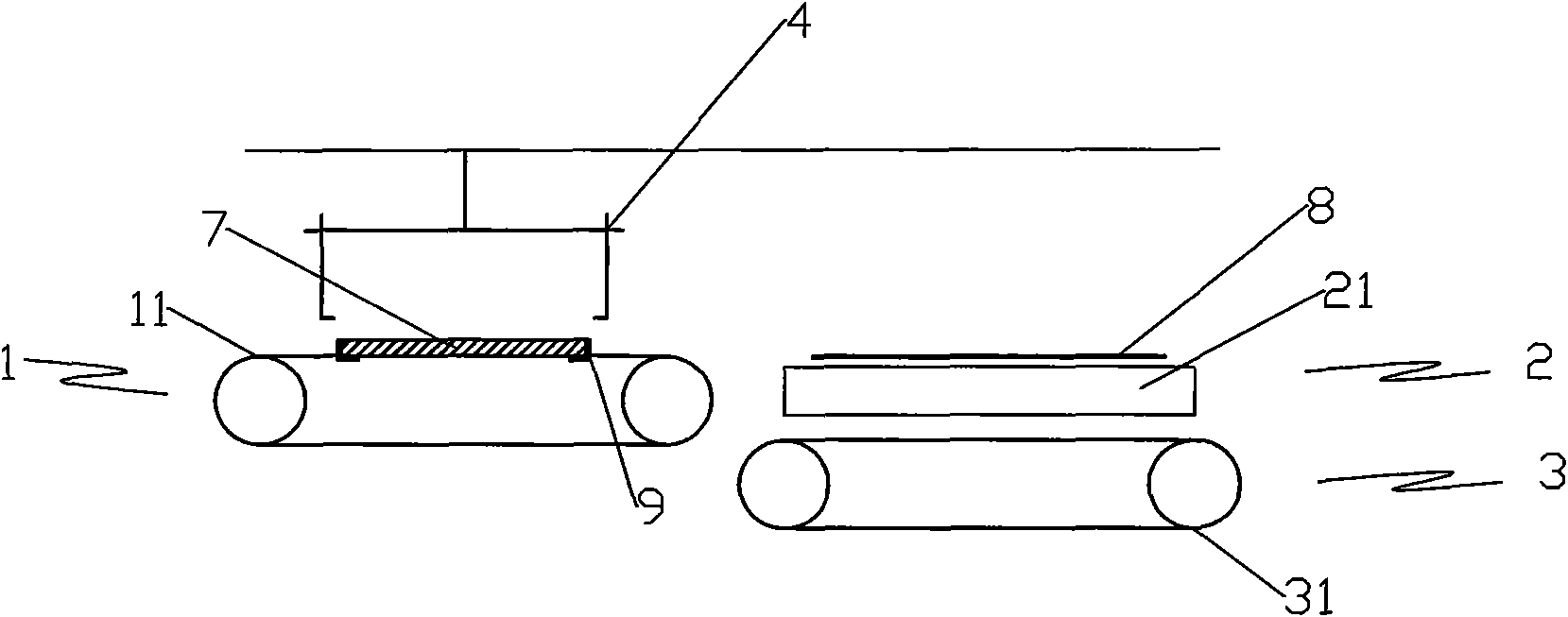

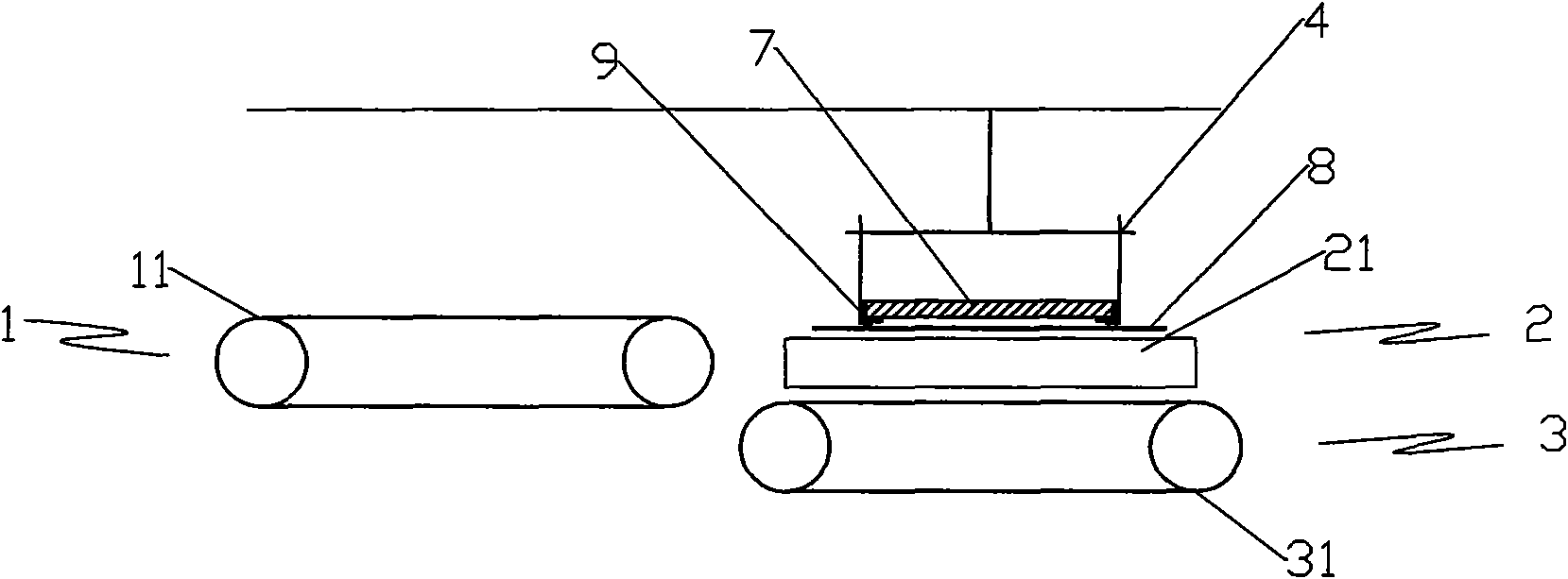

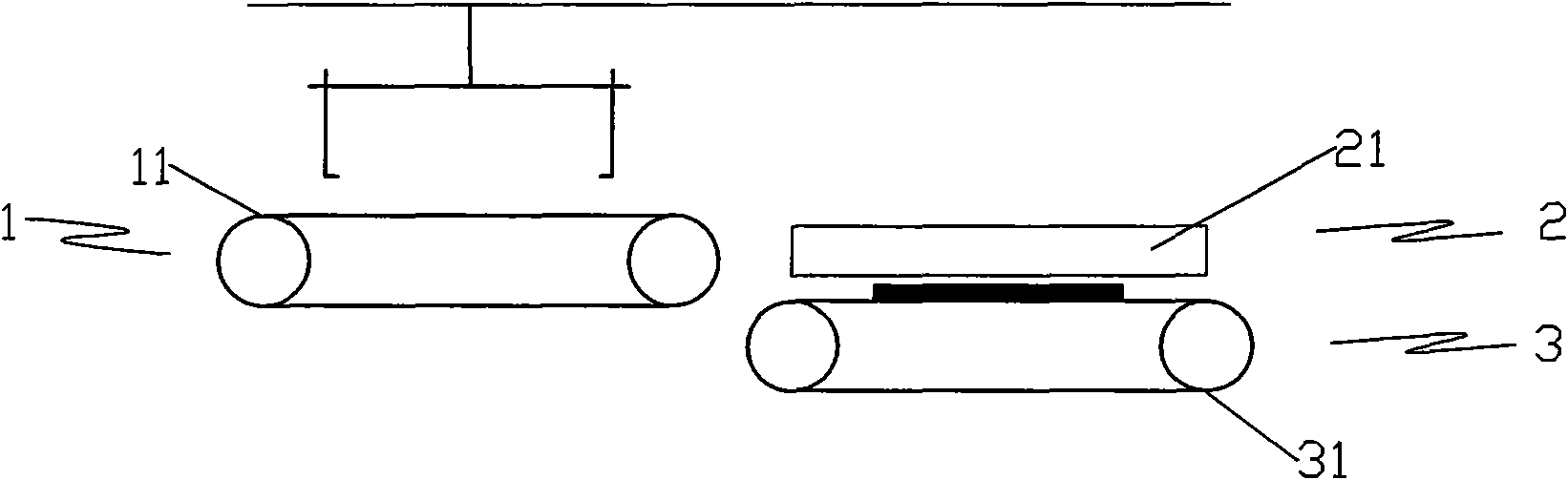

[0029] A kind of packaging process method of large-scale ceramic brick of the present invention, its packaging process is:

[0030] Including three independent working surfaces;

[0031] The brick stacks are sent to the working area of the first working surface and then stop, and the brick stacks complete the centering, aligning and corner wrapping processes in the working area;

[0032] Then the brick stack is lifted and transported to the second working surface together with the corner-wrapping material (that is, the corner protector), where the brick stack and the pre-packed box wrapping paper complete the pre-packaging positioning;

[0033] Then the stack of bricks and the carton wrapping paper fall vertically to the third working surface, and the brick package is completed during the falling process;

[0034] Finally, the brick bag is transported out of the bricks on the third working surface.

[0035] like Figures 3 to 6 As shown, the packaging equipment for realiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com