Patents

Literature

116results about How to "Avoid risk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

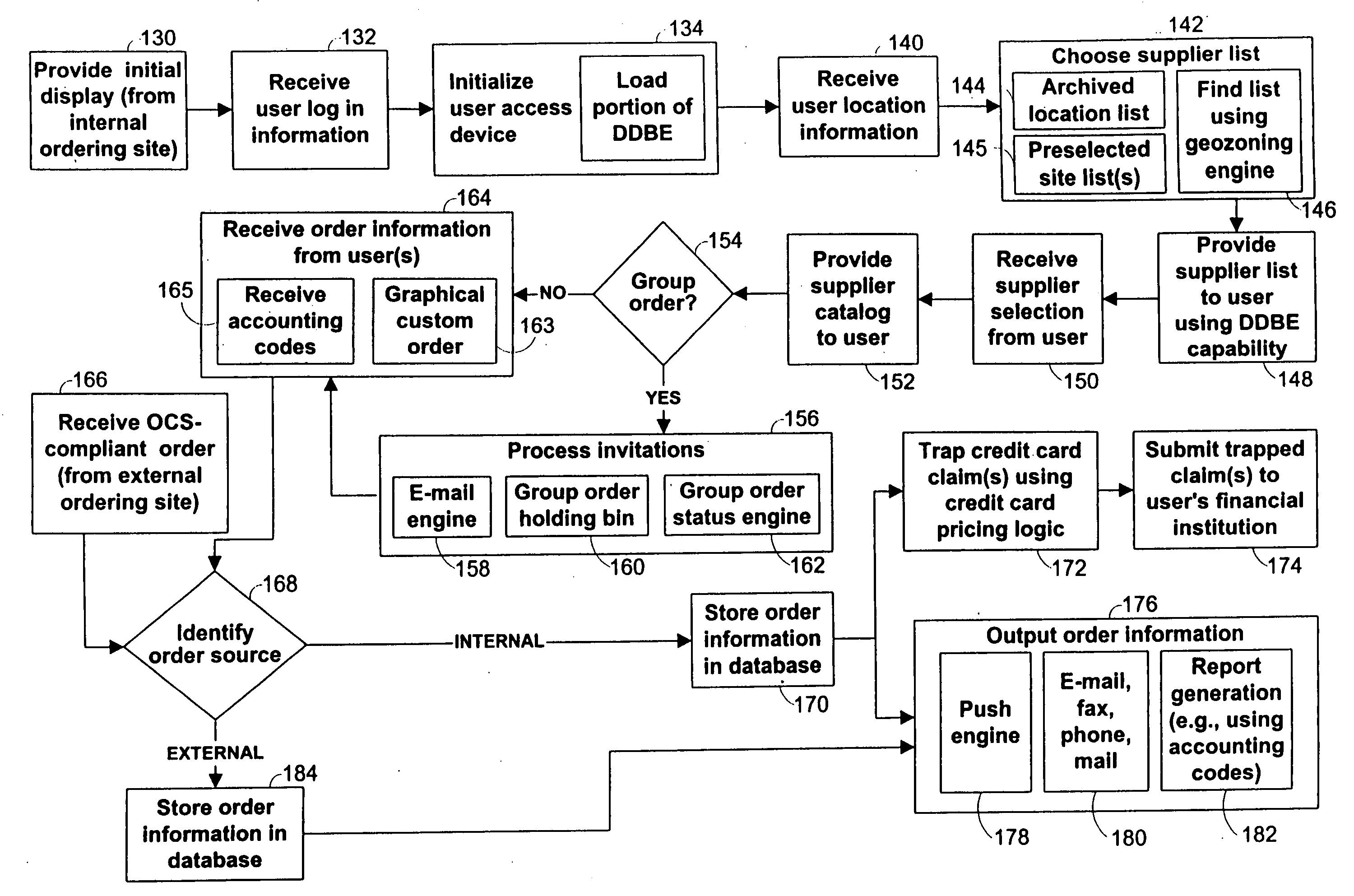

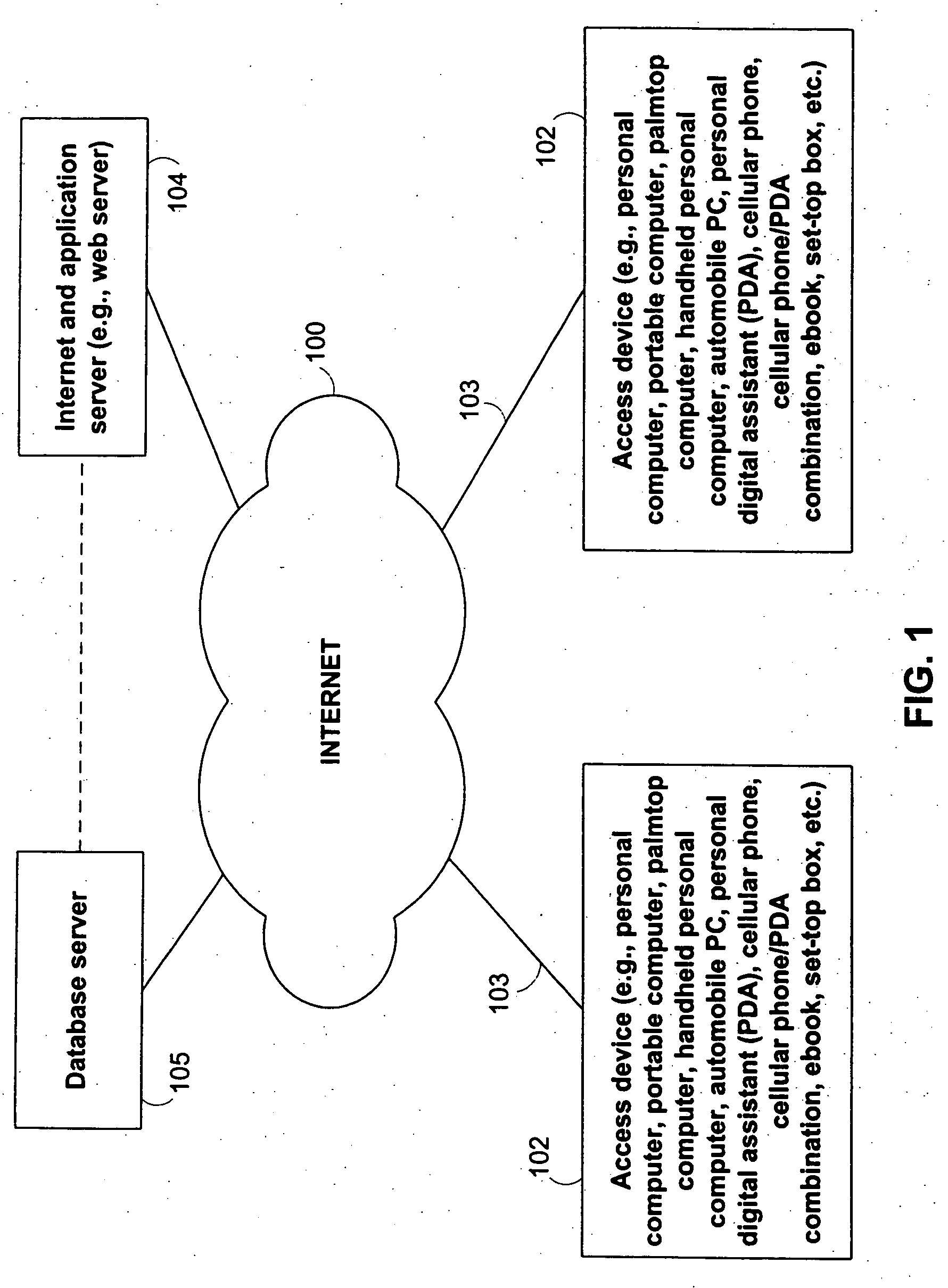

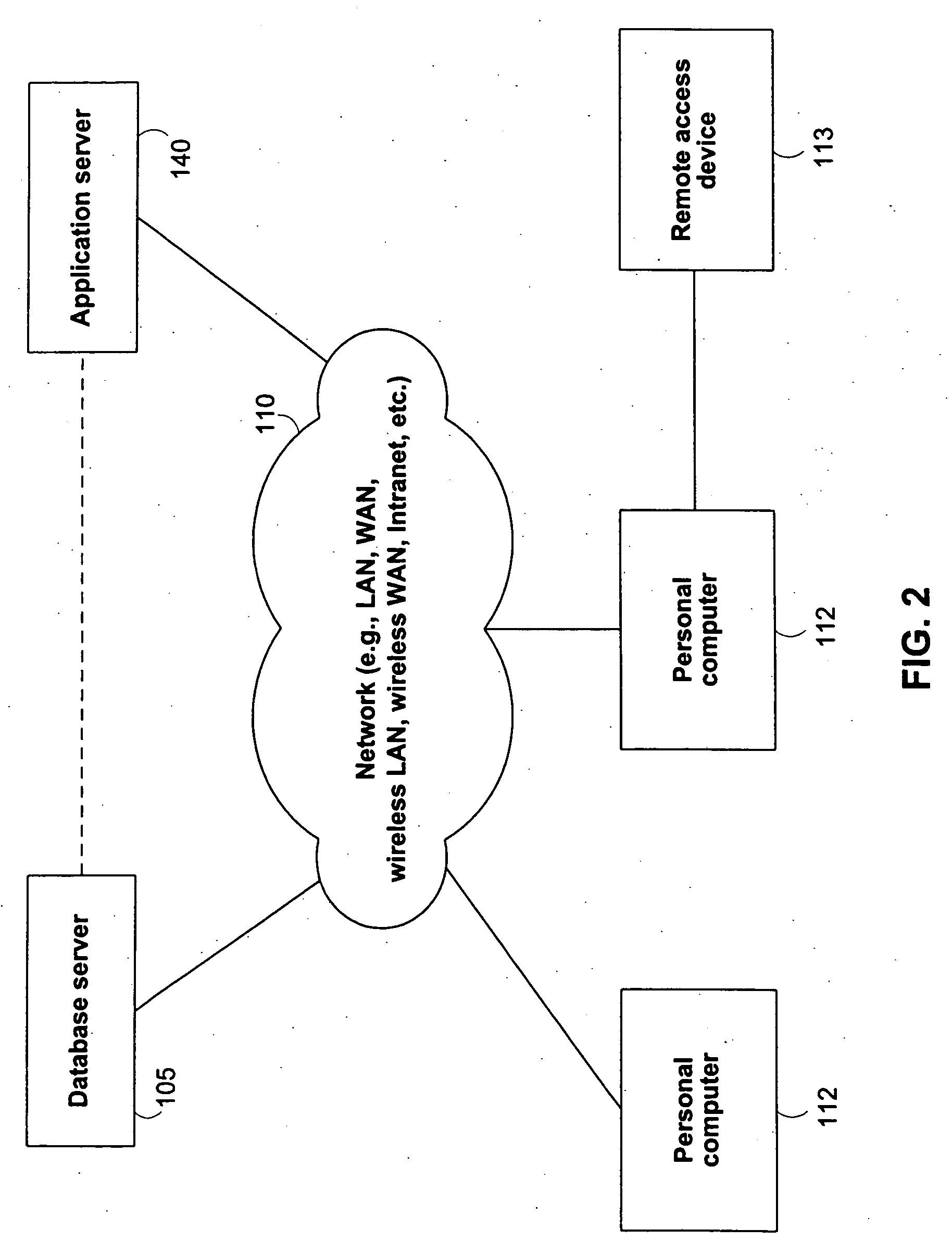

Methods and apparatus for on-line ordering

InactiveUS20060293965A1Avoid riskReduce the amount of informationBuying/selling/leasing transactionsLogisticsE-commerceGraphics

Systems and methods for ordering supplies from suppliers or for other e-commerce activities are described. Standards for placing orders and registering catalog information in a database are described. Systems and methods for placing orders, preprocessing supplier information using geographic information, conducting data searches and analyses locally on user access devices, continuously updating displays of browser frames, tracking orders using accounting codes, placing graphical custom orders, submitting graphical orders to suppliers, placing group orders, reducing risks associated with delinquent accounts receivable, and combinations thereof are described.

