Patents

Literature

471results about How to "Achieve dust removal effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dust removal method and device applied to air conditioner outdoor heat exchanger

InactiveCN104729016AAchieve dust removal effectEfficient removalMechanical apparatusCleaning heat-transfer devicesEngineeringHigh heat

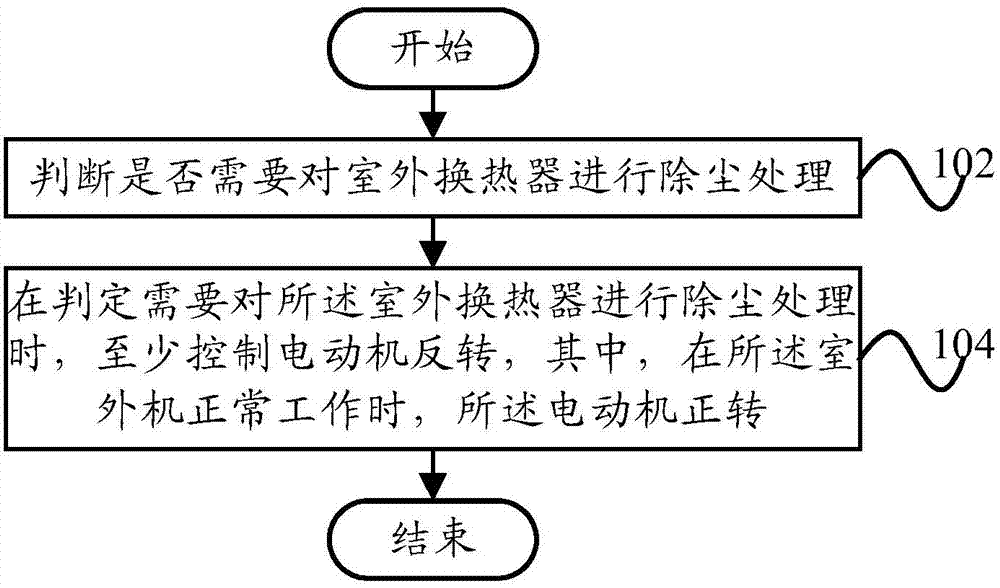

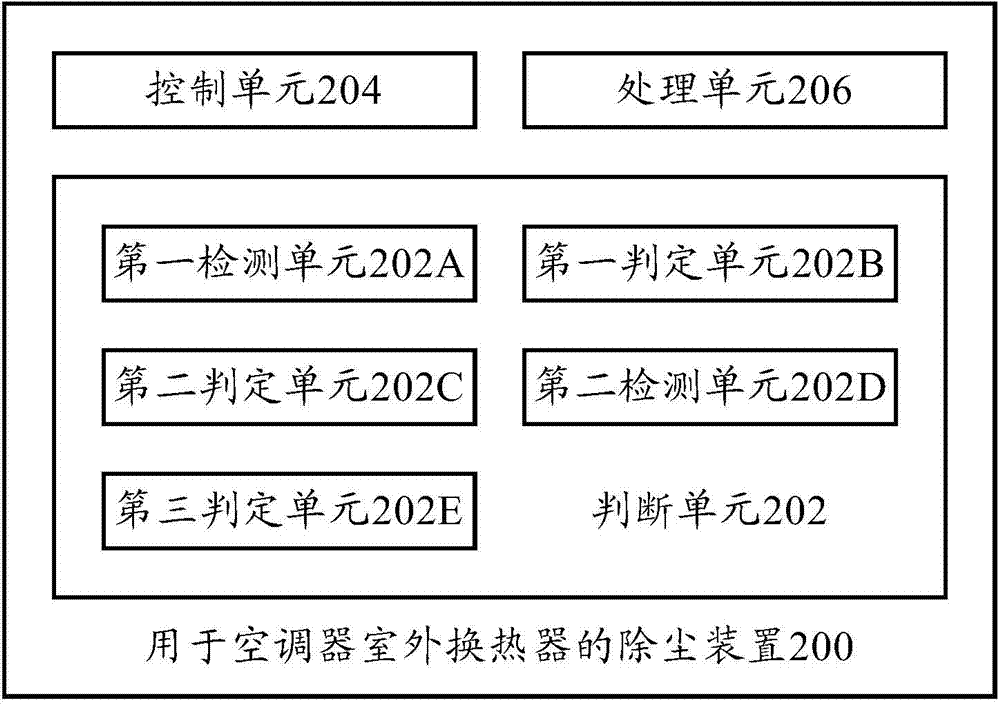

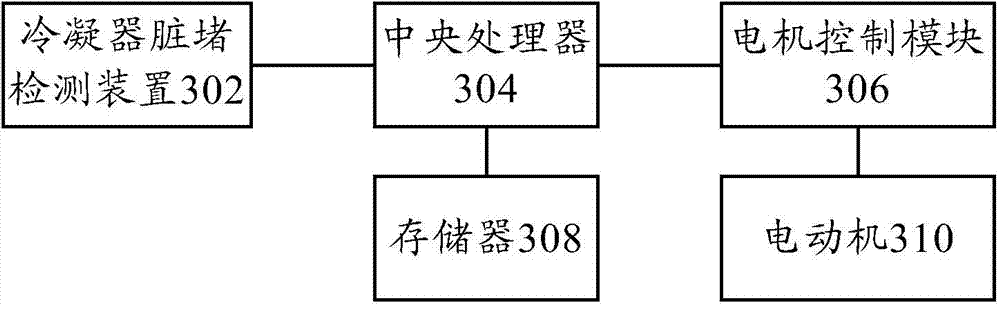

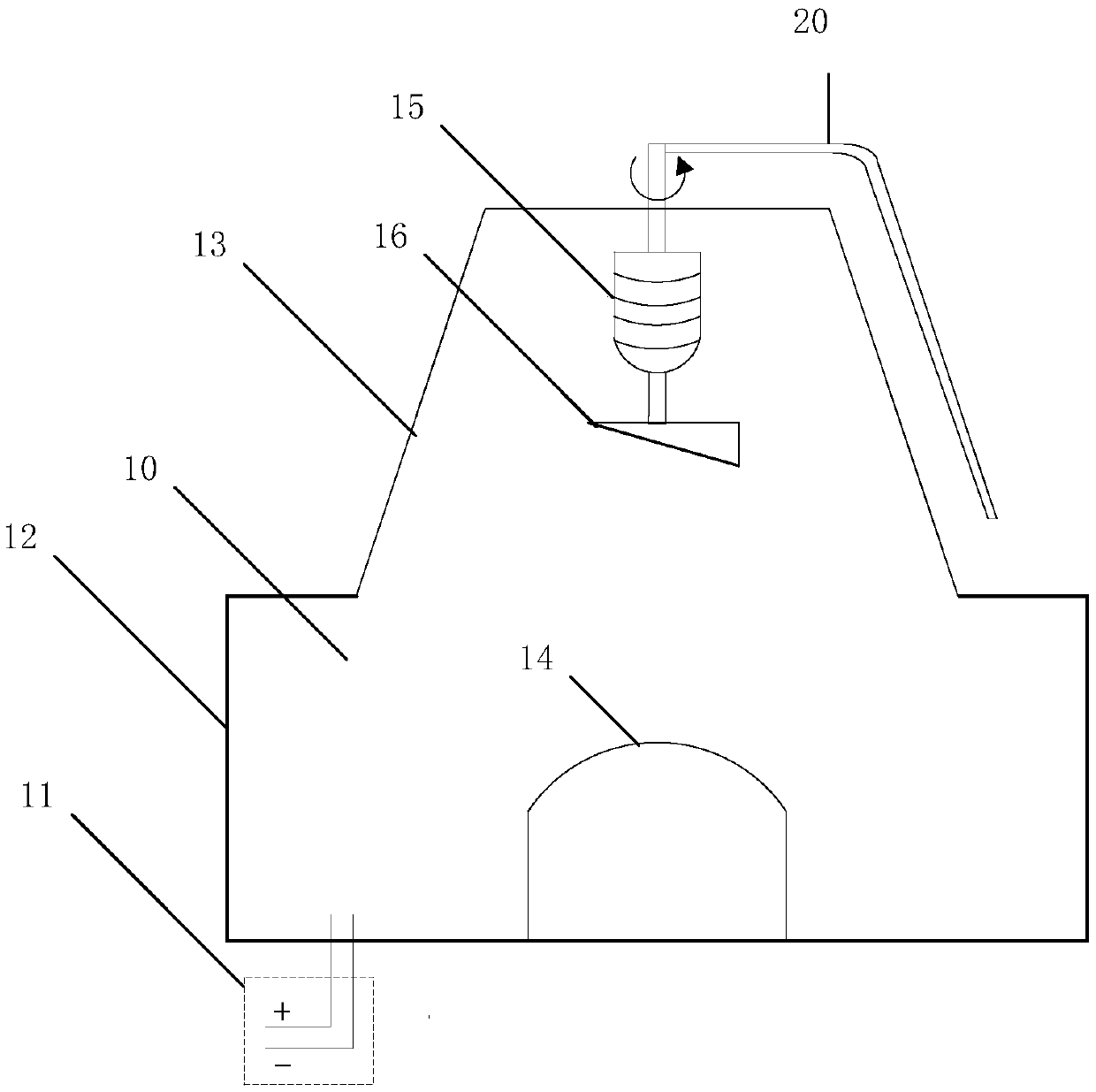

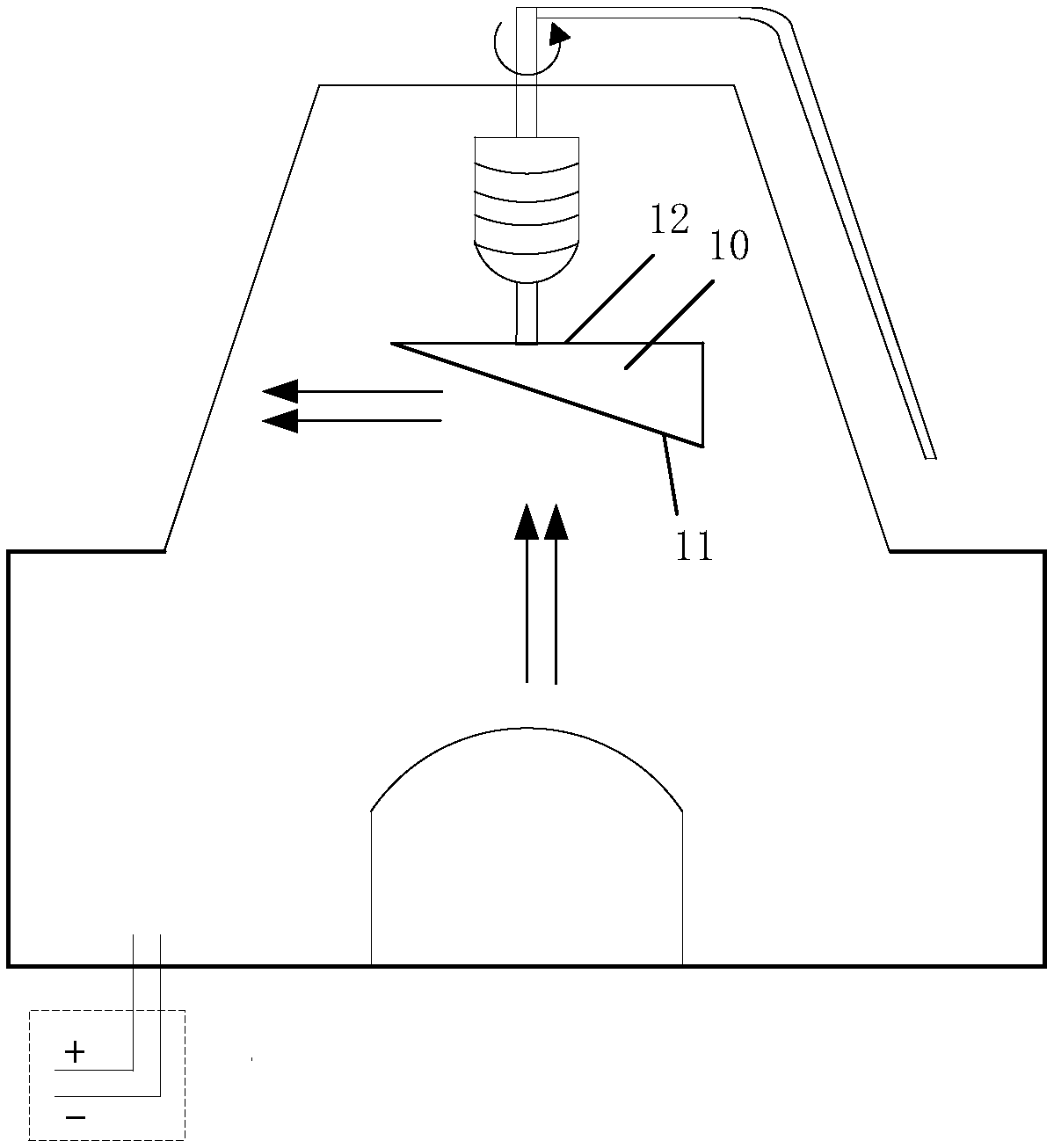

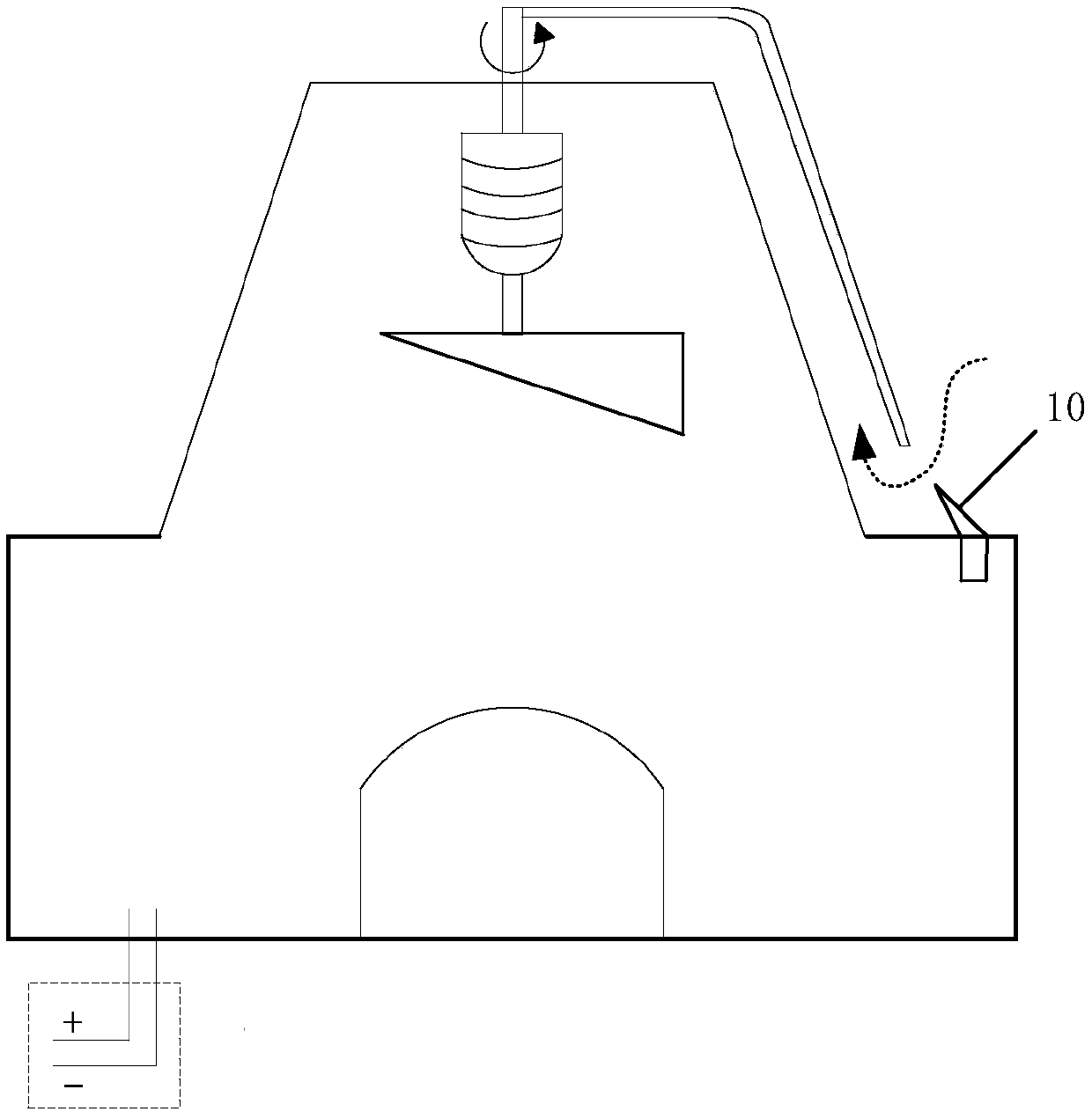

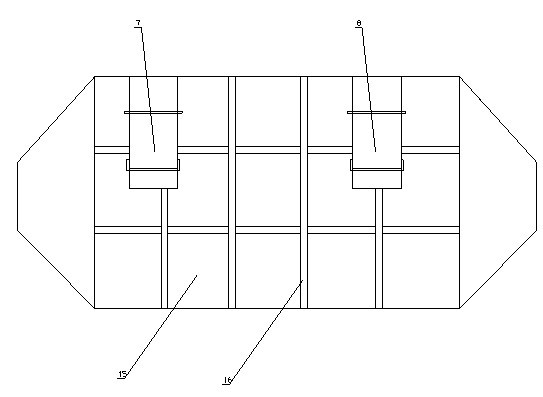

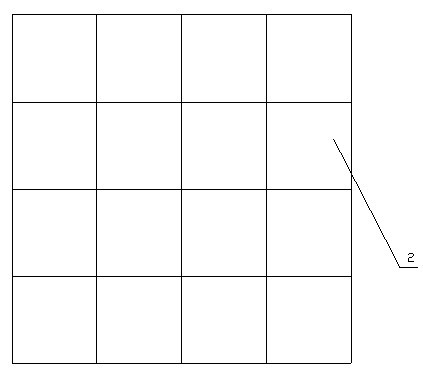

The invention provides a dust removal method and device applied to an air conditioner outdoor heat exchanger. An outdoor unit of an air conditioner comprises the outdoor heat exchanger and an air duct system composed of a motor and vanes. The dust removal method includes the following steps that whether dust removal processing needs to be carried out on the outdoor heat exchanger is judged; when it is judged that the outdoor heat exchanger needs dust removal processing, at least the motor is controlled to rotate reversely, and when the outdoor unit works normally, the motor rotates forwards. By means of the technical scheme, the effect that the air conditioner automatically carries out dust removal on the outdoor heat exchanger is realized, a higher heat exchange efficiency of a condenser is guaranteed, and the complex operation of detaching the outdoor unit when the condenser is cleaned manually is avoided.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

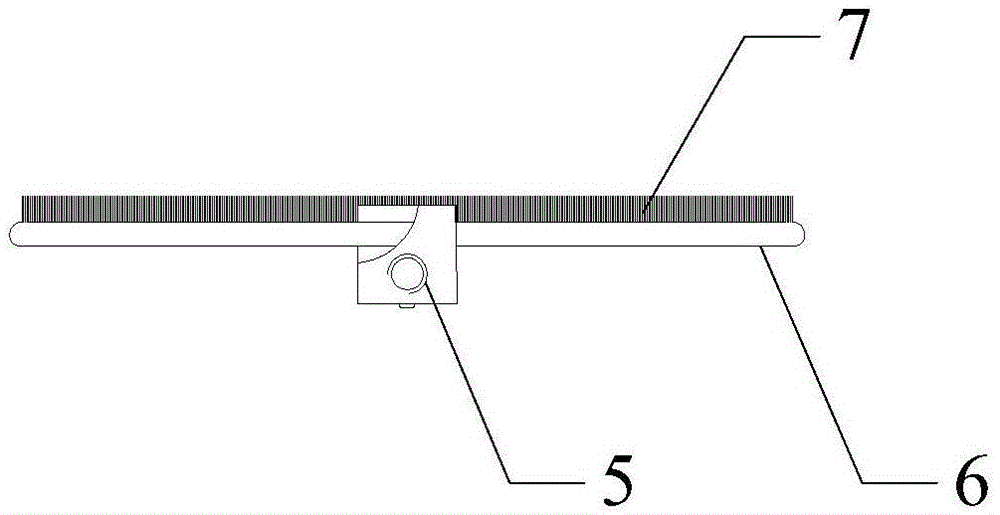

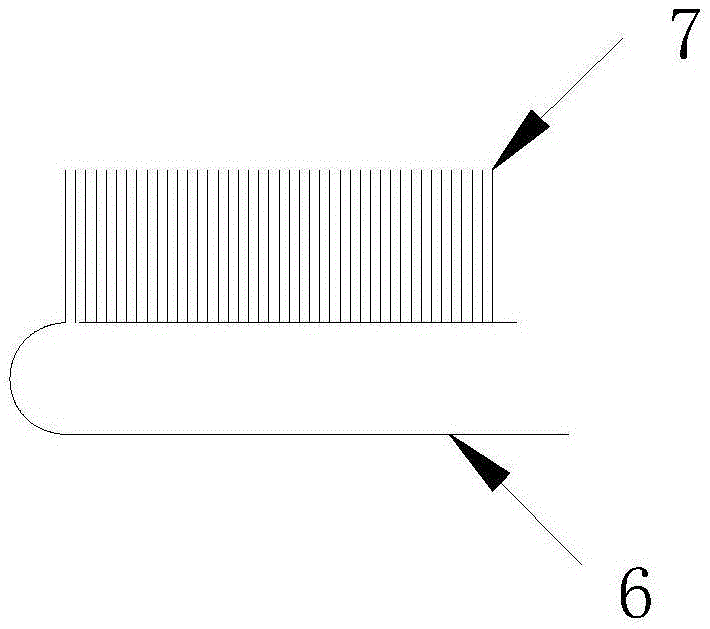

Air conditioner and cleaning method for condenser of air conditioner

InactiveCN105674478ASimple structureEasy to useMechanical apparatusSpace heating and ventilation safety systemsService timeElectrical and Electronics engineering

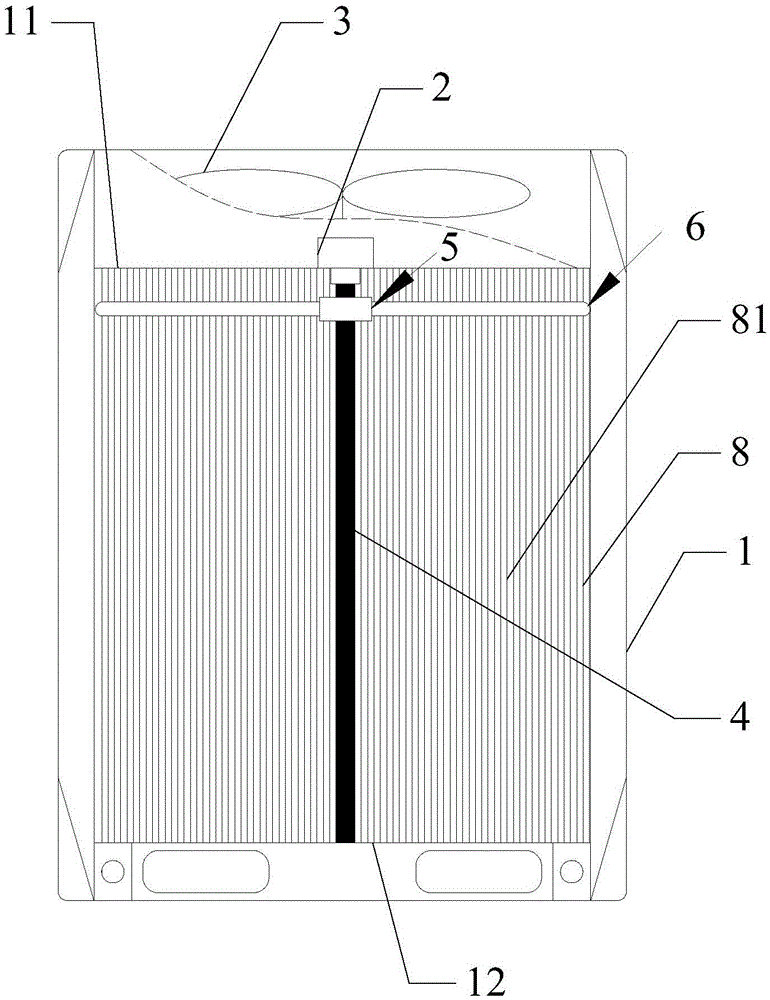

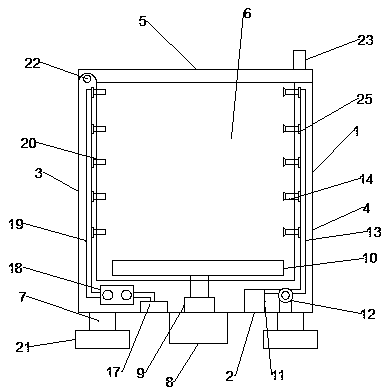

The invention discloses an air conditioner and a cleaning method for its condenser. The air conditioner includes a condenser, and fins are arranged on the condenser. The air conditioner also includes: a cleaning device for cleaning dust on the fins of the condenser. The cleaning device includes : the motor arranged above the condenser, the transmission mechanism connected with the motor and driven by the motor, and the dust brushing part connected with the transmission mechanism and driven by the transmission mechanism to reciprocate, the dust brushing part is set towards the condenser and connected with the condenser fin contact. The invention can effectively remove the dust on the fins of the condenser; in addition, the rain signal can also be detected by the rain detection device, and the fins of the condenser can be cleaned by rain to achieve the effect of dust removal. Its structure is simple, easy to use, and high in efficiency. The heat exchange capacity of the air conditioner, and effectively prolong the service life of the air conditioner.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

