Patents

Literature

65results about How to "Solve flying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

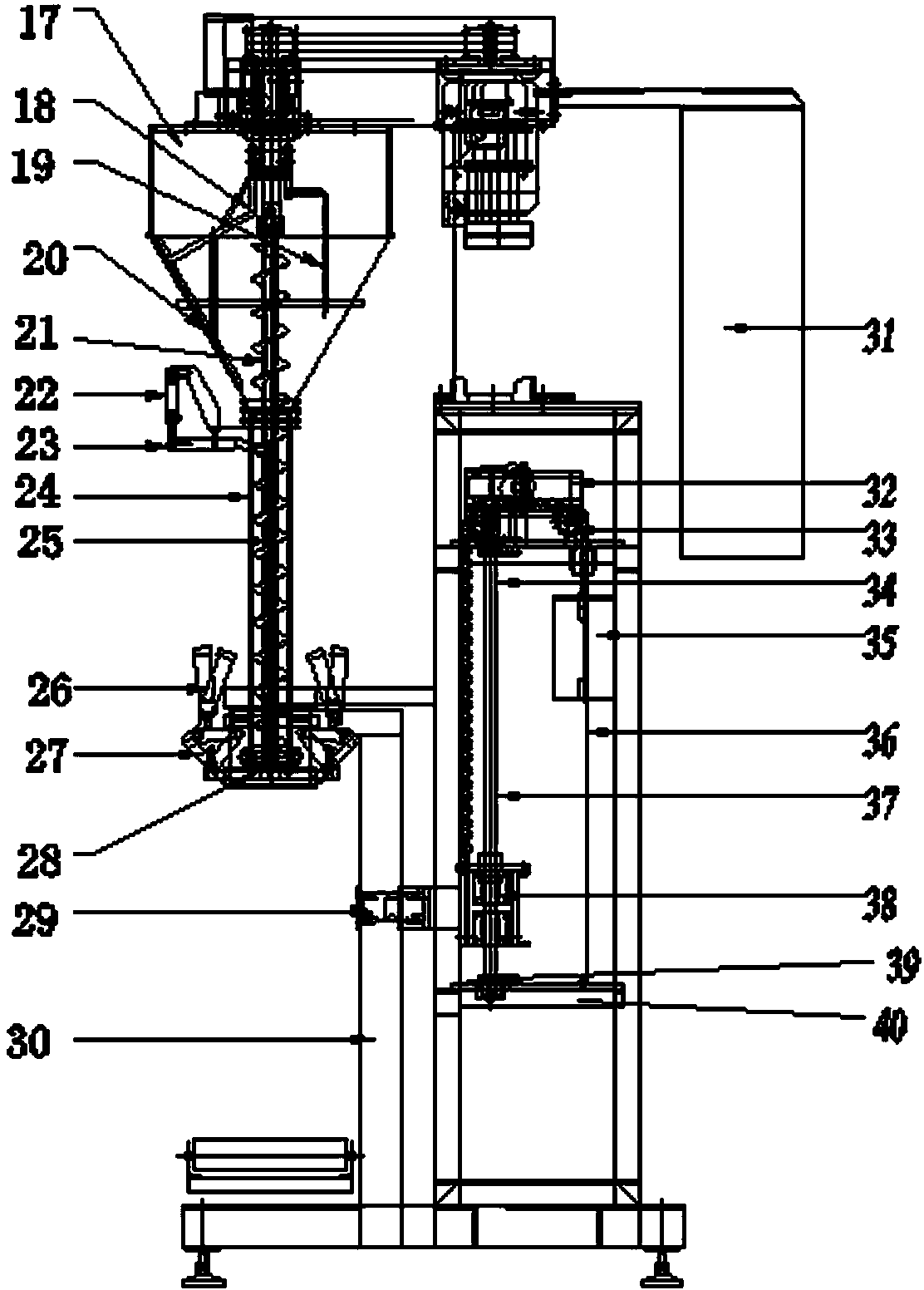

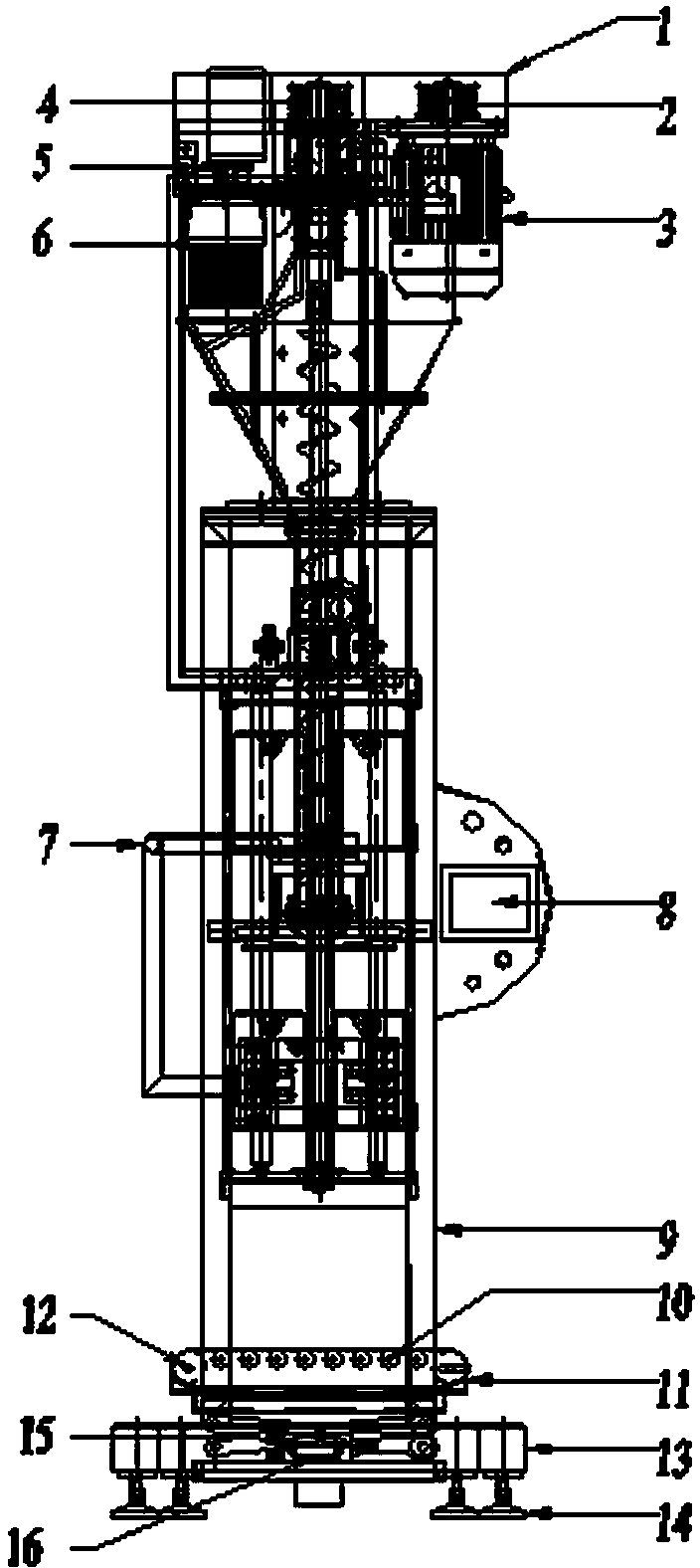

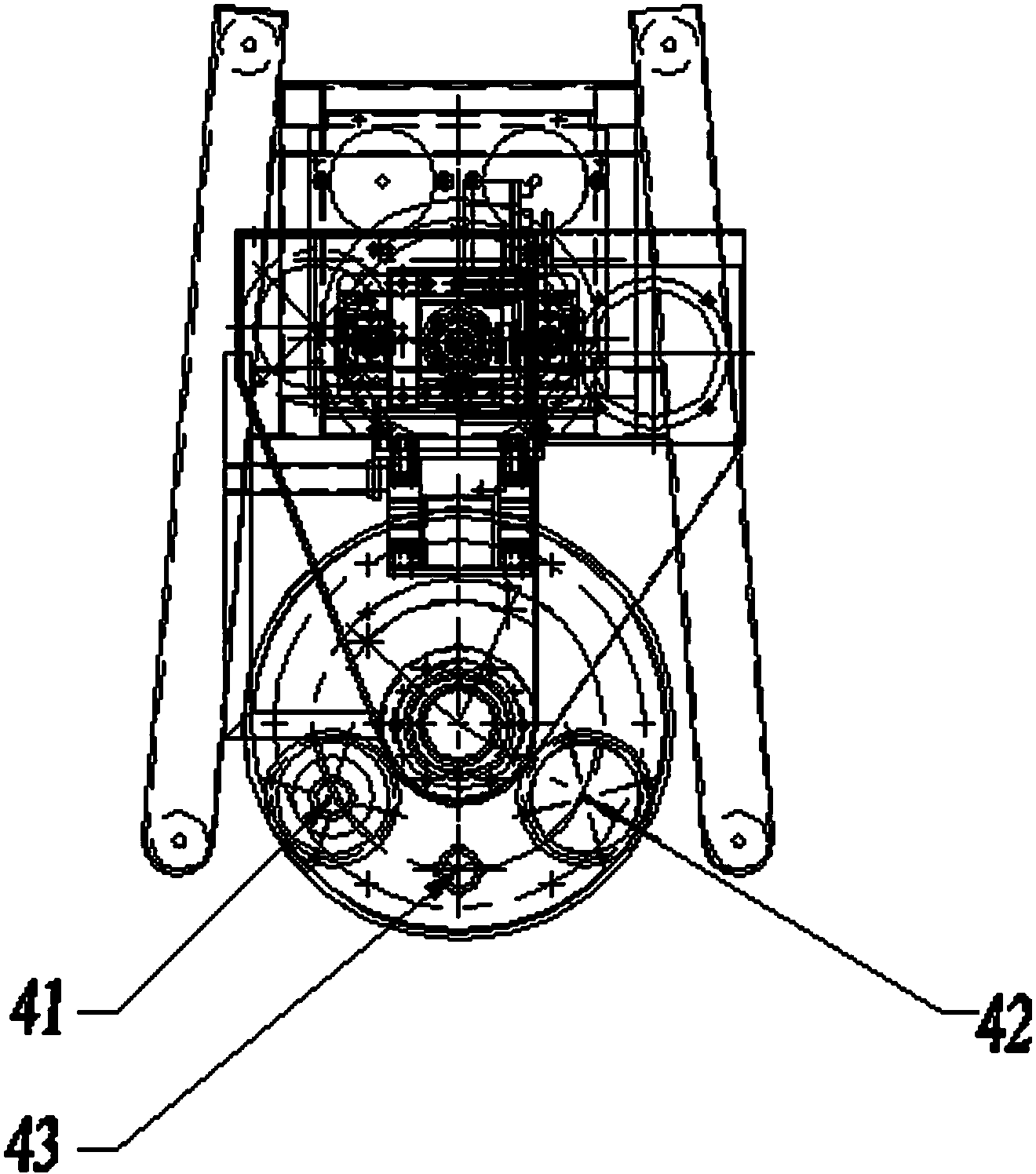

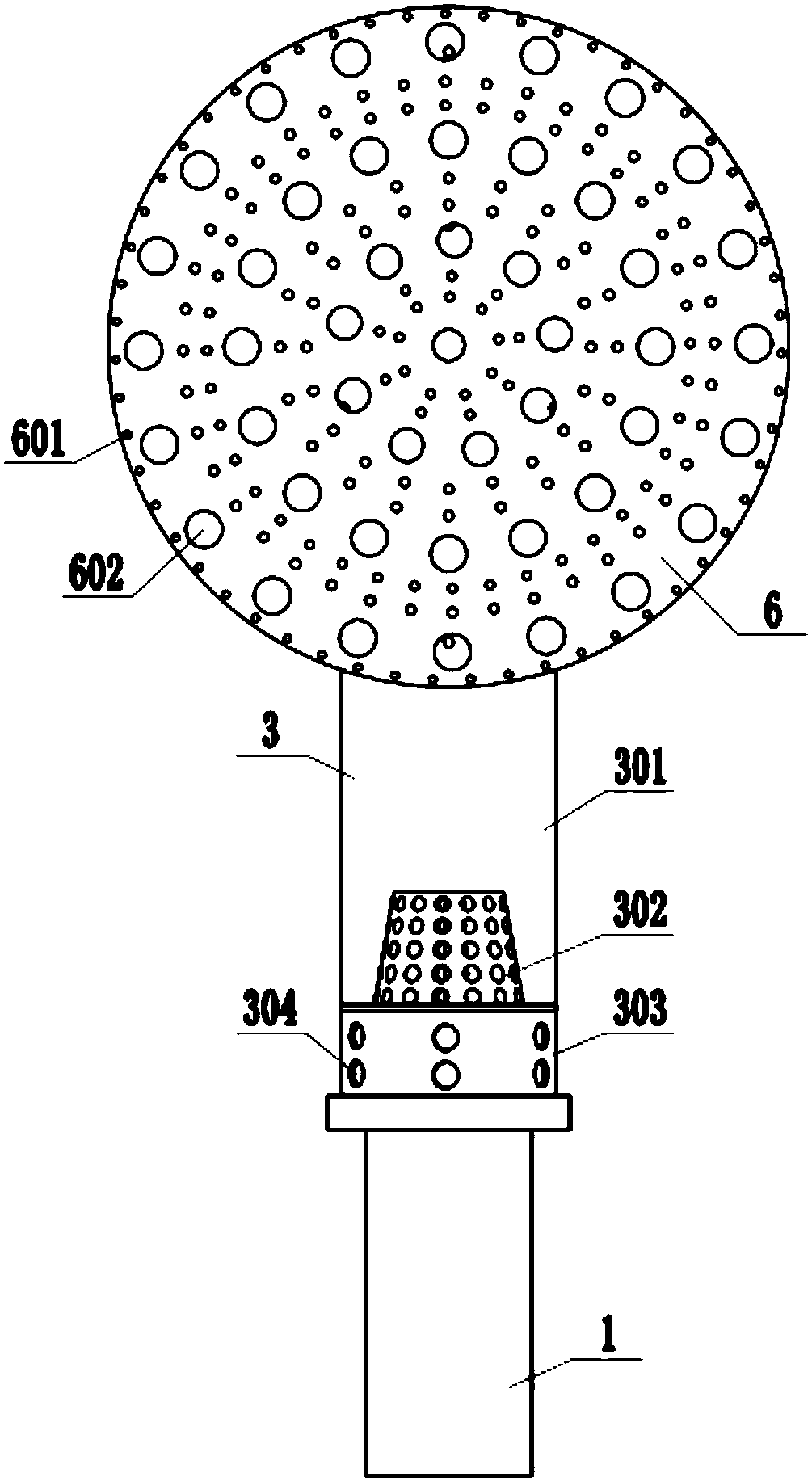

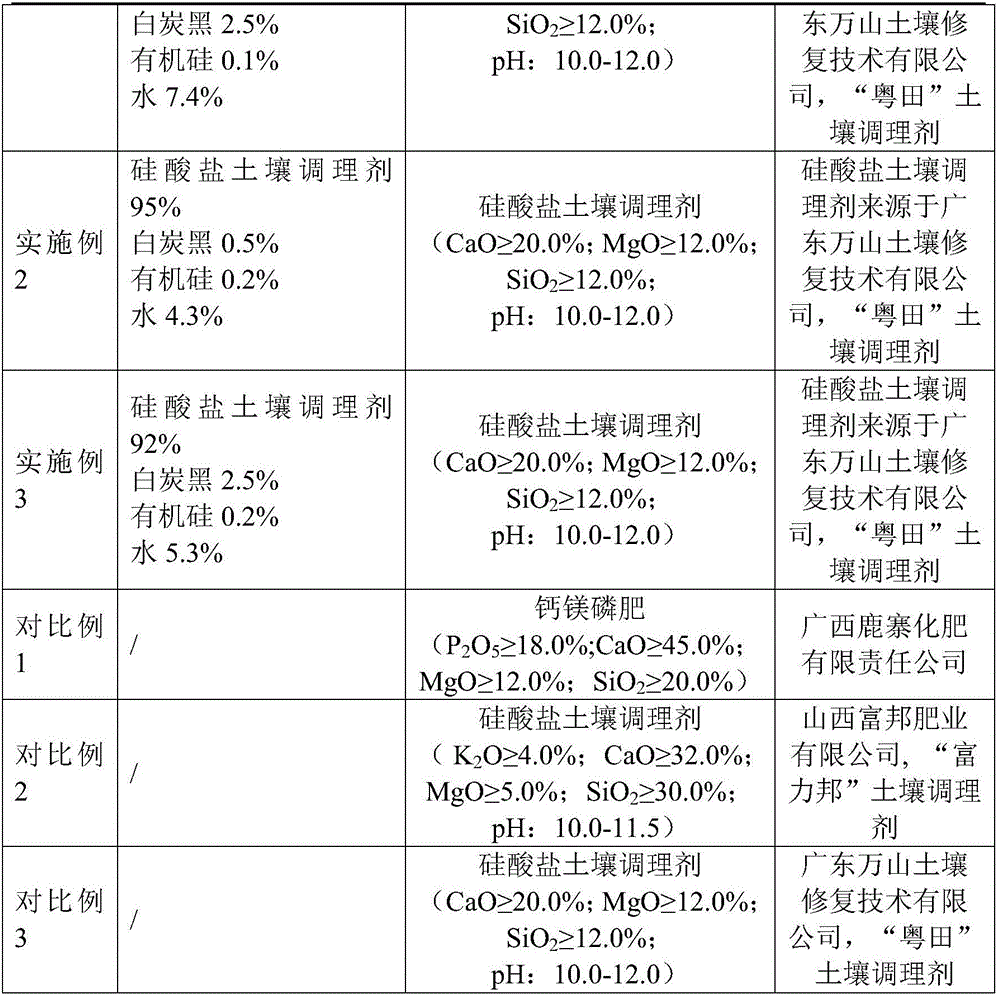

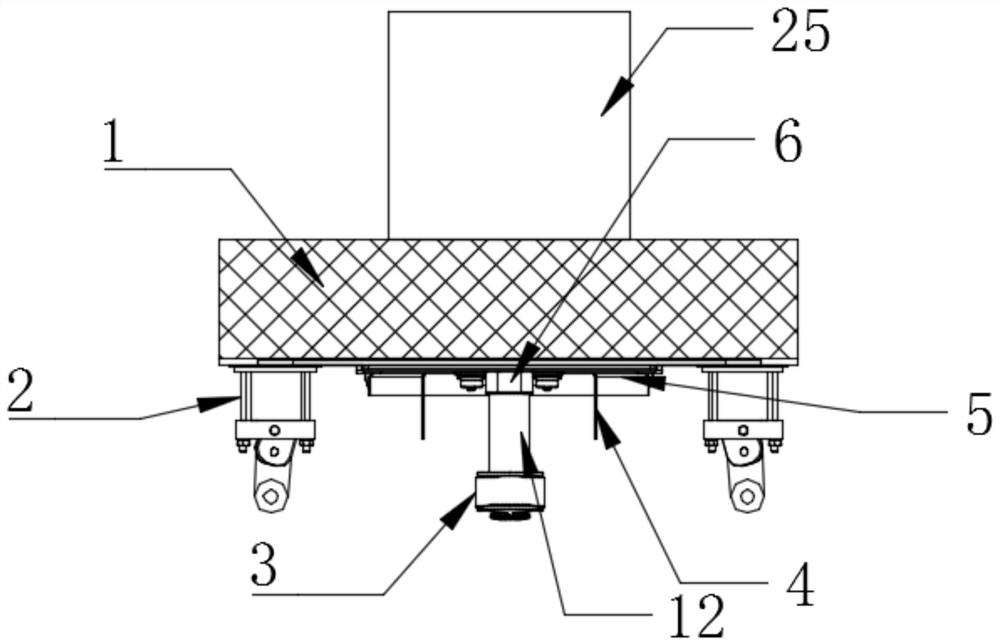

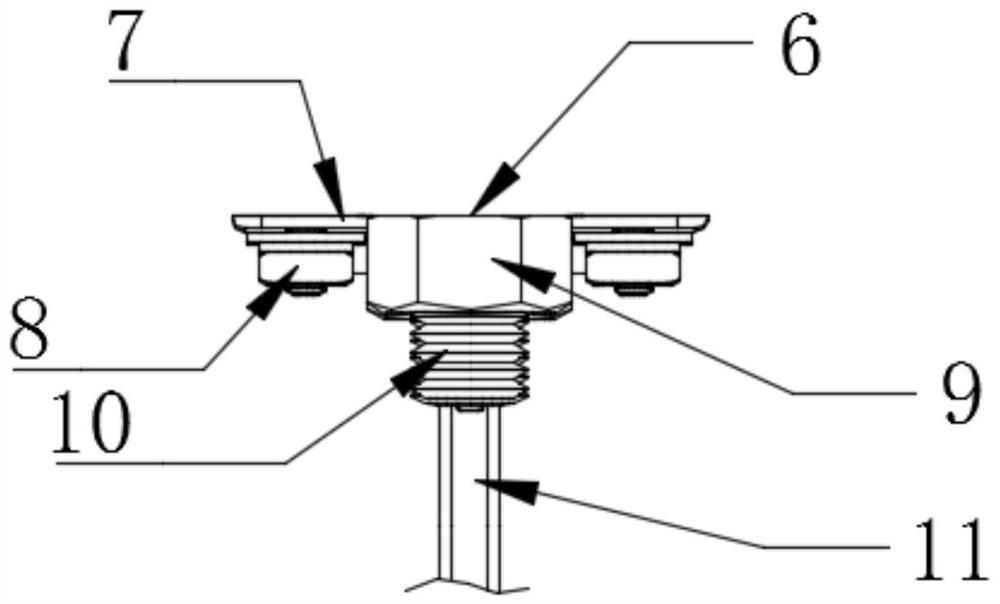

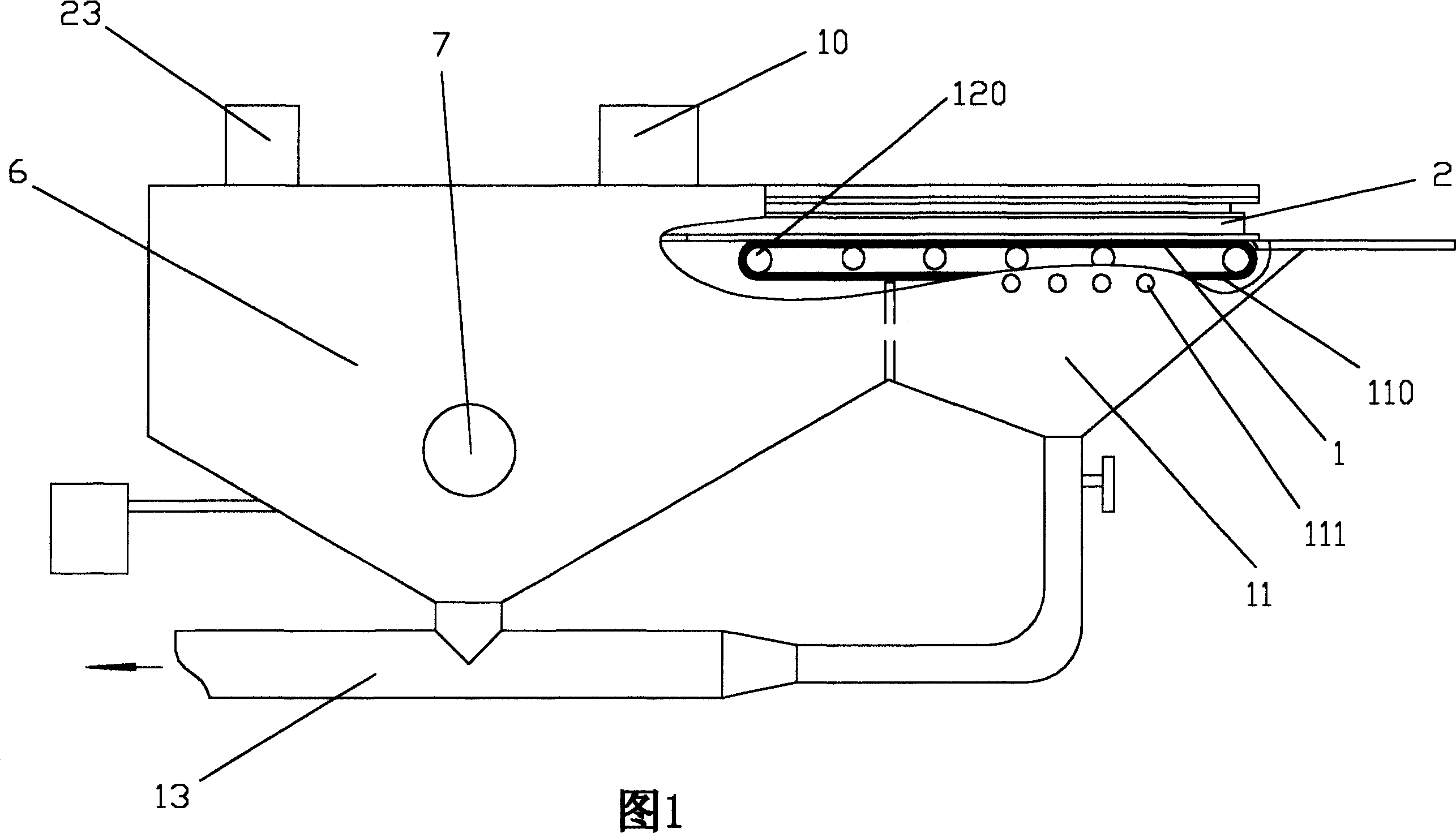

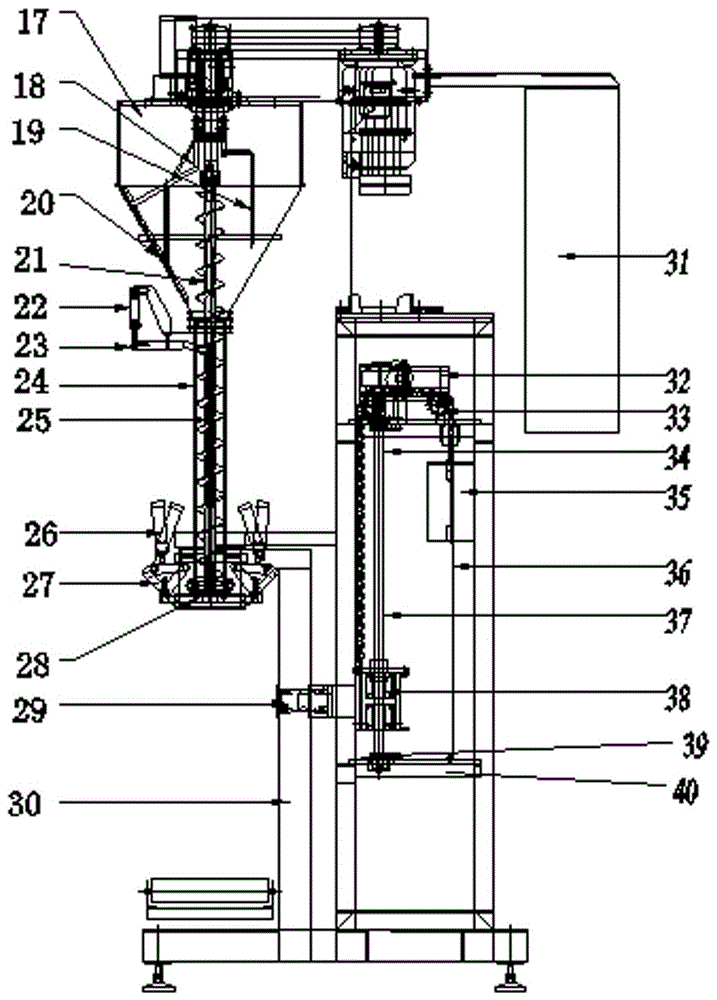

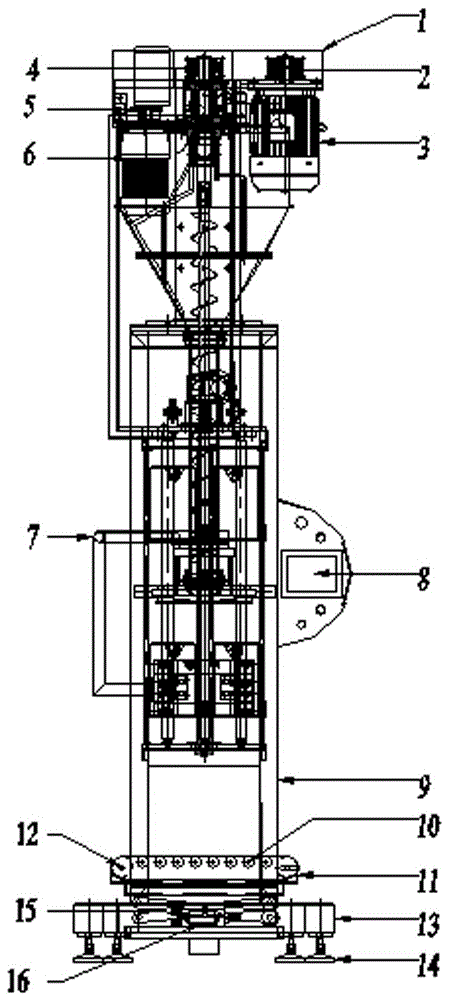

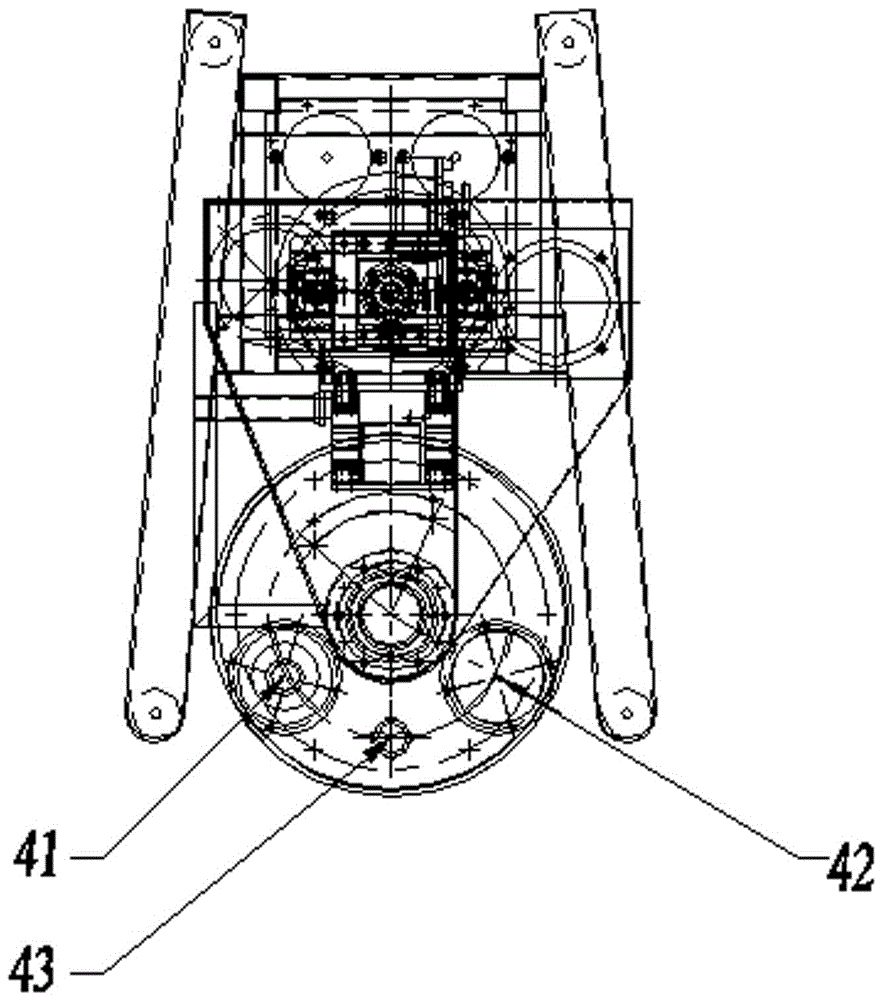

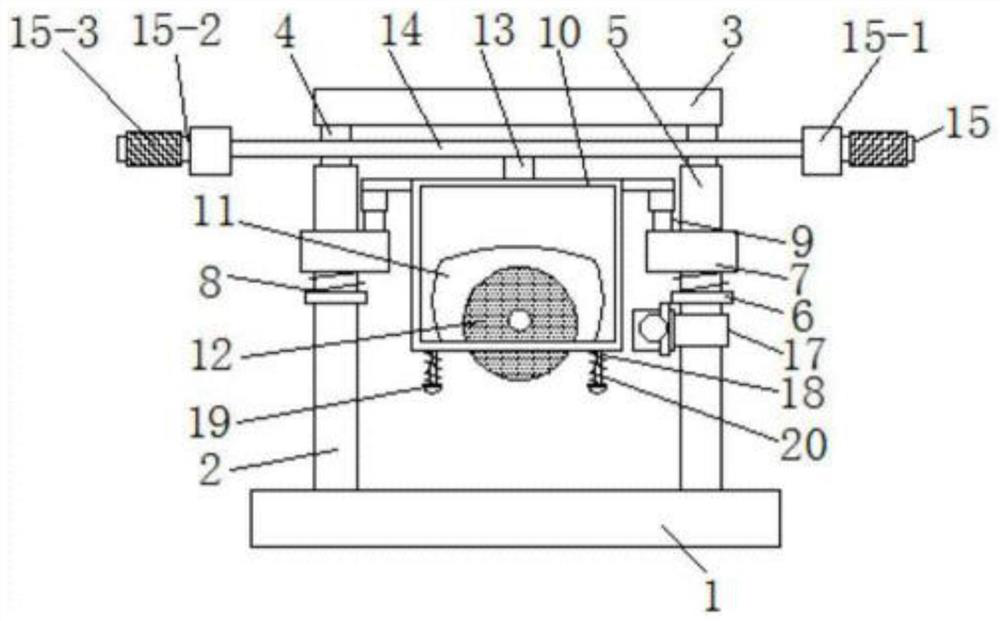

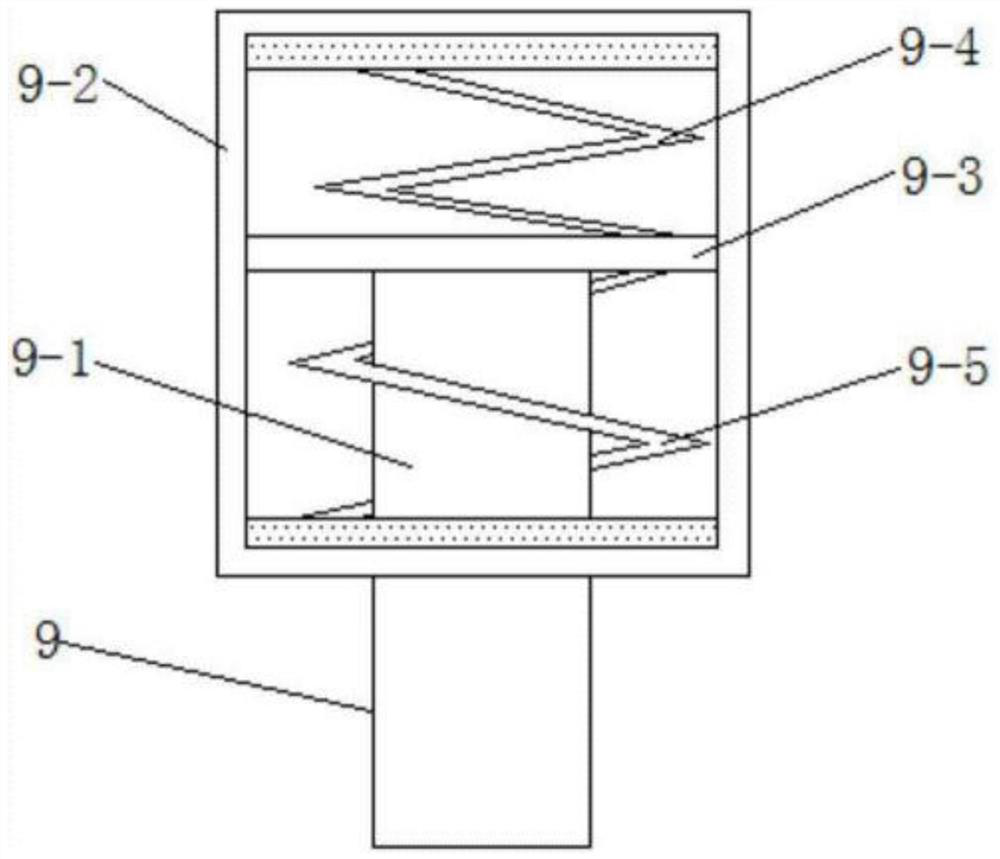

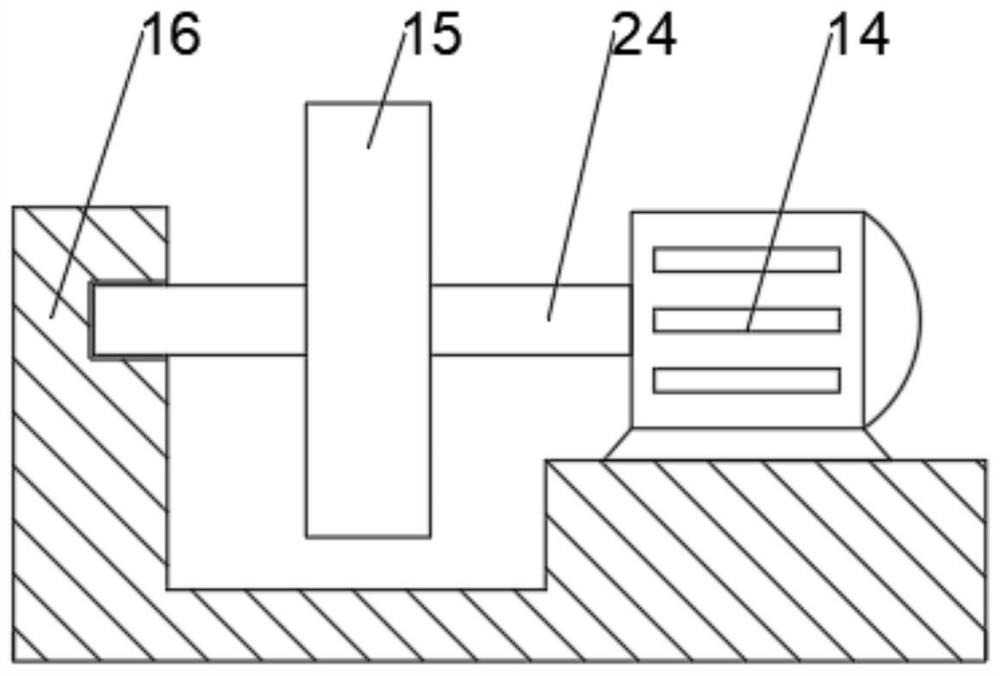

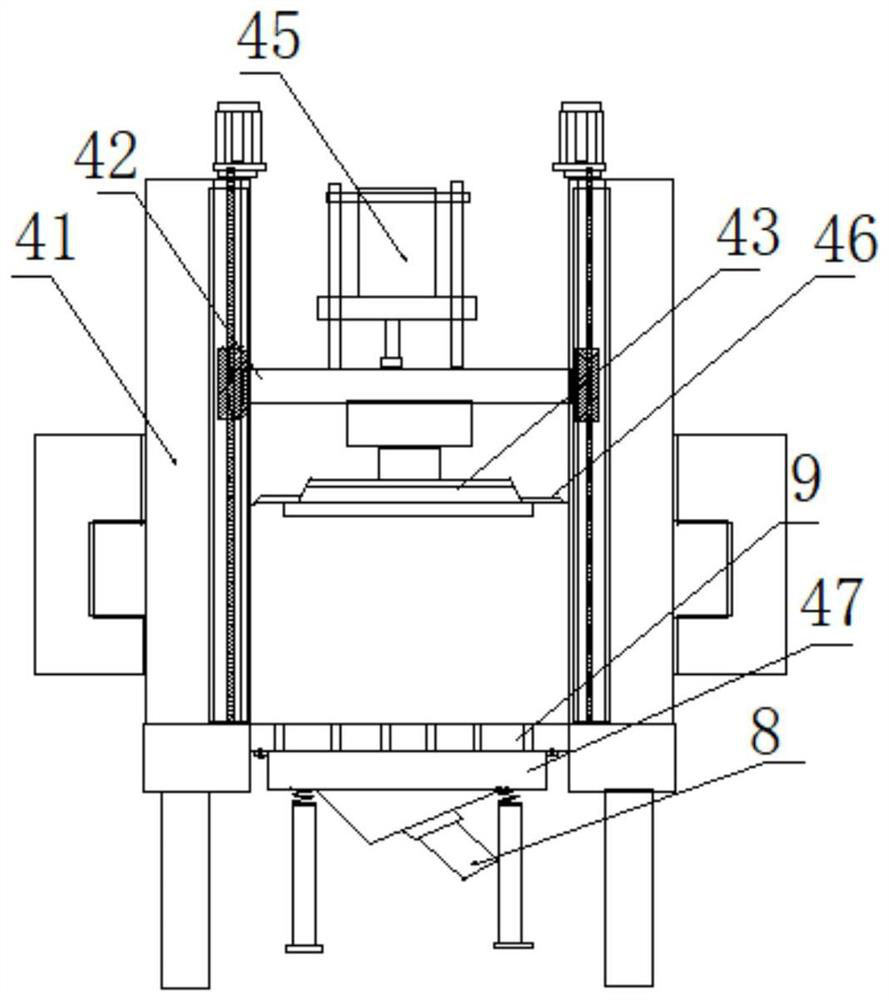

Novel ultrafine-powder packing machine

The invention discloses a novel ultrafine-powder packing machine, and relates to packaging equipment. A machine frame and a lifting column are arranged on a machine frame base, a weighing sensor is arranged on the lifting column, a clamping mechanism is further arranged at the upper end of the lifting column and is connected with a clamping air cylinder, a material stop valve and a dust removal pipeline, the material stop valve is further connected with a screw material cup, a filling screw is arranged inside a discharging hopper, a stirring motor is arranged inside a feeding hopper, a driven synchronous pulley is arranged above the feeding hopper, the driven synchronous pulley is connected with a driving synchronous pulley through a belt, and the driving synchronous pulley is connected with the filling motor. A lifting servo motor is arranged inside the machine frame and connected with a guide rod. The novel ultrafine-powder packing machine is high in production efficiency, and reasonable in design, has the functions of automatic quantification, automatic filling, automatic adjustment of metering errors and the like, is high in packing speed, is high in precision by the adoption of spiral discharging, and solves the problem that dust flies upward in a packing and filling process of ultrafine powder and materials having a great amount of dust.