Owner:AMERICA TO GO

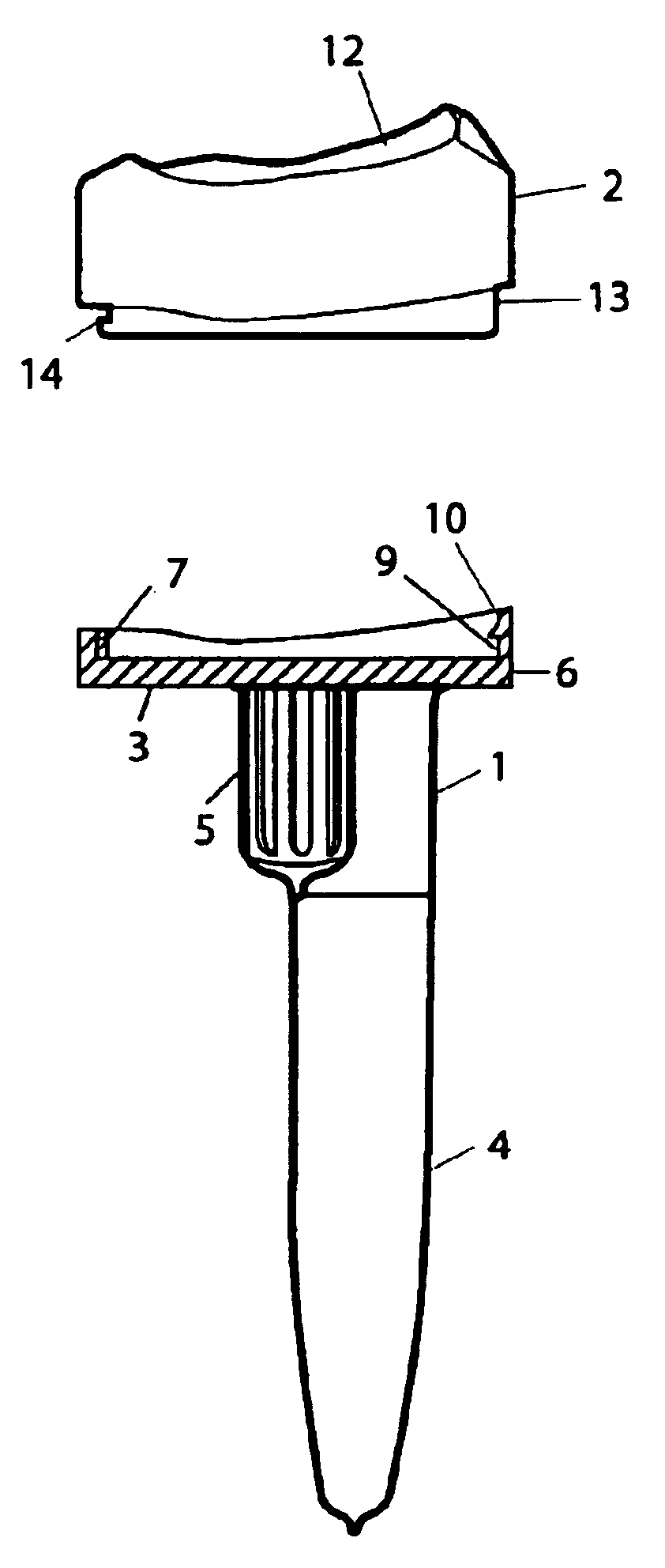

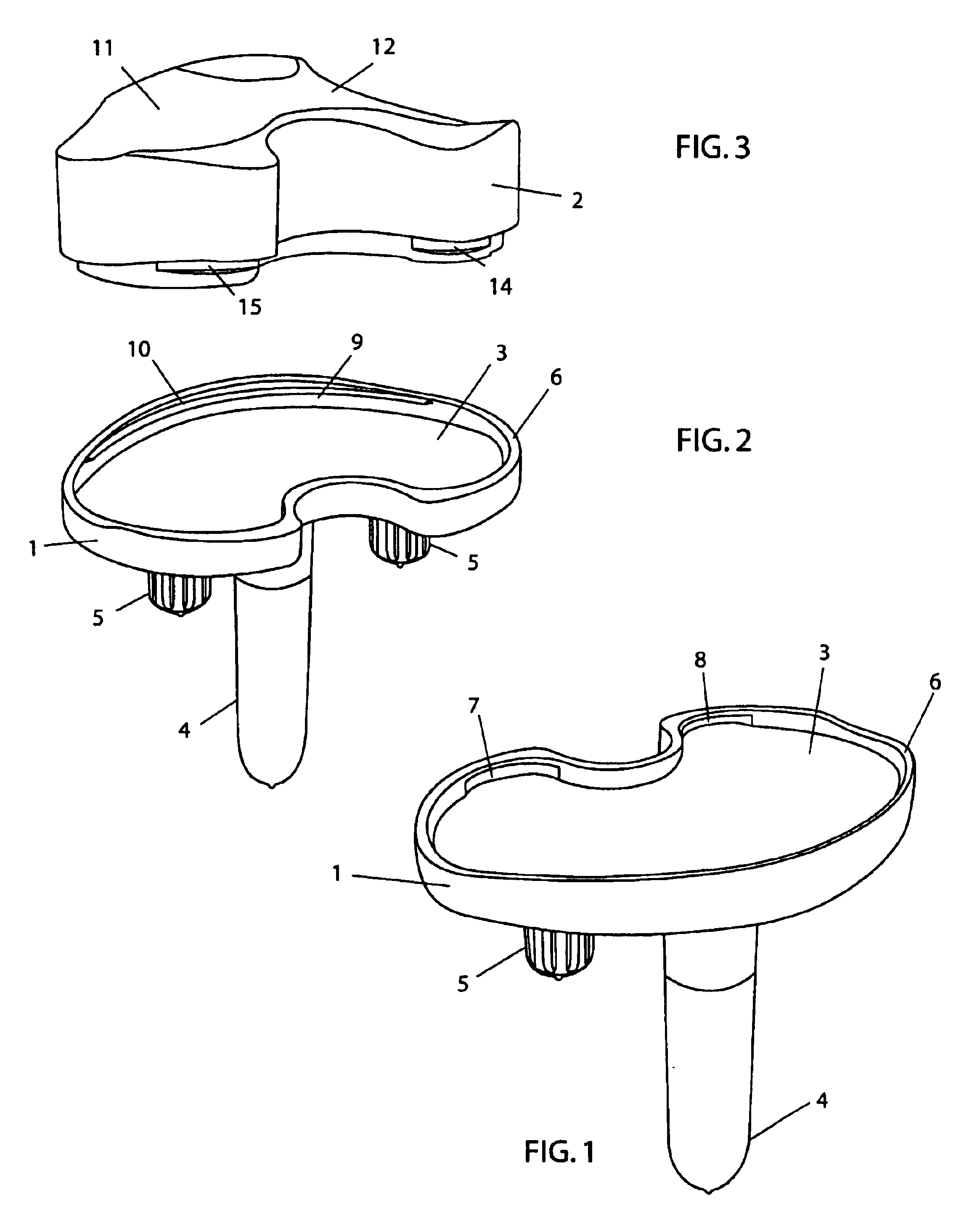

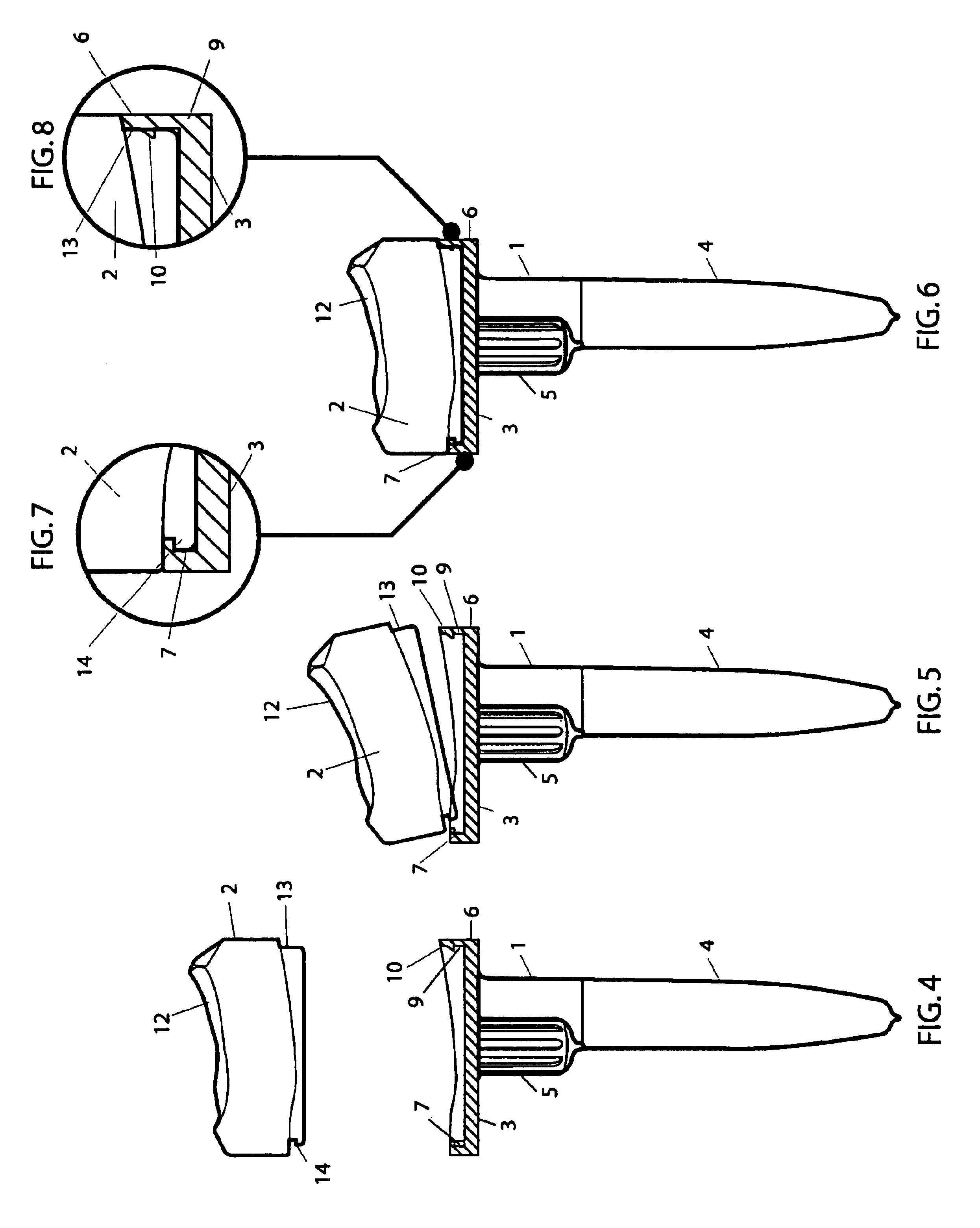

Prosthesis

A tibial prosthesis has a metal tray component (1) comprising a transverse member (3) with a peripheral upstanding rim (6) and a projecting stem (4). The upstanding rim (6) includes a posterior rim portion with an undercut lip forming a pair of recesses (7, 8) and an anterior rim portion with an open angled posterior surface portion (9) and a posteriorly projecting barbed portion (10). The prosthesis also includes a tibia insert (2) made of a plastics material which fits on the tibial implant (1) within the upstanding rim (6) and has on a posterior portion thereof a shaped contour (14, 15) adapted in use to fit snugly under the undercut lip and on an anterior portion thereof an anterior surface (13) having a taper angle substantially corresponding to the angle of the open angled posterior surface portion.

Owner:FINSBURY DEV

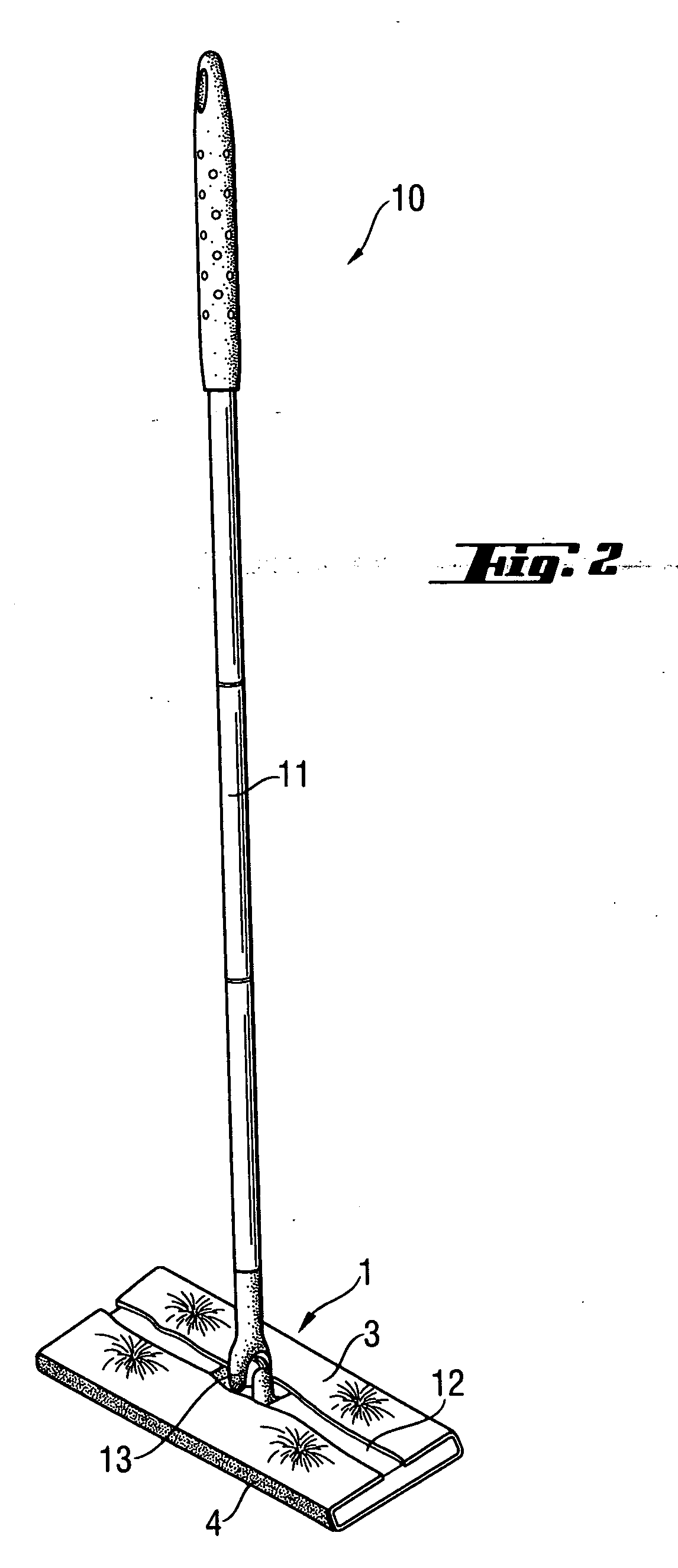

Cleaning pad and cleaning implement

ActiveUS20050081888A1Damage to cleanerAvoid riskBoard cleaning devicesCarpet cleanersSurface cleaningEngineering

The present invention relates to a cleaning implement comprises a handle; a head portion pivotally attached to the handle comprising an upper surface and a lower surface connected to the upper surface by side edges; and a cleaning pad removably attached to the head portion, the cleaning pad comprising an absorbent layer which extends over the lower surface of the head portion and a scrubbing strip which extends along a side edge of the head portion.