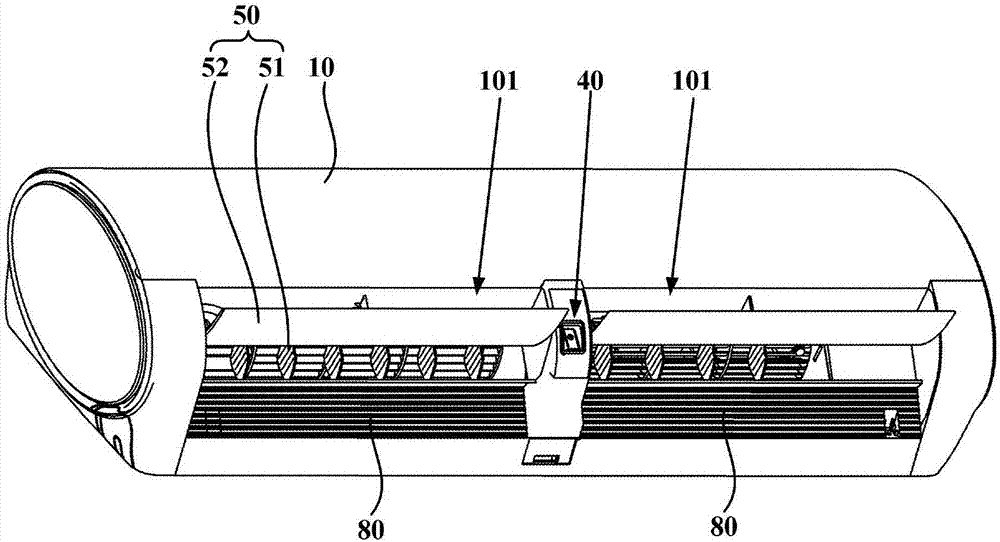

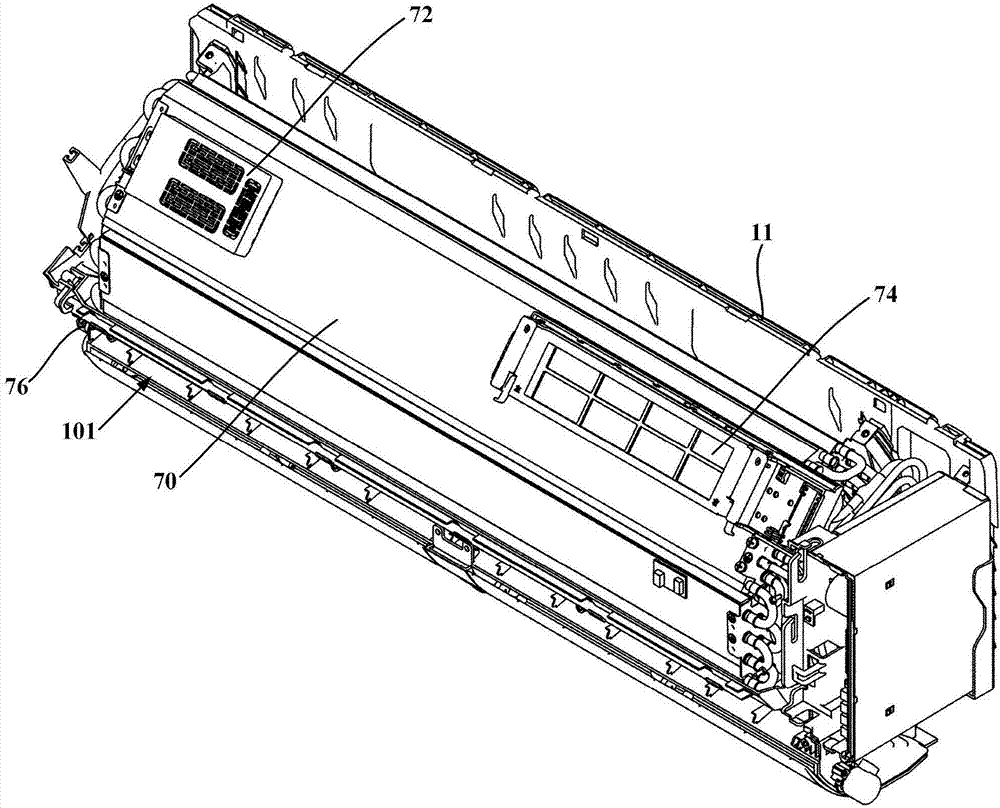

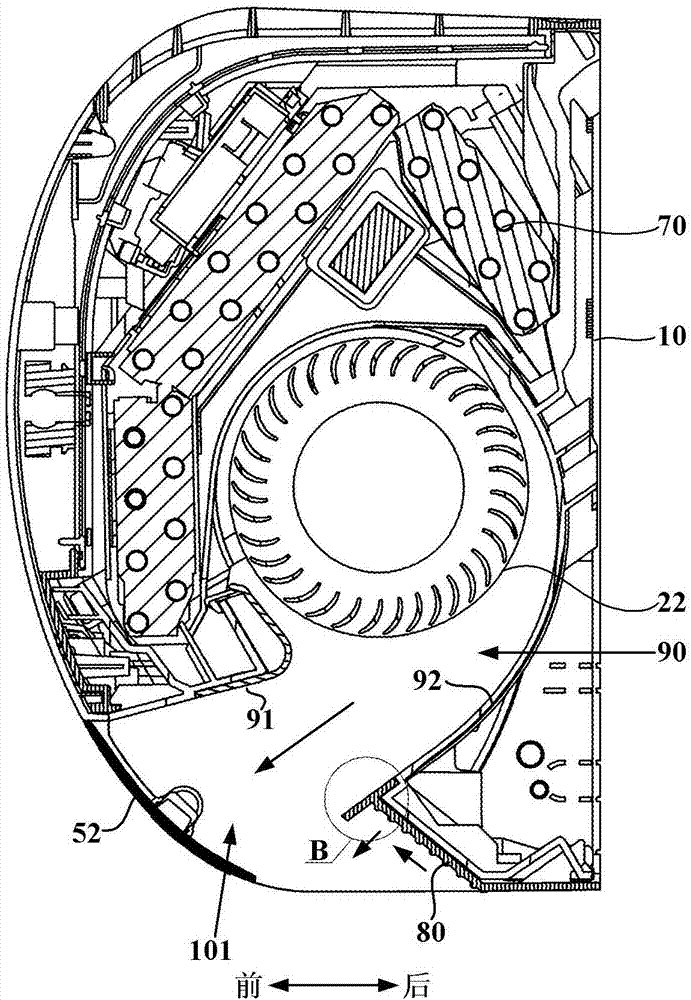

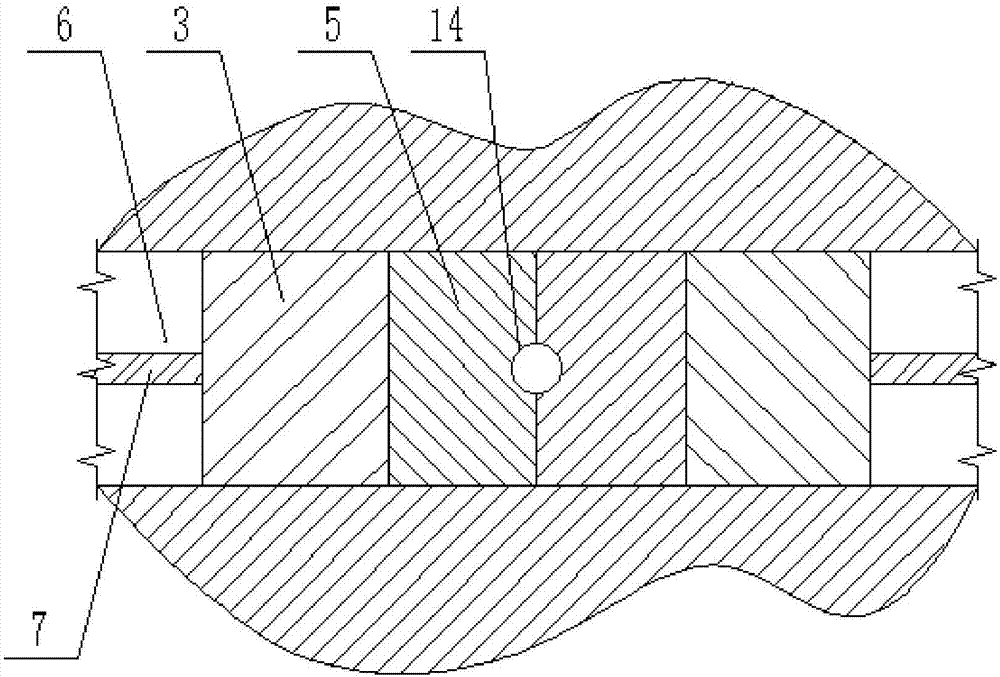

Wall-mounted type air conditioner indoor unit

ActiveCN107388371ARich air supply modeImprove user experienceMechanical apparatusCondensate preventionAir cleaningEngineering

The invention provides a wall-mounted type air conditioner indoor unit. The wall-mounted type air conditioner indoor unit comprises a shell, an evaporator, a first air channel, a second air channel, a first cross flow fan, a second cross flow fan and an air cleaning device. The bottom of the shell is provided with two air outlets which are arranged side by side from in the left-right direction. The evaporator is arranged in the shell. The first air channel and the second air channel are arranged in the shell side by side in the left-right direction and used for guiding heat exchange air obtained after heat exchange with the evaporator to the two air outlets. The axes of the first cross flow fan and the second cross flow fan both extend in the left-right direction, and the first cross flow fan and the second cross flow fan are arranged in the first air channel and the second air channel correspondingly. The air cleaning device is arranged in the shell and used for cleaning indoor air. The wall-mounted type air conditioner indoor unit enriches air supply manners and improves the cleanliness degree of supplied air.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

