Automatic open-type protective cover

A technology of automatic opening and protective cover, which is applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of flying dust, no sealing effect, and non-compliance with environmental protection requirements, and achieve the effect of easy maintenance and inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

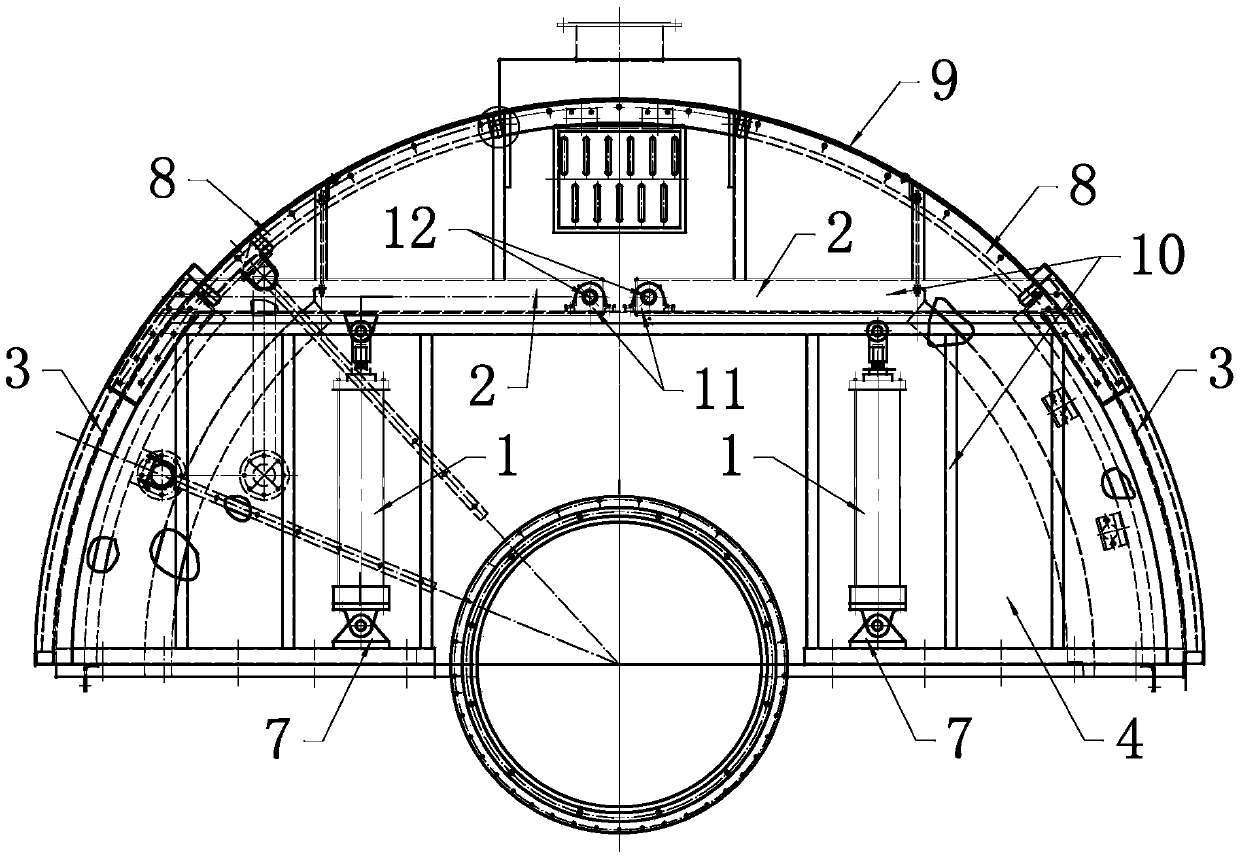

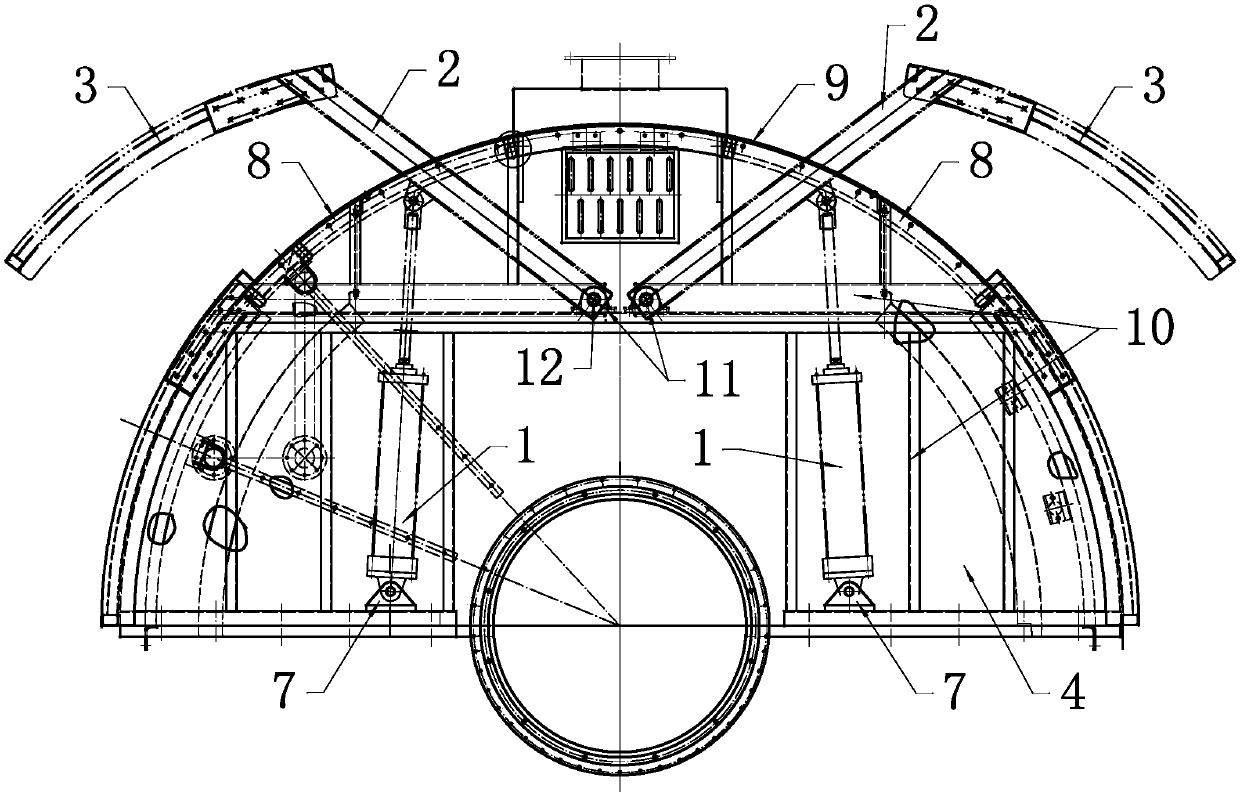

[0025] Such as figure 1 and figure 2 Commonly shown, an automatic opening type protective cover includes a machine cover 4 . The machine cover 4 is a hemispherical shell-like structure, and the machine cover 4 includes a section steel 9 and a bent steel plate 10 fixed on the outside of the section steel 9 . The hood 4 is provided with two openings 6 and a hood door 3 blocking the openings 6 . The two openings 6 are respectively arranged on opposite sides of the hood 4 , and the position of each opening 6 is correspondingly provided with a hood door 3 . The hood door 3 can move; the hood door 3 can move to open or close the opening 6 . Because the hood is provided with an opening and a hood door blocking the opening, the hood door moves to open or close the opening; therefore the opening can be designed much larger than the opening in the prior art, and is more convenient for maintenance and inspection.

[0026] The automatic opening type protective cover also includes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com