Owner:SHANGHAI LUDA PACKING MACHINERY CO LTD

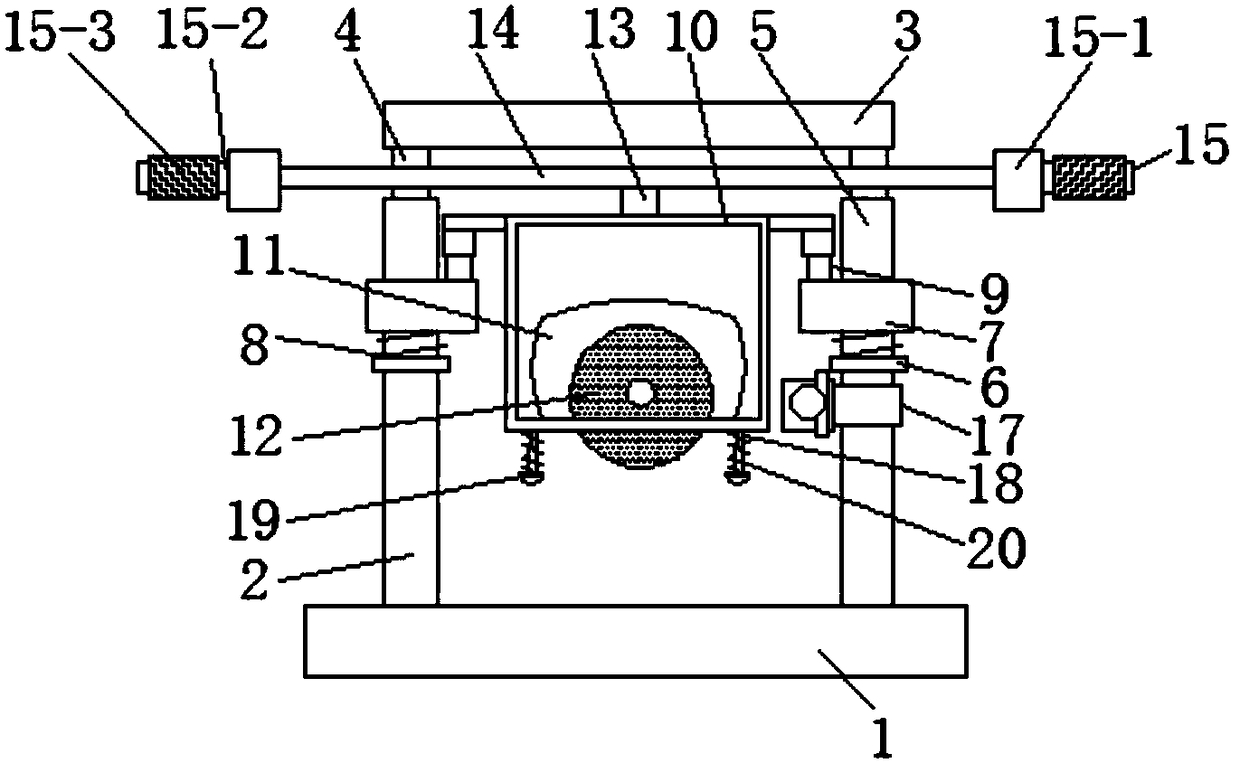

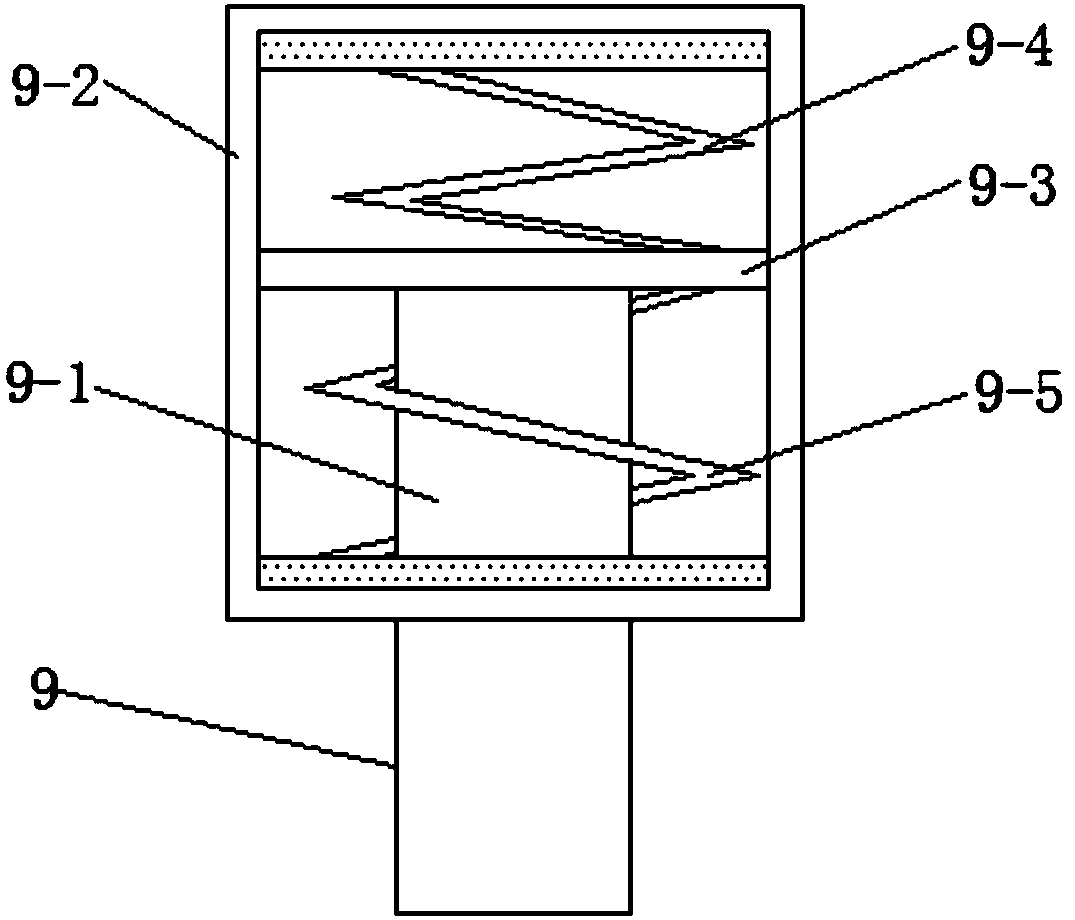

Building wall face grinding machine

InactiveCN107553235ASolve flyingReduce pollutionPlane surface grinding machinesGrinding/polishing safety devicesSanderArchitectural engineering

The invention discloses a building wall grinding machine, which comprises a support platform and a box body. The four corners of the bottom of the support platform are fixedly connected with support legs, and the bottom of the support legs are movably connected with rollers. The left side is fixedly connected with a vacuum cleaner, the bottom of the right side of the vacuum cleaner is connected with a hose, the bottom of the box is movably connected with a handle, and the top and bottom of the right side of the box are fixedly connected with a connecting rod. The building wall grinding machine is used through the cooperation of hoses, vacuum cleaners, motors, first pulleys, belts, dust suction pipes, springs, connecting rods, rotating shafts, grinding wheels, dust covers, second pulleys and cross bars, It solves the problem that the existing building wall grinder will cause flying dust during the grinding process, has the advantages of automatic dust absorption, can reduce the pollution of dust to the working environment, and avoids the health hazards caused by flying dust to users. Useful for users.

Owner:宏锋建工集团有限公司

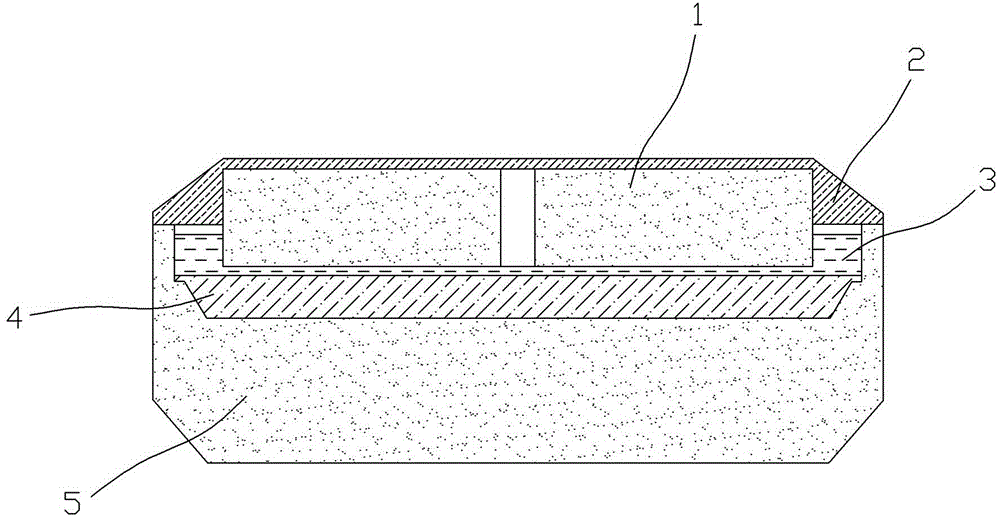

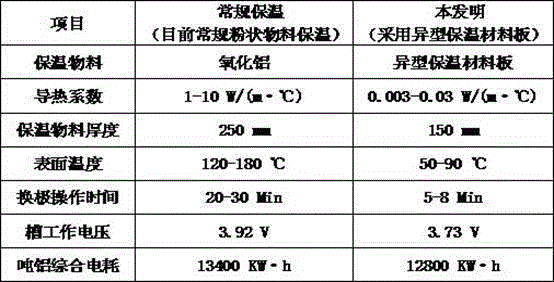

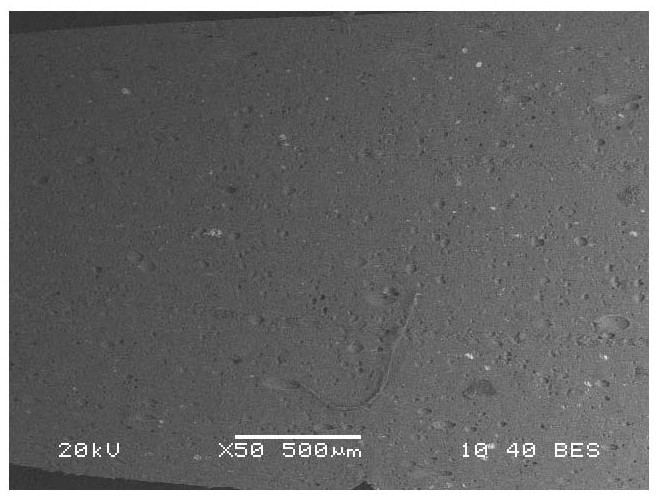

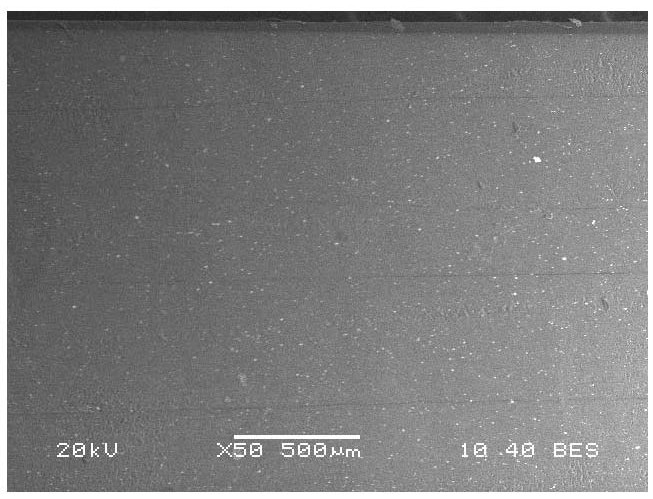

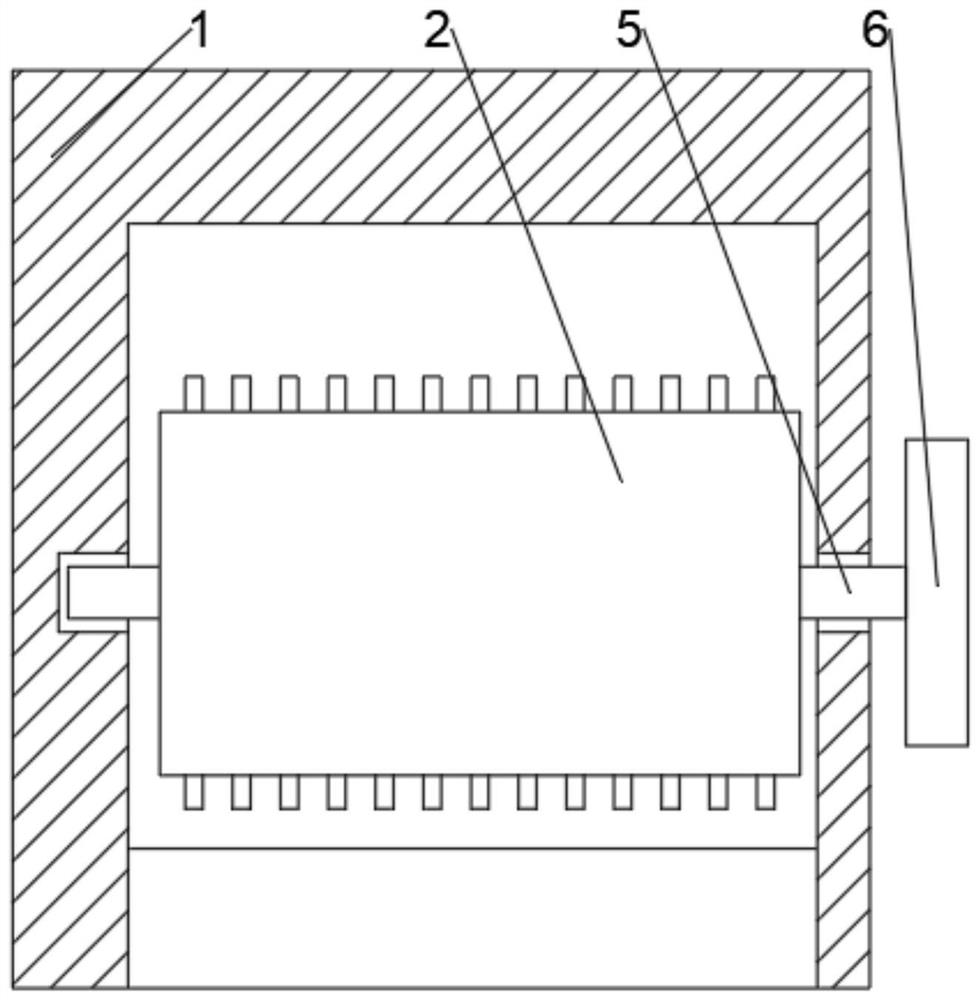

Aluminium electrolysis cell with insulation structure

The invention relates to an aluminium electrolysis cell with an insulation structure. The aluminium electrolysis cell is made of a special insulation board with characteristics of high temperature resistance, light weight, blocky shape and good insulation effect, is covered between the upper part of an anode carbon block and the anode carbon block and a trough edge board, and is used for replacing the traditional mode that the upper part of a trough is insulated by using aluminum oxide and electrolyte powder. The aluminium electrolysis cell has the advantages of being good in insulation effect, being capable of remarkably reducing heat loss of the electrolysis cell, reducing working voltage, reducing direct current electricity consumption per ton of aluminum and increasing economic benefit. Meanwhile, the aluminium electrolysis cell overcomes the remarkable problems of huge workload, influence on stable work of the electrolysis cell and serious environment pollution in the traditional insulation method.

Owner:ZHENGZHOU JINGWEI TECH & IND

Foam master batch for microcellular polystyrene foam material, and its preparation method

Owner:SHANGHAI INTCO INDUSTRIES CO LTD +1

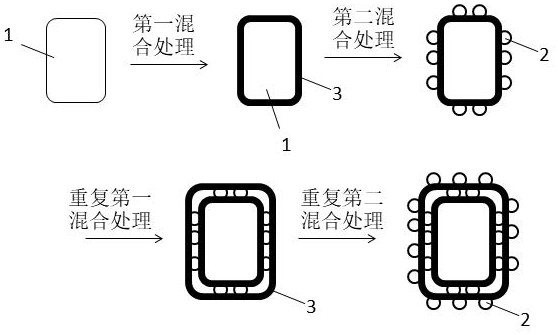

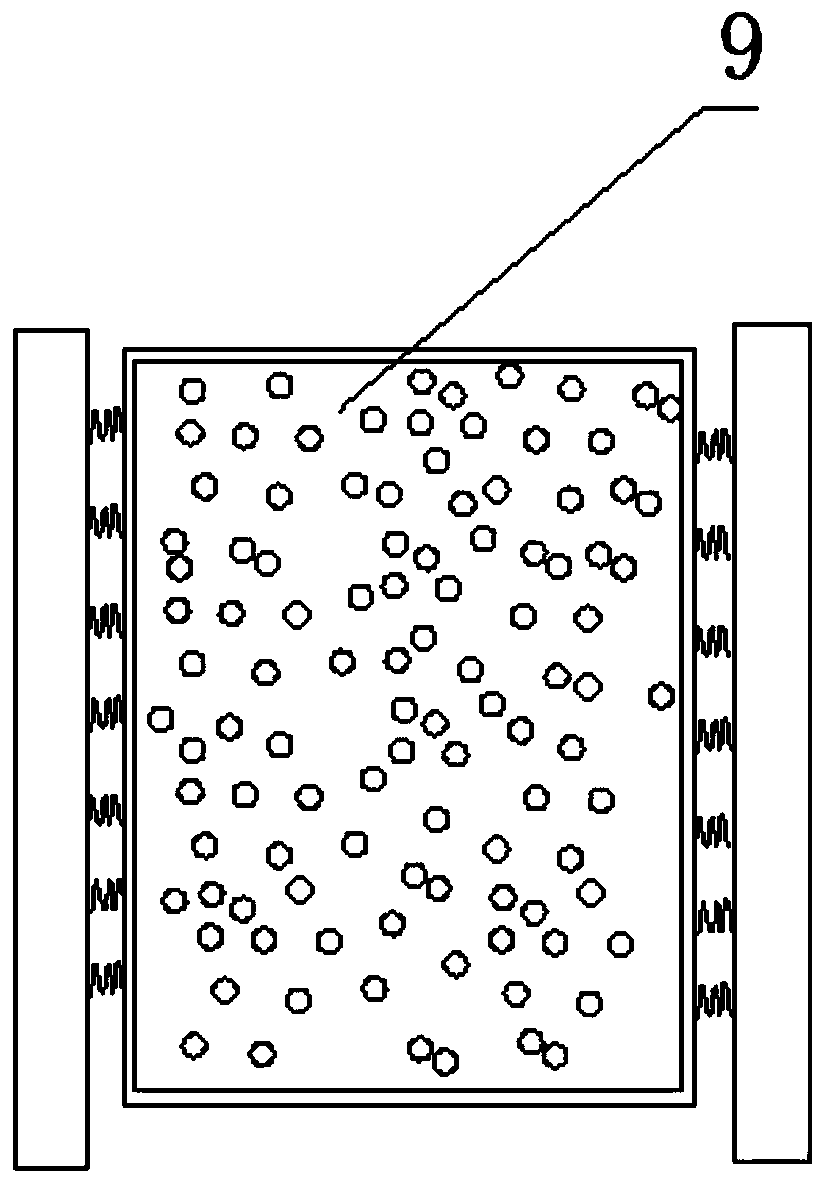

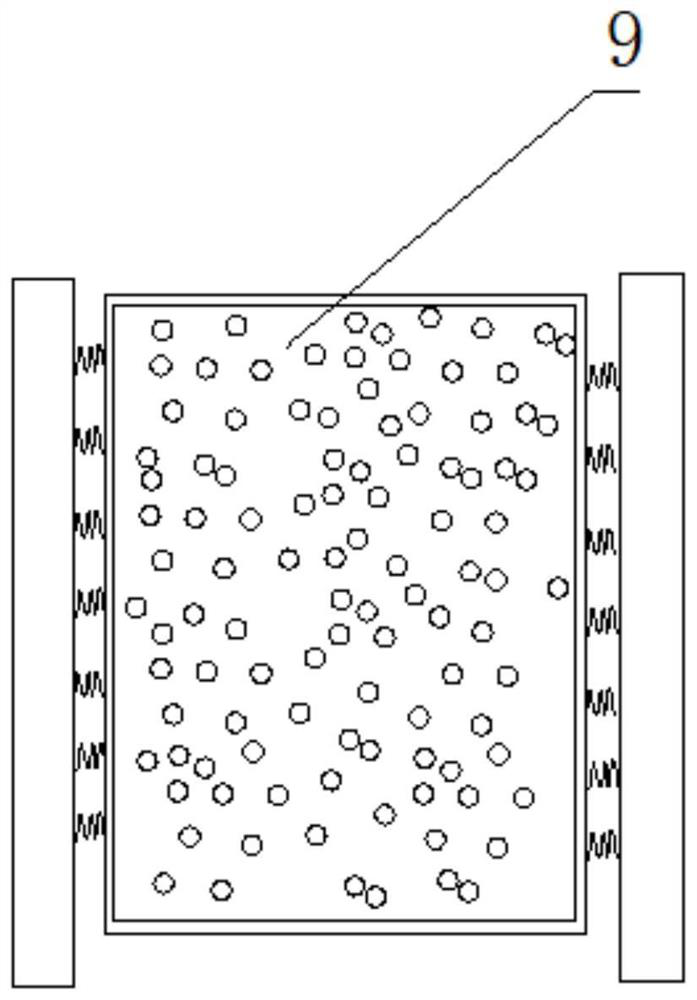

Antibacterial master batch containing high-dispersity inorganic antibacterial agent, and preparation method thereof

PendingCN113336979AImprove the problem of secondary water absorptionUneven distributionPolymer scienceAnti bacterial

The invention relates to an antibacterial master batch containing a high-dispersity inorganic antibacterial agent, and a preparation method thereof. The preparation method comprises the following steps: step A, carrying out first mixing treatment on matrix resin particles and a binder to make the binder spread on at least part of the surfaces of the mixed matrix resin particles; and step B, carrying out second mixing treatment on the matrix resin particles of which at least part of the surfaces are spread with the binder and an antibacterial material so as to adhere the antibacterial material to the surfaces of the matrix resin particles to form the antibacterial master batch.

