A new type of superfine powder packaging machine

A technology of ultra-fine powder and packaging machine, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of powder leakage, loss of materials and packaging bags, and increased enterprise costs. It can automatically adjust measurement errors, The effect of fast packaging speed and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

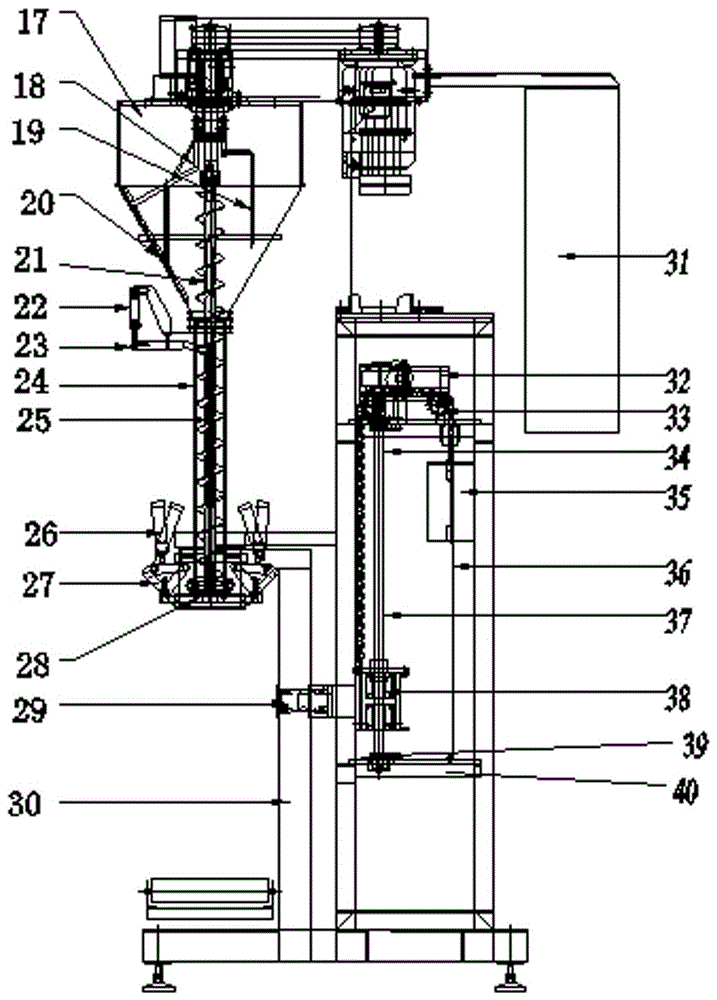

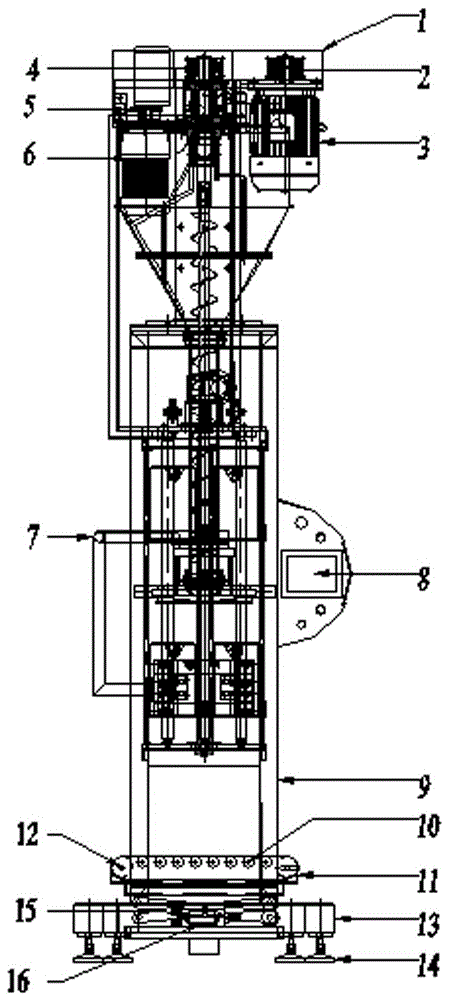

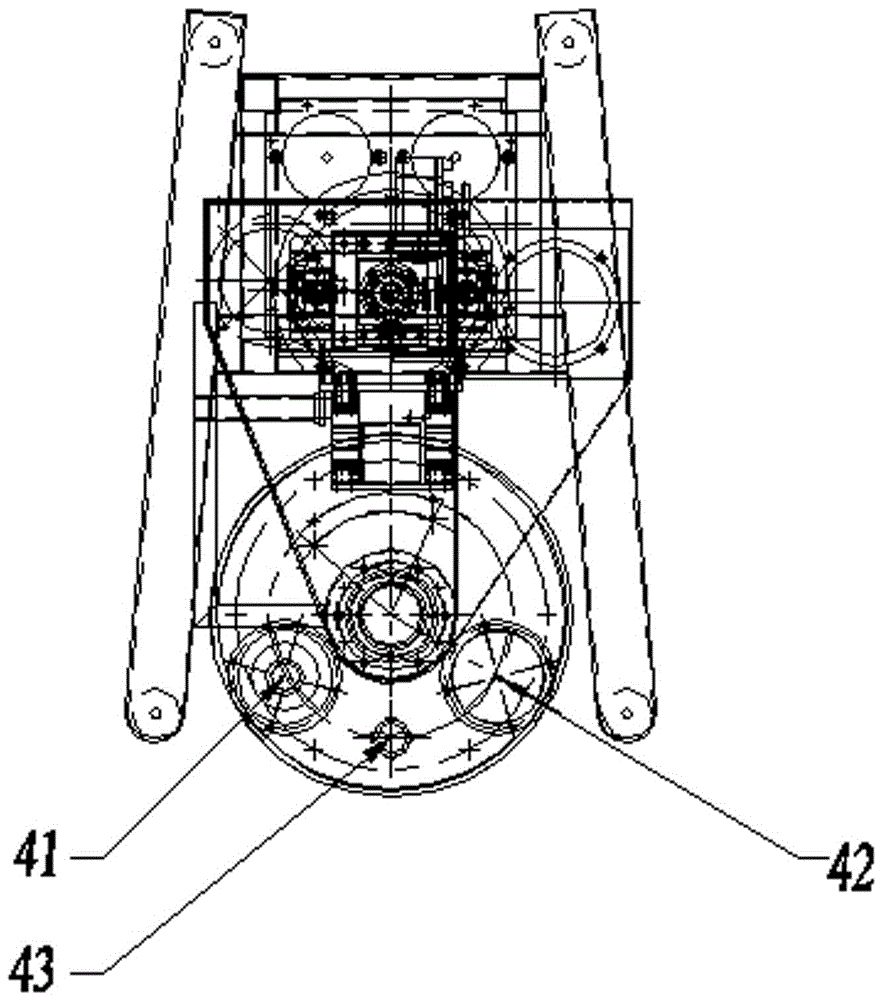

[0012] refer to Figure 1-3 , the specific embodiment adopts the following technical solutions: a new type of ultrafine powder packaging machine, including a head cover 1, an active synchronous pulley 2, a filling motor 3, a passive synchronous pulley 4, a stirring sprocket 5, and a stirring motor 6. Dust removal pipeline 7, touch screen 8, frame 9, unpowered roller 10, power belt conveyor 11, electric roller 12, frame base 13, feet 14, conveyor lifting mechanism 15, lifting cylinder 16, hopper 17, Large agitator 18, small agitator 19, lower hopper 20, filling screw 21, valve cylinder 22, valve swing arm 23, screw material cup 24, valve connecting rod 25, bag clamping cylinder 26, bag clamping mechanism 27, cut-off valve 28. Load cell 29, lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com