Hammer crusher

A hammer crusher and hammer technology, applied in grain processing and other directions, can solve the problems of environmental pollution, not taking into account the problem of sand and gravel diffusion at the outlet, and achieve the effect of solving dust flying and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

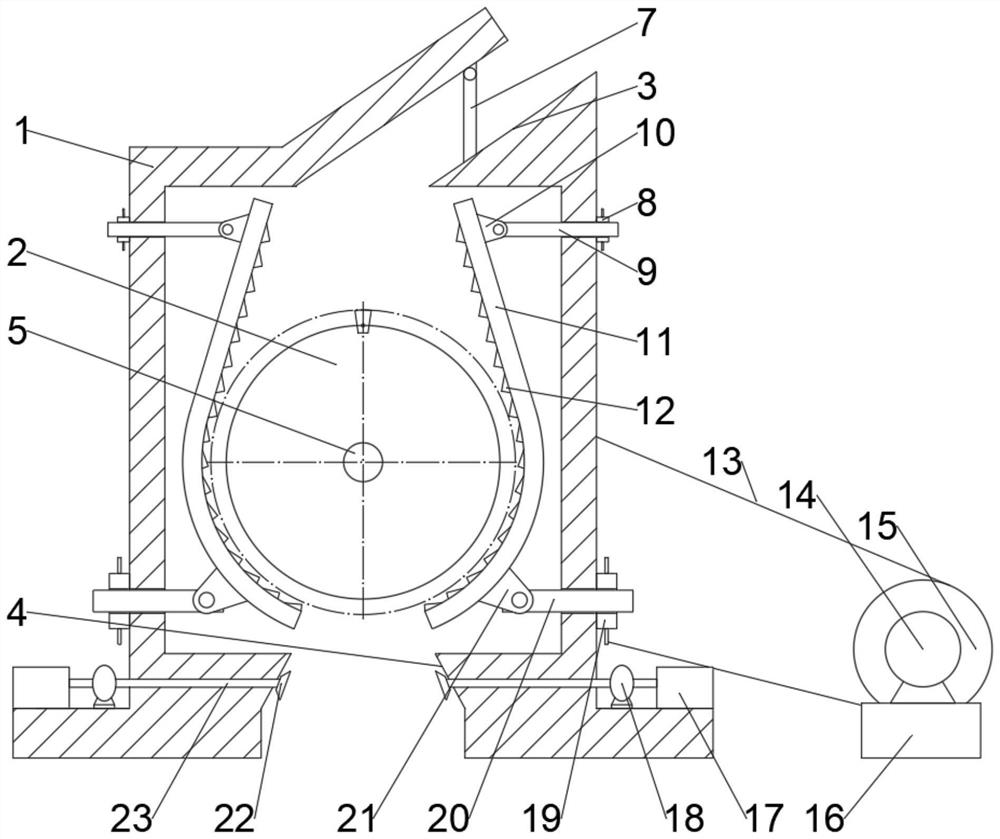

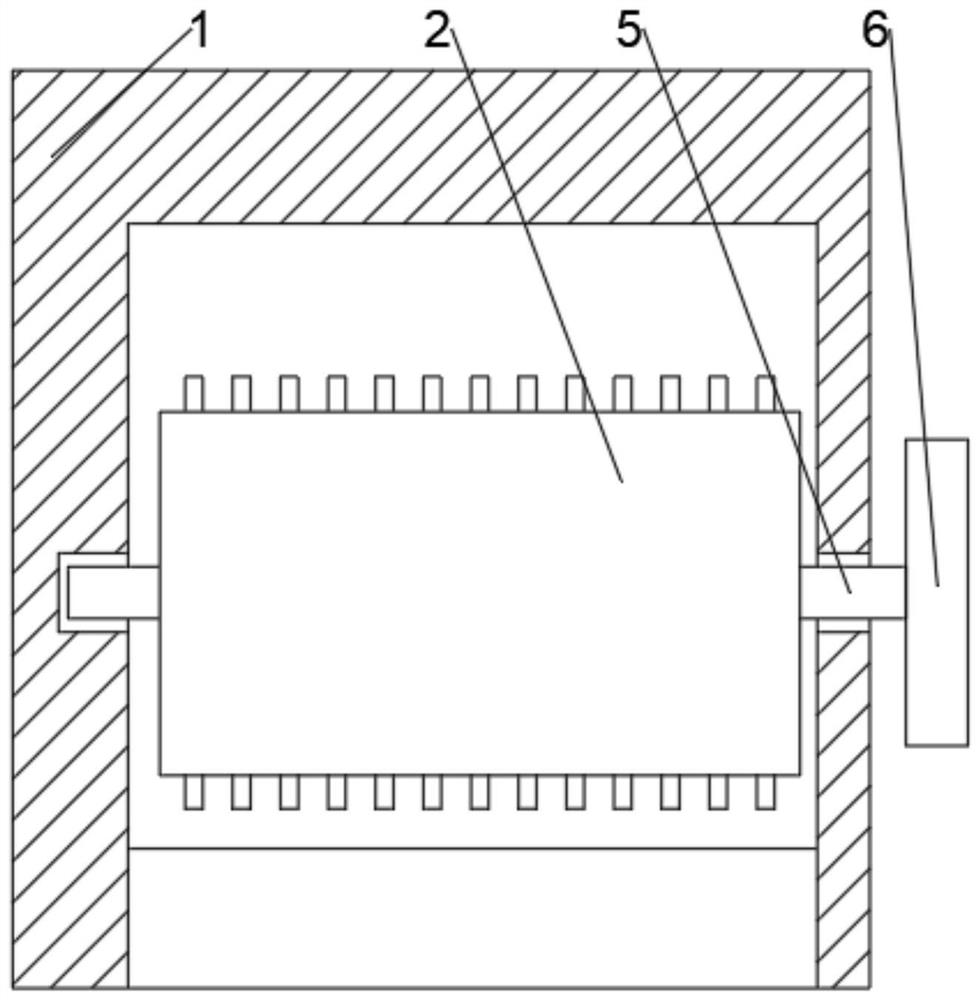

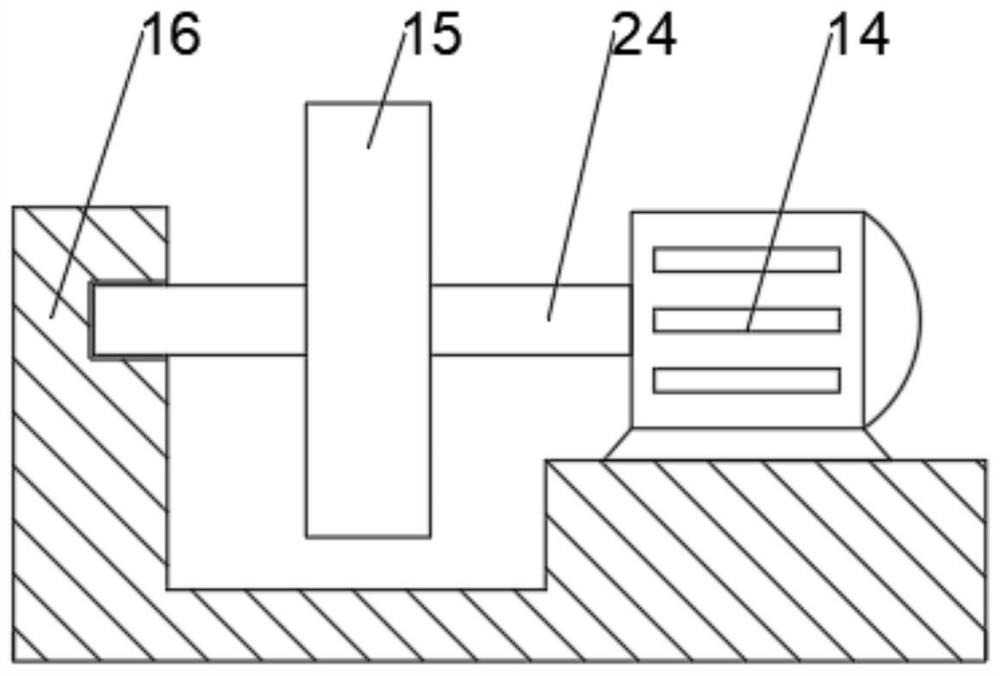

[0021] see Figure 1~3 , in Embodiment 1 of the present invention, a hammer crusher includes a body 1, a feed port 3 is arranged above the body 1, and the feed port 3 is used to guide sand into the interior of the body 1, and the feed port The opening 3 is rotatably connected with a baffle plate 7 for preventing gravel from splashing. A breaker hub 2 is installed directly below the feed opening 3. The breaker hub 2 is rotatably connected with the body 1. The breaker hub 2 Supports 11 are installed on both sides, and the support 11 is connected with a counter-attack plate 12 by bolts. There is a discharge port 4 below, and a number of atomizing nozzles 22 are fixedly connected to both sides of the discharge port 4. The atomizing nozzles 22 communicate with the water pipe 23, and the water pipe 23 communicates with the water storage tank 17. The water pipe 23 is in the A water pump 18 for pressurizing the water is fixedly connected between the atomizing nozzle 22 and the water ...

Embodiment 2

[0028] see Figure 1~3 , the top of the bracket 11 is fixedly connected with an upper lug 10, the upper lug 10 is rotationally connected with the upper screw 9, the upper screw 9 is threaded with the body 1, and the lower side of the bracket 11 is fixedly connected with a lower Hanging ear 21, the lower hanging ear 21 is rotationally connected with the lower screw 20, the lower screw 20 is threadedly connected with the body 1, the upper screw 9 and the lower screw 20 can pull the bracket 11 through the upper hanging ear 10 and the lower hanging ear 21 s position.

[0029] Wherein, the upper screw 9 is threadedly connected to the upper screw 8, the upper screw 8 is fixedly connected to the body 1, the lower screw 20 is threaded to the lower screw 19, and the lower screw 19 is fixed Connected to the body 1, the screw-in length of the upper screw 9 and the lower screw 20 can be adjusted by rotating the upper screw 8 and the lower screw 19 .

[0030] The working principle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com