Owner:THE PROCTER & GAMBNE CO

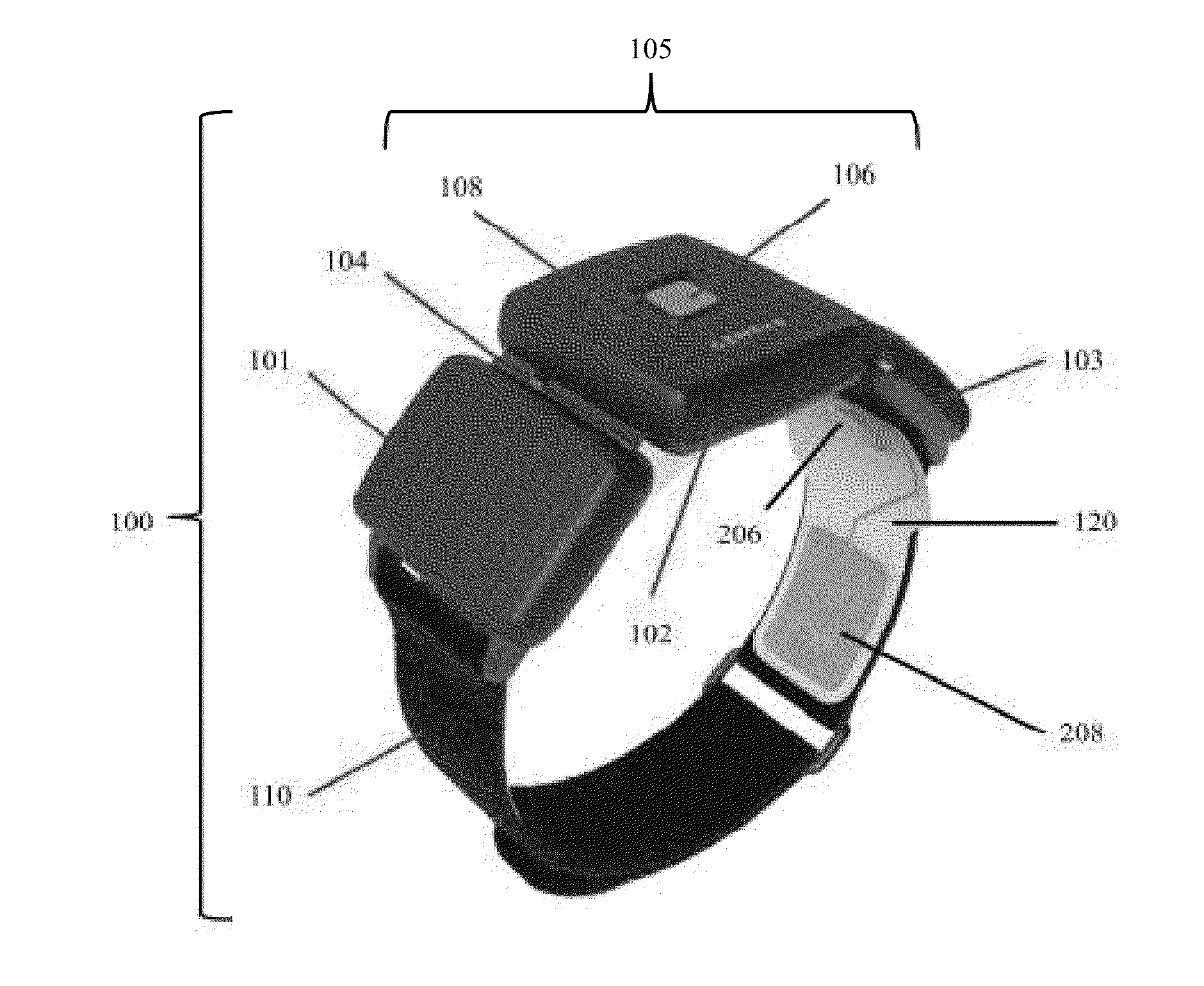

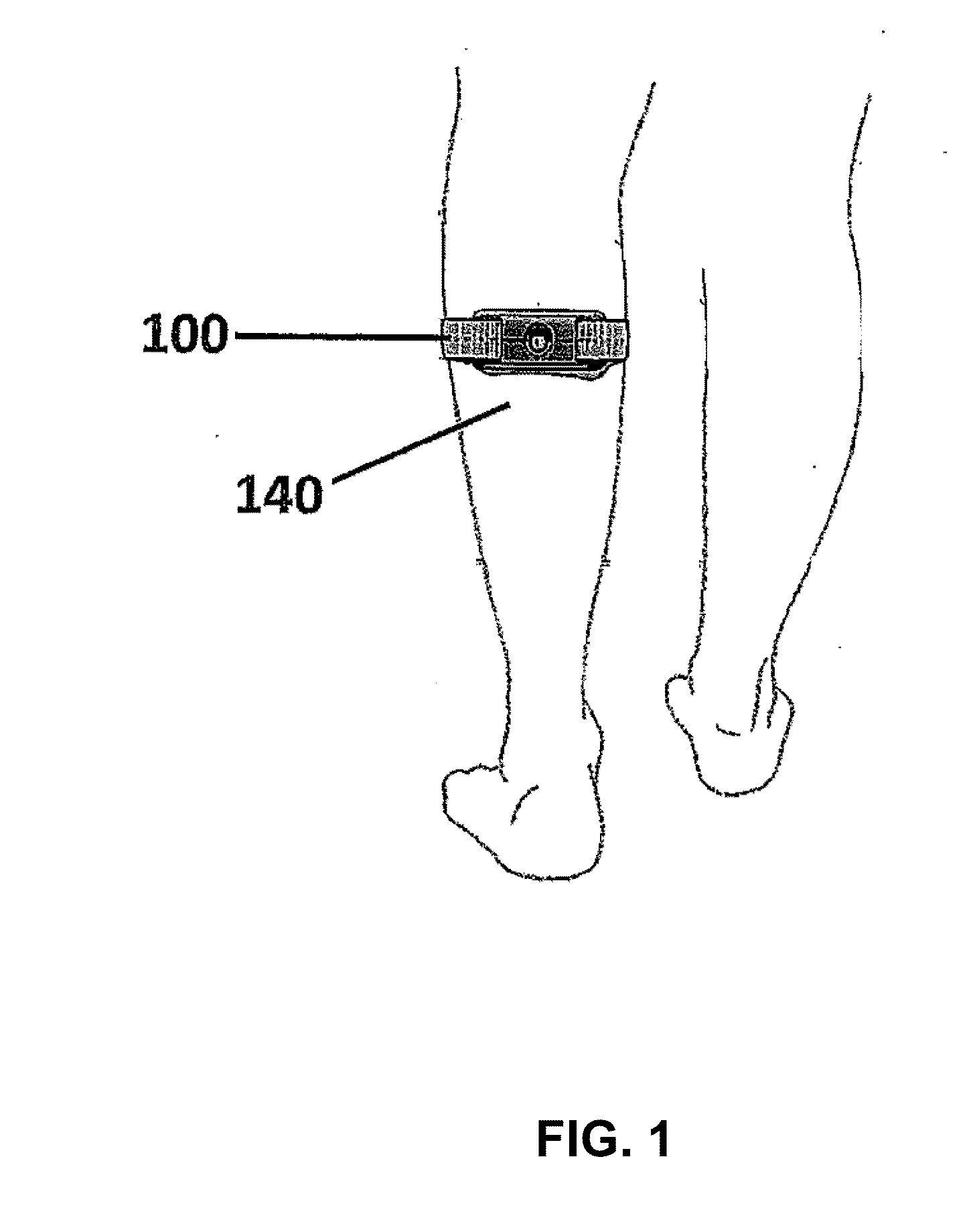

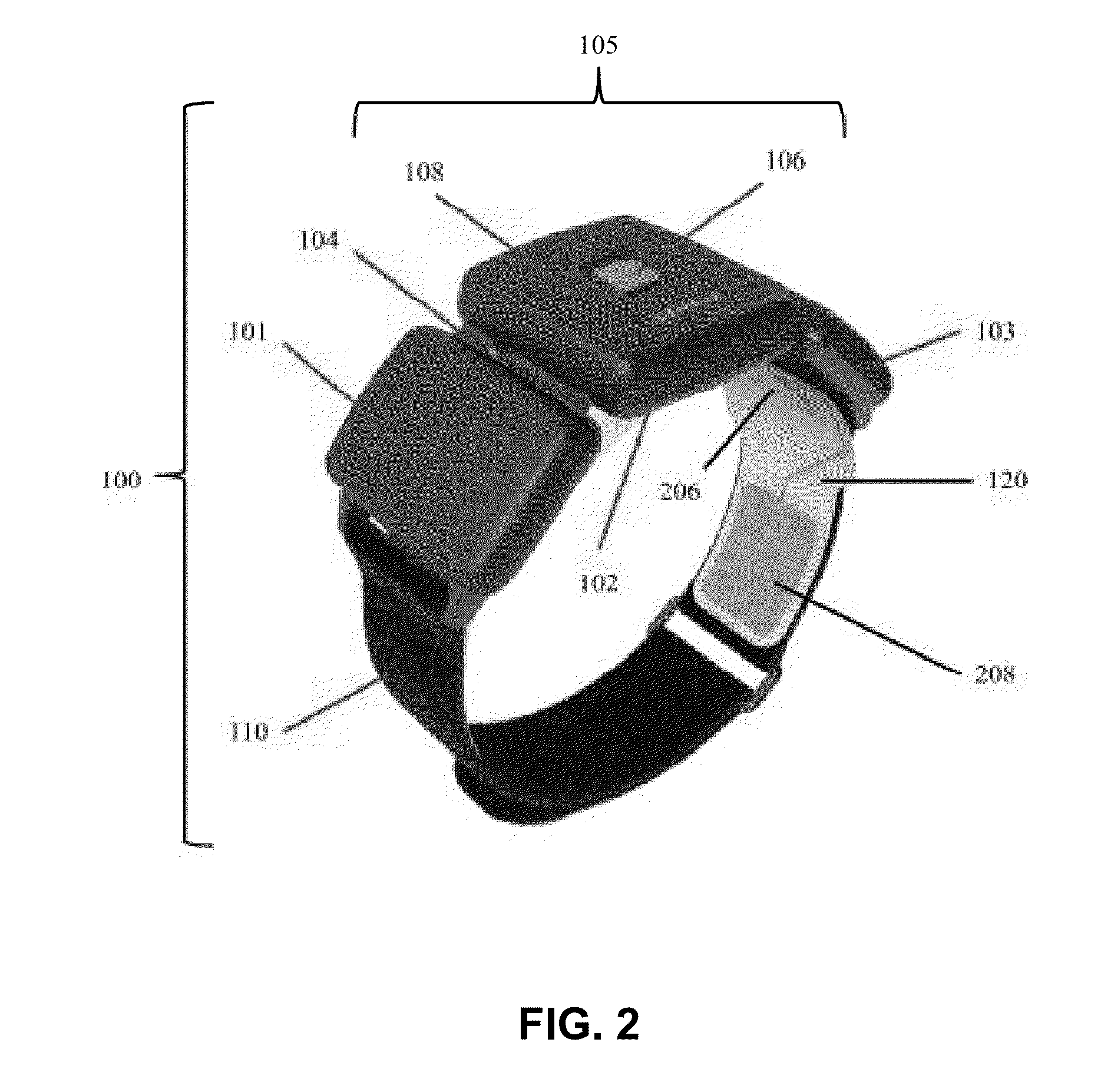

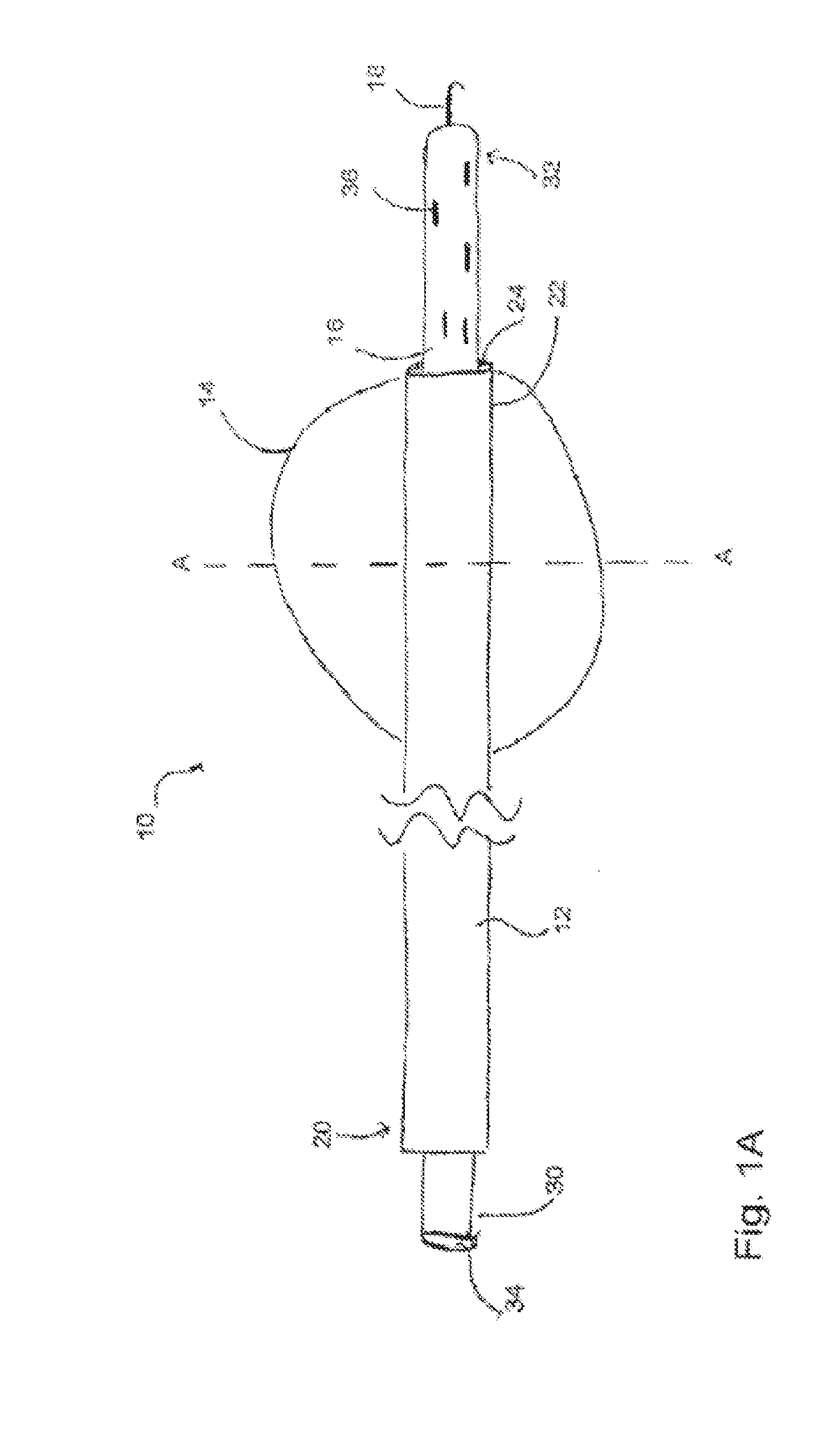

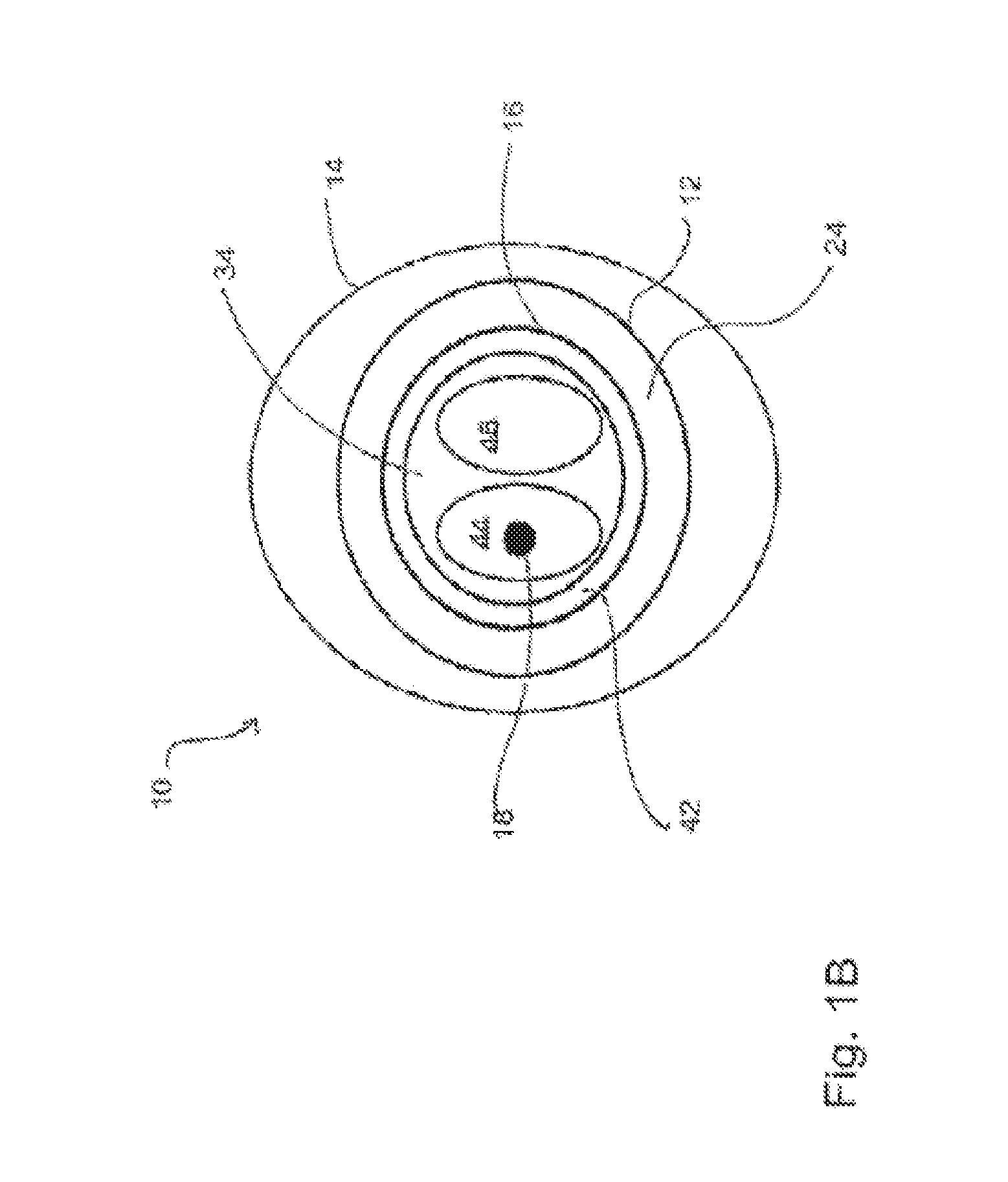

Detecting cutaneous electrode peeling using electrode-skin impedance

ActiveUS20140296934A1Avoid riskReduce riskElectrotherapyDiagnostic recording/measuringElectrode arraySkin impedance

Apparatus for transcutaneous electrical nerve stimulation in a user, the apparatus comprising:stimulation means for electrically stimulating at least one nerve;an electrode array connectable to said stimulation means, said electrode array comprising a plurality of electrodes for electrical stimulation of the at least one nerve, said electrodes having a pre-formed geometry and known electrode-skin contact area size when in complete contact with the user's skin;monitoring means electrically connected to said stimulation means for monitoring