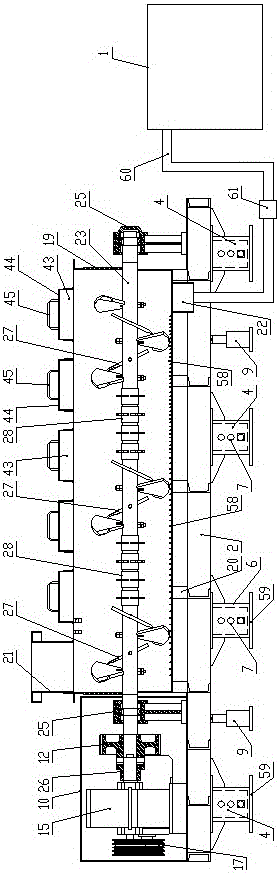

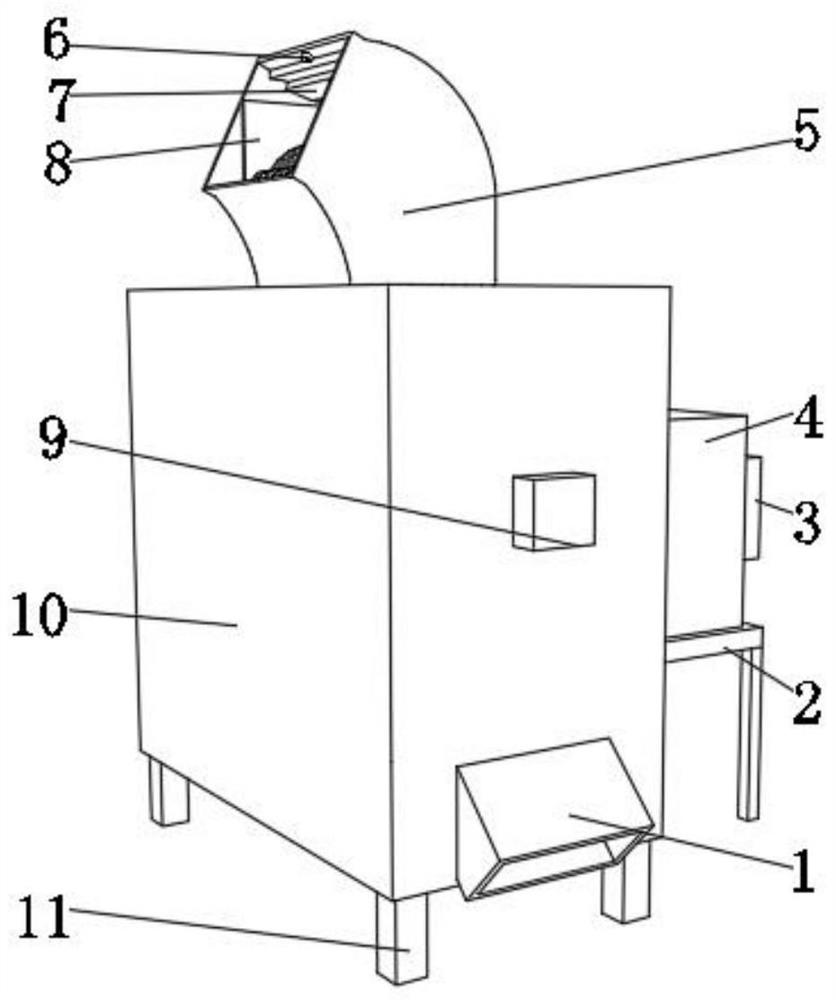

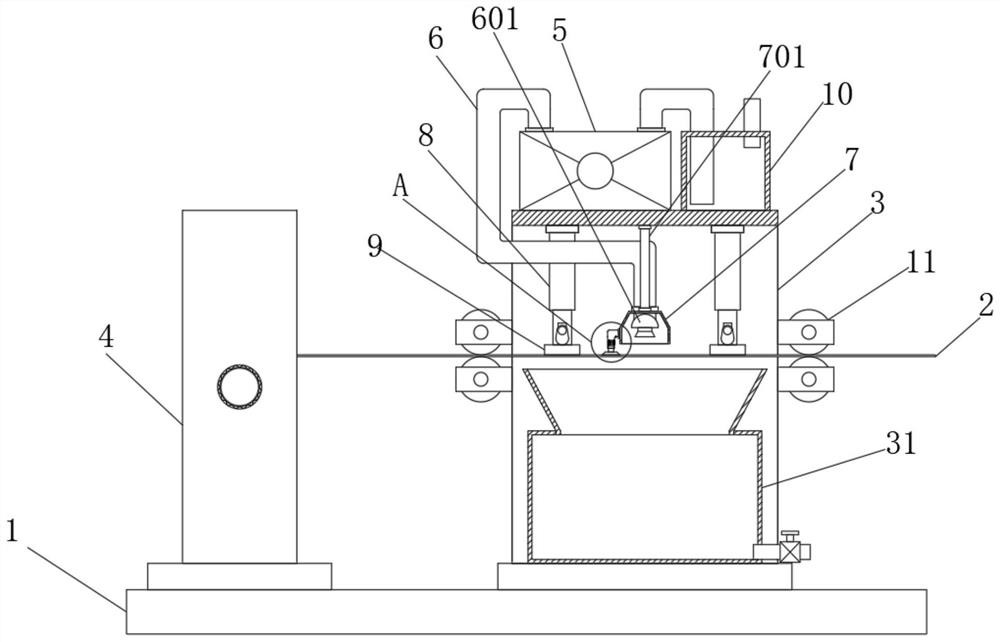

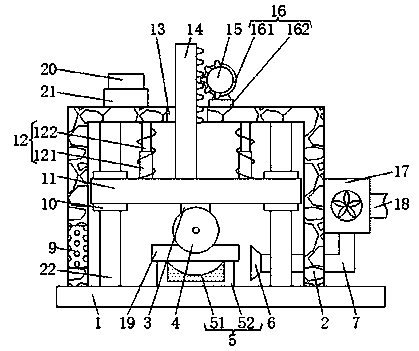

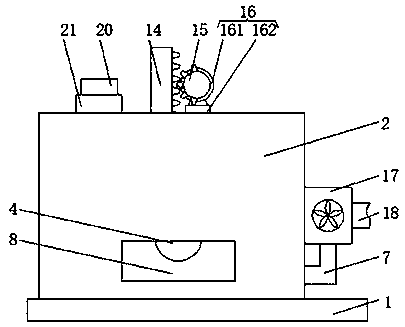

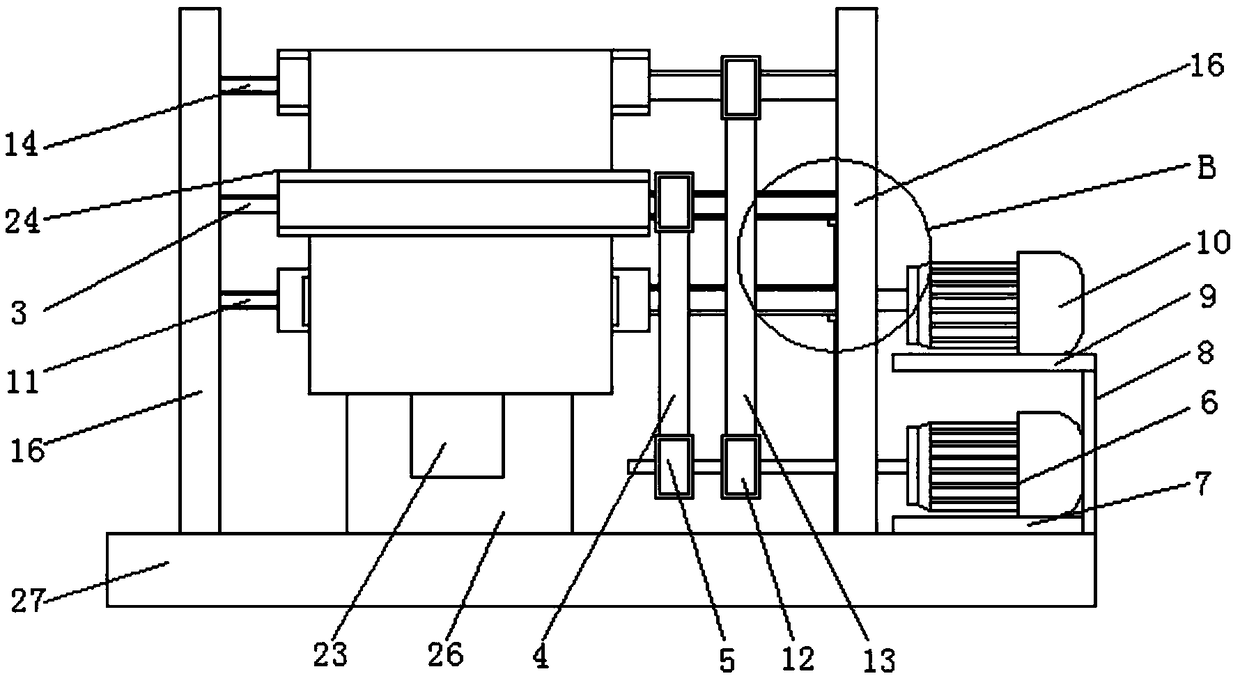

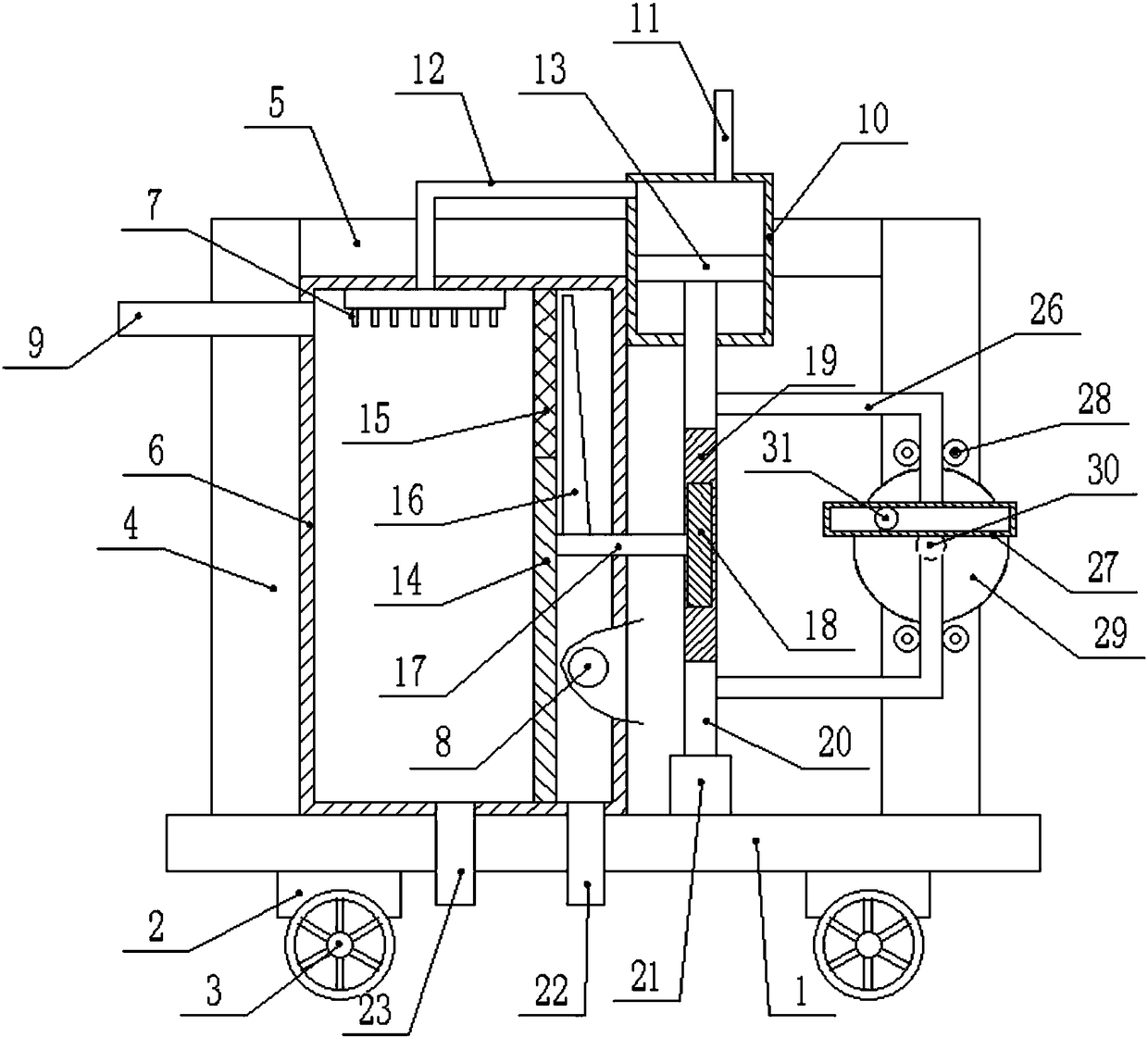

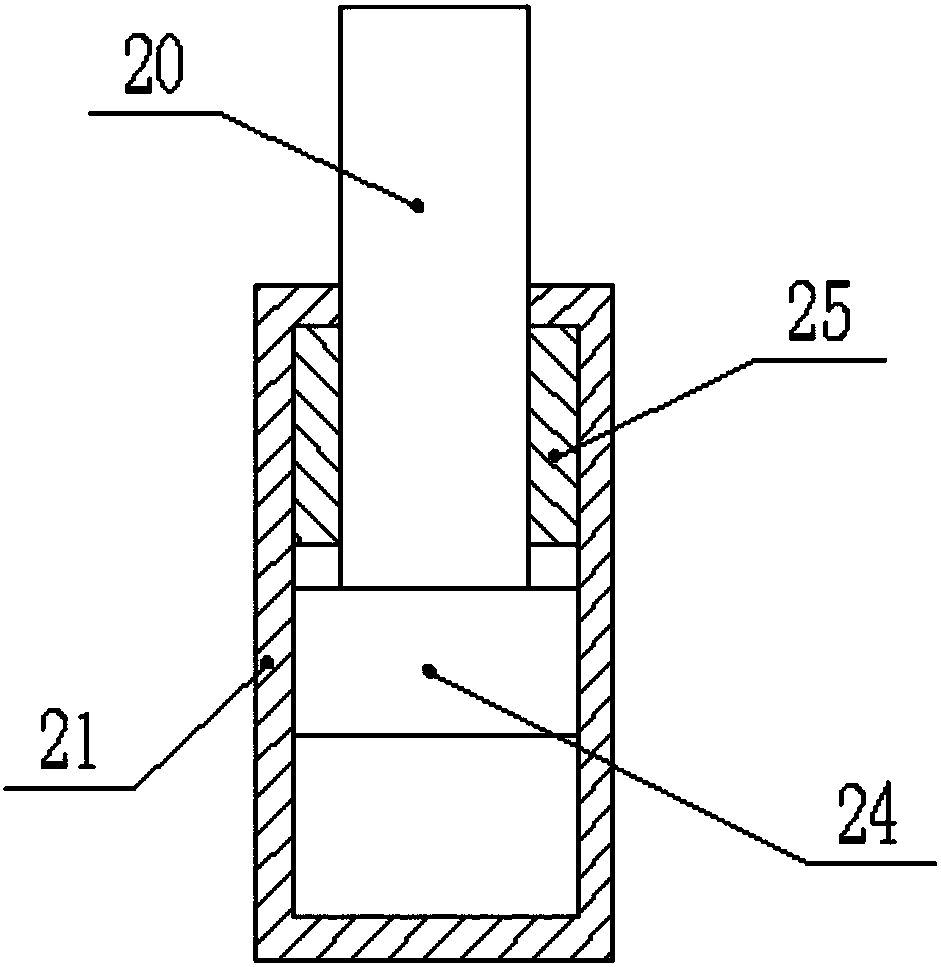

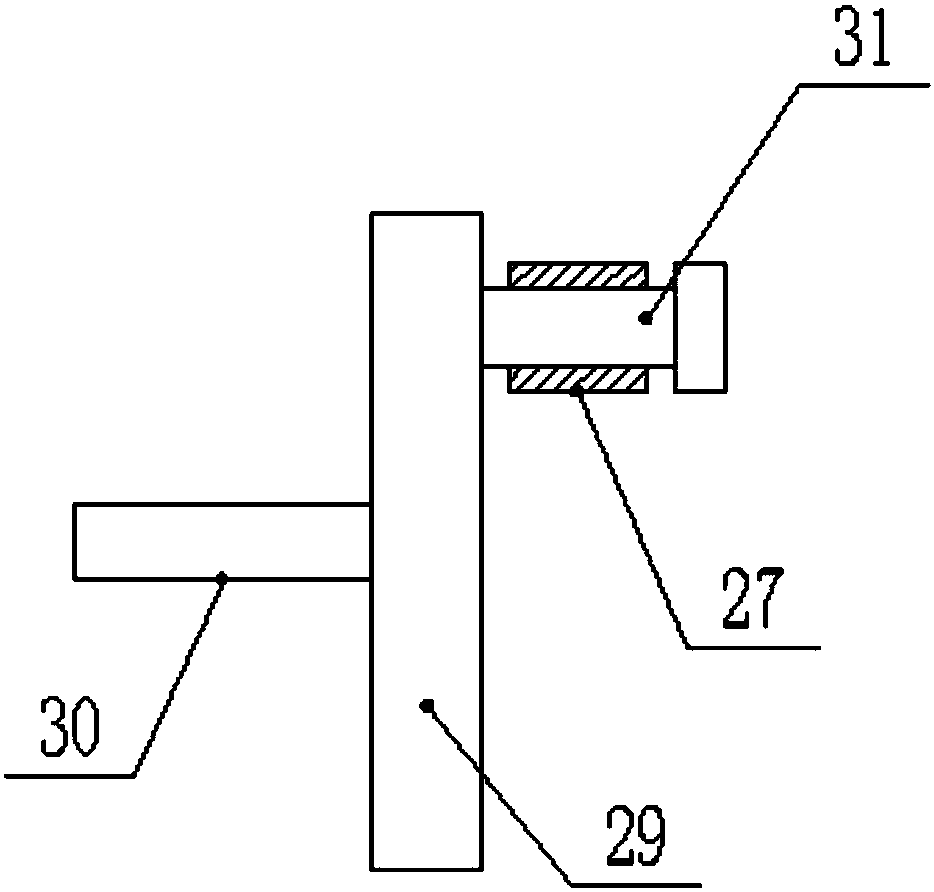

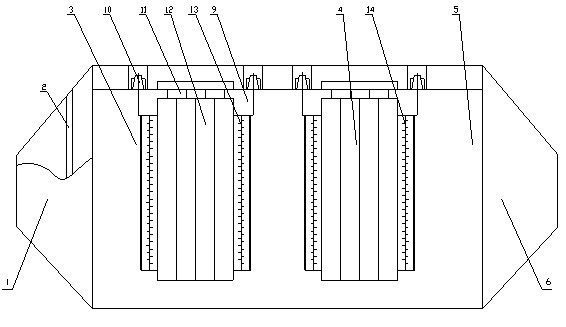

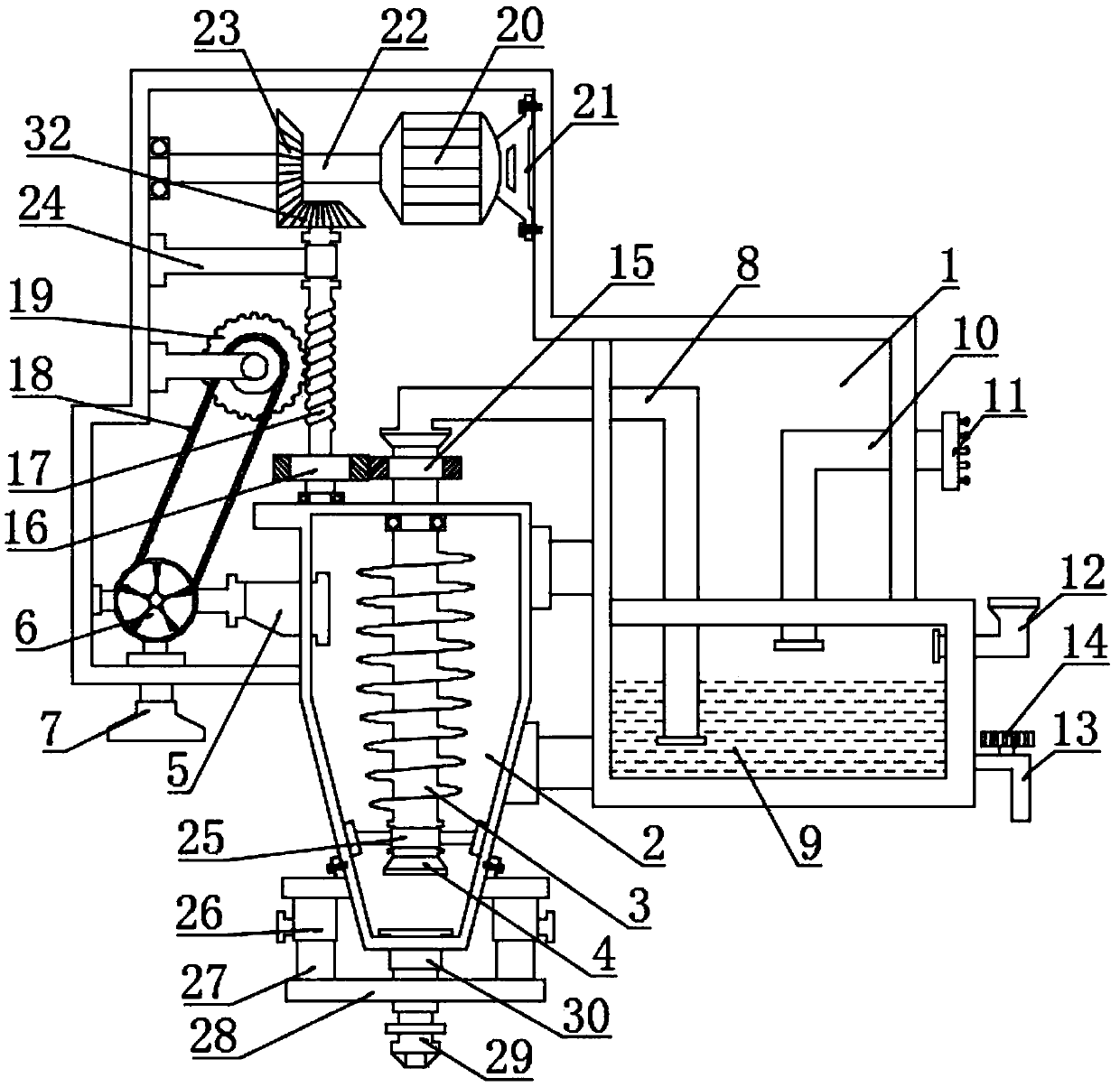

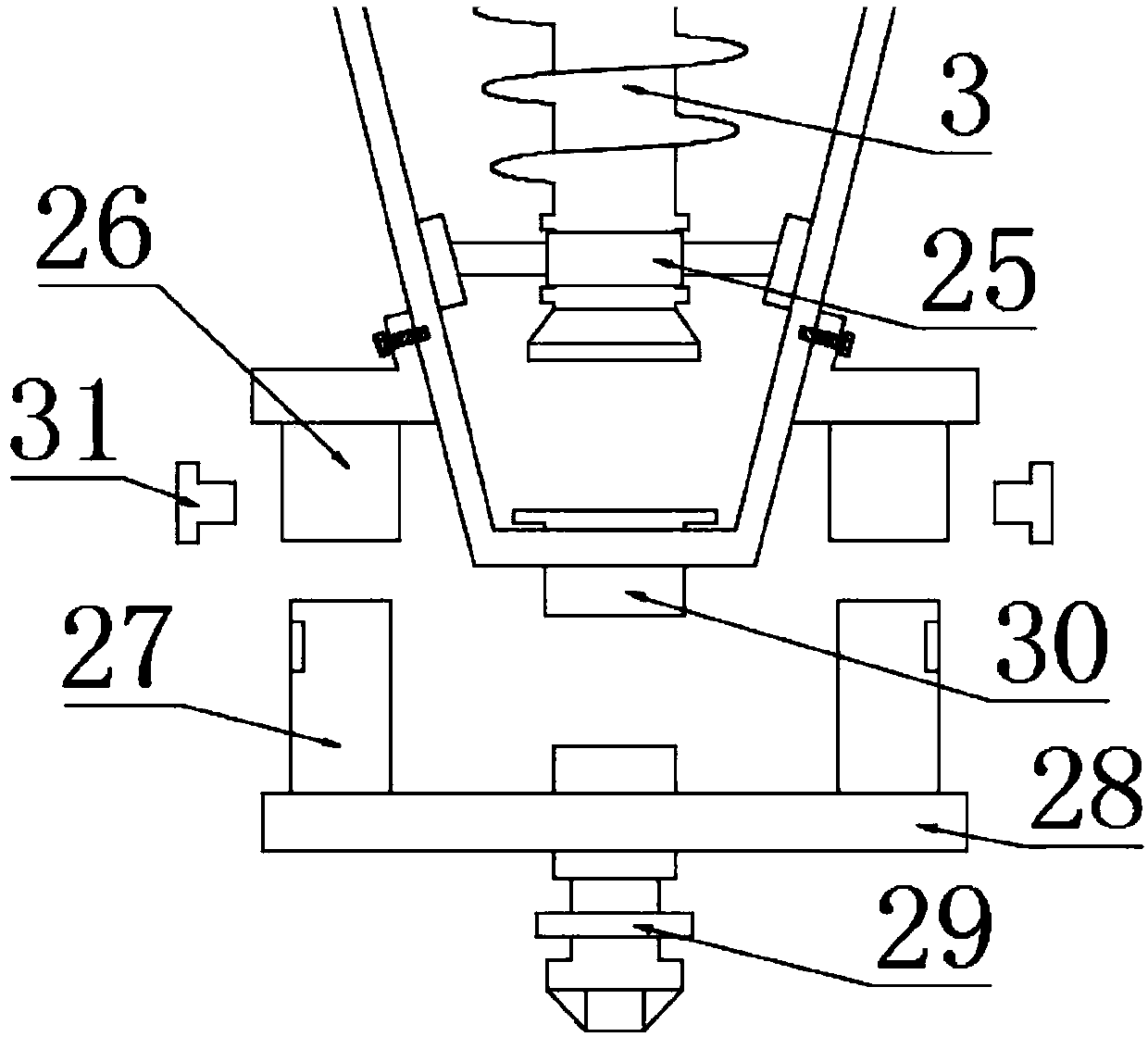

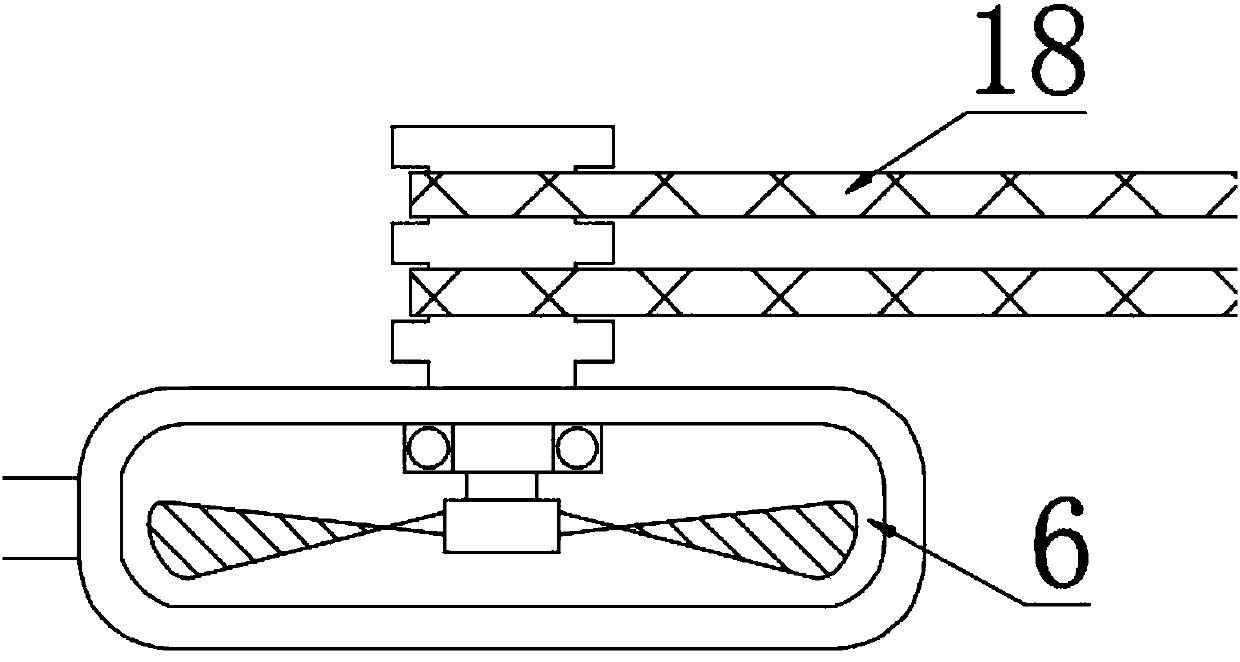

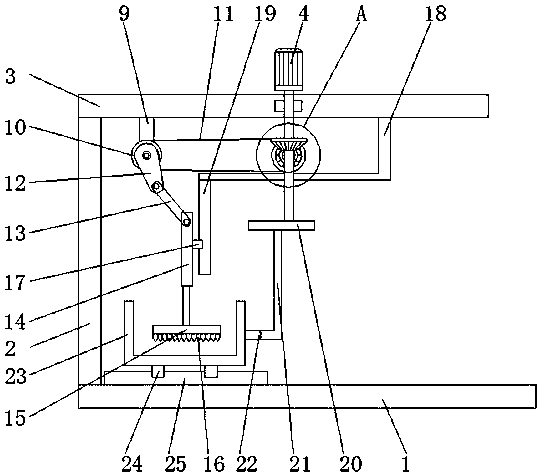

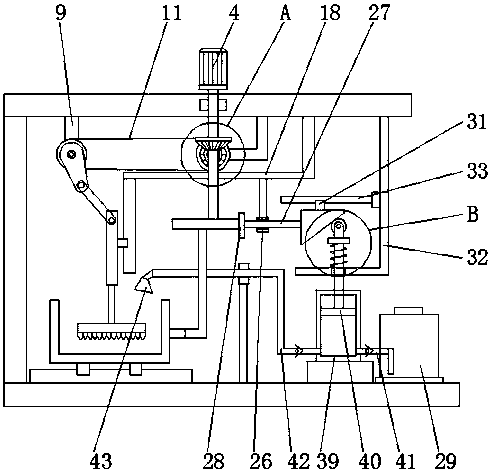

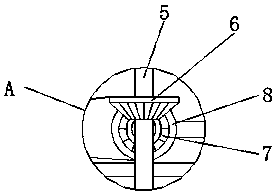

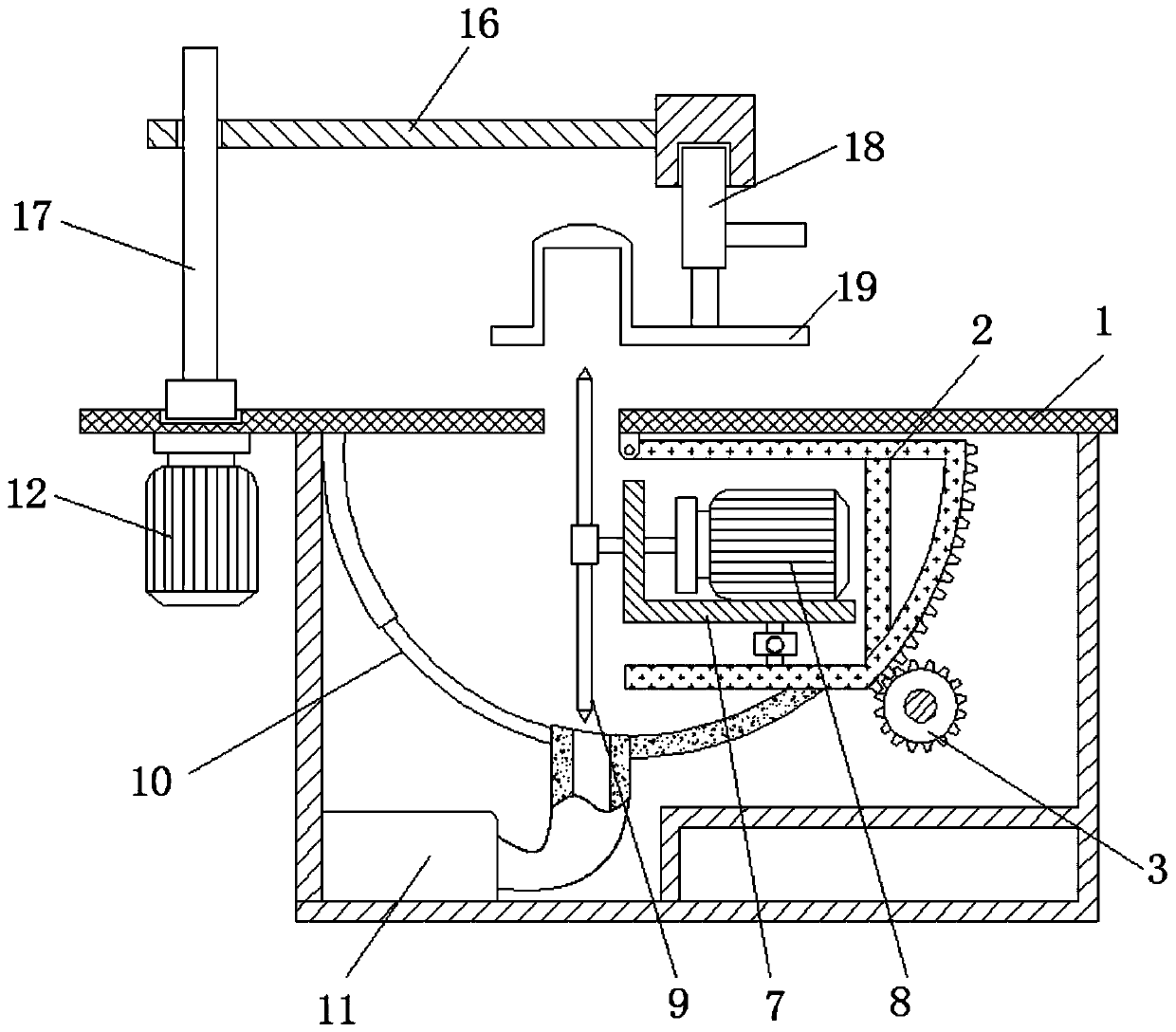

Building garbage crusher

InactiveCN106040362AAchieve recyclingIncrease profitUsing liquid separation agentGrain treatmentsDrive shaftLitter

The invention discloses a building garbage crusher which comprises a rack, wherein the left end part of the rack is provided with a power drive system; the power output end of the power drive system is in transmission connection to a material crushing system positioned at the right side of the power drive system; the material crushing system is fixed to the rack; an automatic spraying and dust-reducing system in front of a charging part of the material crushing system is arranged on the rack; a spraying part of the automatic spraying and dust-reducing system is positioned in the material crushing system; and one side of the rack is provided with a settling tank. According to the building garbage crusher disclosed by the invention, synchronous drive of a primary transmission shaft and a secondary transmission shaft is realized through the power drive system, dust generated in a crushing process is effectively reduced through the automatic spraying and dust-reducing system, cyclic utilization of water flow is realized, and material crushing is realized through the material crushing system, so that building garbage is recycled; and the building garbage crusher is simple to operate, is stable in work, is good in crushing effect, increases a waste utilization rate, reduces production cost, and is energy-saving and environmentally friendly.

Owner:HUANGHE S & T COLLEGE

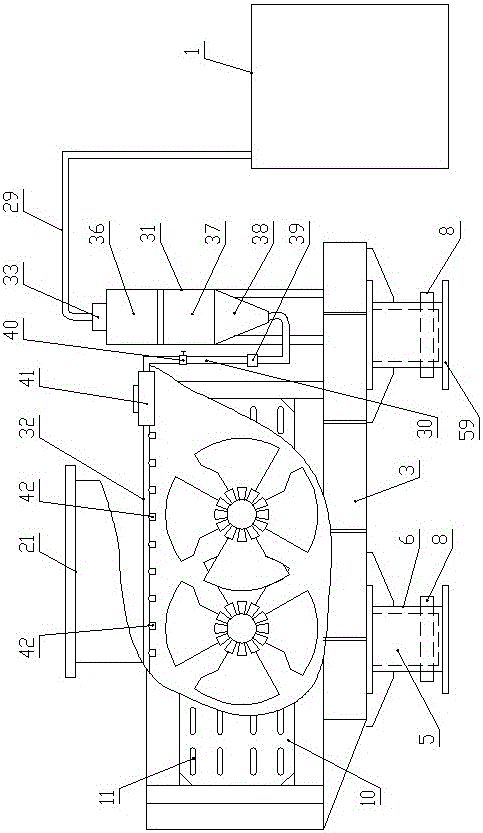

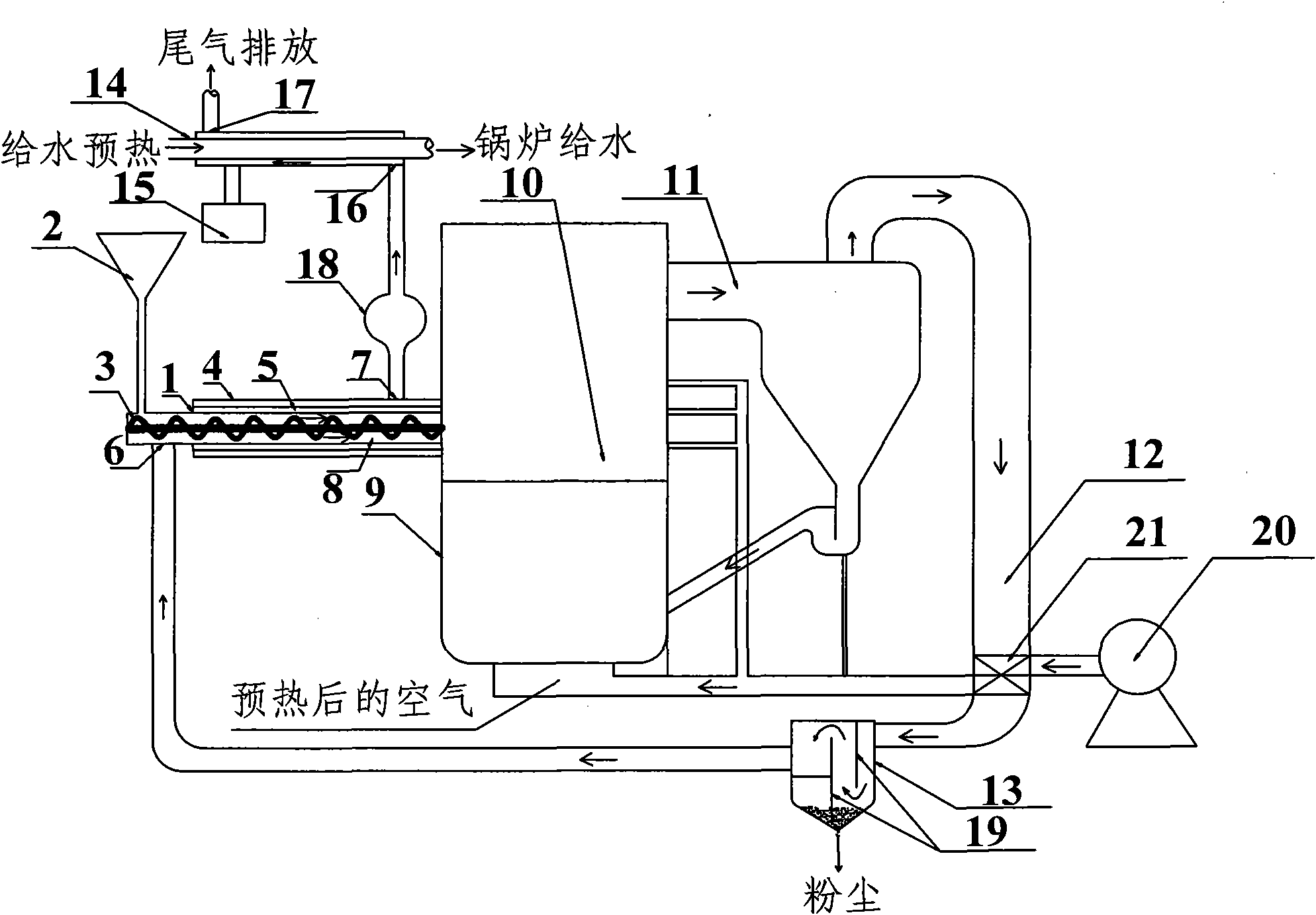

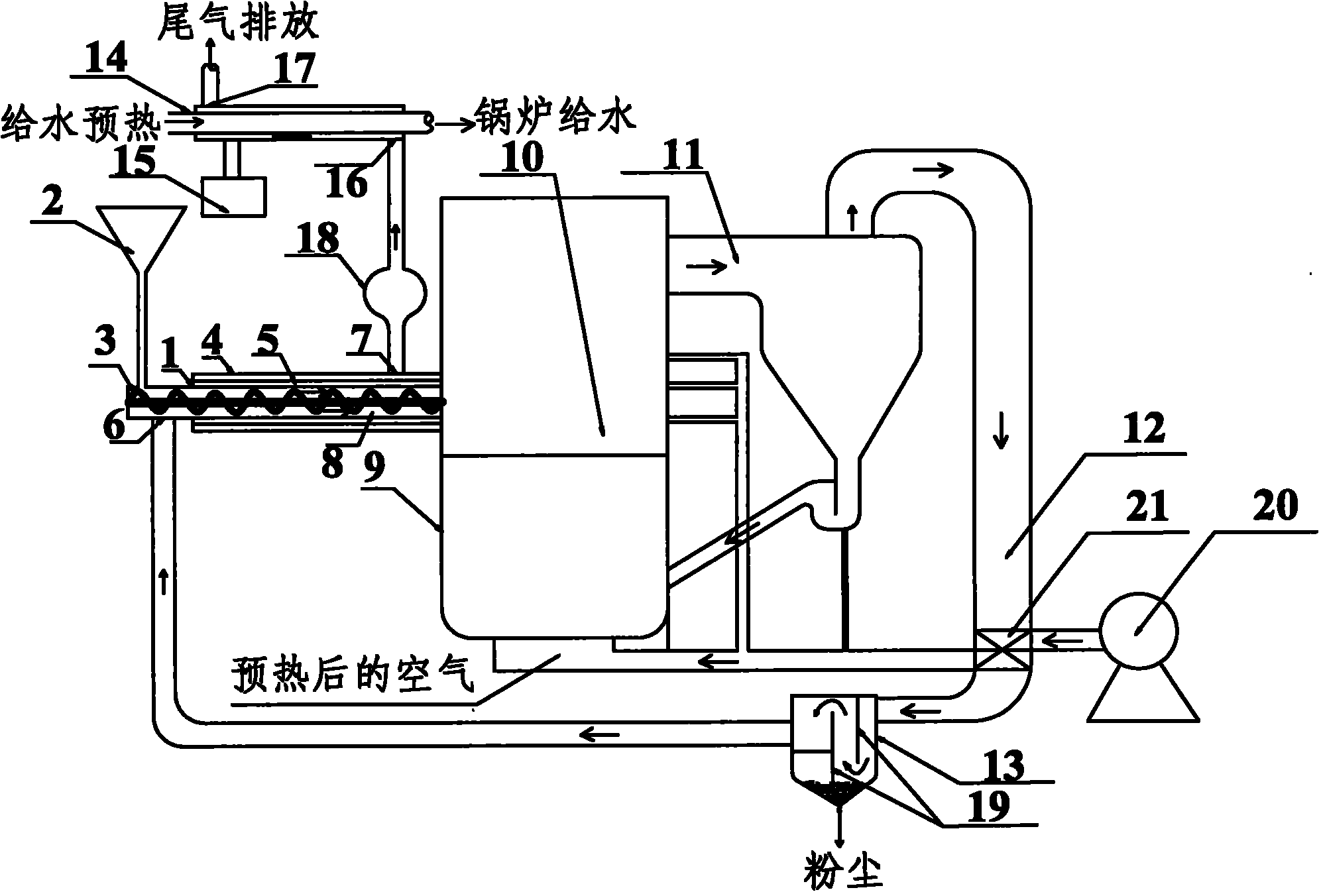

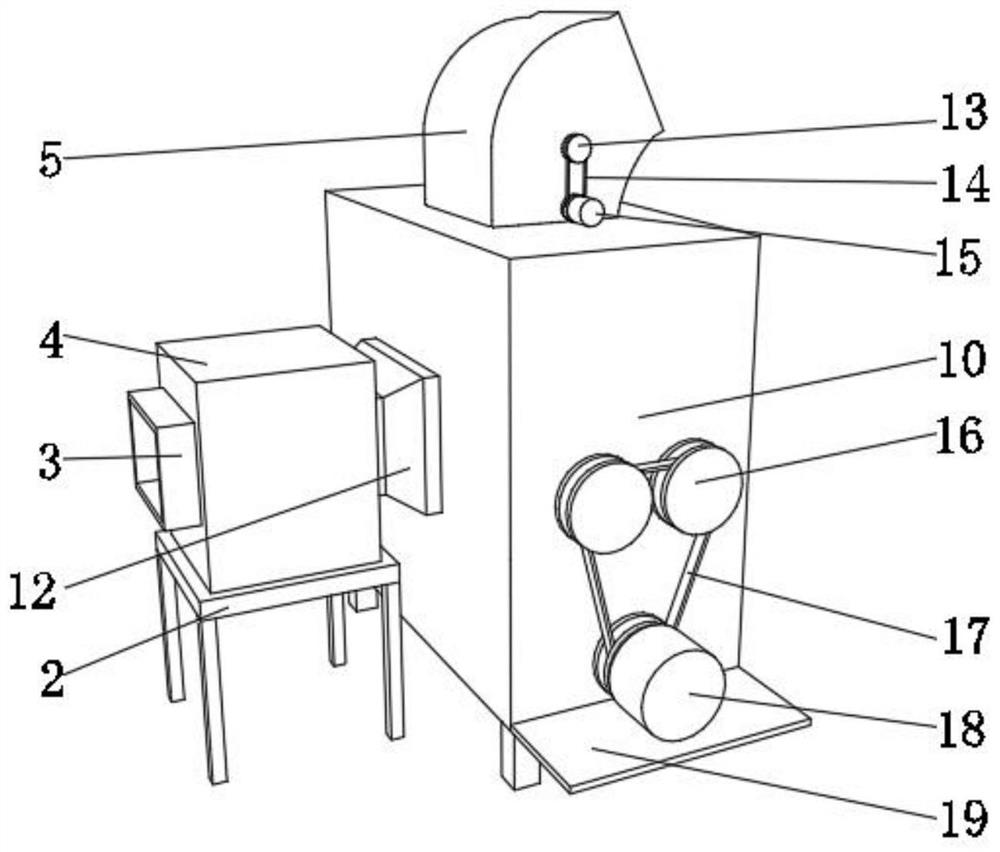

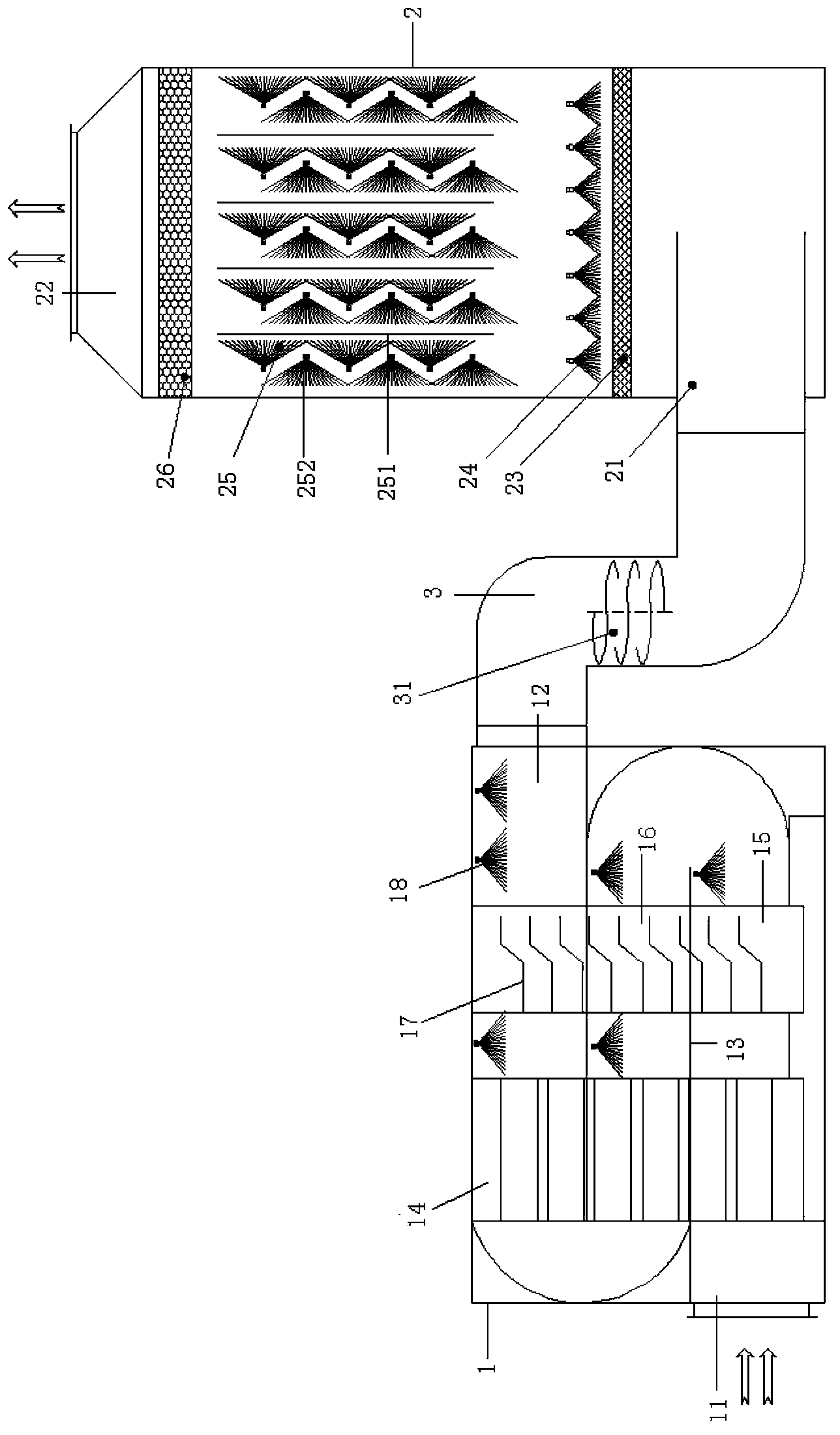

Biomass boiler system capable of saving energy and reducing emission

InactiveCN101975388AHigh efficiency, energy saving and environmental protectionRealize direct combustionSteam boilersFeed-water heatersAir preheaterCombustion chamber

The invention discloses a biomass boiler system capable of saving energy and reducing emission, comprising a dry feeding device, a boiler body, an air preheater and a water supplying preheater. The dry feeding device comprises a spiral feeder and a rotary drier, and the spiral feeder is arranged in the drying chamber in the rotary drier. The boiler body comprises a boiler furnace and a combustion chamber which are mutual connected, the material output end of the spiral feeder is arranged at the material inlet of the boiler furnace, and an exhaust gas outlet is arranged above the rotary drier. The top of the combustion chamber is connected with one end of the flue gas pipeline, the air preheater is arranged on the flue gas pipeline, the other end of the flue gas pipeline is connected with the inlet of a dust precipitation device, and the outlet of the dust precipitation device is connected with the exhaust gas inlet of the drying chamber. A mixing exhaust gas inlet is arranged on the lower side at one end of the water supplying preheater, an exhaust gas outlet is arranged on the upper side at the other end, and the exhaust gas outlet is connected with the mixing exhaust gas inlet. The system of the invention can recover 6 to 8% of the waste heat of the boiler flue gas, and has the advantages of energy saving, environmental protection, safety, and less requirements on the water content of the raw materials.

