Fuel injection valve and fuel injection device

A fuel injection valve and fuel pressure technology, which is applied to fuel injection devices, fuel injection devices with sensors, and charging systems, etc., can solve the problems of increasing labor and time for connector connection operations, and complicated electrical wiring processing. Avoid labor and time, achieve the effect of root number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

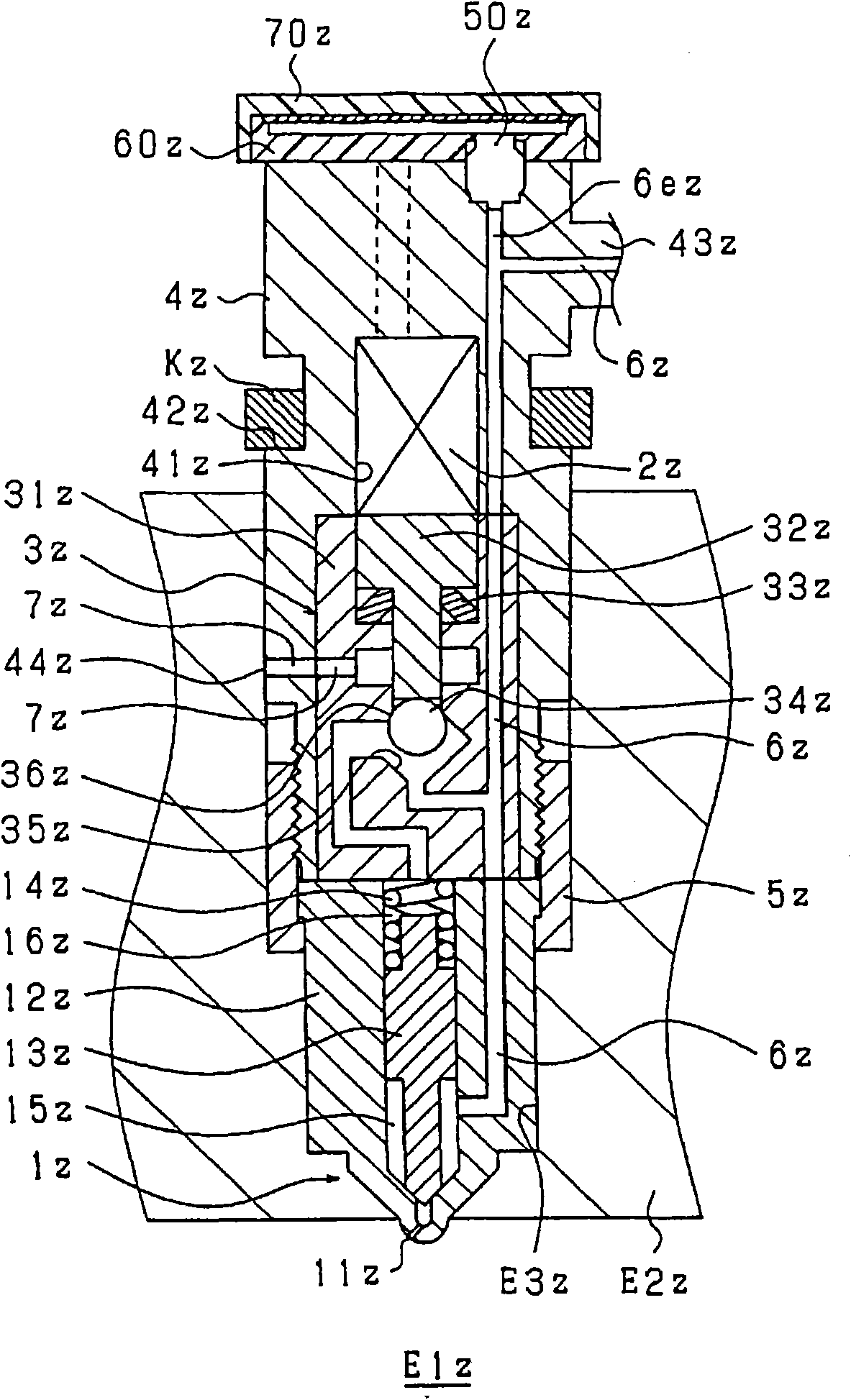

[0070] use figure 1 as well as figure 2 The first embodiment of the present invention will be described. figure 1 is a schematic cross-sectional view showing a schematic internal structure of an injector (fuel injection valve) according to this embodiment, figure 2 is a detailed description figure 1 magnified view of .

[0071] First, according to figure 1 The basic structure and operation of the injector will be explained. The injector injects high-pressure fuel accumulated in a common rail (not shown) into a combustion chamber Elz formed in a cylinder of a diesel internal combustion engine, and includes: a nozzle 1z that injects fuel when the valve is opened; A piezoelectric actuator 2z (opening and closing mechanism) that expands and contracts by charging and discharging, and a back pressure driving mechanism 3z (opening and closing mechanism) that is driven by the piezoelectric actuator 2z to control the back pressure of the nozzle 1z.