the impedance of the electrical stimulation through said electrode array; andanalysis means for analyzing said impedance to estimate a change in the electrode-skin contact area.

Owner:NEUROMETRIX

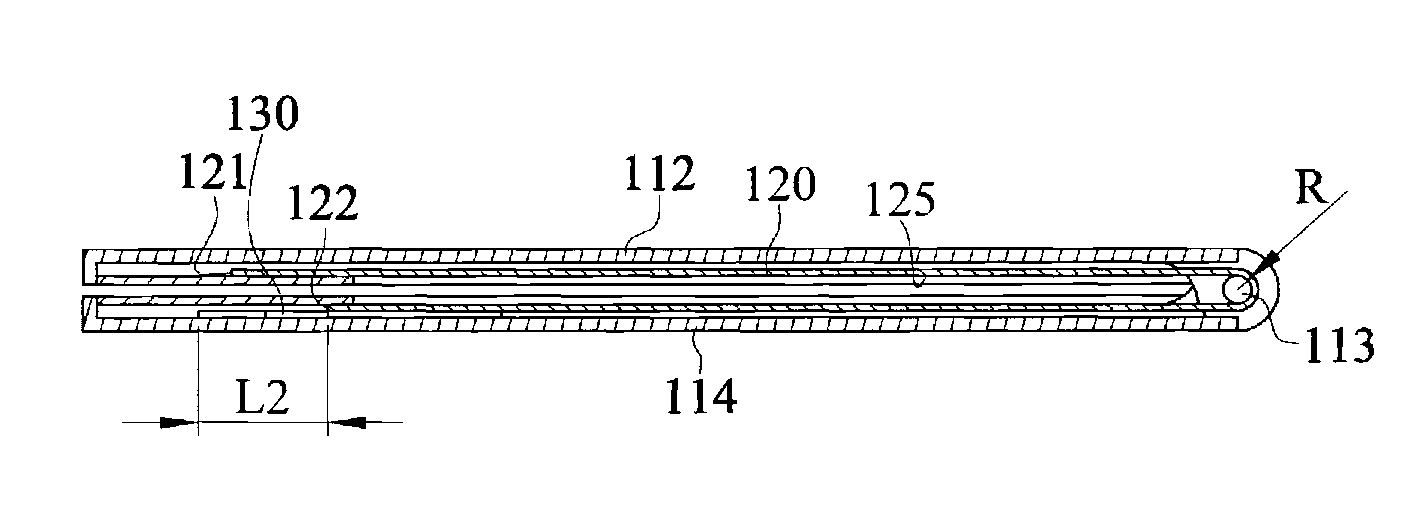

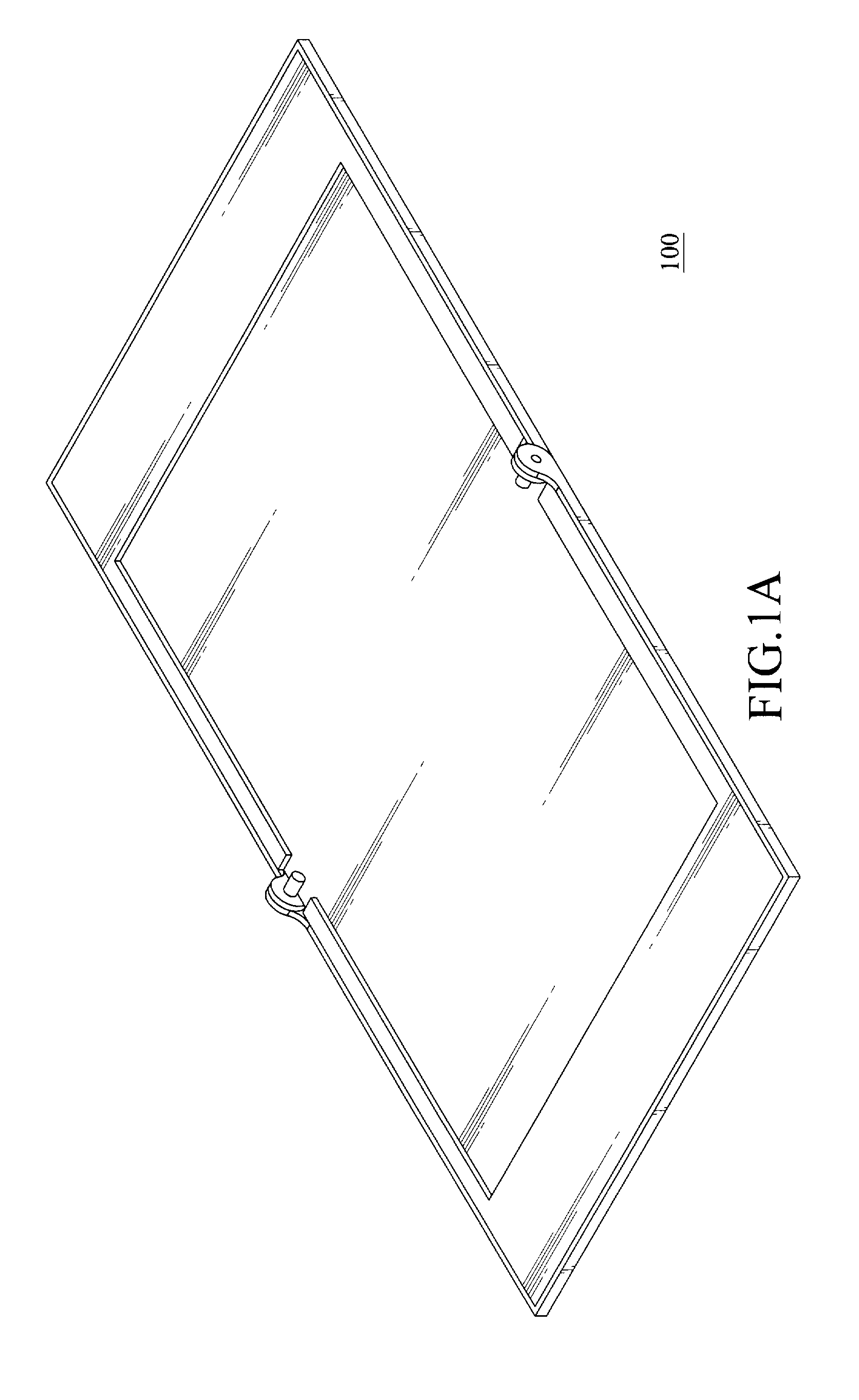

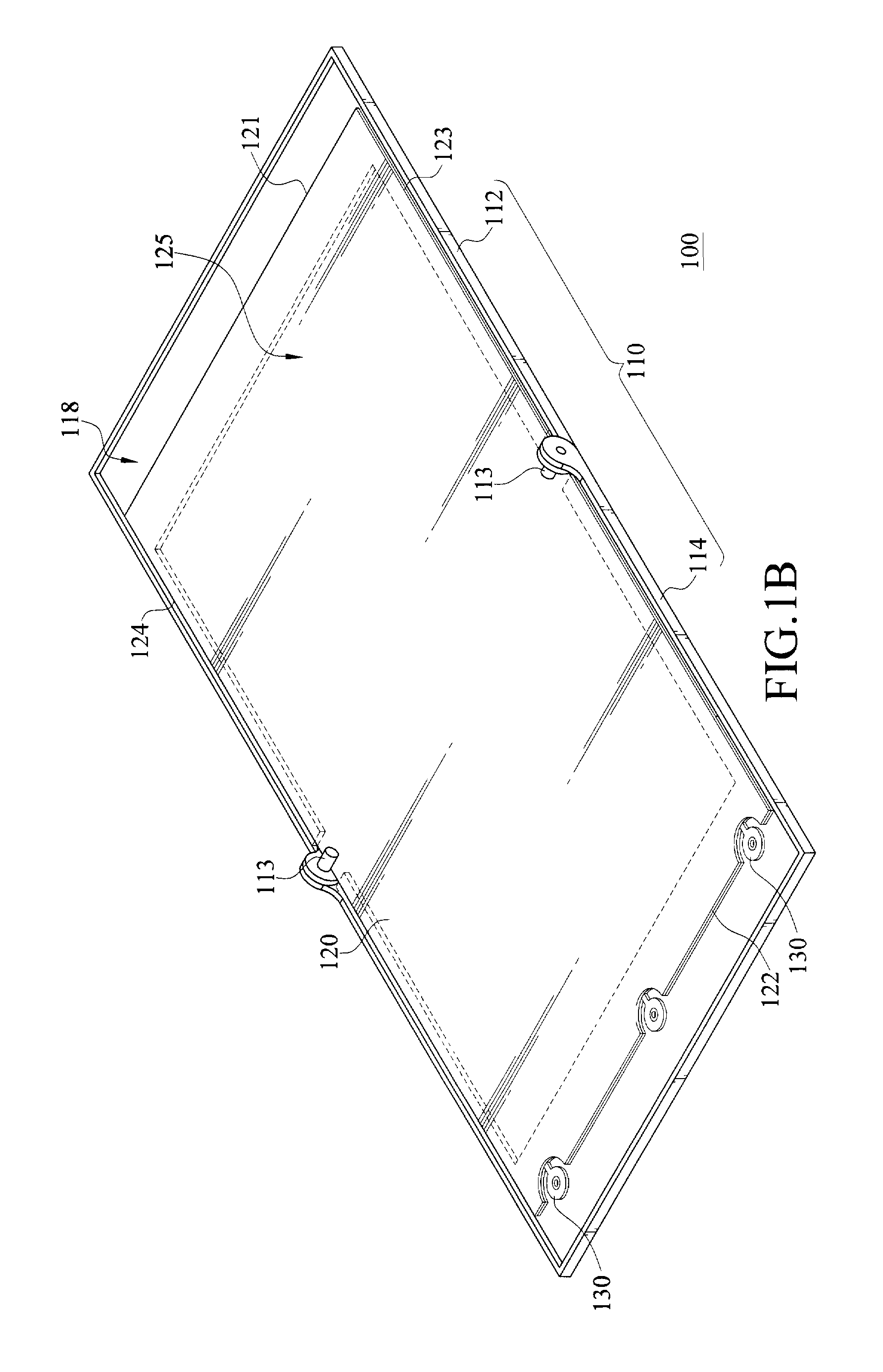

Foldable electronic device

ActiveUS20120033354A1Avoid riskExtend flexibilitySubstation equipmentElectrical apparatus contructional detailsBiomedical engineeringFlexible display

A foldable electronic device includes a foldable casing and a flexible display. The flexible display is disposed in the foldable casing, and is connected to the foldable casing through an elastic member, and the elastic member provides the flexible display the extending flexibility when being unfolded or folded together with the foldable casing, such that the flexible display is capable of being used as a display screen of the foldable electronic device.

