Closed continuous aftertreatment system for metal powder

A technology of metal powder and fine metal powder, which is applied in the field of closed and continuous post-processing system of alloy powder, which can solve the problems of powder pollution, pollution, powder flying, etc., and achieve the effect of optimizing environment, improving environment and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

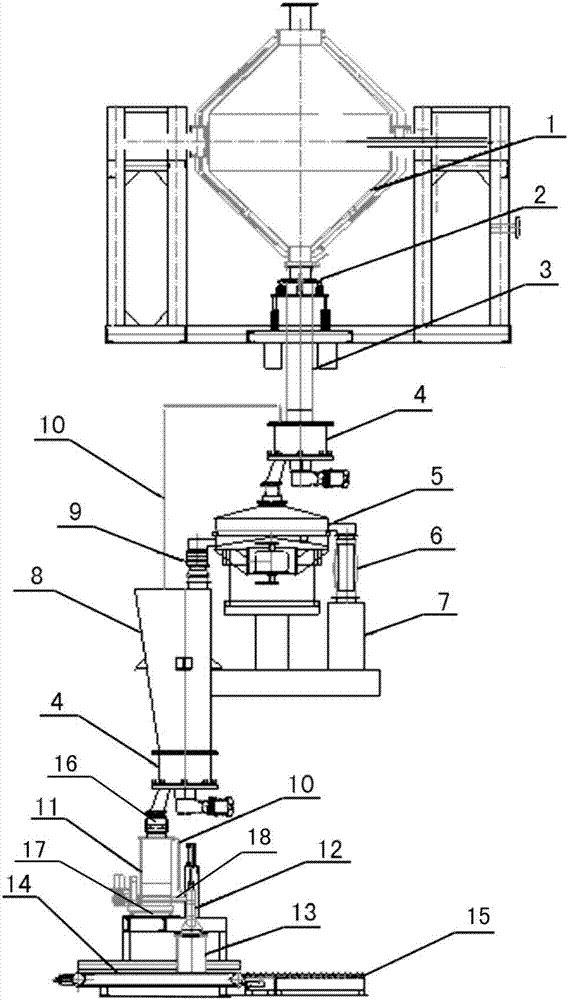

[0031] figure 1 A schematic diagram of a closed continuous post-processing system for metal powder is shown, which realizes direct screening of powder in a drying device, and realizes closed screening and closed automatic weighing and packaging production. The post-treatment system of the present invention is especially suitable for processing ultrafine water atomized alloy powder, with reference to figure 1 , the metal powder airtight continuous post-processing system of the present invention comprises from top to bottom: a metal powder drying device, a screening device, a fine metal powder collection tank 8, a coarse metal powder collection tank 7, a weight loss scale, and a fine powder packaging tank 13 , These devices are all sealed and connected, that is, there will be no direct contact between metal powder and air in the entire system. In this post-processing system, the screening device is arranged below the metal powder drying device and is sealed and connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com