Owner:无菌时代复合新材料(苏州)有限公司

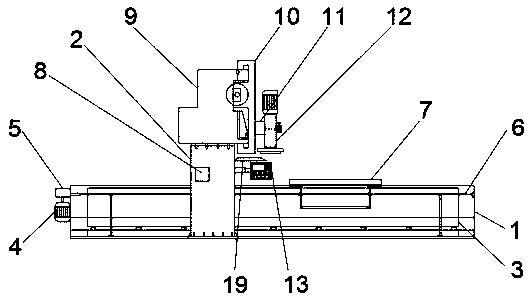

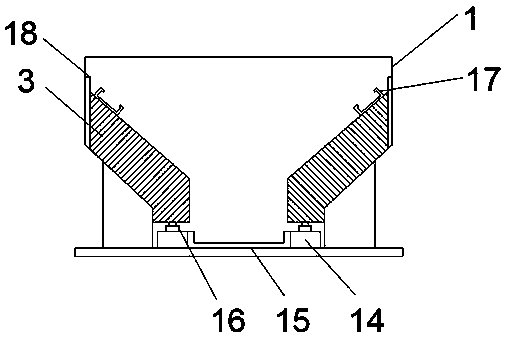

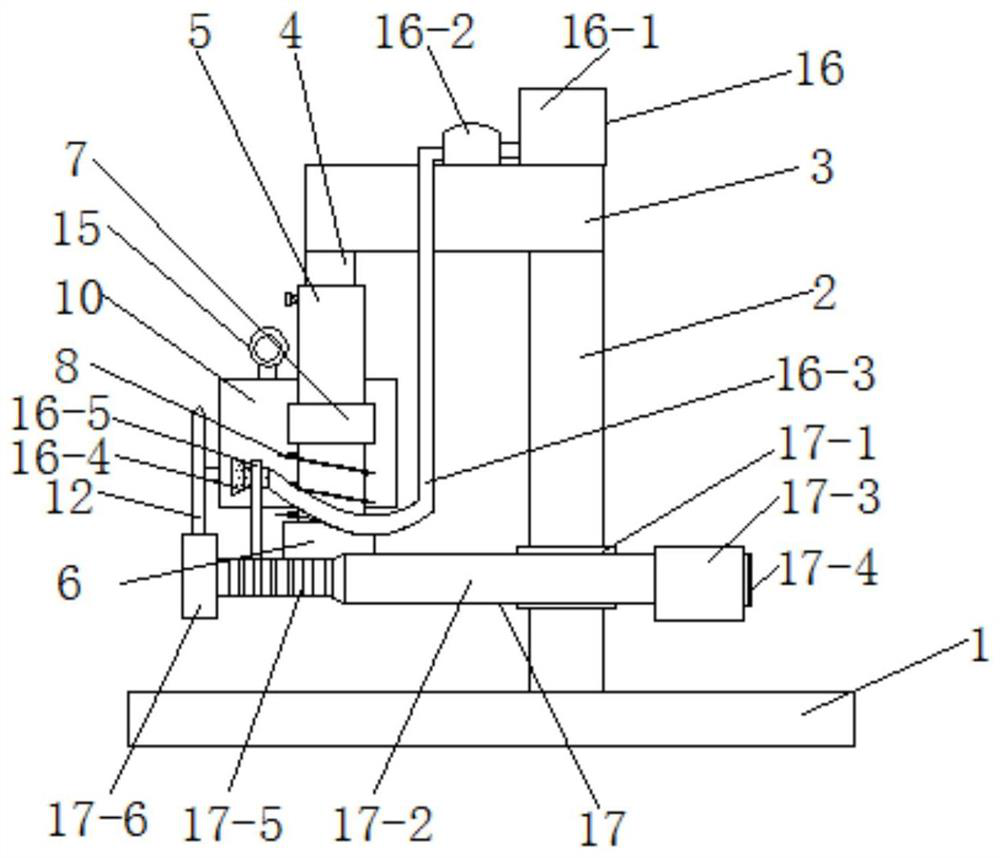

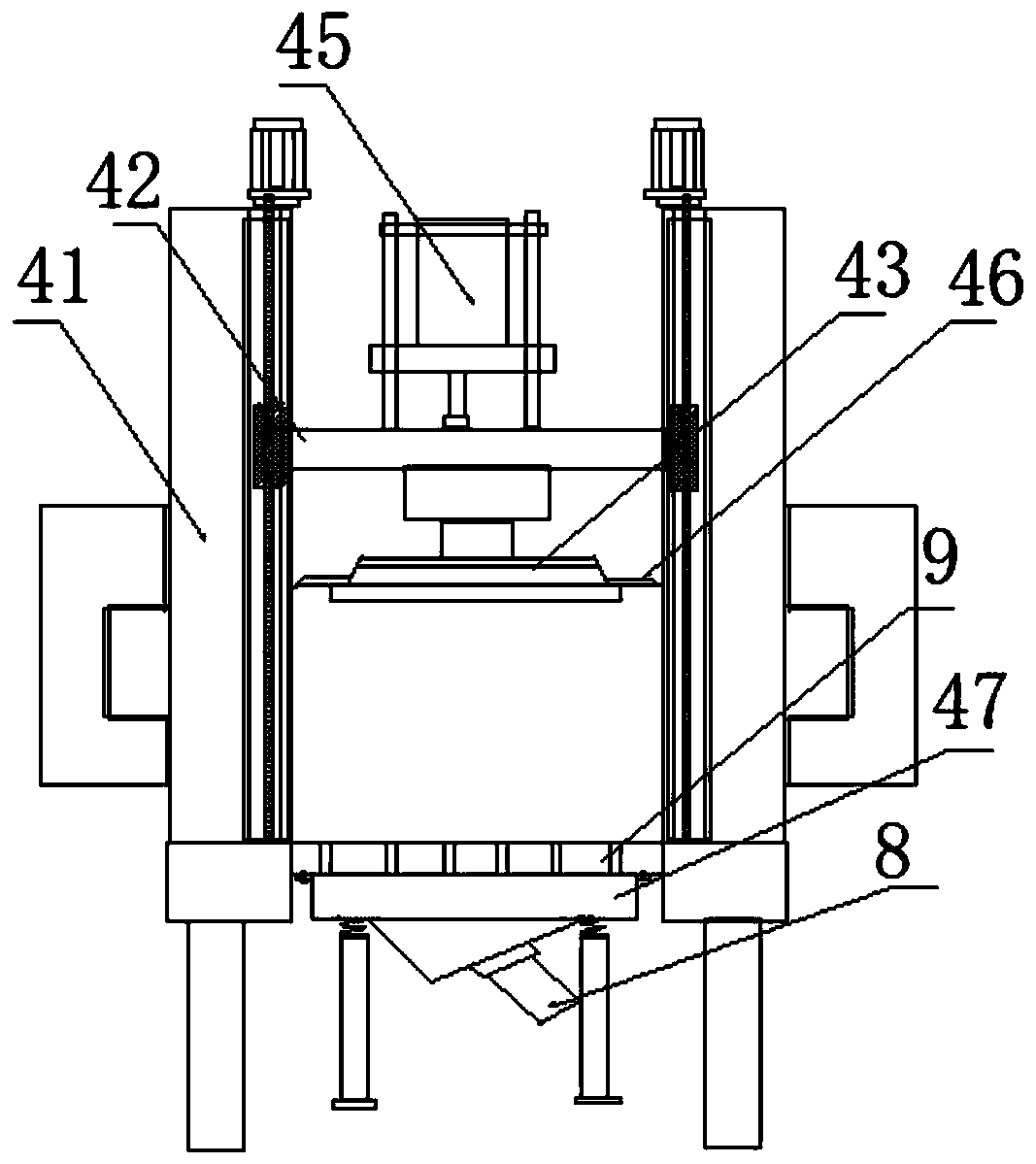

Numerical control gantry linear guide rail forming grinding machine

InactiveCN109968168ALow costAffect the service lifeGrinding carriagesGrinding drivesNumerical controlEngineering

The invention discloses a numerical control gantry linear guide rail forming grinding machine. Stand columns are arranged on the two sides of a machine body, a lifting base is arranged in the machinebody, a first motor and a steering gear box are arranged at one end of the machine body, the first motor is connected with the steering gear box, the steering gear box is movably connected with a workbench mechanism through a long screw rod, and the workbench mechanism is movably connected with the lifting base. A dust removal mechanism is arranged in each stand column, an electrical controller isarranged inside any stand column through a telescopic rod, the upper surfaces of the stand columns are connected with the lower surfaces of sliding base crossbeams, and two rams are movably arrangedat one end of each sliding base crossbeam. Sliding block mechanisms are arranged at the ends, away from the sliding base crossbeams, of the rams. Grinding head mechanisms are arranged at the ends, away from the rams, of the sliding block mechanisms. The numerical control gantry linear guide rail forming grinding machine is reasonable in structure, there is no need to replace a workbench especiallyaccording to the height of a workpiece, the cost is saved, for bevel grinding, grinding can be conducted by rotating grinding heads, and the machining efficiency is greatly improved.