Owner:MSI COMP SHENZHEN

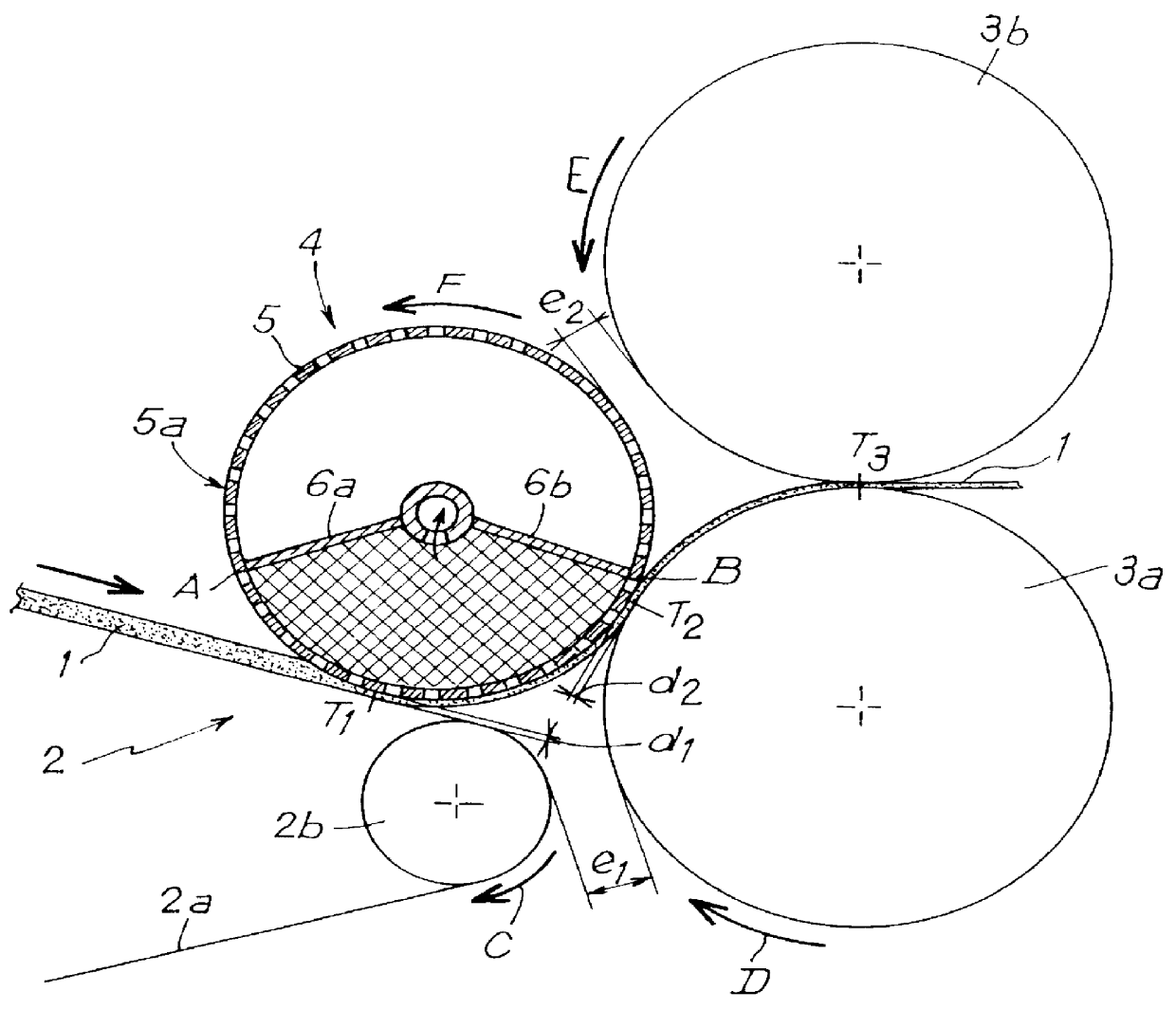

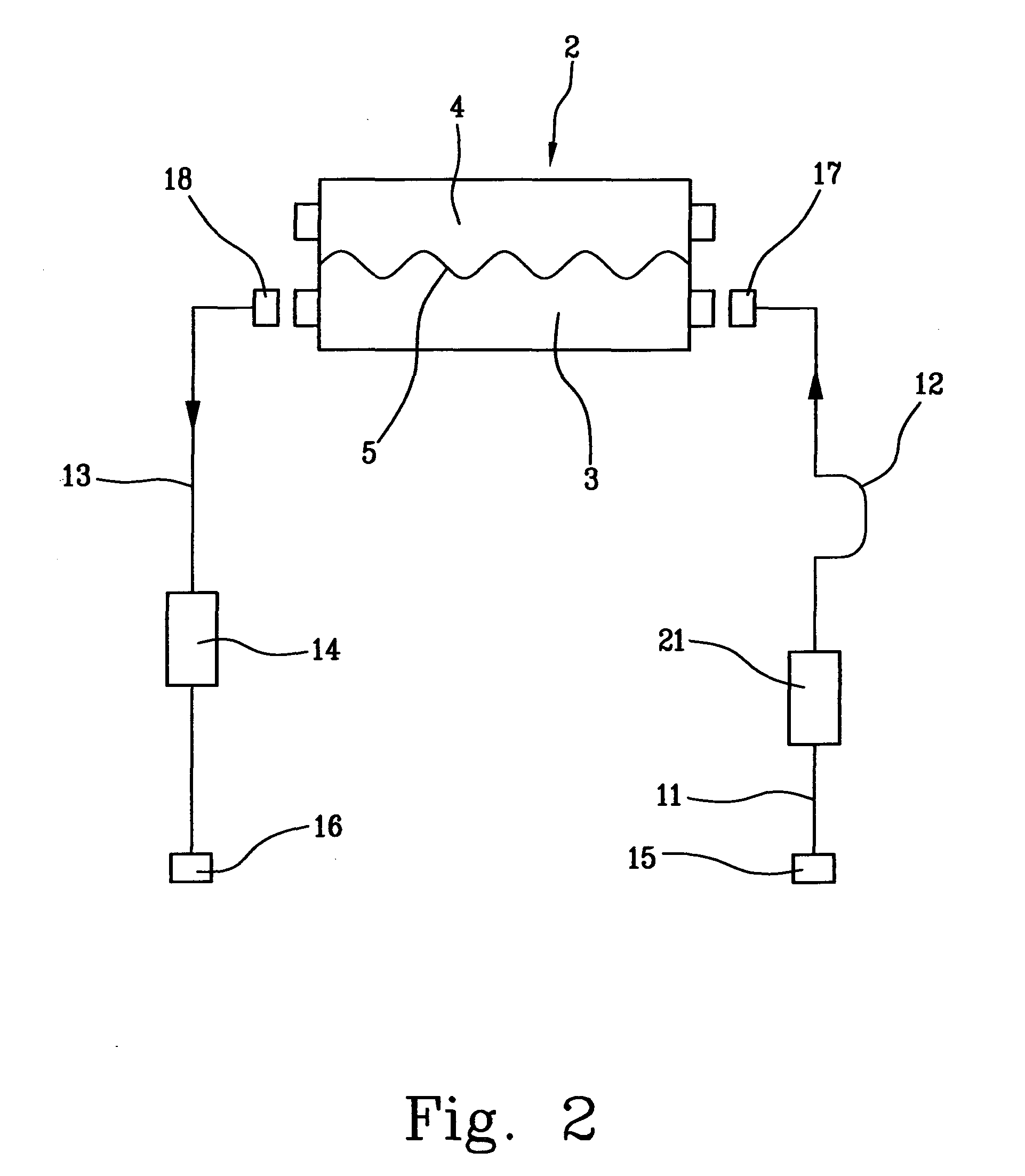

Suction cylinder which transfers fiber web from a conveyer belt to two calendering cylinders

A fiber web transferring device comprising a conveyor belt, a suction cylinder, a lower calendering cylinder and an upper calendering cylinder. The suction cylinder having a stationary suction sector and rotates in a direction which corresponds to a linear moving direction of the conveyor belt. The suction cylinder transfers a non-consolidated fiber web from the conveyor belt to the lower calendering cylinder and is substantially tangential to the lower calendering cylinder so as to cooperate therewith to define a pre-calendering zone for the fiber web. The suction cylinder is positioned such that the suction cylinder sucks the fiber web from the conveyor belt and holds the fiber web against the outer surface of the suction cylinder to the pre-calendering zone. The fiber web then adheres to the outer surface of the lower calendering cylinder past the pre-calendering zone until the fiber web reaches the upper calendering cylinder.

