Patents

Literature

38results about How to "Improve pressure detection accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water tank outflow volume measurement device

ActiveCN104748801AGood teaching effectImproving the accuracy of liquid pressure detectionEducational modelsVolume/mass flow by differential pressureJet flowEngineering

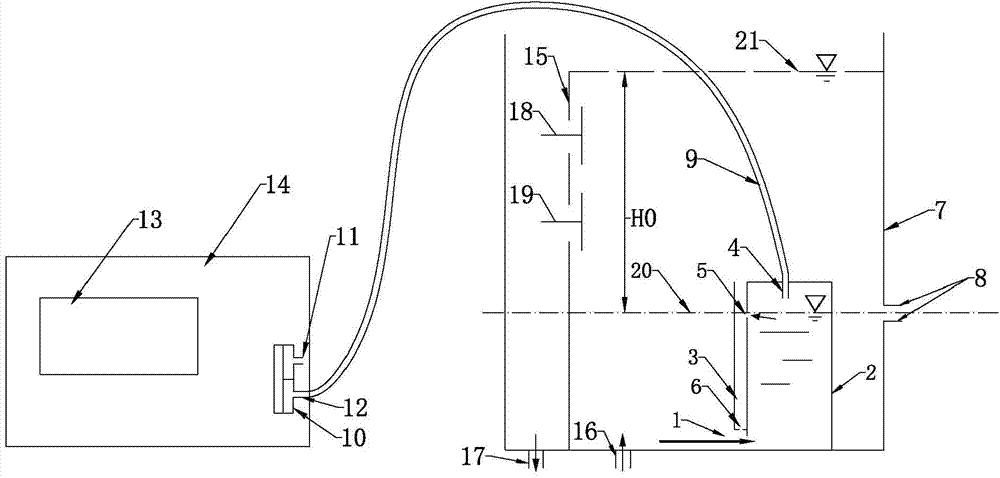

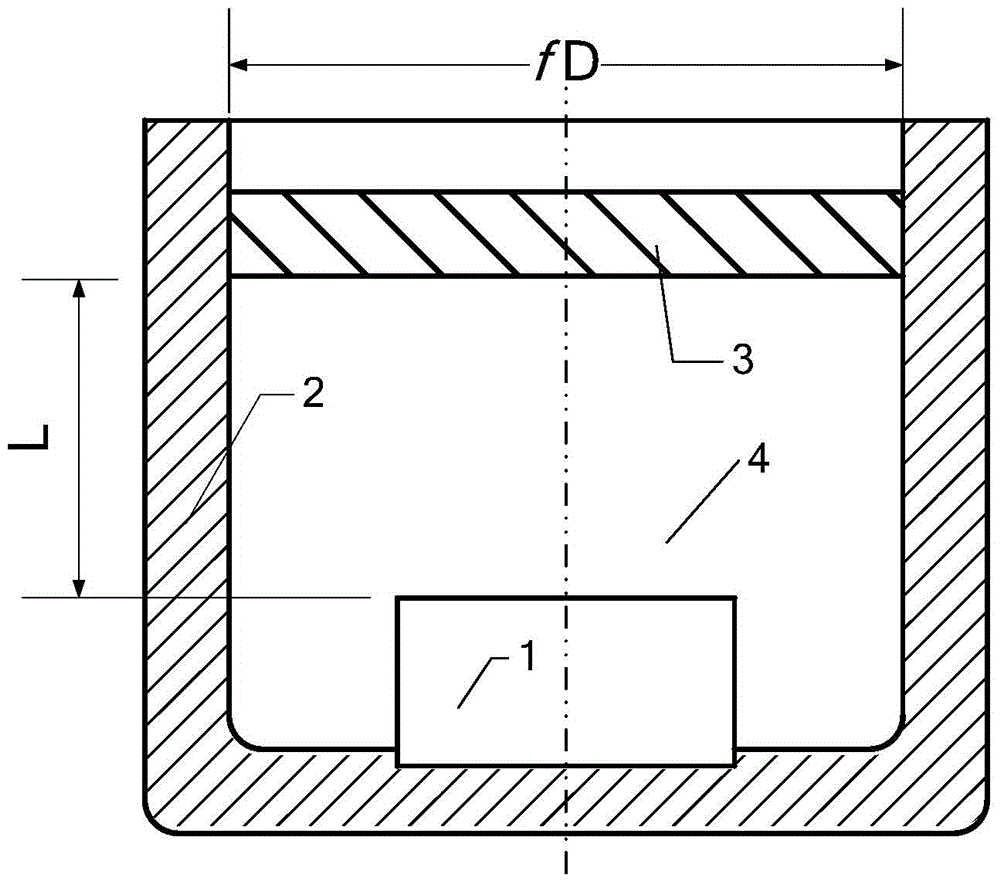

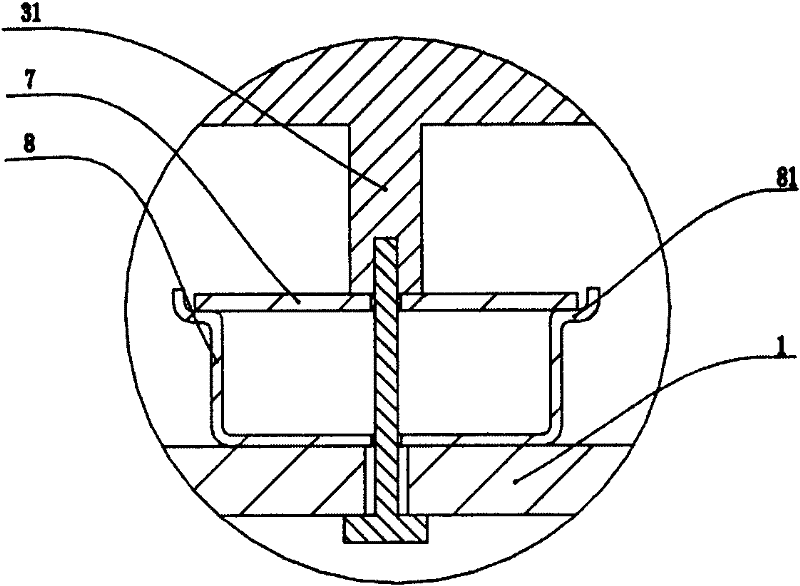

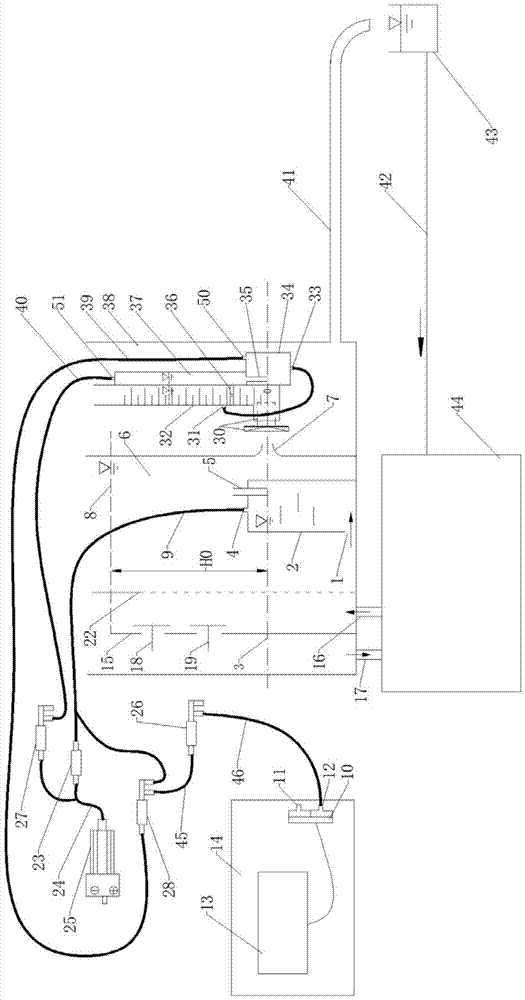

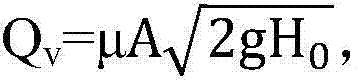

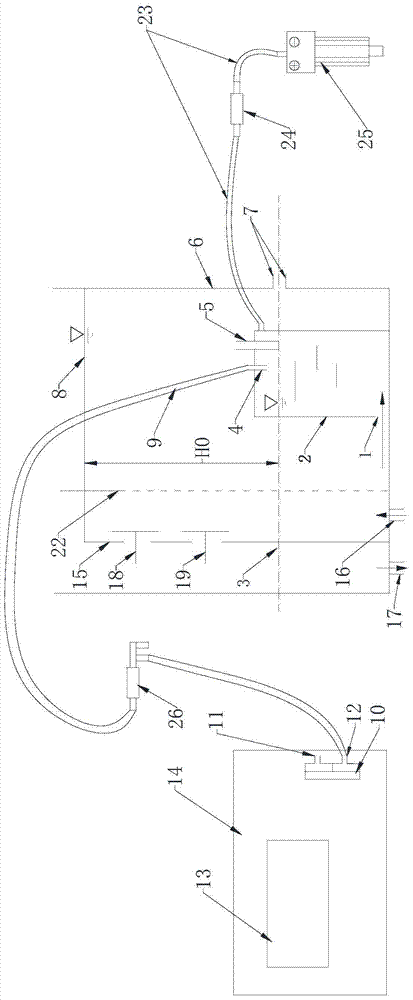

The invention discloses a water tank outflow volume measurement device. The water tank outflow volume measurement device comprises an experiment water tank, a liquid-gas conversion pressure measurement cylinder, a fluid differential pressure sensor and a microcomputer, wherein one side wall of the experiment water tank is provided with an outflow port; the liquid-gas conversion pressure measurement cylinder is arranged inside the experiment water tank, the bottom of the liquid-gas conversion pressure measurement cylinder is communicated with the inside space of the experiment water tank, the side wall of the liquid-gas conversion pressure measurement cylinder is provided with a gas outlet water drainage port, and the upper edge of the gas outlet water drainage port is flush with the middle axis horizontal plane of the outflow port; the fluid differential pressure sensor is connected with the liquid-gas conversion pressure measurement cylinder and is used for detecting the differential pressure between compressed air inside the liquid-gas conversion pressure measurement cylinder and external air; the microcomputer is connected with the fluid differential pressure sensor and is used for converting the differential pressure detected by the fluid differential pressure sensor into the outflow of the outflow port. The water tank outflow volume measurement device can conveniently and accurately measure the jet flow volume of orifices in a momentum experiment instrument and orifices and pipe mouths in a pipe mouth experiment instrument in a hydromechanics fundamental experiment in a digitalized mode.

Owner:ZHEJIANG UNIV

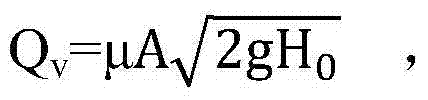

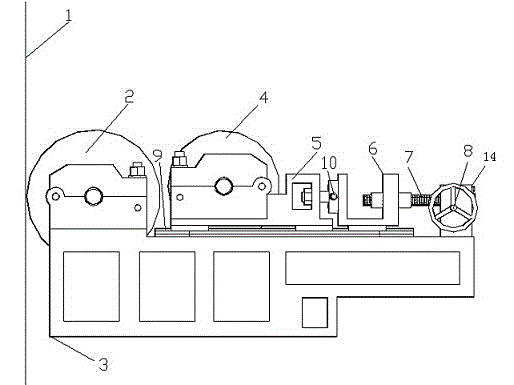

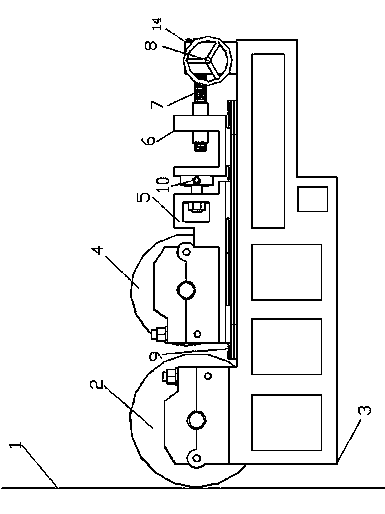

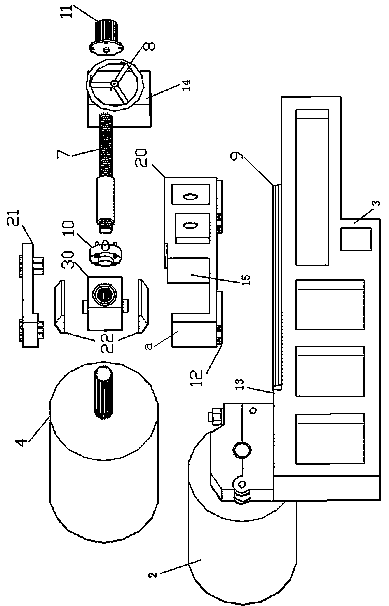

Roller coater

ActiveCN103056063AEliminate the effects ofImprove pressure detection accuracyLiquid surface applicatorsCoatingsElectric machineryEngineering

The invention discloses a roller coater which comprises a painting roller, a roller coater rack, a solution-taking roller, a solution-taking roller rack and a roller rest pressure adjustment device, wherein the roller rest pressure adjustment device comprises an operating side bearing base, a driving side bearing base, a sliding block, a turbine worm, a pressure detection element, a handwheel, a servo motor, linearity guide rails and linearity rails. The roller coater provided by the invention achieves the technical purposes that the automatization feedback and adjustment of the roller coater are realized, and the reaction accuracy is improved. Through the roller coater disclosed by the invention, the pressure detection element contacting the spherical surface of the operating side bearing base and the spherical surface of the driving side bearing base is adopted, a signal is provided for the operation of the servo motor, the regulation and control of a roller interval are beneficial, the accuracy and consistency of the thickness of a painting film are improved, and the quality of the painting film of the surface of a steel band and quality stability are guaranteed.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

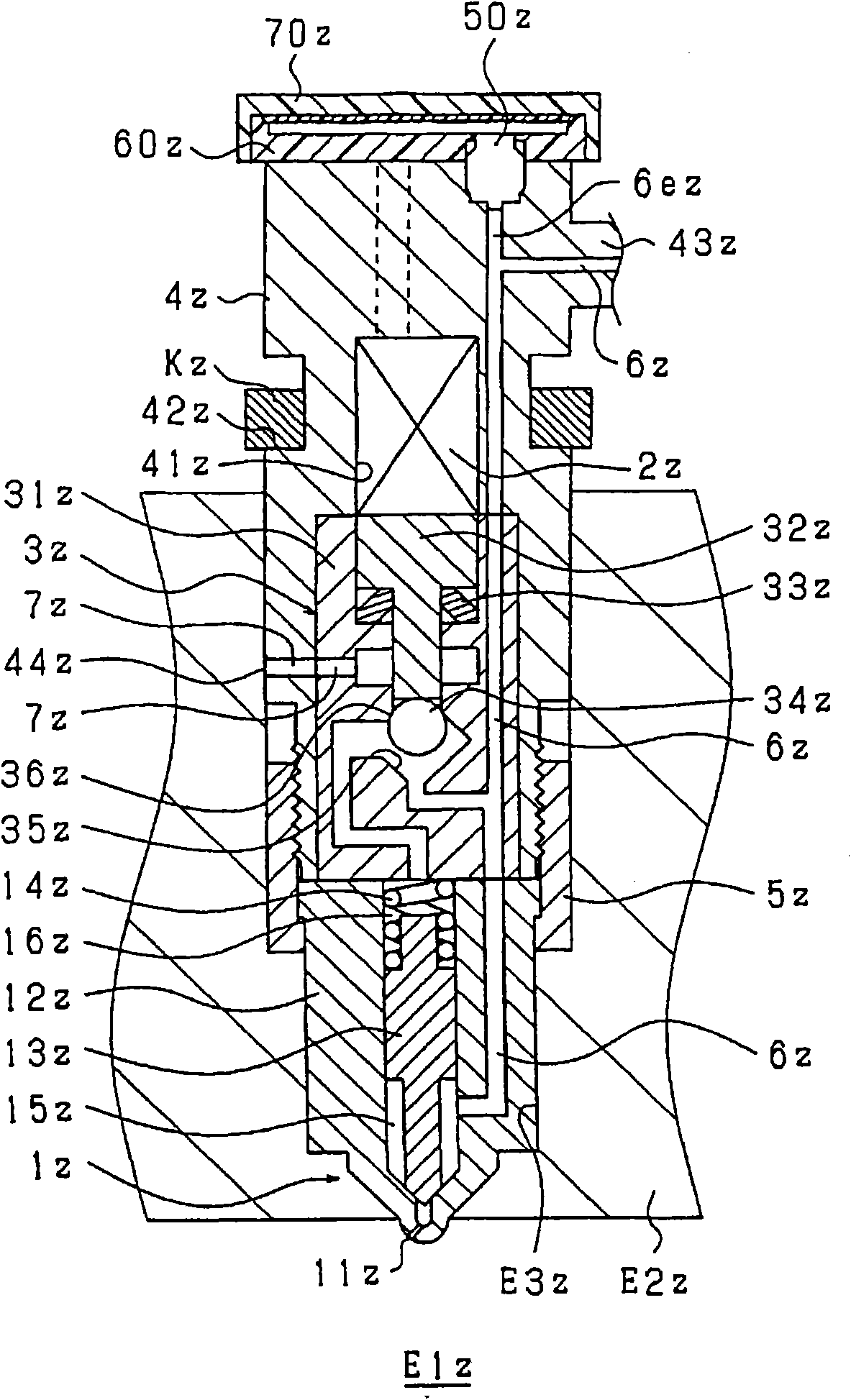

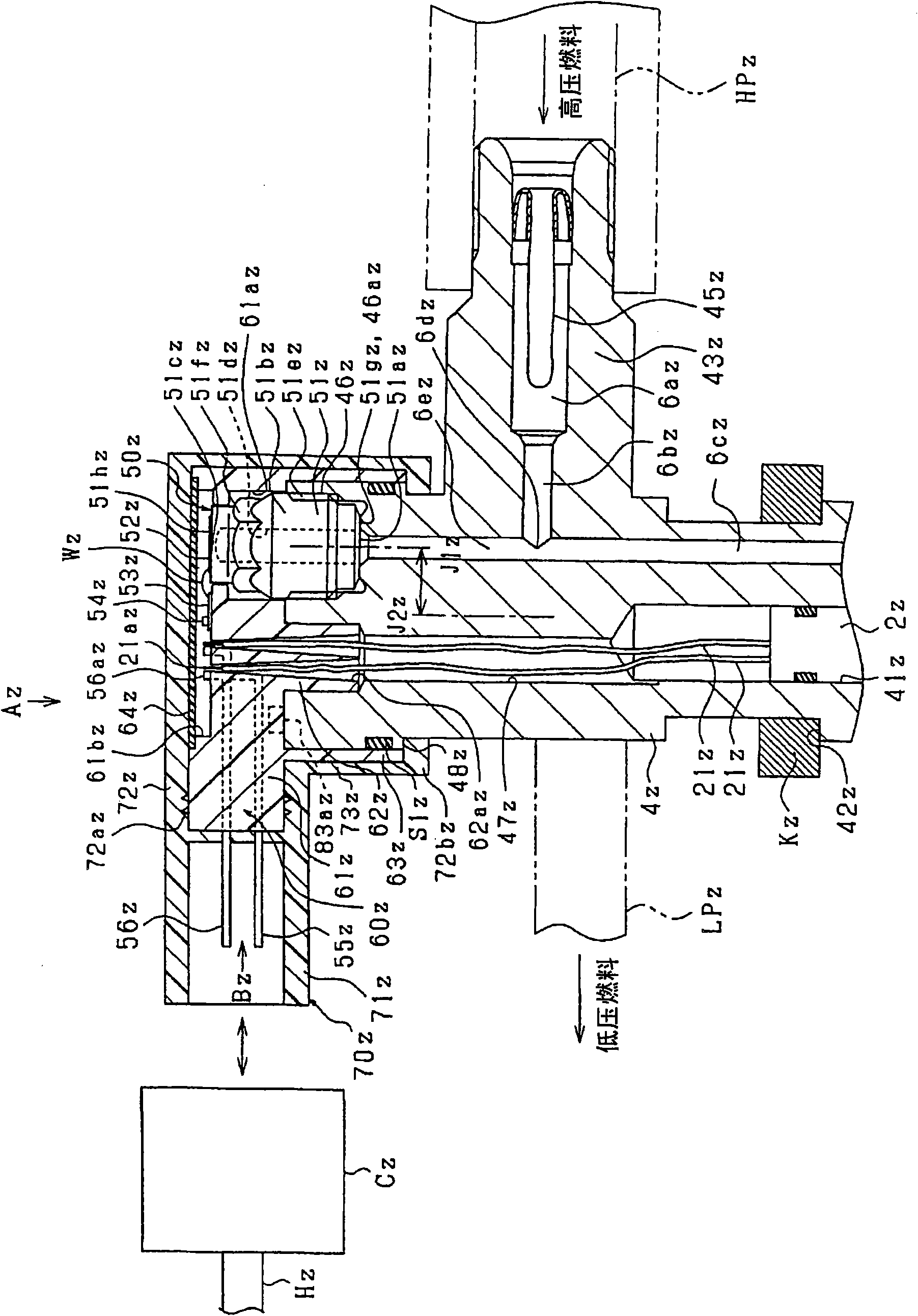

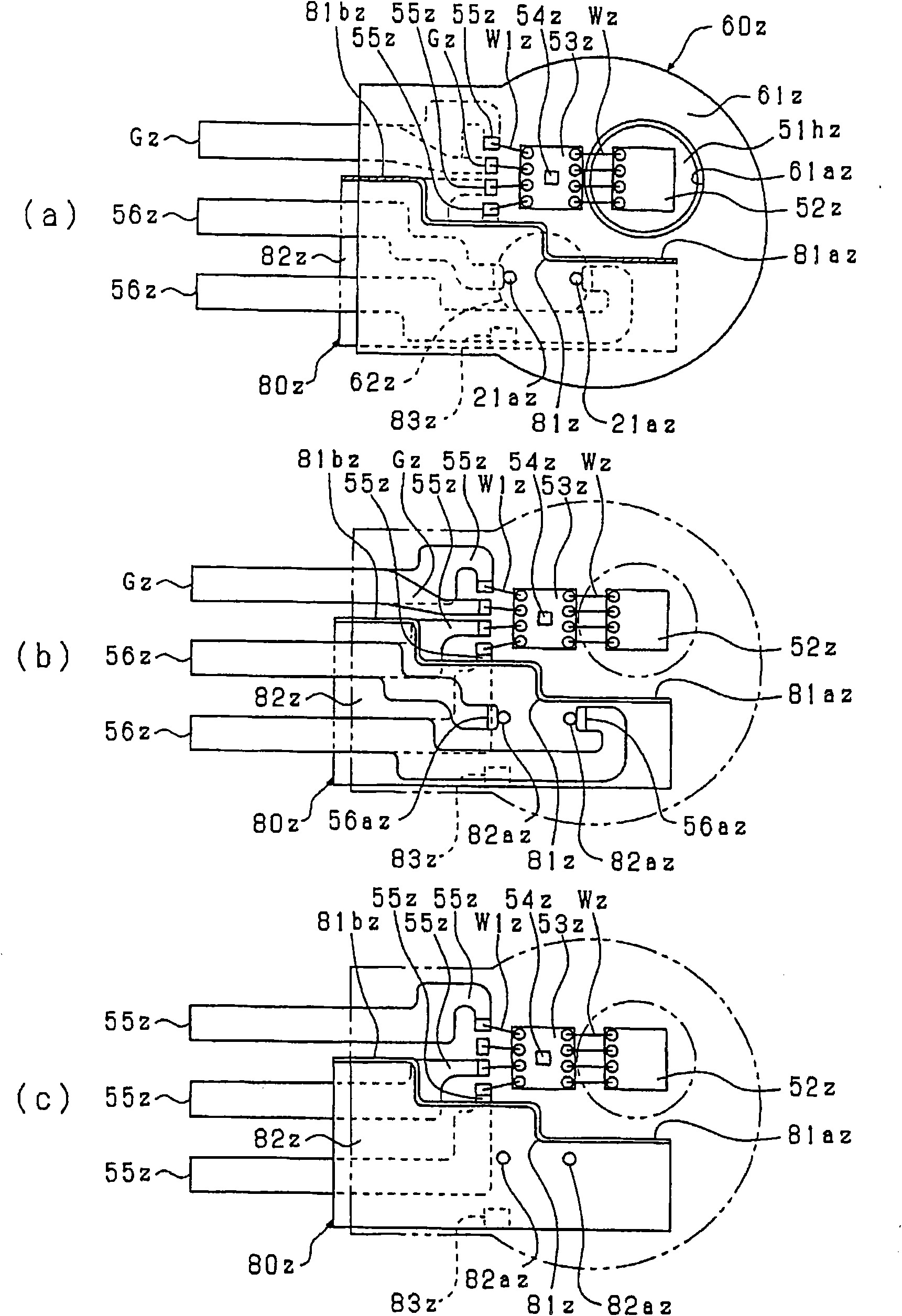

Fuel injection valve and fuel injection device

ActiveCN101821494AEasy to handleReduce sizeElectrical controlMachines/enginesEngineeringHigh pressure

