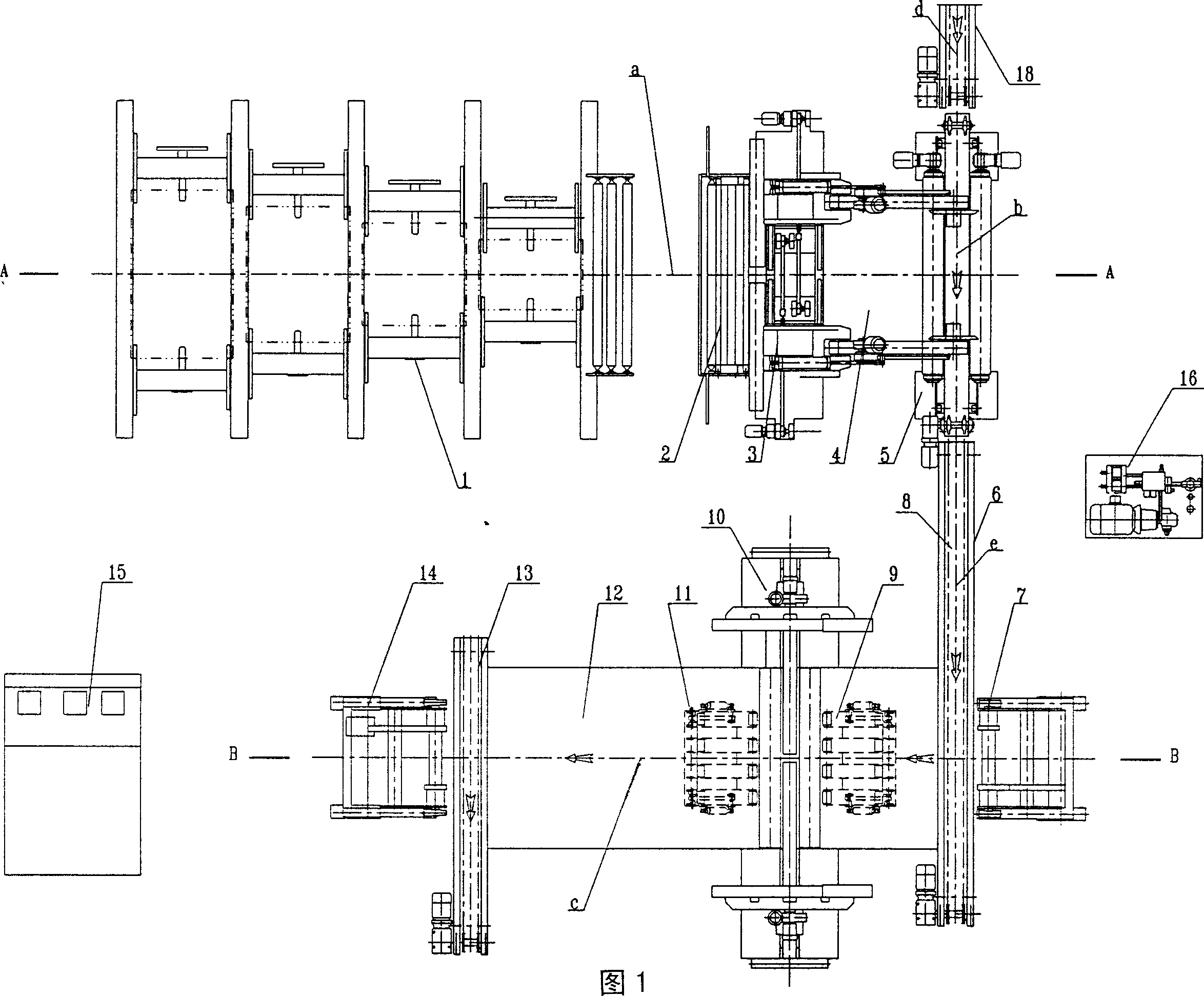

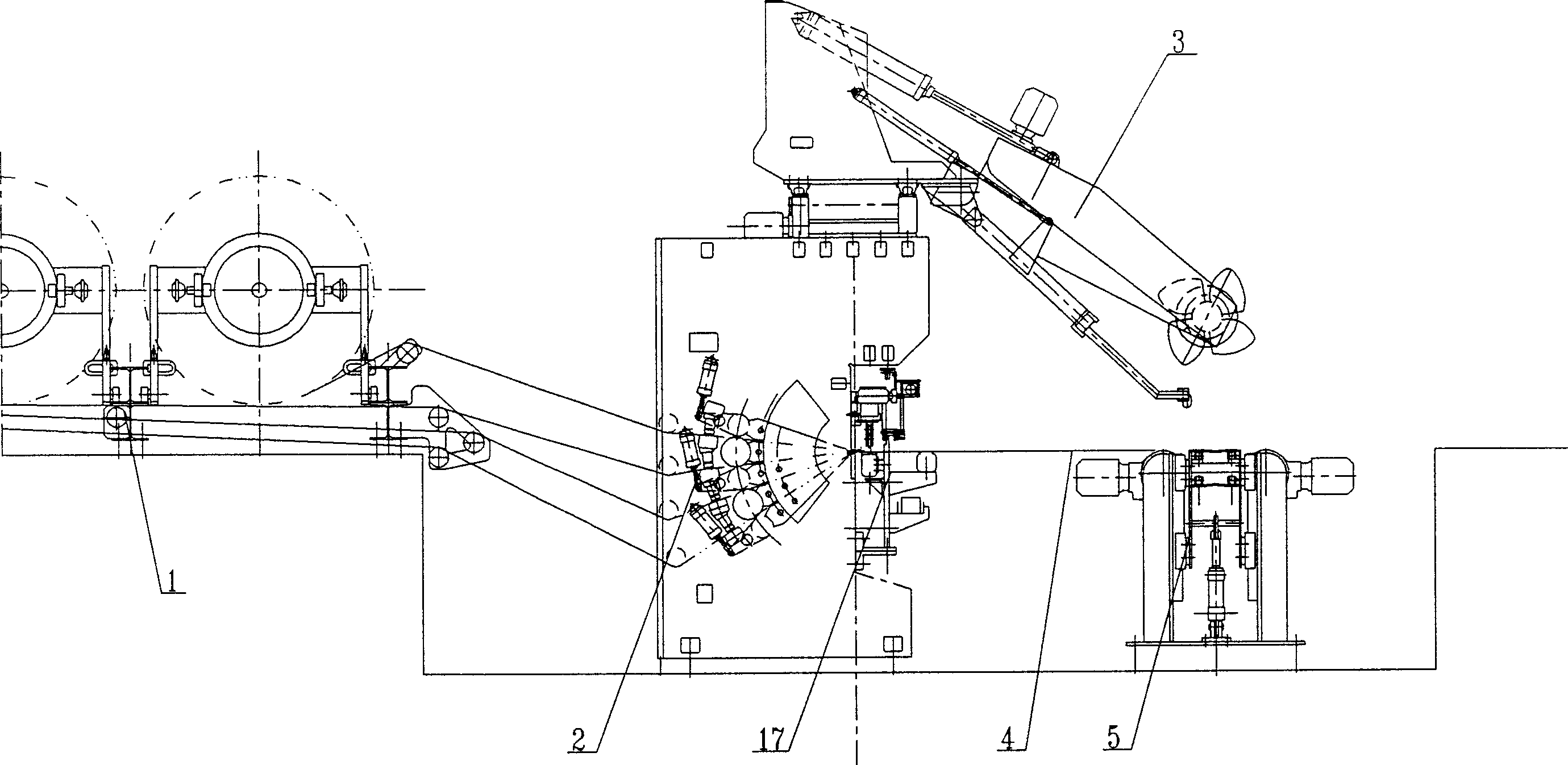

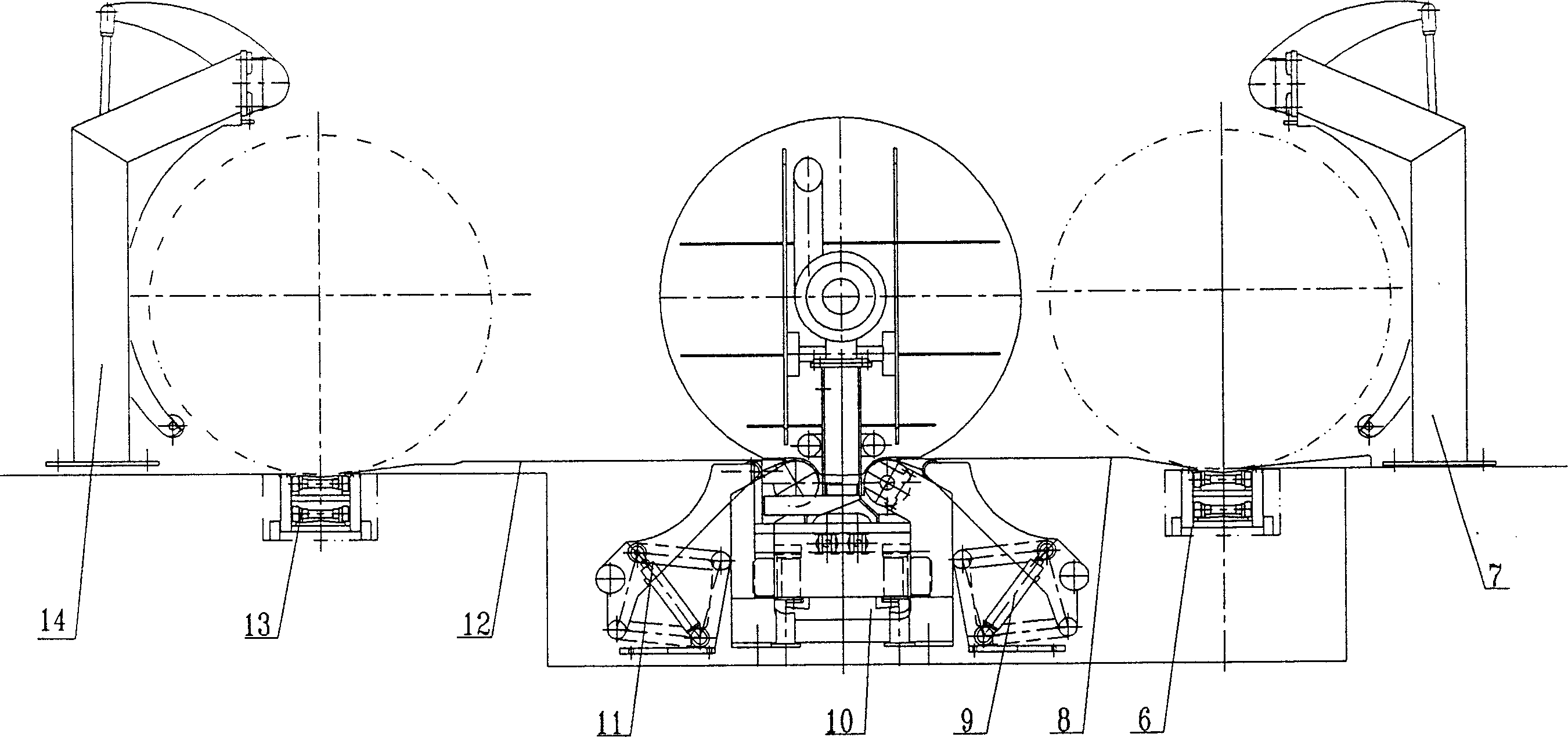

Fully automatic double-workplace paper roll packing method and packing machine

A fully automatic, double-station technology, applied in paper product packaging, packaging, packaging protection, etc., can solve the problems of long packaging time, unfavorable production efficiency, and improvement, and achieve the effect of shortening time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Through the actual use of the automatic paper roll packaging machine, the present invention finds that the automatic paper roll packaging machine needs a certain amount of working time from paper loading to final packaging, and adopts a single-station centralized packaging method. During the process, each station It takes a relatively long time for intermittent actions, especially the roll paper folding station and hot pressing station. When they are set at the same position, there will be a certain standby time for the operation of the previous action and the latter action. Time, in this way, is a waste of manpower and material resources, and the production potential is not fully utilized, making it difficult to meet the needs of the rapid development of modern production. Aiming at the above-mentioned deficiencies, the present invention proposes a double-station automatic paper roll packaging method, which is realized by a fully automatic paper roll packaging machine. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com