Needle thread feeding device of sewing machine

A technology of exporting device and sewing machine, which is applied to sewing machine components, sewing machine thread take-up device, sewing equipment, etc., can solve the problems of oil leakage and dust, unfavorable operator safety, intrusion, etc., and achieve lightweight, prevent oil leakage and dust. The effect of intrusion into the sewing machine arm and shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

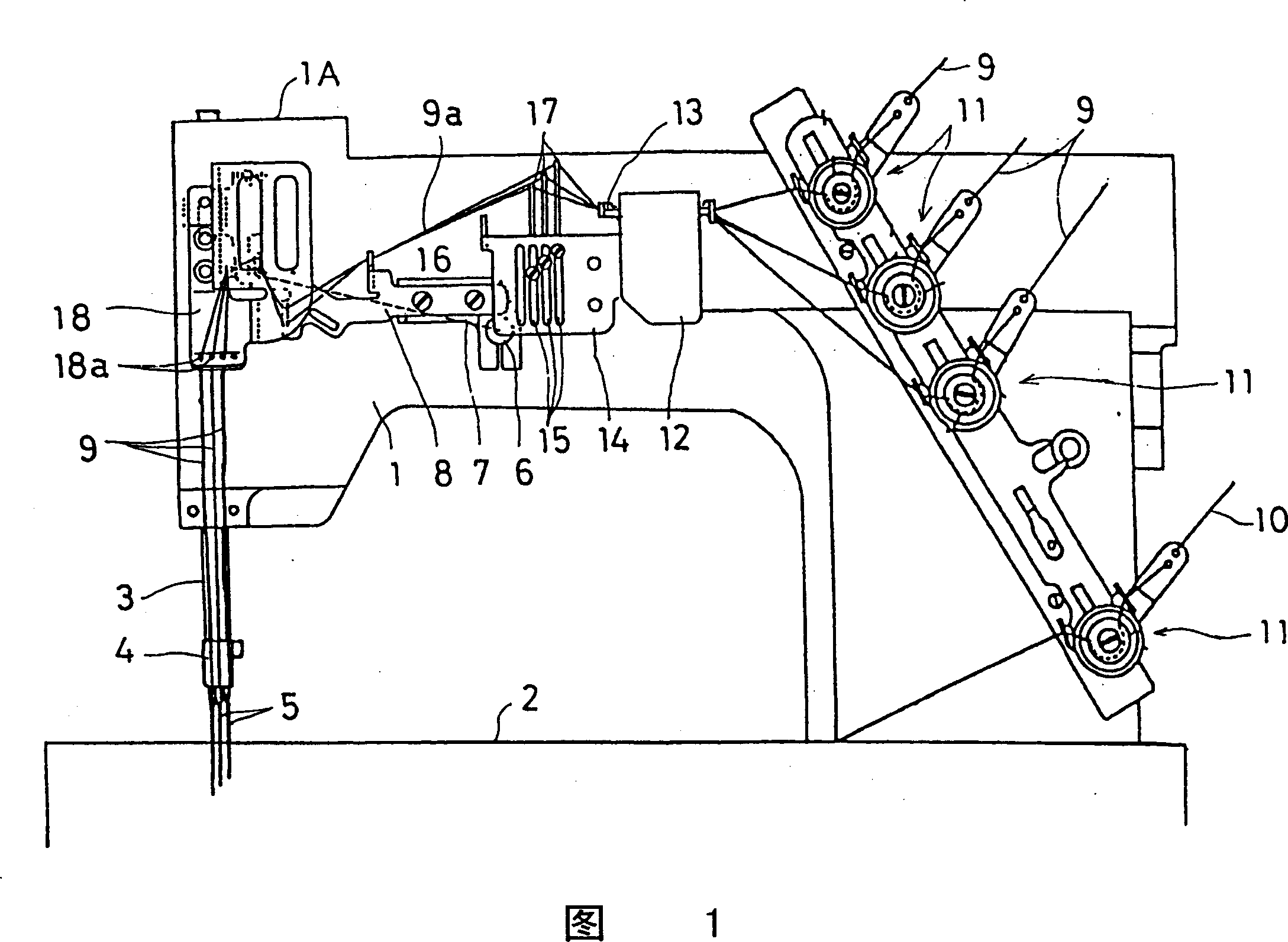

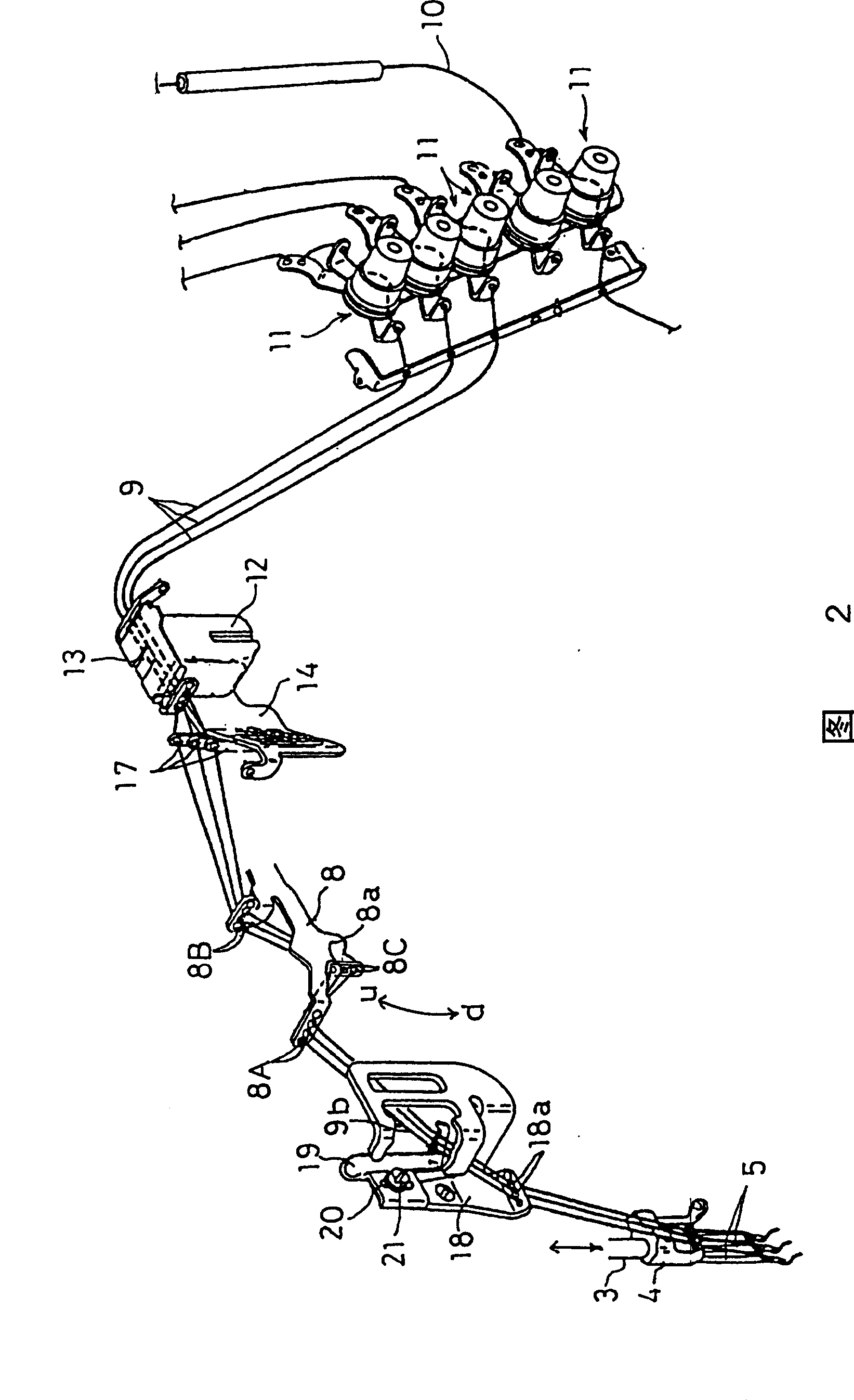