Owner:DENSO CORP +1

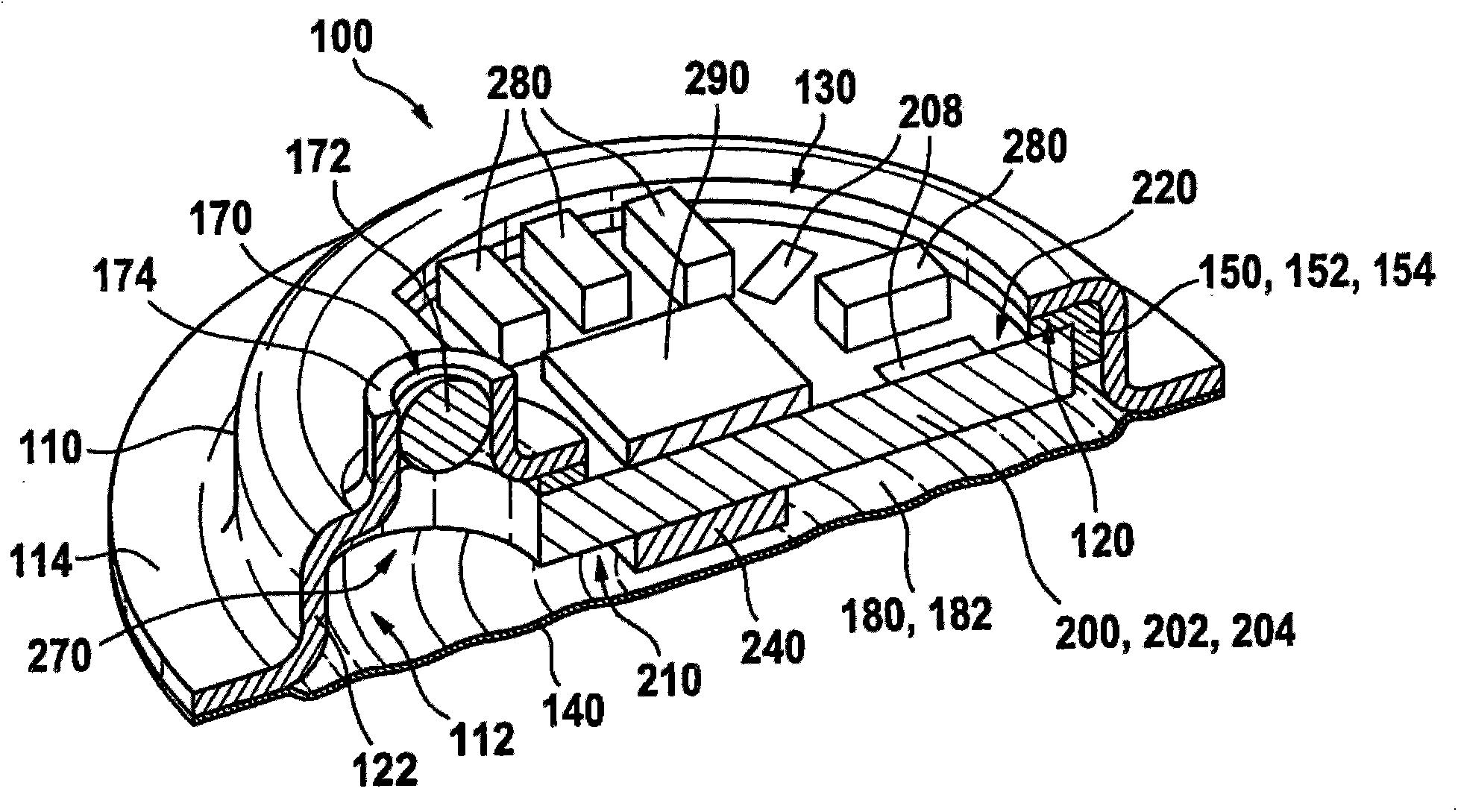

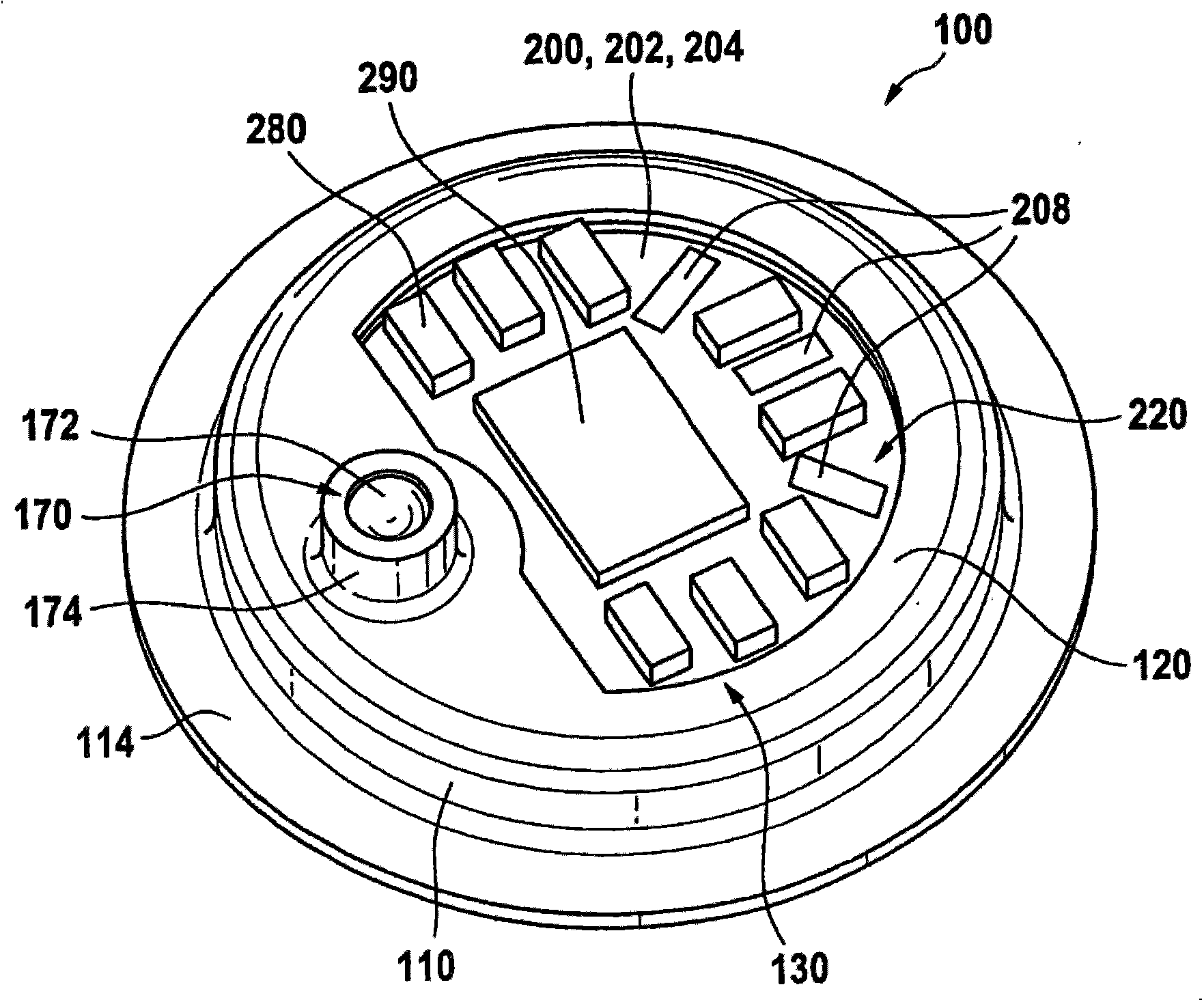

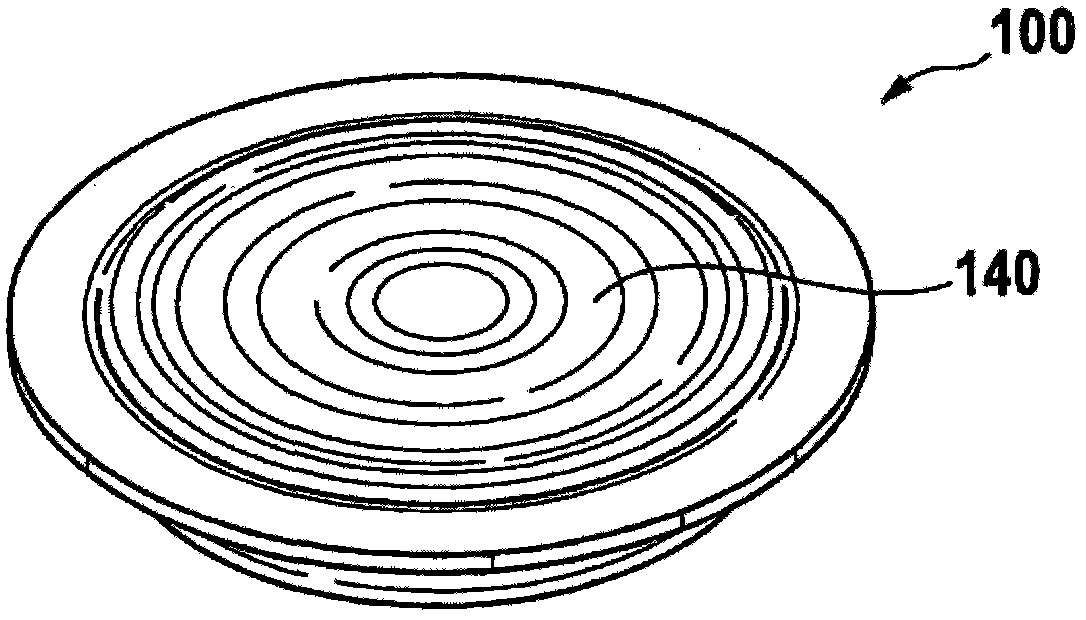

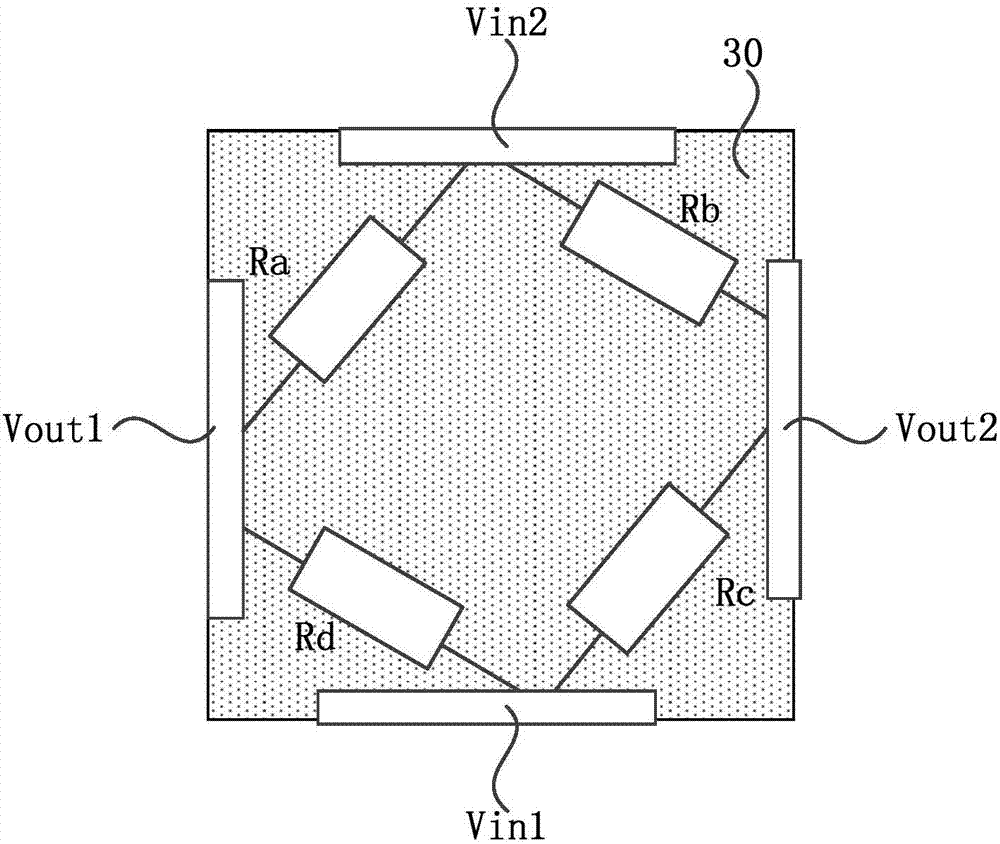

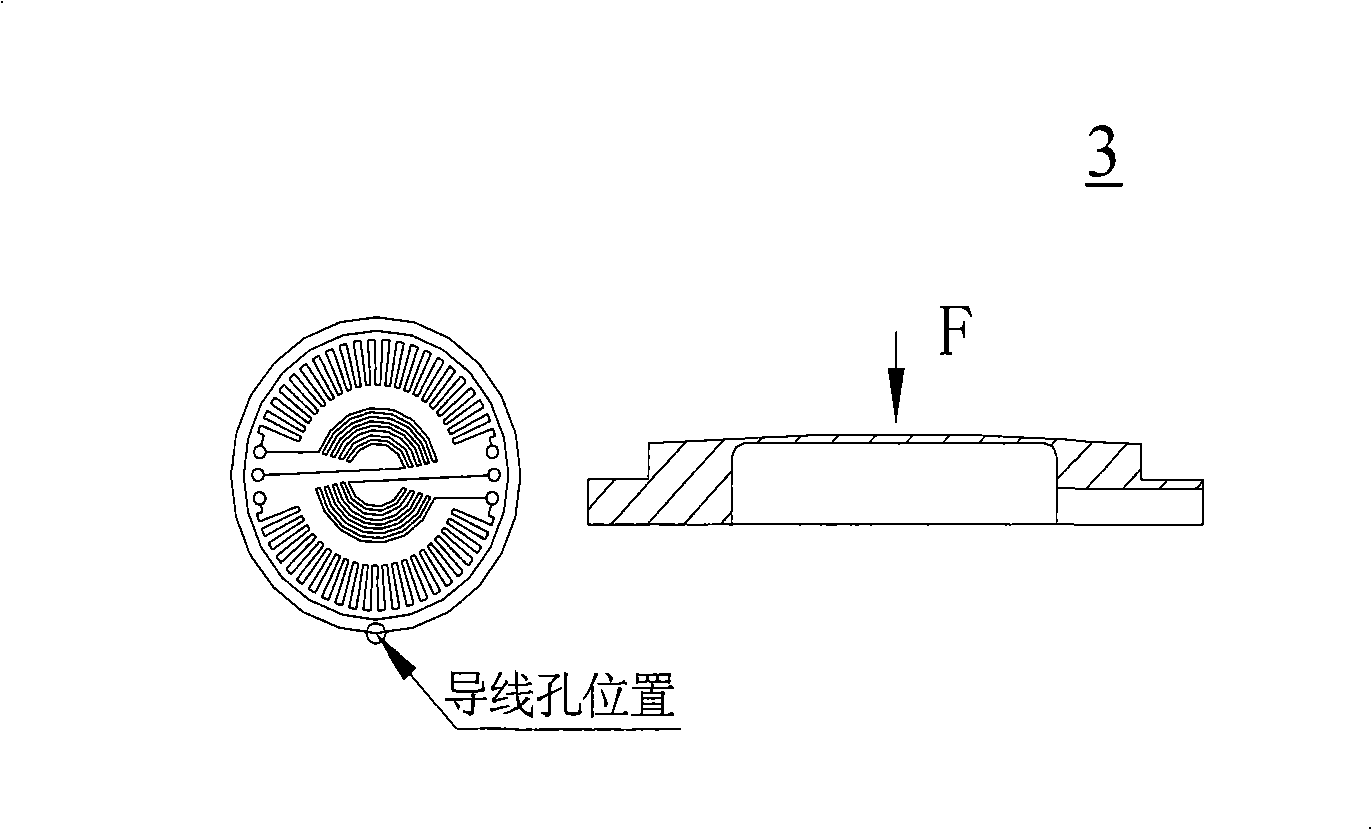

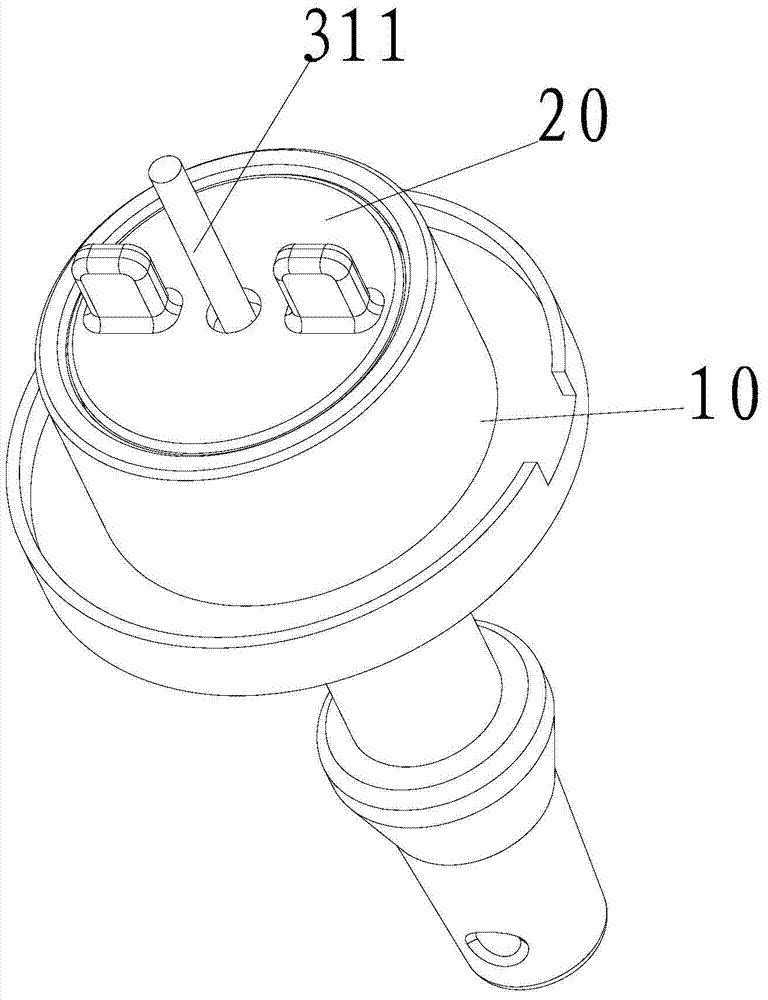

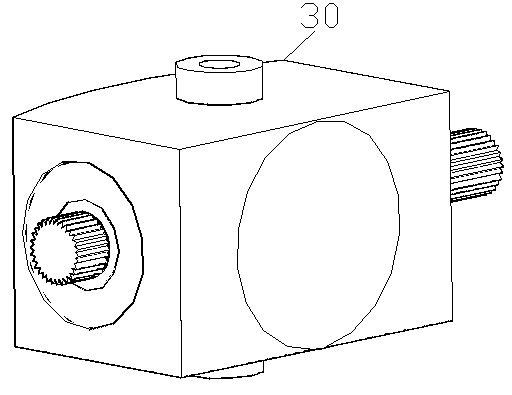

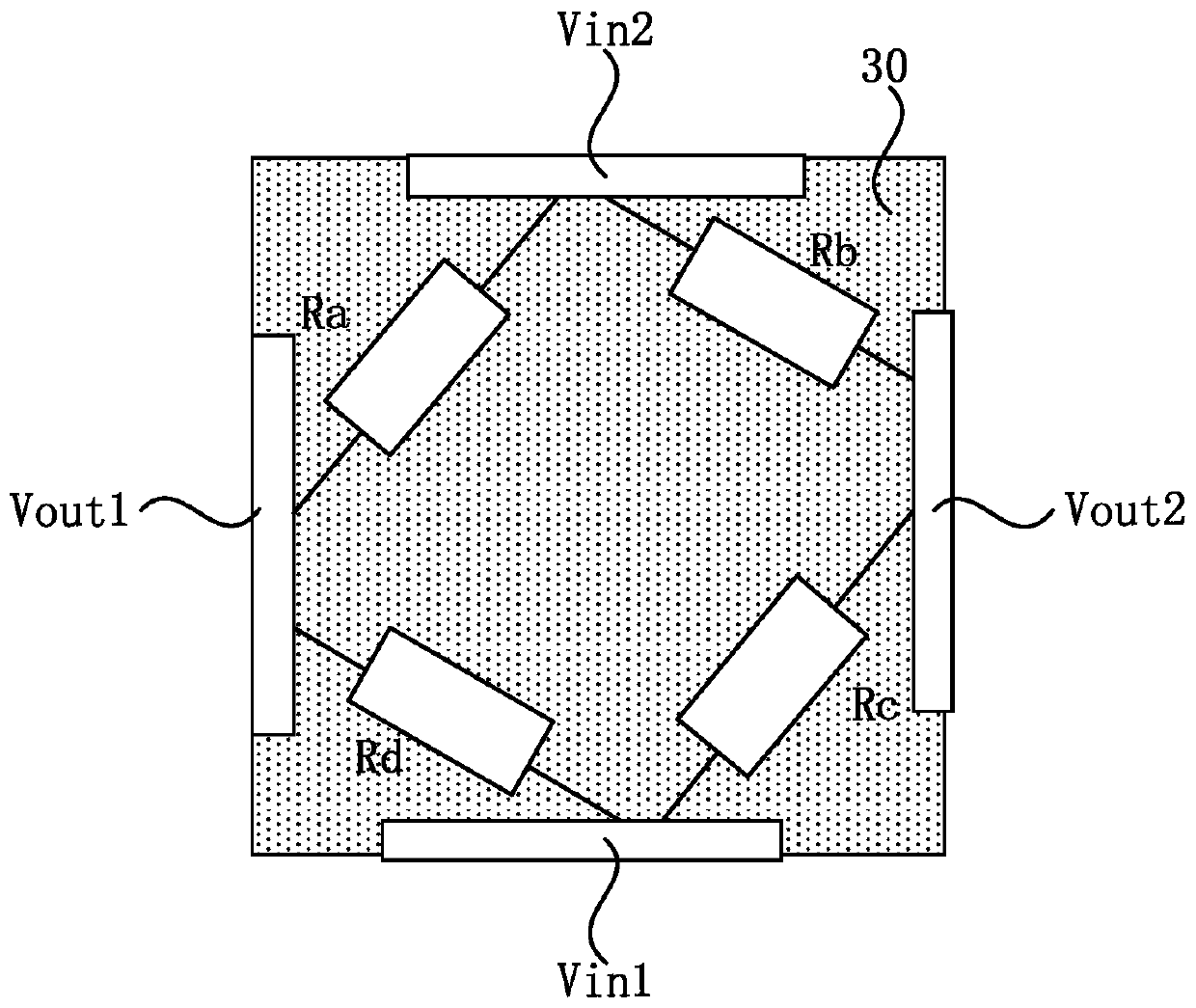

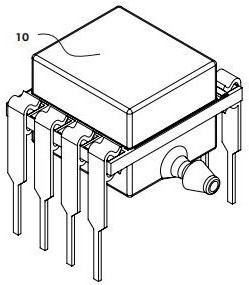

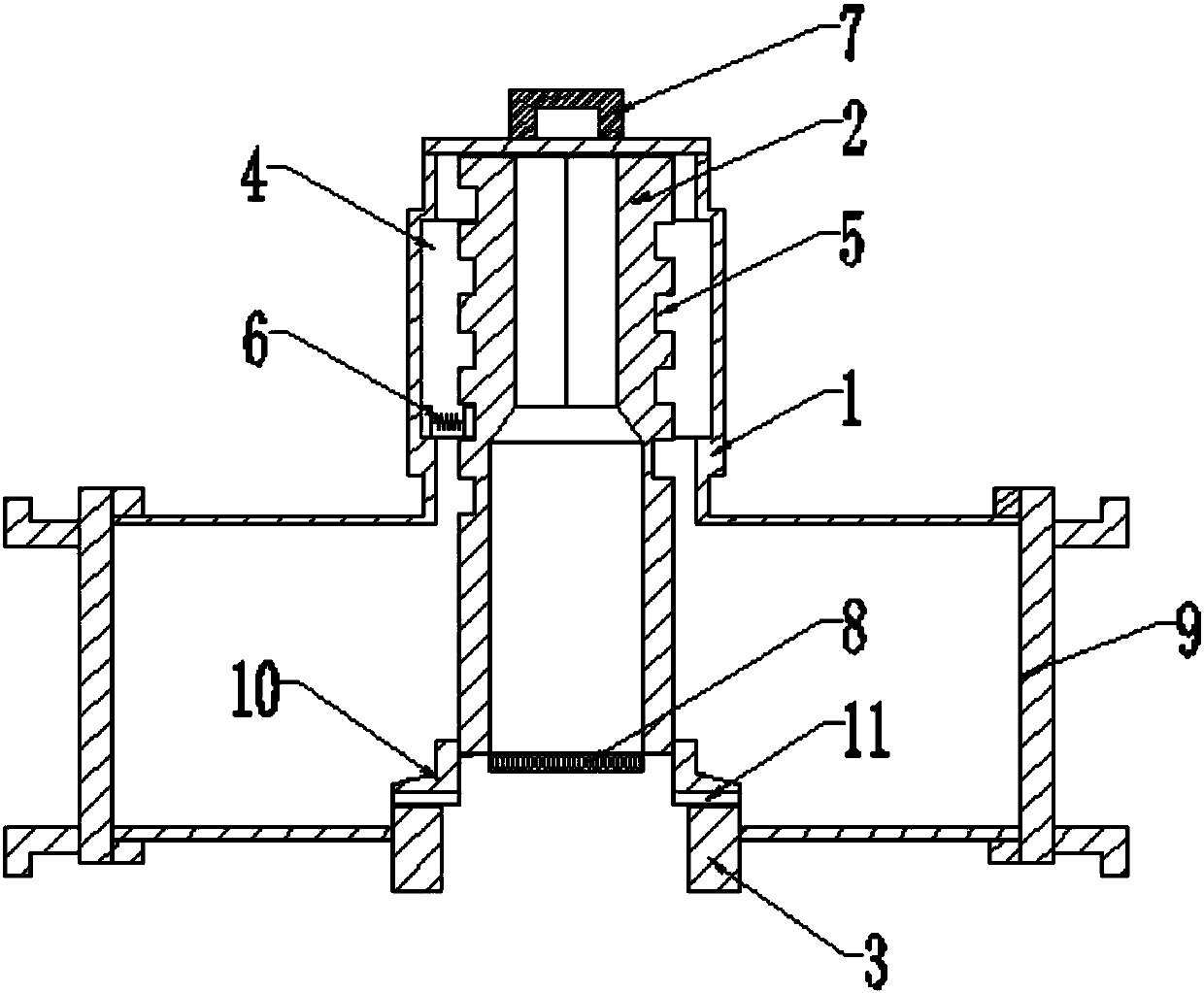

Pressure detection module and pressure sensor device having such a pressure detection module

ActiveCN103512701AAchieve airtight fixationSave construction spaceFluid pressure measurement by electric/magnetic elementsMechanical engineeringStress sensors

The invention relates to a pressure detection module. The pressure detection module includes a receptacle part for receiving a carrier substrate. A first side of the carrier substrate is provided with a pressure detection unit; and the carrier substrate is inserted into the receptacle part by virtue of a second side facing away from the first side; and the carrier substrate is fixed on the bottom of a receptacle groove by virtue of the second side facing away from the first side. In order to construct the pressure detection module as small as possible, and to manufacture it in a cost-effective way, the receptacle part, the receptacle groove and a peripheral flange around the receptacle groove are, for example, provided with a plate-shaped design. The bottom has a contacting opening, through which contact surfaces of the carrier substrate, which are exposed at the contacting opening, are electrically contactable. Besides, the invention also relates to a pressure sensor device having such a pressure detection module.

