Pressure controlled electric pressure cooker

An electric pressure cooker and pressure technology, applied in pressure cookers, cooking utensils, household appliances, etc., to save material costs and process costs, improve fatigue strength and thermal creep resistance, and be conducive to pressure control accuracy and market promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

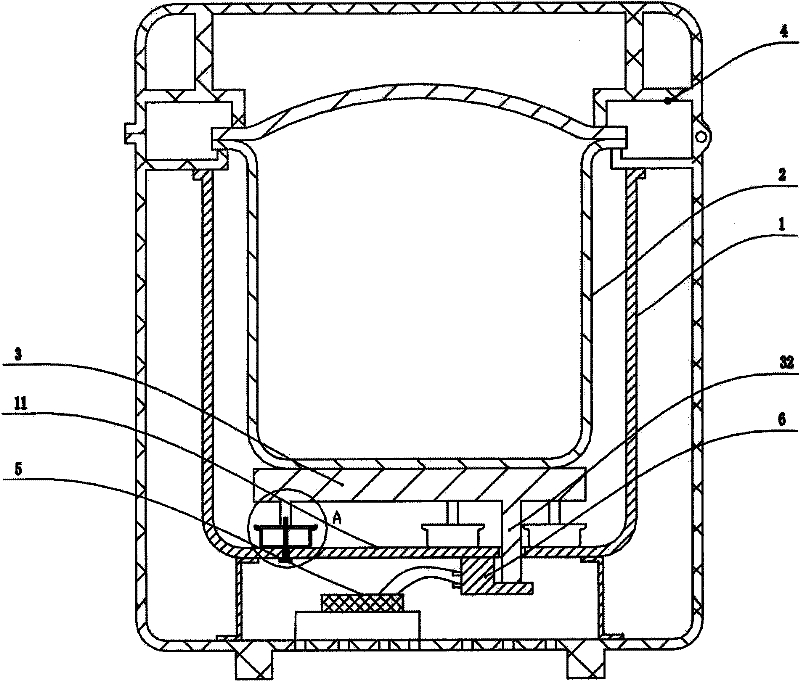

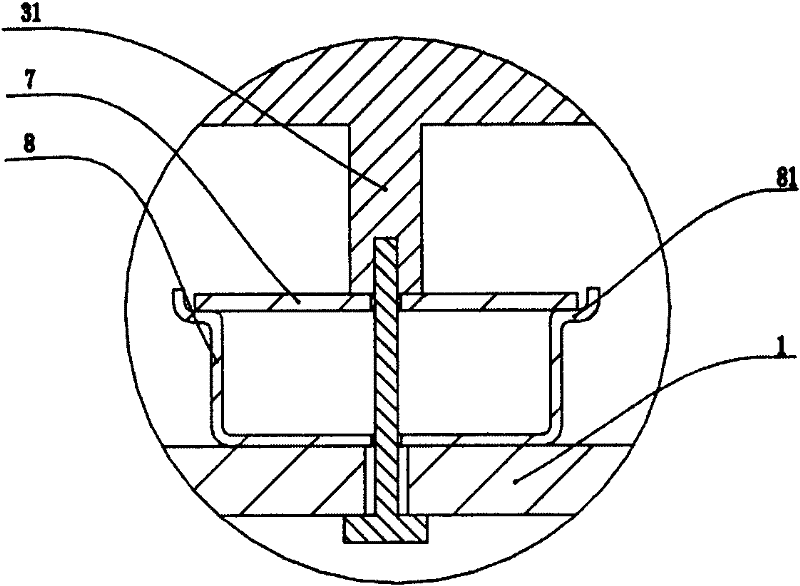

[0028] Depend on figure 1 , figure 2 The shown voltage-controlled electric pressure cooker includes an outer pot 1 , an inner pot 2 , an electric heating plate 3 , a pot cover 4 and a control circuit board 5 . The control circuit board 5 is provided with a control circuit, the inner pot 2 is placed on the electric heating plate 3; the pot cover 4 seals the mouth of the inner pot 2; multiple groups of elastic support devices are arranged between the electric heating plate 3 and the outer pot bottom 11, This embodiment preferably has three groups. The bottom of the outer pot 1 is provided with a pressure detection device 6, and the pressure detection device 6 is a micro switch. The bottom of the outer pot 1 refers to a position close to the bottom of the outer pot 11, which can Above or below, in the present embodiment, the pressure detection device 6 is directly fixedly installed on the outer pot bottom 11, the pressure detection device 6 is electrically connected to the con...

Embodiment 2

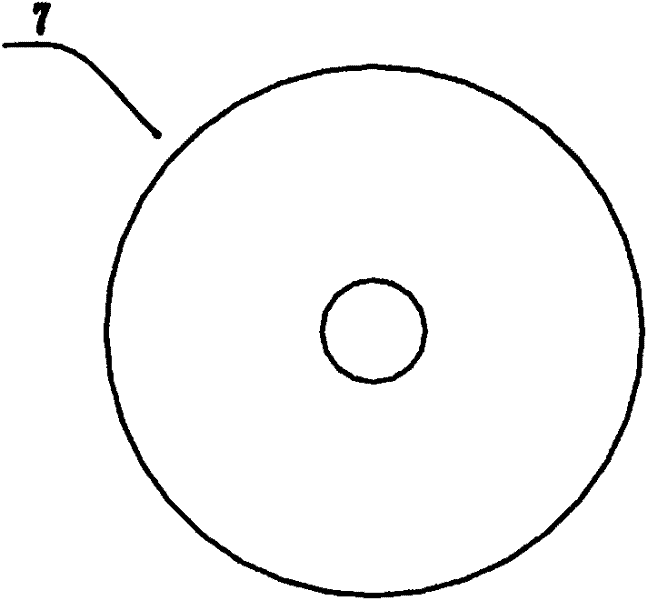

[0032] Such as Figure 4 , Figure 5 and refer to figure 1As shown in , the overall structure of this embodiment is basically the same as that of Embodiment 1, except that the elastic plate 7 is provided with spline teeth 71 pointing to the center of the elastic plate 7, and the overall shape of the elastic plate 7 is a disc spring shape, and the outer circumference The shape is circular, and the pillar 31 is connected with the spline tooth 71 of the elastic plate 7. This structure has two advantages: 1. Under the same pressure, the elastic deformation of the elastic plate 7 is larger, and compared with the flat structure, The linearity of elastic deformation is better, and the force / displacement curve is close to a straight line, while the force / displacement curve of a flat elastic plate is parabolic. This kind of force curve close to a straight line is more conducive to pressure control, especially for the use of The stepless pressure regulation technology of the displace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com