A pressure signal flow measurement device and flow measurement method

A technology of flow measurement device and pressure signal, applied in the field of experimental measurement, can solve the problem of not having a better high-precision digital real-time measurement device, etc., and achieve the effect of improving the detection accuracy of liquid pressure and good teaching effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

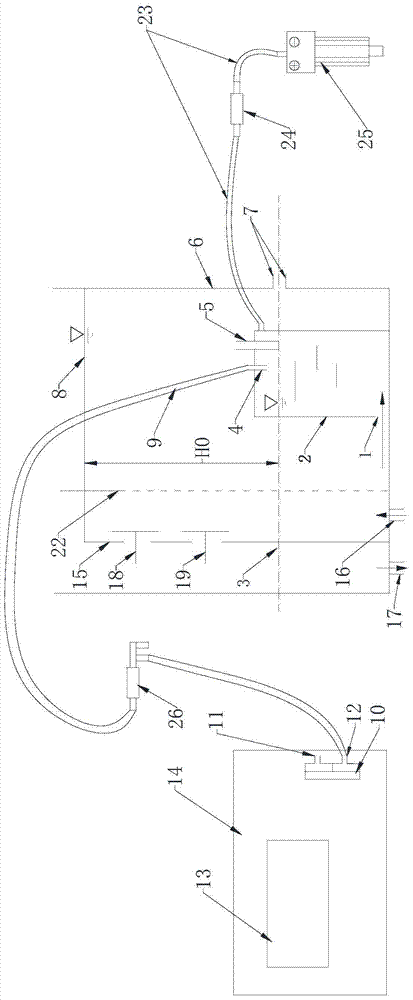

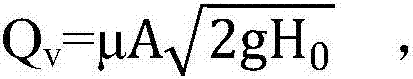

[0041] like figure 1 As shown, a pressure signal flow measurement device includes: an experimental water tank 6 with an outlet 7 on the side wall, and the outflow port 7 is an orifice or a nozzle; a liquid-gas conversion pressure measuring cylinder 2 arranged in the experimental water tank 6 , the bottom of the liquid-gas conversion pressure measuring cylinder 2 is fixed with the bottom surface of the experimental water tank 6, and the bottom of the liquid-gas conversion pressure measuring cylinder 2 is provided with a communication port 1 for communicating with the experimental water tank 6, and the top of the liquid-gas conversion pressure measuring cylinder 2 There is a communication positioning pipe 5, the bottom surface of the communication positioning pipe 5 is located on the central axis horizontal plane 3 of the outlet 7, and the bottom surface of the communication positioning pipe 5 is a horizontal plane; it is connected with the liquid-gas conversion pressure measurin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com