Roller coater

A roll coater and frame technology, which is applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of affecting the quality of the coating film, the accuracy is not high, and the adjustment control, etc., to ensure quality and quality stability. performance, improved accuracy and consistency, improved quality and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

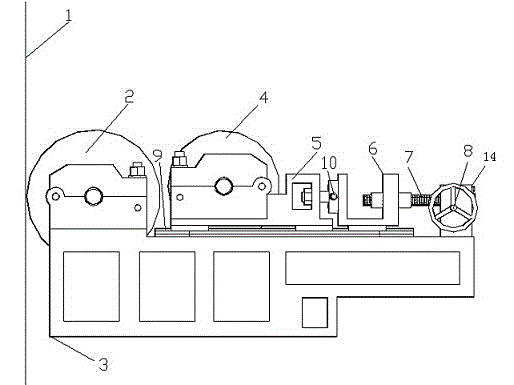

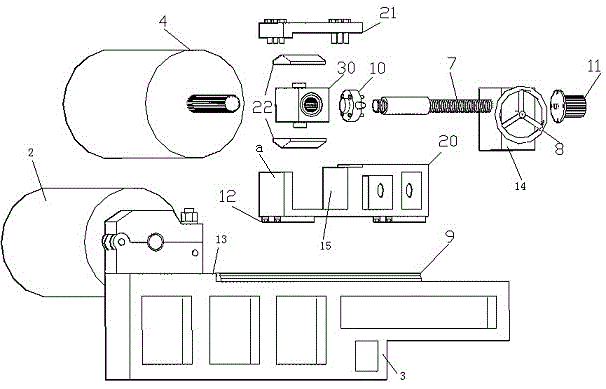

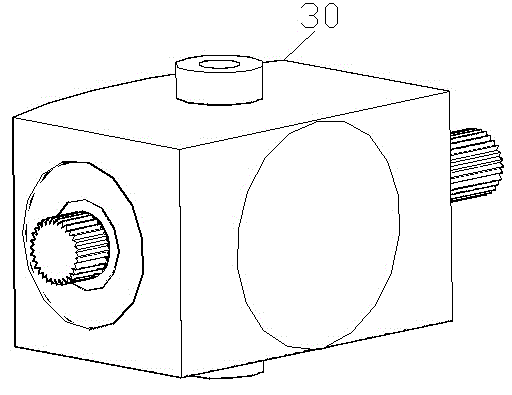

[0030] Such as Figure 2 to Figure 7As shown, the roller coater disclosed in the present invention includes a coating roller 2, a roller coater frame 3, a liquid-taking roller 4, a liquid-taking roller frame 5 and a roller pressure adjustment device, and the roller pressure adjustment device includes an operating side Bearing housing 30, transmission side bearing housing 31, slider 22, worm gear 7, pressure detection element 10, handwheel 8, servo motor 11, linear guide rail 9 and linear rail 12, the upper surface of the roller coater frame is set at one end There is a step shape of the boss 13, the coating roller 2 is arranged on the boss 13 through the bearing seat,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com