Method for detecting pressure of bottom surface of granary and pressure sensor adopted by method

A pressure sensor and pressure detection technology, applied in the field of grain storage and grain detection, can solve problems such as low measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

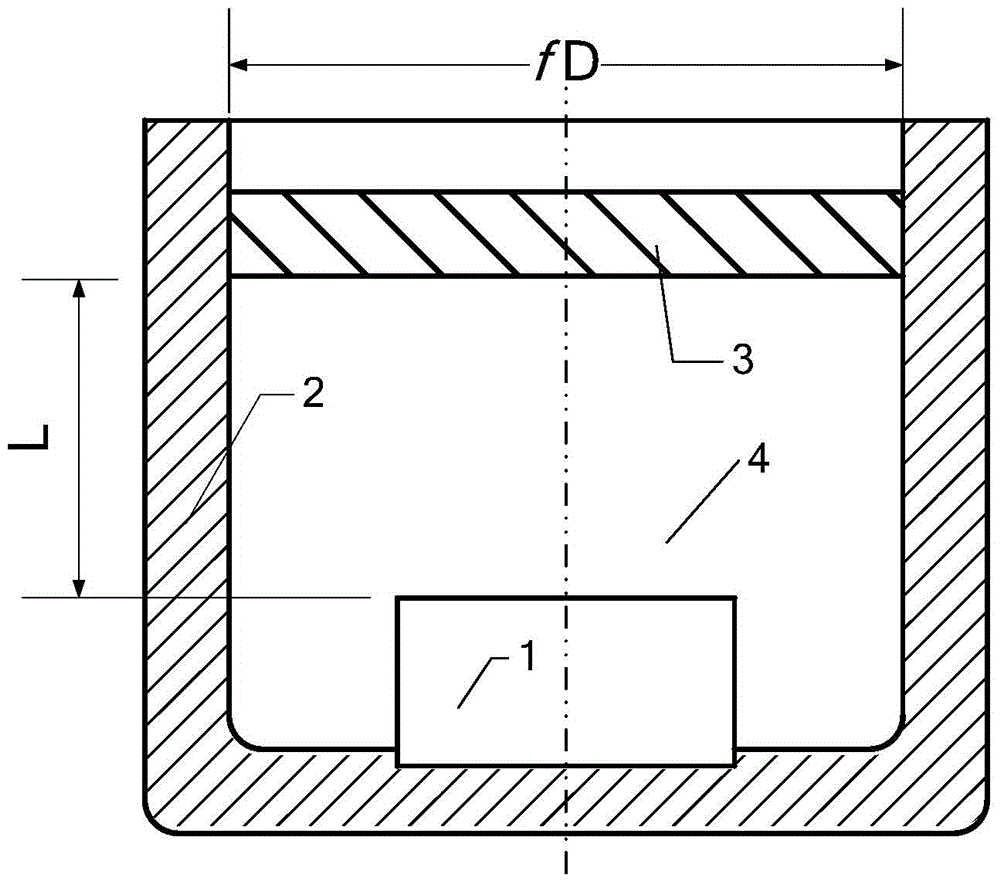

[0036] Figure 6 (a), (b) is a type of sensor applying the concept of the present invention, (a), (b) represent the use of two different elastic pads. In FIG. 6 , the pressure sensor includes a housing 11 and a sensitive diaphragm 12 , and the sensitive diaphragm 12 is provided with an elastic pad. The sensitive diaphragm 12 is a planar diaphragm with a flat top surface, and the elastic pad is closely attached to the top surface of the sensitive diaphragm; the top surface of the elastic pad is flat. In Fig. 6(a), the width of the elastic pad 15 is larger than that of the sensitive diaphragm, and in Fig. 6(b), the width of the elastic pad 16 is equal to that of the sensitive diaphragm.

[0037] The thickness of the elastic pad should be 4-6mm. Resilient pads can be realized by mounted resilient pads or with resilient coatings. The elastic material can be selected from rubber, such as neoprene.

Embodiment 2

[0039] The pressure sensor includes a housing 13 and a sensitive diaphragm 14, and the sensitive diaphragm 14 is provided with an elastic pad. An annular groove is formed on the top surface 14 of the sensitive diaphragm, and the elastic pad fits with the annular groove; the top surface of the elastic pad is flat. The thickness of the elastic pad should be 4-6 mm; the distance between the side of the elastic pad and the ring groove is 1 mm.

[0040] In Fig. 7(a), the width of the elastic pad 15 is larger than that of the sensitive diaphragm, and in Fig. 7(b), the width of the elastic pad 16 is equal to that of the sensitive diaphragm.

[0041] The method for detecting the pressure on the bottom surface of the granary using the above-mentioned pressure sensor at least includes the following steps:

[0042] Calibrate the pressure sensor to obtain a model and a calibration coefficient of the relationship between the sensor output value and the pressure;

[0043] The pressure sen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com