Boiler water film dedustor

A dust collector and boiler water technology, applied in chemical instruments and methods, separation of dispersed particles, use of liquid separation agents, etc., can solve the problems of high desulfurization and dust removal efficiency, discount of dust removal effect, waste of water resources, etc., and achieve simple and reasonable structure, Good dust removal effect and water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

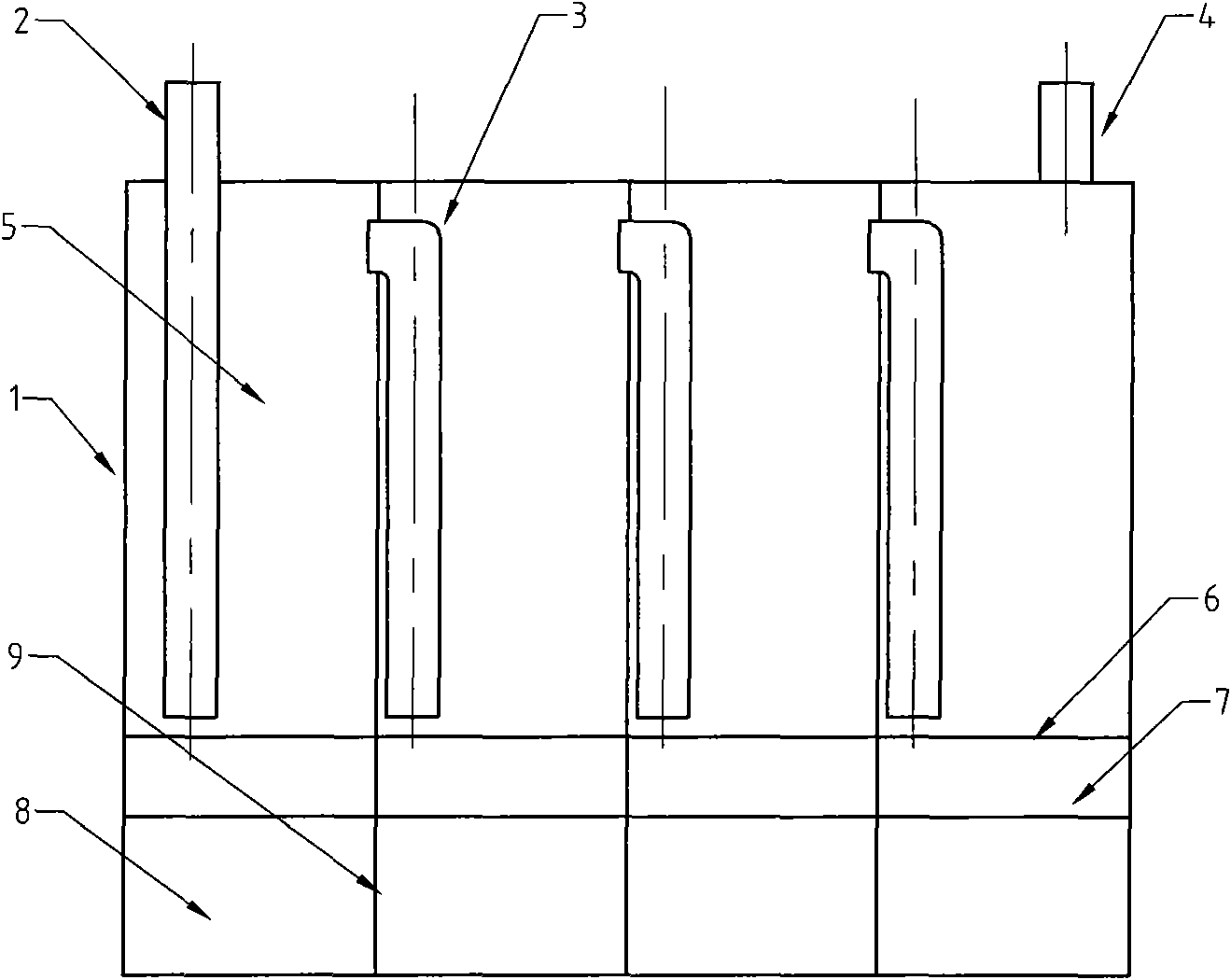

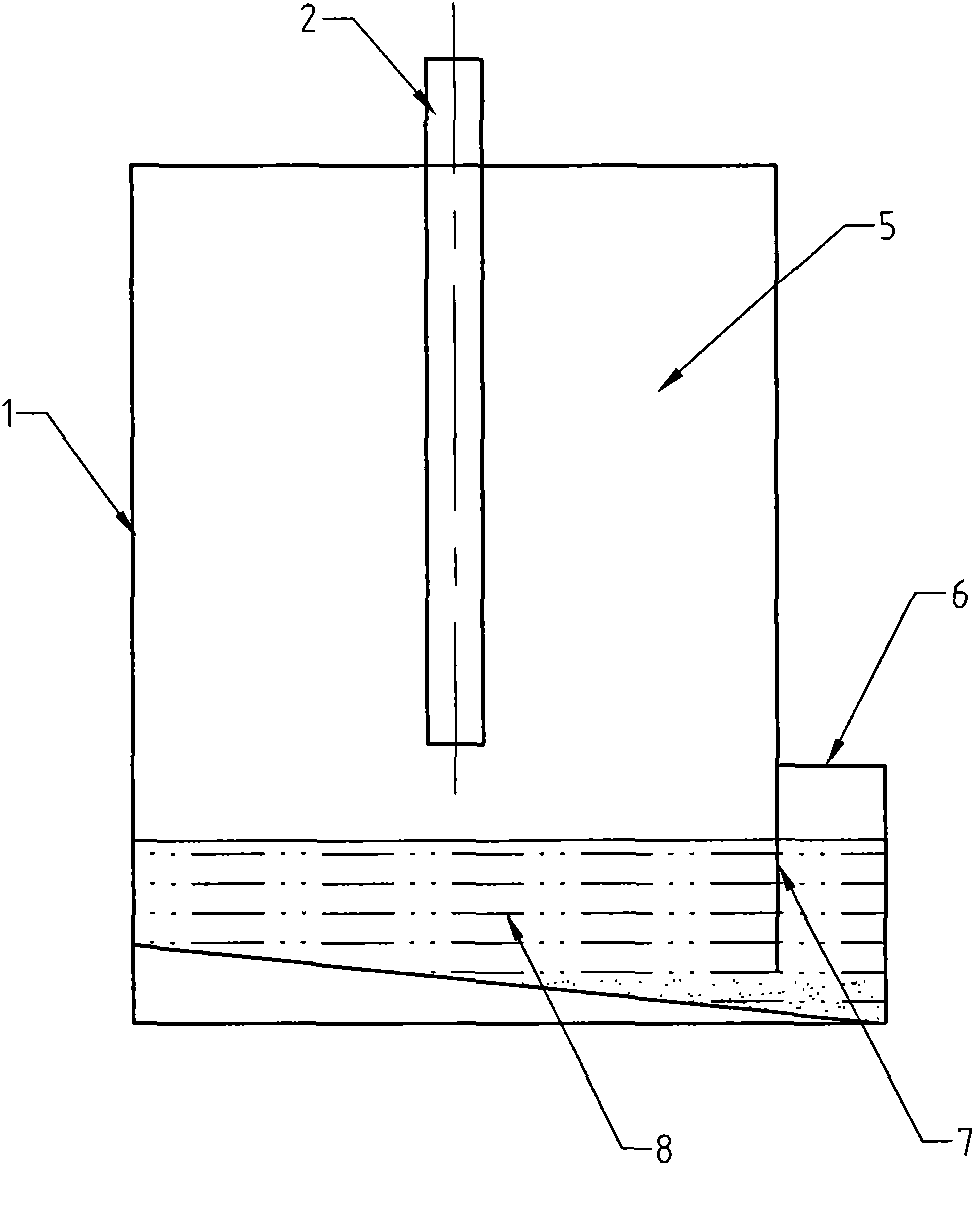