Owner:南通瀚盛机床科技有限公司

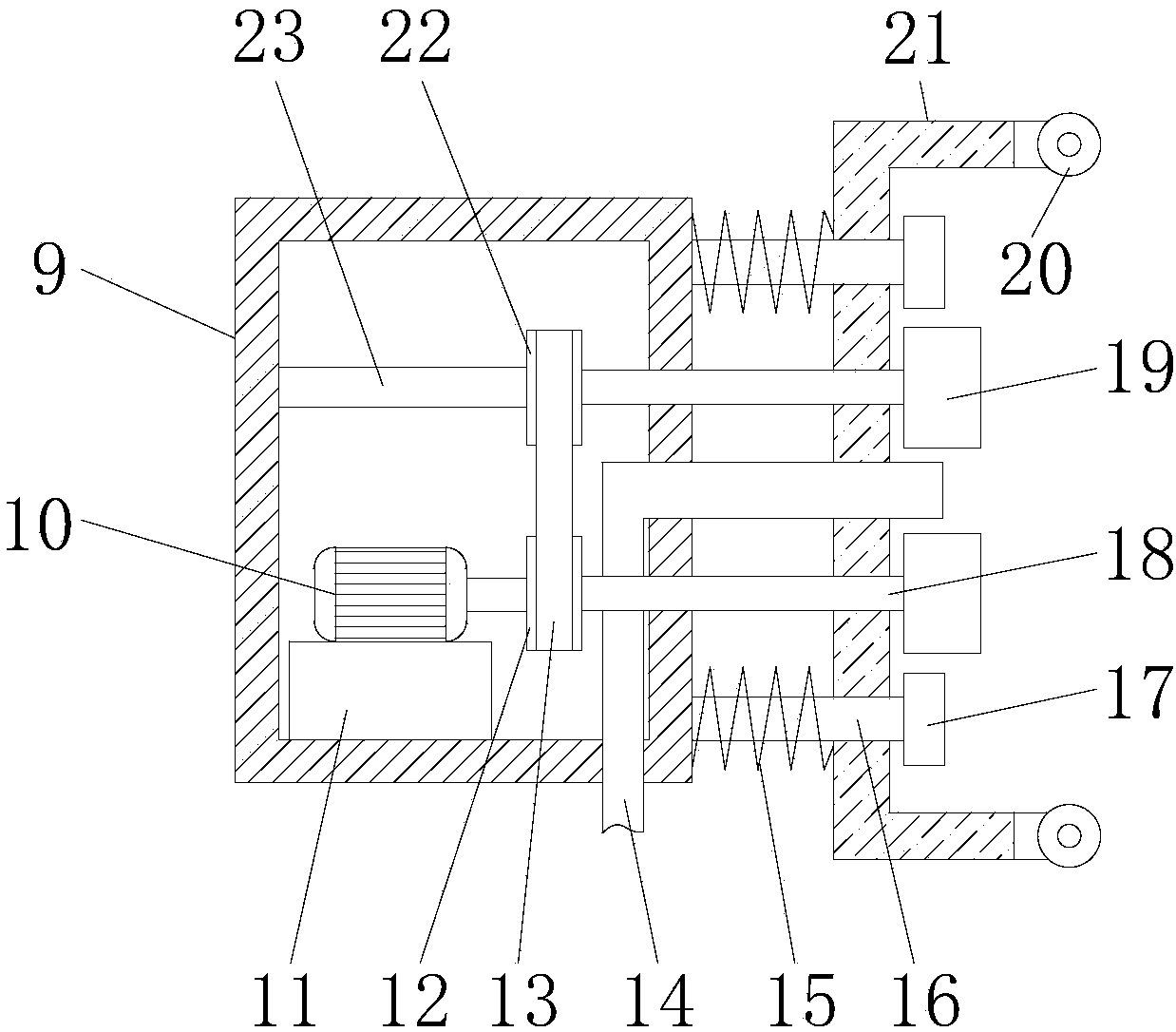

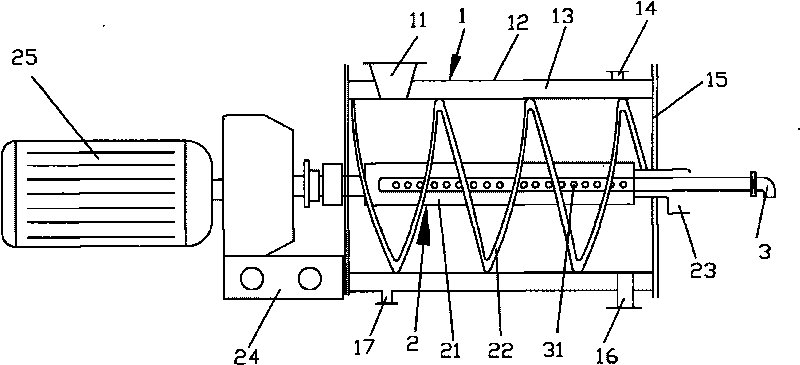

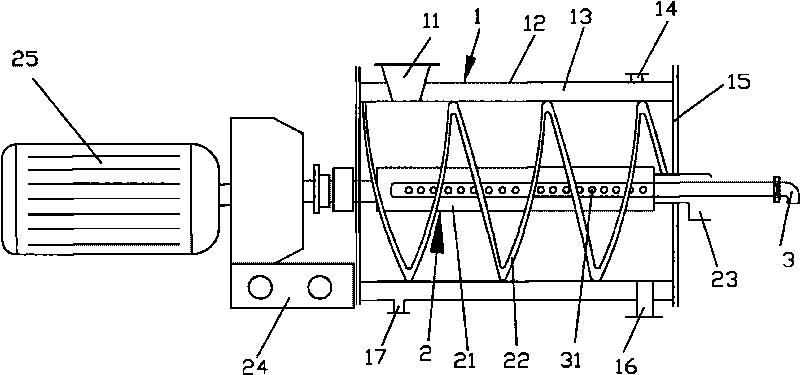

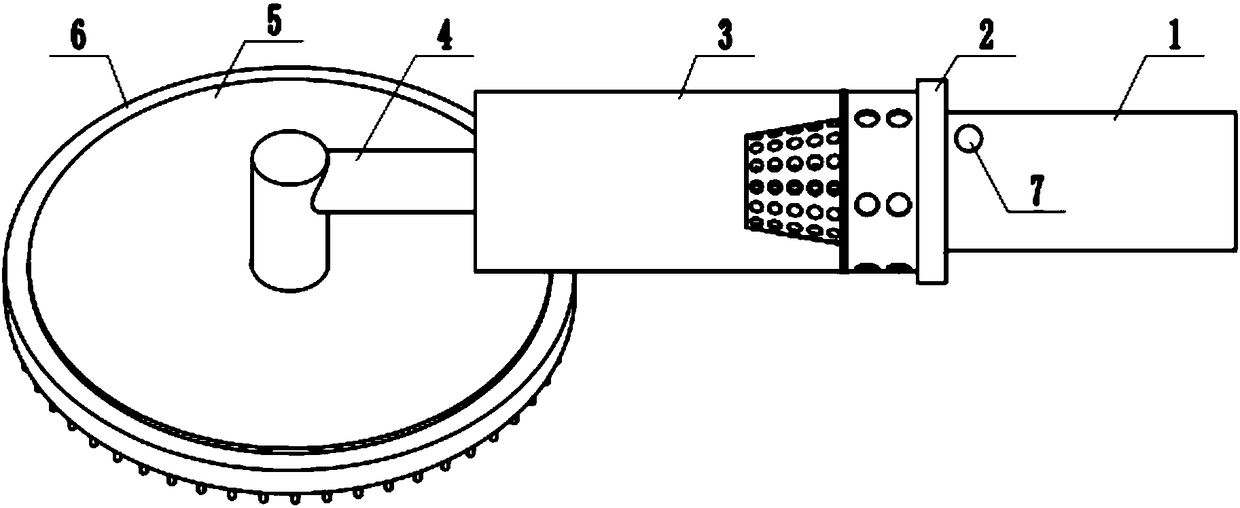

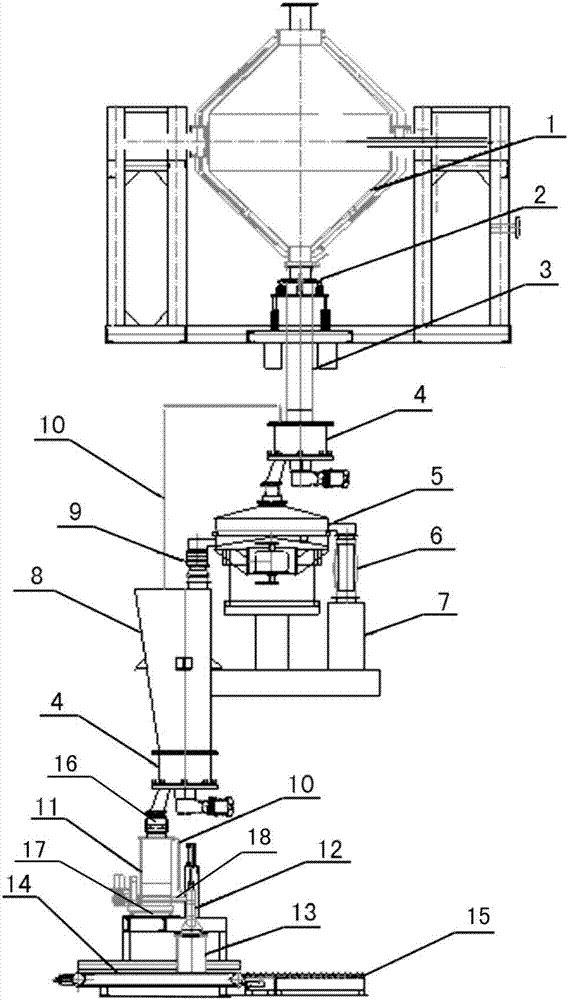

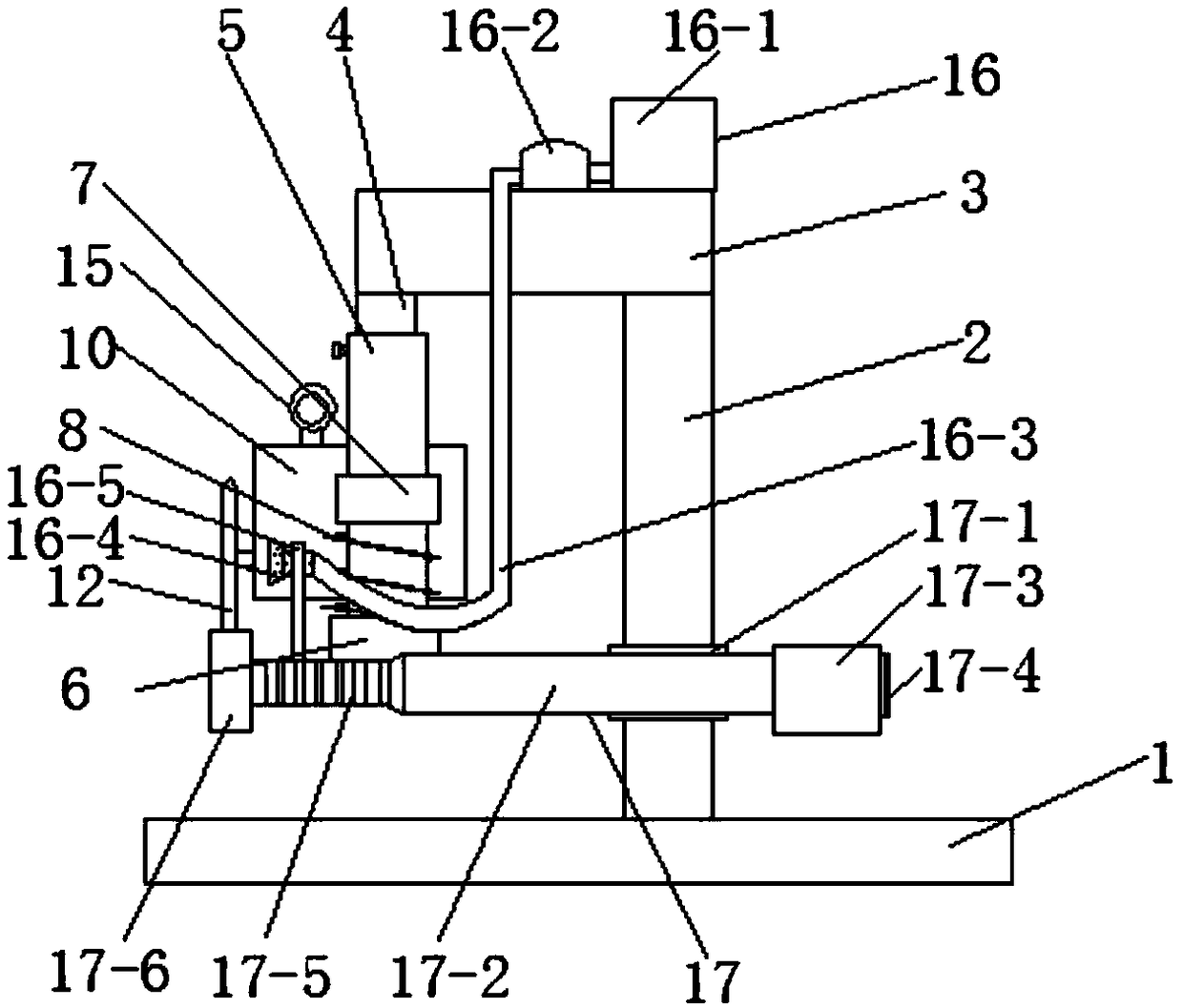

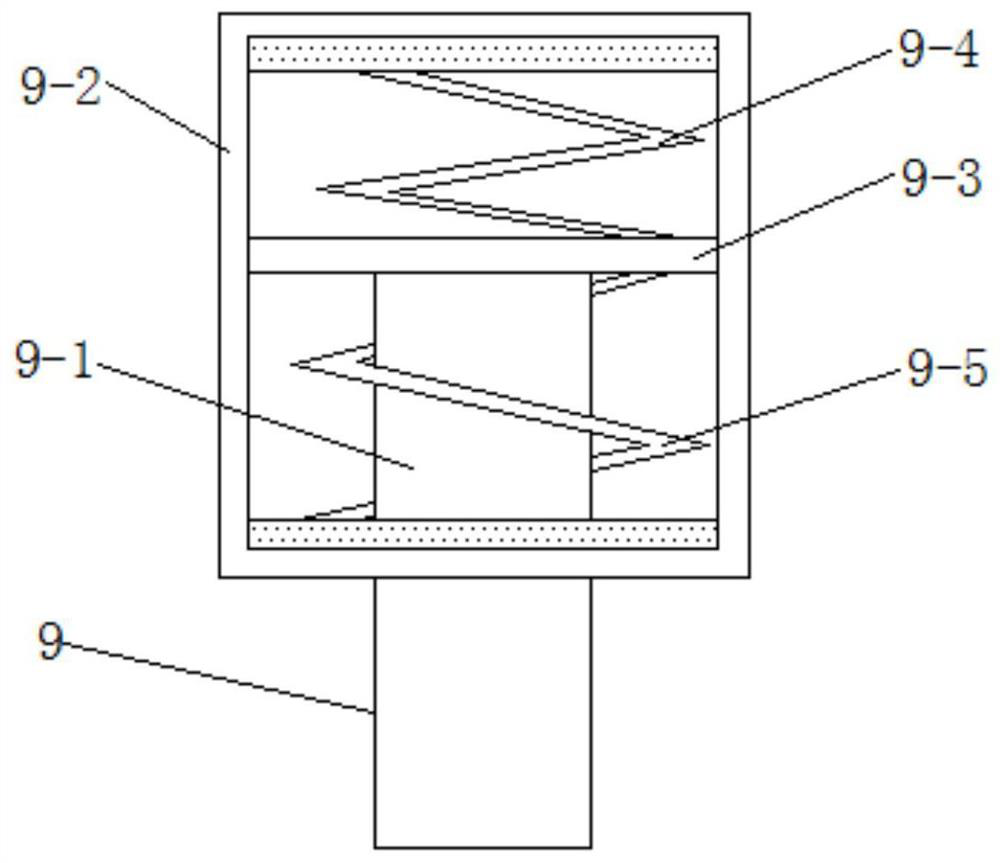

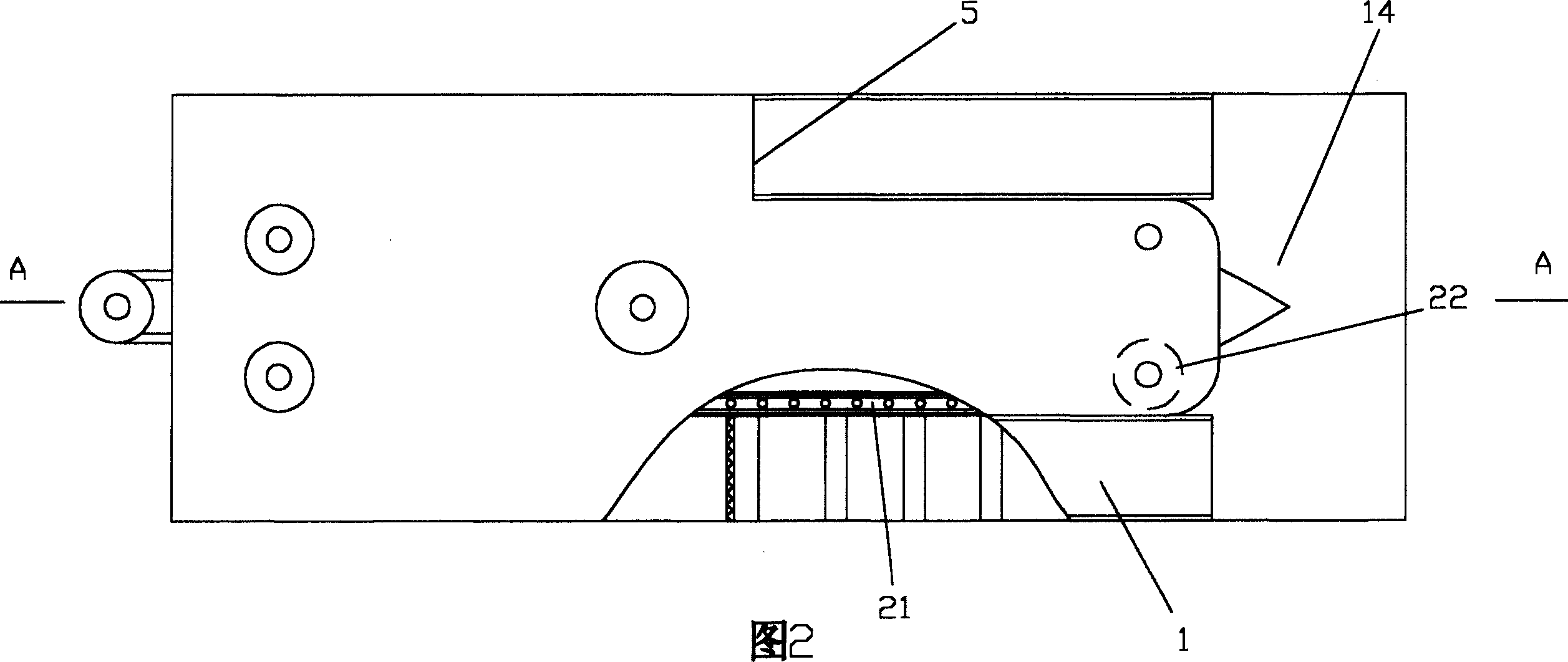

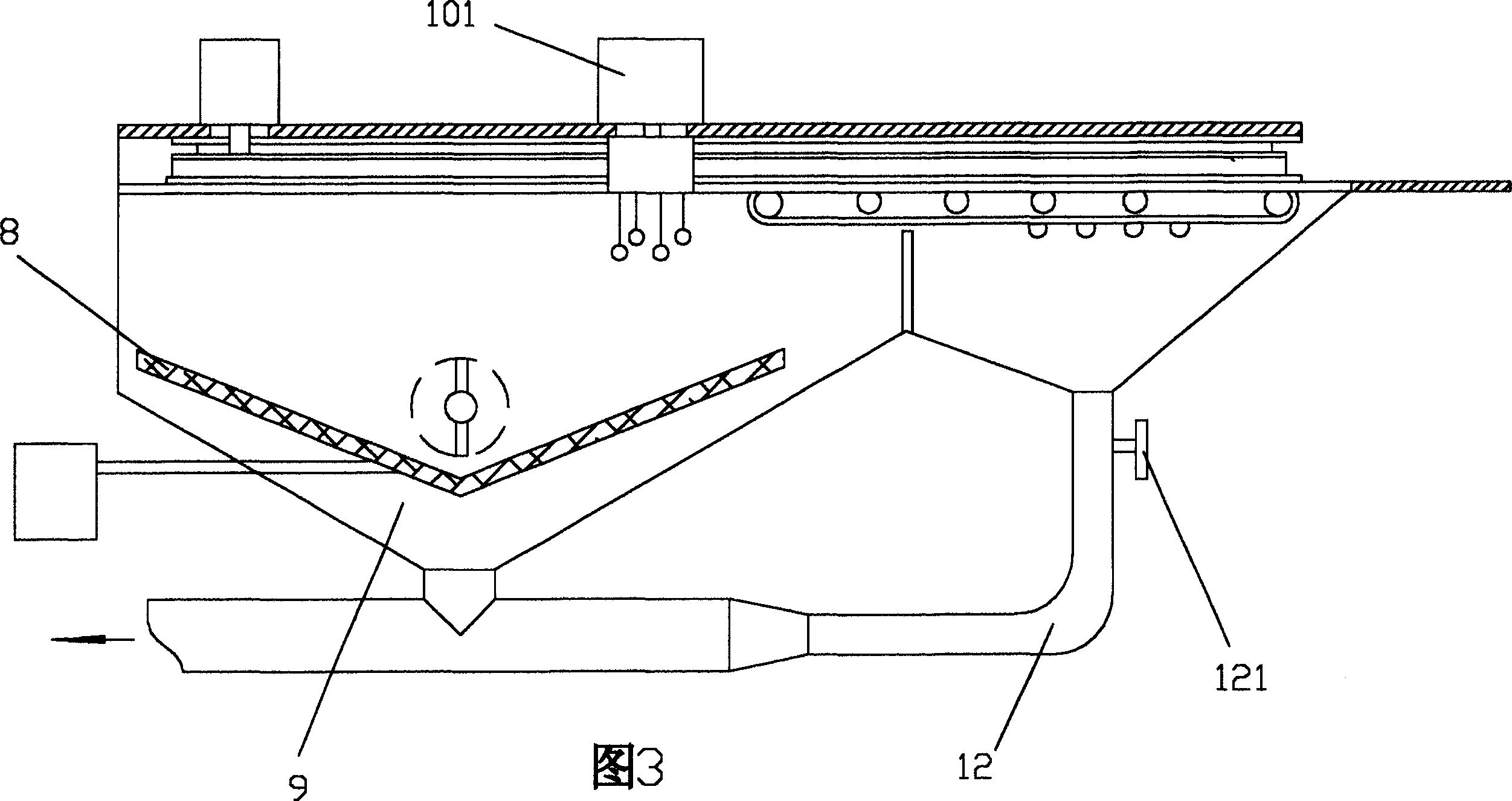

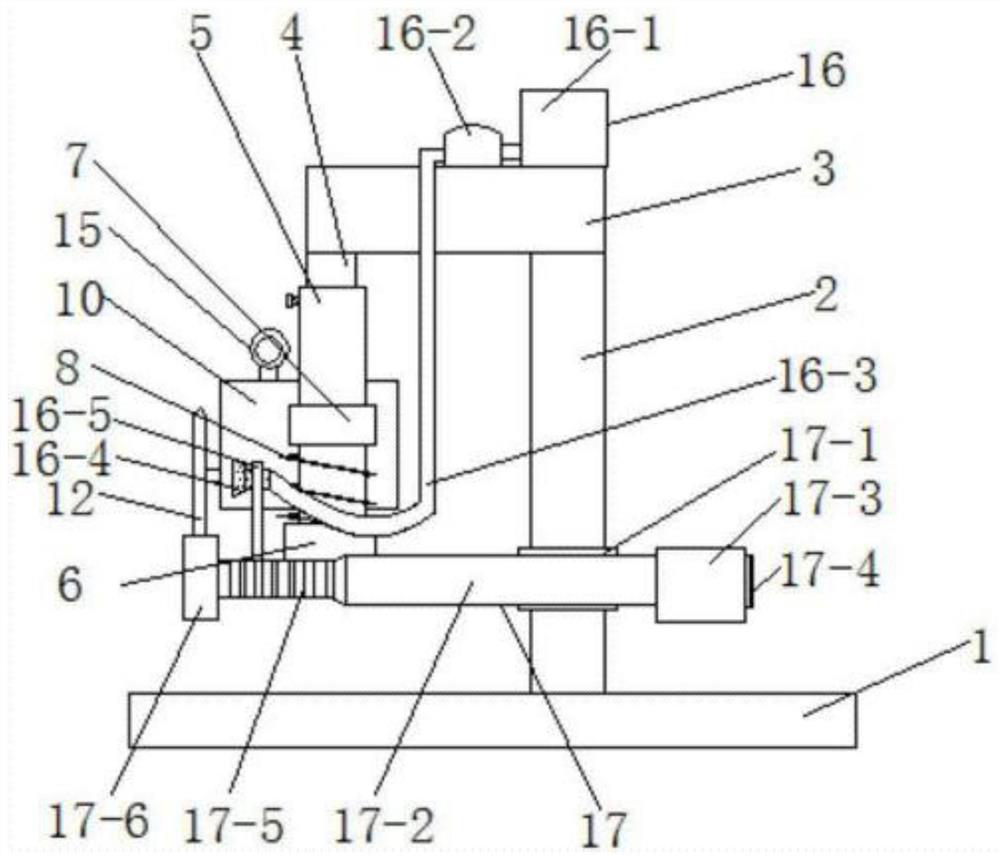

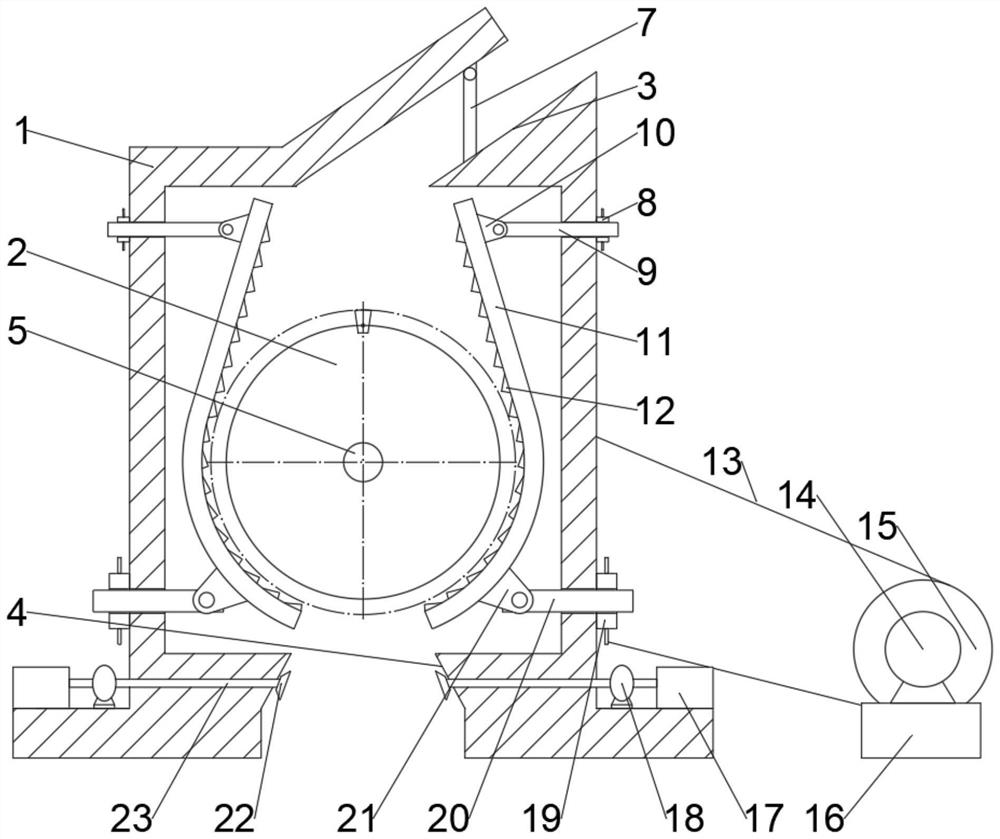

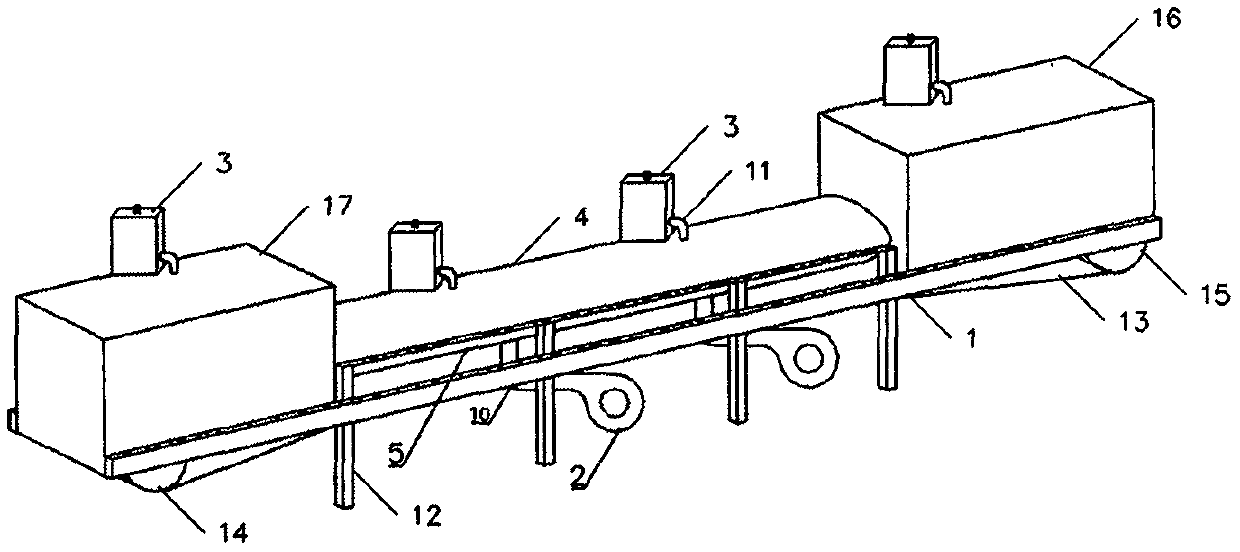

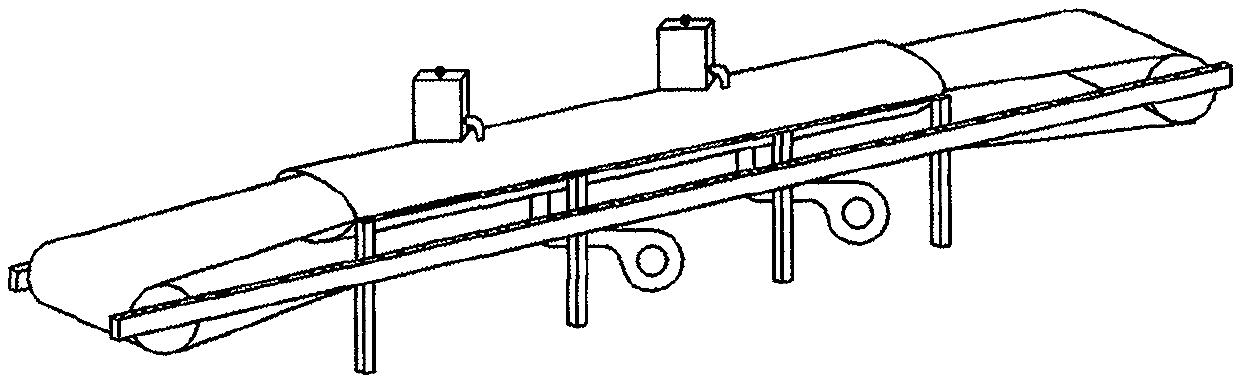

Production technology for bakelite powder and pre-thermoplastic machine thereof

The invention discloses production technology for bakelite powder and a pre-thermoplastic machine thereof. The production technology comprises the steps of: mixing component raw materials, crushing the mixture into powder, stirring the powder uniformly, and adding the powder into an open type plastic purificating set for rubber mixing. The production technology is characterized by adding the powder which is stirred uniformly into a sealed pre-thermoplastic machine for preheating first to make the powder change into slightly fused particles and blocks, and then conveying the particles and blocks to the open type plastic purificating set for rubber mixing. The production technology and the pre-thermoplastic machine thereof effectively solve the problem that a conventional process has flying dust during the rubber mixing of the open type plastic purificating set further to seriously pollute the environment for a long time; and at the same time, the production technology makes a pre-thermoplastic working procedure of a powder raw material which is originally performed in a high-power open type plastic purificating set separated and performed in the pre-thermoplastic machine with a low-power sealing state in advance, which not only greatly reduces the production load of the high-power open type plastic purificating set, but also improves heat utilization rate and thermal efficiency, reduces production energy consumption, and improves production efficiency.