Owner:ROBERT BOSCH GMBH

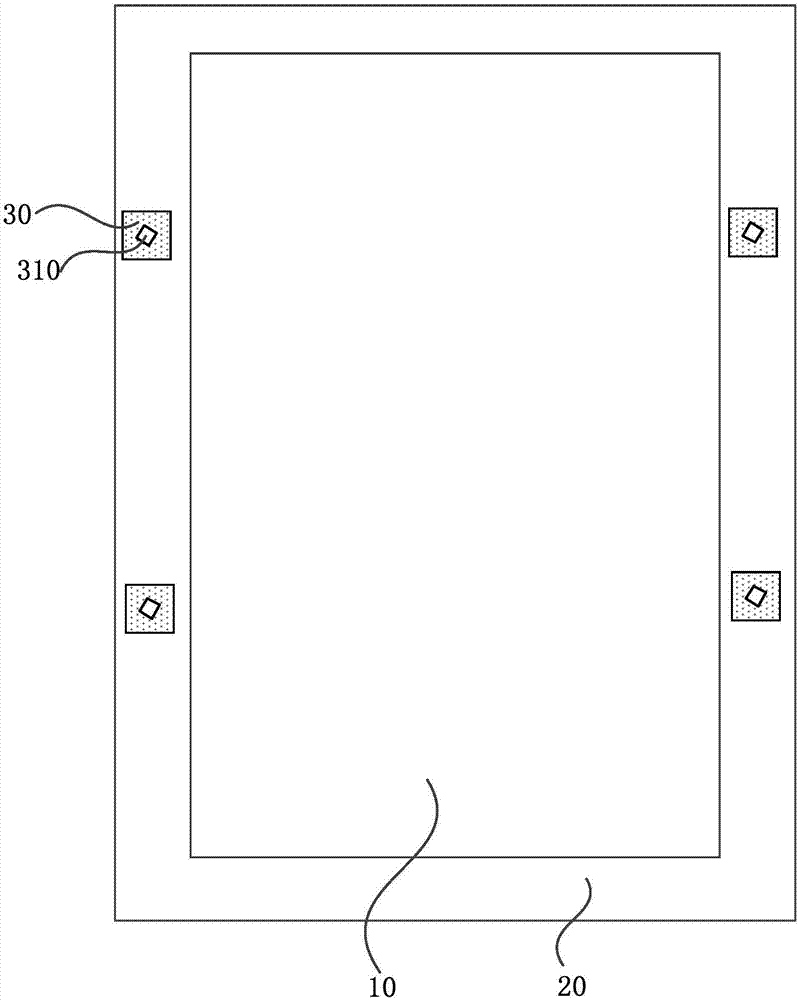

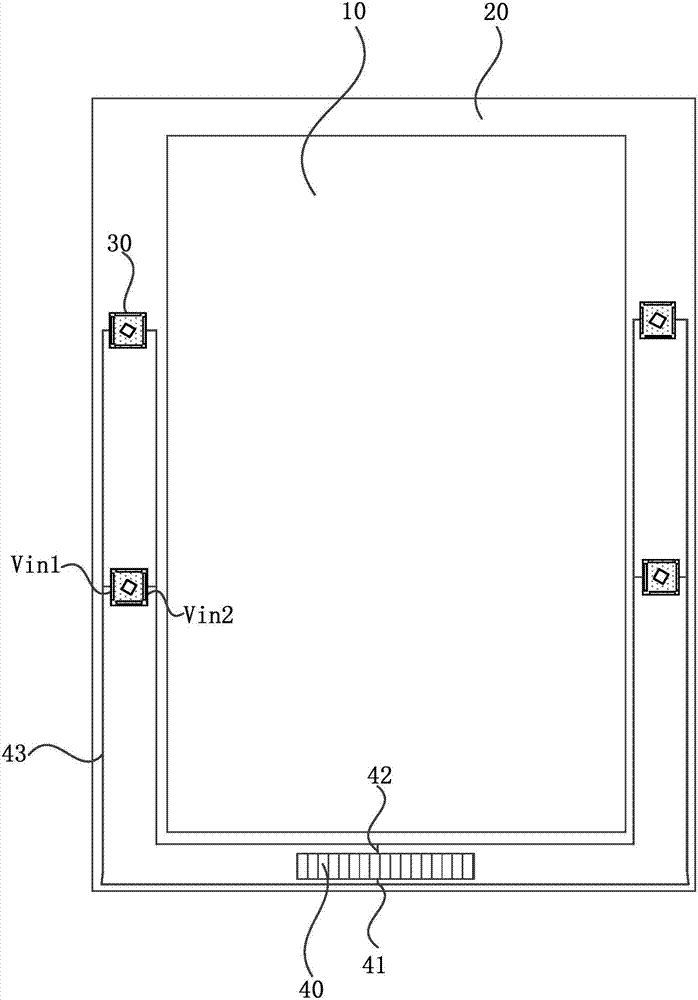

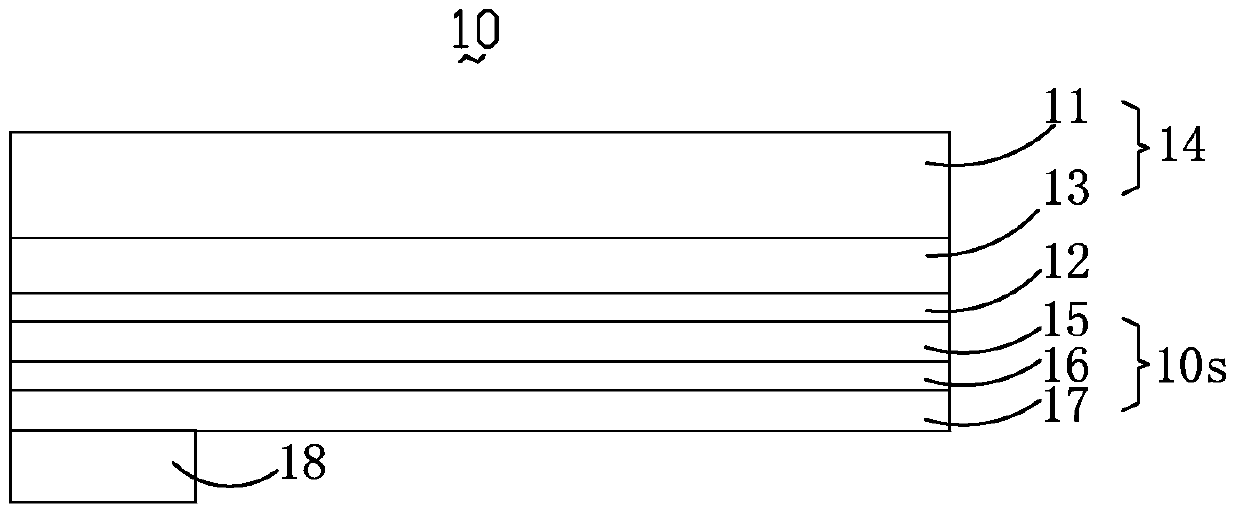

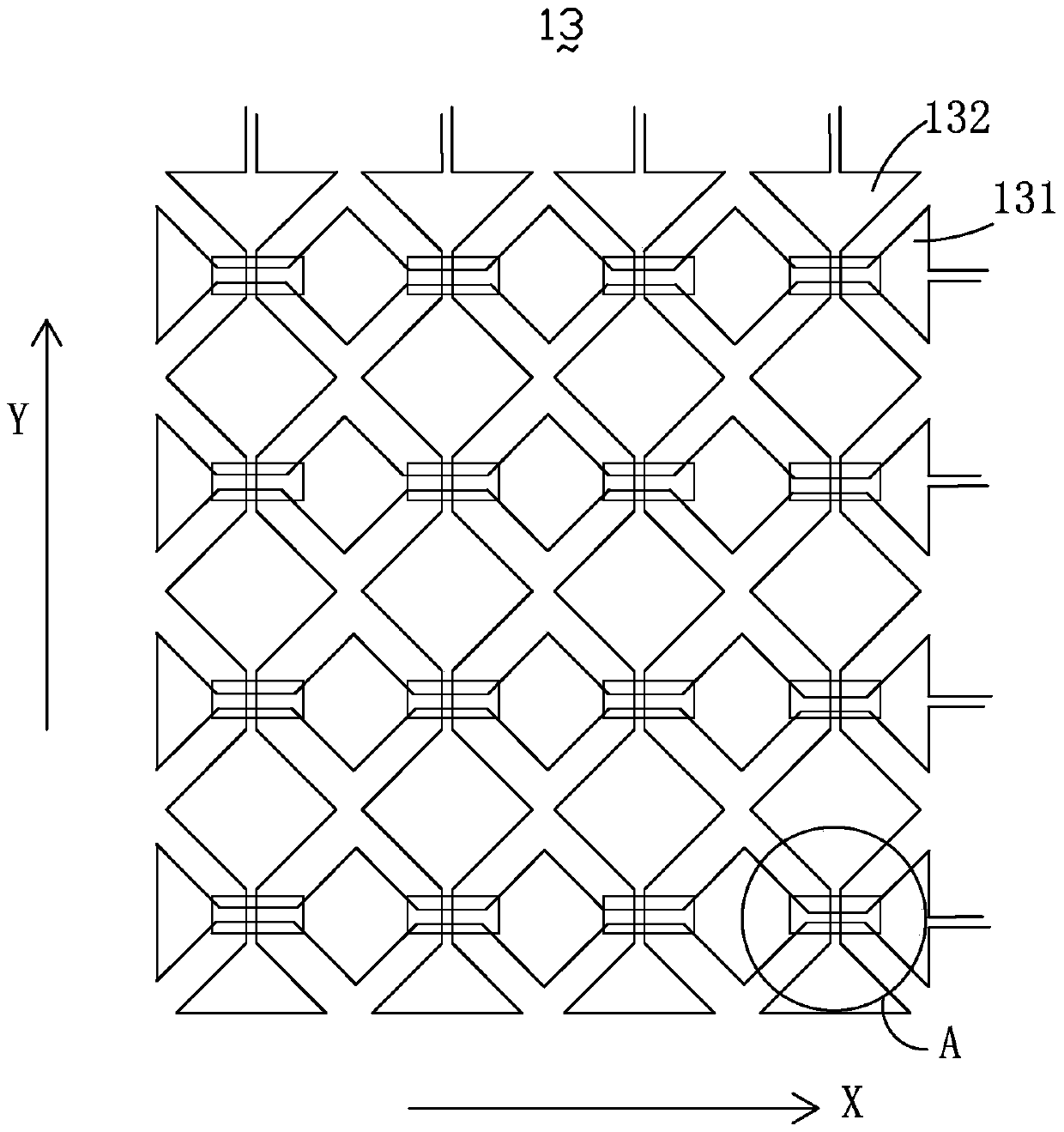

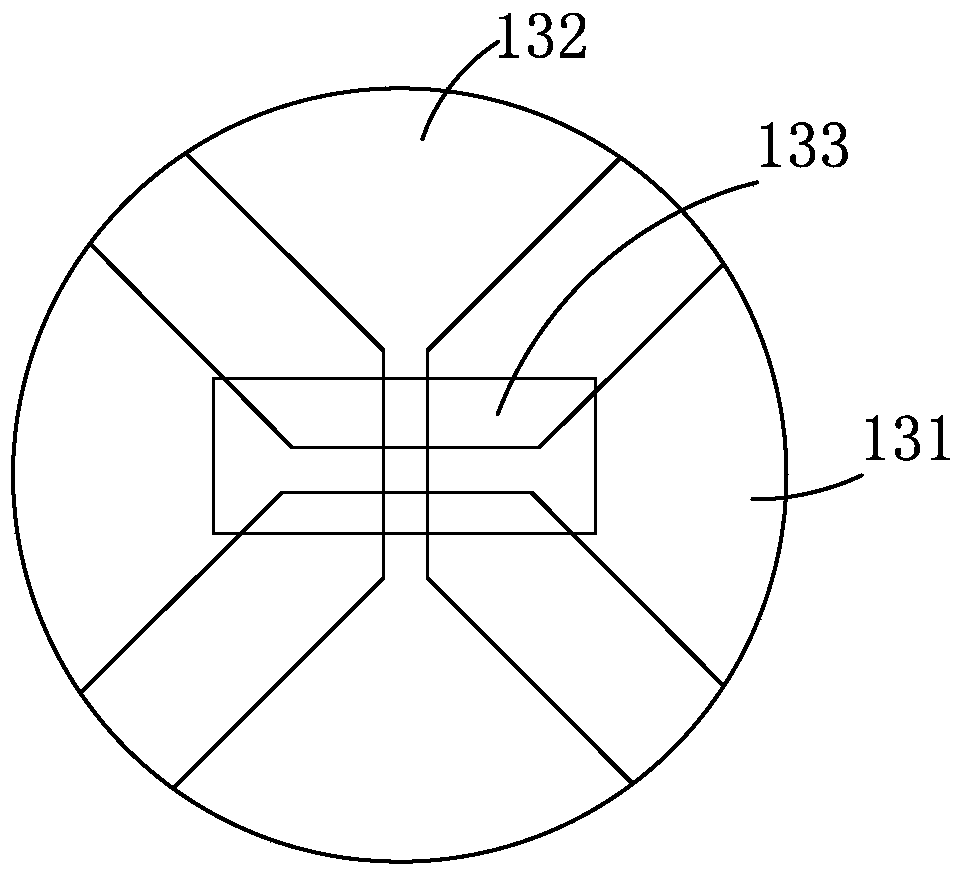

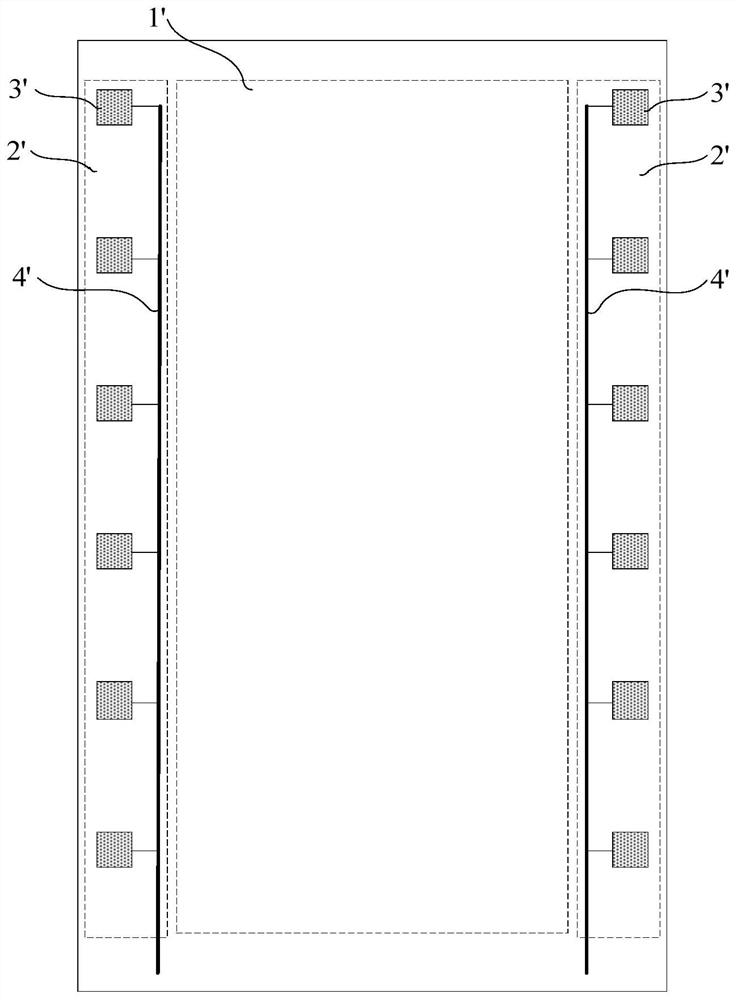

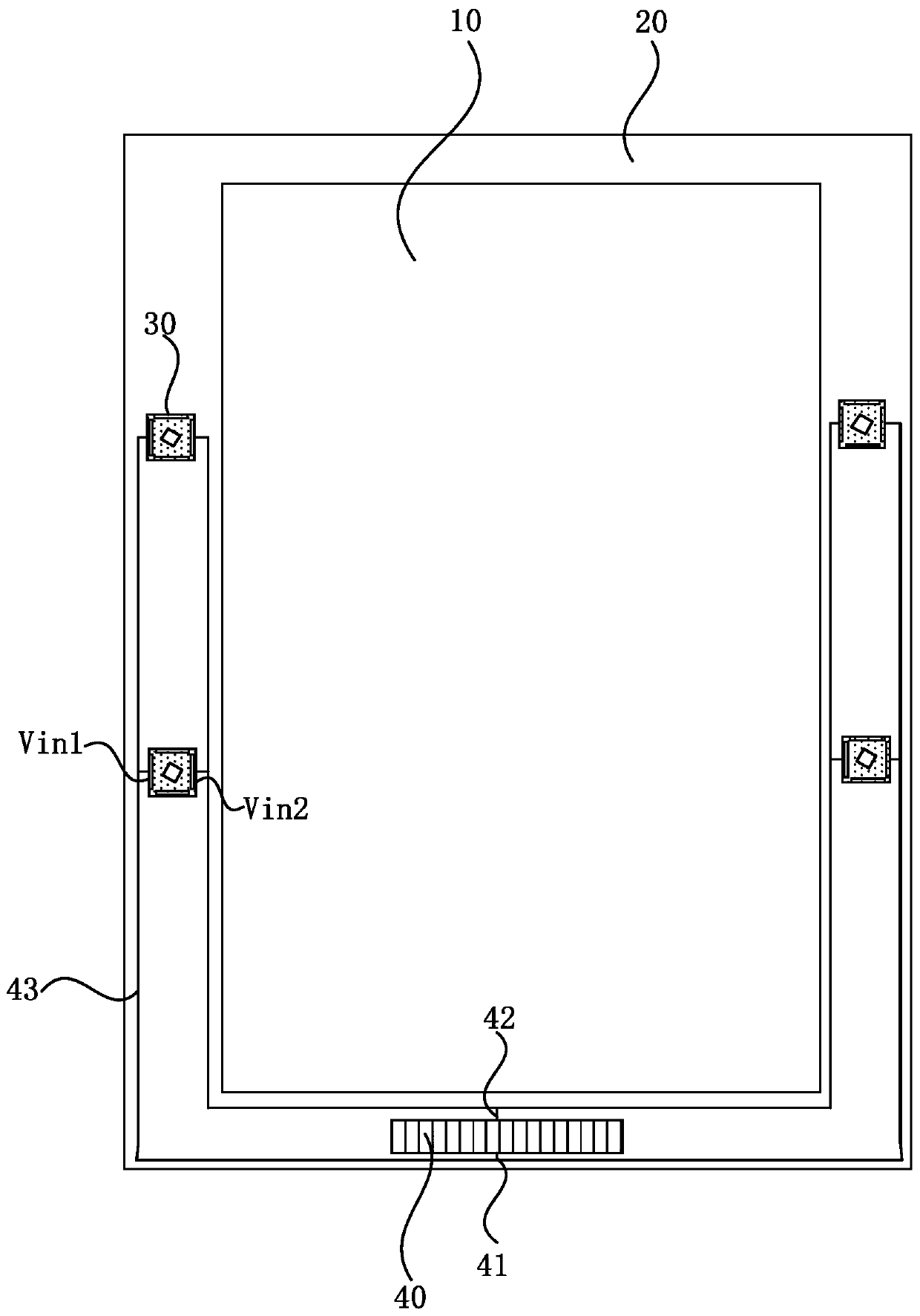

Display panel and display device

ActiveCN107272961AImprove pressure detection accuracyImprove cooling effectSolid-state devicesForce measurementDisplay deviceForce sensor

The embodiment of the invention discloses a display panel and a display device. The display panel comprises a display region and a non-display region around the display region; the display panel comprises at least a semiconductor pressure sensor arranged in the non-display region; the semiconductor pressure sensor is plane-like and is provided with a hollow region. According to the embodiment, the pressure detection precision of the pressure sensor is improved, and the user experience is improved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

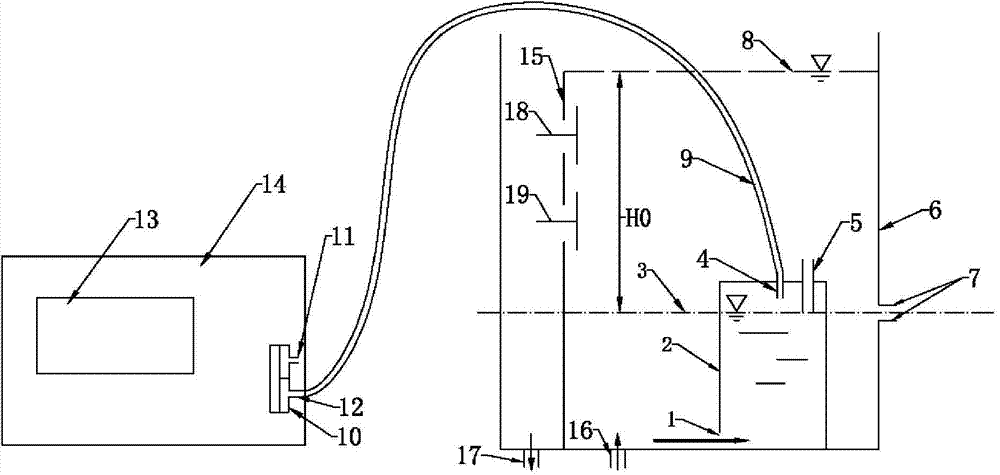

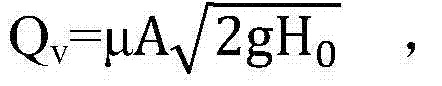

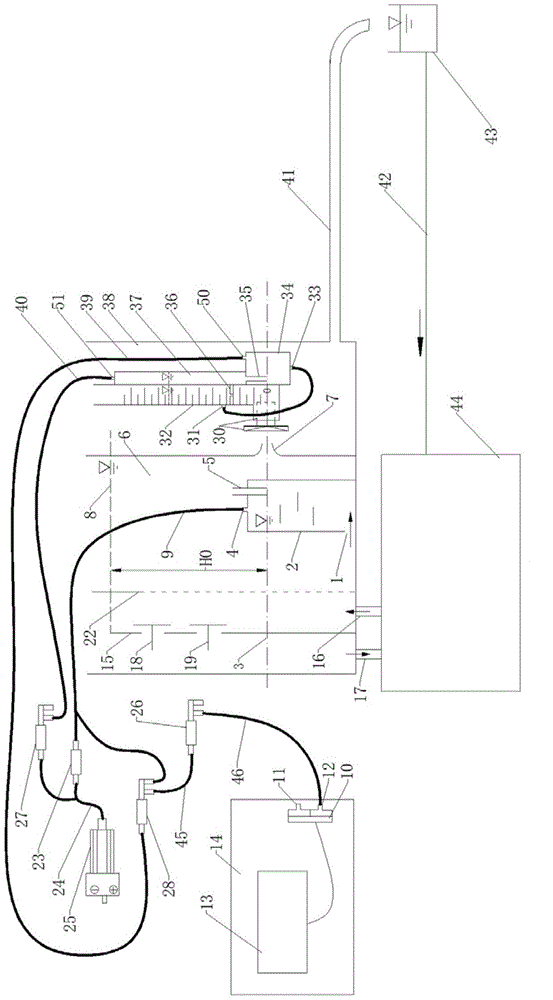

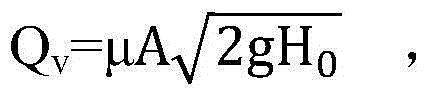

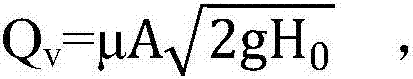

Flow rate measuring device based on efficient water head

ActiveCN104764496AConvenient digital accurate measurementImprove teaching effectHydrodynamic testingEducational modelsMicrocomputerJet flow

The invention discloses a flow rate measuring device based on an efficient water head. The device comprises an experimental water tank of which the sidewall is provided with an outlet, a liquid-air converting pressure measuring barrel arranged in the experimental water tank, a liquid pressure difference sensor which is connected with the liquid-air converting pressure measuring barrel and used for detecting the pressure difference between compressed in the liquid-air converting pressure measuring barrel and the outside air, and a microcomputer which is connected with the liquid pressure difference sensor and used for converting a pressure difference signal detected by the liquid pressure difference sensor into the flow rate of the outlet, wherein the bottom part of the liquid-air converting pressure measuring barrel is communicated with an inner space of the experimental water tank, and while the top part of the liquid-air converting pressure measuring barrel is provided with a communication positioning tube; the bottom surface of the communication positioning tube is positioned on a medium shaft level of the outlet. With the adoption of the device, the jet flow rate of a momentum experiment instrument in the basic liquid mechanics experiment, a hole opening, and a hole opening and a tube nozzle in a tube nozzle experiment instrument can be conveniently digitally accurately measured; the teaching effect is good.