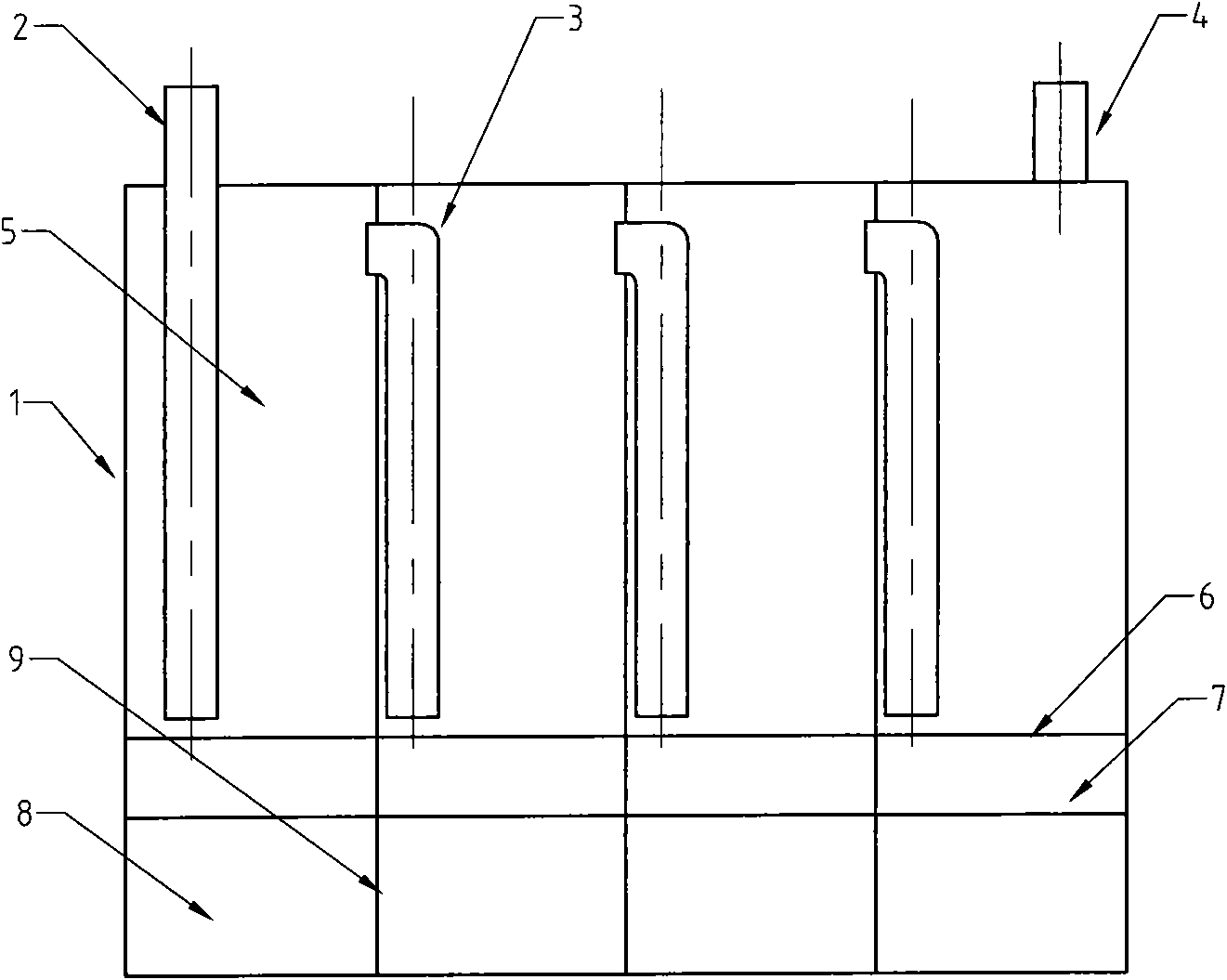

[0010] Reference attached figure 1 , 2, This embodiment is a boiler water film dust collector, including the shell 1, the smoke inlet pipe 2, the smoke outlet pipe 4, the guide pipe 3, the dust removal chamber 5, and the ash tank 8. The shell 1 is divided into several stages of dust removal chambers 5 by partitions 9, and the adjacent stages of dust removal chambers 5 are connected by a guide pipe 3, and one end of the guide pipe 3 extends to the lower part of the dust removal chamber 5 to control the direction of the furnace smoke, so that The furnace smoke moves from the bottom to the top in each dust removal chamber 5; the bottom of the dust removal chamber 5 is a water ash pool 8, and the water in the water ash pool 8 is used to seal the dust removal chamber 5 and form a water film; the water ash pool 8 is both a water pool Be ash pool again, the dust that is removed by dedusting chamber 5 falls in the water ash pool to be convenient to the collection of dust. The furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com