Owner:湖州美卡科技有限公司

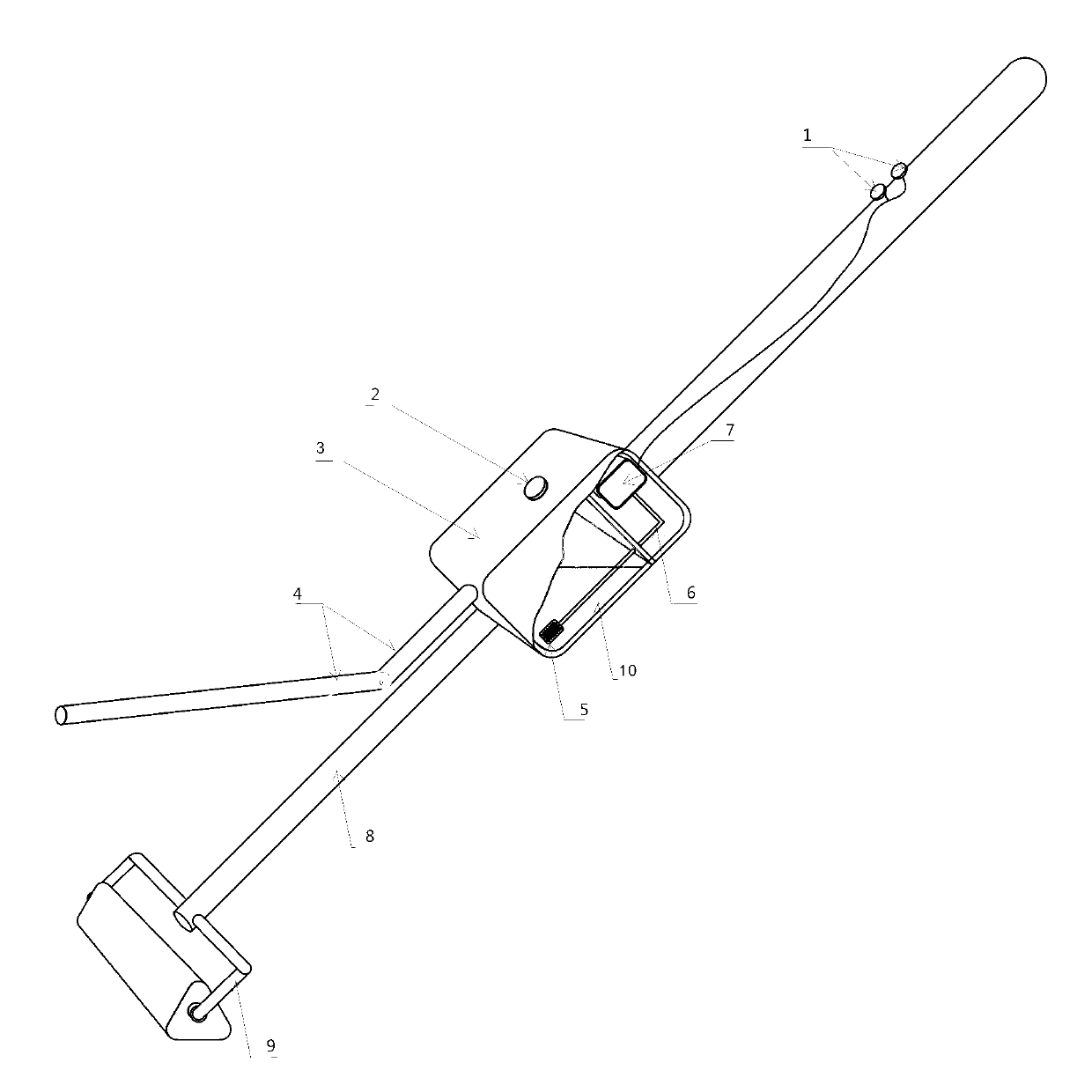

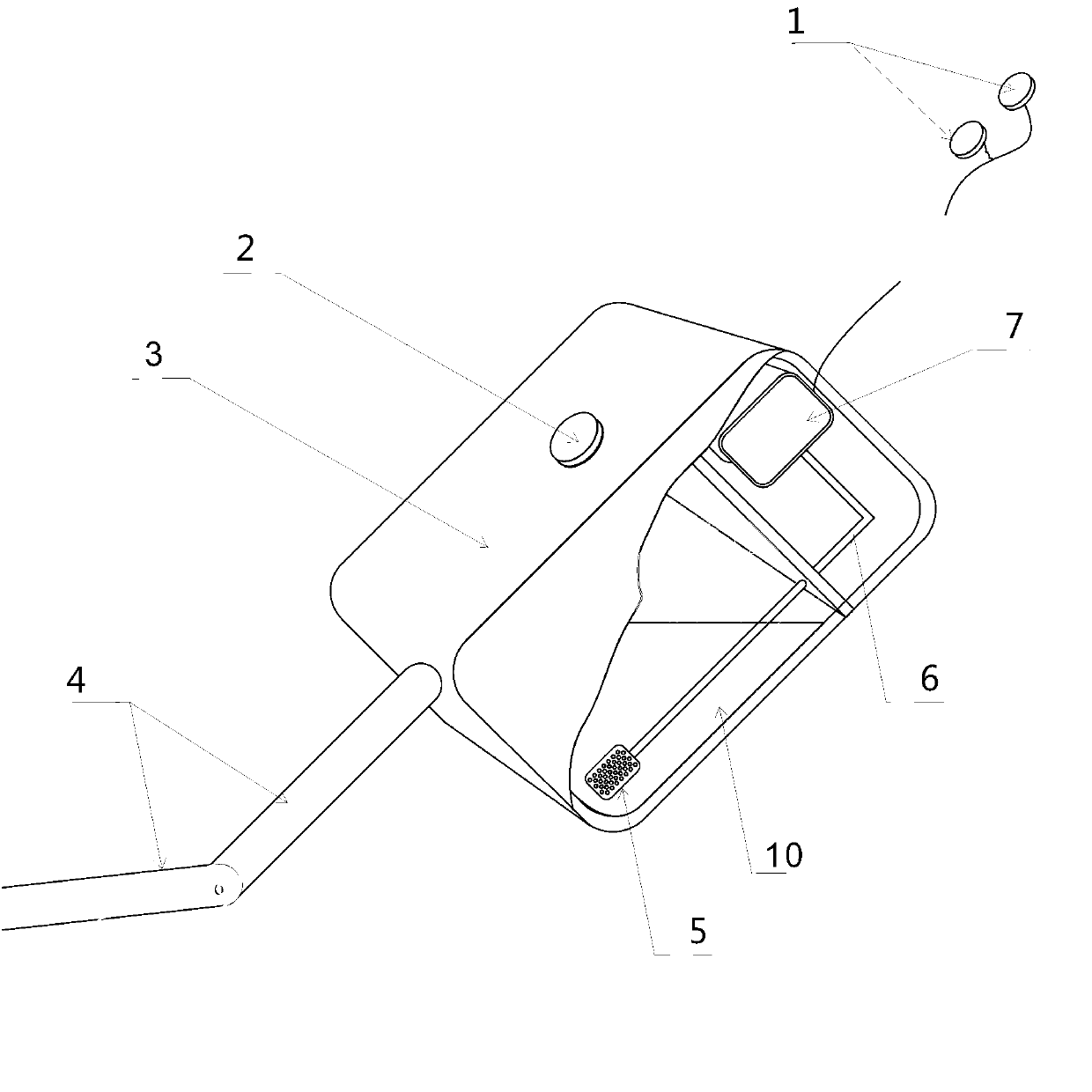

Handheld dust sweeping device

The invention discloses a handheld dust sweeping device. The handheld dust sweeping device comprises a handle and a dust collector connected with the handle and is characterized in that a battery is arranged in the handle, a switch is arranged outside the handle, the battery is electrically connected with the dust collector and the switch, the front end of the dust collector is provided with a dust sweeping head, the front side of the dust sweeping head is provided with soft sweeping bristles and dust collection holes, the dust sweeping head is communicated with the dust collector through a connecting rod, and the back of the dust sweeping head is provided with a metal sheet connected with the connecting rod. The handheld dust sweeping device has the advantages that the device can replacea mop and a wipe, dust can be collected during the sweeping of dust on the surface of a vehicle body, the dust flying problem during sweeping is solved, the situation that dust falls to the surface ofthe vehicle body again is avoided, sweeping efficiency is increased, sweeping time is saved, sanitation during sweeping is guaranteed, clothes can be prevented from being dirtied by the dust, fresh air during sweeping can be achieved, damage, caused by the flying dust, to human bodies is avoided, and user health is guaranteed.

Owner:陈旭澎

Closed continuous aftertreatment system for metal powder

PendingCN107321996ARealize airtightnessEffective connectionSolid materialPackaging TankProcess engineering

The invention discloses a closed continuous aftertreatment system for metal powder. The system comprises a metal powder drying device, a screening device, a fine metal powder collecting tank, a weight loss scale and a fine powder packaging tank. The screening device is arranged below the metal powder drying device and is connected with a discharging port of the metal powder drying device in a sealed mode through a first discharging pipe, and the fine metal powder collecting tank is arranged below a fine powder discharging port of the screening device and is connected with the fine powder discharging port of the screening device in a sealed mode through a second discharging pipe; and the weight loss scale is arranged below the fine metal powder collecting tank and is connected with a discharging port of the fine metal powder collecting tank in a sealed mode through a third discharging pipe, and the fine powder packaging tank is arranged below the weight loss scale and is connected with a feeding port of the weight loss scale in a sealed mode through a fourth discharging pipe. According to the closed continuous aftertreatment system, the gravity feeding mode is adopted, and the problems that as for a conventional powder transferring mode, the loss quantity is a large, and adhering is prone to occurring to the pipe wall are solved; and additionally, through closing and automation of different working procedures, the problem of powder flying is solved, the production efficiency is improved, and the powder quality is ensured.

Owner:ADVANCED TECH BAZHOU SPECIAL POWDER CO LTD +1

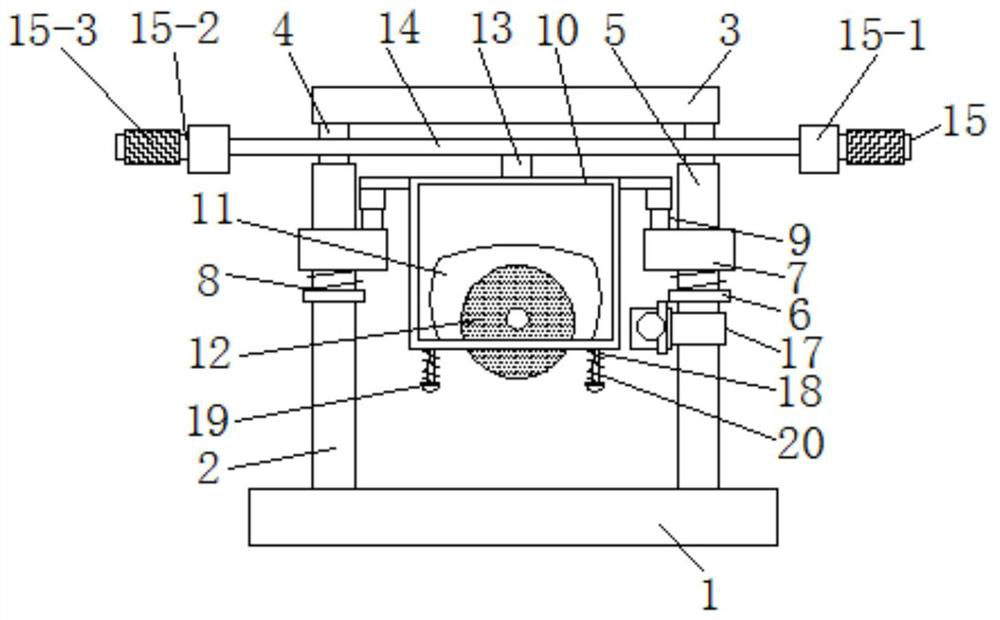

Cutting device for engineering construction

ActiveCN108481583AReduce intensityAvoid harmFeeding apparatusWorking accessoriesArchitectural engineeringUltimate tensile strength

The invention provides a cutting device for engineering construction, and relates to the field of construction instruments. The cutting device for engineering construction comprises a base, a top plate is welded to the top of the base through two supporting rods, inner rods are welded to the side, away from the supporting rods, of the bottom of the top plate, the bottoms of the inner rods are sleeved with outer rods, and a cutting blade is arranged between the two outer rods. According to the cutting device for engineering construction, a worker controls lifting of the cutting blade through agrab mechanism, and a damping spring is arranged around the outer surface of a holding rod. Vibration produced during working of the cutting device is transferred to an outer barrel through a motor box and a transverse rod, the damping spring carried out buffer and energy consumption on the vibration, the strength of the vibration transferred to the holding rod is reduced, meanwhile, the outer surface of the holding rod is sleeved with a rubber sleeve, the strength of cutting vibration transferred to the hands of the worker is greatly reduced, harm of cutting vibration to the body of the worker is avoided, the work fatigue feeling can be reduced, and the working efficiency can be improved.

Owner:WENZHOU ZHENZHONG FOUND CONSTR MASCH TECH CO LTD

A cutting device for engineering construction

ActiveCN108481583BReduce intensityAvoid harmWorking accessoriesFeeding apparatusHand partsStructural engineering

Owner:WENZHOU ZHENZHONG FOUND CONSTR MASCH TECH CO LTD

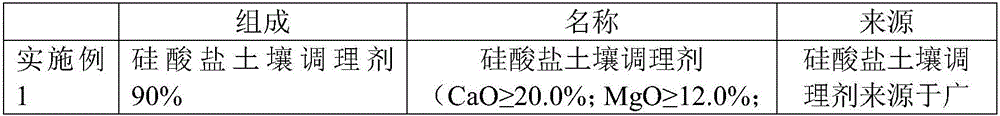

Organic silicon soil conditioner and preparation method thereof

ActiveCN106635044AGood soil permeabilitySolve poor penetrationAgriculture tools and machinesOrganic fertilisersWater contentCarbon black

The invention discloses an organic silicon soil conditioner which comprises the following components by weight percent: 90-95% of silicate soil conditioner, 0.5-2.5% of white carbon black, 0.1-0.3% of organic silicon and 4.0-7.5% of water, wherein the sum of the weight percent of the components is 100%. The water content of the soil conditioner is about 4-7%, so that the problems of hydration hardening and flying dust can be effectively avoided. The problem of poor permeation of the present silicate oxide can be solved, so that the capacity of nutrition absorption of the crops can be increased and the lasting effect of the soil conditioner can be enhanced. The invention also discloses a preparation method for the organic silicon soil conditioner. The preparation method has the advantages of few steps, simple process and safe operation.

Owner:广东万山环境科技有限公司

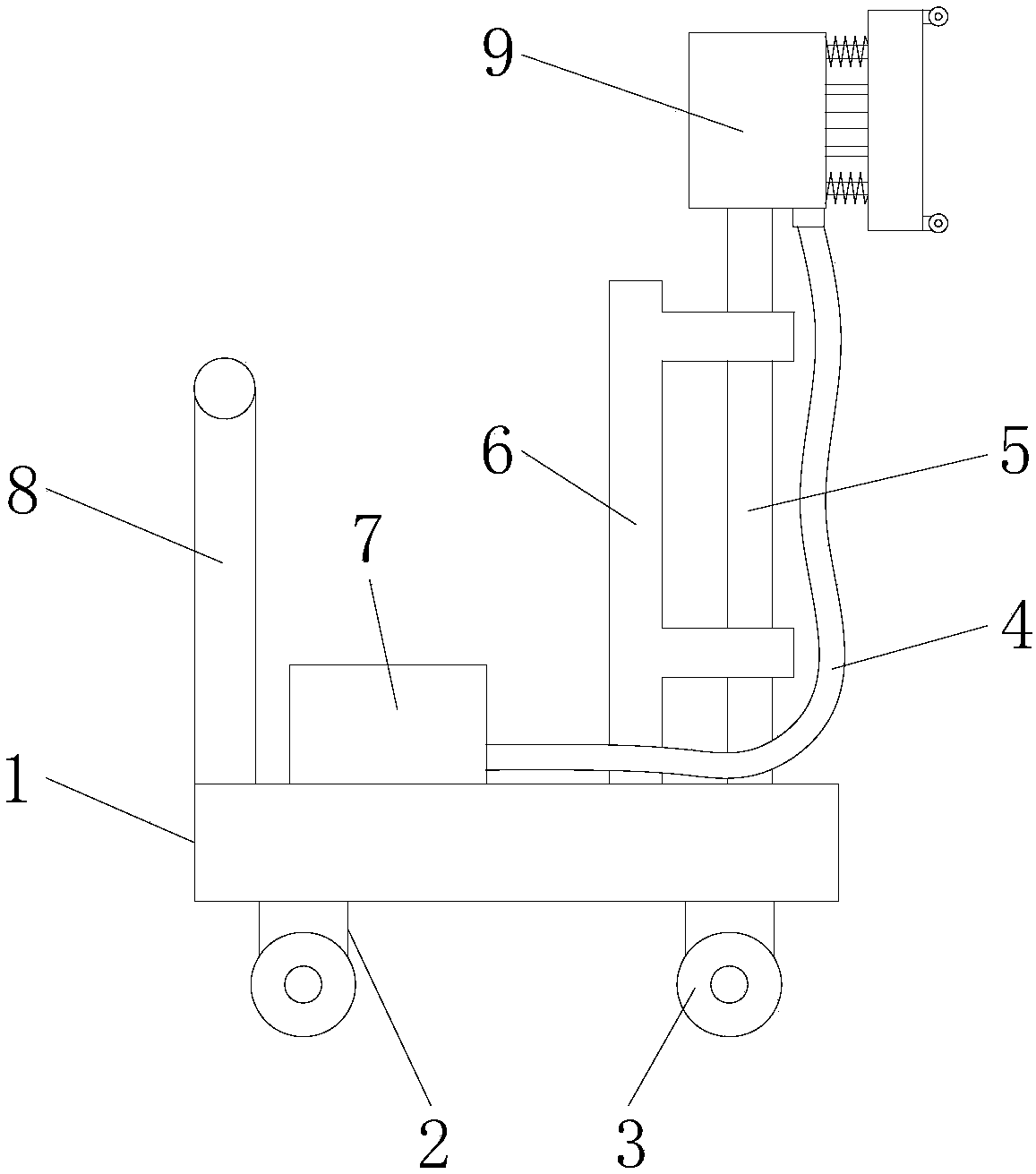

Lift car type lifting cargo lift

InactiveCN109437000ASolve the problem of dust flyingSolve the problem of foreign objects fallingElevatorsMine liftsReducerEngineering

The invention discloses a lift car type lifting cargo lift which comprises a supporting frame, a dragging mechanism, a loading mechanism and a damping mechanism. The dragging mechanism is installed atthe middle position of the upper portion the supporting frame. The dragging mechanism comprises a dragging motor, a speed reducer and a dragging wheel. The dragging wheel is connected with the loading mechanism through a steel wire rope. Guide rail frames are installed at the positions, below the dragging mechanism, on the supporting frame, and the number of the guide rail frames is four. The carrying mechanism comprises an installation frame, a sliding frame, a double-shaft motor and a loading box. The damping mechanism is installed at the middle position of the lower portion of the supporting frame. The installation position of the damping mechanism corresponds to the installation position of the loading mechanism. The damping mechanism comprises a sliding pressing plate and a spring damper. By means of the lifting car type lifting cargo lift, the loading mechanism is arranged, and the problems that in the prior art, the labor intensity is high, and the work efficiency is low are solved.

Owner:河南省通用矿山起重机械有限公司

Preparation method of clindamycin phosphate injection

ActiveCN102144966BImprove stabilityGood curative effectAntibacterial agentsOrganic active ingredientsMedicineClindamycin Phosphate

The invention discloses a chemical injection, and particularly relates to a preparation method of a clindamycin phosphate injection. The clindamycin phosphate injection is prepared from the following raw materials in grams: clindamycin phosphate 300-400 g and sodium hydroxide 24.3-25.5 g. The preparation method comprises the following steps: dissolving 24.3-25.5g of sodium hydroxide in 1500-1900 g of water for injection, dissolving 300-400 g of clindamycin phosphate in the sodium hydroxide solution, stirring uniformly, adding water for injection to a constant volume of 2,000 mL, performing coarse filtering with a 0.65 mu m microporous filter membrane, performing fine filtering with a 0.22 mu m microporous filter membrane for sterilizing, and filling to obtain the clindamycin phosphate injection. The preparation method provided by the invention has the characteristics of applicability to mass production, high product yield, stable drug quality, and good therapeutic effect of drugs.

Owner:原研药港生物制药(沈阳)股份有限公司

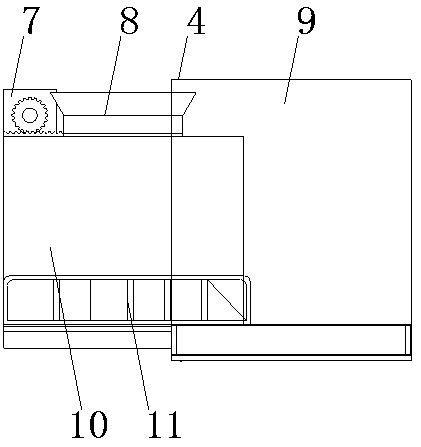

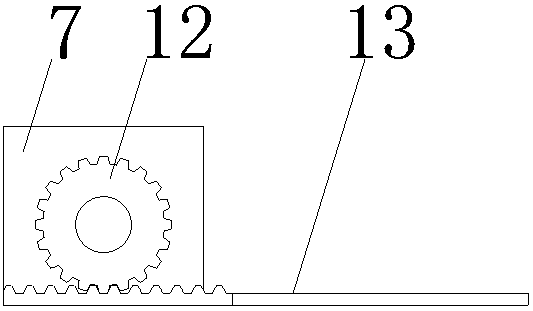

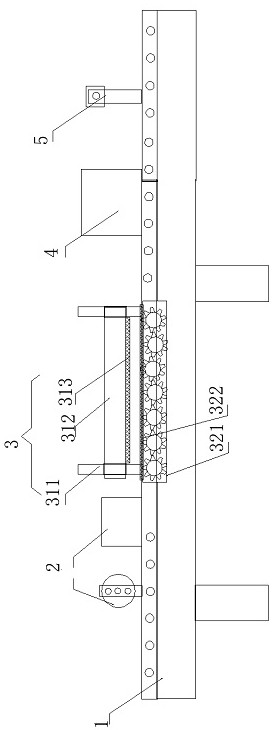

Ecological board sanding device

InactiveCN108994700ASolve flyingImprove work efficiencyBelt grinding machinesGrinding feedersEngineeringMechanical engineering

The invention provides an ecological board sanding device. The device includes a first roller conveying device; a first abrasive belt is arranged on the first roller conveying device; the end of the first abrasive belt is provided with a first baffle plate device; the conveying end of the first roller conveying device is provided with a second abrasive belt; a second roller conveying device is arranged on the second abrasive belt; the end of the second abrasive belt is provided with a second baffle plate device; the conveying end of the second abrasive belt is provided with a third roller conveying device; the third roller conveying device is provided with round brushes; dedusting covers are arranged under the first roller conveying device, the second roller conveying device and the thirdroller conveying device; the dedusting covers are connected to a dust collector through a dust-absorbing pipe; the outlet of the dust collector is connected to a wood powder storage bin; and a fan isarranged in the dust-absorbing pipe. The device can simultaneously perform sanding operation on two faces of ecological boards, and therefore, working efficiency can be effectively enhanced, the problem of sawdust flying can be effectively solved, and wood powder can be collected to perform secondary utilization.