Owner:SOUTH CHINA UNIV OF TECH

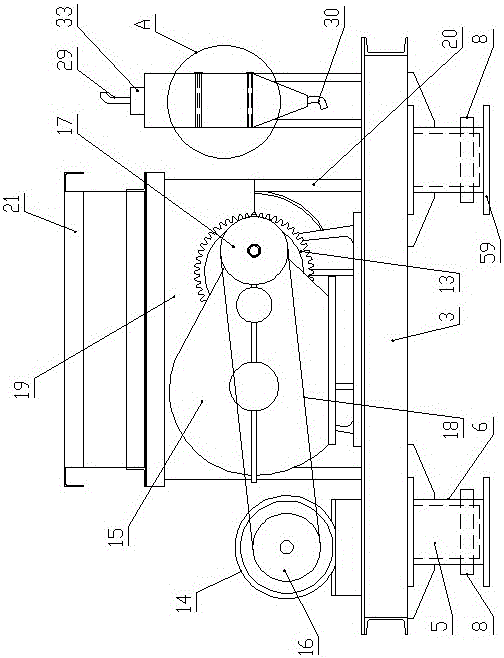

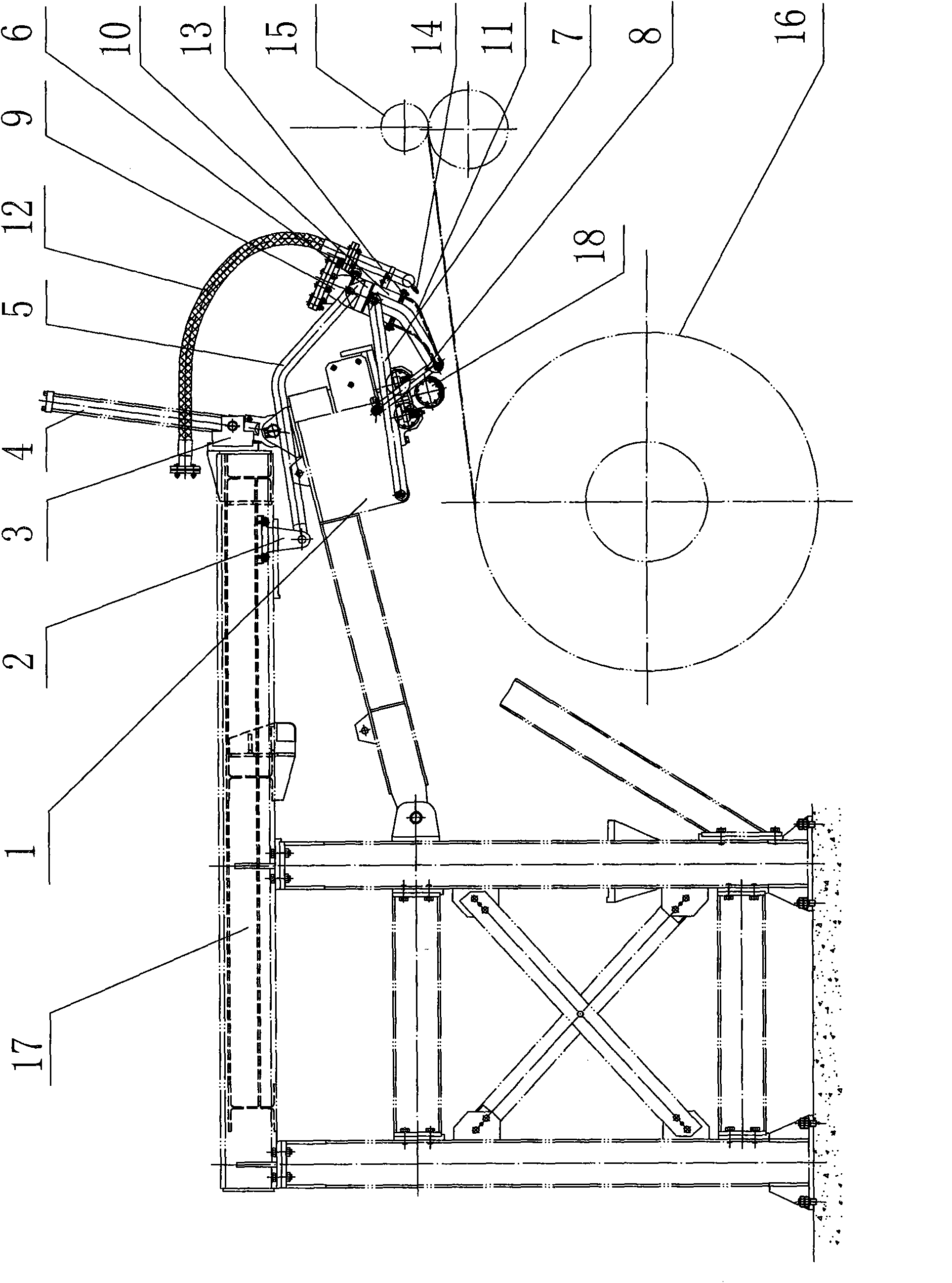

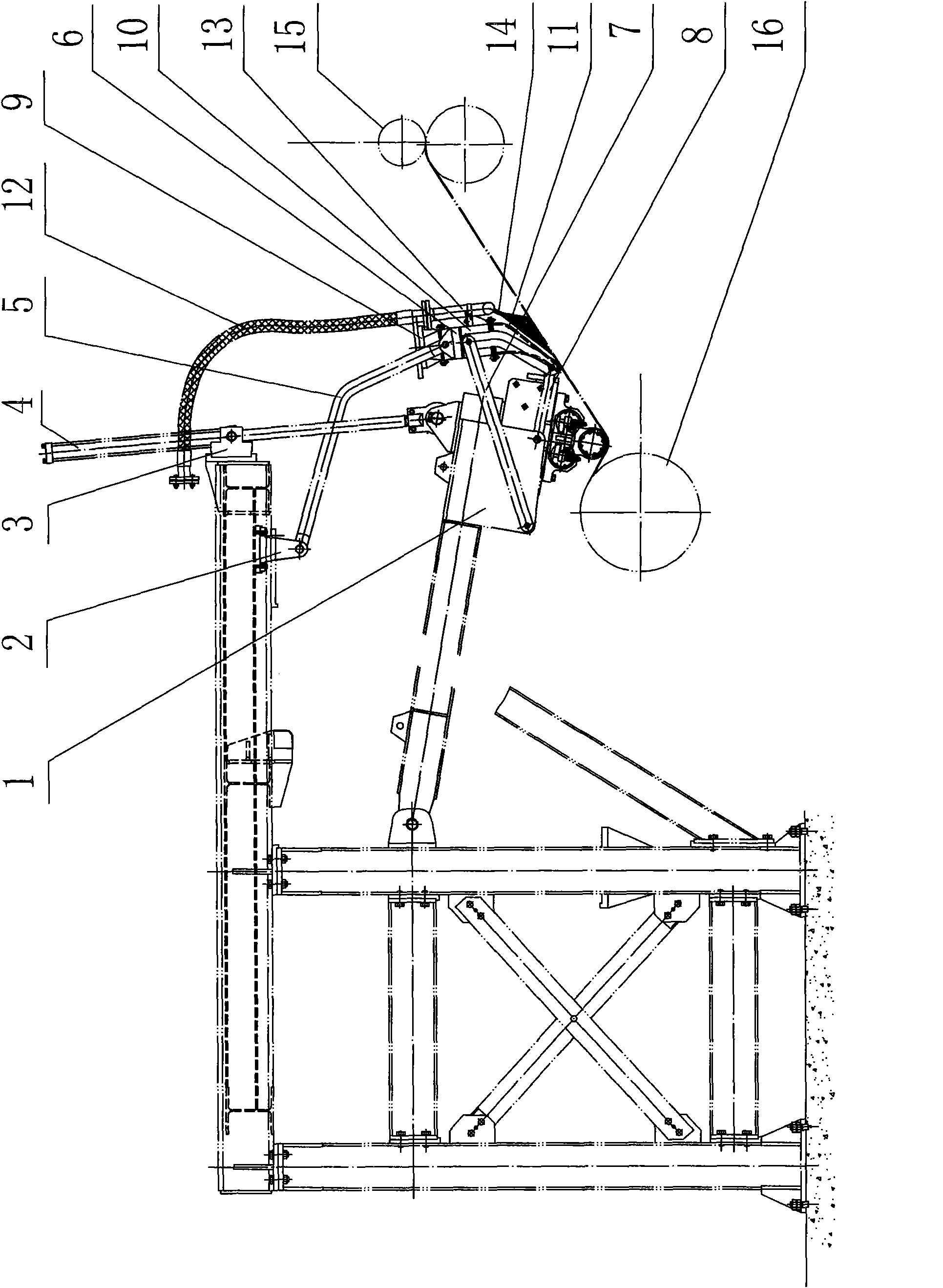

Deep bending roll dust remover

ActiveCN101642784AClean up thoroughlyConstant distanceDirt cleaningCleaning using gasesArchitectural engineeringStrip steel

The invention relates to a dust remover, in particular to a deep bending roll dust remover characterized by comprising a first connecting rod bracket, a first connecting rod, a blowing-absorbing dustremover, a second connecting rod and a third connecting rod. The left end of the first connecting rod is articulated with the first connecting rod bracket which is fixed on a supporting frame of a deep bending roll device; the right end of the first connecting rod is articulated with the upper part of the blowing-absorbing dust remover; the left end of the second connecting rod is articulated withthe right part of a deep bending roll swinging frame of the deep bending roll device; the right end of the second connecting rod is articulated with the middle of the blowing-absorbing dust remover;the left end of the third connecting rod is articulated with the right part of the deep bending roll swinging frame of the deep bending roll device; and the right end of the third connecting rod is articulated with the lower part of the blowing-absorbing dust remover comprising a dust-blowing device and a dust-absorbing device which are fixed. The deep bending roll dust remover is not driven by asingle driving mechanism, keeps a certain distance between a dust-absorbing hole and the surface of a strip steel with a variable inclined angle and adopts a blowing-absorbing dust-removing technologyto further thoroughly clean the surface oxide scale of the strip steel.

Owner:WISDRI ENG & RES INC LTD

Crushing device for building construction and using method thereof

PendingCN112354622AAvoid the phenomenon of accumulation and agglomerationAvoid affecting the filtering effectGrain treatmentsElectrode constructionsArchitectural engineeringCrusher

The invention discloses a crushing device for building construction and a using method thereof, and relates to the technical field of building construction. The problem of blockage in the crushing process is solved. The crushing device specifically comprises a box body, a shell is fixed to the top of the box body through bolts, a magnetic attraction plate is fixed to the outer wall of the oppositeside of the shell through bolts, a metal sensor is fixed to the inner wall of one side of the top of the shell through bolts, a crushing mechanism is arranged on the inner wall of the shell, four supporting legs are fixed to the outer wall of the bottom of the box body through bolts, a discharging pipe is fixed to the outer wall of one side of the bottom of the box body through threads, a fan isfixed to the outer wall of one side of the box body through bolts, a partition plate is fixed to the inner wall of one side of the box body through bolts, an extrusion mechanism is arranged on the outer wall of one side of the top of the partition plate, and a filter plate is placed on the outer wall of one side of the partition plate. According to the crushing device, an electric motor is started, so that the output end of the electric motor drives the filter plate and spines to reciprocate, and it is avoided that stones stay and accumulate on the filter plate and are crushed again at the same time.

Owner:魏雪

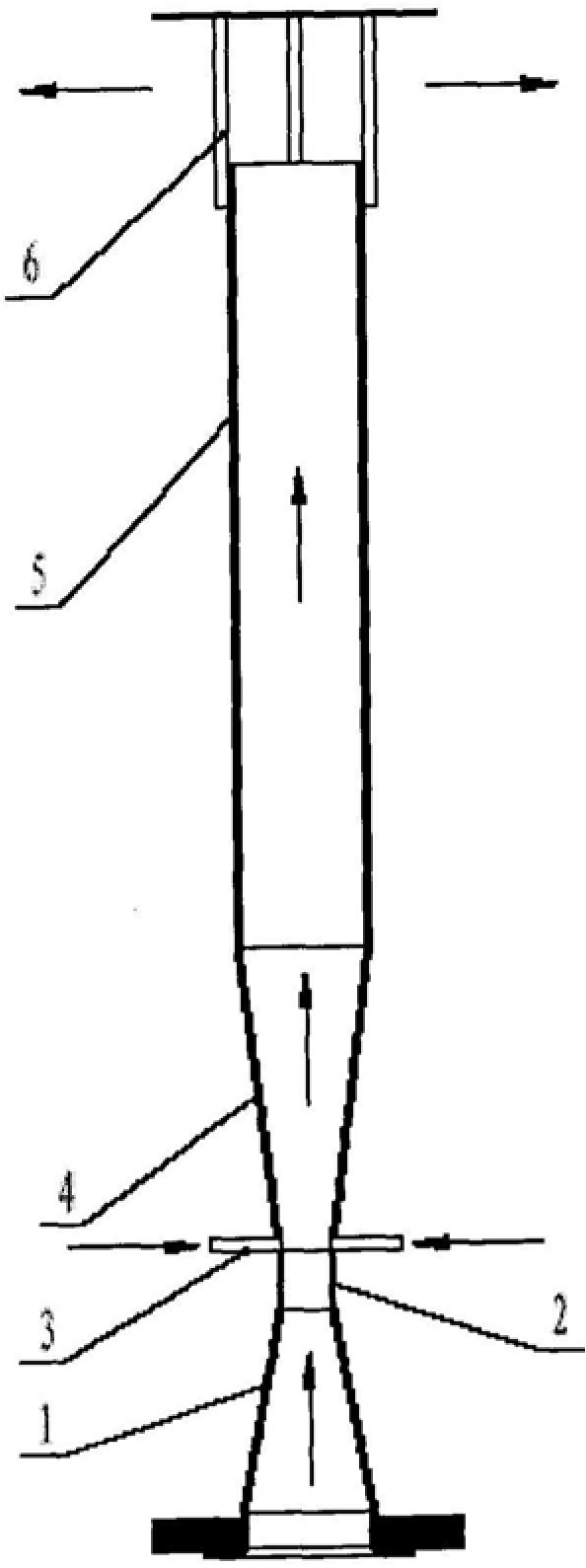

Venturi nozzle

ActiveCN106341987BAchieve dust removal effectSimple structureUsing liquid separation agentRadioactive decontaminationPipetteSpray nozzle

The invention relates to a venturi nozzle, comprising a nozzle body, a liquid suction pipe and a baffle plate, and peripheral equipment includes a gas pipe, a tank body and a washing liquid; wherein the nozzle body is composed of a shrinking pipe, a throat pipe, an expanding pipe and a straight pipe section from bottom to top. It consists of a uniformly distributed liquid suction port at the intersection of the expansion pipe and the throat pipe. The liquid suction port is welded with the liquid suction pipe, and the baffle is connected to the upper part of the straight pipe section through the strut. The liquid level of the washing liquid in the tank is higher than the height of the suction pipe; the invention actively sucks the liquid into the suction pipe through negative pressure, so that the dust particles and the washing liquid droplets are fully mixed, thereby achieving the dust removal effect, and no additional power device is required. The gas and the washing liquid are fully mixed, the structure is concise, the operation is convenient, and the practicability is strong.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

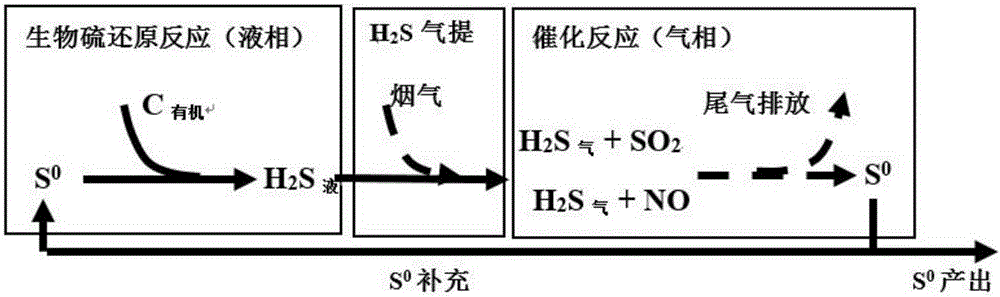

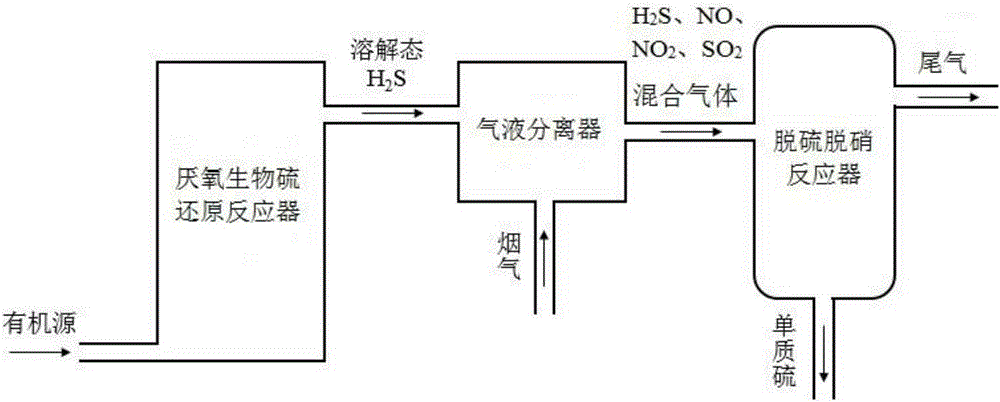

Synchronous desulfurization and denitrification technology of coal-fired flue gas by taking hydrogen sulfide as reducing agent

InactiveCN105214495ARealize integrationHigh outputUsing liquid separation agentSulfur preparation/purificationFlue gasEnvironmental engineering

The invention discloses synchronous desulfurization and denitrification technology of coal-fired flue gas by taking hydrogen sulfide as a reducing agent. The technology comprises the following steps: 1) preparation of dissolved H2S; 2) preparation of a mixed gas of H2S, NO, NO2, and SO2; and 3) synchronous desulfurization and denitrification. According to the technology, integration of a desulfurization and denitrification device is authentically realized. NO and NO2 in the coal-fired flue gas are converted into N2 and water; SO2 and H2S are converted to high-purity elemental sulfur; and organic matters in waste water are further removed, so that treatment of wastes with other wastes is realized. Elemental sulfur is recycled through the technology; one part of elemental sulfur is cycled and utilized to maintain equipment operation; and the other part of elemental sulfur is output as a product. The reducing agent of H2S in the technology is prepared from an in-situ product of elemental sulfur through reduction, can be prepared when used, and does not need to be bought outside. Therefore, cost of purchase, transportation, and storage and potential security risk are avoided. Compared with a mainstream device, the desulfurization and denitrification device is significantly lower with respect to land occupation, construction cost, operation cost, and the like.

Owner:SOUTH CHINA NORMAL UNIVERSITY

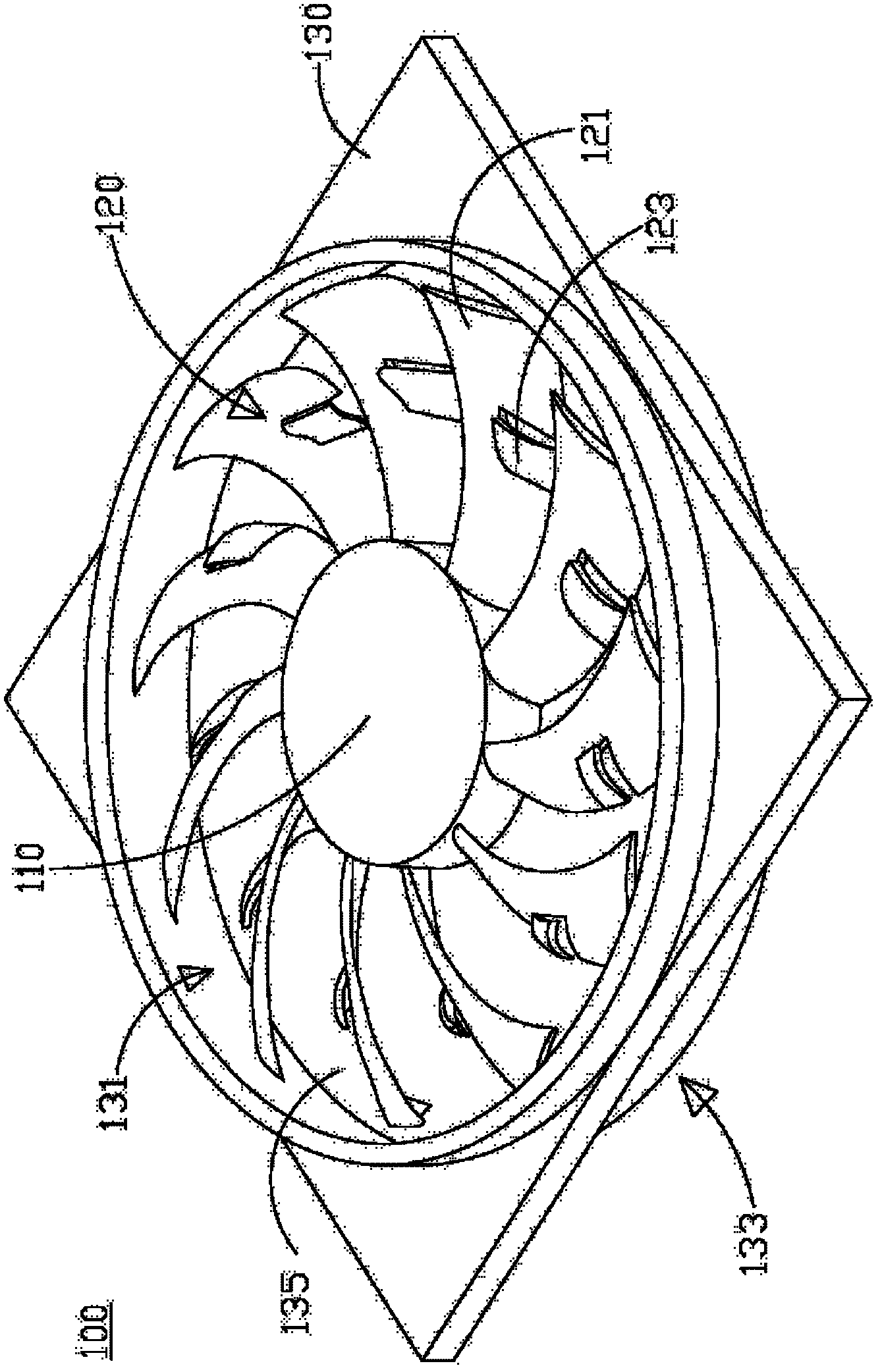

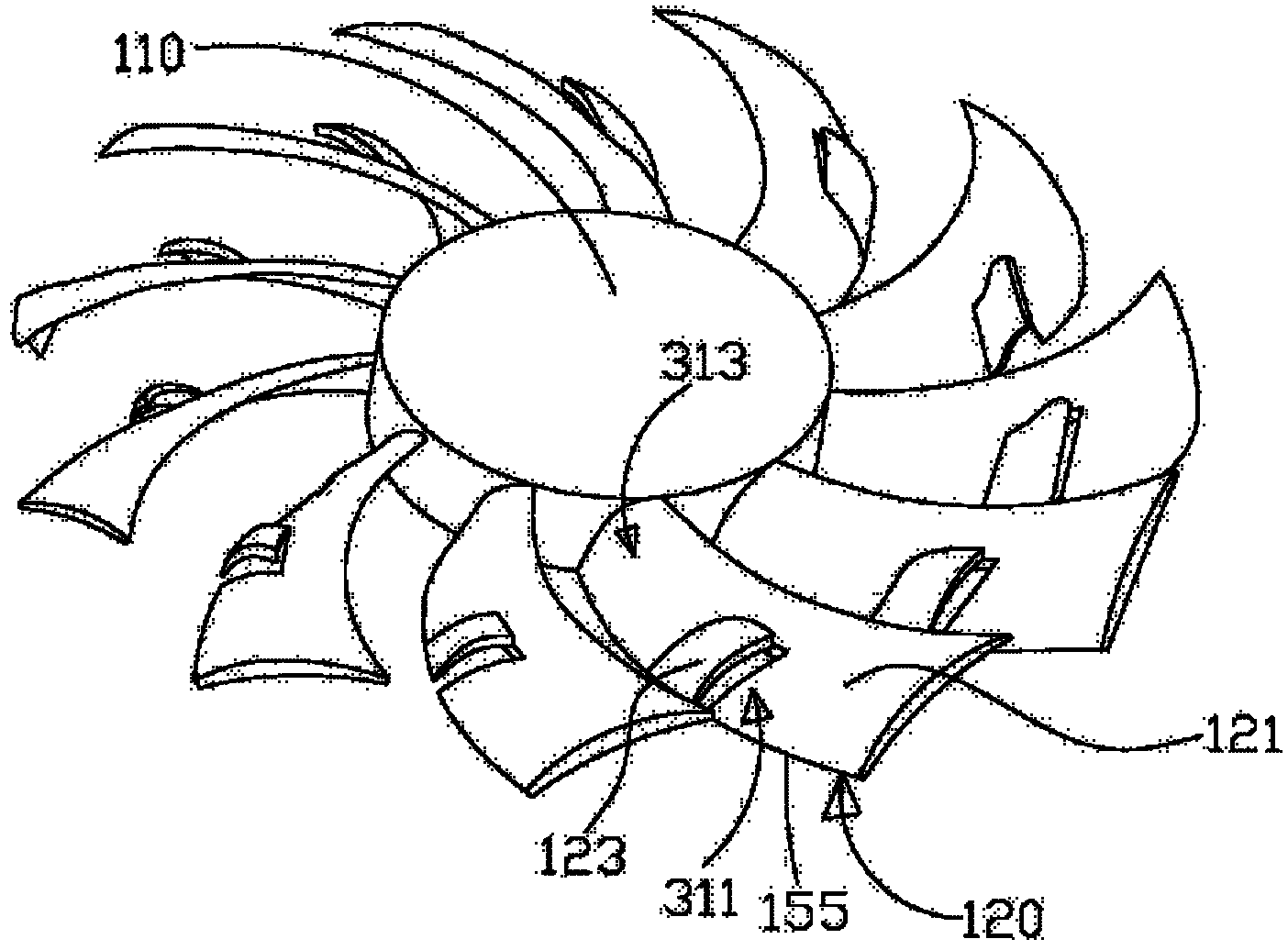

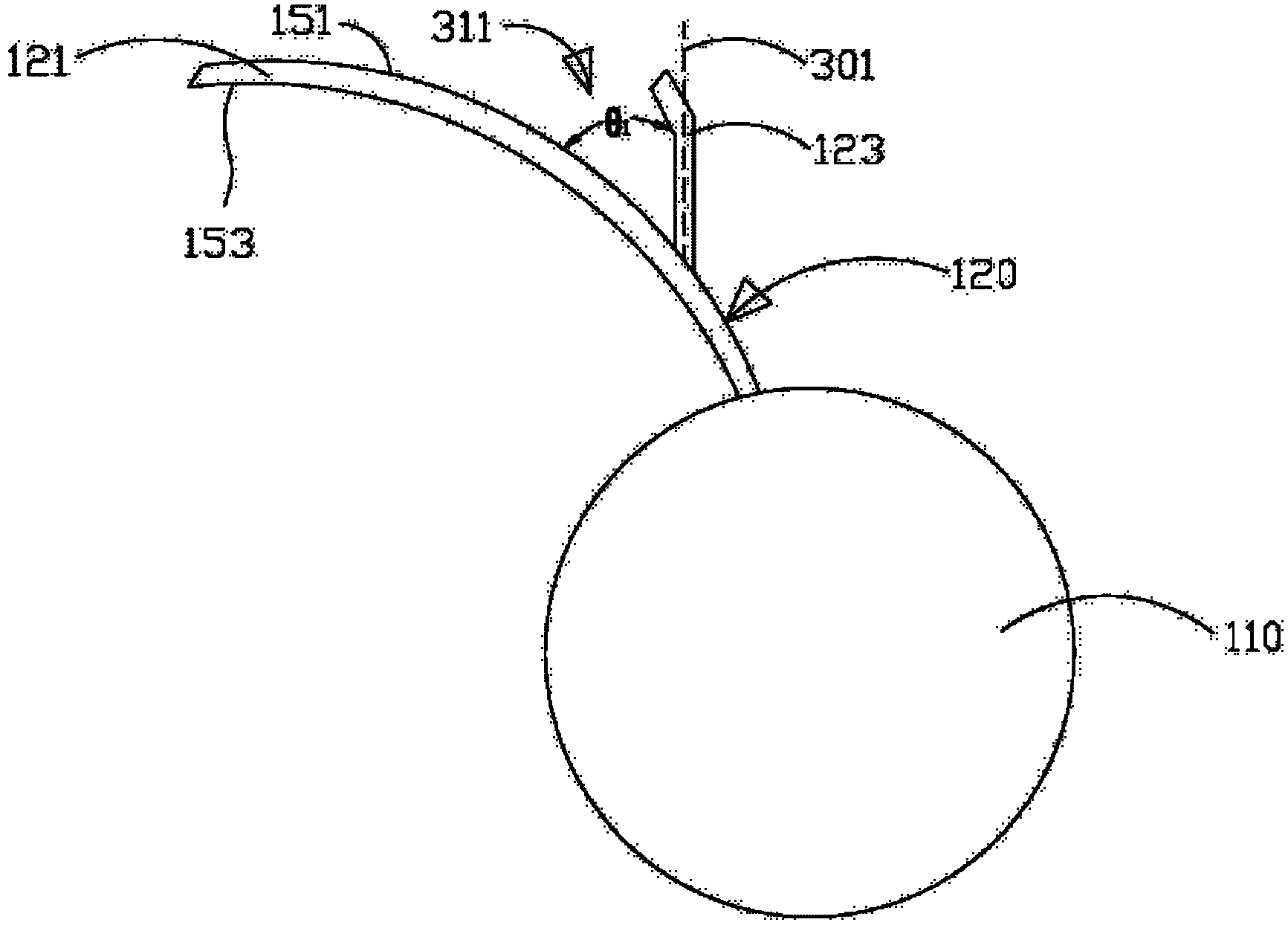

Heat radiation fan

ActiveCN103032371AIncrease in sizeImprove cooling effectPump componentsPumpsEngineeringRadiation effect

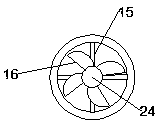

The present invention relates to a heat radiation fan, comprising a hub and a plurality of blades respectively arranged at the outer edge of the hub, wherein at least one blade comprises a main blade and a first auxiliary blade, one end of the main blade is connected with the hub, the main blade has opposite first and second side surfaces, the first auxiliary blade is arranged at one side of the main blade, the first auxiliary blade and the first side surface include a first angle and form a first opening, such that the blades generate air flow through the opening formed by the first auxiliary blade, thereby enhancing the heat radiation effect and achieving the effect of dust removal.

