Shield tunneling machine

A technology of shield machine and main engine, which is applied in safety devices, mining equipment, earthwork drilling and mining, etc. It can solve the problems of stubborn impurities stuck in the slot knife gap and dust flying, so as to avoid blockage, reduce wear and save consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

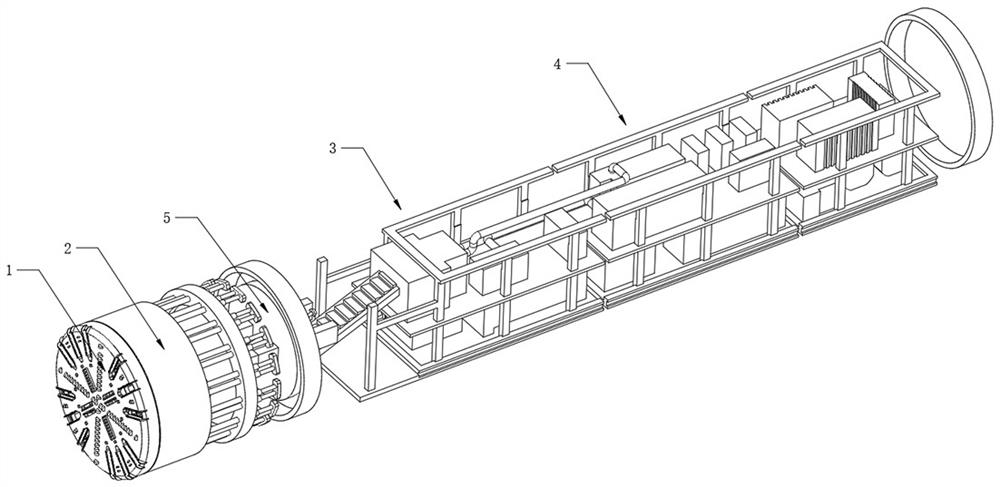

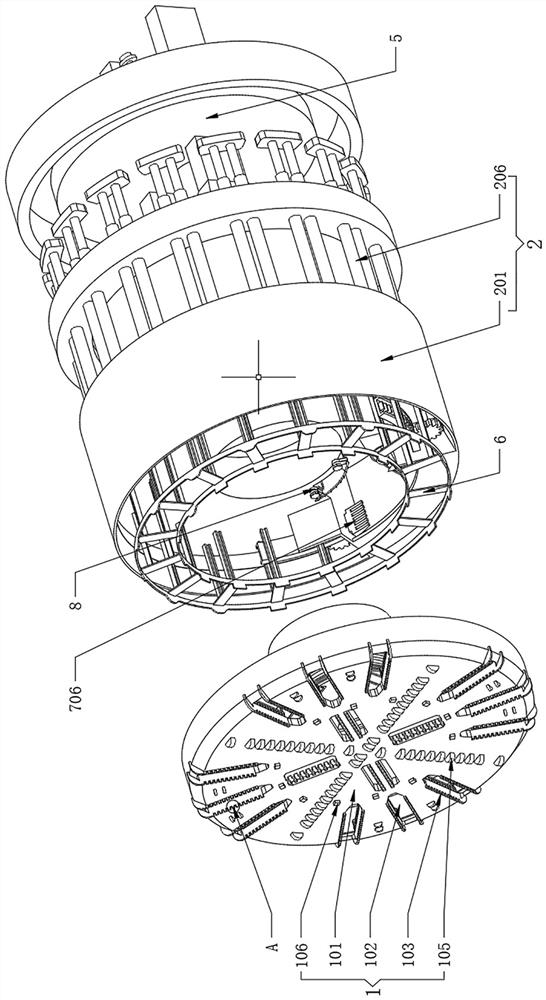

[0040] see Figure 1-7 , a shield machine, including a cutter head 1 and a host structure 2;

[0041] refer to figure 2 , the cutter head 1 is fixedly assembled at one end of the host structure 2, the inner wall of the host structure 2 close to the cutter head 1 is fixedly assembled with an internal structure 6, and the bottom of the inner wall of the host structure 2 near the cutter head 1 is fixedly provided with a crushing mechanism 7, The inner wall of the host structure 2 is located above the crushing mechanism 7 and is fixedly assembled with a water mist dust removal assembly 8. The host structure 2 is used to control the rotation of the cutter head 1 to complete the work of excavating the tunnel. Component 8 is then used to realize the work of dedusting.

[0042] refer to figure 1 , the host structure 2 is fixedly installed with a transporter 9 inside, the end of the host structure 2 facing away from the cutter head 1 is fixedly assembled with a segment mounting mac...