[0072] The nozzle 1z includ...

no. 2 approach

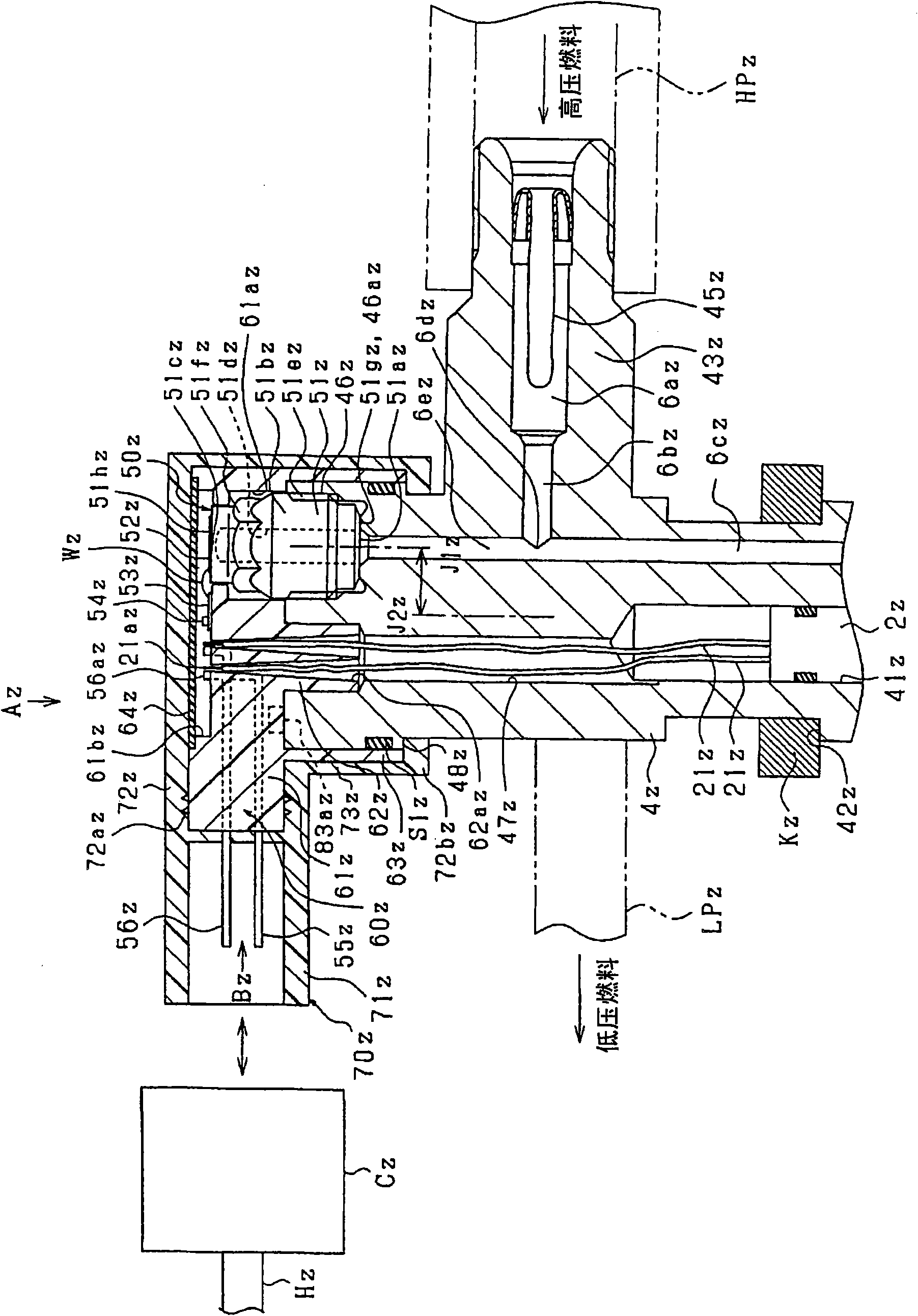

[0135] In the present embodiment, a memory chip Mz that stores a correction value for the pressure detection value detected by the fuel pressure sensor 50z (see Figure 5 ). Specifically, the deviation between the pressure detection value of the strain gauge 52z and the actual fuel pressure is acquired in advance through a test or the like, and the deviation is stored as a correction value in the memory chip Mz in advance, and a signal of the correction value is output to the outside such as the engine ECU. equipment. Accordingly, in the engine ECU, a correction value specific to the fuel pressure sensor 50z can be obtained, and the pressure detection value obtained from the fuel pressure sensor 50z can be corrected based on the obtained correction value.