Owner:GIGA BYTE TECH CO LTD

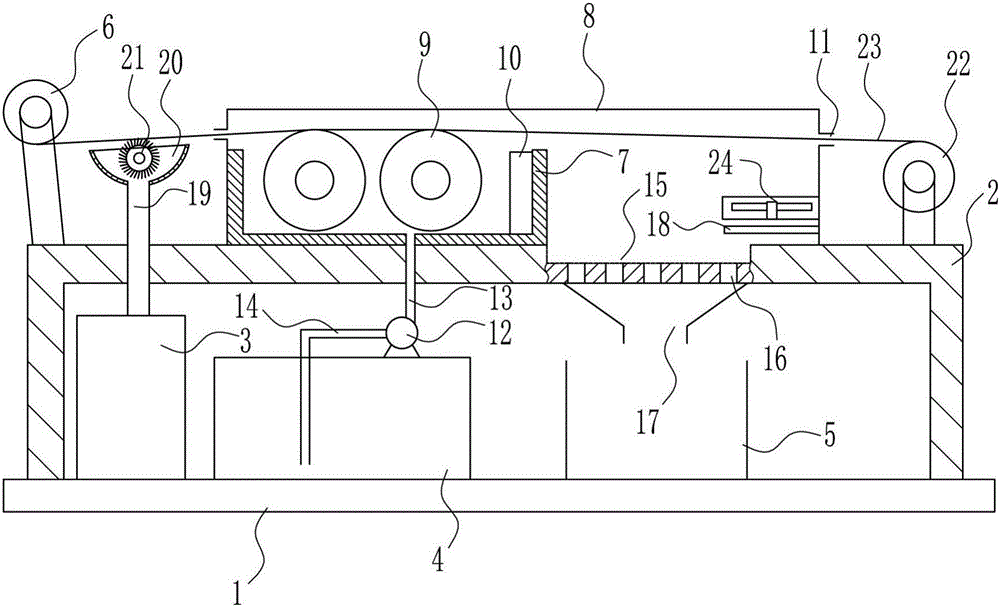

Release film dust removal device

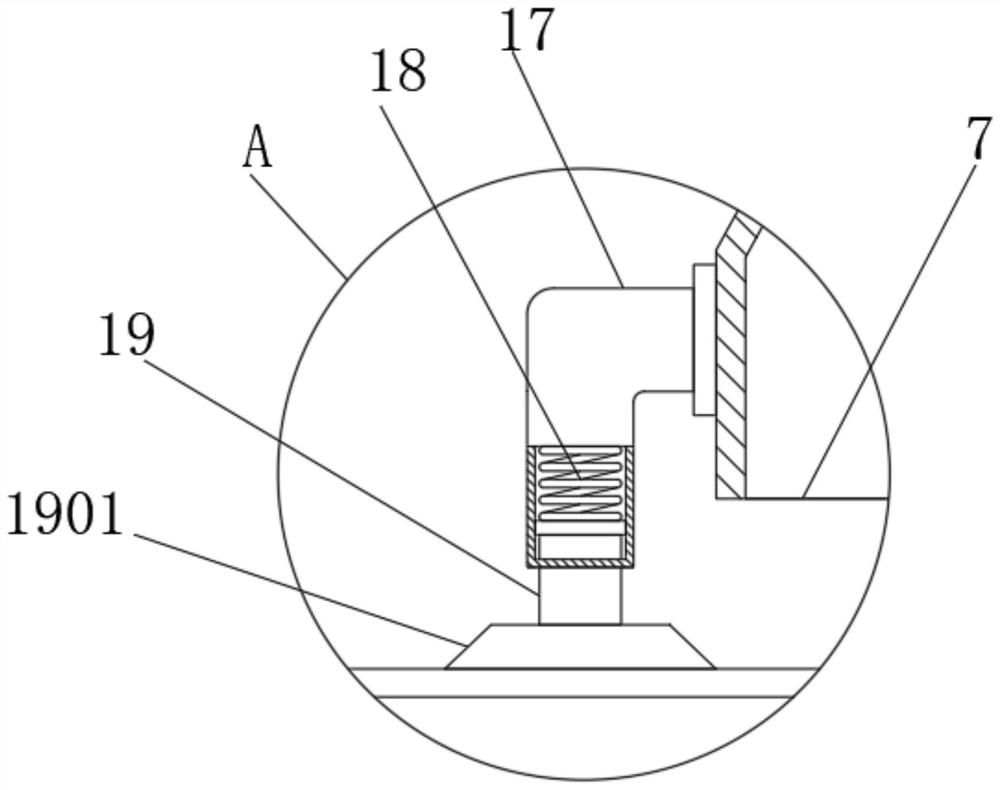

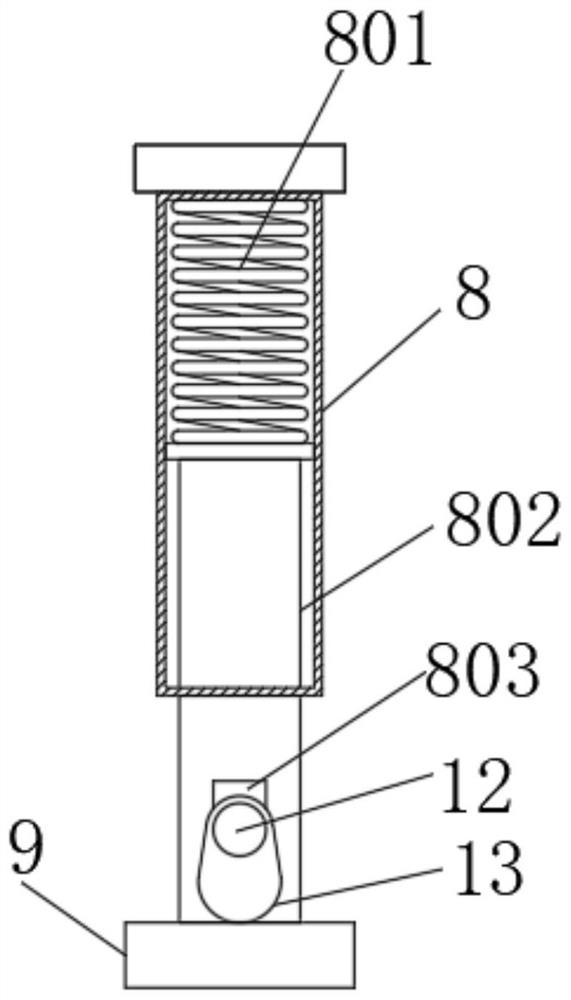

PendingCN112808651AAchieve dust removal effectImprove dust removal effectUsing liquid separation agentCleaning using toolsPhysicsEngineering

The invention relates to the technical field of release film production equipment, and particularly discloses a release film dust removal device which comprises a fixed bottom plate, a release film and a first motor. A left-right through door-shaped supporting frame is fixedly connected to the top of the fixed bottom plate, a centrifugal exhaust fan is installed at the top of the door-shaped supporting frame, an output port of the centrifugal exhaust fan communicates with a dust suction pipe, and the dust suction pipe extends to the middle of an inner cavity of the door-shaped supporting frame after being bent and is connected with a dust suction cover. According to the dust removal device, high-frequency vibration can be effectively conducted on a passing release film through rotation of an eccentric wheel, then dust attached to the surface of the release film is separated from the release film and jumps on the surface of the release film, and the jumped dust can be sucked away in time through suction force from a dust suction head and conveyed into a first dust collection box, so that the dust removal effect on the release film is realized.

Owner:李丽荣

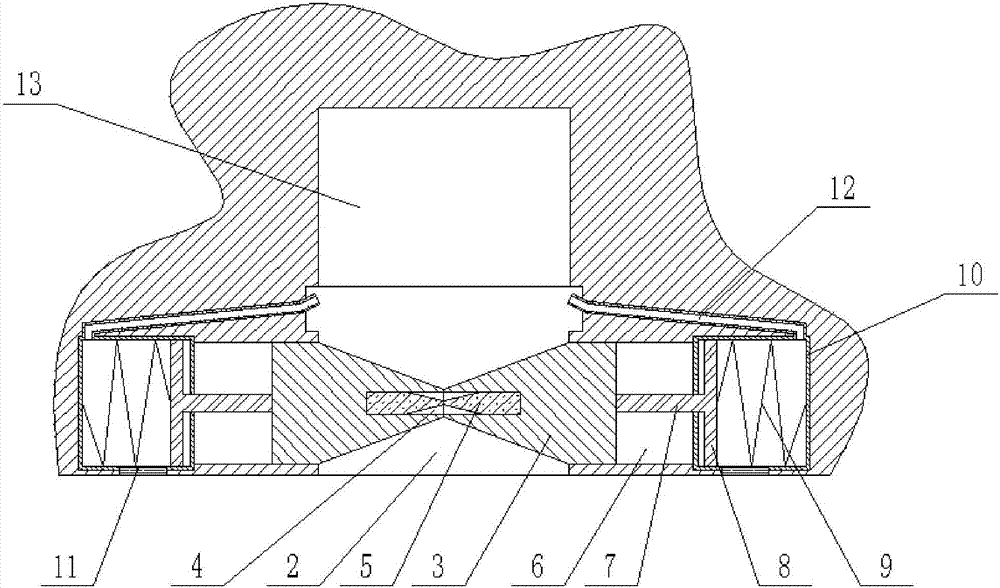

Network switch capable of preventing network cable looseness

ActiveCN107995132AAvoid excessive accumulationPlay a positioning effectCleaning using gasesData switching networksEngineeringNetworking cables

The invention belongs to the technical field of a transmission device for digital information and specifically discloses a network switch capable of preventing network cable looseness. The network switch comprises a switch, wherein mounting slots are set on the side wall of the switch, and a network cable socket, a dustproof positioning part and a dedusting part are fixedly mounted in each mounting slot. Each dustproof positioning part comprises blink holes set on the side wall of each mounting slot; first dustproof positioning doors are in slide connection with the blind holes; through holesare set on the first dustproof positioning doors; cross sections of the first dustproof positioning doors are trapezoidal; and short sides of the first dustproof positioning doors stretch out of one end of the blind holes. Each dedusting part comprises piston rods fixedly connected with the first dustproof positioning doors; piston plates are fixedly at the other end of the piston rods; cylinder tubes are fixed in the blind holes; the piston plates and the cylinder tubes are in slide seal; springs are fixed between the piston plates and the cylinder tubes; the side walls of the cylinder tubesare connected with dedusting pipes; and the other end of the dedusting pipes faces each network cable socket. The network switch aims at solving the problem that in the prior art, after clips on modular plugs are deformed, the modular plugs cannot be clamped tightly by the network cable sockets and dust deposits in the network cable sockets and is difficult to clean.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

Cutting device for PVC plate processing with dust removal effect

The invention discloses a cutting device for PVC plate processing with a dust removal effect, and relates to the technical field of PVC plates. The cutting device comprises a bottom plate, wherein theupper surface of the bottom plate is fixedly connected with the lower surface of a shell, the right side surface of the shell is fixedly connected with the left side surface of a fan, and the air outlet end of the fan communicates with the left end of an air outlet pipe. According to the cutting device for PVC plate processing with the dust removal effect, through the mutual cooperation of a collecting opening, an air inlet pipe, the air outlet pipe, the fan, the shell and a positioning device, when a plate is cut under a cutting blade, a worker controls the fan to work, the fan sucks air from the inner portion of the shell through the air inlet pipe, debris flows along with the air under the suction effect of the fan and is discharged out of the shell, and one end of the air outlet pipeis connected to a water tank or a container for collecting the debris, so that the worker can conveniently the debris generated in the cutting process of the plate, and harm to human bodies caused bythe debris or dust inhaled by the worker is reduced.

Owner:黄山豪泰塑胶有限公司

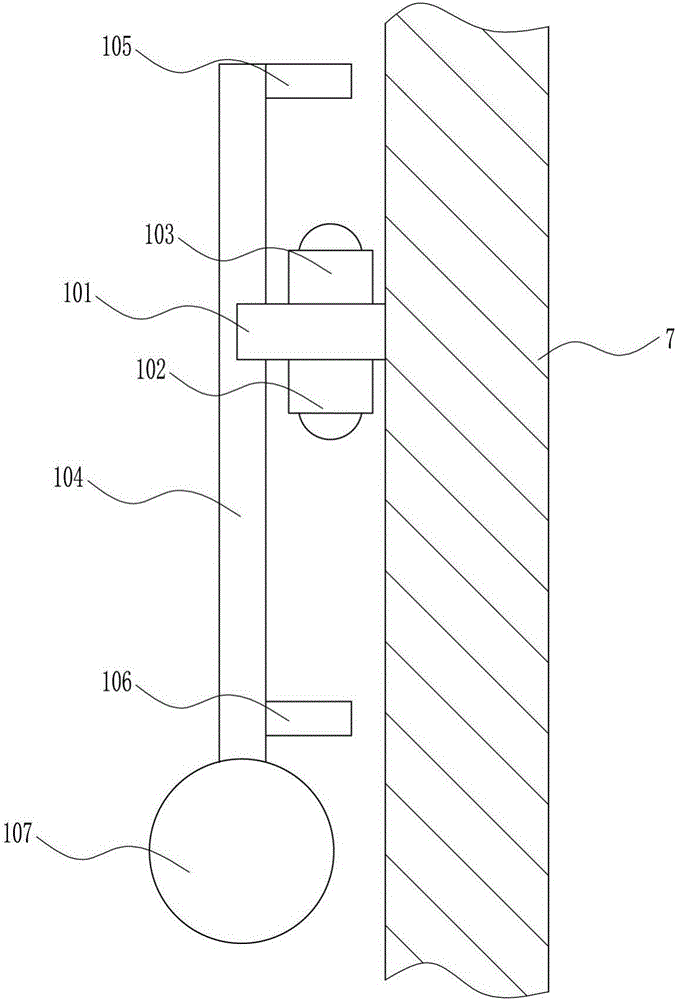

Lidar dust removal device and lidar

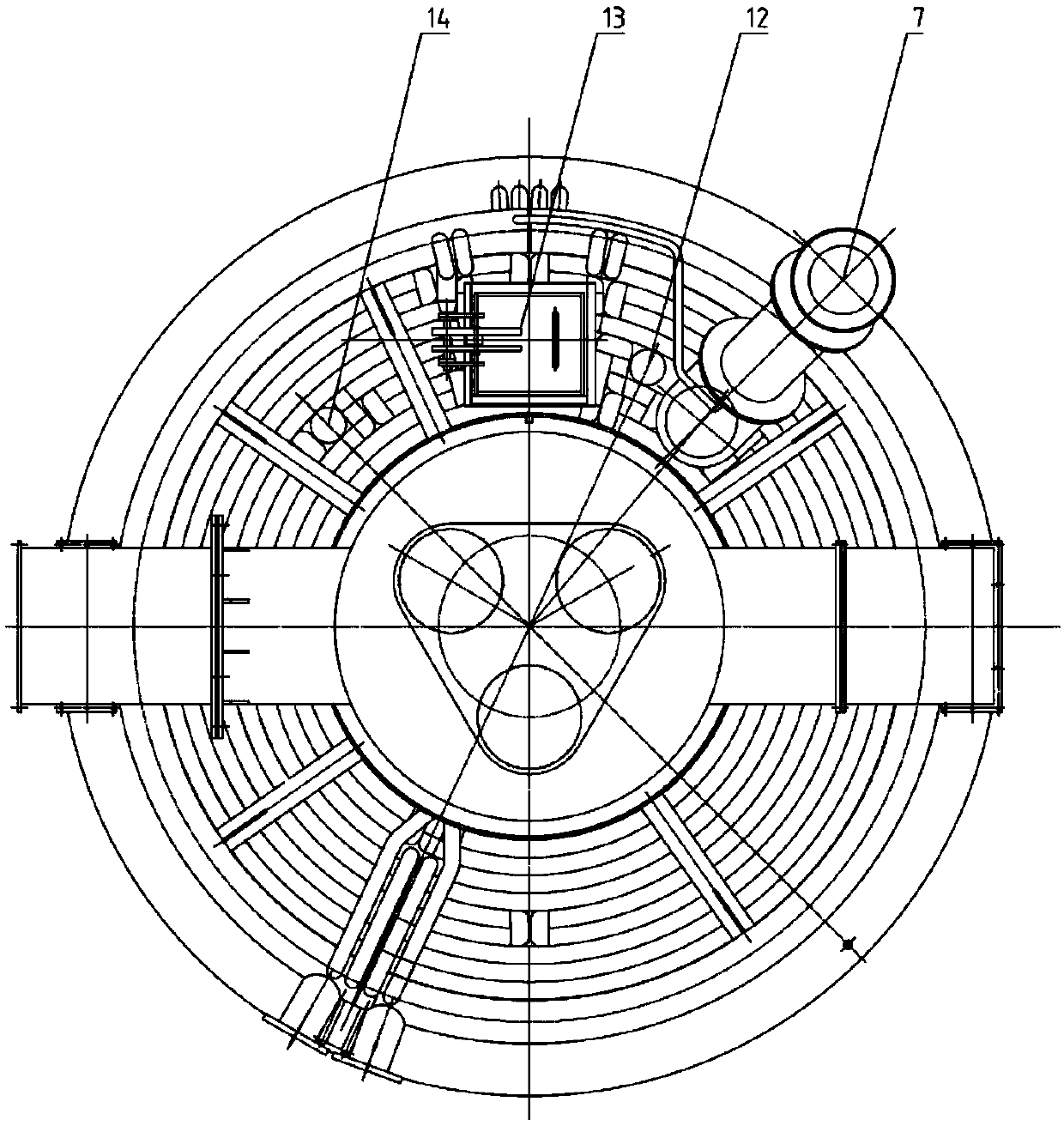

PendingCN109622229AAchieve dust removal effectTroubleshoot technical inefficienciesWave based measurement systemsElectric supply techniquesMotor shaftEngineering

The invention discloses a lidar dust removal device and a lidar. The lidar dust removal device comprises a connecting part and a fan module, wherein the connecting part is connected with a motor shaftof a motor in the lidar; and the fan module is connected with the connecting part and covers the window cover of the lidar, and the fan module rotates coaxially with the motor shaft for rotate aroundthe window cover to remove dust from the window cover. The technical problem of low efficiency caused by manual cleaning of the window cover of the lidar in a related technology can be solved.

Owner:WUHAN WANJI INFORMATION TECH

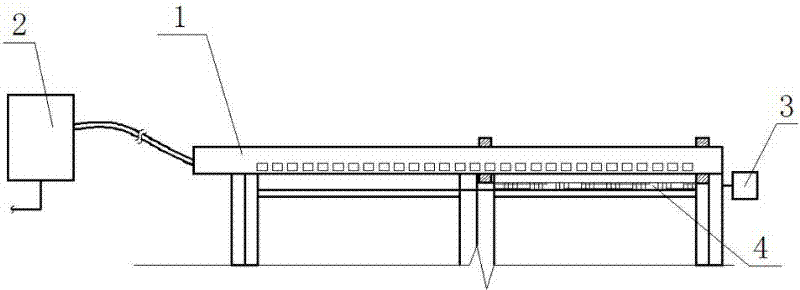

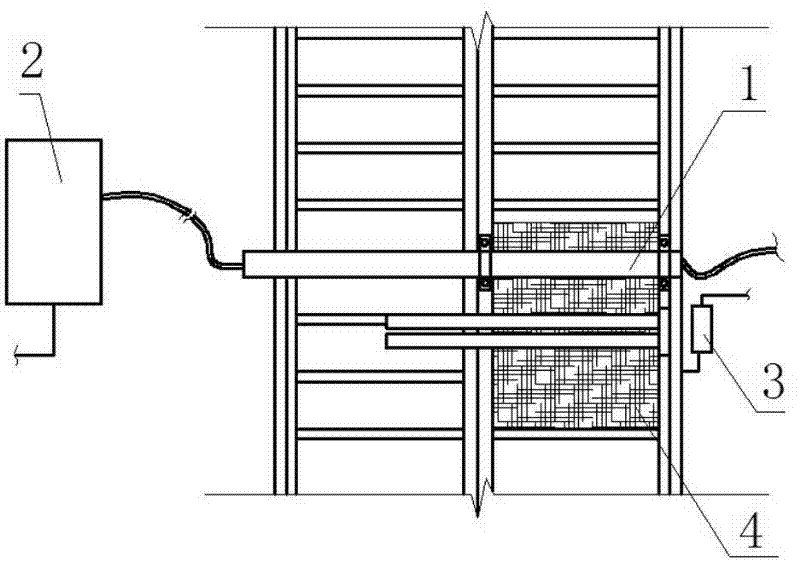

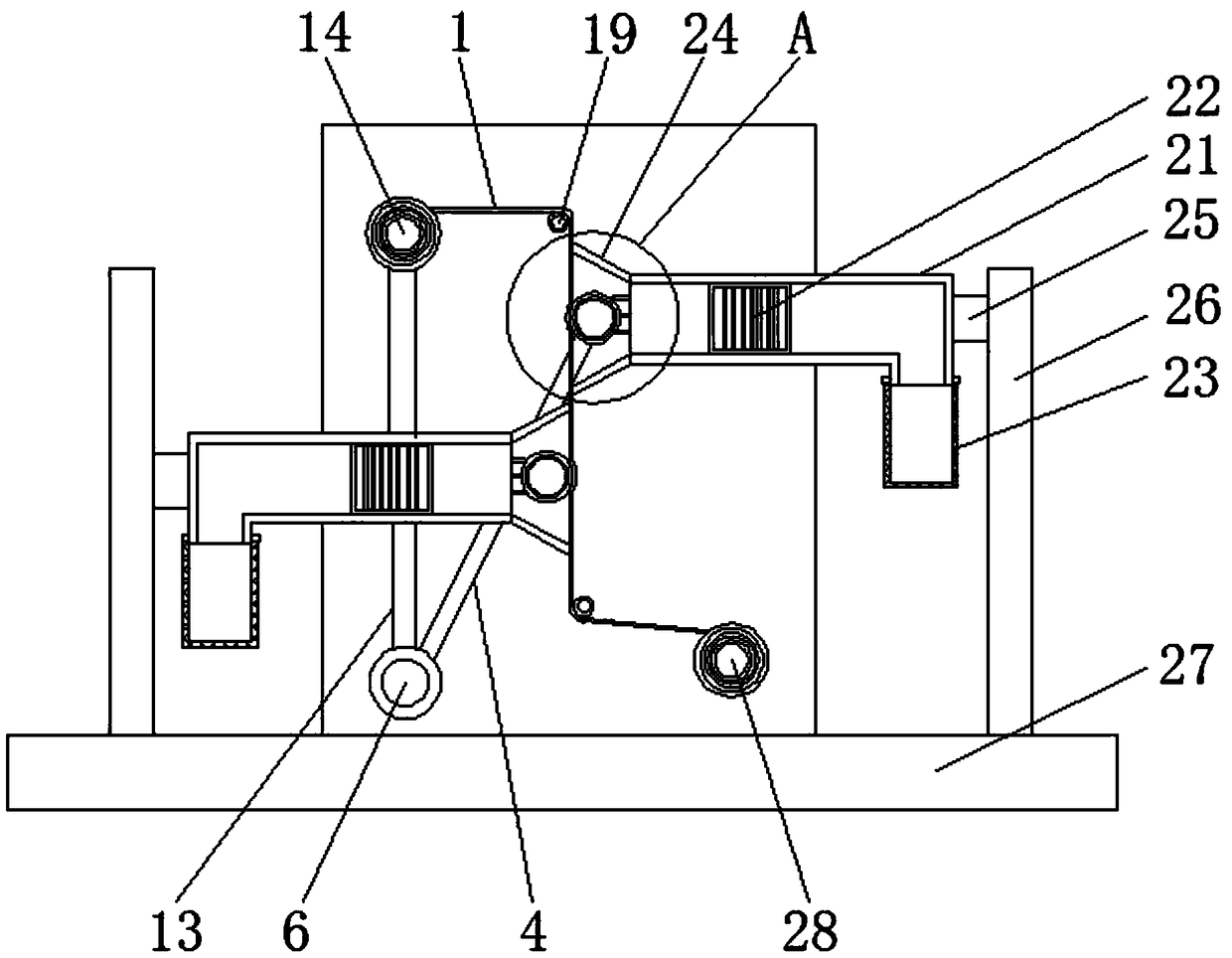

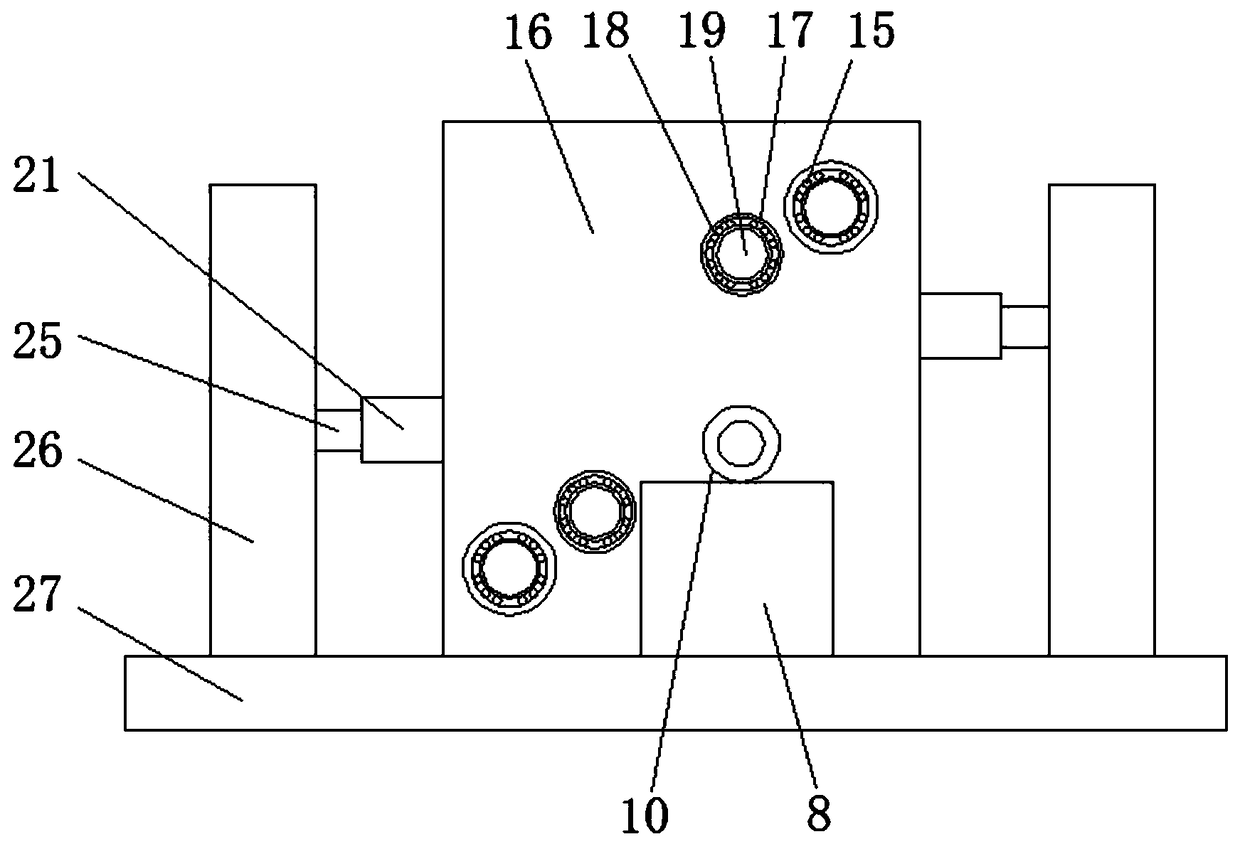

PCB surface dust removal and static elimination equipment

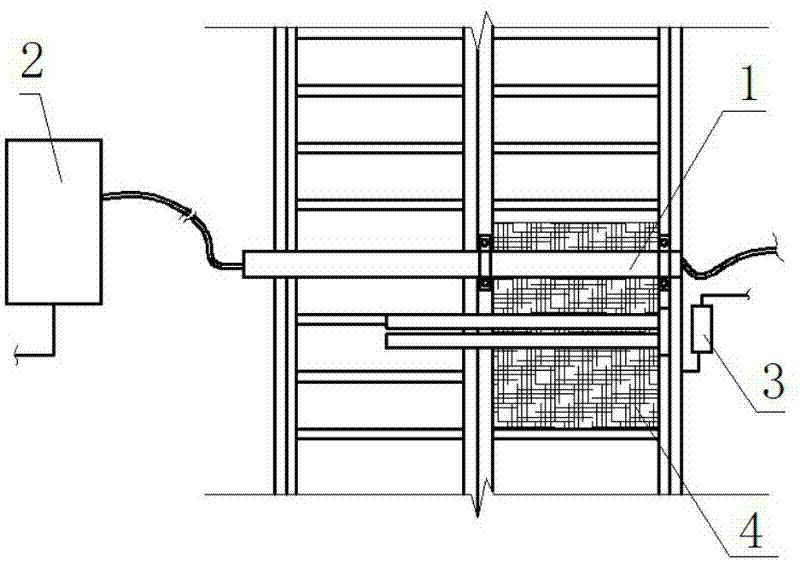

InactiveCN102294333AEliminate static electricitySimple structureCleaning using gasesConductive pattern polishing/cleaningIonAerospace engineering

The invention discloses a device for removing dust on the surface of a PCB board and eliminating static electricity, which includes a conveying device for conveying the PCB board, and is characterized in that: the conveying device is provided with guide rails for conveying the PCB board, and rollers are arranged between the guide rails ; An ion air knife is provided above the guide rail, and its tuyere is set downward, and the ion air knife is connected with the high-voltage generator. Further, the conveying device is provided with an inductor for inducting the PCB board, and the inductor is arranged at the front end of the conveying device. The invention has the advantages of simple structure, easy installation, high work efficiency and good effects of dust removal and static electricity removal.