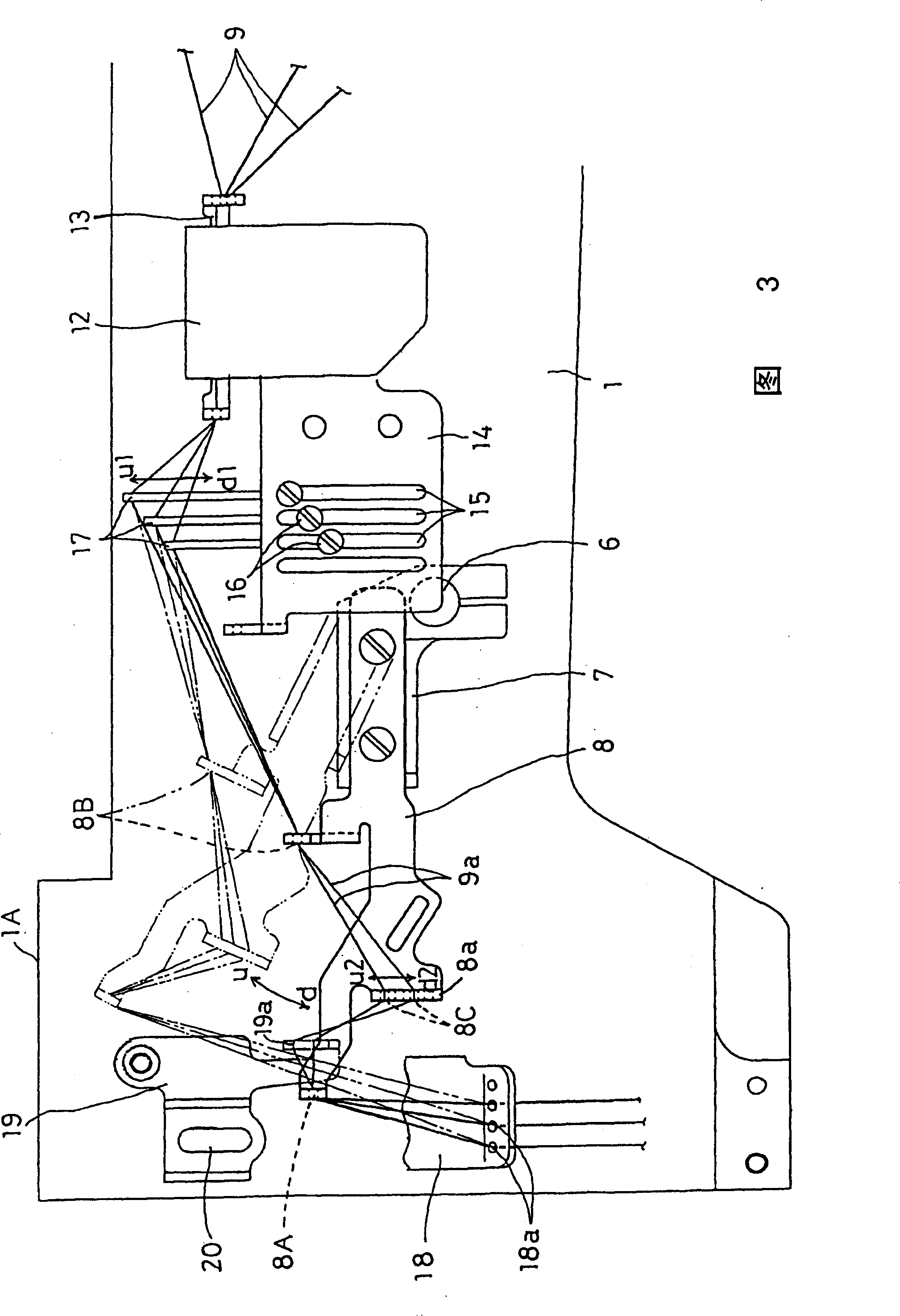

[0017] Embodiments of the present invention will be described below with reference to the drawings.

[0018] Figure 1 ~ Figure 3 Among them, 1 is the arm of the sewing machine, and 2 is the bottom plate of the sewing machine. The needle bar 3 is supported at the left end (front end) of the arm of the sewing machine 1, and the needle bar 3 is supported on the arm of the sewing machine by a known crank mechanism and insertion. The drive spindle (not shown) in 1 is interlocked and can reciprocate in the up and down direction, and at the needle bar 3, a blank pressing mechanism is adjacently provided (because it is known, so the detailed description is omitted).

[0019] At the lower end of the needle bar 3, three needles 5 are installed through the needle clamp 4. At the same time, the range of the up and down reciprocating movement of the needle bar 3 is set to: In this state, the upper end portion does not protrude upward from the upper wall portion 1A of the left end portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com