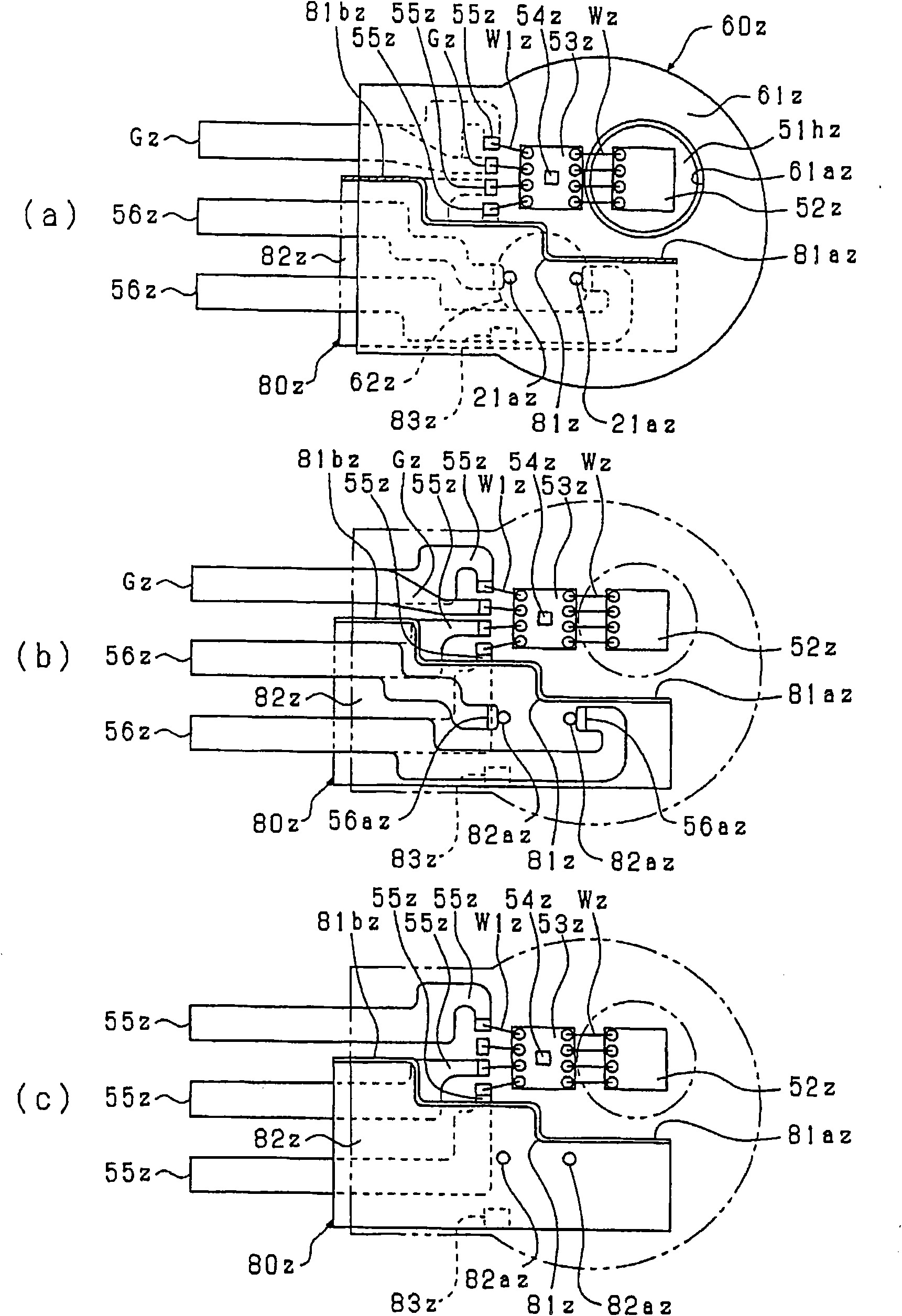

[0136] In addition, one of the three sensor terminals 55z used in the first embodiment is used as the memory terminal 55z for outputting the correction value. Therefore, in addition to the drive terminal 56z, the sensor t...

no. 3 approach

[0139] The lead wires 21z of the piezoelectric actuator 2z and the fuel pressure sensor 50z are located inside the connector housing 70z, and these lead wires 21z and the fuel pressure sensor 50z need to be sealed from the outside of the connector housing 70z. Regarding this sealing structure, in the above-mentioned first embodiment, by disposing the O-ring S1z (sealing member) between the inner peripheral surface of the cylindrical portion 63z of the molded resin 60z and the outer peripheral surface of the main body 4z, one O-ring S1z The ring S1z seals both the lead wire 21z and the fuel pressure sensor 50z.

[0140] In contrast, in Image 6 In the present embodiment shown, the lead wire 21z and the fuel pressure sensor 50z each include different O-rings S2z and S3z (sealing members). Specifically, an O-ring S2z is disposed between the cylindrical portion 51bz of the fuel pressure sensor 50z and the recessed portion 46z of the molded resin 60z. In addition, an O-ring S3z i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com