Owner:THIBEAU

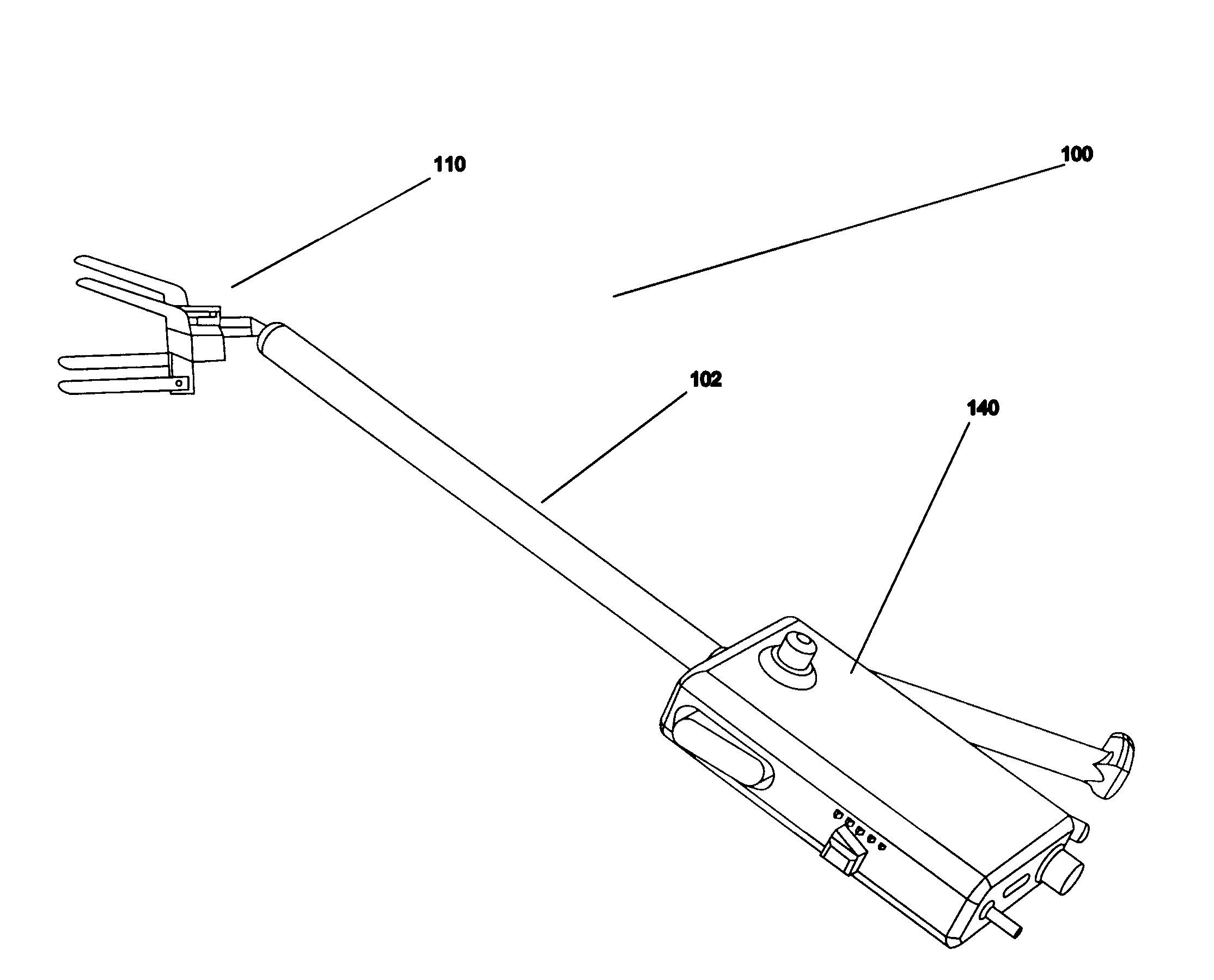

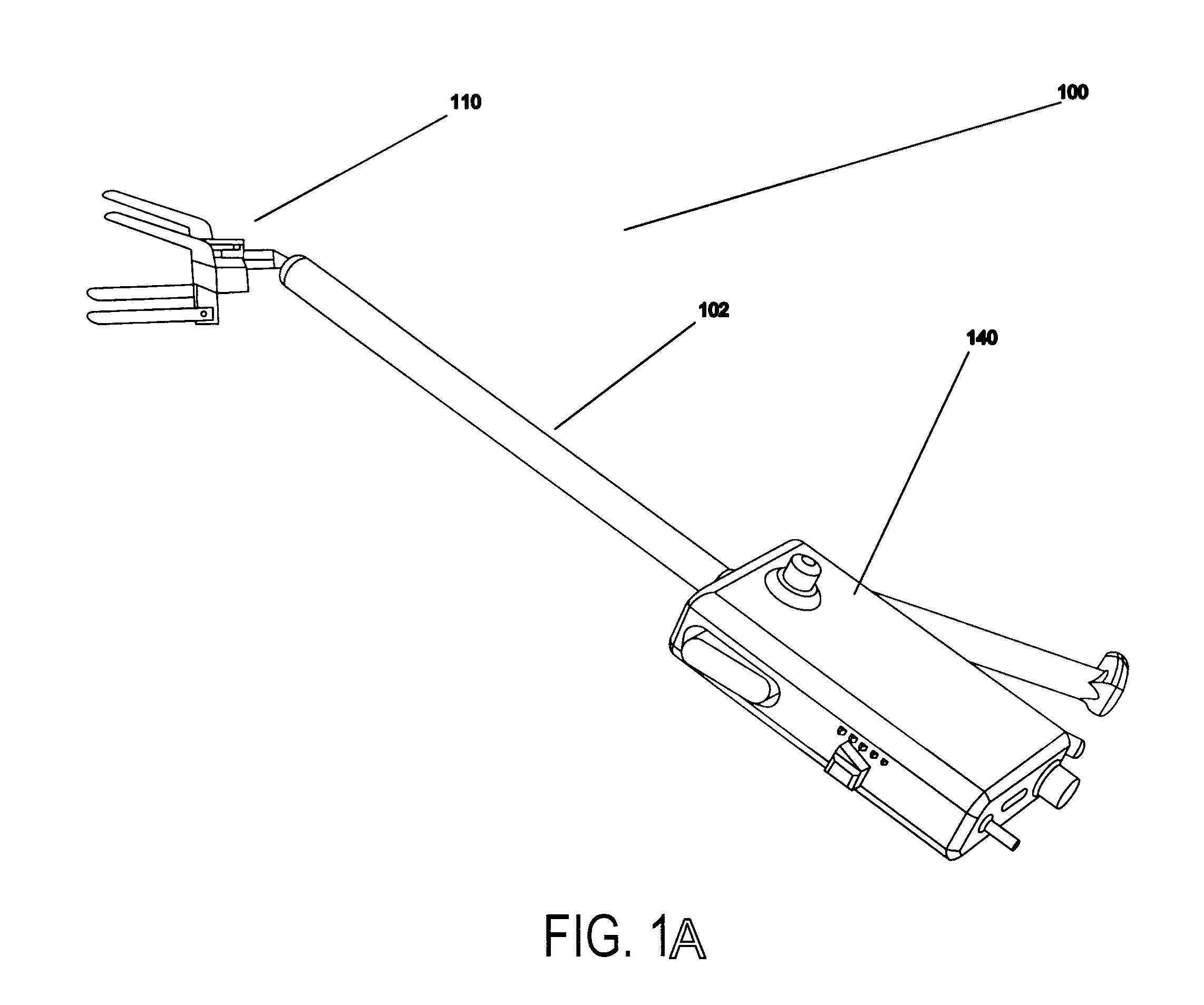

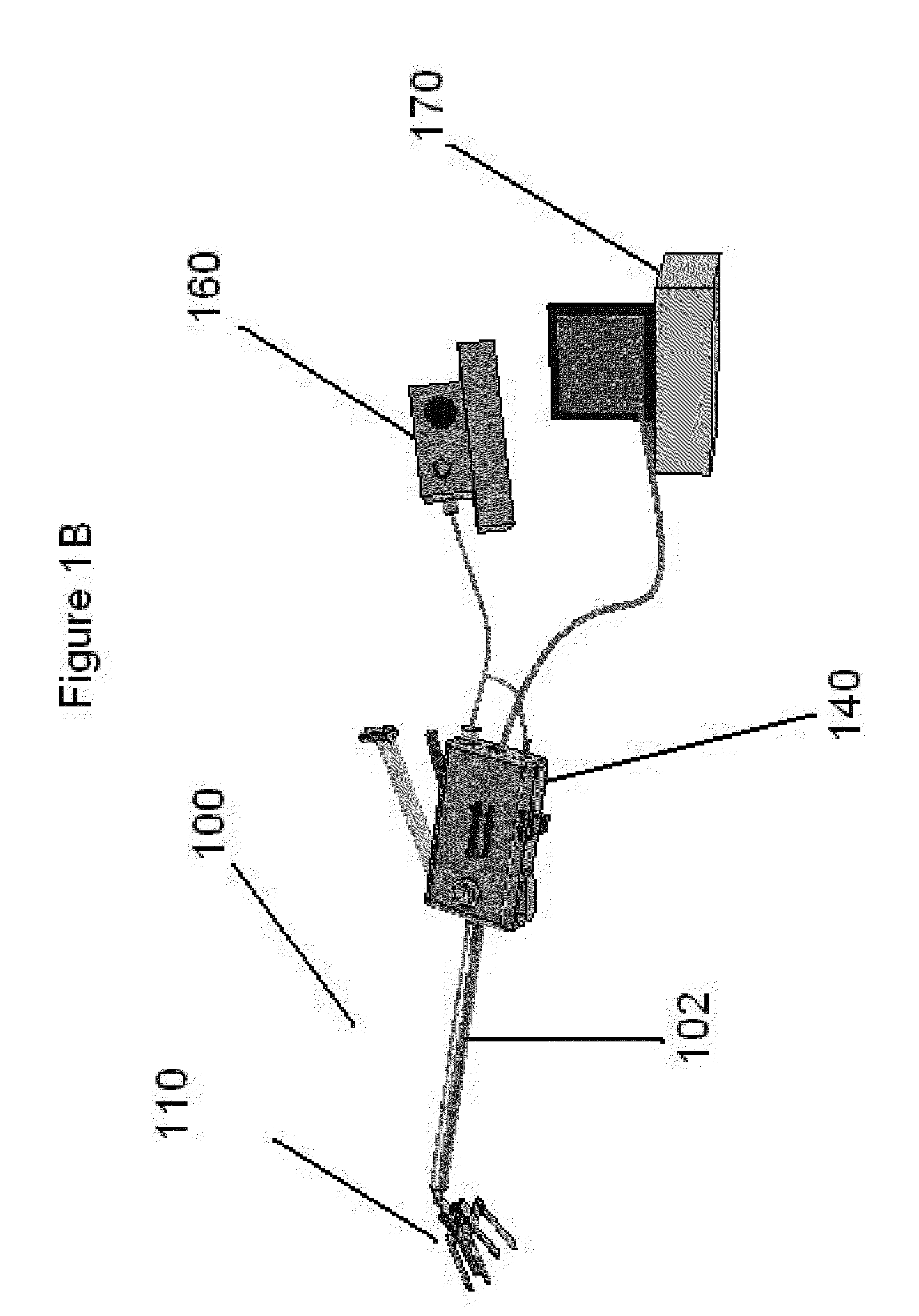

Device for harvesting a blood vessel

InactiveUS20100198241A1Improve safetyAvoid riskEndoscopesSurgical forcepsCoronary Artery BypassesCoronary artery bypass surgery

The present invention relates to an apparatus, device and a method for harvesting blood vessels, and in particular, to such an apparatus, device and method in which the internal mammary artery (IMA) is harvested for coronary artery bypass graft (CABG) surgery using a minimally invasive approach or a conventional procedure.

