Water-cooling furnace cover of ladle refining furnace and using method thereof

A technology of ladle refining furnace and water-cooled furnace cover, applied in furnaces, furnace components, waste heat treatment, etc., can solve problems such as inability to realize micro-positive pressure control, increase electrode consumption, affect operation and maintenance, and reduce flue gas Escaping, reducing power consumption and electrode consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

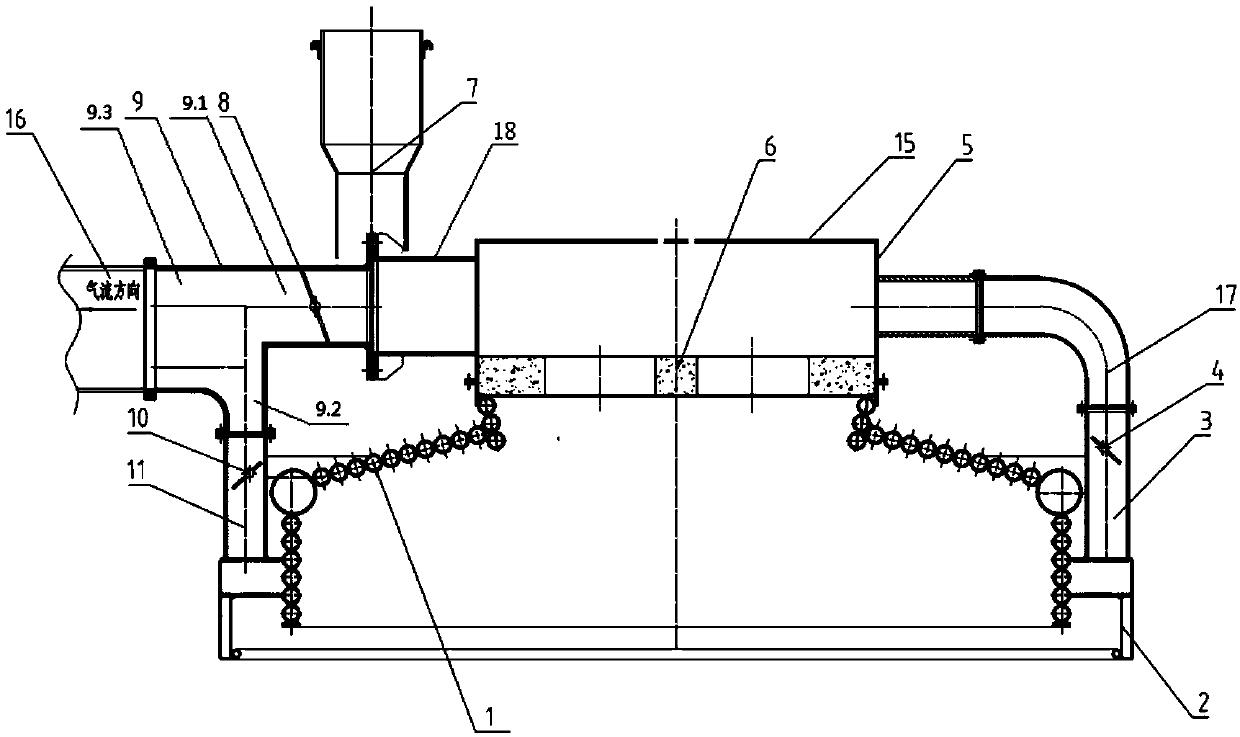

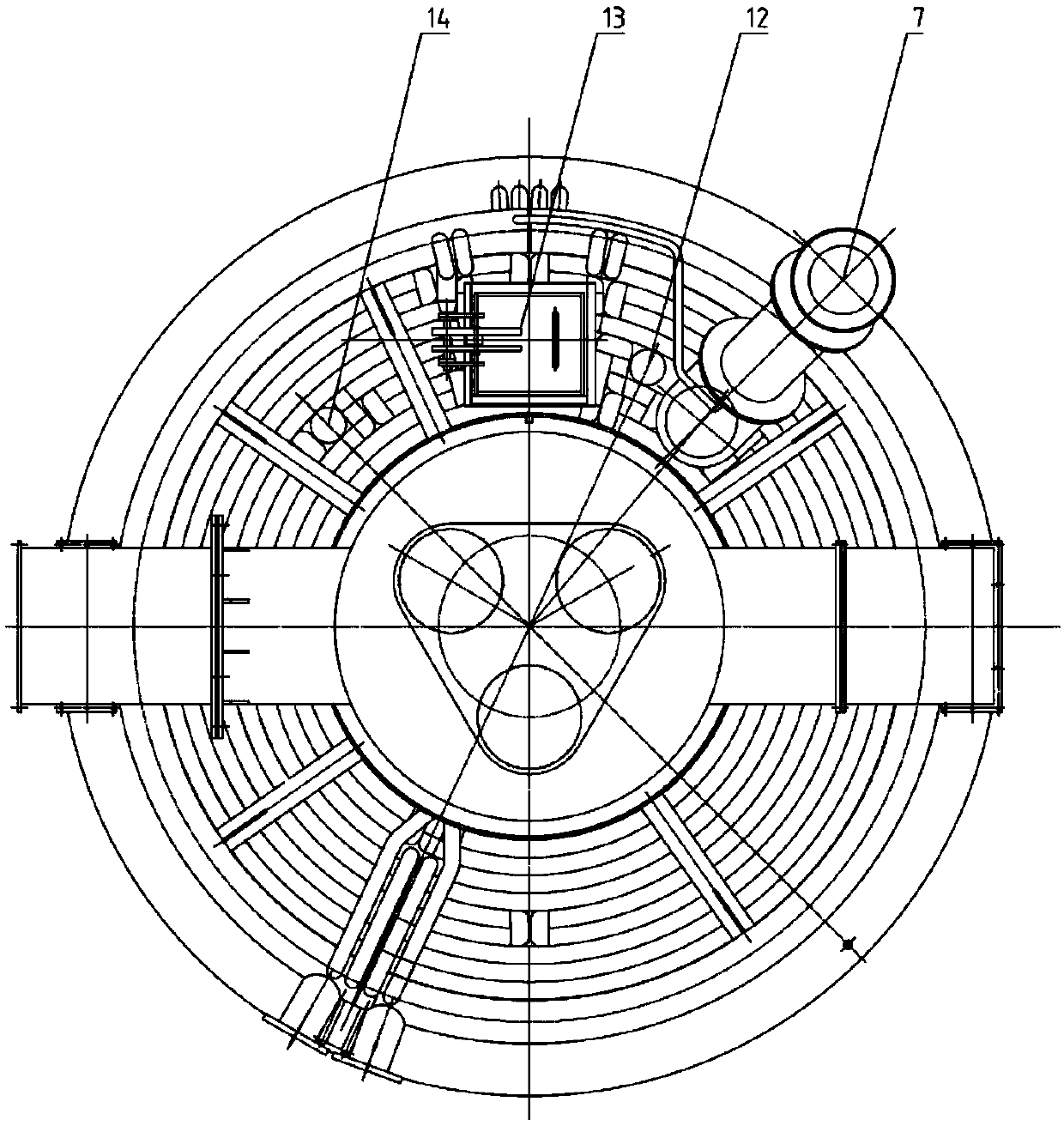

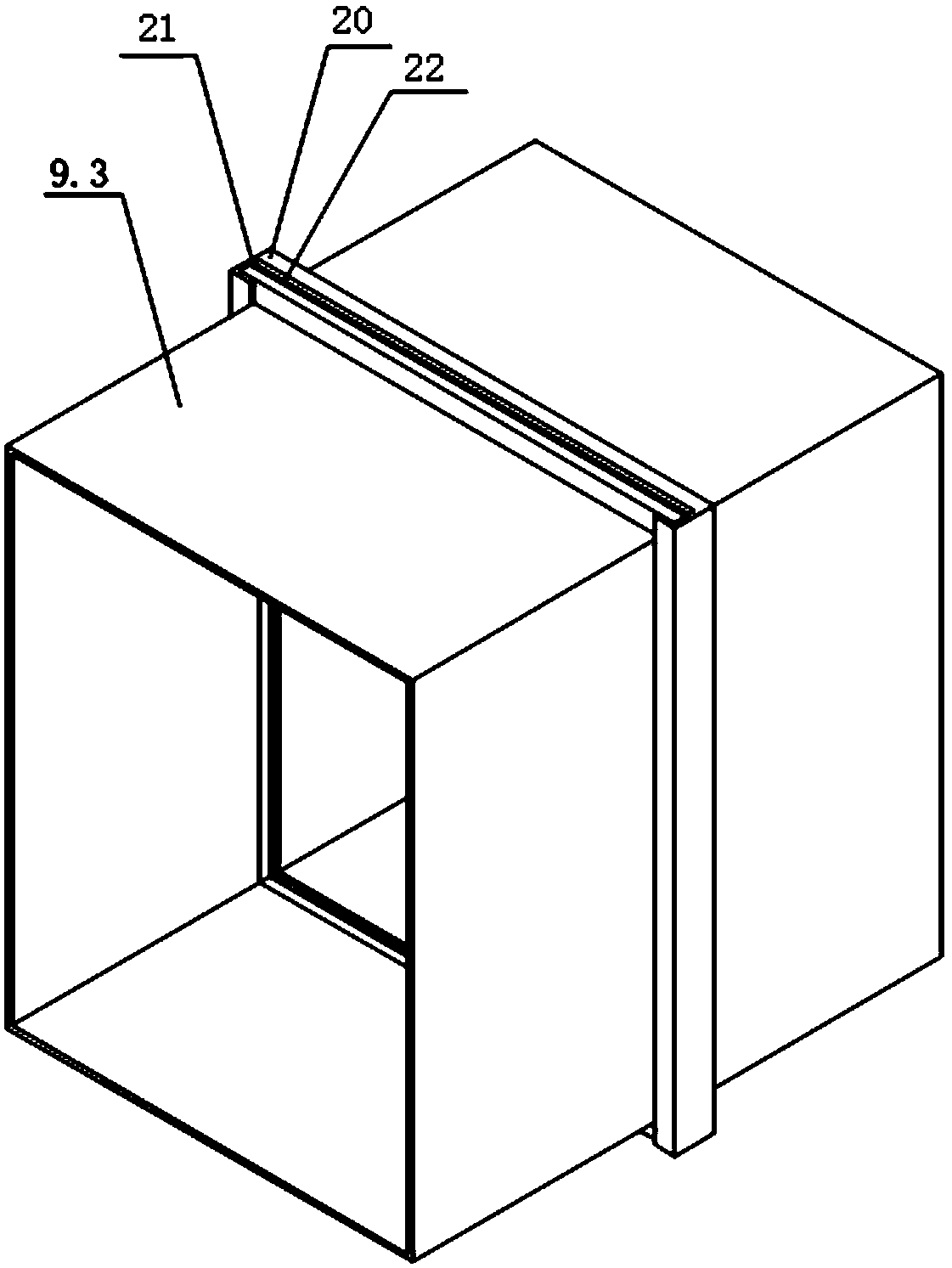

[0028] Such as figure 1 As shown, a water-cooled furnace cover of a ladle refining furnace at least includes a furnace cover body 1, a main exhaust flue 9, and a dust removal pipeline 16. The furnace cover body 1 is a water-cooled structure made of several heat-resistant seamless steel tubes. The lower end of the furnace cover body 1 is open and is fixedly connected with a skirt flue 2. The upper end of the furnace cover body 1 is open and provided with a support ring, and a refractory furnace ring 6 is placed on the support ring, and the refractory furnace ring 6 is covered A smoke hood 5 is