Owner:湖北三峡快捷居集成房屋有限公司

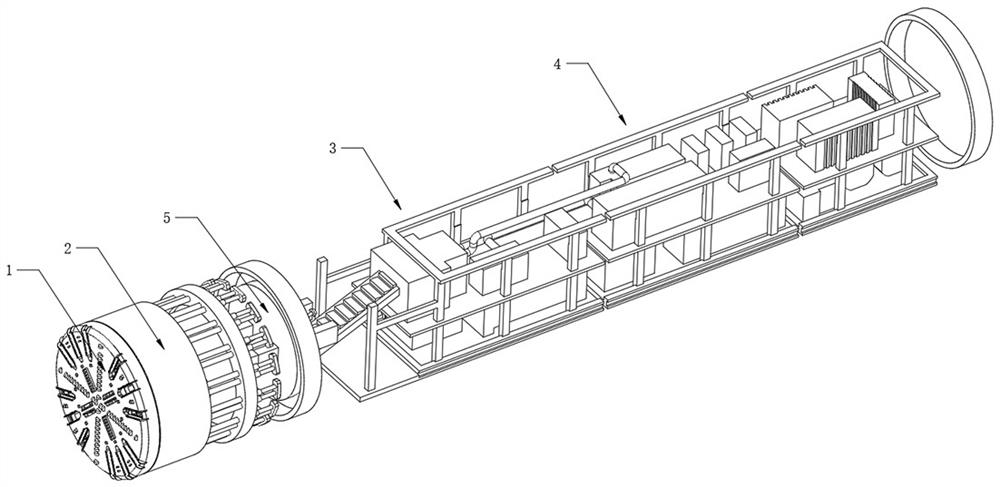

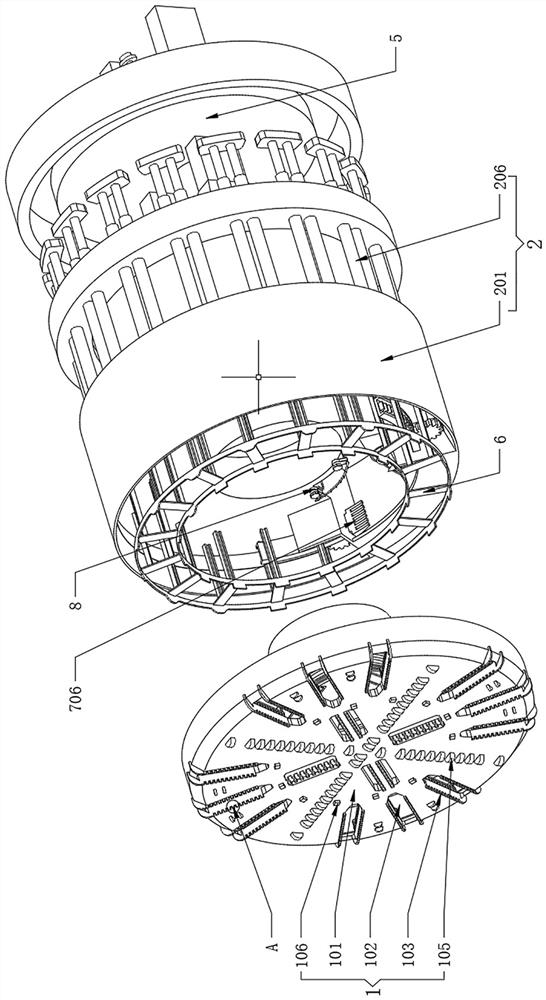

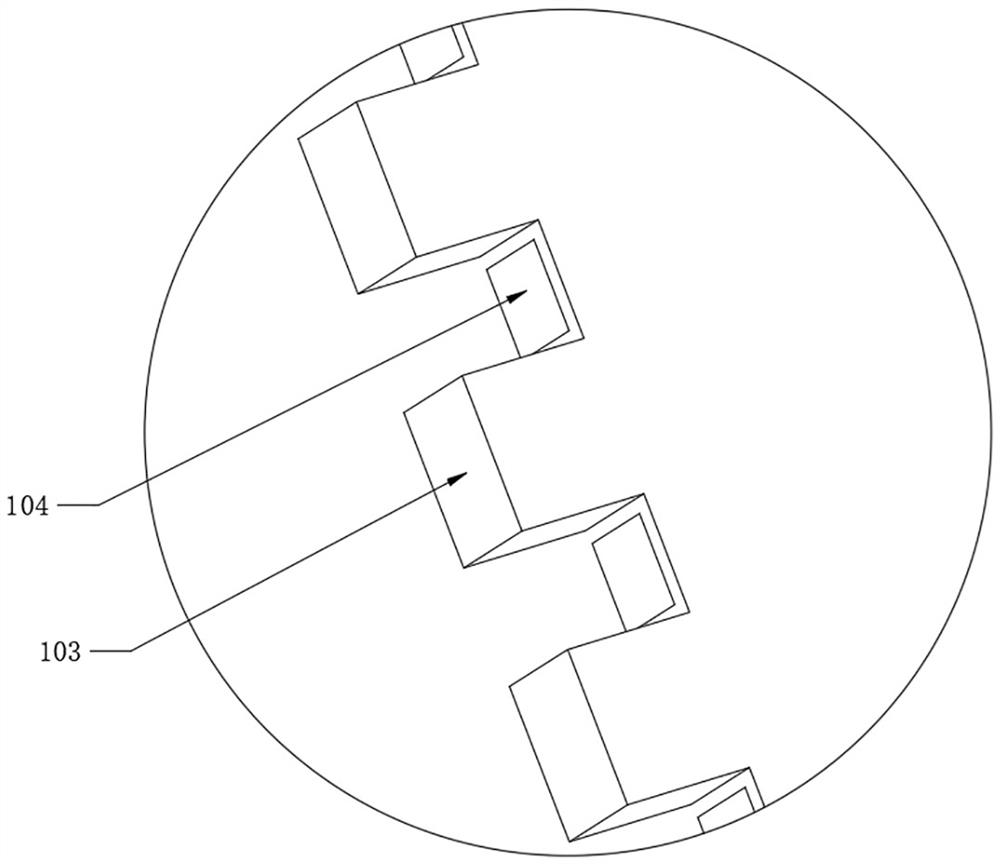

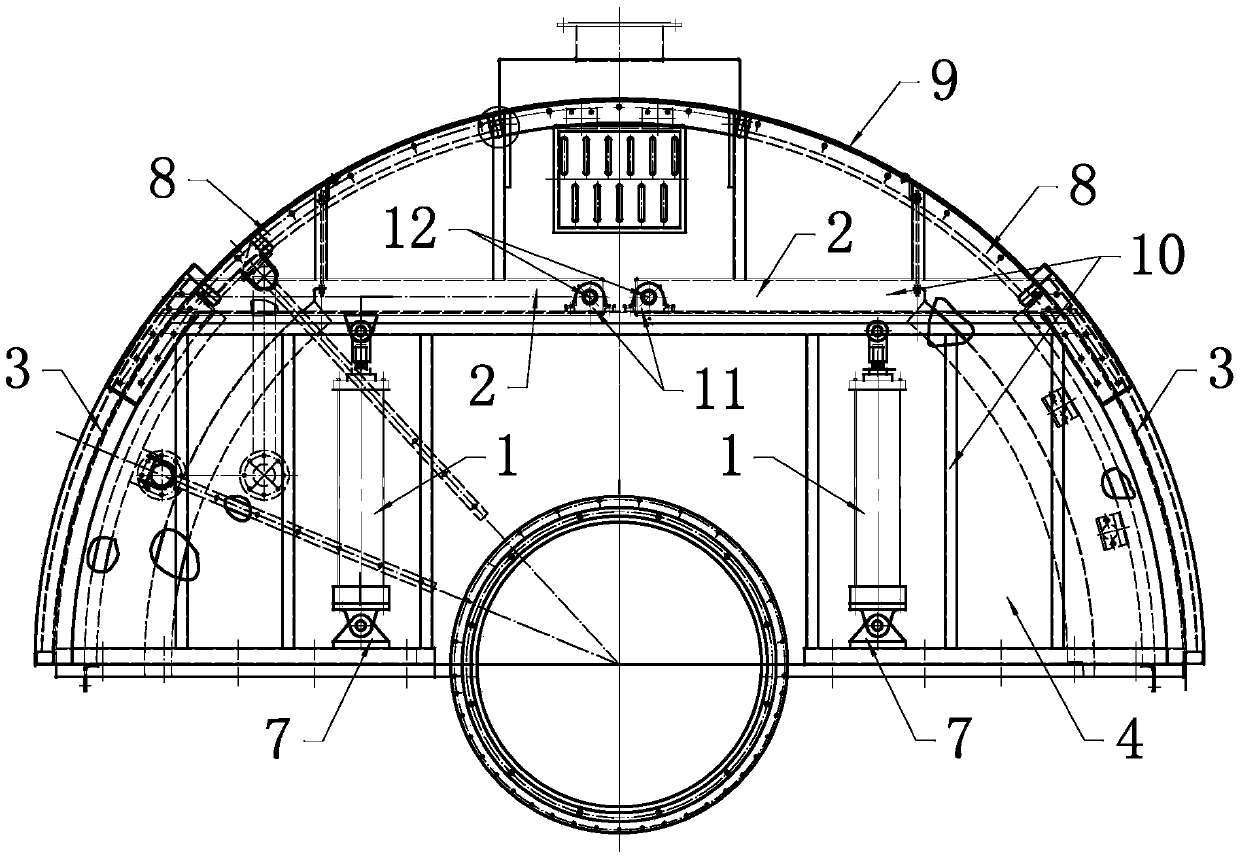

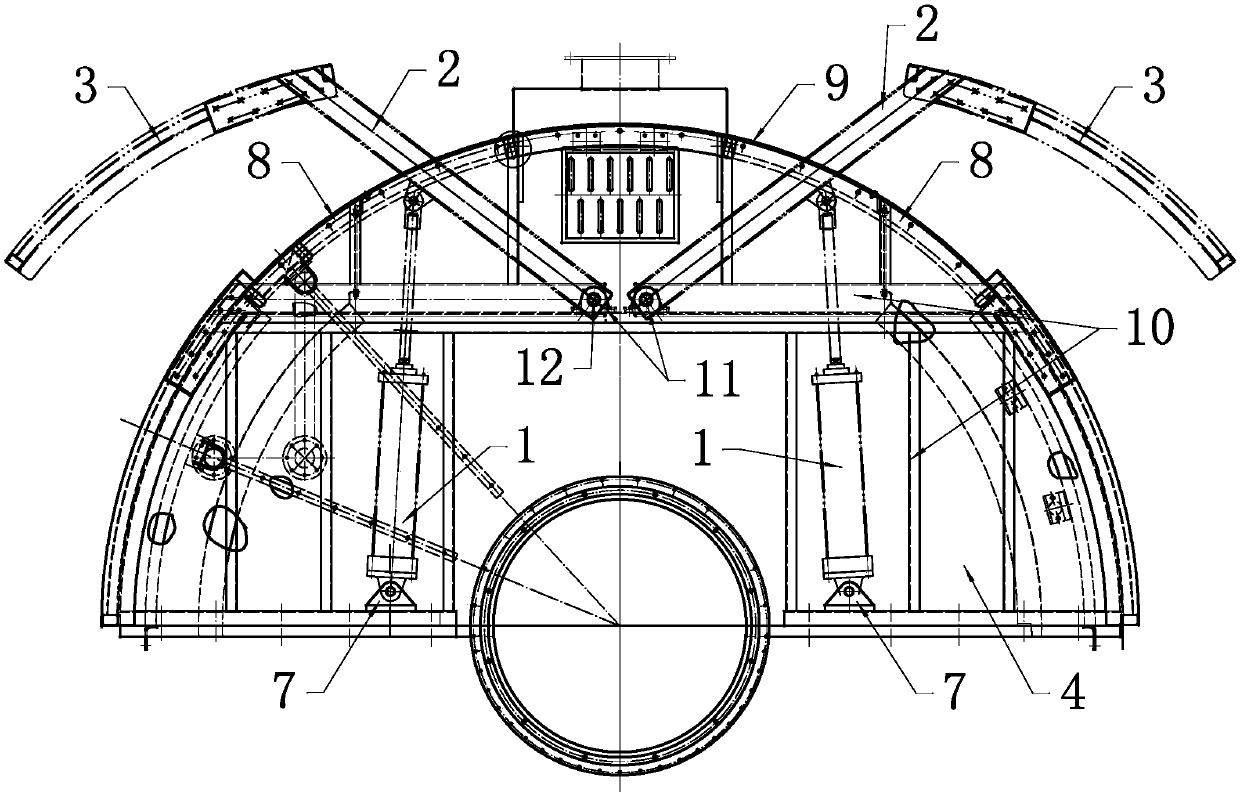

Shield tunneling machine

PendingCN113898357AReduce consumptionEasy to transportDust removalFire preventionShield tunnelingDust control

The invention discloses a shield tunneling machine, and belongs to the field of tunneling machine equipment. The shield tunneling machine comprises a cutterhead and a main machine structure, the cutterhead is fixedly assembled at one end of the main machine structure, an inner fixing frame is fixedly assembled on the inner wall of the side, close to the cutterhead, of the main machine structure, a crushing mechanism is fixedly arranged at the bottom of the inner wall of the side, close to the cutterhead, of the main machine structure, a water mist dust removal assembly is fixedly assembled on the portion, located above the crushing mechanism, of the inner wall of the main machine structure, a conveyor is fixedly installed in the main machine structure in a penetrating mode, and a pipe piece installing machine is fixedly assembled at the end, facing away from the cutterhead, of the main machine structure. The problems that stubborn impurities are clamped in gaps of groove cutters and dust flies can be solved, the equipment can save consumption of electric power resources, and has the characteristics of saving energy and reducing emission, in addition, the shield tunneling machine has the functions of crushing pretreatment before soil residue transportation, and transportation of a transporter is facilitated.

Owner:朱国庆

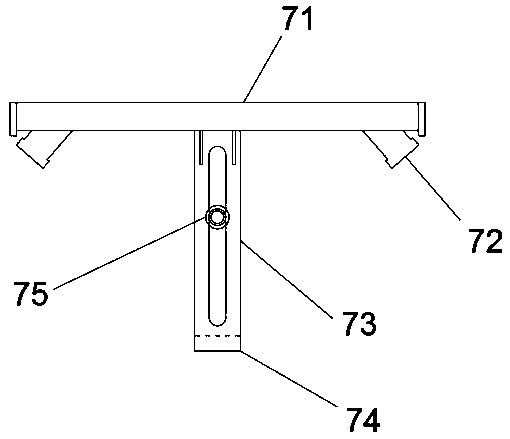

Weeding device and agricultural spraying vehicle with same

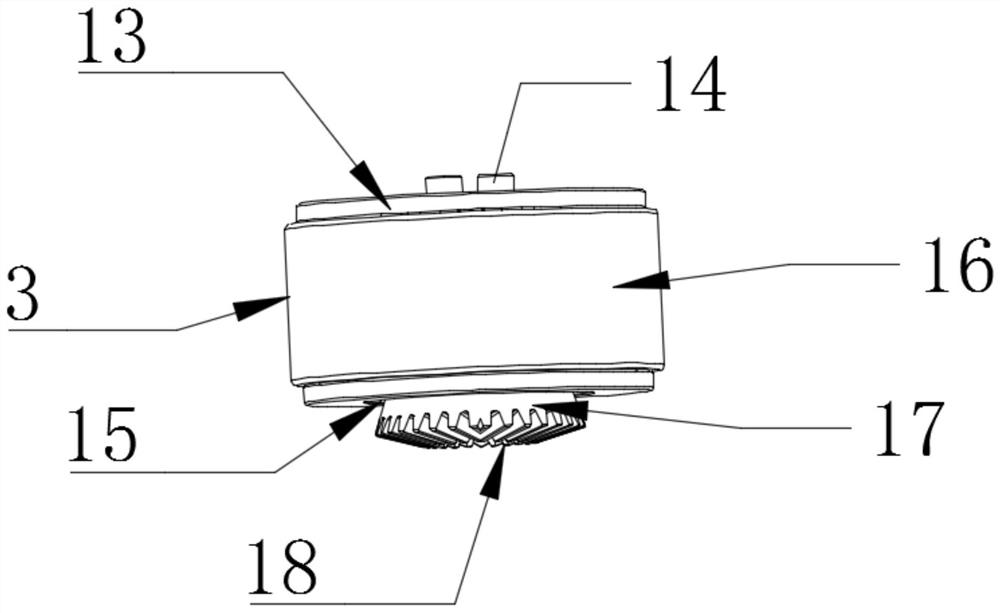

InactiveCN111642229ASolve flyingReduce flyingPropulsion partsMowersAgricultural engineeringMechanical engineering

The invention is applicable to the field of agricultural machinery, and provides a weeding device and an agricultural spraying vehicle with the weeding device. The weeding device comprises a first shell, a storage box and a cutting assembly, the cutting assembly is used for rotating around the axis of the cutting assembly to cut weeding and spray liquid materials stored in the storage box, a driving assembly is arranged on an outer side wall of the first shell, the driving assembly comprises a communication pipe and a limiting bearing, one end of the communication pipe is rotatably connected with the storage box, and a travelling mechanism is arranged on the first shell. According to the device, the connecting pipe is matched with the limiting bearing to drive the cutting assembly to rotate so as to cut and weed, meanwhile, liquid materials are conveyed to the cutting assembly through the connecting pipe to be sprayed, liquid materials can be sprayed to remove dust while cutting and weeding are carried out, working environment of weeding operation is effectively improved, and a problem that waste chips fly around when an existing weeding device carries out cutting and weeding is solved.

Owner:罗凤英

Apparatus for making high dust-containing material bag get off and recovering bag

The present invention discloses a powder material bag bag-cleaning method and its empty bag recovering equipment, including bag conveying platform, chain conveying mechanism, bag holder, bag holder opening and closing mechanism, bag inlet, discharging chamber, material pulverizing machine, grid vibration sieve, powder-collecting bin, main air channel, working table and empty bag platform. When it is worked, the package bag can be placed on the bag conveying platform, the chain is driven by motor and moved, under the action of the bag holder opening and closing mechanism, the bag holder is opened, after it is contacted with the edge of the package bag, the edge of said package bag can be tightly held by said bag holder, after said package bag, the edge of said package bag can be tightly held by said bag holder, after said package bag is fed into bag inlet, said package bag will fal down from conveying platform, the powder is poured into discharging chamber, pulverized, filtered and fed into powder-collecting bin, passed through main air channel.

Owner:孙东园 +2

A new type of superfine powder packaging machine

The invention discloses a novel ultrafine-powder packing machine, and relates to packaging equipment. A machine frame and a lifting column are arranged on a machine frame base, a weighing sensor is arranged on the lifting column, a clamping mechanism is further arranged at the upper end of the lifting column and is connected with a clamping air cylinder, a material stop valve and a dust removal pipeline, the material stop valve is further connected with a screw material cup, a filling screw is arranged inside a discharging hopper, a stirring motor is arranged inside a feeding hopper, a driven synchronous pulley is arranged above the feeding hopper, the driven synchronous pulley is connected with a driving synchronous pulley through a belt, and the driving synchronous pulley is connected with the filling motor. A lifting servo motor is arranged inside the machine frame and connected with a guide rod. The novel ultrafine-powder packing machine is high in production efficiency, and reasonable in design, has the functions of automatic quantification, automatic filling, automatic adjustment of metering errors and the like, is high in packing speed, is high in precision by the adoption of spiral discharging, and solves the problem that dust flies upward in a packing and filling process of ultrafine powder and materials having a great amount of dust.

Owner:SHANGHAI LUDA PACKING MACHINERY CO LTD

Preparation method of dust-free molybdenum disulfide for lubricant additive

InactiveCN107216685ASolve flyingReduce flyingAdditivesPigment treatment with macromolecular organic compoundsMaterials preparationDistillation

The invention relates to the technical field of lubricating material preparation, in particular to a preparation method of dust-free molybdenum disulfide for lubricating additives; molybdenum disulfide powder and dust suppressant are added into a mixing and stirring device according to the ratio, and the temperature is raised by high-speed stirring. The mixing and stirring device is designed to detect the vaporization temperature or distillation range of the dust suppressant used in advance. During the mixing and stirring process, after the temperature of the material in the device exceeds the gasification temperature of the dust suppressant or enters the distillation range temperature, heat preservation and cooling are carried out to make the dust suppressant Dust agent is coated on the surface of molybdenum disulfide to obtain dust-free molybdenum disulfide; it solves the problem of dust flying when molybdenum disulfide is used as a lubricating additive, and the prepared dust-free molybdenum disulfide does not affect the preparation and production of lubricating additives. Use performance.

Owner:SONGXIAN EXPLOITER MOLYBDENUM

Cutting device for engineering construction and using method

ActiveCN111761743AReduce intensityAvoid harmFeeding apparatusWorking accessoriesHand partsConstruction engineering

The invention provides a cutting device for engineering construction and a using method, and relates to the field of construction instruments. The cutting device for engineering construction comprisesa base, a top plate is welded to the top of the base through two supporting rods, an inner rod is welded to the side, away from the supporting rods, of the bottom of the top plate, the bottom of theinner rod is sleeved with outer rods, and a cutting blade is arranged between the two outer rods. According to the cutting device for engineering construction, a worker controls lifting of the cuttingblade through a grabbing mechanism, a damping spring is arranged on the outer surface of a holding rod in a surrounding mode, vibration generated when the cutting device works is transmitted to an outer cylinder through a motor box and a transverse rod, the damping spring buffers and dissipates energy of the cutting device, and the strength of the vibration transmitted to the holding rod is reduced; meanwhile, the outer surface of the holding rod is sleeved with a rubber sleeve, so that the strength of cutting vibration transmitted to the hand of a worker is greatly reduced, the harm of the cutting vibration to the body of the worker is avoided, meanwhile, the working fatigue is reduced, and the working efficiency is improved.