Owner:GERRAH RABIN +1

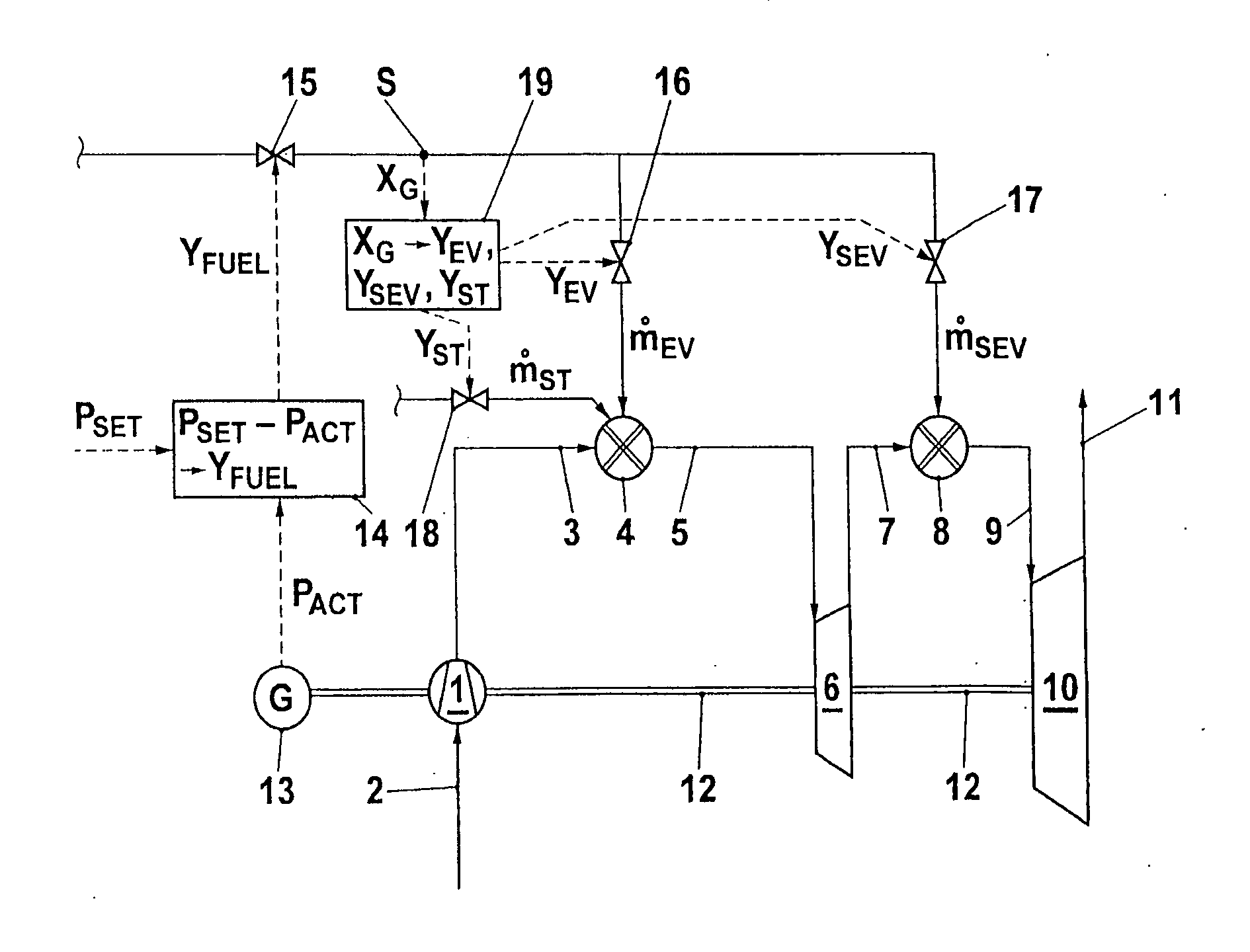

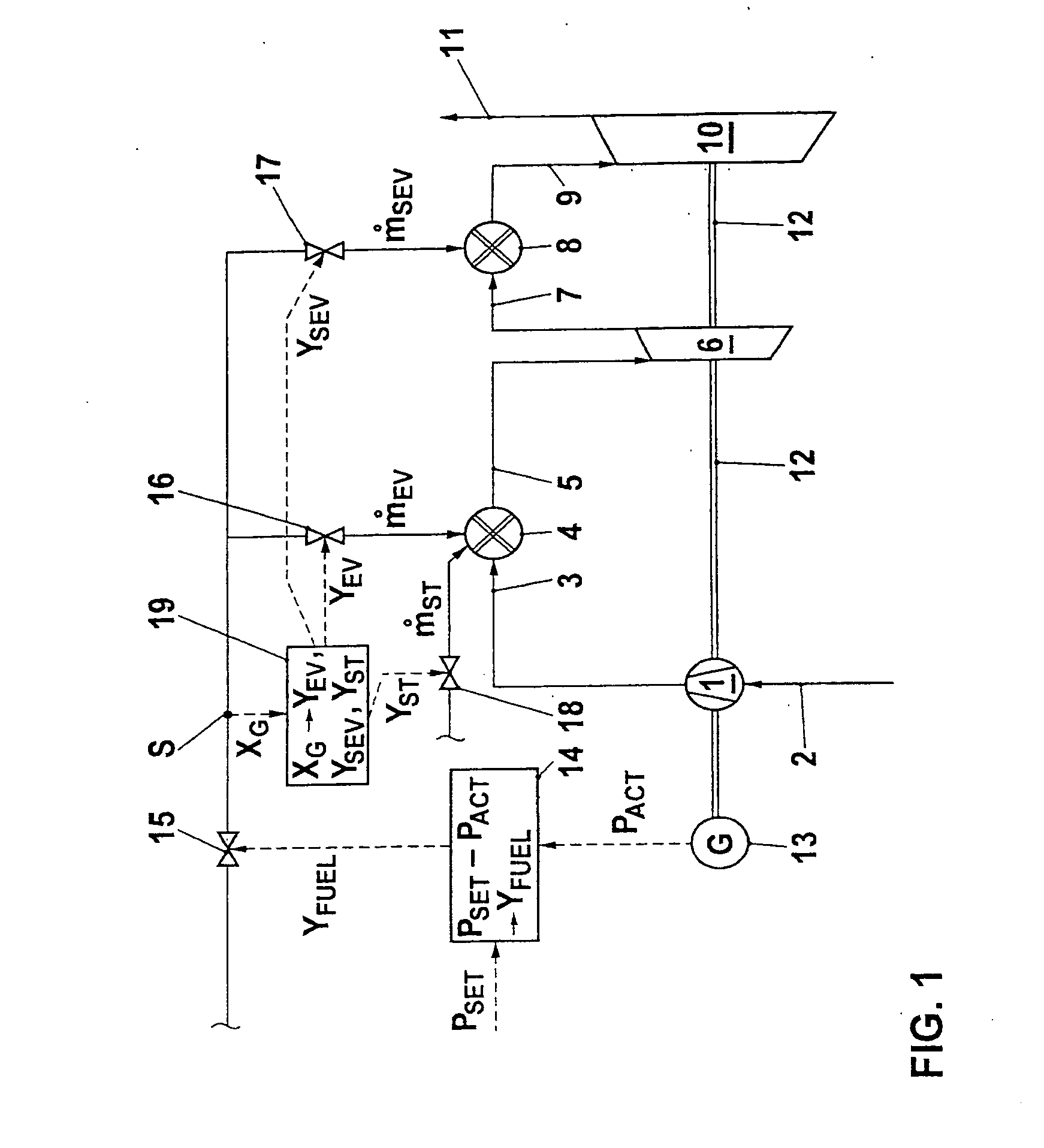

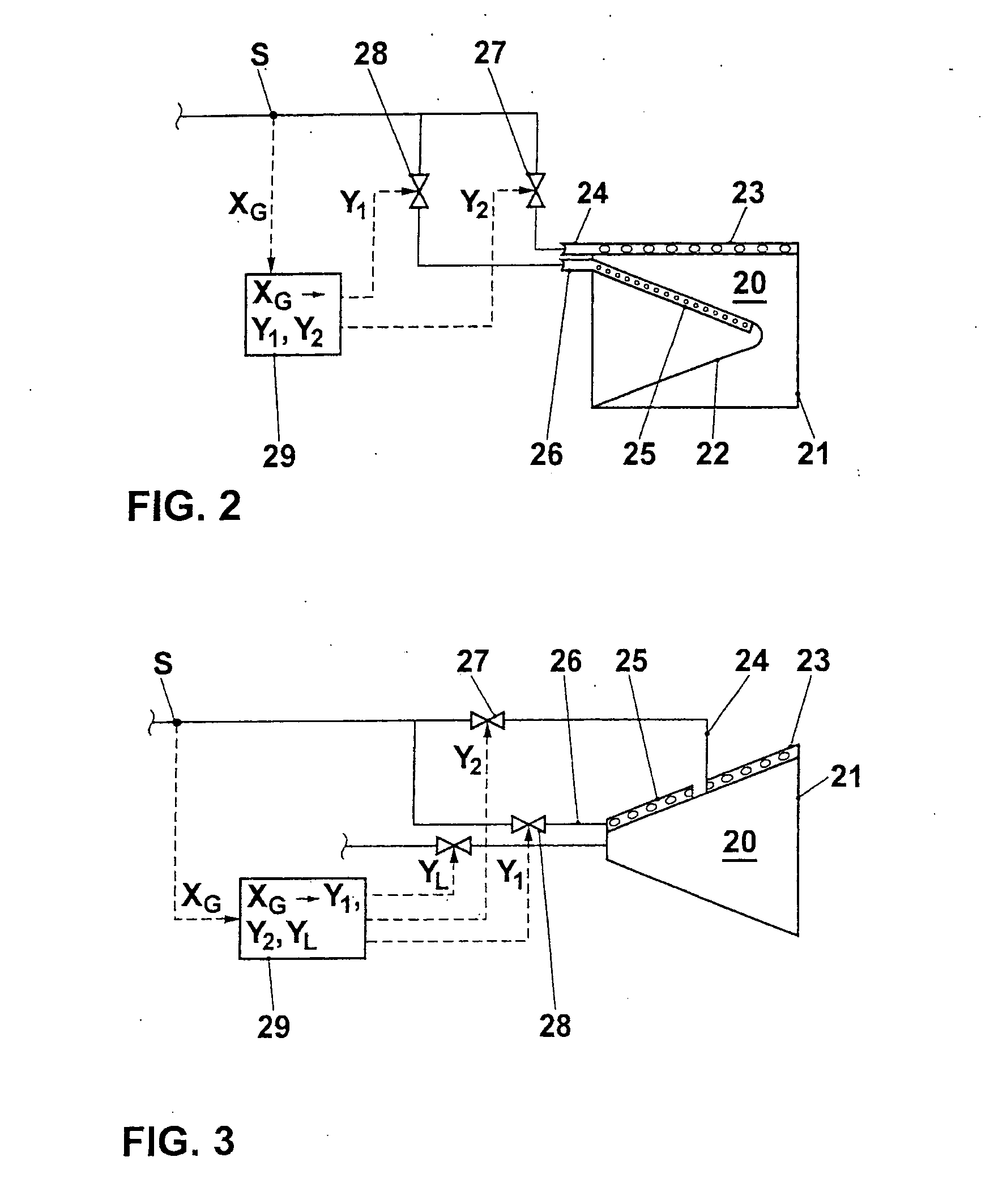

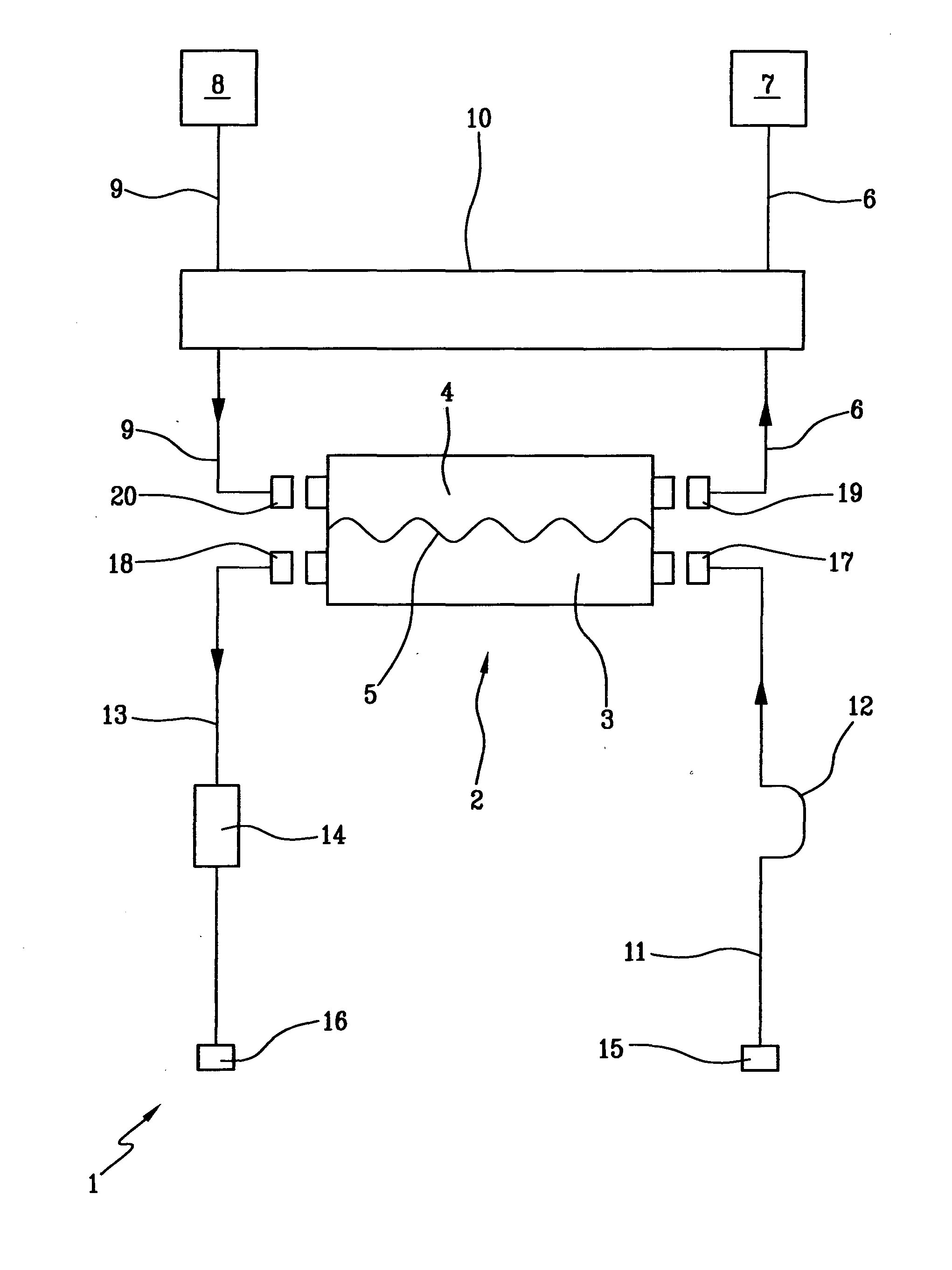

Method for operating a turbine group

InactiveUS20050028530A1Avoid riskSufficient flame stabilityContinuous combustion chamberTurbine/propulsion engine ignitionAutomotive engineeringGas turbines

Relevant fuel-gas properties (XG) are measured on an ongoing basis while a gas turbine group is operating. The C2+alkane content of the fuel gas is of particular interest in this context, since it has a significant influence on the ignitability of the fuel gas in the combustion chamber. The operating parameters of the gas turbine group are acted on directly as a function of the measured fuel-gas properties. In particular, in the case of the example of a gas turbine group with sequential combustion, the distribution of the fuel mass flows ({dot over (m)}EV, {dot over (m)}SEV) between the combustion chambers (4, 8) of the gas turbine group is varied. Furthermore, if there is provision for inert media, such as water or steam, to be introduced, it is possible for the mass flow of inert media ({dot over (m)}ST) to be controlled as a function of the measured fuel properties.

Owner:ANSALDO ENERGIA IP UK LTD

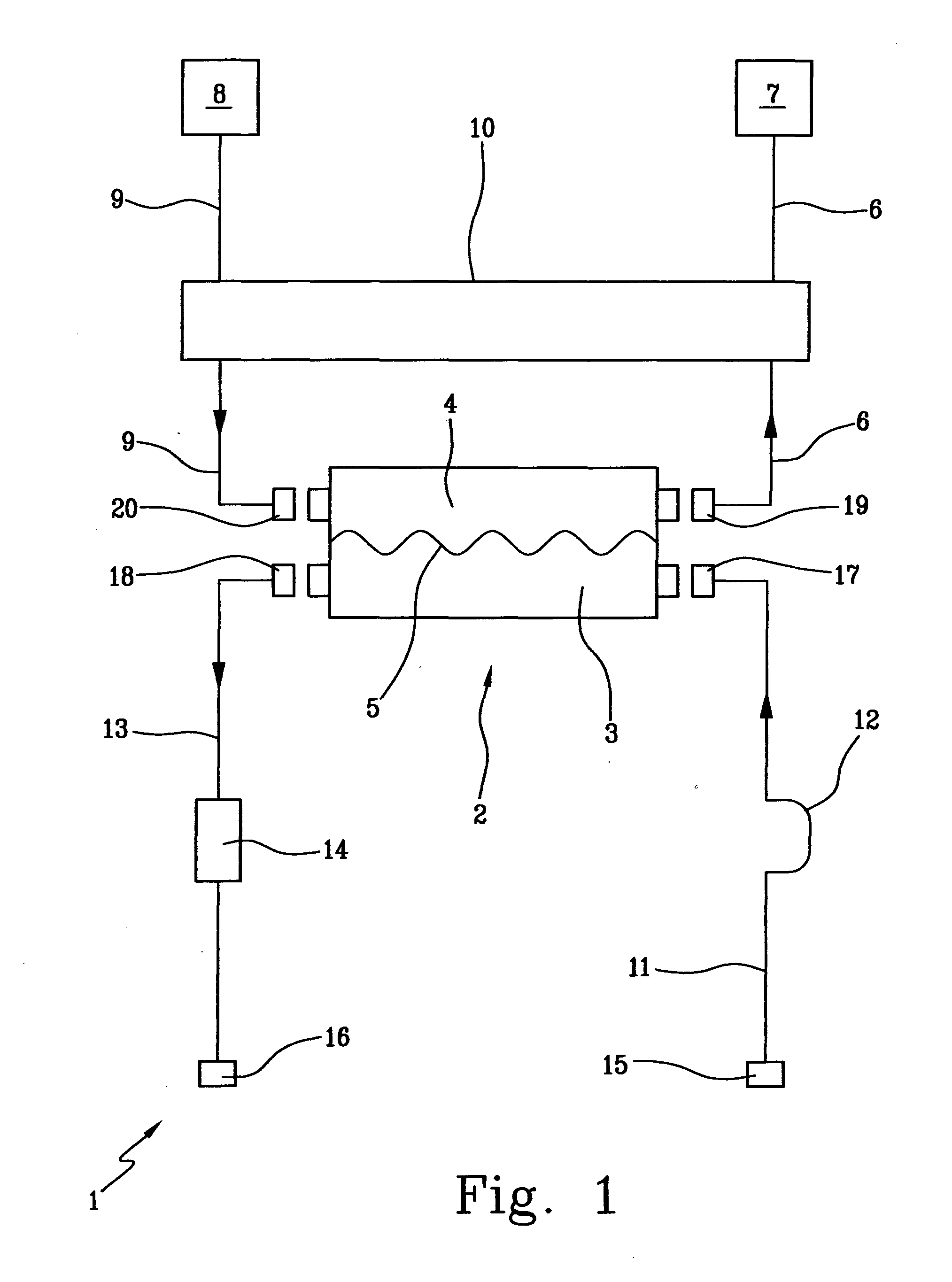

Extracorporeal blood circuit

ActiveUS20100274171A1Simple and economicalAvoid riskOther blood circulation devicesFiltering accessoriesBlood circulationDialysis

An extracorporeal blood circuit, comprising an expansion chamber for air-blood separation, wherein a filter (38) retains the solid particles in the blood. The filter has a trunco-conical filtering wall with a vertical axis surmounted by a top head (43) provided with upper openings (44) conformed and arranged such as to define a fluid passage which is asymmetrical with respect to the vertical axis. The top head does not retain air bubbles internally thereof, thus preventing a situation in which the air bubbles are directed towards an outlet of the expansion chamber and thus towards the patient. The extracorporeal circuit is used in a dialysis apparatus.