Owner:ZHEJIANG UNIV +1

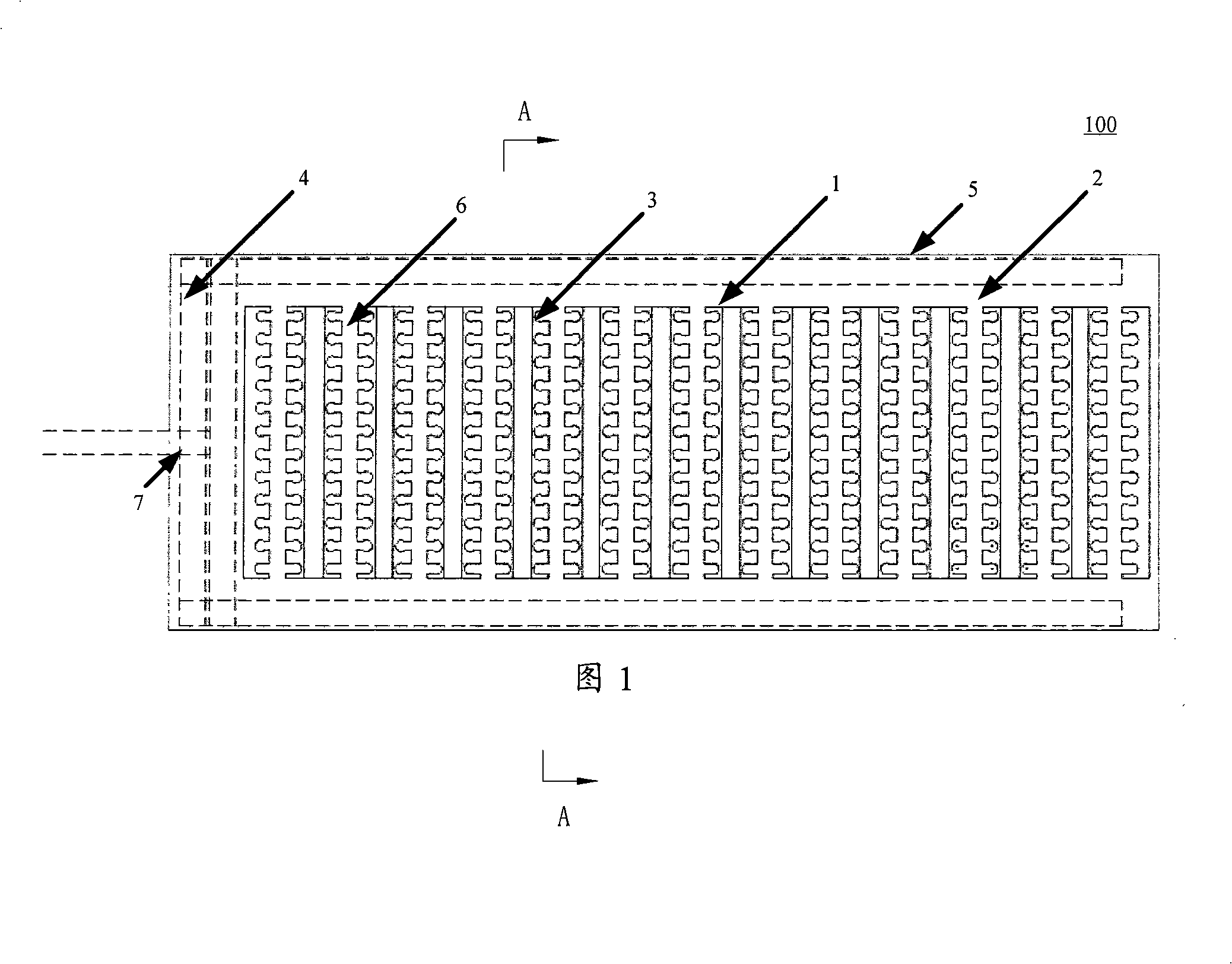

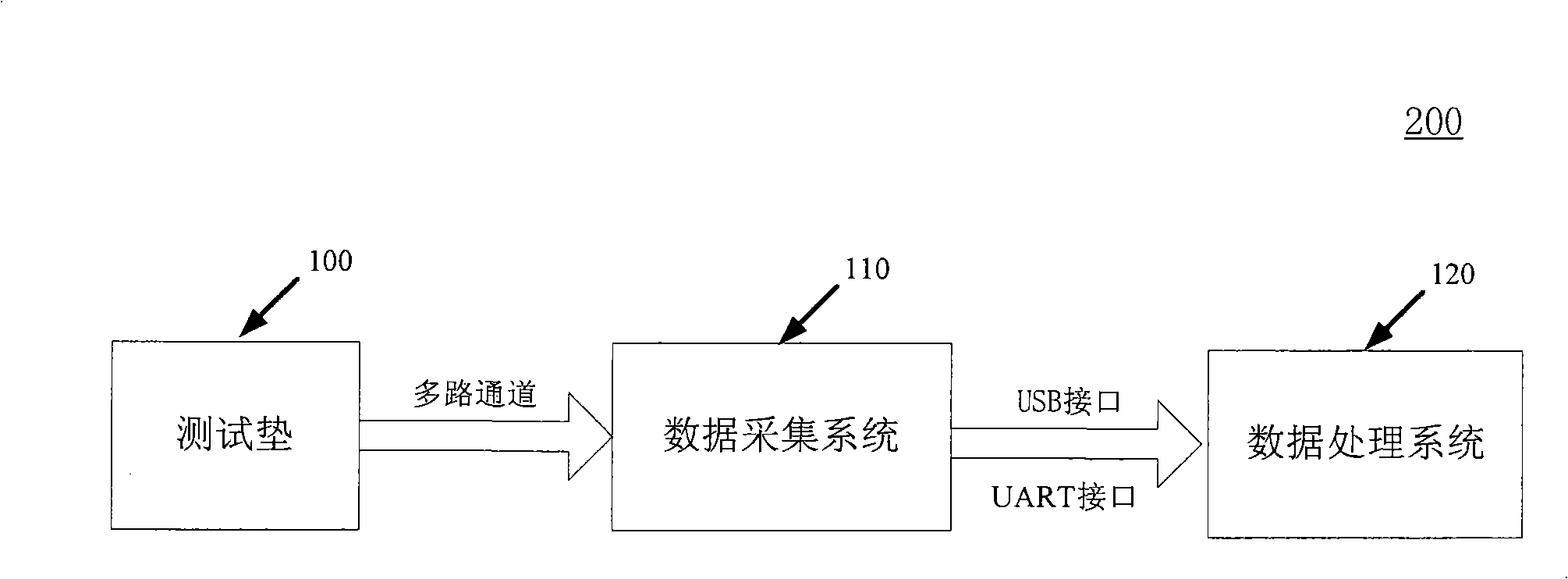

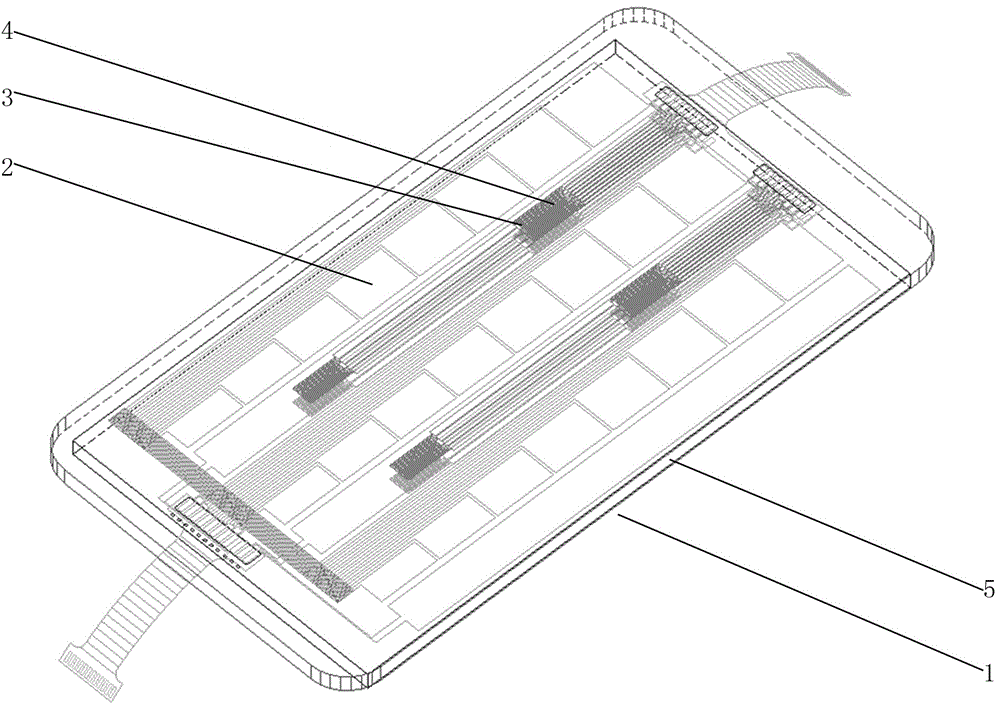

Multi-point body pressure test mattress

InactiveCN101514929AOvercome complex and difficult to operate defectsEasy to foldForce measurementEvaluation resultEngineering

The invention provides a multi-point body pressure test mattress, which comprises a top layer, a bottom layer, a pressure sensor, and a jacket, and also comprises a circuit arranging wire and at least one circuit board, wherein the pressure sensor is arranged on the circuit board and positioned between the top layer and the bottom layer; the circuit boards are distributed in a shape of a strip array, so that the pressure sensors are generally distributed in a shape of a matrix; and the circuit arranging wire is connected with the circuit boards. The multi-point body pressure test mattress solves the problems of poor evaluation results, overlong evaluation time and not objective evaluation results caused by sensory evaluation of the prior technicians, improves scientificalness and efficiency of mattress design, improves pressure detection accuracy, overcomes the defects of complicated circuits and difficult operation of the prior test mattress, and has the advantages of easy folding and movement.