Owner:昆山元崧电子科技有限公司

Dust removing device for shell fabric processing arrangement device

InactiveCN109403002AAchieve dust removal effectMechanical cleaningPressure cleaningEngineeringDust collector

The invention discloses a dust removing device for a shell fabric processing arrangement device, and the device comprises a shell fabric, wherein one side of the shell fabric is movably connected witha static brush, and the inner wall of the static brush is fixedly connected with a first transmission rod. One end of the first transmission rod is movably connected with a first belt, and the innerwall of the first belt is in transmission connection with a first belt pulley. The inner wall of the first belt pulley is fixedly connected with an output shaft of a first motor. The bottom surface ofthe first motor is fixedly connected with a first support plate, and the back surface of the first support plate is fixedly connected with a support plate. The device provided by the invention achieves the clearing of the thread residues and dust on the shell fabric via the static brush through the setting of rotation of the motor and the belt, achieves the scraping and suction of the thread residues and dust on the shell fabric through a dust collector motor and a scraping plate, can enable the thread residues and dust in a cloth bag to be taken out and cleared through a dust cloth bag and arope, and achieves the effect of removing the dust on the shell fabric.

Owner:王飞

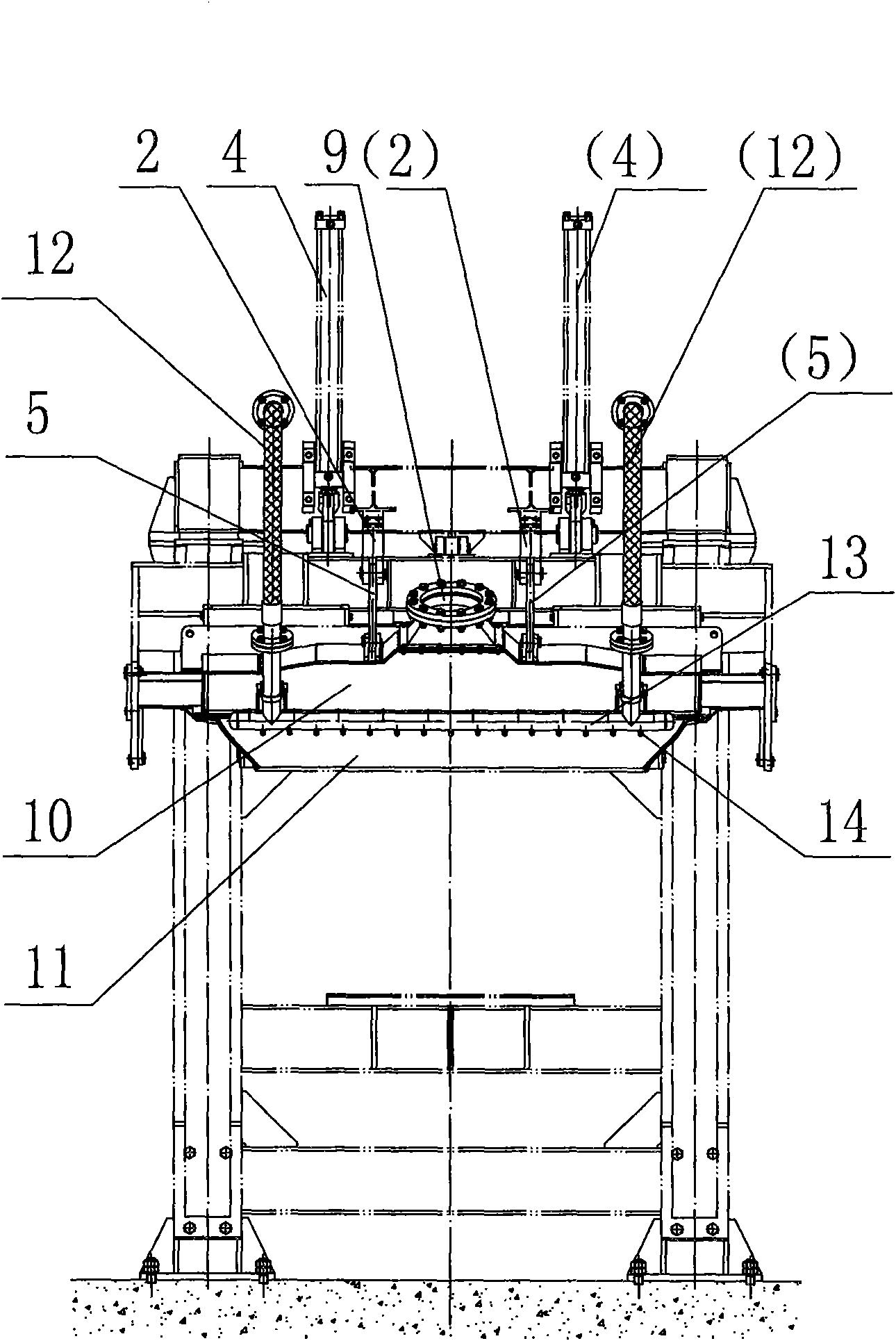

Eccentric hoisting type environment-friendly waste gas spraying treatment device

InactiveCN108310953AReasonable structureInnovative designCombination devicesAlkaline waterDrive wheel

The invention discloses an eccentric hoisting type environment-friendly waste gas spraying treatment device. The eccentric hoisting type environment-friendly waste gas spraying treatment device comprises a supporting base, wherein supporting frames are mounted at two sides of the upper end of the supporting base; the top ends of the supporting frames are connected with a top plate; a water diversion cylinder is mounted in the middle of the right side of the top plate; a piston plate is arranged in the water diversion cylinder; a hoisting rod is connected with the lower end of the piston plate;a limiting block is mounted at the bottom end of the hoisting rod; a limiting cylinder is arranged at the outer side of the limiting block; a treatment box is arranged at the left side of the upper end of the supporting base; a baffle plate is arranged in the middle of the treatment box; a filtering screen is arranged at the upper end of the baffle plate; a rotary gear is mounted at the right endof the rotary shaft; a driving wheel is mounted in the middle of the front end of the driving shaft; an eccentric column is mounted in the middle of the front end of the driving wheel; a guide framesleeves the outer side of the eccentric column; upper and lower ends of the guide frame are connected with guide columns. The eccentric hoisting type environment-friendly waste gas spraying treatmentdevice disclosed by the invention has the advantages that on one hand, a scraping plate to clean dust attached on the filtering screen; on the other hand, the water diversion cylinder works and alkaline water is sprayed out through a spraying head, so that the effect of removing dust before sulfur-containing waste gas is sprayed is realized.

Owner:卢庆芝

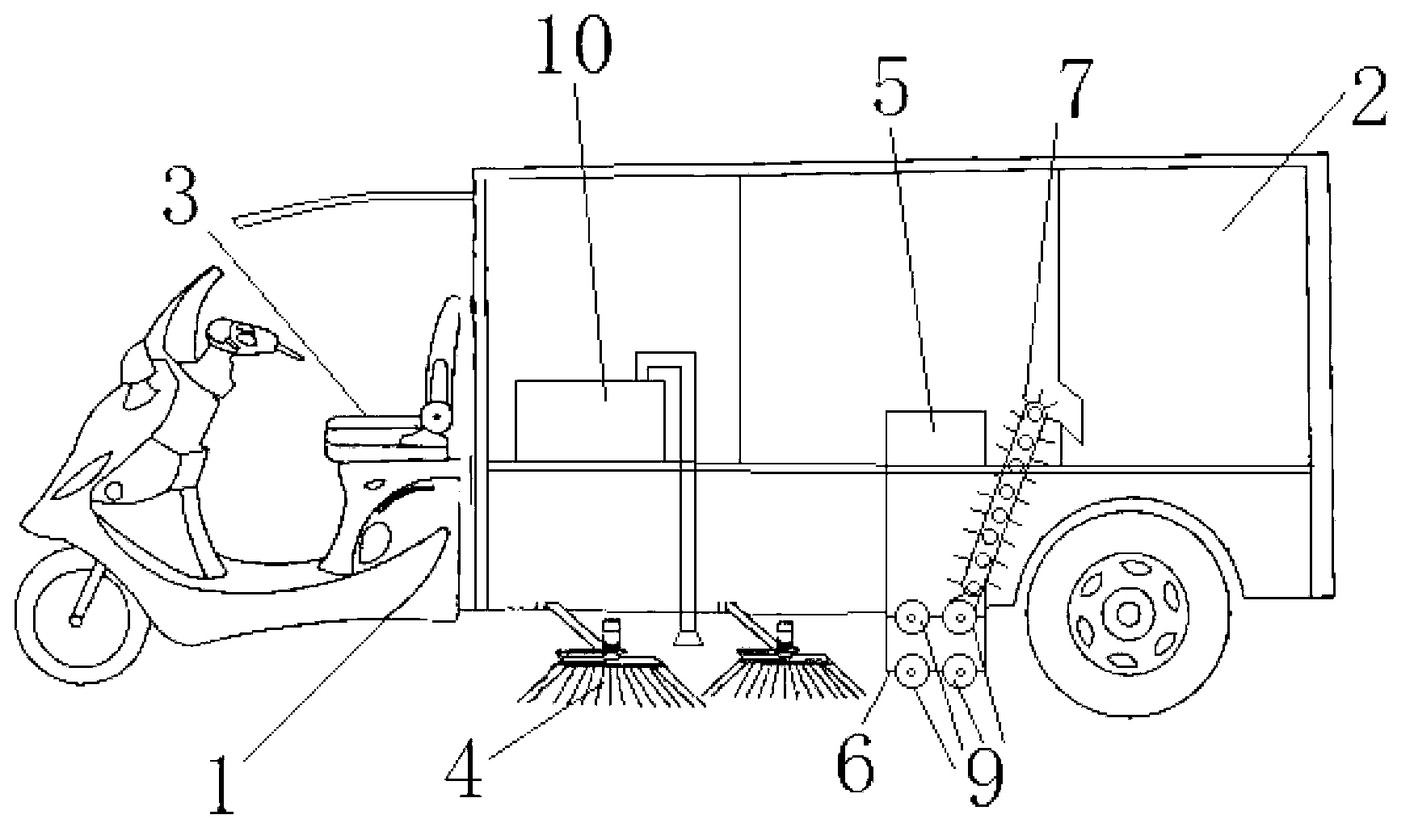

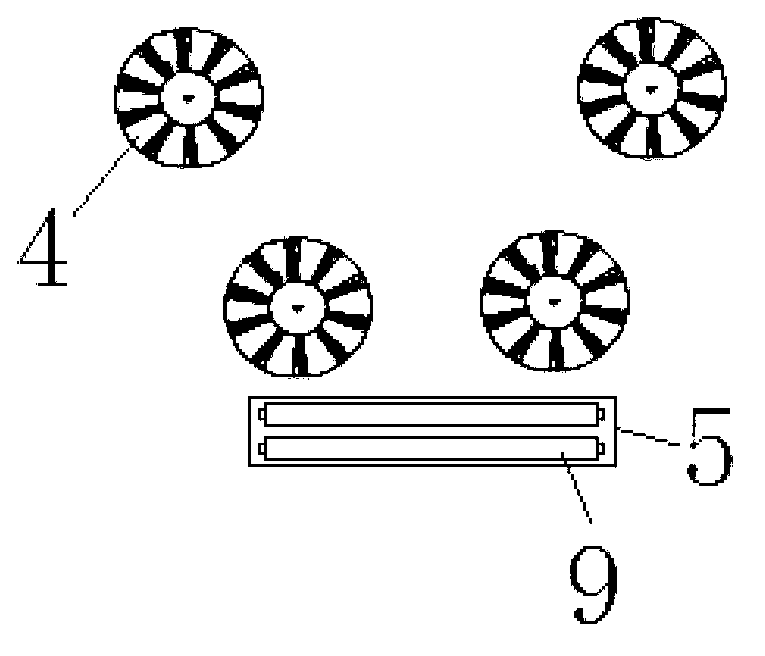

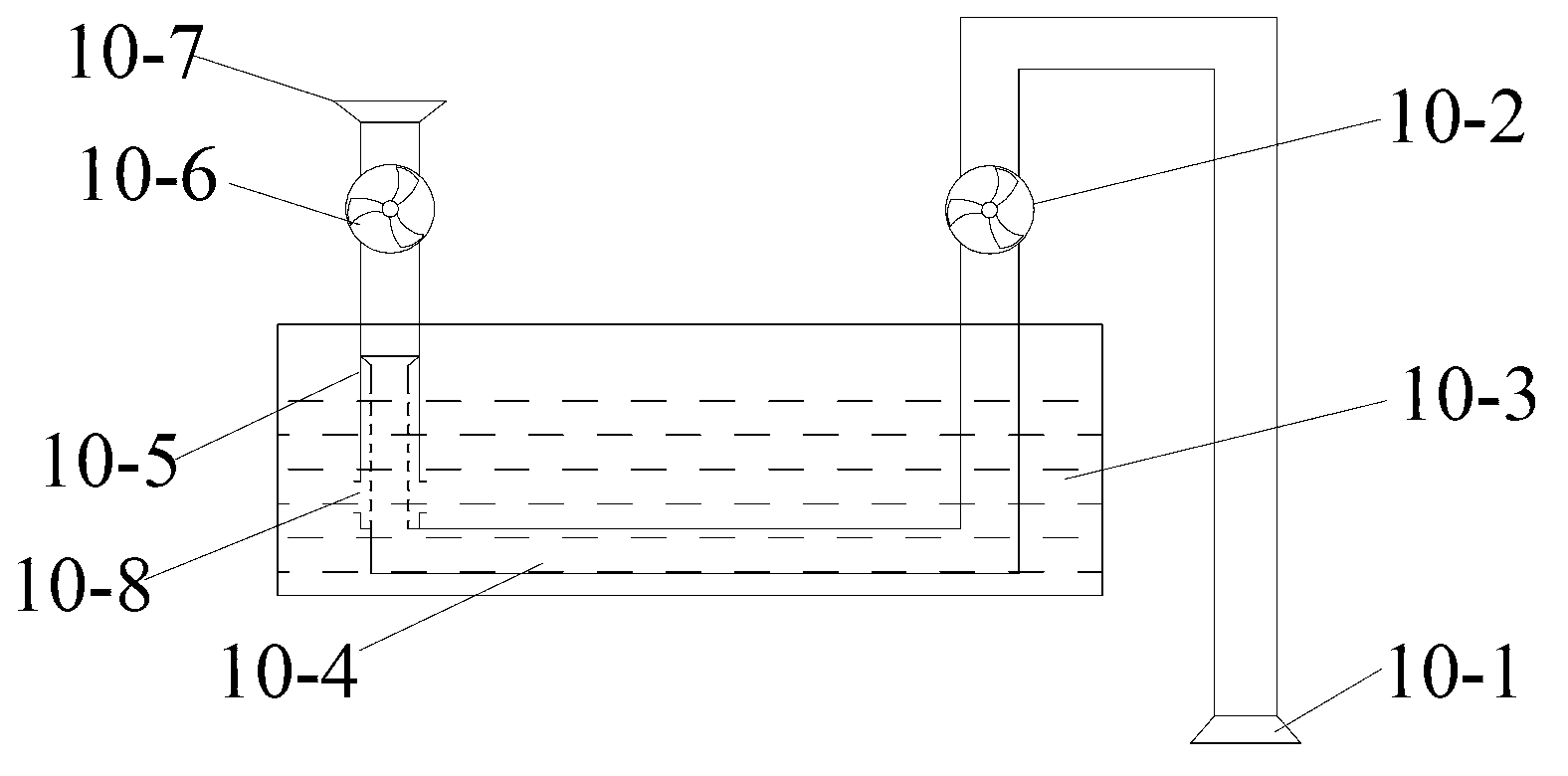

Multifunctional three-wheel sanitation vehicle

InactiveCN102852112AImprove work efficiencyReduce work intensityRoad cleaningRoad surfaceEnergy consumption

The invention discloses a multifunctional three-wheel sanitation vehicle comprising a vehicle body, wherein a garbage can, a road surface cleaning device which is used for cleaning a road surface and a garbage conveying device which is used for conveying road surface garbage into the garbage can are arranged on the vehicle body; the road surface cleaning device and the garbage conveying device are arranged in sequence in the direction from the head to the tail of the vehicle body; a garbage inlet of the garbage conveying device faces the road surface; and a garbage outlet of the garbage conveying device extends into the garbage can, and the height of the garbage outlet is greater than that of the bottom surface of the garbage can. Compared with the prior art, the three-wheel sanitation vehicle disclosed by the invention is high in working efficiency, low in energy consumption, capable of reducing the labor intensity of a worker, convenient to operate, small in size, wide in application, flexible and suitable for various road surfaces and situations and in particular for narrow roads such as town streets, town roads, road surfaces pitted with holes, urban roadways, village roads and the like; and with the adoption of the multifunctional three-wheel sanitation vehicle, the level of mechanization of the sanitation service can be effectively enhanced and the manpower cost can be greatly reduced.

Owner:陈佩 +1

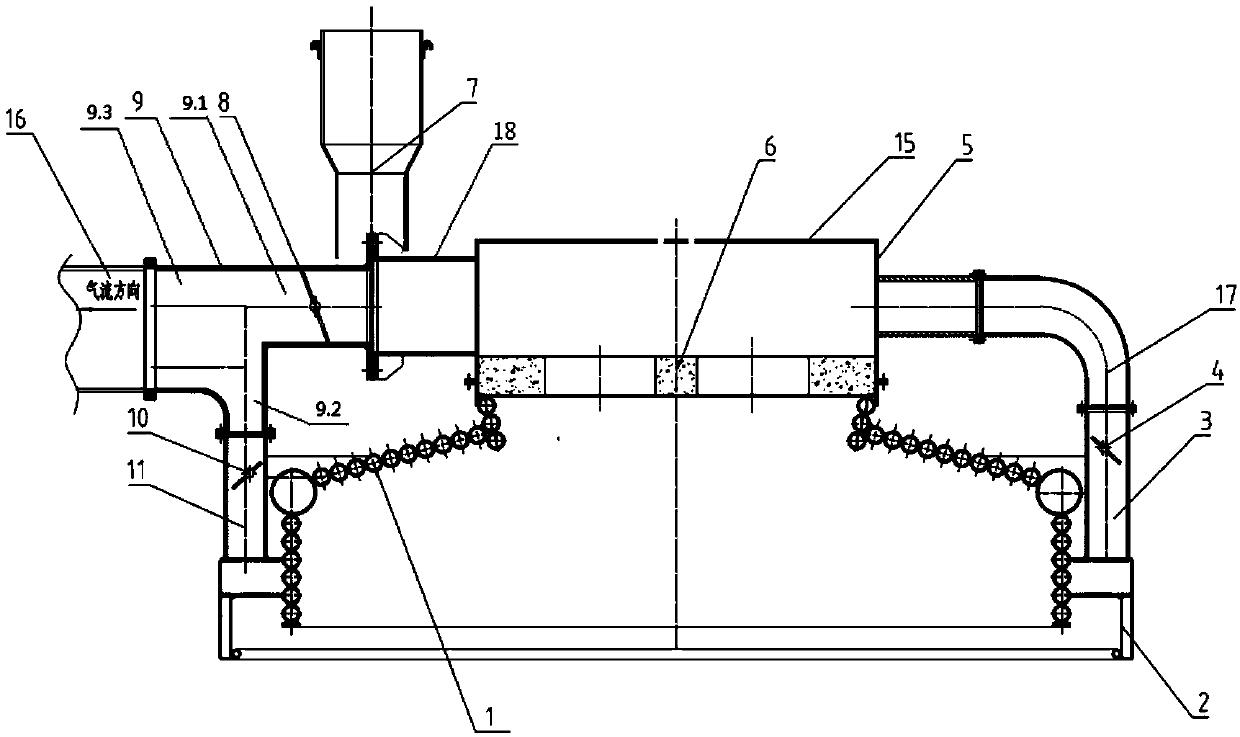

Pipeline type high wind speed double charged area electro coagulation device

InactiveCN102671763AImprove dust removal effectSimple designExternal electric electrostatic seperatorVapor flow controlElectro coagulationEngineering

The invention provides a pipeline type high wind speed double charged area electro coagulation device, which is characterized by comprising a hollow shell, wherein the two ends of the hollow shell are respectively provided with an inlet and an outlet, the inner portion of the hollow shell is orderly provided with a negative corona area, a positive corona area and an electric coagulation area from the inlet direction to the outlet direction, and the negative corona area and the positive corona area comprise electrode plates, and the rear portions of the electrode plates are provided with auxiliary electrodes. Compared with the prior art, the pipeline type high wind speed double charged area electro coagulation device has the advantages of low cost, less occupied area, high collection efficiency and low dust emission concentration.

Owner:LAIWU IRON & STEEL GRP

Medical instrument dust removing storage box

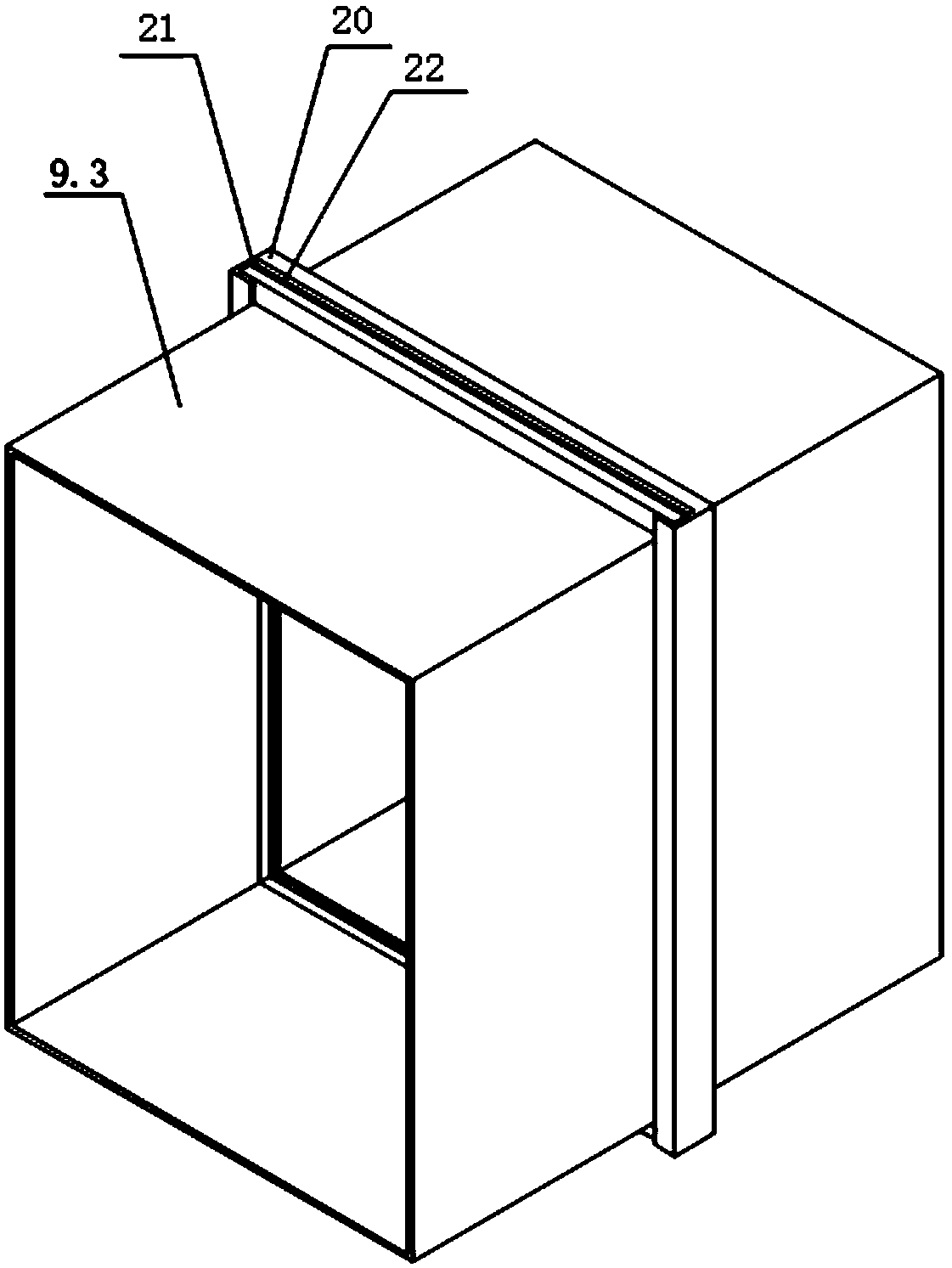

InactiveCN108704898AAchieve dust removal effectImprove dust removal efficiencyDirt cleaningCleaning using gasesHydraulic cylinderAir pump

The invention discloses a medical instrument dust removing storage box. The medical instrument dust removing storage box comprises a box body. The bottom of the box body is provided with a bottom plate. The upper end of the bottom plate is provided with a first side plate, a second side plate and a cover plate. The middle of the box body is provided with a storage cavity. The lower end of the bottom plate is provided with a plurality of supporting rods. The lower end of the middle of the bottom plate is provided with a hydraulic cylinder. The upper end of the hydraulic cylinder is provided with a hydraulic lifting rod and a storage plate. The part, located at one end of the hydraulic lifting rod, in the bottom plate is provided with an air purifier. The end, far away from the hydraulic lifting rod, of the air purifier is provided with an air pump. One end of the air purifier is provided with a blowing pipe and a blowing nozzle. The hydraulic lifting rod is provided with a dust collection box and a dust collector. One end of the dust collection box is provided with a dust collection pipe and a dust collection nozzle. The medical instrument dust removing storage box has the beneficial effects that the effect of removing dust for medical instruments is achieved, and the dust collection efficiency is improved.