provided; a side smoke passage 11 and a side smoke passage 2 3 are arranged above the skirt flue 2, and the side smoke passage 2 3 is connected to the side wall of the smoke hood 5 through a flange connection pipe 2 17 The main exhaust flue 9 is a three-channel structure welded by heat-resistant steel, including a channel 9.1, a channel 2 9.2 and a channel 9.3, and the channel 9.1 connect...

Embodiment 2

[0031] On the basis of embodiment 1, the skirt flue 2 is a box-type water-cooled structure welded by heat-resistant steel plates, the skirt flue 2 lower end openings, and the opening size is adapted to the diameter of the ladle.

[0032] Flap valve one 10 is installed in described side smoke passage one 11, and flap valve two 4 is installed in side smoke passage two 3. The first passage 9.1 of the main smoke passage 9 is provided with a turn-over valve three 8. The flap valve can adjust the draft volume and flue gas volume of different flues.

[0033] There are multiple side smoke passages 2 3 , which are distributed along the circumference of the skirt flue 2 , and the number of side smoke passages 2 3 is determined by the diameter of the furnace cover body 1 .

[0034] The top fume hood of the present invention is connected to the side smoke passage two through the flange connection pipe two 17. Such a design structure can realize that part of the exhaust gas in the furnace...

Embodiment 3

[0036] On the basis of the foregoing embodiments, the fume hood 5 is welded from heat-resistant steel, and its lower part is connected to the furnace cover body 1 support ring; the upper part is a heat-resistant steel plate 15 with a hole in the middle, and the heat-resistant steel plate 15 The opening area is determined according to the diameter of the electrode and the diameter of the pole center circle; the side wall of the smoke hood 5 is provided with a flange connection pipe 18 to connect with the channel 1 9.1 of the main exhaust duct 9; the side wall of the smoke hood 5 is also provided with a flange connection pipe Two 17 are connected with side smoke passage two 3.

[0037] The present invention designs a smoke hood 5 with a top opening on the upper part of the refractory furnace ring 6, which is mainly used to collect the flue gas that escapes from the electrode hole of the refractory material furnace ring, and enters the dust removal pipeline 16 through the main air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com