Owner:KELI SENSING TECH NINGBO CO LTD +1

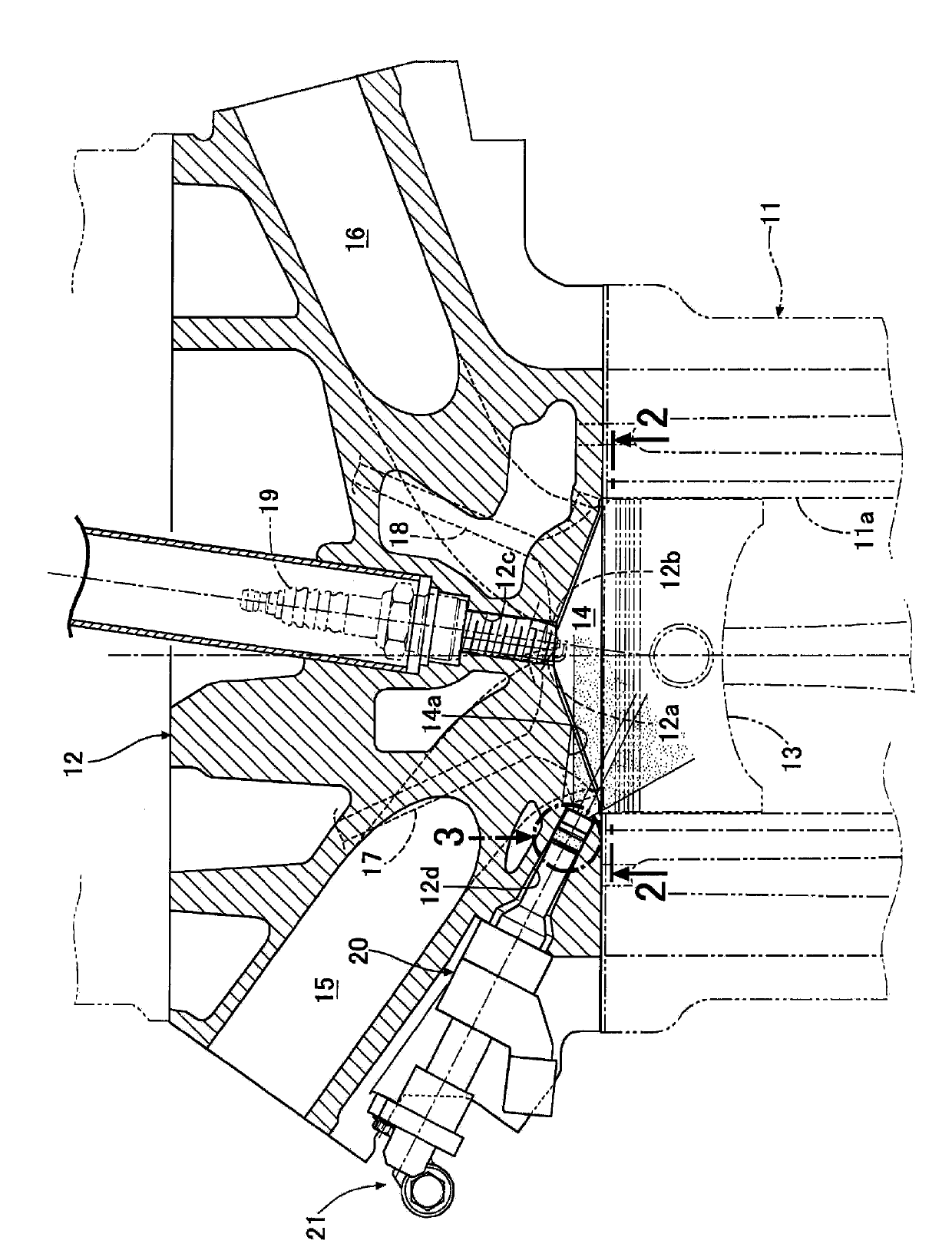

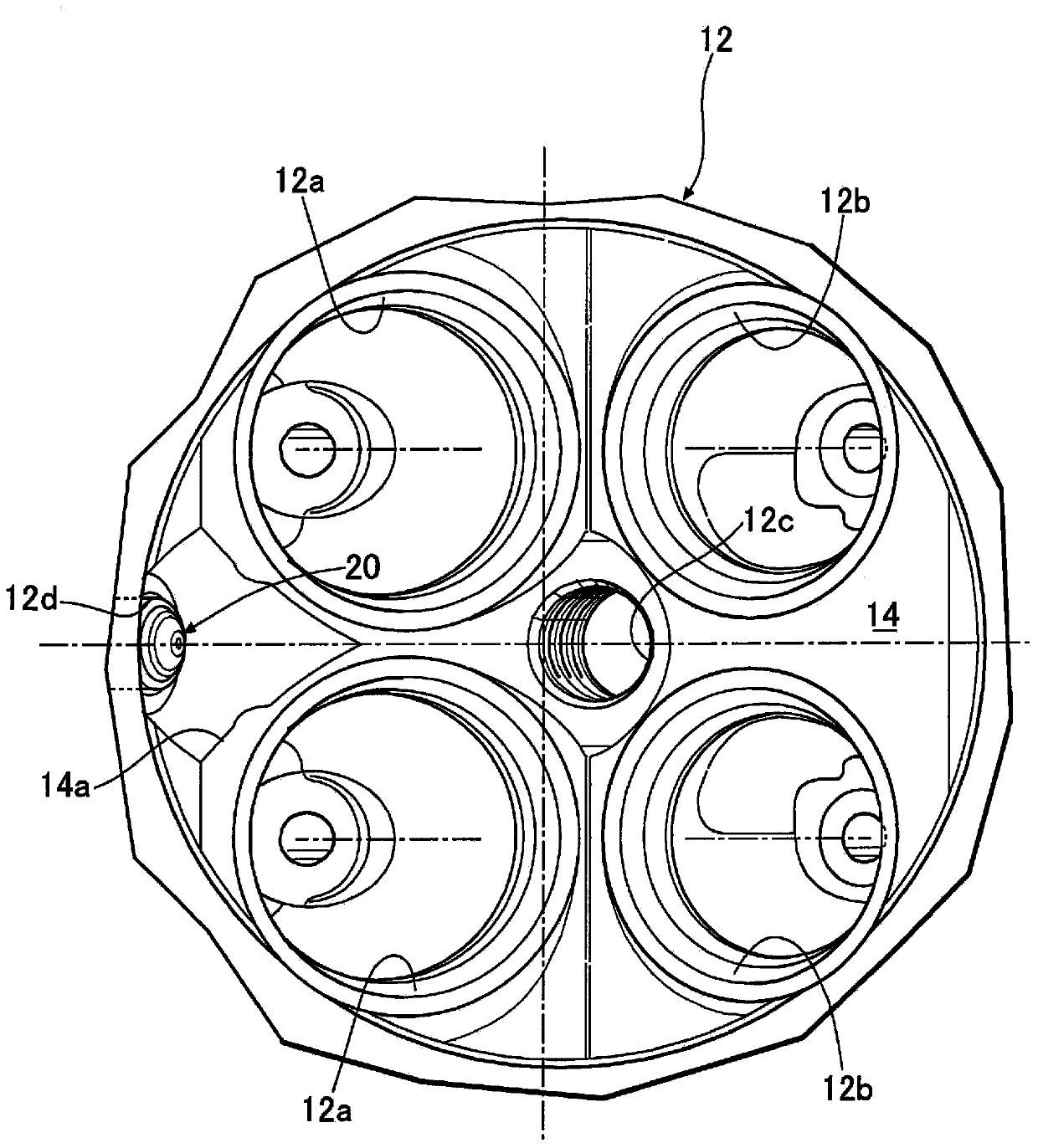

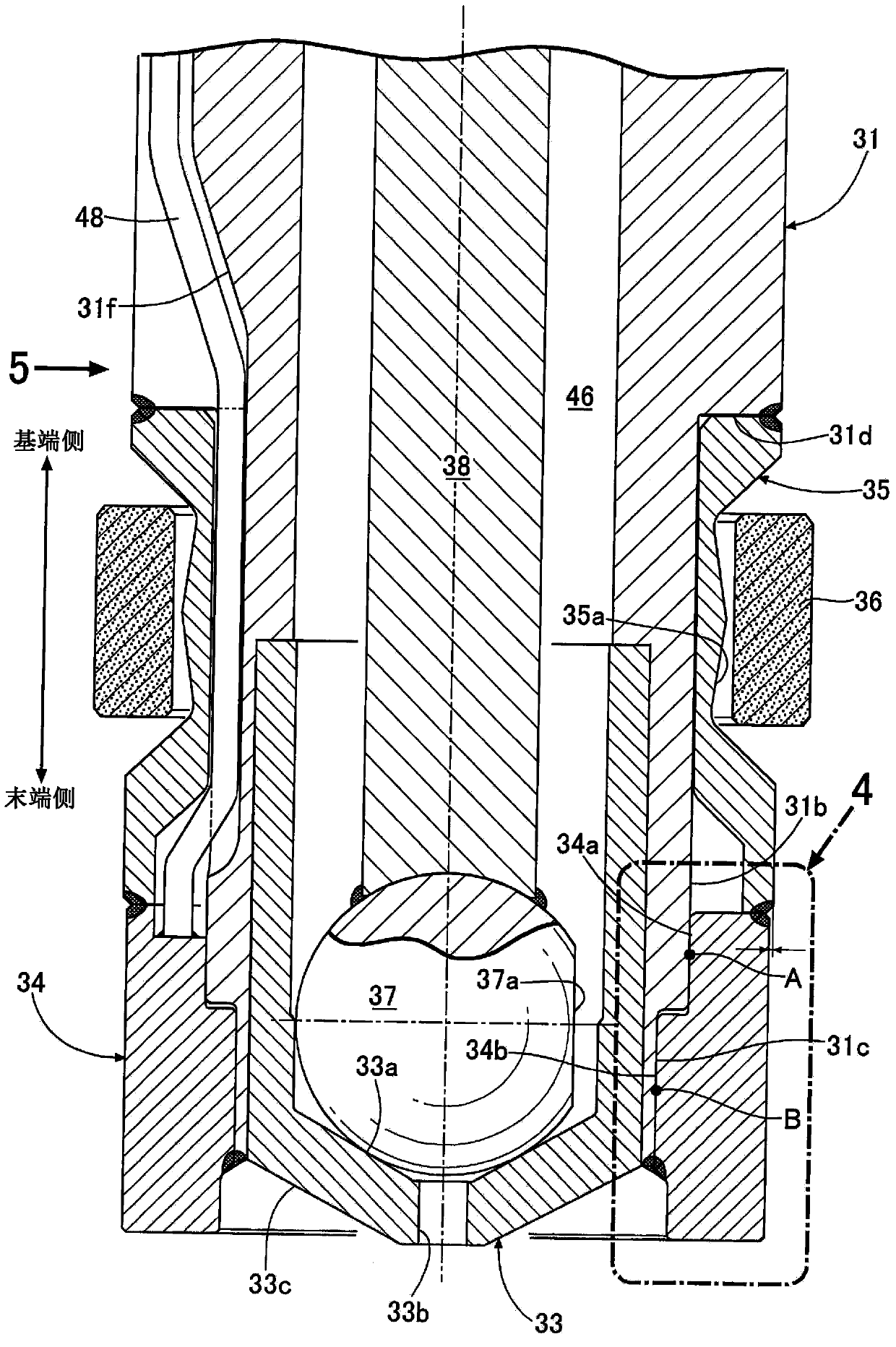

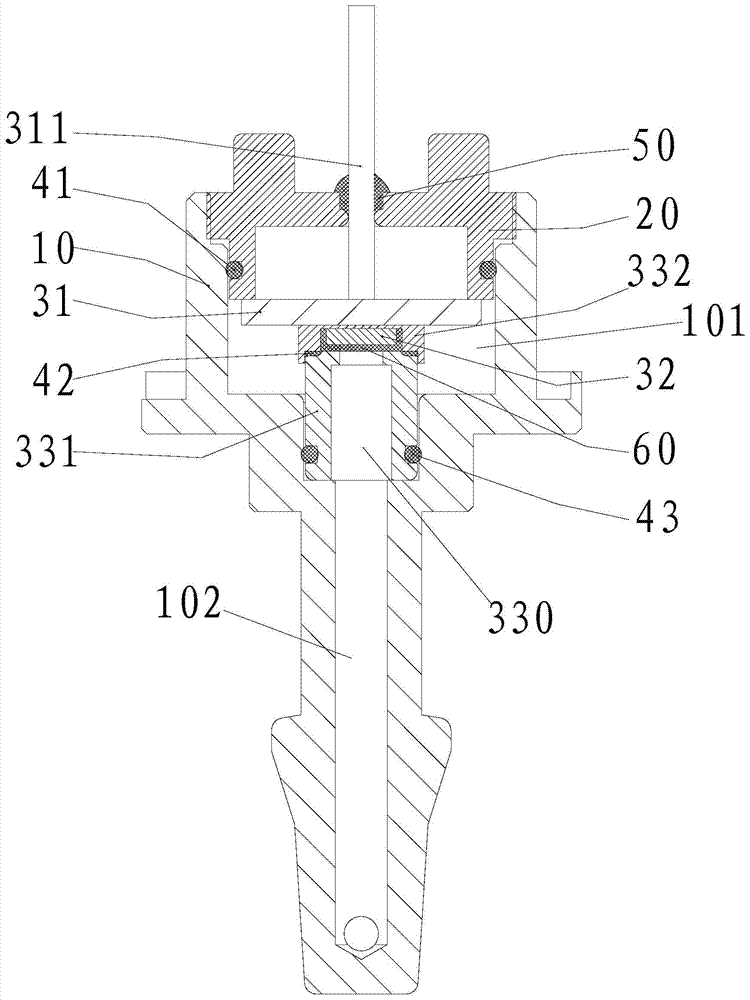

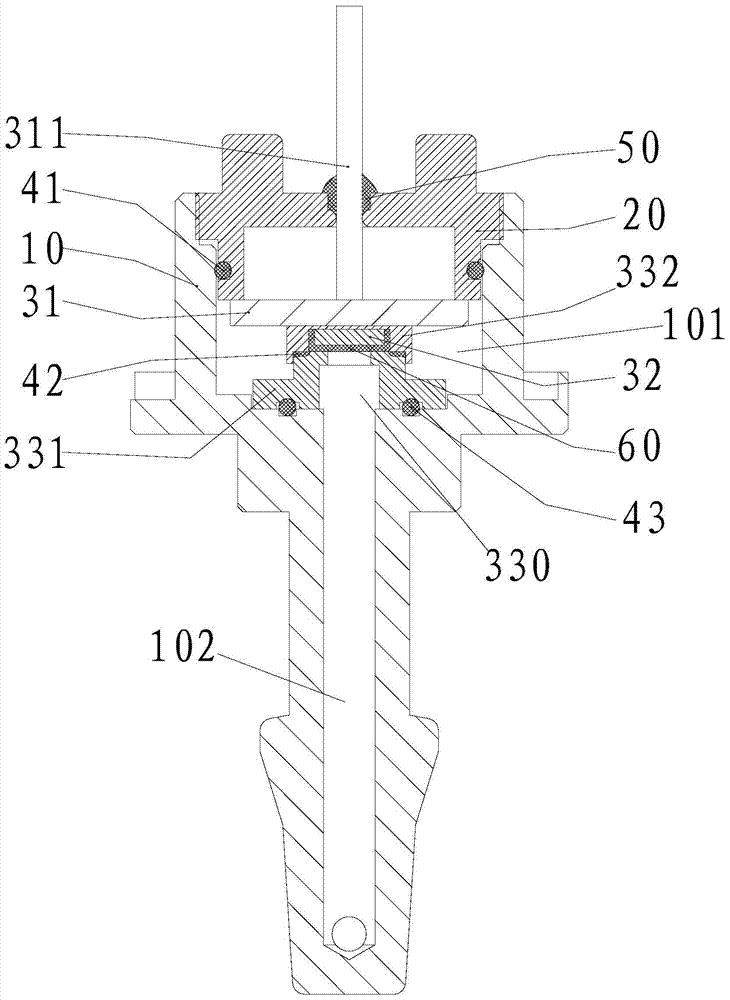

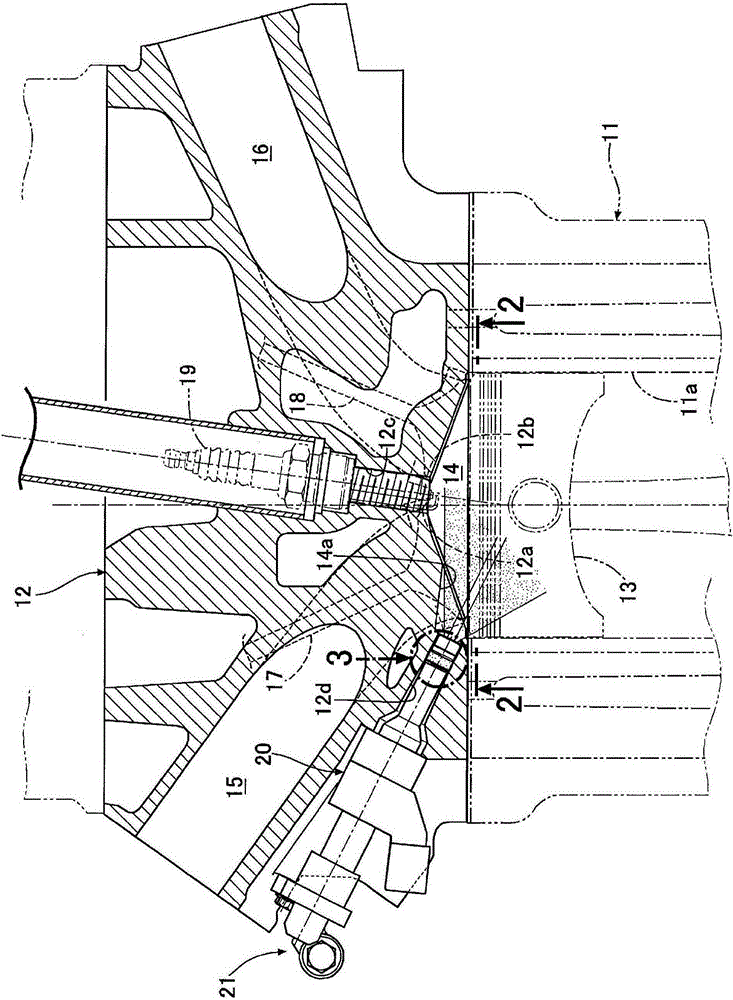

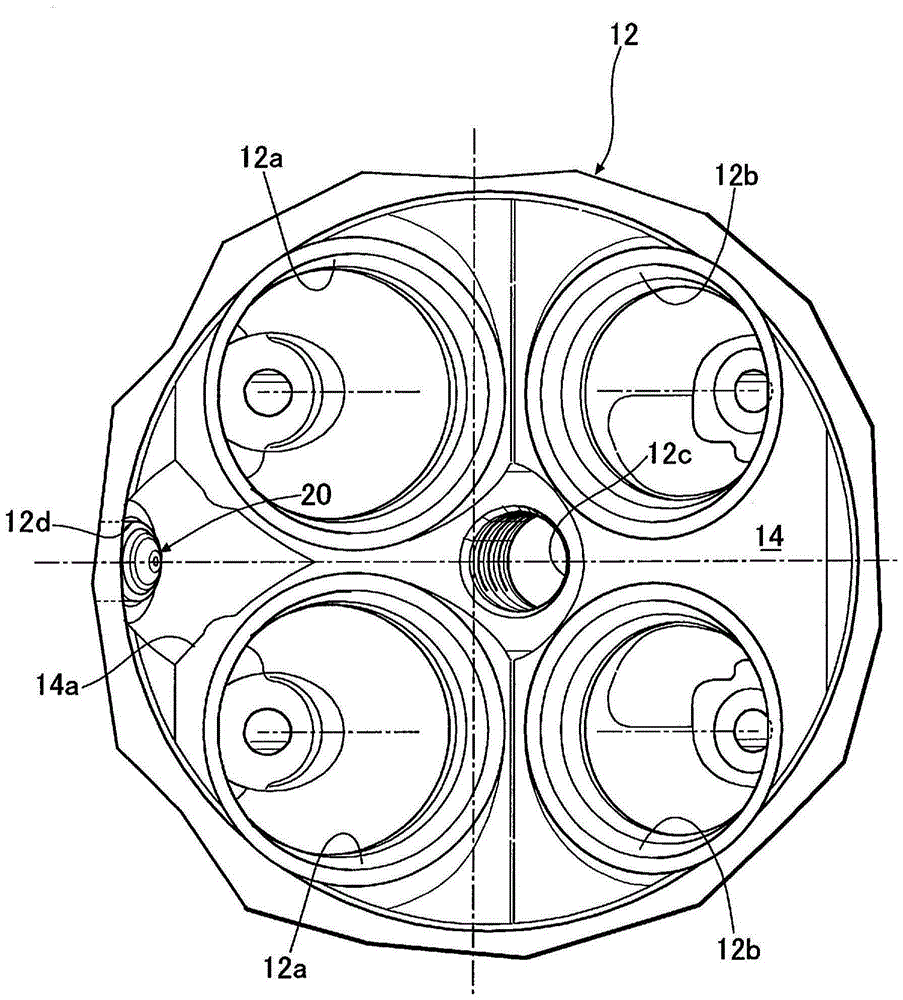

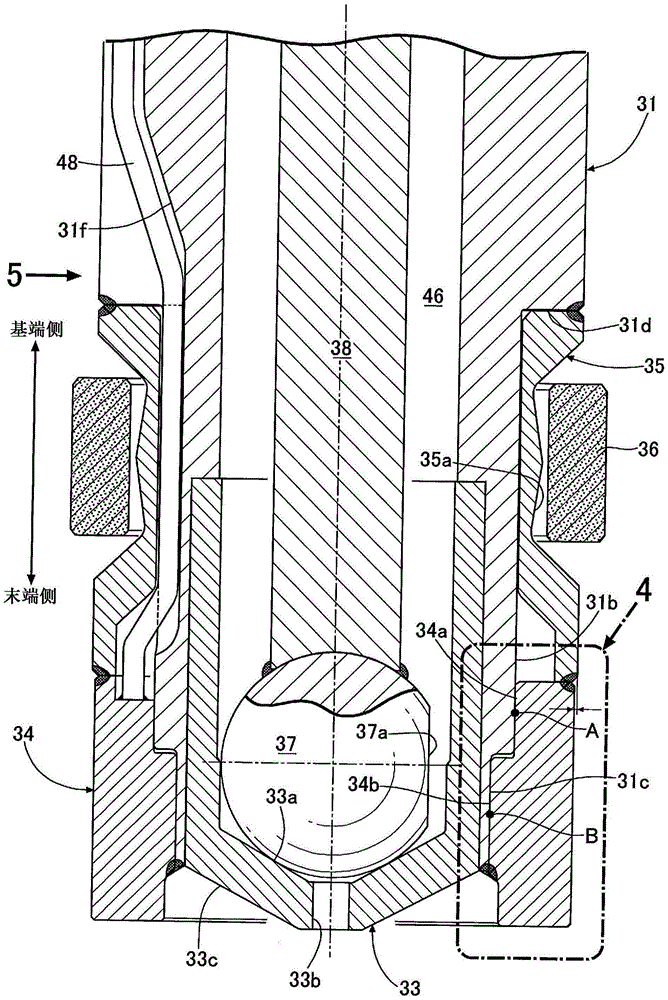

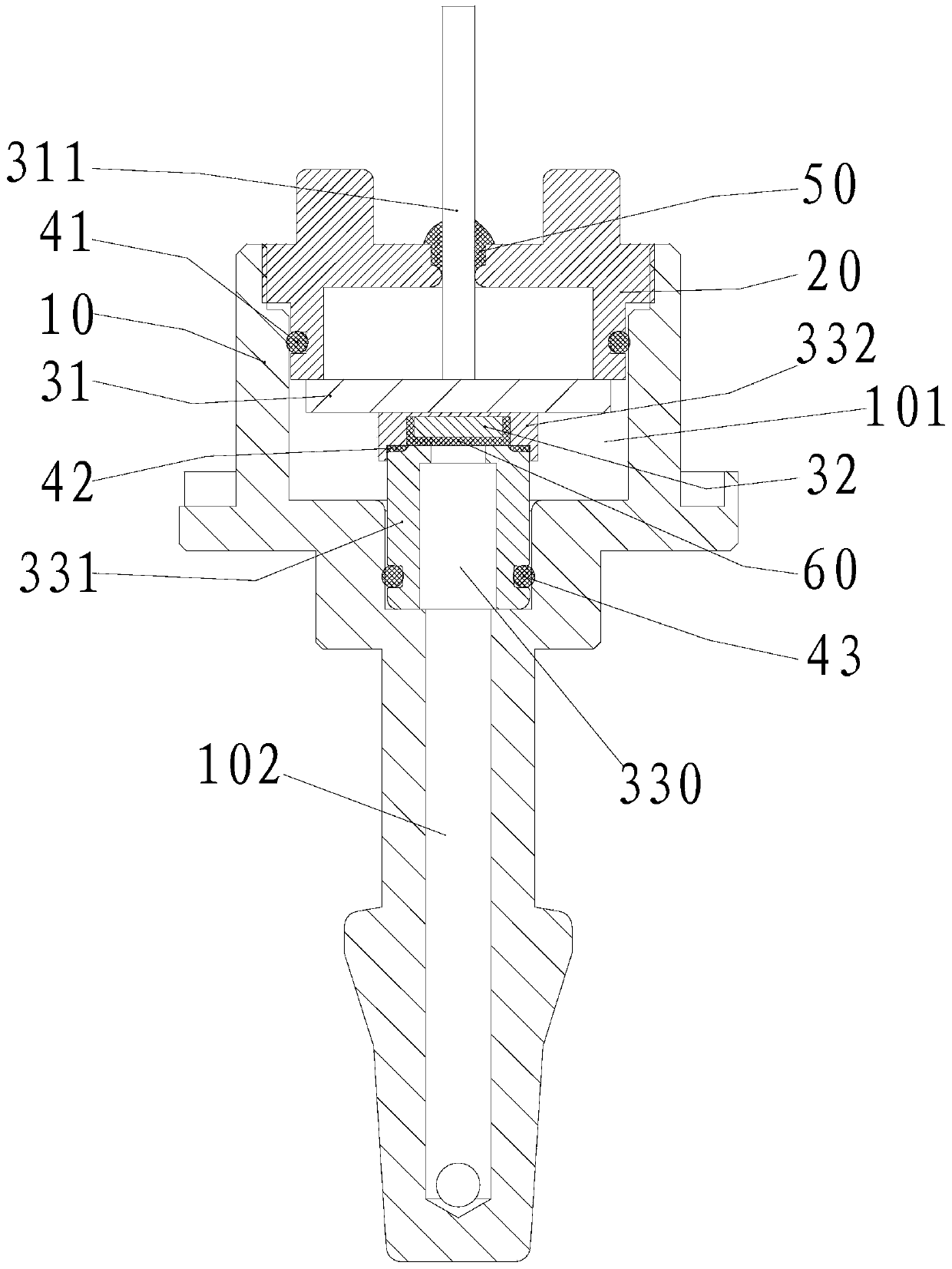

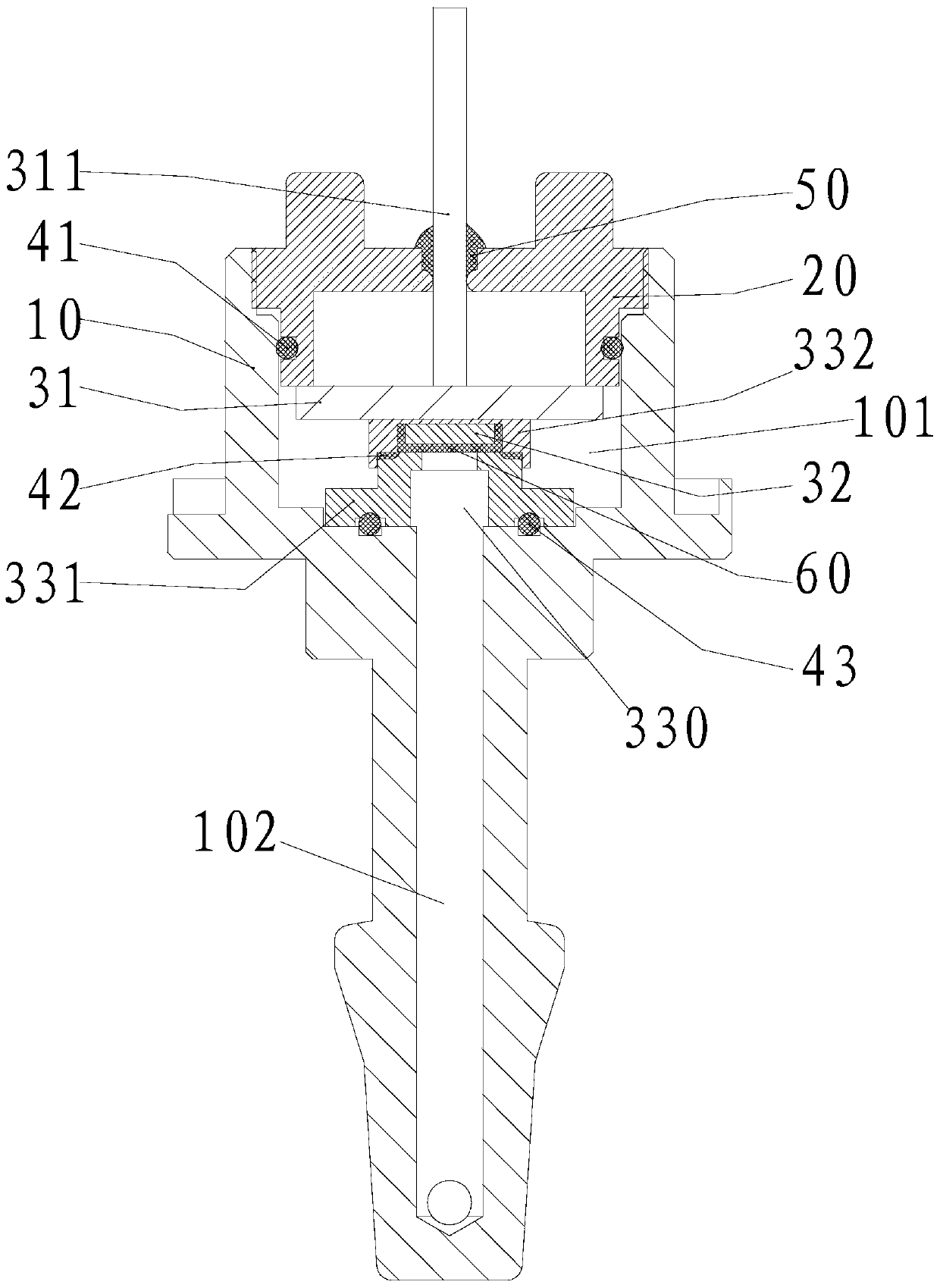

In-cylinder pressure detecting device of direct injection type internal combustion engine

ActiveCN103380357AAvoid interferenceInhibit overheatingElectrical controlInternal combustion piston enginesCombustion chamberCylinder head

In an in-cylinder pressure detecting device of a fuel direct injection type internal combustion engine, an annular pressure detecting element (34) is installed around a fuel injection hole (33b) at a position close to the tip end of an injector used to inject fuel into a combustion chamber. Since the pressure detecting element (34) is installed on the injector, it is not necessary to change the shape or structure of a cylinder head or the combustion chamber for installing the pressure detecting element (34), and since the pressure detecting element (34) can be cooled by fuel passing through the injector, the pressure detecting precision and durability of the pressure detecting element (34) can be improved. In addition, since the pressure detecting element (34) is disposed around the fuel injection hole (33b), the size of the pressure detecting element (34) can be maximally increased while preventing interference between the pressure detecting element (34) and fuel injected through the fuel injection hole (33b), so as to guarantee pressure detecting precision.

Owner:HONDA MOTOR CO LTD +1

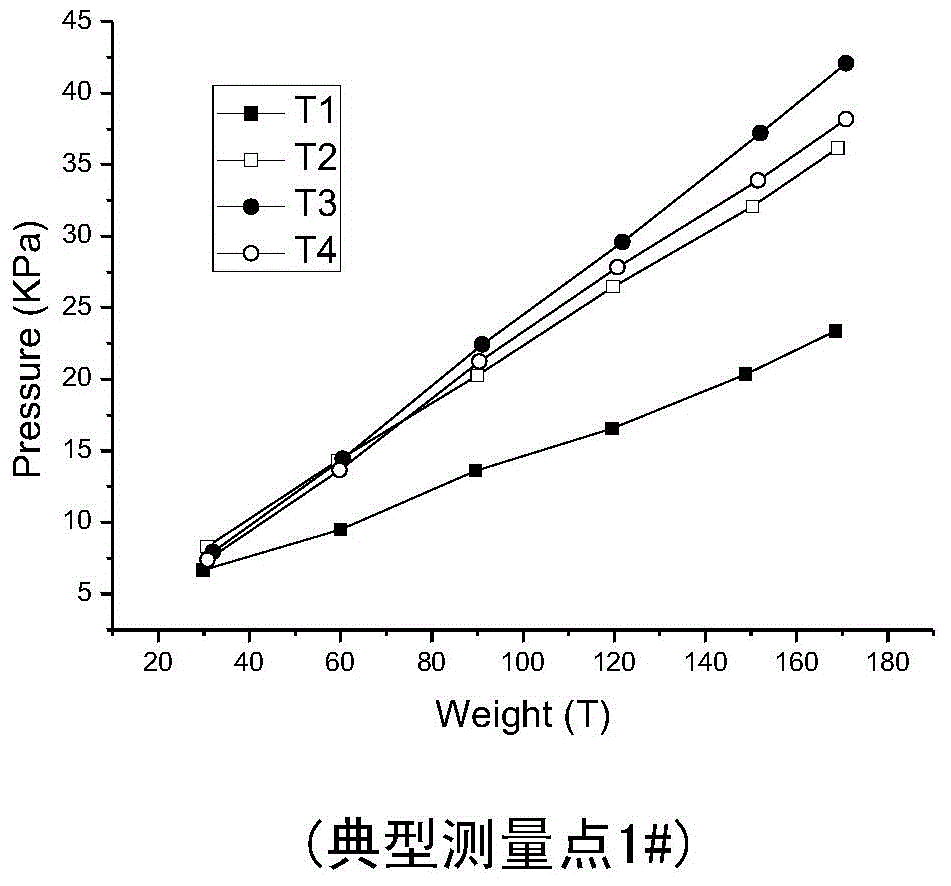

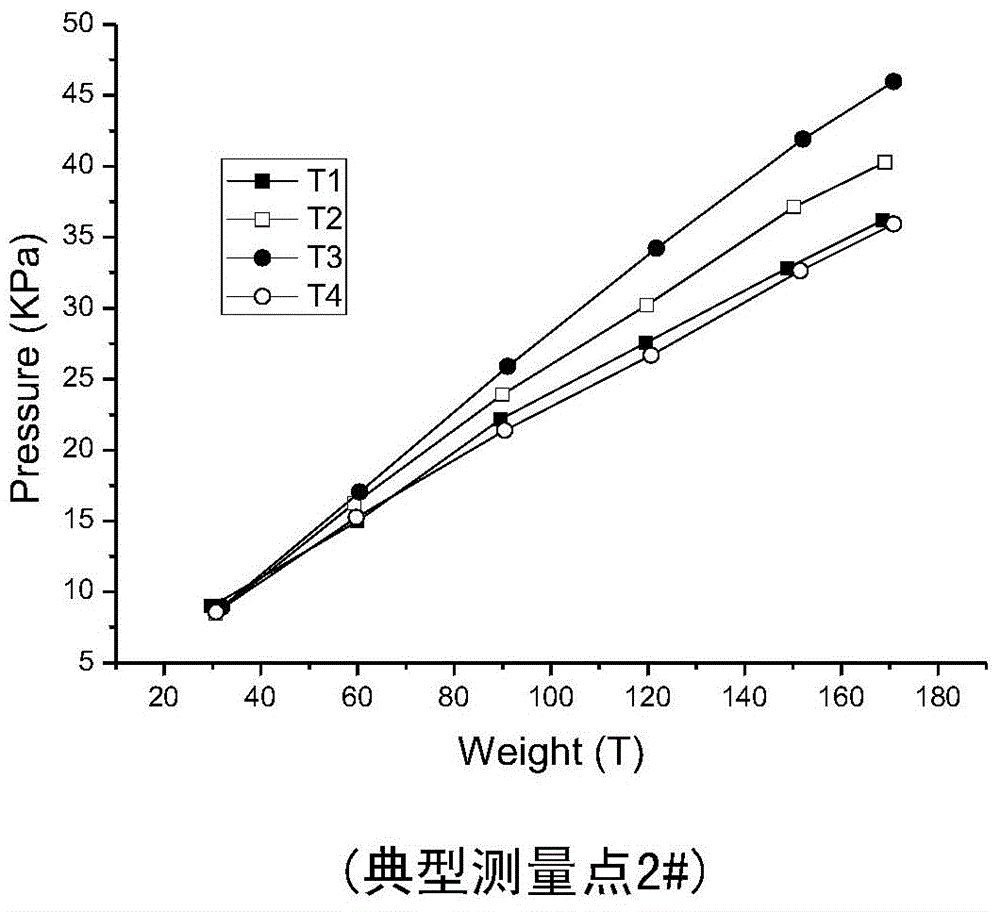

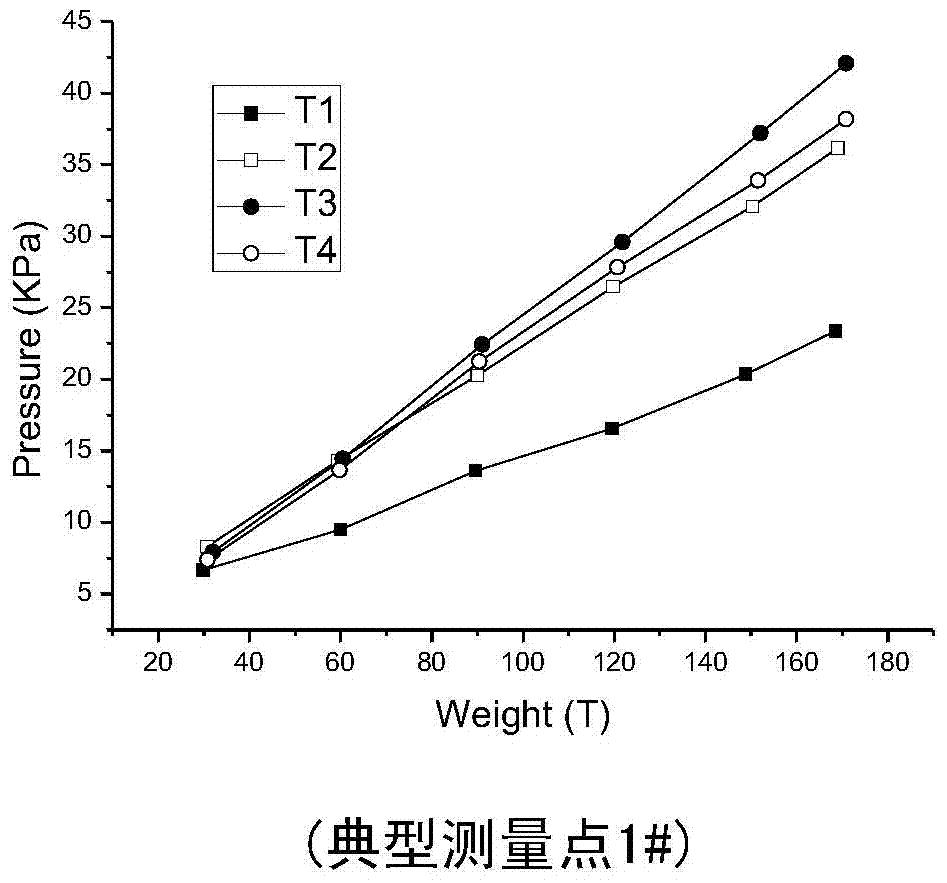

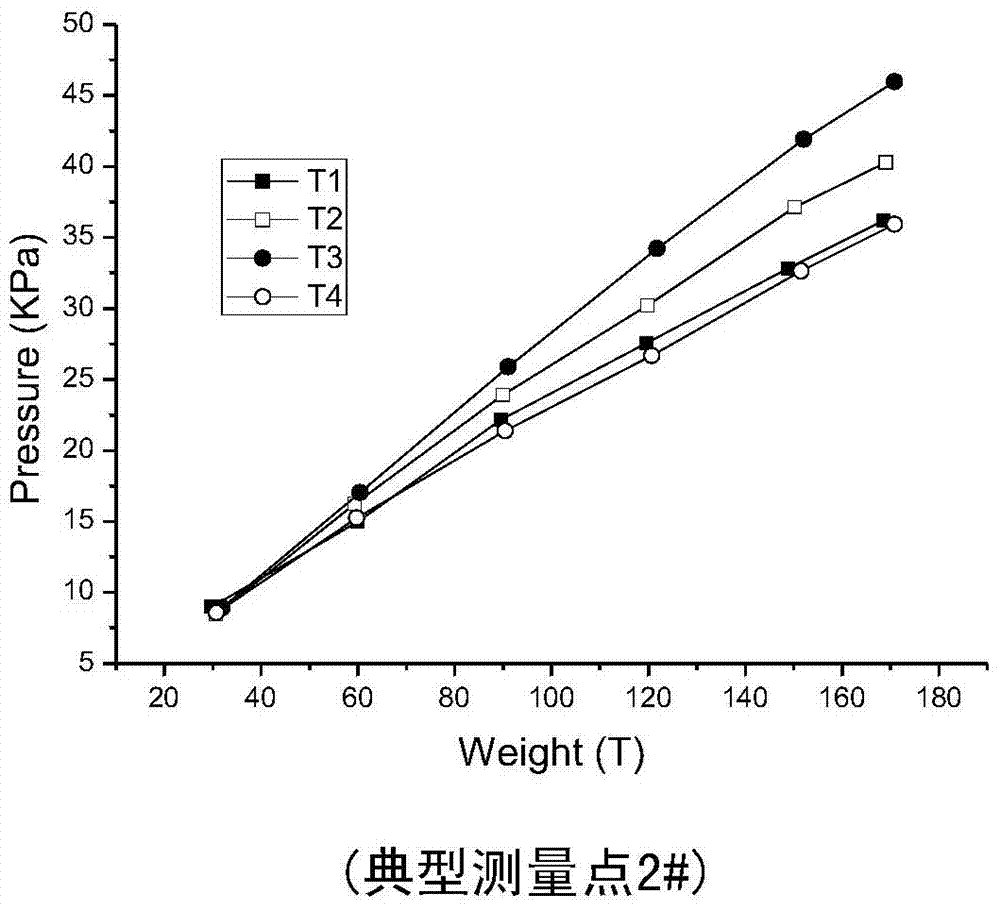

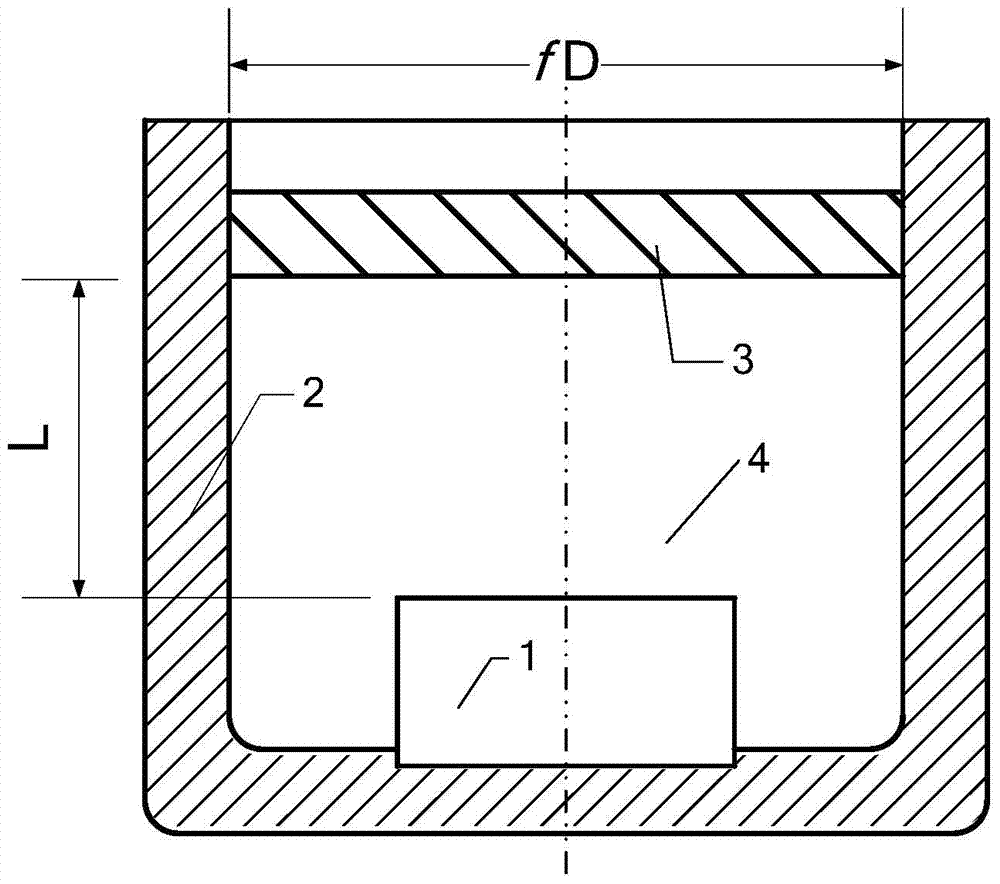

Method for detecting pressure of bottom surface of granary and pressure sensor adopted by method