Embodiment 2

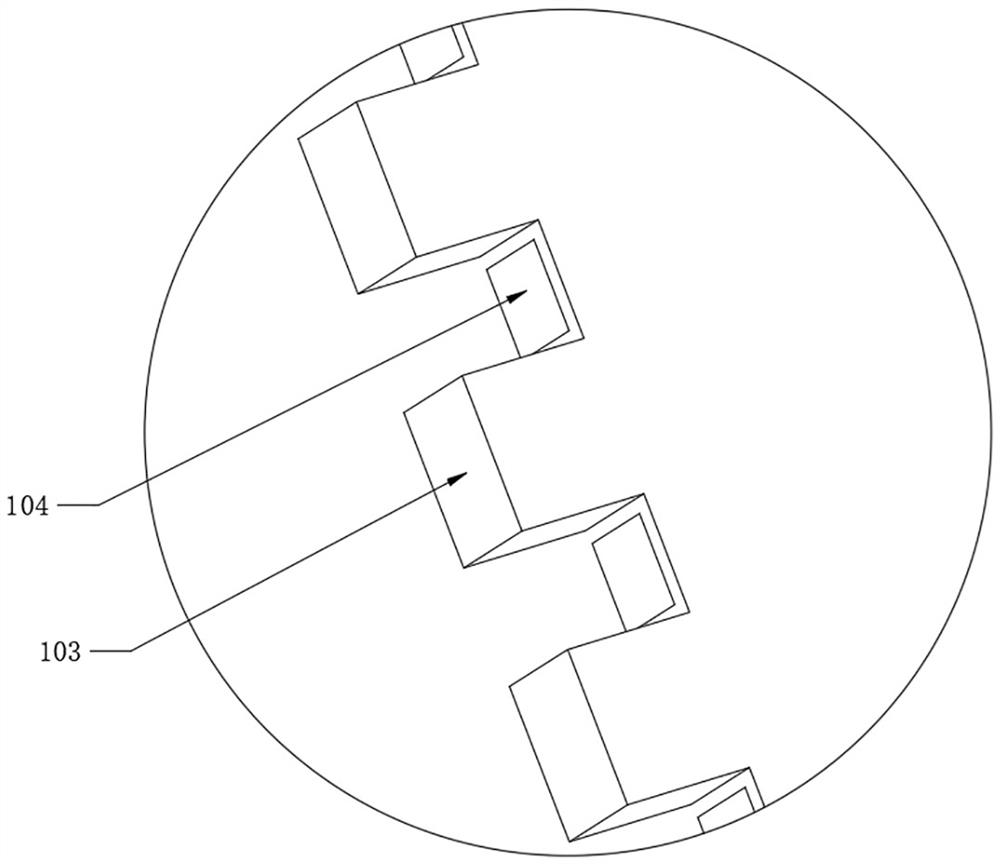

[0050] see Figure 6 and Figure 8 , a shield machine, including a cutter head 1 and a host structure 2;

[0051] refer to Figure 6 The crushing mechanism 7 also includes a rockfall chamber 701, which is fixedly arranged at the bottom end of the outer wall of the support pipe 201. Both sides of the rockfall chamber 701 are slidably assembled with sliding channel steel 703, and the inside of the sliding channel steel 703 is equidistantly fixed with guide rails The movable teeth 704, the opposite ends of the two driven teeth 704 are located inside the rockfall chamber 701 and are fixedly welded with crushing rakes 706. During the excavation process, soil residue enters the inner side of the disc body 101 after passing through the through hole 102. Finally, it automatically falls into the rockfall chamber 701 .

[0052] refer to Figure 8 , both sides of the inner bottom of the support tube 201 are fixedly installed with three-phase motors, and the output shafts of the three...

Embodiment 3

[0055] see Figure 9-10 , a shield machine, including a cutter head 1 and a host structure 2;

[0056] refer to Figure 10 , the water mist dedusting assembly 8 also includes a water injector 801, the two water injectors 801 are fixedly installed on the upper surface of the rockfall chamber 701, and are fixedly connected with the inner wall of the support pipe 201, and a driving wheel 802 is installed on the side wall of the water injector 801 for rotation , and the drive wheels 802 are all embedded in the grooves provided on the outer surface of the ring groove frame 208, the water injector 801 is rotatably installed with a crankshaft 808 fixedly connected with the drive wheel 802, and the end of the crankshaft 808 is rotatably equipped with a deflection rod 809, and the deflection rod 809 The end is rotatably connected with a piston 810, and the other side of the water injector 801 is fixedly connected with a water outlet pipe 803 and a water suction pipe 806 on both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com