Needle thread feeding device of sewing machine

一种导出装置、缝纫机的技术,应用在缝纫机元件、缝纫机挑线装置、缝纫器械等方向,能够解决缝制速度的高速化防碍、作业者安全性不利、漏油尘埃等问题,达到实现短缩化、防止漏油及尘埃侵入缝纫机臂部内、实现轻量化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

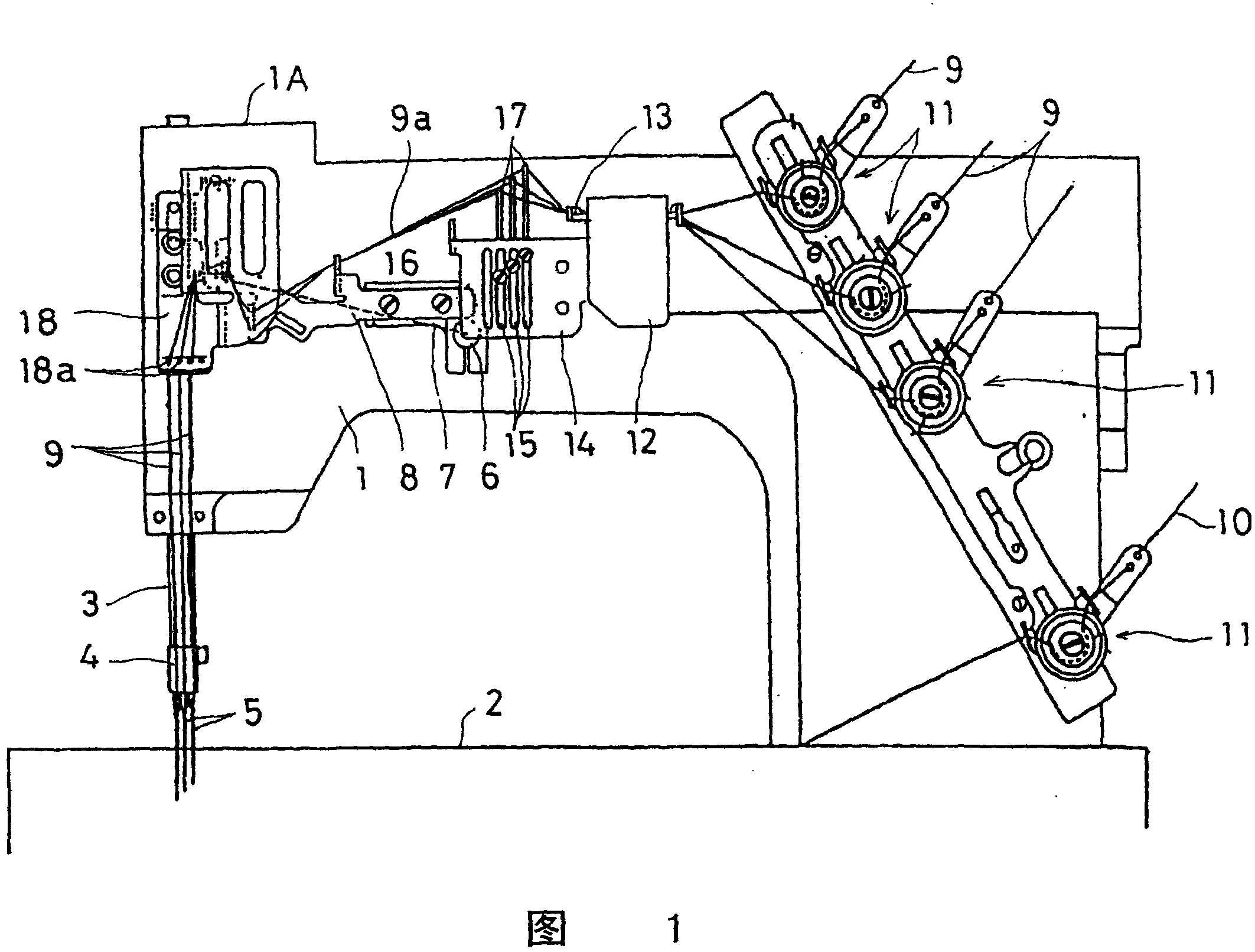

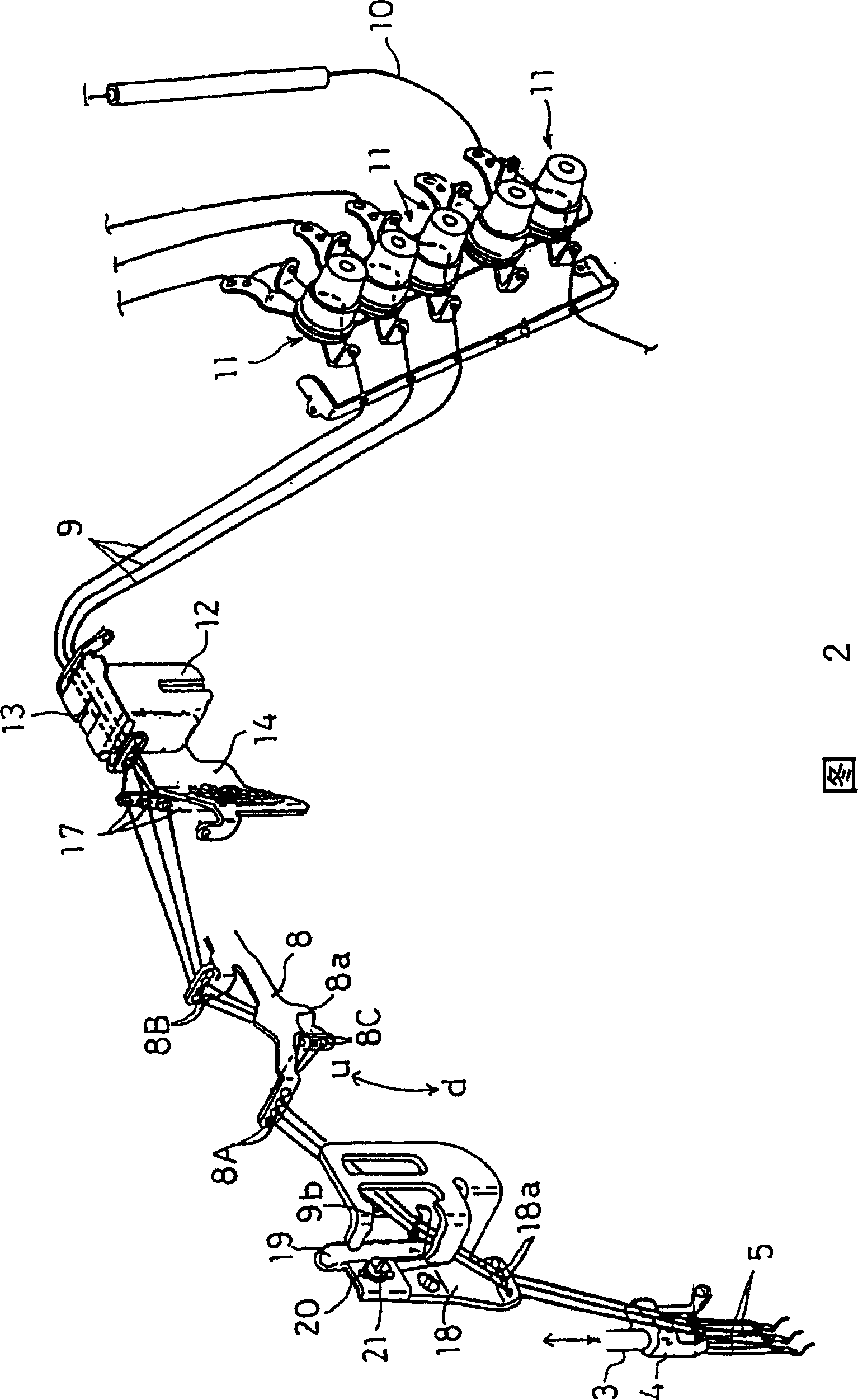

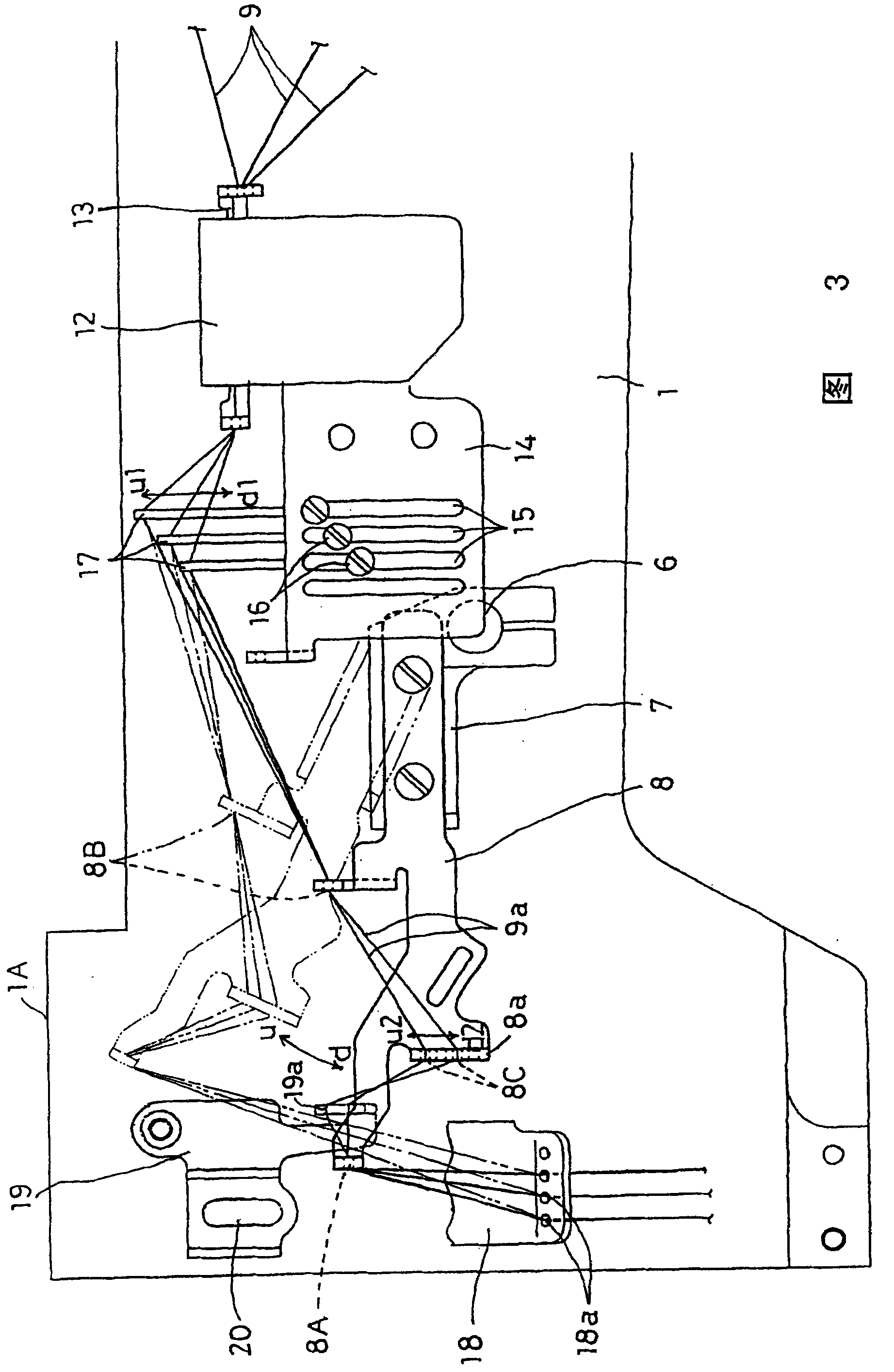

[0017] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0018] Figure 1 ~ Figure 3 Among them, 1 is the sewing machine arm, and 2 is the sewing machine bottom plate. A needle bar 3 is supported at the left end (front end) of the sewing machine arm 1. The needle bar 3 is supported by a well-known crank mechanism and inserted through the sewing machine arm. The drive spindle (not shown) in 1 is linked to reciprocate in the vertical direction, and the needle bar 3 is provided with a blank pressing mechanism adjacent to it (because it is well known, detailed description is omitted).

[0019] At the lower end of the needle bar 3, three needles 5 are installed through the needle clamp 4, and at the same time, the range of the up and down reciprocating movement of the needle bar 3 is set to: even when the needle bar 3 moves up to the top dead center In the state, the upper end does not extend upward from the upper wall portion 1A of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com