ActiveCN104655242AEasy CalibrationImprove pressure detection accuracyWeighing apparatus for materials with special property/formEngineeringCalibration coefficient

The invention relates to a method for detecting the pressure of the bottom surface of a granary and a pressure sensor adopted by the method. The pressure sensor which is used for detecting the pressure of the bottom surface of the granary comprises a casing and a sensitive diaphragm, wherein an elastic cushion is arranged on the sensitive diaphragm. The method for detecting the pressure of the bottom surface of the granary adopting the pressure sensor comprises the following steps: calibrating the pressure sensor, obtaining a relational model of an output value of the sensor and the pressure and a calibration coefficient, and using the pressure sensor to detect the pressure of the bottom surface of the granary. According to contact characteristics between the sensitive surface of the pressure sensor and the bottom surface of a grain pile and an influence rule of a contacting state on the output value of the pressure sensor, the method in which the elastic cushion is additionally arranged between the sensitive surface of the pressure sensor and the bottom surface of the grain pile to improve the pressure detection accuracy of the bottom surface of the granary is provided by the invention, and the method has the characteristics of being convenient for use and maintenance, convenient for calibrating of the sensor and the like.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

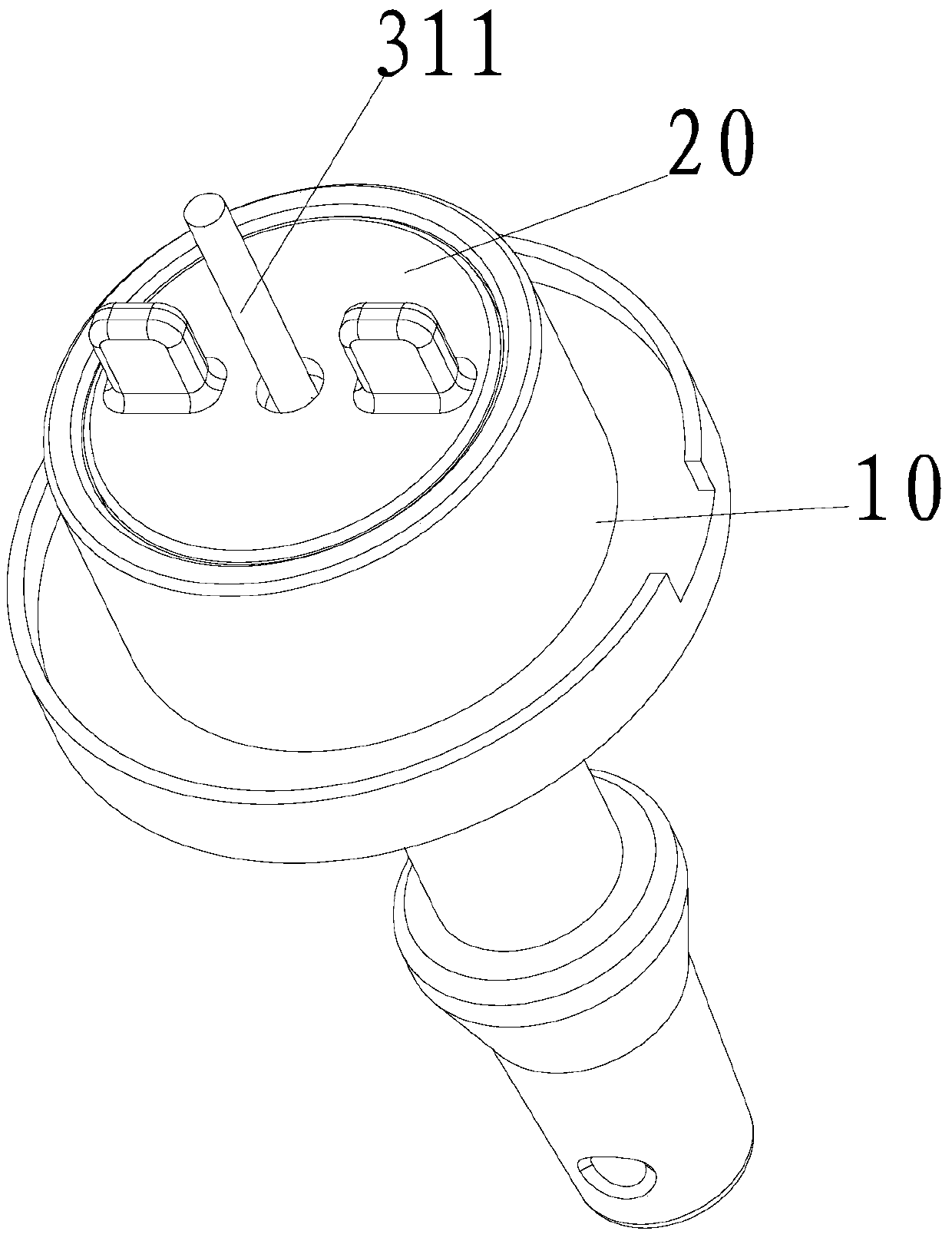

Pressure sensor for pressure cooking utensil, and pressure cooking utensil

ActiveCN104515641AWide range of workImprove pressure detection accuracyFluid pressure measurementEngineeringHigh pressure

The invention discloses a pressure sensor for a pressure cooking utensil, and a pressure cooking utensil. The pressure sensor comprises a housing, wherein one end of the housing is constructed to have a cavity with an opening, and the other end of the housing is provided with an air inlet channel communicating with the cavity; a sealing cover which is connected with one end of the housing so as to seal the opening; a positioning assembly which is arranged at a connecting position of the cavity and the air inlet channel, is in sealing connection with the housing and comprises a detection channel communicating the cavity and the air inlet channel; and a pressure detection assembly which is arranged on the positioning assembly, breaks connection of the connection channel, and has a pressure sensor chip arranged in the detection channel. According to the pressure sensor for the pressure cooking utensil, the working scope of the pressure sensor is wider, and the pressure cooking utensil can be enabled to have higher pressure detection precision.

Owner:MIDEA GRP CO LTD +1

Electric toothbrush capable of monitoring tooth brushing degree

PendingCN109646133AAdjust the working vibration frequency in timeReduce manufacturing costForce measurementTooth cleaningElectricityElectrical battery

The invention relates to the technical field of electric toothbrushes, in particular to an electric toothbrush capable of monitoring tooth brushing degree. The electric toothbrush comprises a toothbrush handle and a toothbrush head movably connected with the toothbrush handle, the toothbrush handle comprises a shell, and a battery and an electric motor are fixedly arranged in the shell; a motor shaft is arranged in the electric motor, the electric motor is connected with the toothbrush head through the motor shaft, and an indicator light is arranged on the outer side wall of the shell; a PCB circuit board is arranged on the inner side wall of the shell, a sensor element is arranged on the outer side of the electric motor, and the battery, the electric motor, the indicator light and the sensor element are electrically connected with the PCB circuit board. The electric toothbrush is reasonable and compact in design, the manufacturing cost of the electric toothbrush is reduced, the pressure detection accuracy is high, and using is convenient.

Owner:东莞微感电子技术有限公司

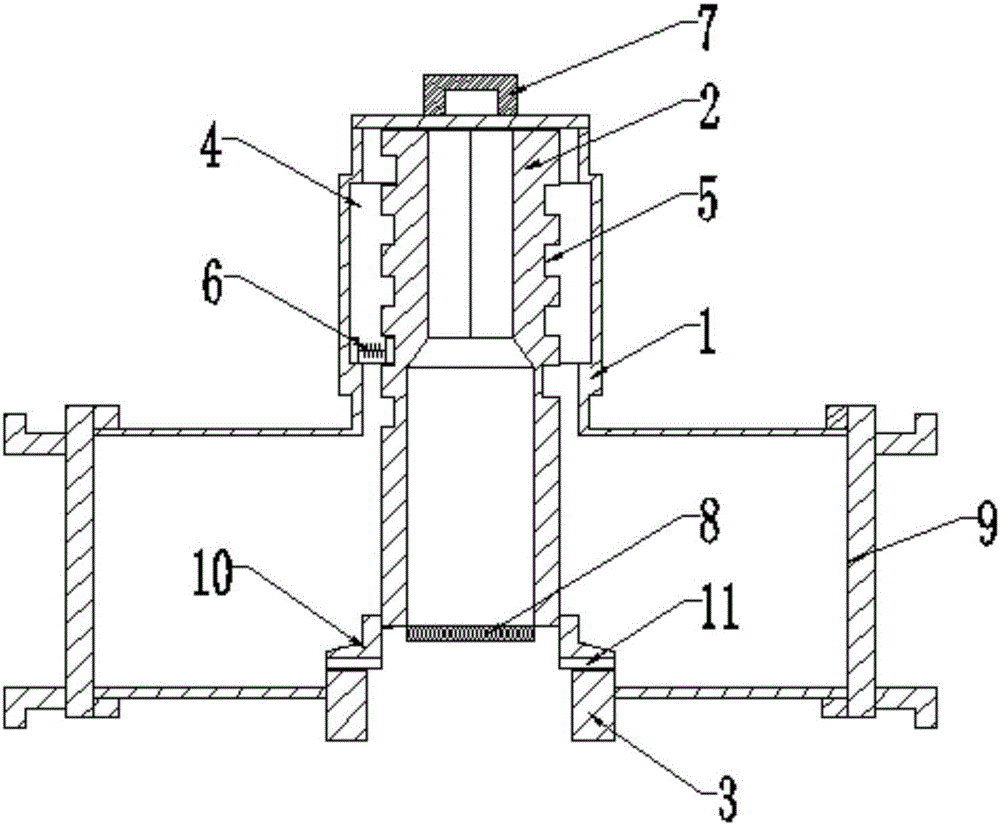

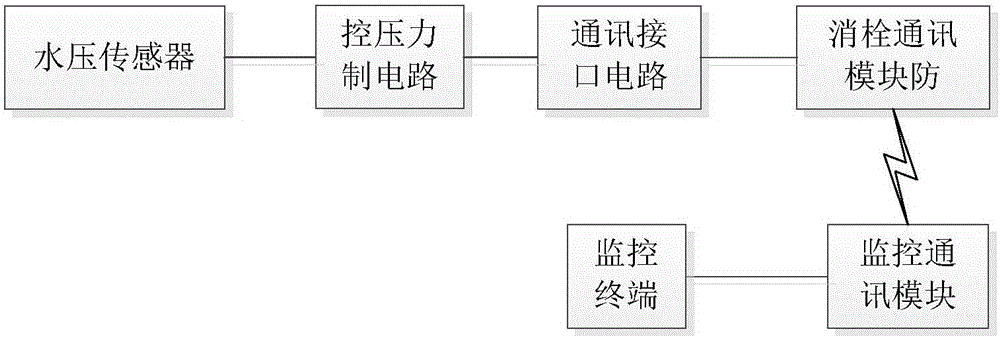

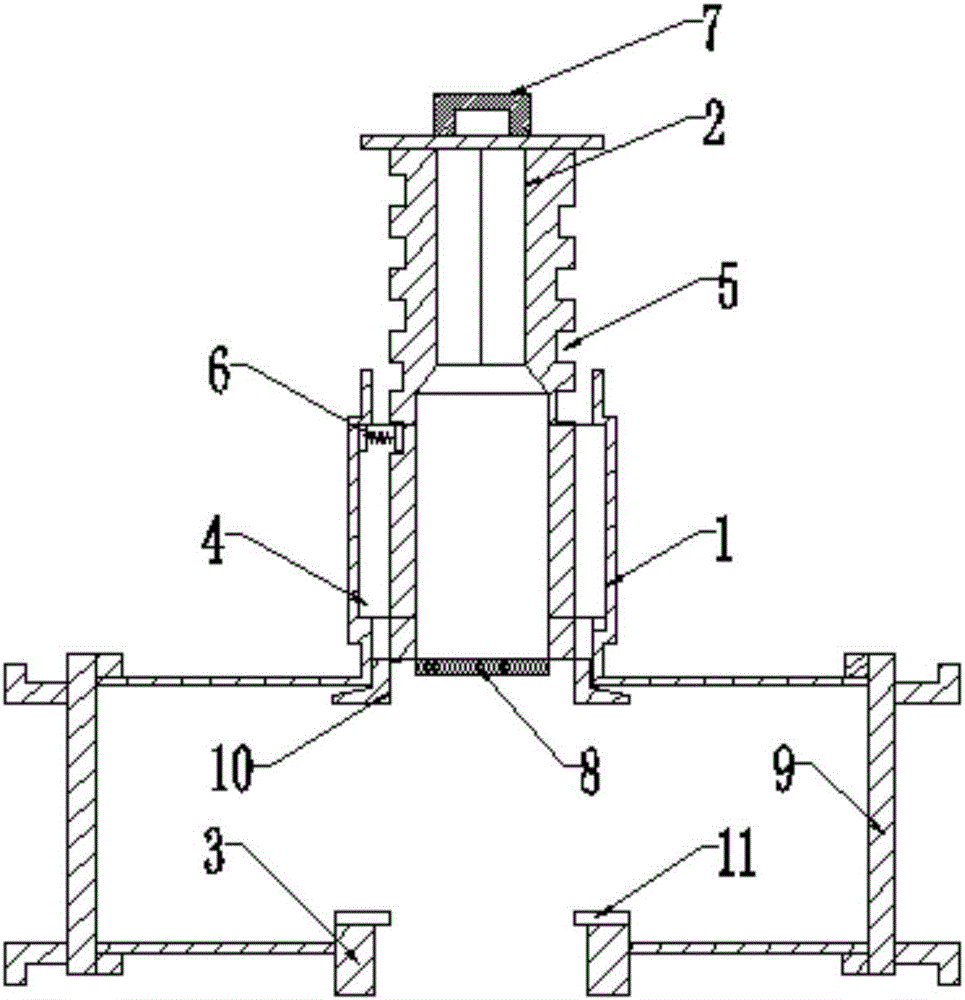

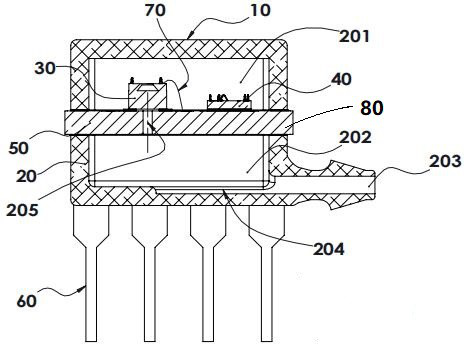

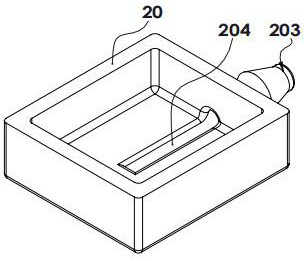

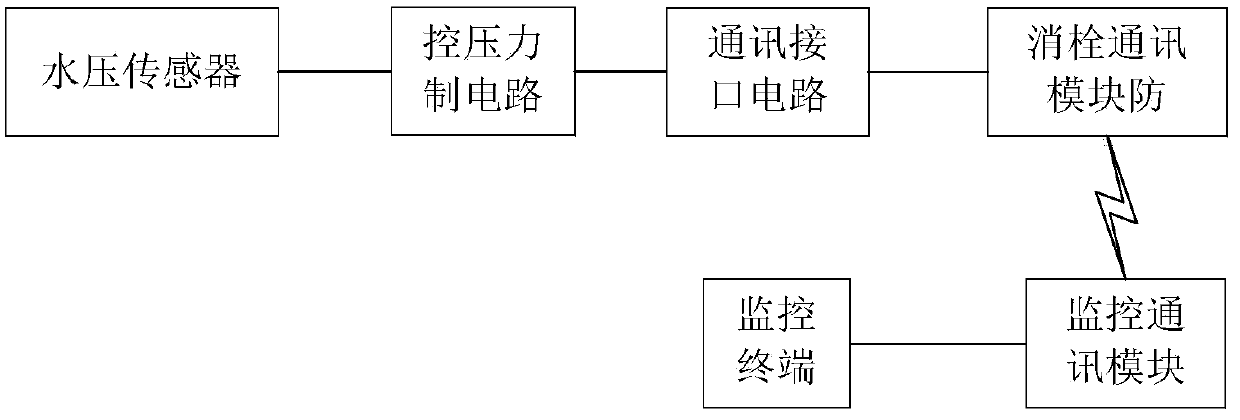

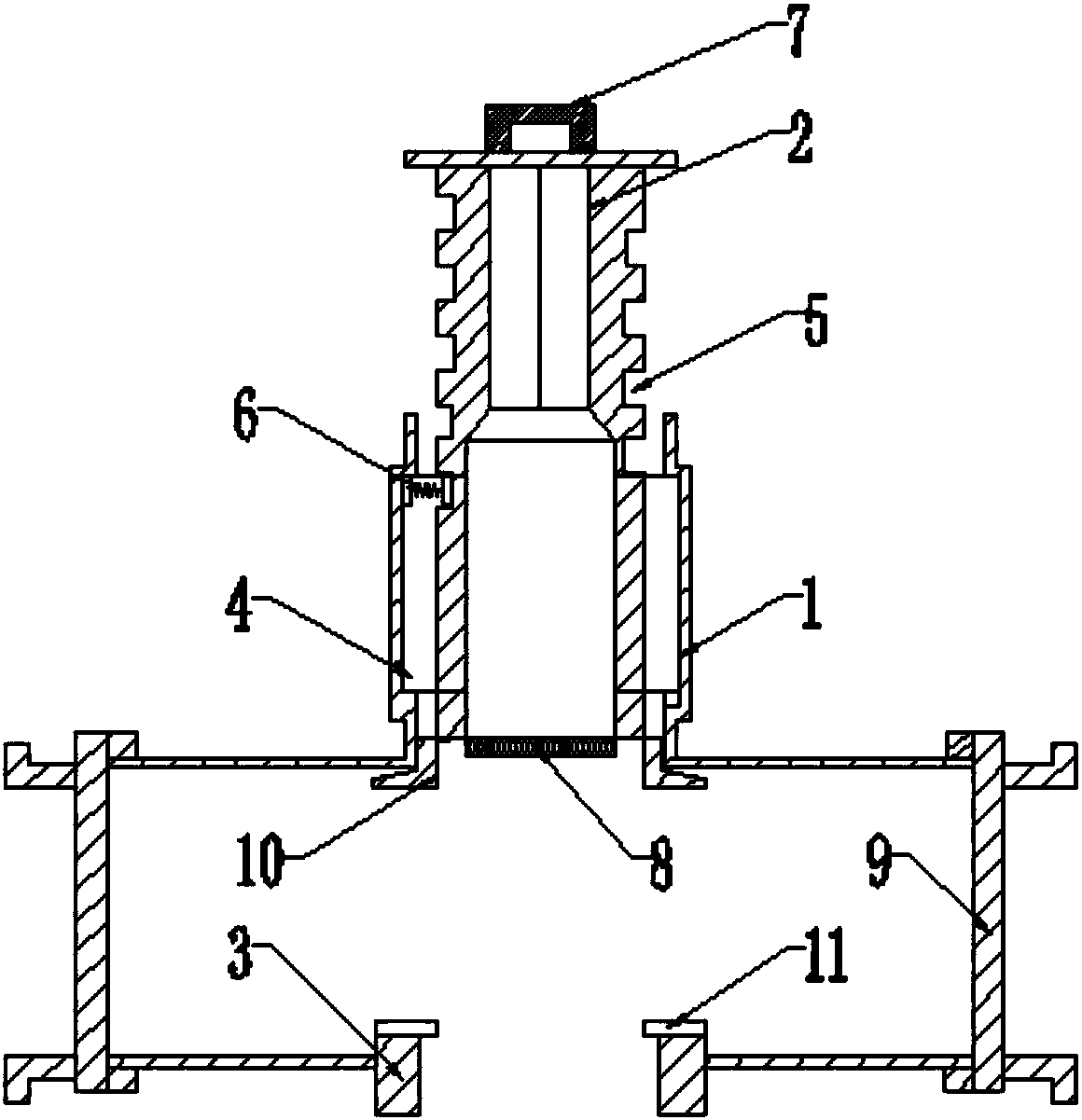

Intrinsic safety type high-pressure fire hydrant

ActiveCN106090248AImprove pressure resistanceImprove securityFire rescueLift valveIntrinsic safetyEngineering

The invention discloses an intrinsic safety type high-pressure fire hydrant comprising a valve, a valve rod and a valve base arranged at the bottom of the valve. A water inlet is arranged at the bottom of the valve, a water outlet is arranged on the side wall of the valve, the water inlet penetrates the valve base to be communicated with the inside of the valve, and the water inlet directly faces the valve rod and moves back and forth along the water inlet direction; a concave limit groove is arranged in the inner wall of the valve, a spiral groove is arranged in the outer wall of the valve rod, a limit device is arranged between the valve and the valve rod, one end of the limit device abuts against the limit groove, and the other end of the limit device is slidably fixed in the spiral groove. The intrinsic safety type high-pressure fire hydrant has the advantages that the intrinsic safety type high-pressure fire hydrant is simple in structure, convenient to install and maintain, resistant to high pressure, long in service life and low in equipment cost, and water pressure in the fire hydrant can be monitored in real time through a water pressure sensor.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