Owner:安徽曲阳建设有限公司

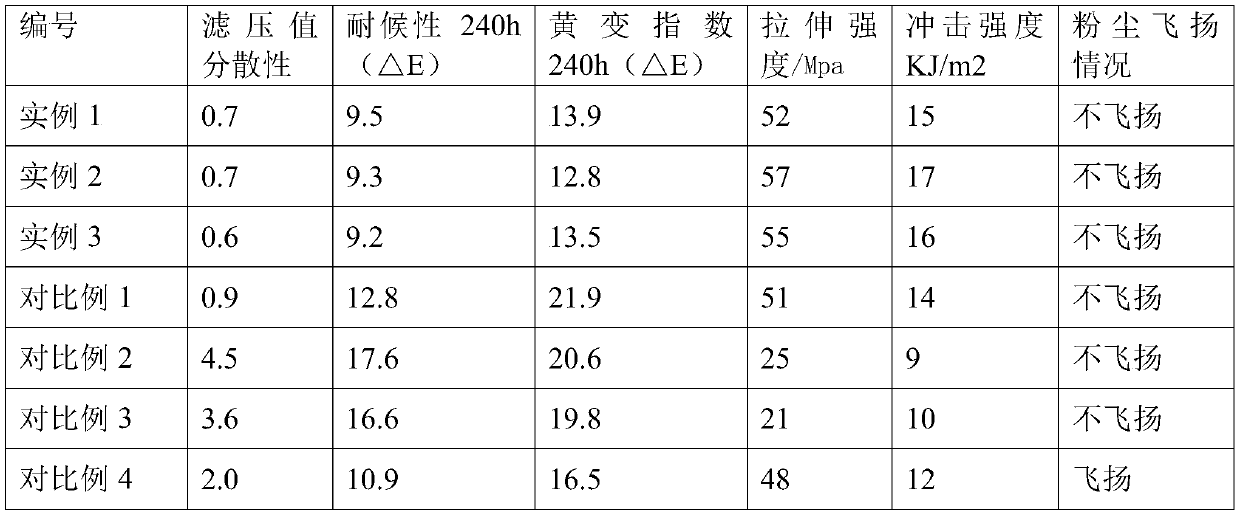

Preparation method of high-weather-resistance and high-dispersion plastic color master batch titanium dioxide pigment

PendingCN111073351AClose to spherical high proportionSmall particle sizePigment flushingPigment treatment with macromolecular organic compoundsAluminatePolyolefin

The invention relates to a preparation method of a high-weather-resistance and high-dispersion plastic color master batch titanium dioxide pigment, and the method comprises the following steps: producing a titanium dioxide primary product by a chlorination process, pulping in desalted water to prepare a slurry, regulating the pH value with an inorganic acid or alkali, dispersing, and grinding; heating the slurry, adding an alkaline aluminate compound, and simultaneously maintaining the pH value constant by using inorganic acid or an acidic aluminum compound to form an inorganic aluminum film coating layer on the surface of titanium dioxide particles; adjusting the pH value by adopting an inorganic alkali solution, and adding a polysiloxane liquid containing an active group to form an organic silicon film coating layer; filtering with deionized water, washing, and drying; adding a citrate ester organic treating agent in the steam-pulverizing process, and performing steam-pulverizing treatment to obtain a titanium dioxide finished product. The advantages are that: the titanium dioxide pigment prepared by the method has high weather resistance, high whiteness, high covering power andexcellent dispersion processability, has low dust flying in the production and use processes, is environment-friendly, and is suitable for the application fields of high-end color master batches suchas polyolefin, engineering plastics and the like

Owner:中信钛业股份有限公司

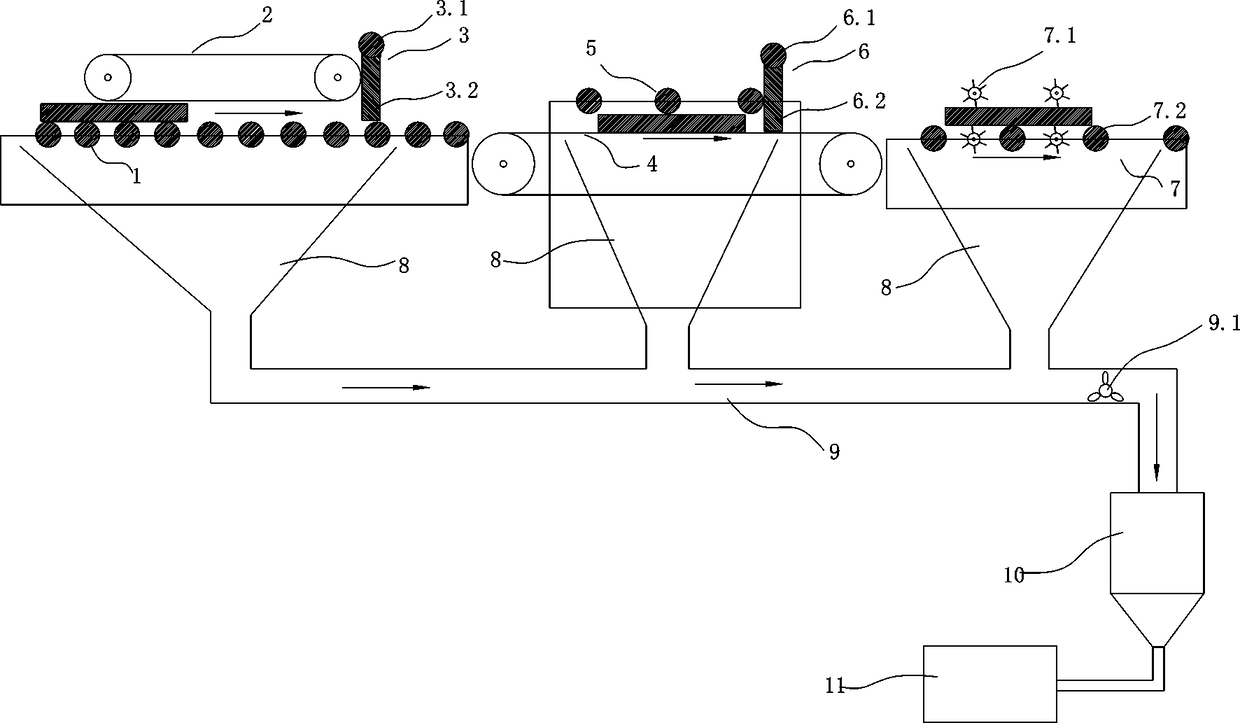

Polishing equipment for marine metal castings and working method thereof

ActiveCN111590446AIncrease productivityImprove work efficiencyPolishing machinesBelt grinding machinesPolishingEngineering

The invention discloses polishing equipment for marine metal castings. The polishing equipment comprises a rack, a shaping mechanism, a double-sided sanding mechanism, a polishing mechanism, a detection mechanism for detecting polishing quality, a turnover mechanism, a limiting device and a control mechanism, the shaping mechanism is arranged at the front end of the rack, the double-sided sandingmechanism is arranged behind the shaping mechanism, the polishing mechanism is arranged at the tail end of the double-sided sanding mechanism, the detection mechanism is arranged behind the polishingmechanism, the turnover mechanism is arranged behind the detection mechanism, the limiting device is arranged on the position, corresponding to the lower portion of the polishing mechanism, of a workbench, and the shaping mechanism, the double-sided sanding mechanism, the polishing mechanism, the detection mechanism, the turnover mechanism and the limiting device are all connected with the controlmechanism. According to the polishing equipment, the castings are shaped through the shaping mechanism firstly, then the castings are subjected to sanding through the sanding mechanism, the castingssubjected to sanding are polished through the polishing mechanism, the turnover mechanism is further arranged, machined products can be turned over, and the working efficiency of the polishing equipment is greatly improved.

Owner:徐州中盛远达新材料有限公司

Fiber-reinforced exhaust duct

ActiveCN102276220BSave resourcesHigh tensile strengthSolid waste managementPortland cementWorking environment

The invention belongs to component and fittings in the field of architecture, and specifically relates to a fiber-reinforced exhaust duct. The fiber-reinforced exhaust duct is characterized by being made from the following raw materials of: by weight, 100 parts of portland cement, 5-10 parts of waste paper pulp fiber, 10-17 parts of asbestos fiber, 1-3 parts of a polypropylene substance and 1-1.2parts of a special-purpose auxiliary agent. By changing wastes into the main raw materials of the product, the invention is energy saving and environmentally friendly, and simultaneously is used to save a large amount of national resources and completely solve the problem of flying dust generated during the whole production process. In addition, a lot of machines are adopted to replace artisan craftsmanship, thus greatly improving the working environment for workers and mitigating their labor intensity.

Owner:HANGZHOU KANGJU KINGDEE HOUSING EXHAUST

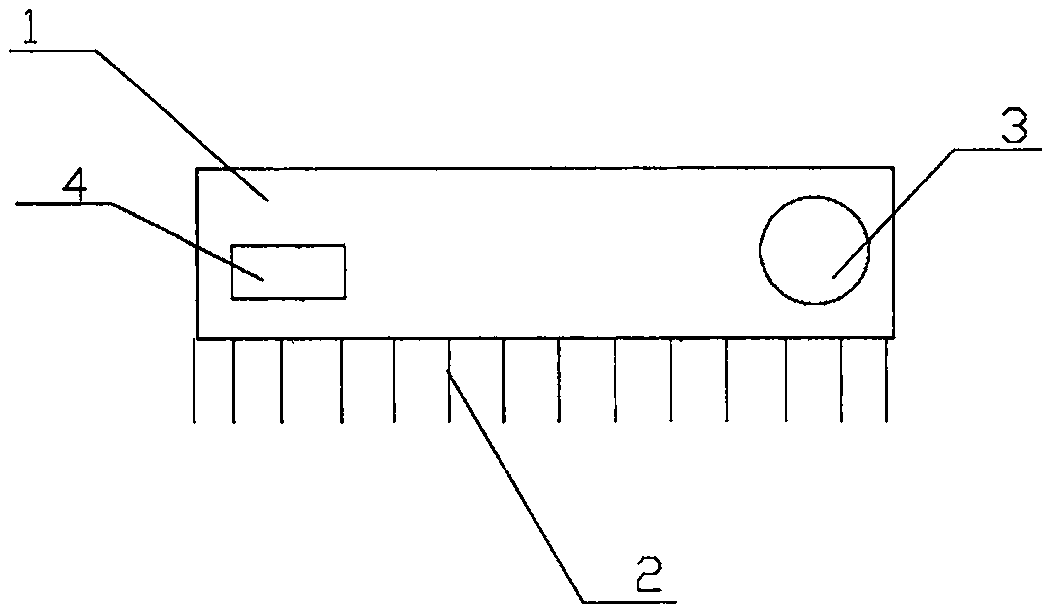

Blackboard eraser

The invention provides a blackboard eraser, and belongs to the field of education supplies. The blackboard eraser aims at achieving environment protection. According to the adopted technical scheme, the blackboard eraser is mainly formed by combining a shell and bristles. A micro dust collector and a storage box are installed in the shell. Due to the adoption of the structure mentioned above, during use, the micro dust collector can be turned on, work is started, dust brushed down by the bristles is sucked and then stored in the storage box, and the problem that the dust flies is solved. The device is simple in structure and ingenious in design and has application and popularization prospects.

Owner:高向阳

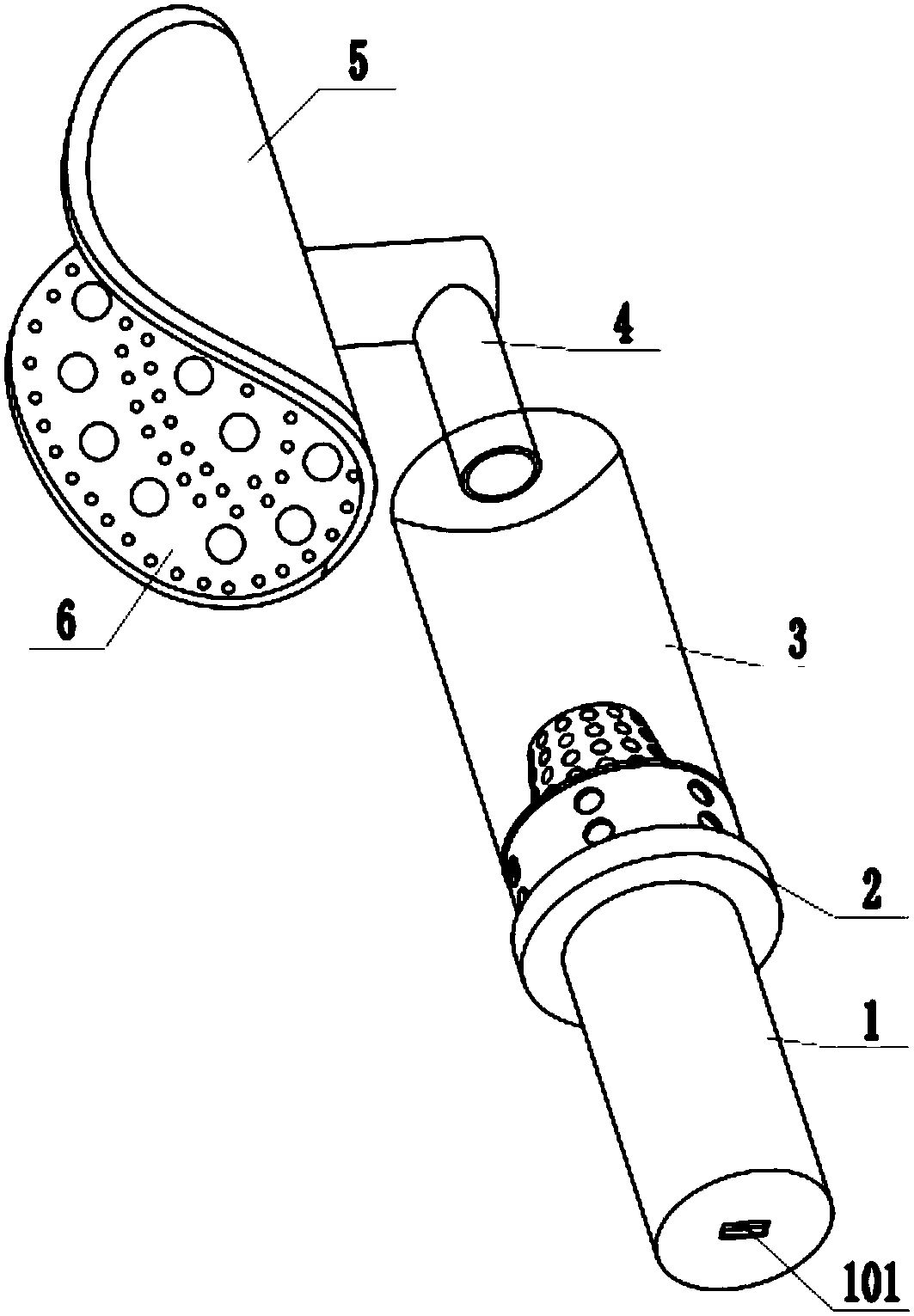

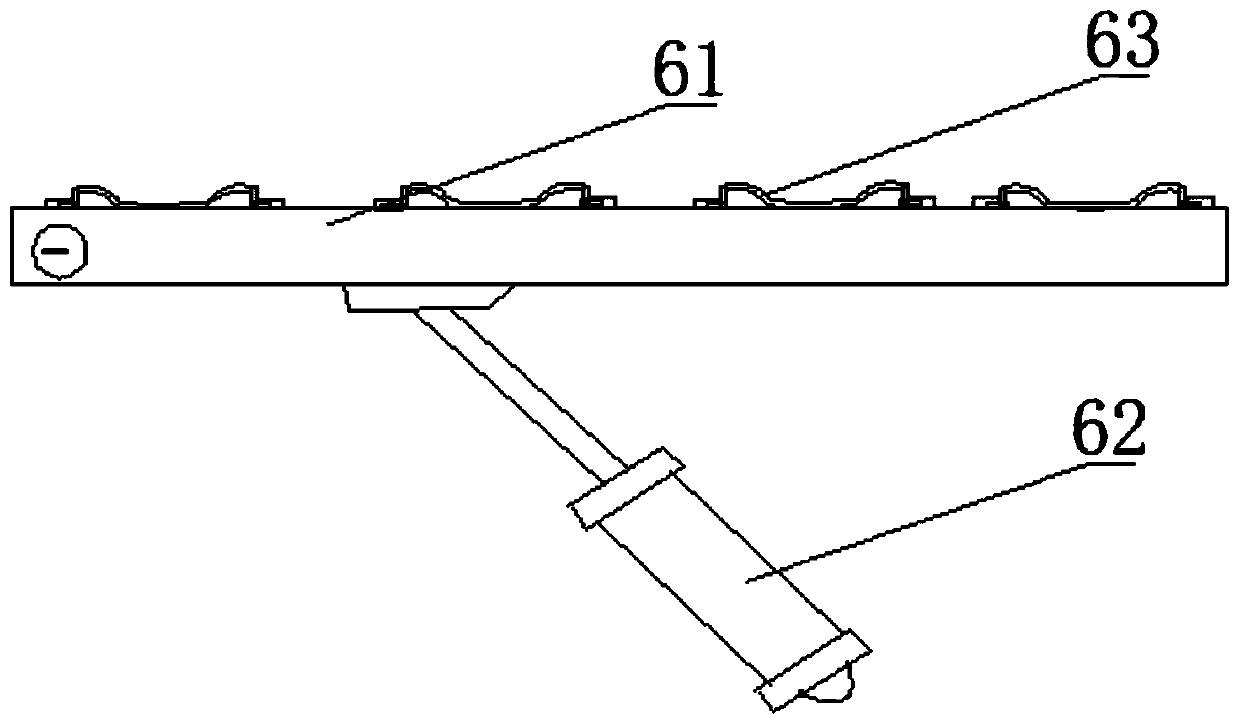

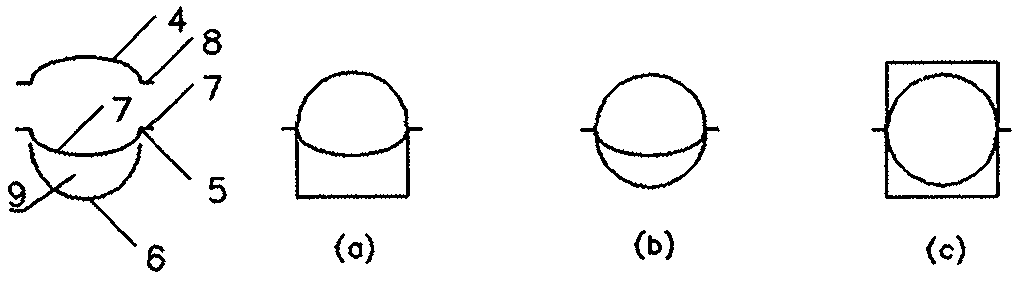

Mop cleaned by utilizing foam

InactiveCN103300800ASolve flyingSolve problems that require watering firstCarpet cleanersFloor cleanersEngineeringProduct gas

The invention discloses a mop cleaned by utilizing foam, which is capable of wrapping and wetting dust by utilizing the foam so as to prevent the dust from flying upward; decontamination ingredients can be used for cleaning a floor; and the amount of water is reduced in the whole process, so that the mop is convenient to use. According to the mop cleaned by utilizing the foam provided by the invention, a foam gas generator 7, a foam gas conduit 6 and a porous foam head 5 in a foam generation box 3 are controlled through a foam control switch 1 on a mop handle 8, foam is generated in expanding foam solution10 with the decontamination ingredients and is ejected to the floor through a foam delivery tube 4 with an adjustable angle, so that the dust is wrapped and is wet, thus the dust cannot fly upwards, and water consumption is reduced.

Owner:范信龙

Hammer crusher

InactiveCN112221605ASolve flyingReduce pollutionGrain treatmentsWater storage tankArchitectural engineering

The invention discloses a hammer crusher, and relates to the technical field of crushers. The hammer crusher comprises a body, wherein a feeding port is formed in the upper part of the body, a baffleused for preventing crushed stone from splashing is rotationally connected to the feeding port, a crushing hammer hub is installed under the feeding port and is rotationally connected with the body, supports are installed on the two sides of the crushing hammer hub, counterattack plates are connected to the supports through bolts, a discharging port is formed in the position, located under the crushing hammer hub, of the bottom of the body, a plurality of atomization nozzles are fixedly connected to the two sides of the discharging port, the atomization nozzles communicate with a water pipe, the water pipe communicates with a water storage tank, and the water pipe is fixedly connected with a water pump for pressurizing water between the atomization nozzles and the water storage tank. According to the hammer crusher, the atomization nozzles are arranged in the position of the discharge port and spray water to crushed sand, so that the problem that dust flies at the discharge port is solved, and environmental pollution is effectively reduced.

Owner:ZAOZHUANG SNKSAN INTELLIGENT MACHINERY CO LTD

Automatic open-type protective cover

The invention discloses an automatic open-type protective cover. The automatic open-type protective cover comprises a machine cover and a power device, wherein the machine cover is provided with two openings and two machine cover doors which respectively block the two openings; the machine cover doors can move; when the machine cover doors move, the openings can be opened or closed; the machine cover doors are fixedly connected with a support rod; the support rod is hinged to the machine cover; the power device is connected with the support rod; the power device acts to drive the support rod to rotate along a hinged shaft hinged with the machine cover; the power device is a cylinder; a fixed seat is arranged on the machine cover; the tail end of the cylinder is hinged to the fixed seat; atelescopic rod of the cylinder is hinged with the support rod; an avoidance hole is formed in the machine cover; and the support rod swings in the avoidance hole when swinging. According to the automatic open-type protective cover disclosed by the invention, automatic opening and closing of the machine cover can be realized, the structure is simple, the view port is large, the maintenance and inspection are facilitated, the sealing effect is good, the problems of dust flying on site and poor and dirty, disorderly and bad environment are solved, no pollutants are discharged and the environmental protection requirement is satisfied.

Owner:WENRUI MACHINERY SHANDONG

Polishing equipment and working method for marine metal castings

ActiveCN111590446BIncrease productivityImprove work efficiencyPolishing machinesBelt grinding machinesPolishingEngineering

The invention discloses a polishing device for marine metal castings, comprising: a frame, a shaping mechanism, a double-sided sand opening mechanism, a polishing mechanism, a detection mechanism for testing the polishing quality, a turning mechanism, a limit device and a control mechanism , the shaping mechanism is set at the front end of the frame, the double-sided sand-opening mechanism is set at the rear of the shaping mechanism, the polishing mechanism is set at the end of the double-sided sand-opening mechanism, the detection mechanism is set at the rear of the polishing mechanism, and the turning mechanism is set at the detection mechanism At the rear, the limit device is set on the corresponding workbench under the polishing mechanism, and the shaping mechanism, double-sided sand opening mechanism, polishing mechanism, detection mechanism, turning mechanism and limit device are all connected with the control mechanism. In the present invention, the casting is first reshaped by setting the shaping mechanism, and then the casting is sanded by the sand opening mechanism, and the casting after the sand opening is polished by the polishing mechanism, and a turning mechanism is also provided to allow it to be processed. The product is turned over, which greatly improves its work efficiency.

Owner:徐州中盛远达新材料有限公司

No-dust air cushion conveyor and modular groove pipe prefabrication and installation method

InactiveCN109649935AReduce manufacturing costSolve scatteredConveyorsPackagingRolling resistanceMaterial scattering

The invention discloses a no-dust air cushion conveyor and a modular groove pipe prefabrication and installation method. The no-dust air cushion conveyor is characterized by comprising a frame, a modular groove pipe, a conveying system, an air feeding device, a sealing box and a filter device. The modular groove pipe is prefabricated as a standard module according to a certain specification length, so that the field installation and construction are simple and fast, and the manufacturing and installation cost is saved; and the no-dust air cushion conveyor changes rolling friction supported bya general conveyor support roller to air fluid friction, achieves the sliding performance of the support roller supporting and the operation stability and tightness of the pipe supporting, and is particularly suitable for powder conveying. The no-dust air cushion conveyor solves the problems of high operation resistance of a conveying belt, easy material scattering, generation of flying dust, environmental pollution and influence on the material purity by invasion of external pollutants in a belt conveyor in the prior art, and solves the problem of material pollution due to easy wear and degumming of the edge of the conveying belt of the tubular belt conveyor.

Owner:林广成 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com