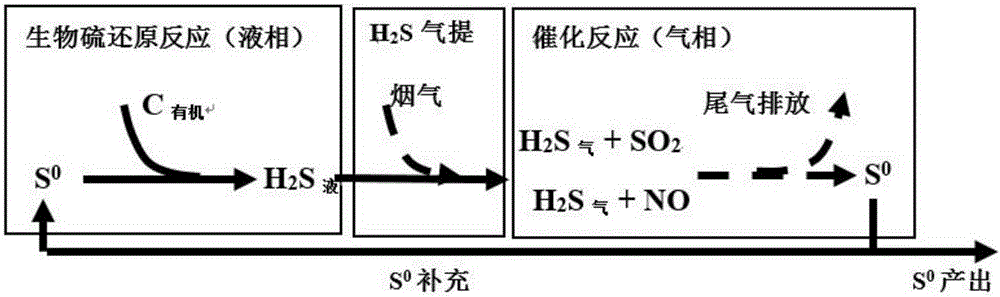

Synchronous desulfurization and denitrification technology of coal-fired flue gas by taking hydrogen sulfide as reducing agent

A technology for desulfurization, denitrification, and coal-burning flue gas, which is applied in the preparation/purification of sulfur, anaerobic digestion treatment, air quality improvement, etc. cost, realize the effect of waste heat utilization, and reduce load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

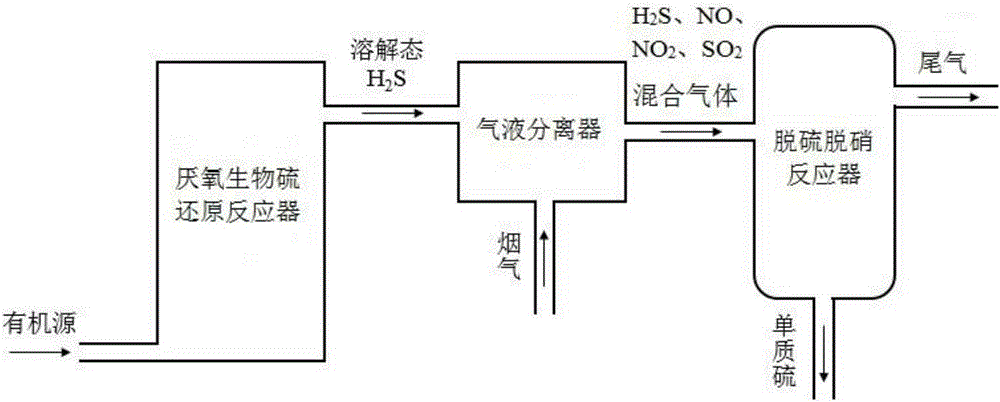

[0054] 1) Dissolved H 2 Preparation of S: Add organic sources, elemental sulfur and sulfur-reducing bacteria into the anaerobic biological sulfur reduction reactor to fully contact the organic source, elemental sulfur and sulfur-reducing bacteria. Under the action of sulfur-reducing bacteria, the organic matter is oxidized and removed, and the elemental sulfur Sulfur is converted to H 2 S, the effluent of the reactor is rich in dissolved H 2 S;

[0055] 2)H 2 S, NO, NO 2 , SO 2 Preparation of mixed gas: will be rich in dissolved H 2 The effluent of S is passed into the gas-liquid separator from the top, and the coal-fired flue gas is passed into the gas-liquid separator from the bottom at the same time, the water flow and the flue gas are in reverse contact, and the gas-liquid separation is carried out to obtain H 2 S, NO, NO 2 , SO 2 mixed composition;

[0056] 3) Synchronous desulfurization and denitrification: H 2 S, NO, NO 2 , SO 2 The mixed gas and catalyst ar...

Embodiment

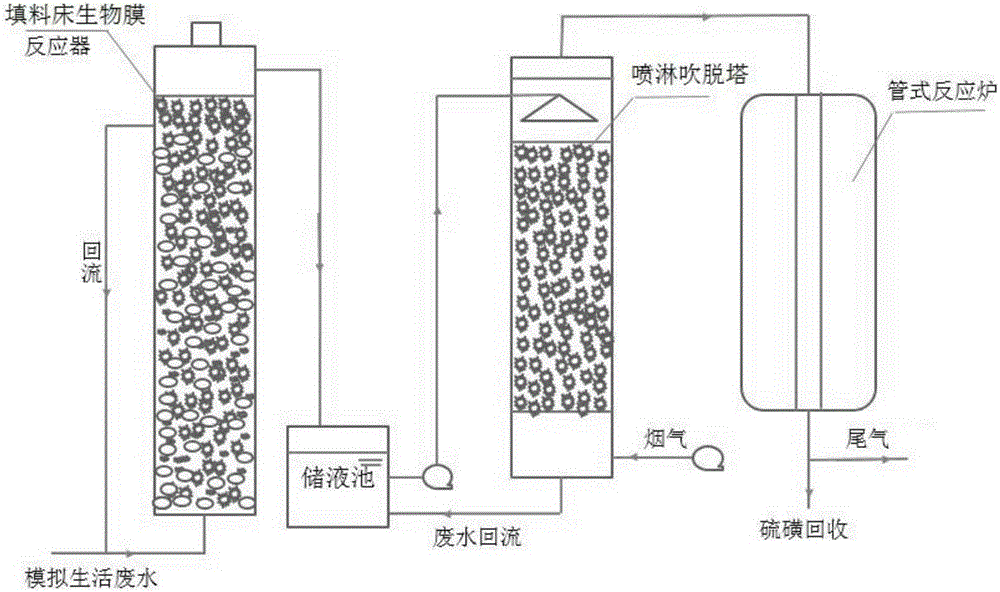

[0068] like image 3 As shown, a reaction device for coal-fired flue gas synchronous desulfurization and denitrification process using hydrogen sulfide as a reducing agent includes the following main components: packed bed biofilm reactor, tube furnace reactor, and spray stripping tower.

[0069] The anaerobic biological sulfur reduction reactor is a packed bed biofilm reactor with a dissolved oxygen concentration of <0.2mg / L. The total volume of the reactor is 1.3L, the filler is sulfur, the filler volume is 0.5L, and the effective volume is 0.8L. The container is made of plexiglass. The gas-liquid separator adopts a spray blow-off tower, and the spray blow-off tower adopts a conventional packing mode. The packing is a multi-faceted hollow ball, which adopts the method of water inlet from the upper part and flue gas from the bottom. There is a rectifying plate on the top. The total volume of the blow-off tower is 2.5L, the packing volume is 1.8L, the air-water ratio is 1: (2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com