Owner:蚌埠市诚海医疗器械有限公司

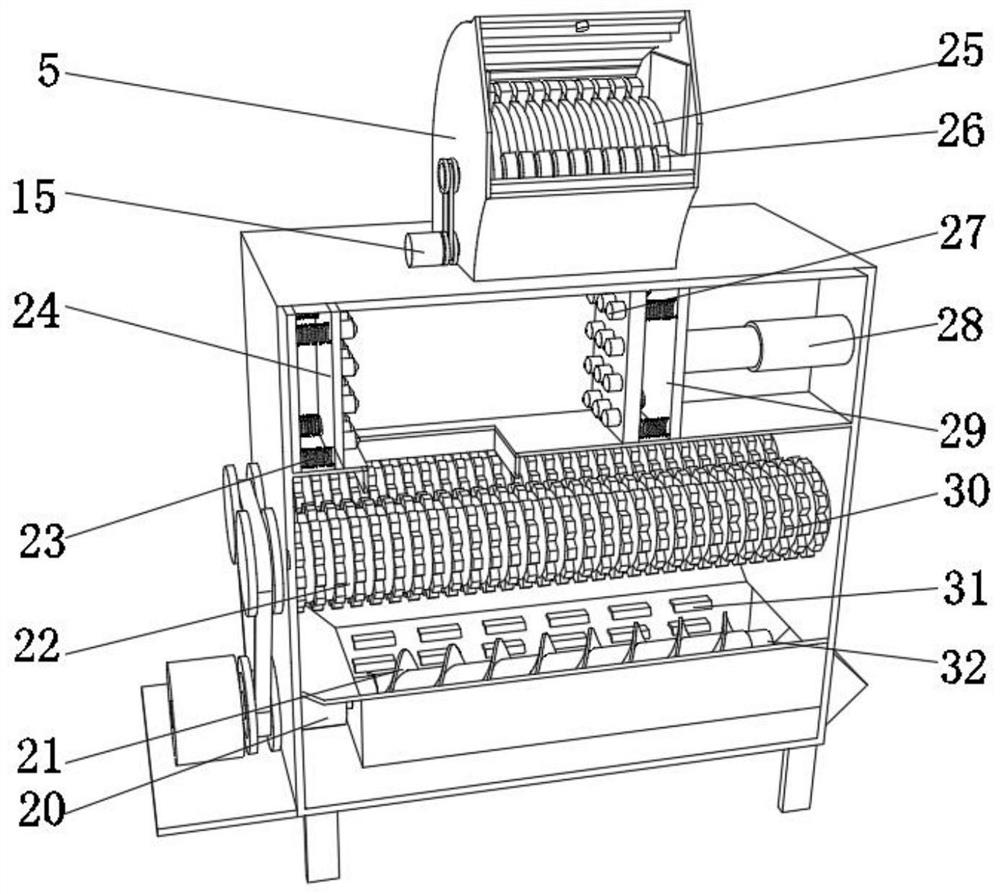

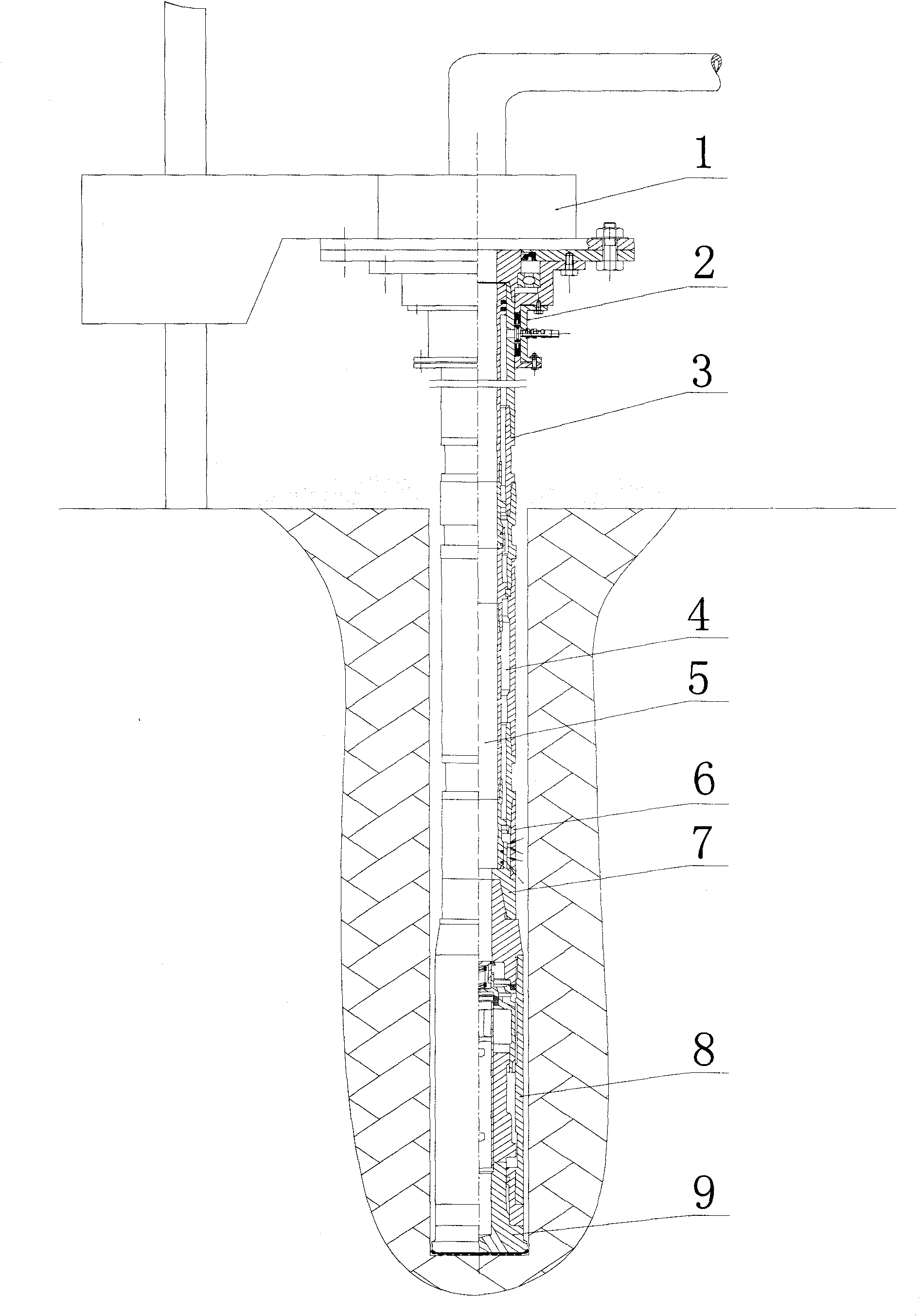

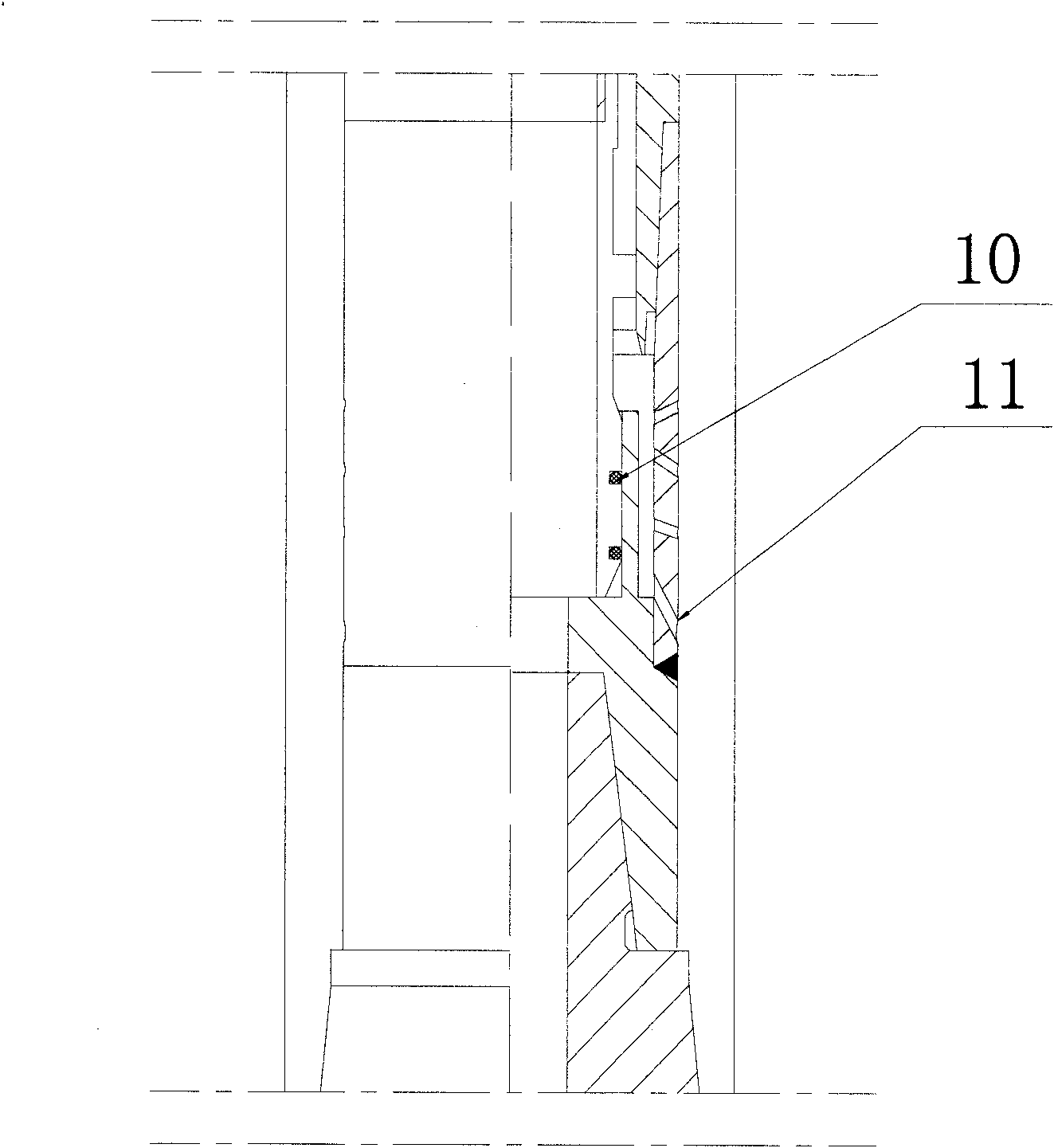

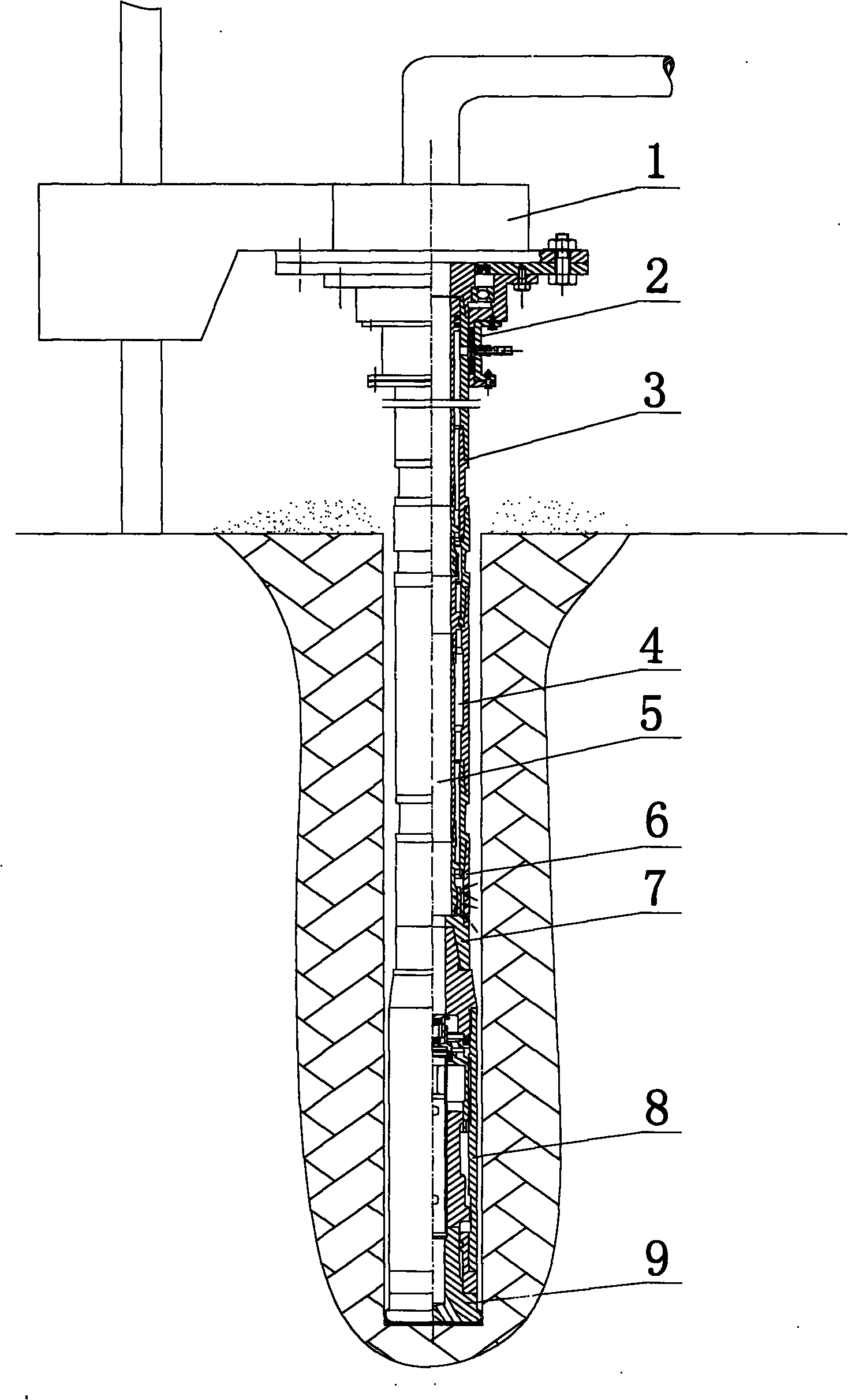

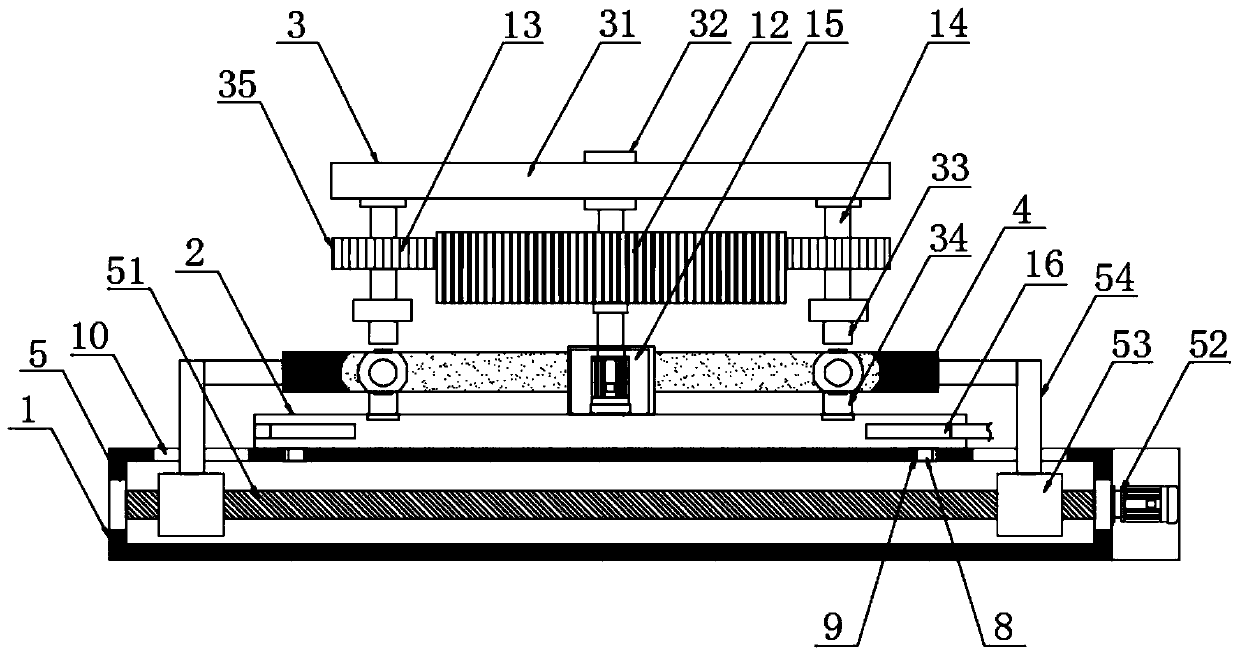

Positive-circulation drilling and dedusting technique of chamber down-hole hammer and double-wall pipe

InactiveCN101864895AReduce or eliminate hazardsAchieve dust removal effectBorehole drivesSlagDouble-walled pipe

The invention relates to a positive-circulation drilling and dedusting technique of a chamber down-hole hammer and a double-wall pipe, which is specially used for a positive-circulation drilling and dedusting method of combination of an ordinary down-hole hammer and a double-wall pipe. The dedusting portion is realized by three parts, i.e. a water delivering box, a double-wall pipe and a water injection conversion joint. Compared with other chamber injected hole drilling dedusting methods, the dedusting method has simple and reliable structure and favorable dedusting efficiency and does not affect the impact drilling efficiency of ordinary down-hole hammers. When the hammer head of the down-hole hammer is drilled, water with a certain pressure is fed to an annular gap of the double-wall pipe through a water box; water enters in the water injection conversion joint through the annular gap; pressure water is sprayed from holes circumferentially arranged on the water injection conversion joint to form a water spray area; waste gas carries rock powder to mix in the water spray area; and the formed multiphase flow of water, gas and rock slag is discharged outside through the annular gap between the double-wall pipe and the hole wall to realize positive-circulation drilling wet-type dedusting of ordinary down-hole hammers.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

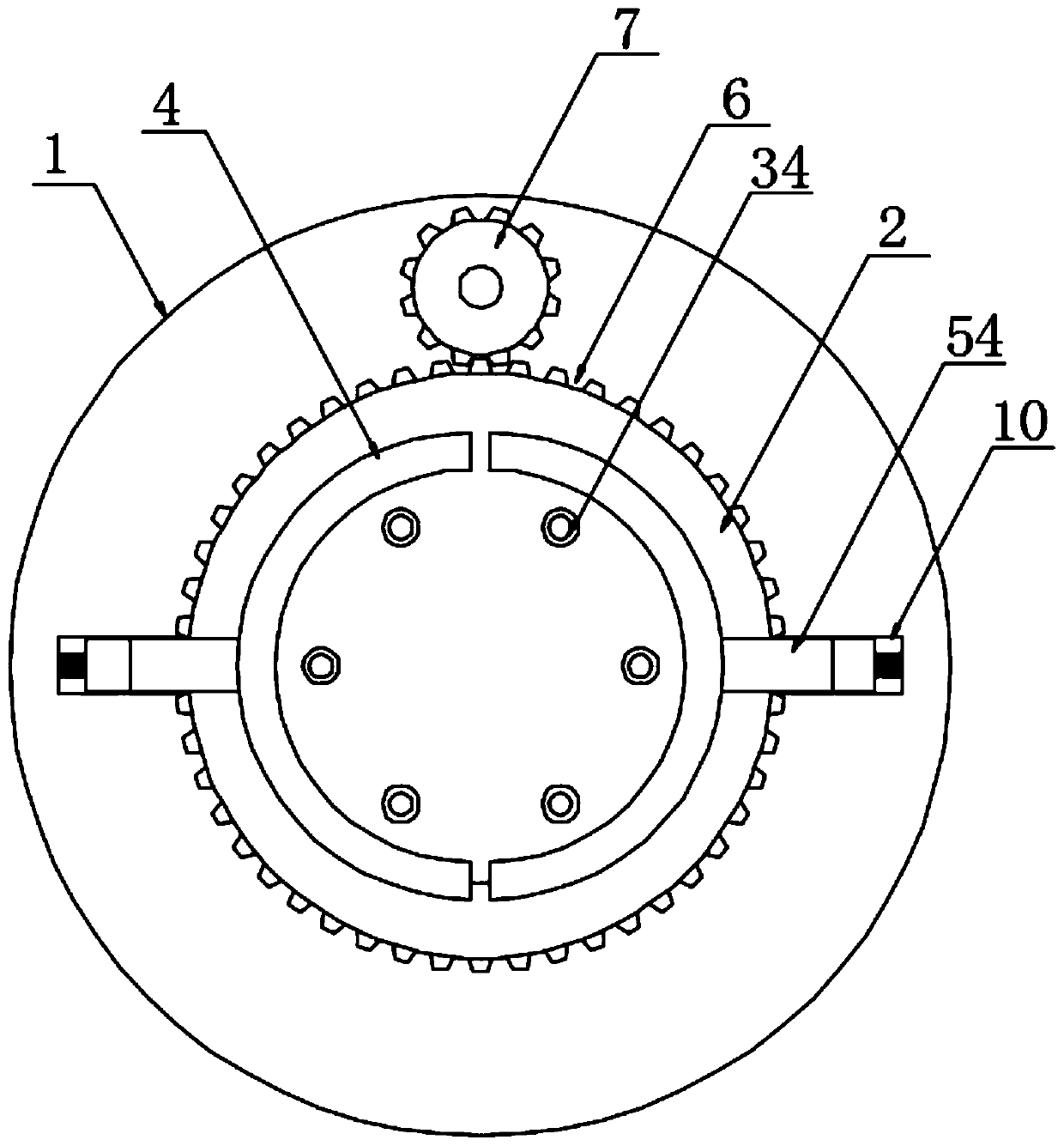

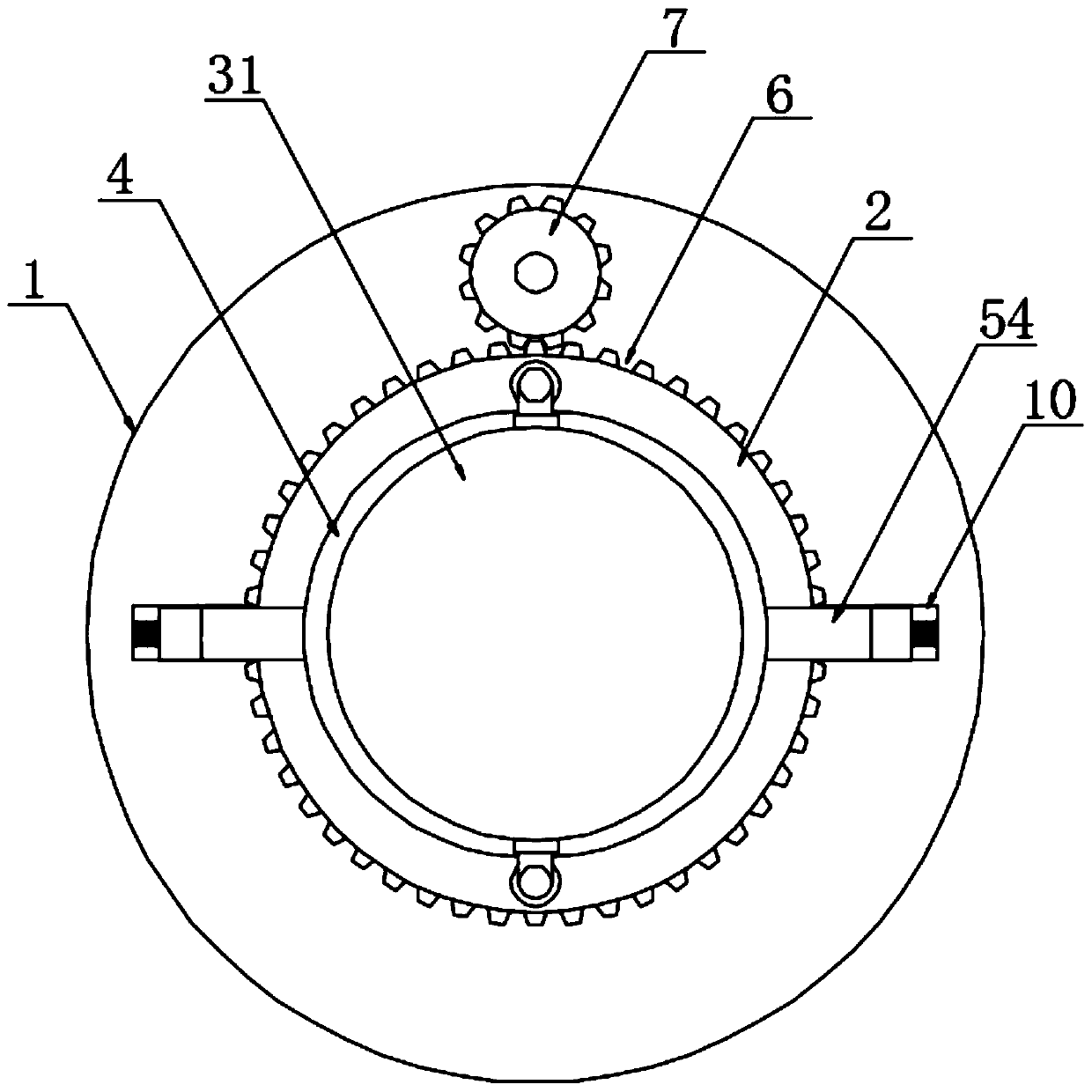

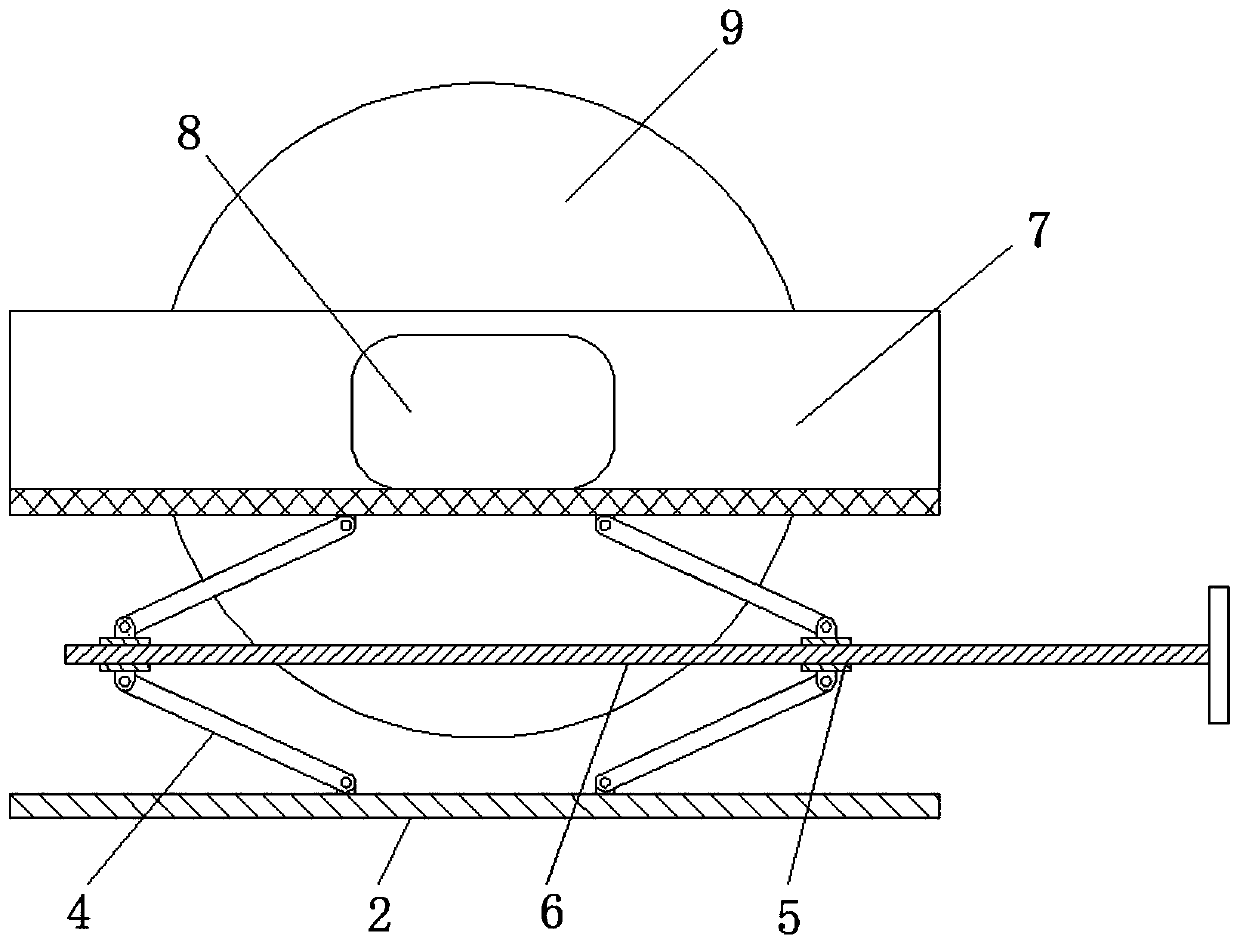

Spherical surface grinding device for ball valve cores

ActiveCN111113198AImprove work efficiencyEasy to useGrinding drivesSpherical surface grinding machinesRotary stageGear wheel

The invention discloses a spherical surface grinding device for ball valve cores and particularly relates to the field of ball valve element machining. The spherical surface grinding device for the ball valve cores comprises a worktable, a rotating table is arranged at the top of the worktable, a multi-ball-core clamping mechanism is arranged at the top of the rotating table, outer grinding platesare arranged on the two sides of the multi-ball-core clamping mechanism respectively, the two outer grinding plates are driven through a reciprocating mechanism to do reciprocating linear movement and are used for grinding the spherical surfaces of ball cores fixed by the multi-ball-core clamping mechanism, tooth grooves are formed in the outer wall of the rotating table, and a driving gear engaged with the tooth grooves is arranged on the rear side of the rotating table. The spherical surface grinding device can grind multiple ball cores at the same time, and the working efficiency is greatly improved; besides, when the contact faces of the outer grinding plates and the ball cores are worn, position offset replacement of multiple ball core clamps can be achieved simply by driving the rotating table through the driving gear, and the grinding faces of the outer grinding plates and the ball cores are replaced; and the grinding device is very convenient to use, adjustment is quick, and the machining efficiency and the precision of the ball cores are not influenced.