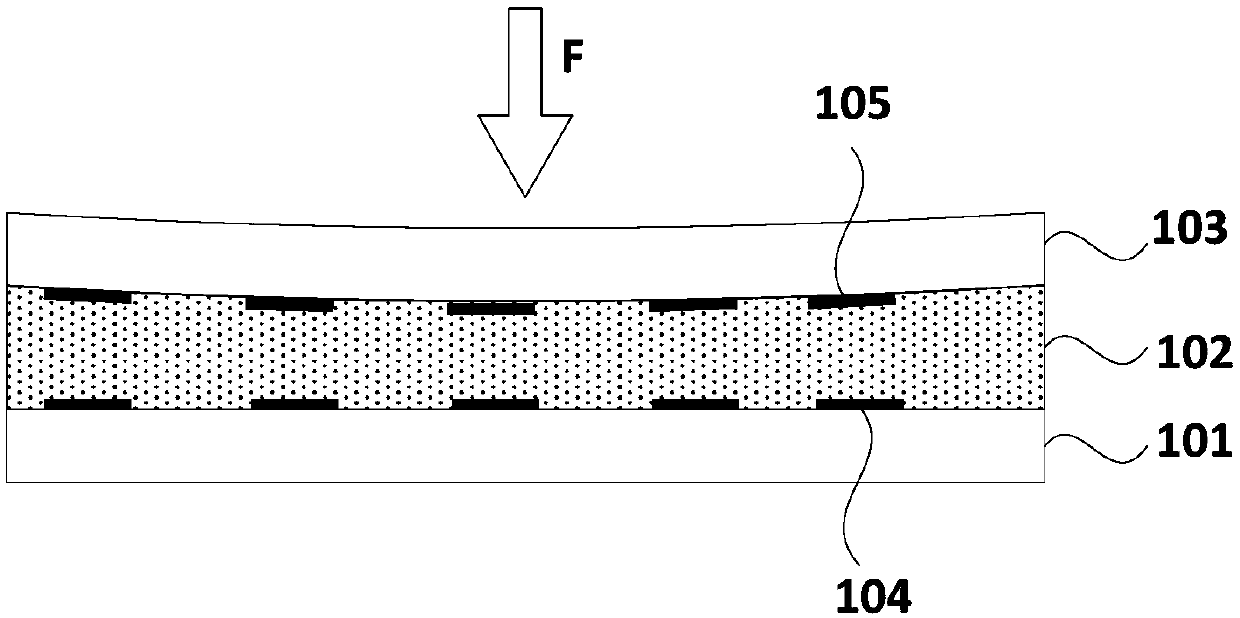

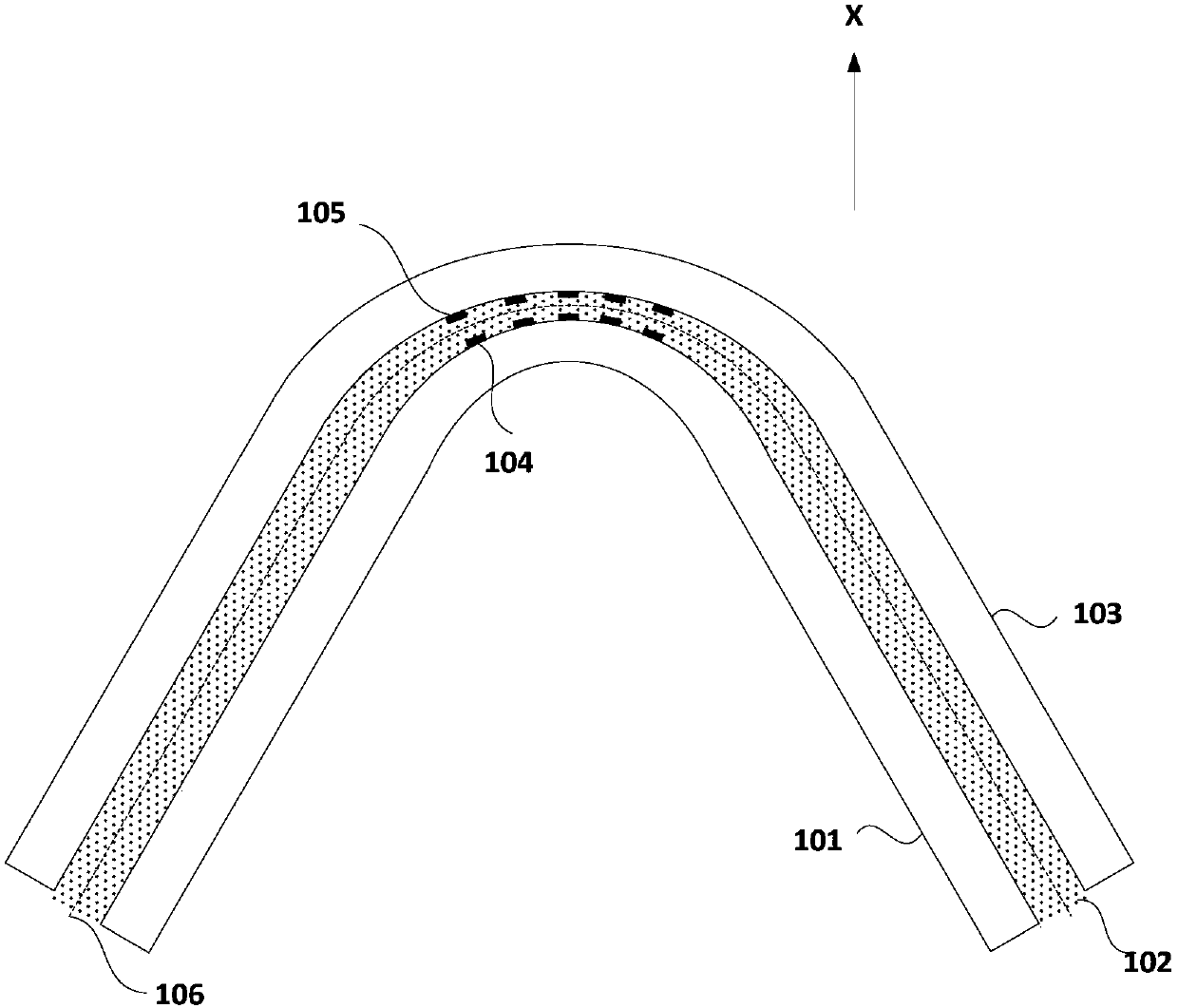

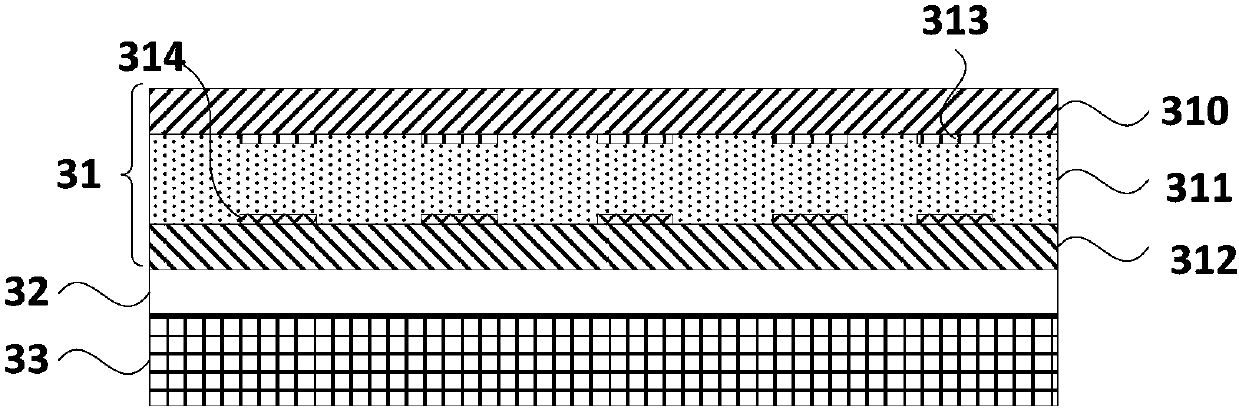

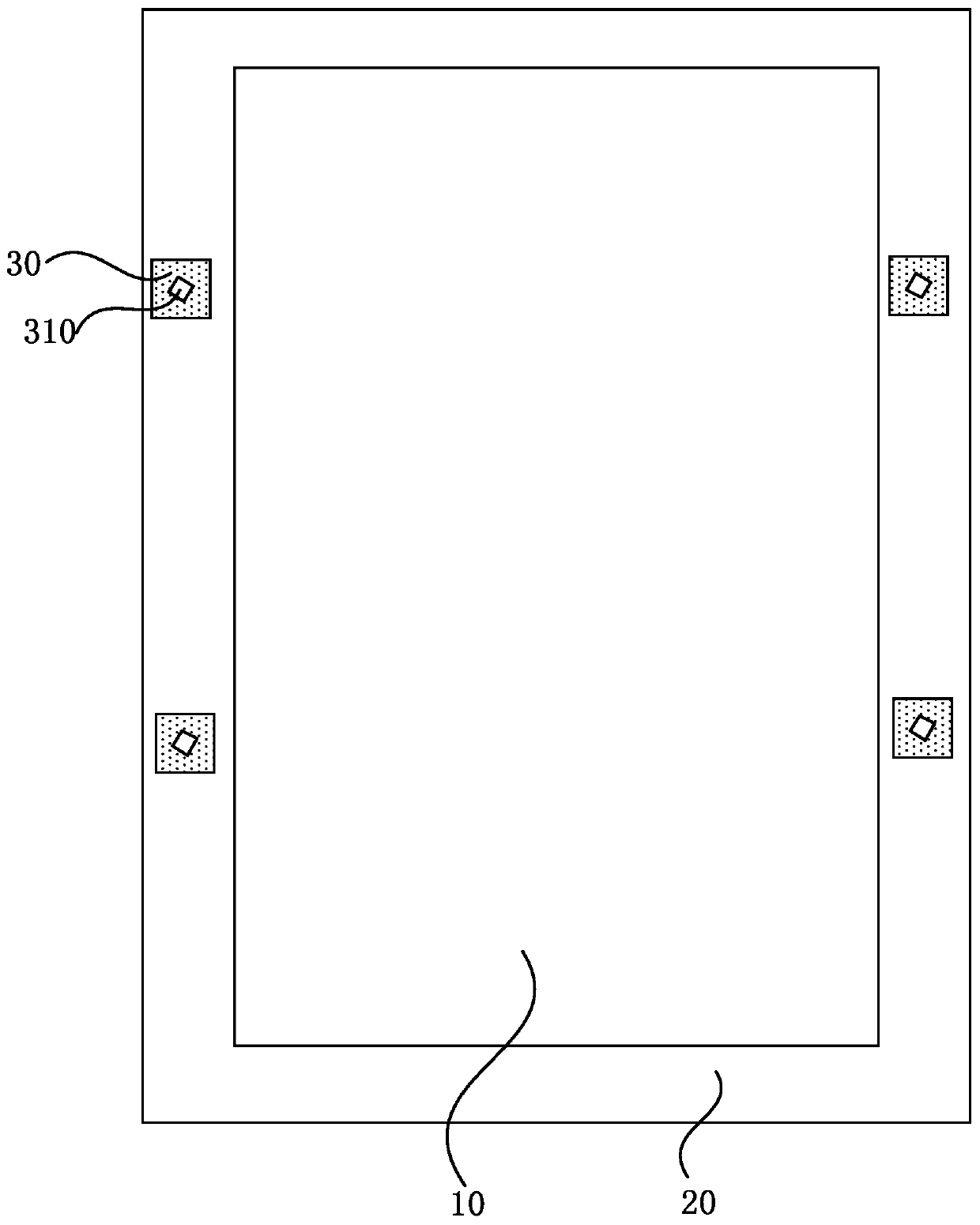

Flexible display panel and display device

ActiveCN110347276AImprove pressure detection accuracyPhotovoltaic energy generationInput/output processes for data processingVertical projectionBiochemical engineering

The embodiment of the invention discloses a flexible display panel and a display device. The flexible display panel comprises a pressure detection module, a pressure compensation module and a displaymodule arranged between the pressure detection module and the pressure compensation module, wherein the pressure detection module is arranged on the light emitting side of the display module; the pressure detection module comprises a first substrate, a second substrate and a first elastic spacer layer arranged between the first substrate and the second substrate, a first pressure detection electrode is arranged on the side, close to the first elastic spacer layer, of the first substrate, and a second pressure detection electrode is arranged on the side, close to the first elastic spacer layer,of the second substrate. Vertical projections of the first pressure detection electrode and the second pressure detection electrode on the first substrate are at least partially overlapped; the pressure compensation module is used for detecting the bending curvature of the flexible display panel. According to the scheme of the embodiment of the invention, the pressure detection precision of the flexible display panel is improved.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

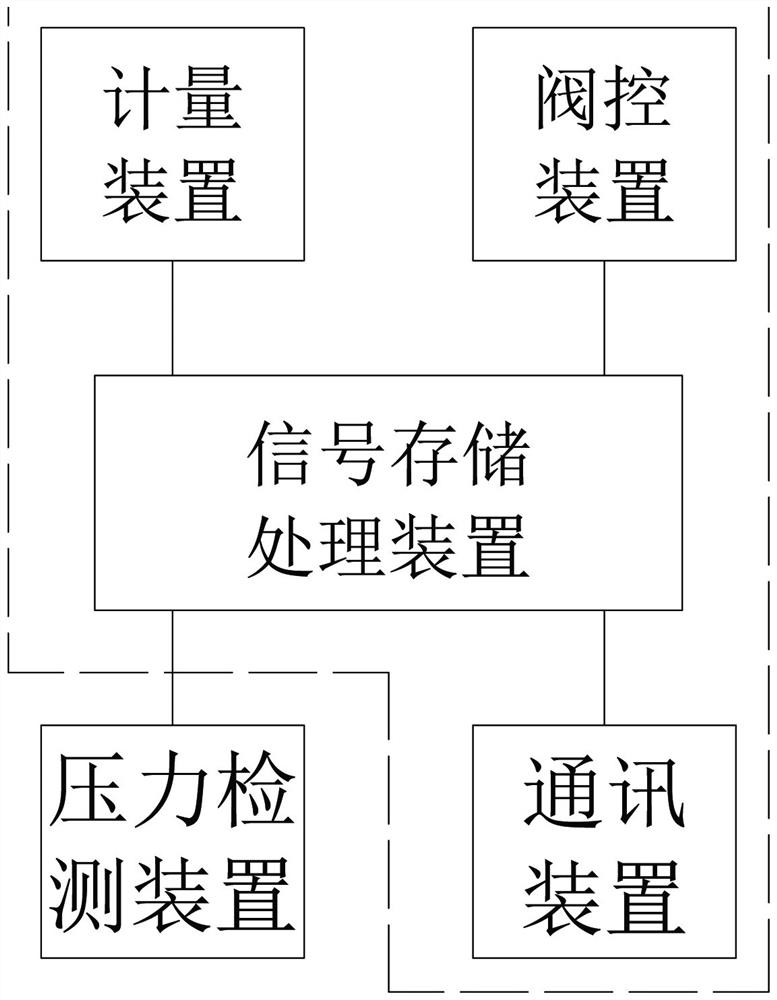

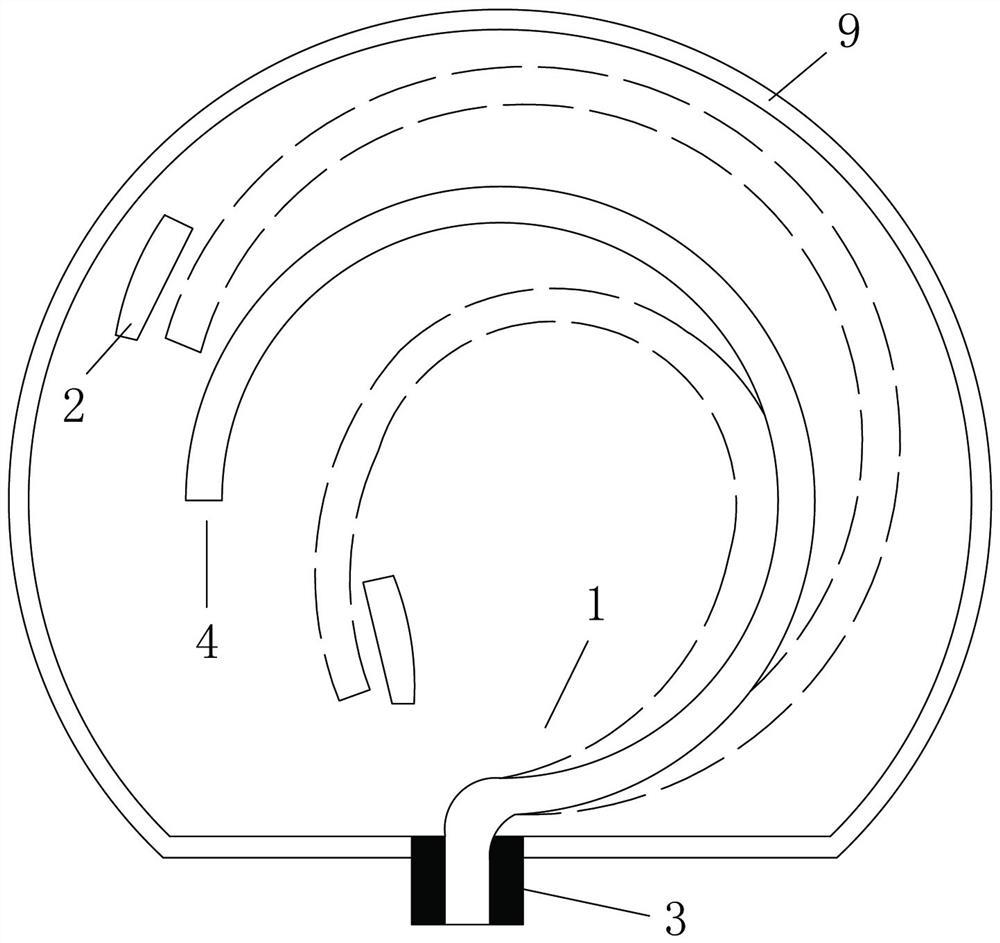

Gas pressure abnormity control system based on Internet of Things intelligent gas meter

PendingCN112763131AReal-time monitoring of stress conditionsRealize automatic controlFluid pressure measurementVolumetric apparatus damage preventionAutomatic controlThe Internet

The invention discloses a gas pressure abnormity control system based on an internet-of-things intelligent gas meter, which comprises an existing internet-of-things intelligent gas meter, a pressure detection device is arranged on the internet-of-things intelligent gas meter, the pressure detection device comprises an arc-shaped hollow spring tube, one end of the spring tube is open and fixed, and the other end of the spring tube is closed and freely stretches out and draws back. The opening is communicated with a gas channel to obtain gas pressure, signal switches are installed on the two sides of the free end of the spring pipe, the pressure detection device monitors the pressure condition of a gas pipeline in real time, switching signals are transmitted to the signal storage processing device when the abnormal condition of overpressure or underpressure occurs, the valve control device is instructed to cut off the gas pipeline, and the communication device is instructed to wirelessly send gas pressure abnormity alarm information, so that automatic control and remote alarm are realized, the pressure abnormity type can be distinguished, and the system has the advantages of low cost and high pressure detection precision.

Owner:深圳市金逸通微电子有限公司

Roller coater

The invention discloses a roller coater which comprises a painting roller, a roller coater rack, a solution-taking roller, a solution-taking roller rack and a roller rest pressure adjustment device, wherein the roller rest pressure adjustment device comprises an operating side bearing base, a driving side bearing base, a sliding block, a turbine worm, a pressure detection element, a handwheel, a servo motor, linearity guide rails and linearity rails. The roller coater provided by the invention achieves the technical purposes that the automatization feedback and adjustment of the roller coater are realized, and the reaction accuracy is improved. Through the roller coater disclosed by the invention, the pressure detection element contacting the spherical surface of the operating side bearing base and the spherical surface of the driving side bearing base is adopted, a signal is provided for the operation of the servo motor, the regulation and control of a roller interval are beneficial, the accuracy and consistency of the thickness of a painting film are improved, and the quality of the painting film of the surface of a steel band and quality stability are guaranteed.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

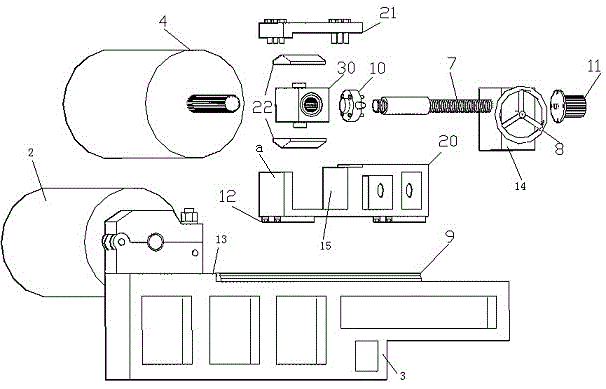

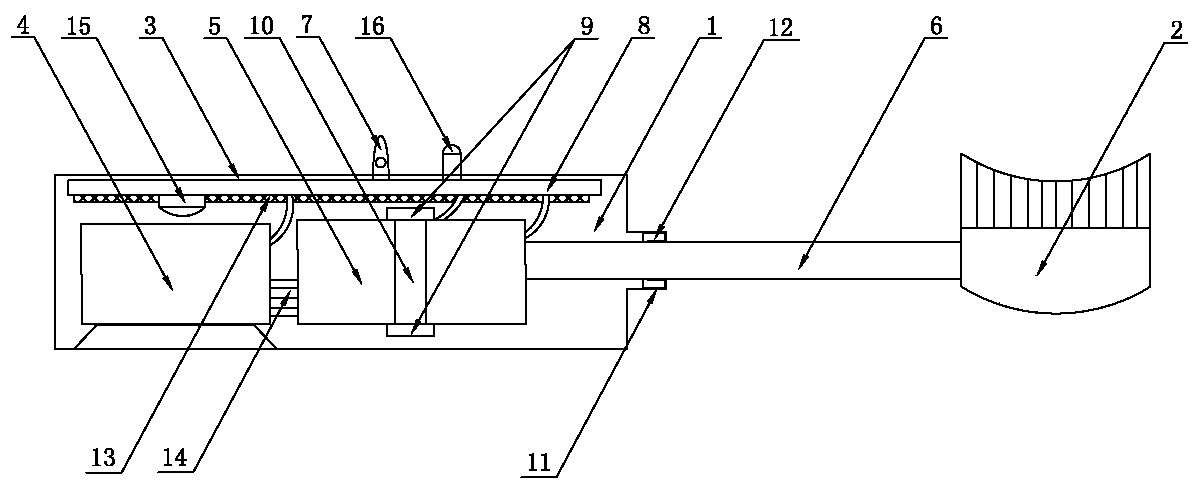

Piston-type momentum experiment instrument with teaching effect flow digital-display function

ActiveCN104882048AConvenient digital accurate measurementConvenient real-time zero adjustmentEducational modelsEngineeringPressure difference

The invention discloses a piston-type momentum experiment instrument with a teaching effect flow digital-display function. The experiment instrument comprises a constant-pressure water supply tank, a water collection tank, a momentum tube, a liquid-gas conversion pressure measuring cylinder, a pressure difference sensor, a microcomputer digital display meter, and a self-circulating water supply device. The side wall of the constant-pressure water supply tank is provided with an outlet, and the outlet is a nozzle. The water collection tank is connected with the outlet of the constant-pressure water supply tank. The momentum tube is used for measuring the jet flow momentum force at the outlet of the constant-pressure water supply tank, and is fixed in the water collection tank. The liquid-gas conversion pressure measuring cylinder is arranged in a stable-water working area inside the constant-pressure water supply tank, and the top of the liquid-gas conversion pressure measuring cylinder is provided with a communicated positioning tube which is disposed in the central-axis horizontal plane of the outlet. The microcomputer digital display meter is used for converting a pressure signal detected by the pressure difference sensor into flow. The experiment instrument of the invention can reset automatically, can eliminate the error of air compression, can be zeroed in real time, is high in precision, can conveniently, digitally and accurately measure two basic physical quantities of a fluid mechanics momentum law experiment instrument, namely, jet flow rate and jet flow momentum, and has a very good teaching effect.

Owner:ZHEJIANG UNIV +1

A granary bottom surface pressure detection method and pressure sensor adopted therefor

ActiveCN104655242BEasy CalibrationImprove pressure detection accuracyWeighing apparatus for materials with special property/formEngineeringPressure sensitive

The invention relates to a method for detecting the pressure on the bottom surface of a granary and a pressure sensor used therefor. The method for detecting the pressure on the bottom surface of a granary using the pressure sensor includes: calibrating the pressure sensor to obtain a model and a calibration coefficient of the relationship between the sensor output value and the pressure; and using the pressure sensor to detect the pressure on the bottom surface of the granary. According to the contact characteristics between the sensitive surface of the pressure sensor and the bottom surface of the grain pile, and the influence law of the contact state on the output value of the pressure sensor, the invention proposes a method to improve the granary by adding an elastic pad between the sensitive surface of the pressure sensor and the bottom surface of the grain pile. The method for detecting the accuracy of the bottom surface pressure has the characteristics of convenient use and maintenance, and convenient sensor calibration.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

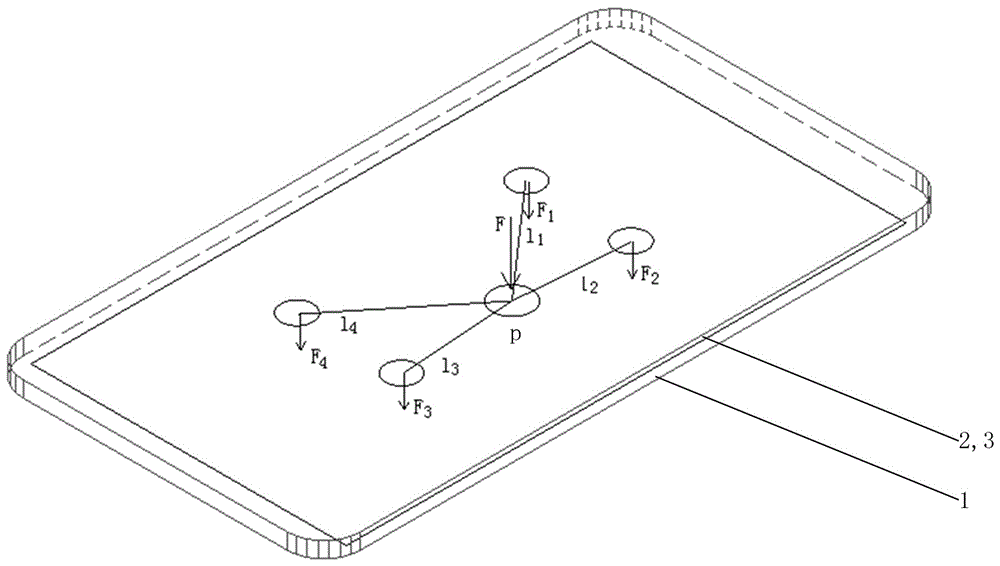

Force detection method used for substrate

ActiveCN106527797AReduce the numberOptimize layoutInput/output processes for data processingElectrical resistance and conductancePressure transmission

The invention discloses a force detection method used for a substrate. The method comprises the steps of detecting a touch position P, on the substrate, of a finger through a touch induction layer; detecting pressure transmission components fn generated by the touch position P through n mechanical induction units on a mechanical induction layer; calculating distances ln between the touch position P and the mechanical induction units; and calculating pressing force components Fn of the touch position P according to the pressure transmission components fn detected by the mechanical induction units and the distances ln between the touch position P and the mechanical induction units, and calculating a total pressing force F of the touch position P through the pressing force components Fn. The total pressing force F of the touch position P is obtained through the mechanical induction units around the touch position P, and the mechanical induction units do not need to be arranged in the touch position P, so that the number of mechanical strain units on a mechanical induction plate is reduced, strain resistance and circuits are arranged more easily, or the pressure detection precision is improved.

Owner:SHANTOU GOWORLD DISPLAY TECH CO LTD

A detection method of a capacitive three-dimensional detection module

ActiveCN106557213BReduce lossImprove detection efficiencyInput/output processes for data processingPressure senseEngineering

The invention provides a detection method of a capacitive three-dimensional detection module. A capacitive three-dimensional detection module is provided, the capacitive three-dimensional detection module comprises a capacitive touch sensor, a piezoelectric pressure sensor and a capacitive three-dimensional controller integrated on a chip, the capacitive touch sensor comprises a plurality of touch units, the piezoelectric pressure sensor comprises at least one pressure sensing unit, the detection method comprises the following steps: S1, detecting a touch signal of the plurality of touch units in a mutual capacitance manner to determine the position of a touch point; and S2, detecting a pressure signal of the at least one pressure sensing unit in a self capacitance manner to determine the size of a pressing pressure, wherein the touch signal and the pressure signal are calculated by the capacitive three-dimensional controller. The capacitance detection method is simple and good in practicability.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

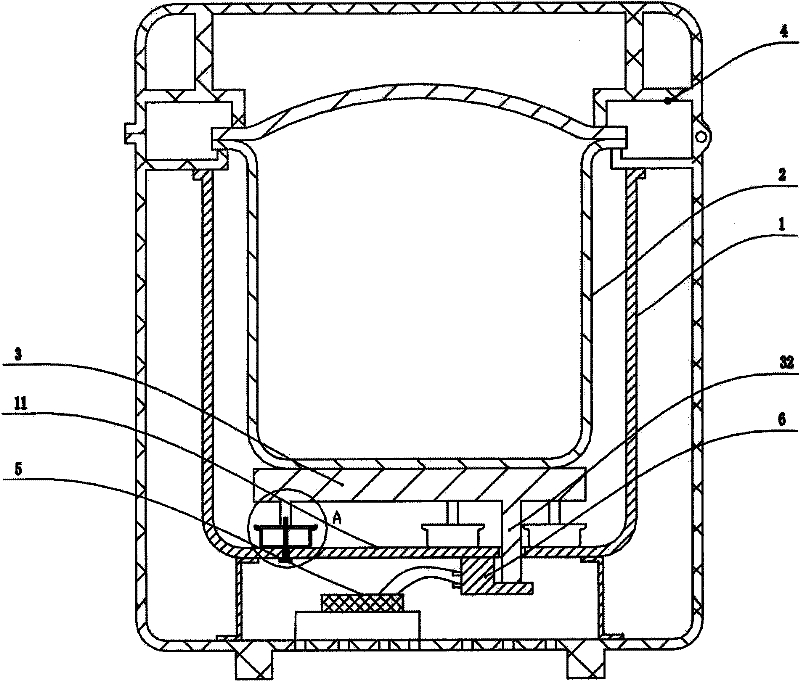

Pressure controlled electric pressure cooker

ActiveCN101731939BReduce heat treatment process requirementsImprove flatnessPressure-cookersEngineeringControl circuit

The invention relates to a pressure controlled electric pressure cooker, comprising an outer cooker, an inner cooker, an electric hot tray, a cover and a control circuit. The inner cooker is arranged on the electric hot tray, the cover seals the mouth of the inner cooker, the bottom of the outer cooker is provided with a pressure detector, the pressure detector is electrically connected with the control circuit, a plurality of groups of elastic supporting devices are arranged between the electric hot tray and the bottom of the outer cooker, the electric hot tray or the elastic supporting device is provided with a touch rod capable of touching the pressure detector to act, corresponding to the elastic supporting device, the electric hot tray is provided with a strut, the elastic supportingdevice comprises an elastic plate and a pedestal, and the strut, elastic plate, pedestal and the outer cooker are sequentially connected. The invention has the advantages of simple structure, low cost and high pressure control precision.

Owner:JOYOUNG CO LTD

A Piston Momentum Experimental Instrument with Teaching Effect and Flow Digital Display

ActiveCN104882048BRealize synchronous digital tour measurementRealize real-time traffic detectionEducational modelsDifferential pressureEngineering

Owner:ZHEJIANG UNIV +1

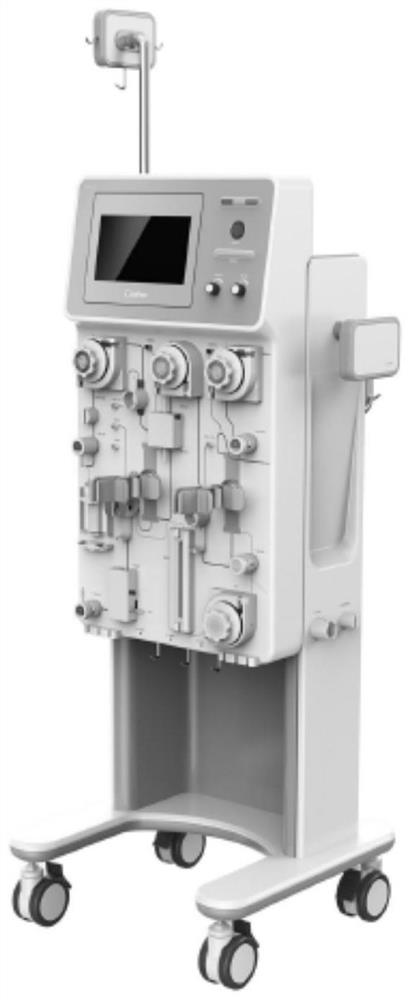

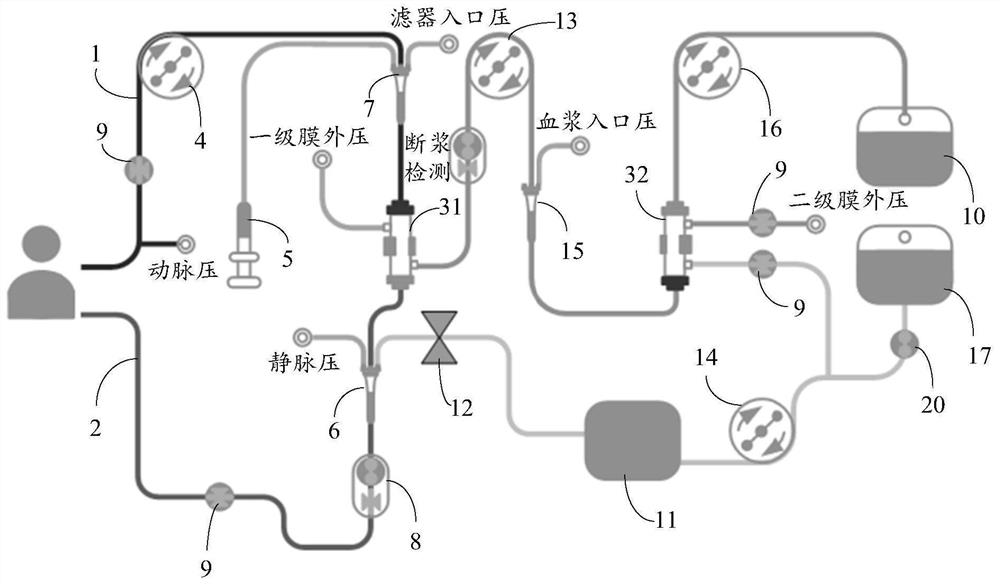

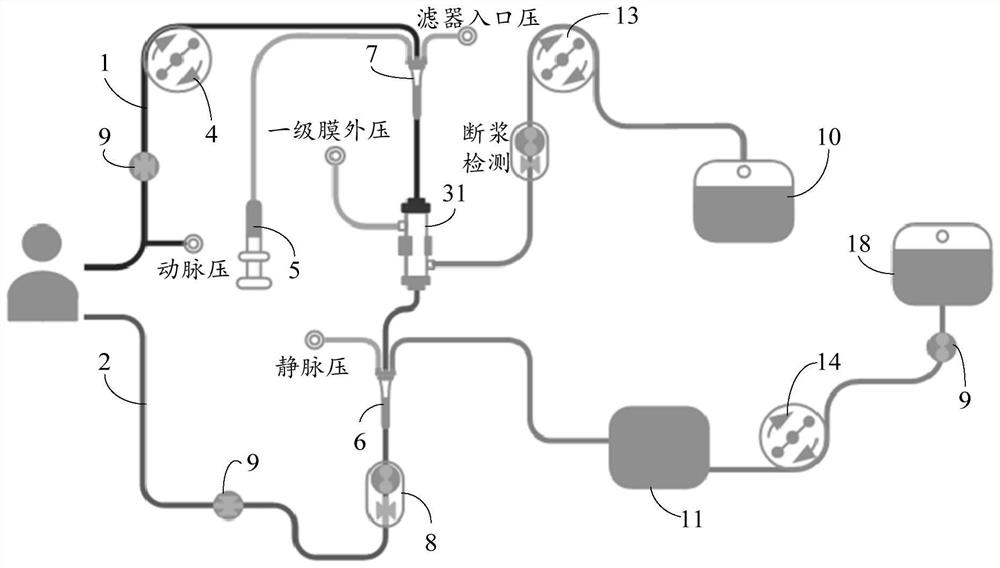

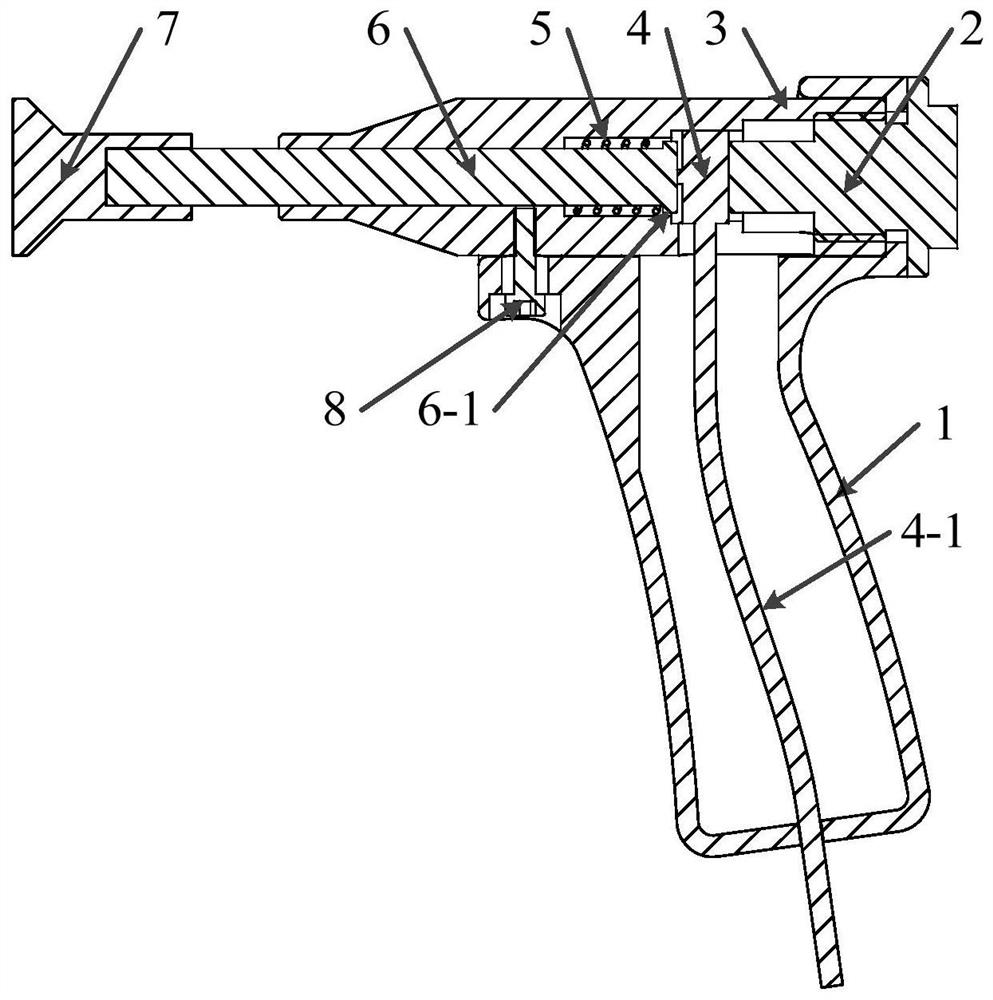

Pressure detection method of blood purification equipment, blood purification equipment and storage medium

PendingCN113633841AFully respond to the actual stress stateImprove pressure detection accuracyOther blood circulation devicesDialysis systemsProcess engineeringIntensive care medicine

The invention discloses a pressure detection method of blood purification equipment, the blood purification equipment and a storage medium. The pressure detection method comprises the following steps that a current treatment mode of the blood purification equipment is determined; pressure detection points are activated according to the current treatment mode, so that a pressure detection mode formed based on the activated pressure detection points is matched with the current treatment mode, wherein a plurality of pressure detection points are arranged on the blood purification equipment, and the pressure detection points are located at different positions of the blood purification equipment respectively; and the pressure under the activated pressure detection points is detected. In this way, the pressure detection precision of the blood purification equipment in each treatment mode can be improved.

Owner:BEIJING JAFRON MEDICAL EQUIP CO LTD

Device for detecting sensitivity of human body local part to pressure-induced pain

PendingCN111973162AIncrease contactEliminate gapsDiagnostics using pressureSensorsHuman bodyPhysical medicine and rehabilitation

The invention discloses a device for detecting the sensitivity of a human body local part to pressure-induced pain. The device comprises a detection main body and a handle, wherein a telescopic guiderod is arranged in the detection main body; a pressure sleeve in contact with the body surface of a human body is arranged at the outer end of the guide rod; the inner end of the guide rod is limitedin the detection main body and can telescopically move in the detection main body; a pressure sensor is arranged at the inner end, close to the guide rod, in the detection main body; and the pressuresensor is connected with an external pressure display through a data line and is used for displaying a pressure value of the guide rod on the pressure sensor in real time.

Owner:JIANGSU PROVINCIAL HOSPITAL OF TCM +1

Inner cylinder pressure detection device of fuel direct injection internal combustion engine

ActiveCN103380357BAvoid interferenceInhibit overheatingElectrical controlInternal combustion piston enginesEngineeringFuel injection

In the cylinder pressure detection device of a direct fuel injection type internal combustion engine, an annular pressure detection element (34) surrounding the periphery of the fuel injection hole (33b) is provided near the distal end of the injector that injects fuel into the combustion chamber. Since the pressure detection element (34) is provided in the injector, it is not necessary to change the shape and structure of the injector or the combustion chamber in order to install the pressure detection element (34), and it is possible to use the fuel passing through the injector to the pressure detection element (34). 34) Cooling is performed to improve pressure detection accuracy and durability. In addition, since the annular pressure detection element (34) surrounds the fuel injection hole (33b), it is possible to avoid interference between the pressure detection element (34) and the fuel injected from the fuel injection hole (33b), and to maximize the The size of the pressure detection element (34) is increased to ensure the pressure detection accuracy.

Owner:HONDA MOTOR CO LTD +1

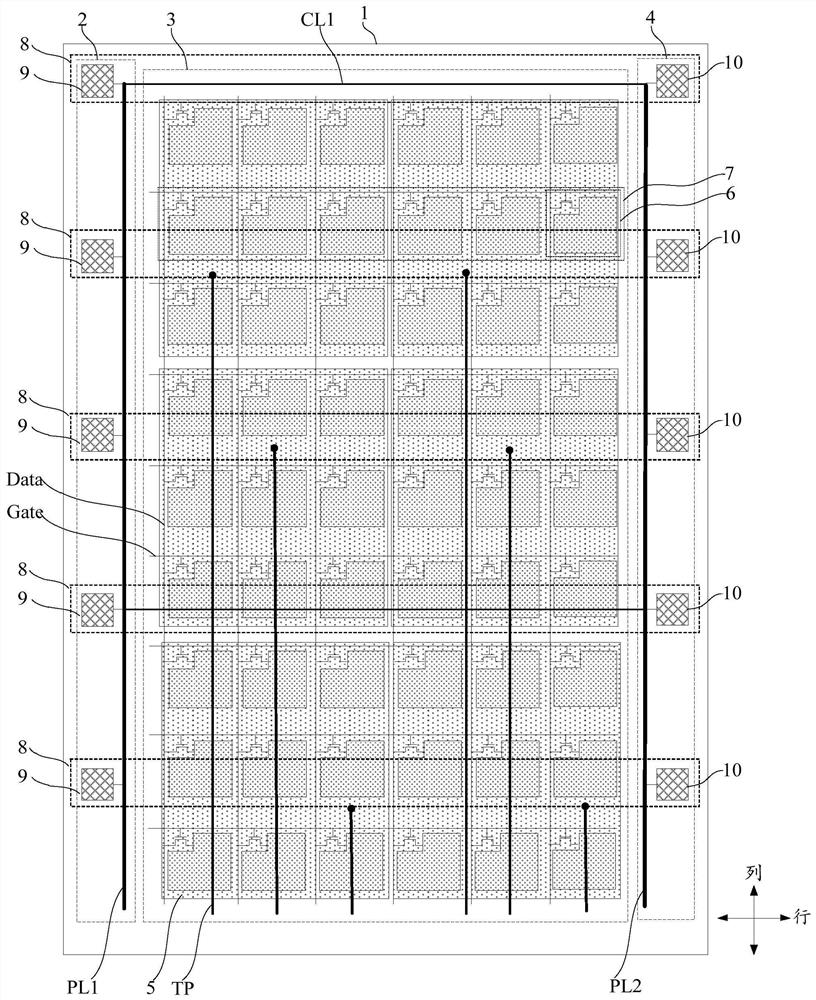

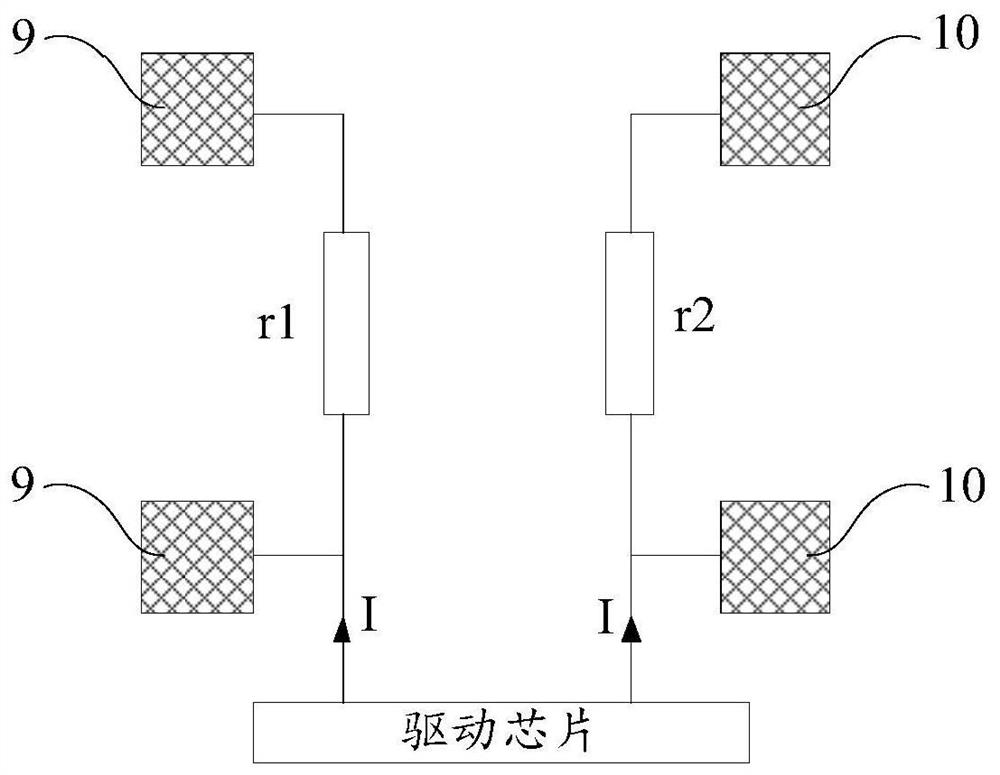

Display panel and display device

ActiveCN108445663BReduce equivalent trace resistanceSmall attenuationNon-linear opticsInput/output processes for data processingComputer hardwareSignal on

Embodiments of the present invention provide a display panel and a display device, which relate to the field of display technology and are used to reduce the attenuation of a power signal and effectively improve the difference in drive capability of the power signal to pressure sensing units at different positions. The display panel includes M pressure sensing unit groups, a first signal line, a second signal line and at least one first connection signal line; the pressure sensing unit group includes a first pressure sensing unit and a second pressure sensing unit; A pressure sensing unit is set in the first non-display area, a second pressure sensing unit is set in the second non-display area; the first signal line is set in the first non-display area, the first signal line and the first pressure sensor The unit is electrically connected; the second signal line is arranged in the second non-display area, and the second signal line is electrically connected to the second pressure sensing unit; the first connection signal line is arranged between the first signal line and the second signal line, The first connection signal line is electrically connected to the first signal line and the second signal line. The above-mentioned display panel is used to realize screen display.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Display panel and display device

ActiveCN107272961BImprove pressure detection accuracyImprove cooling effectSolid-state devicesForce measurementDisplay deviceSemiconductor

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Pressure sensor for pressure cooker and pressure cooker

ActiveCN104515641BImprove pressure detection accuracyWide range of workFluid pressure measurementInlet channelHigh pressure

The invention discloses a pressure sensor for a pressure cooking utensil, and a pressure cooking utensil. The pressure sensor comprises a housing, wherein one end of the housing is constructed to have a cavity with an opening, and the other end of the housing is provided with an air inlet channel communicating with the cavity; a sealing cover which is connected with one end of the housing so as to seal the opening; a positioning assembly which is arranged at a connecting position of the cavity and the air inlet channel, is in sealing connection with the housing and comprises a detection channel communicating the cavity and the air inlet channel; and a pressure detection assembly which is arranged on the positioning assembly, breaks connection of the connection channel, and has a pressure sensor chip arranged in the detection channel. According to the pressure sensor for the pressure cooking utensil, the working scope of the pressure sensor is wider, and the pressure cooking utensil can be enabled to have higher pressure detection precision.

Owner:MIDEA GRP CO LTD +1

A pressure signal flow measurement device and flow measurement method

ActiveCN104766513BRealize real-time traffic detectionRealize real-time traffic digital detectionEducational modelsVolume/mass flow by differential pressureHorizontal axisDischarge measurements

The invention discloses a pressure signal flow measurement device and a flow measurement method for improving the precision. The pressure signal flow measurement device comprises an experimental water tank, a liquid-gas conversion pressure measurement cylinder, a fluid pressure difference sensor and a microcomputer, wherein the experimental water tank is provided with an outflow port, and a water stabilizing pore plate used for dividing a water inlet working area into an water inlet area and a water stabilizing working area is arranged in the experimental water tank; the liquid-gas conversion pressure measurement cylinder is arranged in the water stabilizing working area of the experimental water tank, a communication positioning pipe is arranged on the top of the pressure measurement cylinder, and the bottom surface of the communication positioning pipe is located on the horizontal axis plane of the outflow port; the fluid pressure difference sensor is used for detecting the pressure difference between compressed air in the liquid-gas conversion pressure measurement cylinder and the outside air; the microcomputer is used for converting a pressure difference signal detected by the fluid pressure difference sensor into the flow of the outflow port. According to the pressure signal flow measurement device and the flow measurement method, automatic resetting and real-time zero setting can be achieved, measurement precision is improved, the jet flow of a momentum experiment instrument and an orifice in a basic hydromechanics experiment and the jet flow of an orifice and a pipe nozzle of a pipe nozzle experiment instrument can be measured conveniently, digitally and accurately, and a good teaching effect is achieved.

Owner:ZHEJIANG UNIV +1

Pressure sensor

ActiveCN114264402AReduce cloggingAvoid depositionFluid pressure measurementEngineeringMechanical engineering

The invention relates to a pressure sensor, which comprises a pressure detection unit, a mounting part and a lower box body, and is characterized in that the pressure detection unit is used for detecting the pressure of liquid; the pressure detection unit is arranged on the upper side of the mounting part, and a pressure opening used for allowing the liquid to enter and exit is formed in the position, opposite to the pressure detection unit, of the mounting part; a lower box body is connected to the lower side of the mounting part, a guide transition groove is formed in a bottom plate of the lower box body, and a liquid opening communicated with one end of the guide transition groove is further formed in the lower box body. The pressure sensor provided by the invention is used for detecting the pressure of the liquid so as to improve the detection precision.

Owner:东莞市华芯联科技有限公司

An intrinsically safe high-pressure fire hydrant

ActiveCN106090248BImprove pressure resistanceImprove securityFire rescueLift valveIntrinsic safetyEngineering

The invention discloses an intrinsic safety type high-pressure fire hydrant comprising a valve, a valve rod and a valve base arranged at the bottom of the valve. A water inlet is arranged at the bottom of the valve, a water outlet is arranged on the side wall of the valve, the water inlet penetrates the valve base to be communicated with the inside of the valve, and the water inlet directly faces the valve rod and moves back and forth along the water inlet direction; a concave limit groove is arranged in the inner wall of the valve, a spiral groove is arranged in the outer wall of the valve rod, a limit device is arranged between the valve and the valve rod, one end of the limit device abuts against the limit groove, and the other end of the limit device is slidably fixed in the spiral groove. The intrinsic safety type high-pressure fire hydrant has the advantages that the intrinsic safety type high-pressure fire hydrant is simple in structure, convenient to install and maintain, resistant to high pressure, long in service life and low in equipment cost, and water pressure in the fire hydrant can be monitored in real time through a water pressure sensor.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com