Owner:顶红科技发展(浙江)有限公司

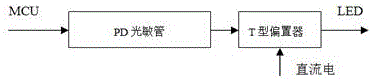

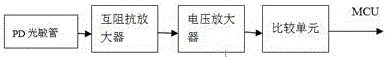

Photovoltaic energy-saving intelligent haze adsorption street lamp

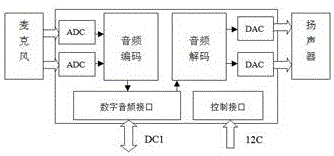

InactiveCN106195887AAvoid damageIncrease humidityMechanical apparatusElectric circuit arrangementsMicrocontrollerSignal processing circuits

The invention discloses a photovoltaic energy-saving intelligent haze adsorption street lamp which comprises a receiving antenna, a signal processing circuit, a power circuit and a white light LED. The intelligent street lamp is a single chip microcomputer and is used for controlling a voice coder-decoder to collect, compress and code voice data and sending the collected data to an LED driving circuit through a serial port, and the LED driving circuit sends an on-off signal according to an instruction. A photoelectric detection module controls a PD photosensitive tube to receive an optical signal and output the optical signal to the intelligent street lamp, and the intelligent street lamp sends the received data to the voice coder-decoder to be decoded and output. According to the system, the complexity and the cost are low, the communication distance is short, and illumination and real-time voice talkback can be achieved at the same time; and meanwhile, the system can also transmit other data except voice.

Owner:SUZHOU TIANQING ELECTRONICS COMM

Environmental protection device capable of efficiently removing dust and haze

InactiveCN107670405AQuality improvementProtect healthGas treatmentDispersed particle separationDrive shaftDrive motor

The invention discloses a high-efficiency dust and haze removal environmental protection device. The left end of the driving motor is rotatably connected to the right end of the transmission shaft, and the bearing at the left end of the transmission shaft is rotatably connected to the body of the device; The bevel gear, and the second bevel gear are fixedly connected to the top of the worm, the upper end of the worm is sleeved on the right end of the stabilizer bar, and the left end of the stabilizer bar is fixedly connected to the device body; the left end of the worm is meshed and connected to the worm wheel, the front end of the worm wheel is rollingly connected to the upper end of the transmission belt, and the lower end of the transmission belt is rollingly connected to the air pump. The device drives the spiral descending barrel to rotate through the pinion, and the rotating spiral descending barrel forms a downward spiral flow, and the dust suspended in the spiral flow falls and gathers on the side wall of the dust-gas separator under the action of centrifugal force. To achieve dust removal effect. The structural design of the device is reasonable and applicable, which greatly reduces the content of PM. in the air, effectively improves the air quality, is beneficial to improving people's living environment, and provides protection for human health.

Owner:曹茂娟

Plastic waste efficient processing device for decoration

InactiveCN110124771AEvenly distributedQuality is not affectedUsing liquid separation agentGrain treatmentsPlastic wasteEngineering

The invention discloses a plastic waste efficient processing device for decoration. The plastic waste efficient processing device comprises a bottom plate, one side of the bottom plate is provided with a side plate, the top of the side plate is provided with a top plate, and the top of the top plate is provided with a servo motor; an output shaft of the servo motor penetrates through the top plateto be connected with a rotary rod; the rotary rod is sleeved with a first bevel gear, the rear side of the first bevel gear is provided with a second bevel gear, and the rear side of the second bevelgear is connected with a first belt wheel; the bottom of the top plate is provided with a strut, the bottom of the strut is rotationally connected with a second belt wheel, and the second belt wheeland the first belt wheel are sleeved with the same belt; the front side of the second belt wheel is connected with a first cam; a first connection rod is hinged to the front side of the first cam, a first moving rod is hinged to the end of the first connection rod, a pressing block is connected to the bottom of the first moving rod, and conical teeth are uniformly distributed at the bottom of thepressing block; and the end of a transmission block is connected with an elastic mechanism, and the end of the elastic mechanism is connected with a breaking frame. The plastic waste efficient processing device for decoration achieves the effects of being good in breaking effect, high in breaking speed and capable of removing dust effectively.

Owner:翁宇彬

Water-cooling furnace cover of ladle refining furnace and using method thereof

PendingCN109099716AReduce power consumption and electrode consumptionReduce the escape of smokeIncreasing energy efficiencyWaste heat treatmentFlueEnergy consumption

The invention discloses a water-cooling furnace cover of a ladle refining furnace and a using method thereof. The water-cooling furnace cover comprises a furnace cover body, a main exhaust flue and adust removing pipeline. The lower end of the furnace cover body is opened and is fixedly connected with a skirt flue, the upper end of the furnace cover body is opened and is provided with a supporting ring, a refractory furnace ring is placed on the supporting ring, and a smoke hood is arranged on the refractory furnace ring in a covering mode; a first lateral suction flue and a second flue lateral suction flue are formed in the upper portion of the skirt flue, and the second flue lateral suction flue is connected with the side wall of the smoke hood through a second flange connecting pipe; and the main exhaust flue is of a three-channel structure made by heat-resistant steel in a welded mode and comprises a first channel, a second channel and a third channel, the first channel is connected with the smoke hood through a first flange connecting pipe, the second channel is connected with the first lateral suction flue, and the third channel and the dust removing pipeline are connected through a flexible sealing piece in a dynamically sealed mode. The water-cooling furnace cover has the good dust removing effect and is small in air consumption volume, the requirement for the micro-positive pressure in the furnace in the refining process is ensured, and meanwhile, the purposes of reducing energy consumption and reducing electrode consumption are achieved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

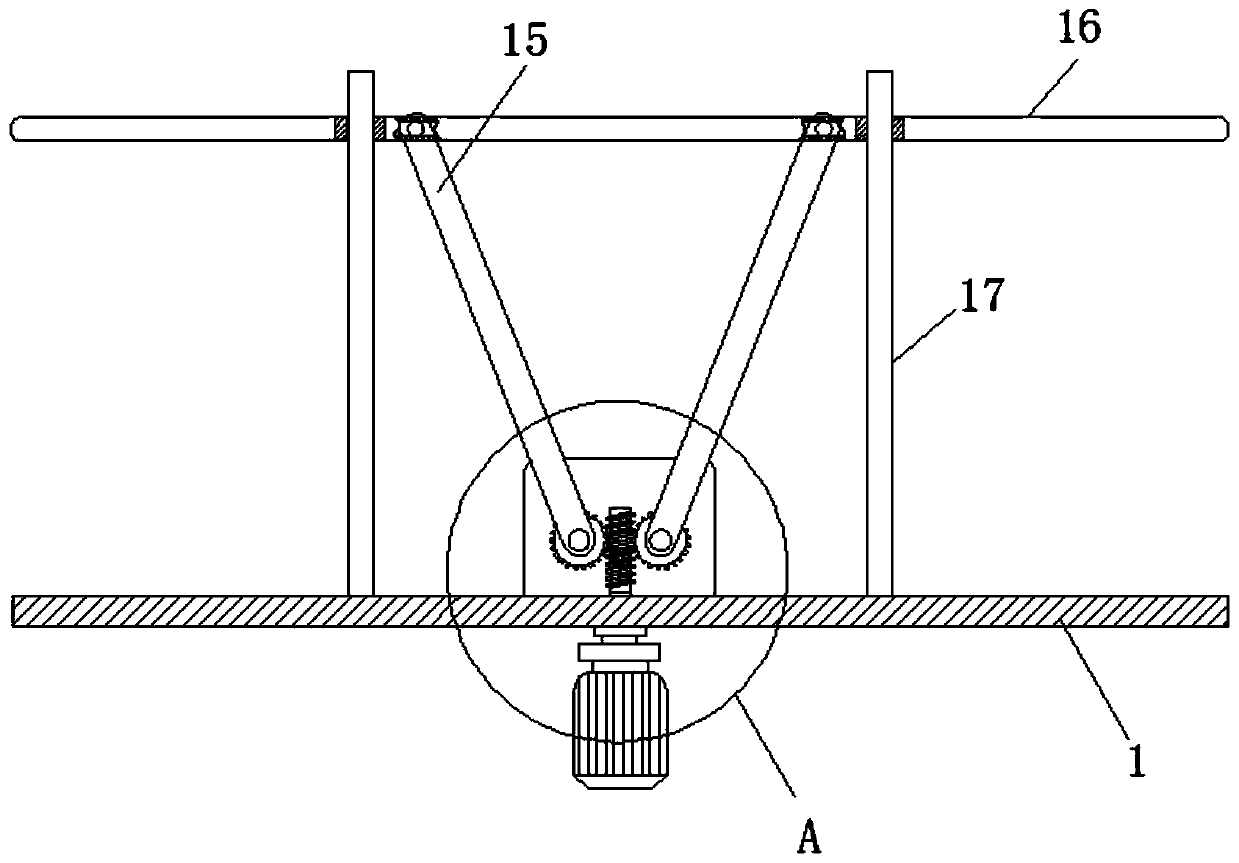

Blockboard cutting device based on screw drive theory

InactiveCN111452139AMeet processing needsEasy to processFeeding devicesGripping devicesGear wheelElectric machinery

The invention relates to the technical field of blockboards, and discloses a blockboard cutting device based on the screw drive theory. The blockboard cutting device comprises a workbench, and a rotary frame is connected in the workbench in a hinged manner. The outside of the rotary frame is engaged with a rotary gear, and a supporting rod is connected in the rotary frame in a hinged manner. The outside of the supporting rod is connected with a threaded block in a hinged manner, and an adjusting screw rod is in threaded connection with the interior of the threaded block. The outside of the supporting rod is connected with a supporting plate in a hinged manner, and the top of the supporting plate is fixedly connected with a cutting motor. The outside of the cutting motor is movably connected with a saw web. By means of cooperative use of the rotary frame, the rotary gear, the supporting rod, the threaded block, the adjusting screw rod and the supporting plate, the effect of adjusting the cutting angle and height of the saw web is achieved, and various machining needs of blockboards are met; and oblique incisions of the blockboards can be cut conveniently, the use range of the equipment is effectively widened, and the cutting effect of the device is improved.

Owner:湖州林立木业有限公司

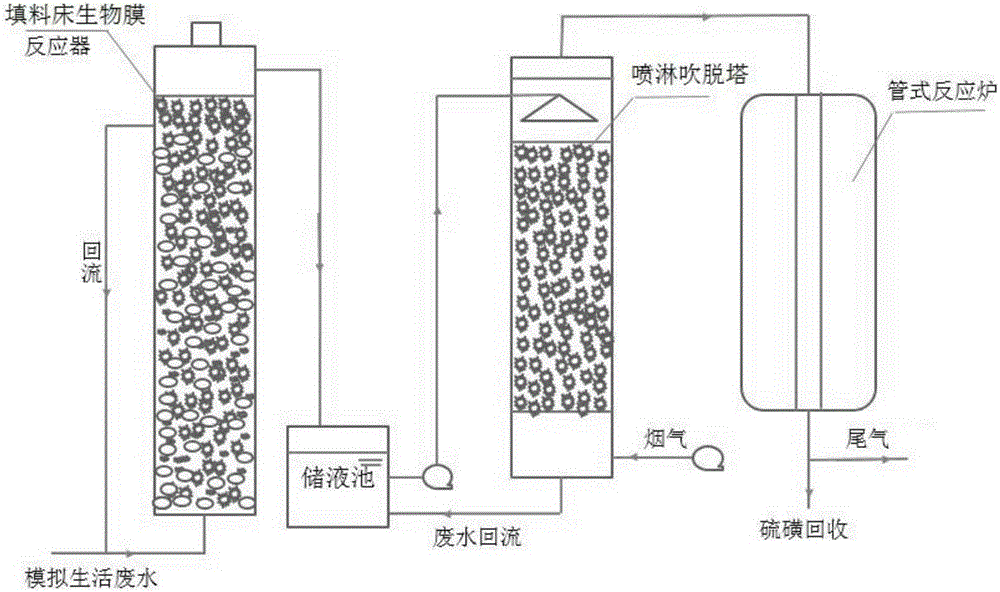

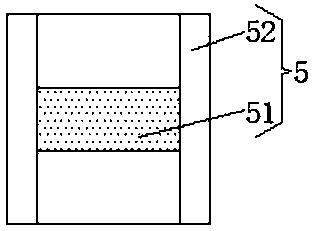

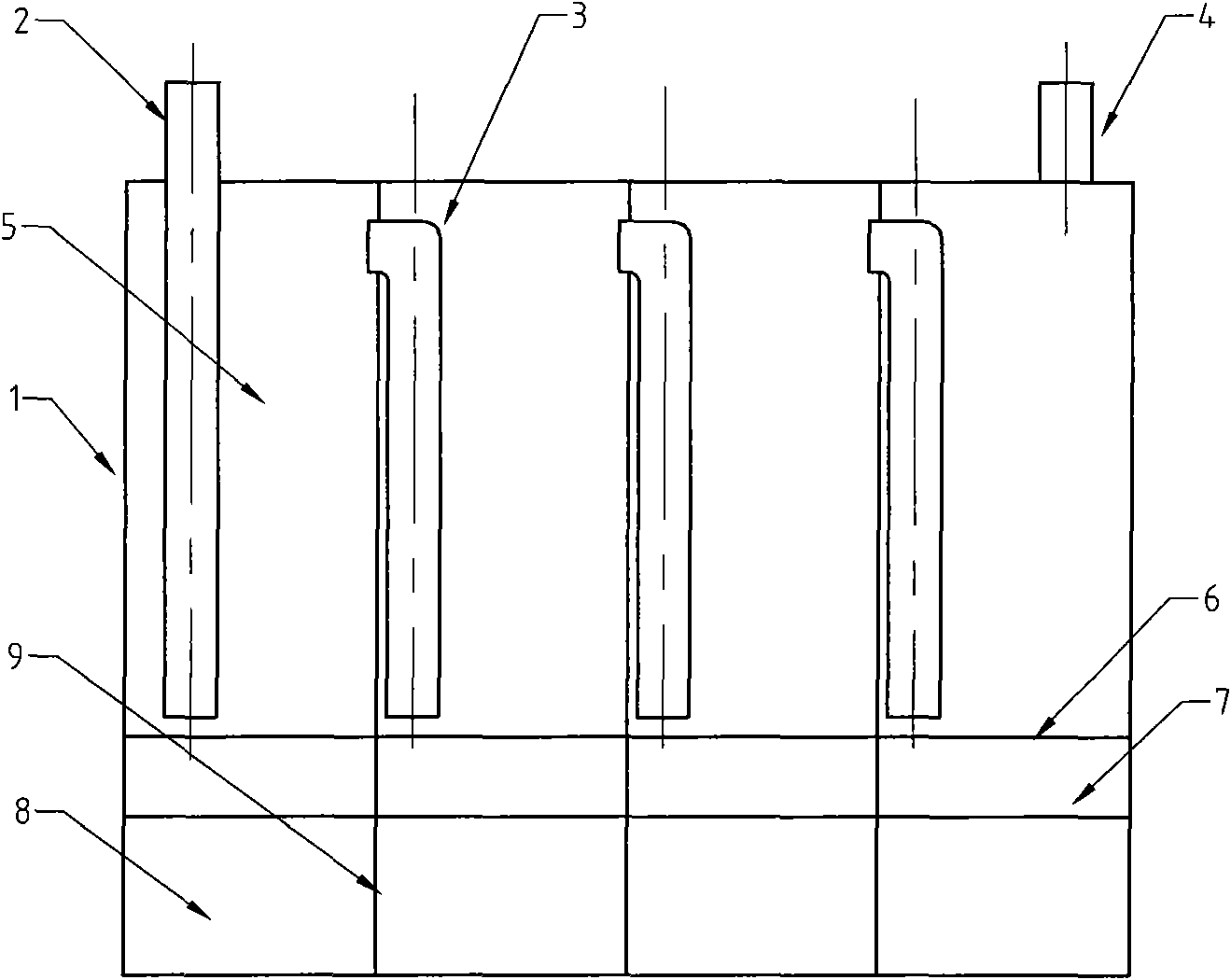

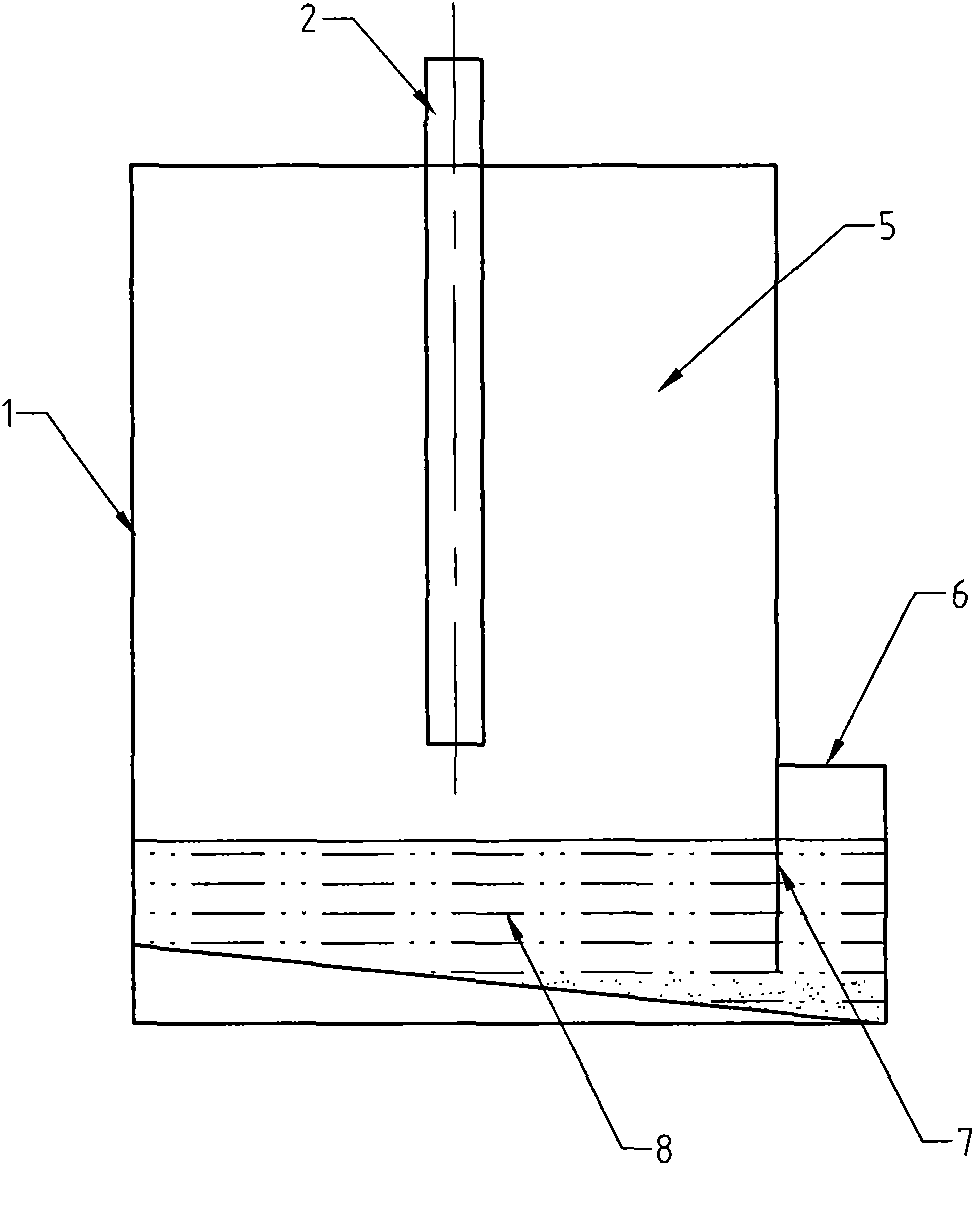

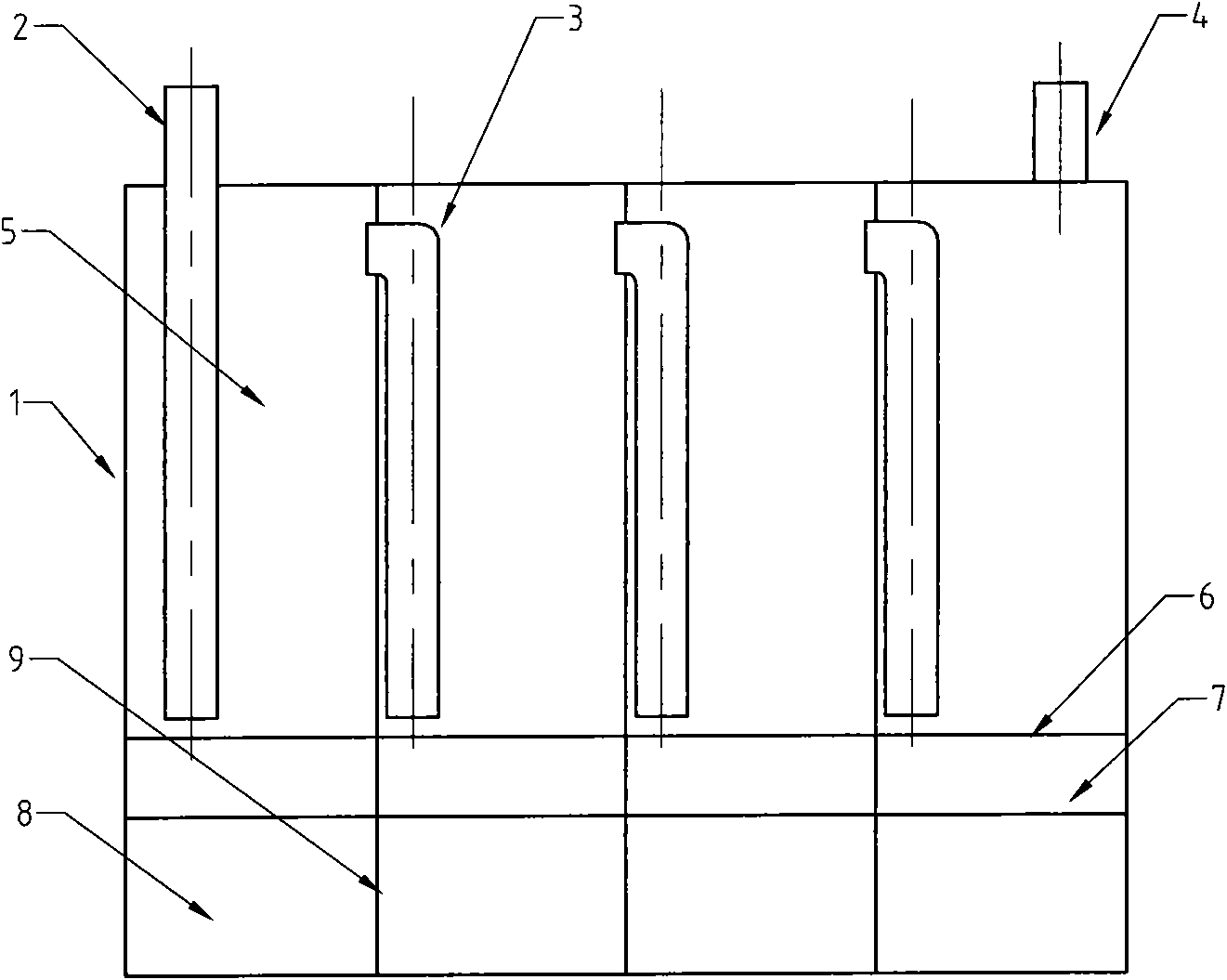

Boiler water film dedustor

InactiveCN102008863AAchieve dust removal effectImprove dust removal effectUsing liquid separation agentEngineeringAdjacent level

The invention relates to a boiler water film dedustor, and belongs to the field of boiler dedustors. The main structure of the boiler water film dedustor comprises a shell body (1), a smoke inlet pipe (2), a smoke outlet pipe (4), guide pipes (3), dedusting chambers (5) and water ash pools (8), wherein the shell body (1) is divided into a plurality of levels of the dedusting chambers (5) through partition plates (9); the adjacent levels of the dedusting chambers (5) are connected through the guide pipes (3); each water ash pool (8) is positioned at the bottom of each level of the dedusting chamber (5); one end of the smoke inlet pipe (2) is connected with a boiler smoke pipe; the other end is extended to the lower part of the dedusting chamber (5) and is parallel with the guide pipes (3);and the smoke outlet pipe (4) is introduced from the upper part of the last level of the dedusting chamber (5) and is connected with a draught fan externally. The boiler water film dedustor has a simple and reasonable structure, a good dedusting effect and high efficiency, saves water and is an ideal water film dedustor.

Owner:CHENZHOU HAOLUN BIOCHEMICAL AUXILIARY CO LTD

Multi-stage spray treatment device for waste gas of printing and dyeing setting machine

InactiveCN103405977AImprove dust collection efficiencyReduce manufacturing costUsing liquid separation agentSpray nozzleTower

The invention discloses a multi-stage spray treatment device for waste gas of a printing and dyeing setting machine. The multi-stage spray treatment device comprises purification chambers including a primary purification chamber and a secondary purification chamber, wherein the interior of the primary purification chamber is divided into multiple layers of purification areas through partition boards; the partition boards are horizontally arranged in parallel in a staggered manner; an all-directional fine atomization area is arranged above a second air inlet of the secondary purification chamber; a water curtain wall blockage area is arranged at the upper part of the fine atomization area; a plurality of tower plates are vertically arranged in the water curtain wall blockage area, a plurality of spray nozzles are placed between the inner wall of the water curtain wall blockage area and the tower plates and between every two tower plates in a staggered manner, and the outlet directions of the spray nozzles are opposite; the spray nozzles spray airflow and water to the inner wall of the water curtain wall blockage area or the tower plate walls simultaneously to form a water curtain wall, so that liquid drops flow downwards along the tower plate walls or the inner wall of the water curtain wall blockage area, and the purified gas runs upwards continuously. According to the invention, the spray mechanism has three different effects, so that the dust collecting efficiency is improved, the production cost is reduced, and the multi-stage spray treatment device can be widely applied to treatment of waste gas of the printing and dyeing setting machine.

Owner:ZHEJIANG HAILIANG ENERGY MANAGEMENT +2

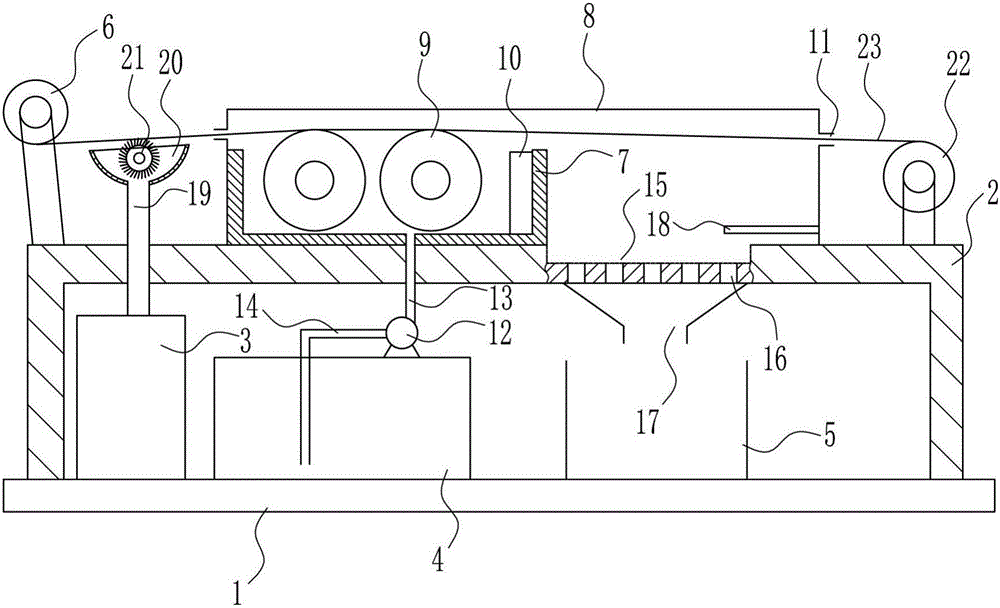

Printing and dyeing equipment with dust removal and drying device

InactiveCN106192261ANot easy to affect qualityImprove qualityLiquid/gas/vapor removalTextile treatment machine arrangementsWorking environmentEngineering

The invention relates to printing and dyeing equipment, in particular to printing and dyeing equipment with a dust removal and drying device. The printing and drying equipment with the dust removal and drying device has the technical purposes of removing dust on fabric before printing and dyeing, improving fabric quality, collecting printing and dyeing liquid dropped on the fabric in time, ensuring working environment, carrying out drying in time after printing and dyeing are completed and facilitating fabric storage. The printing and drying equipment with the dust removal and drying device comprises a bottom plate, an N-shaped support, a dust collector, a printing and drying liquid box, a collection box, an unreeling roller wheel, a printing and dyeing box, a dustproof cover, an electric printing and dyeing roller wheel, a liquid level detection device and the like. The bottom plate is provided with the N-shaped support. The printing and drying equipment with the dust removal and drying device can remove dust on fabric before printing and dyeing, improve fabric quality, collecte printing and dyeing liquid dropped on the fabric in time, ensure working environment and carry out drying in time after printing and dyeing are completed.

Owner:绍兴明业印染有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com