Owner:GAMBRO LUNDIA AB

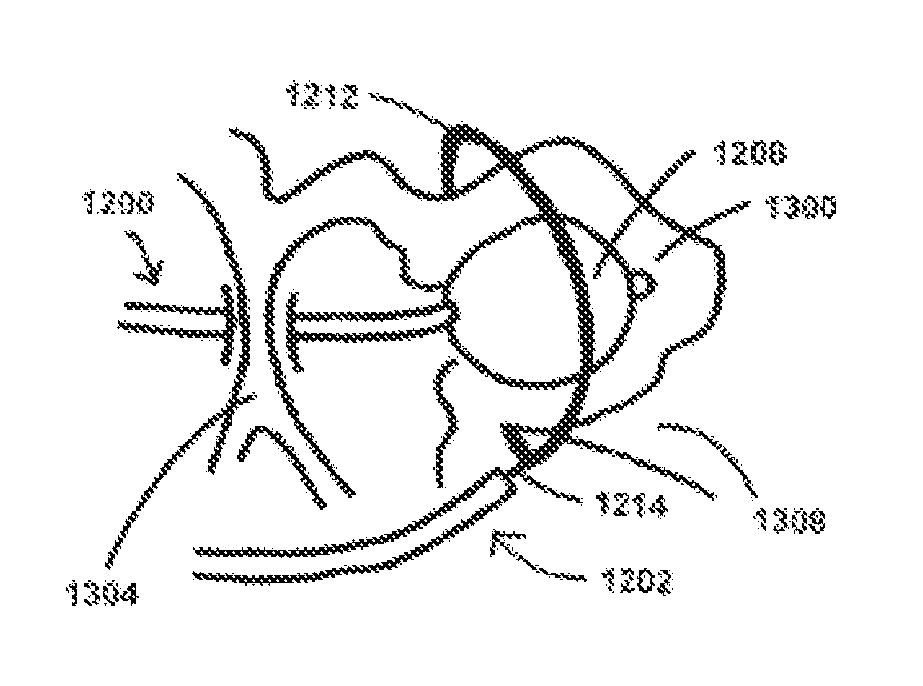

Devices, systems, and methods for atrial appendage occlusion using light cure

Atrial appendage occlusion devices and methods of using the same that employ the application of light having a desired wavelength range. The devices of the present disclosure comprise a telescoping catheter assembly coupled with an adhesive delivery device and a suction source, and comprise at least one optical fiber disposed therein. The catheter assembly is configured to isolate an atrial appendage cavity, deliver suction and adhesive thereto, and, using the optical fiber(s), cure the adhesive present within the cavity all without withdrawing any components of the catheter assembly from the body. Methods for using such device in the treatment of atrial appendage occlusion are also provided.

Owner:CVDEVICES

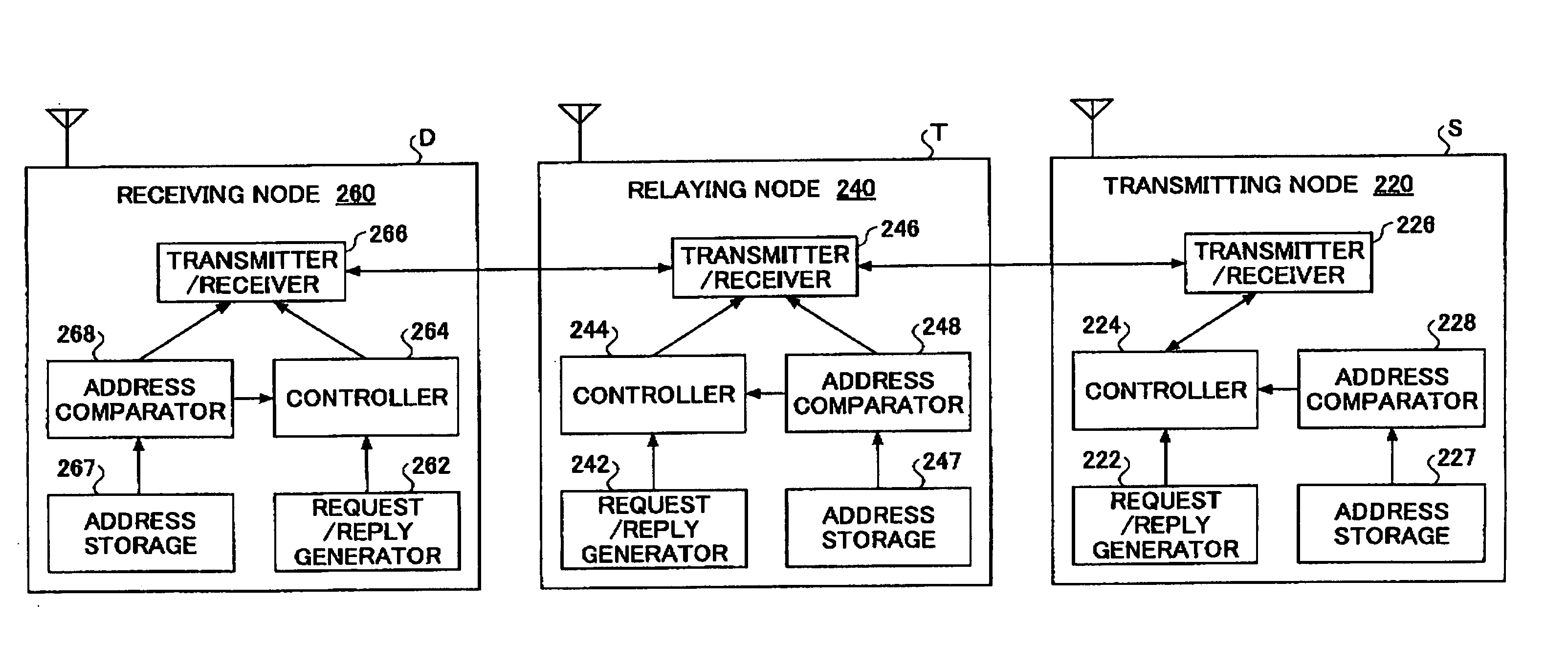

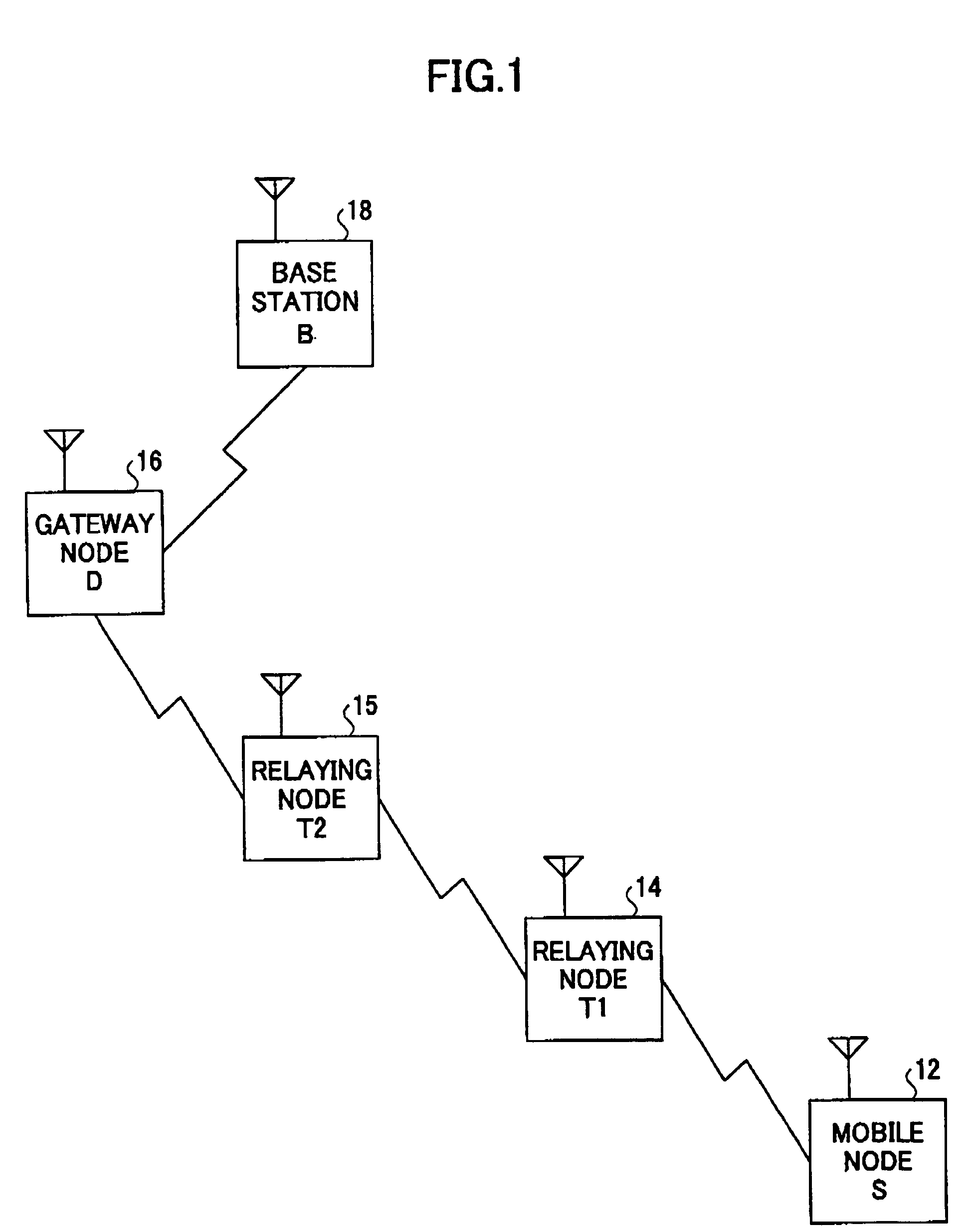

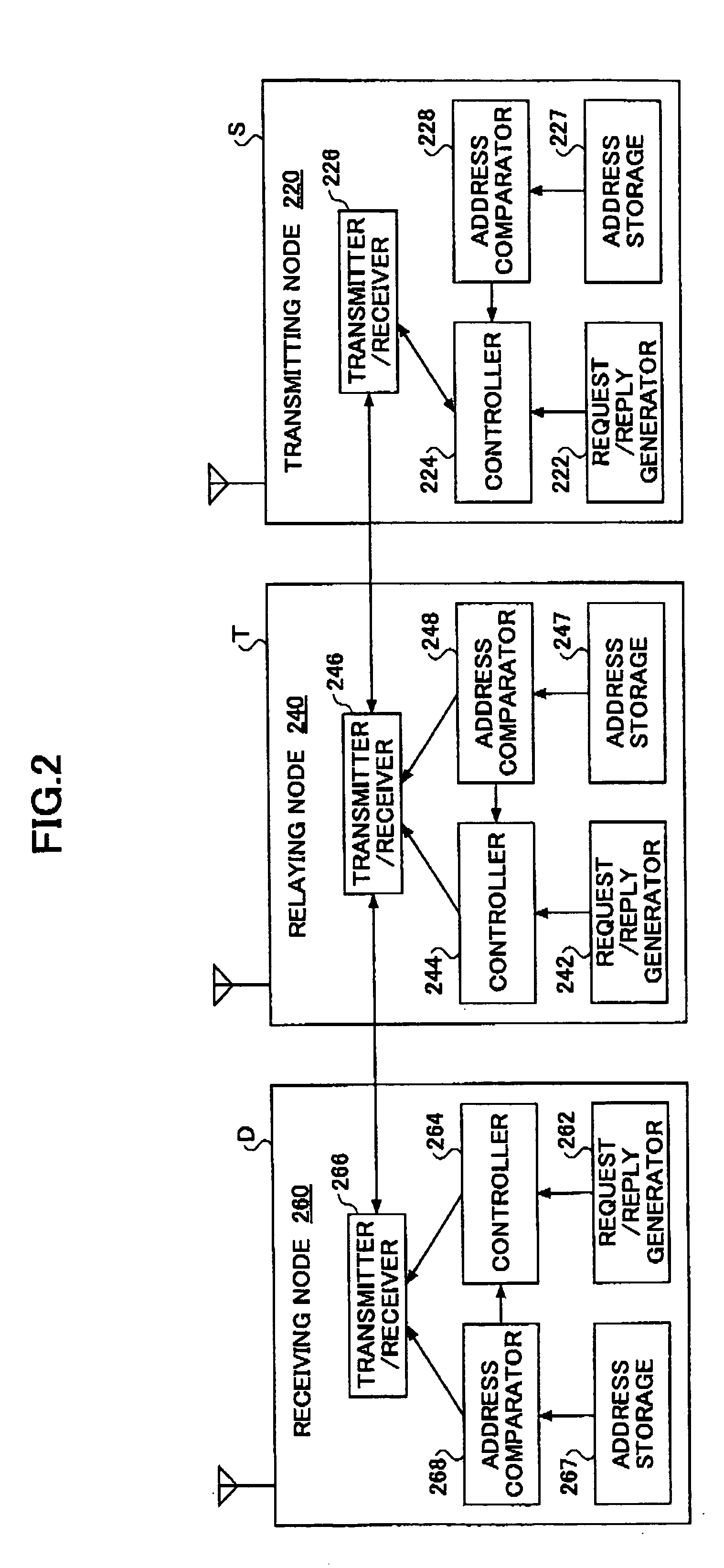

Mobile node, an ad hoc network routing controlling method and an ad hoc network system

ActiveUS20050195814A1Avoid riskReduce riskKey distribution for secure communicationNetwork topologiesSelf-organizing networkAd hoc network routing

A mobile node (400) capable of establishing an ad hoc network routing is disclosed. The mobile node comprises a transmitting / receiving unit (426) for communicating with other communication unit and a routing request generator (422) for generating a routing request message for requiring an ad hoc network routing. The mobile node further comprises: an address storage (427) for storing an address of the mobile node (400) and an address of a receiving node; a random number generator (430) for generating a random number; a certificate issuing unit (440) for issuing a certificate of the mobile node (400); a digital signature creator (450) for creating a digital signature of the mobile node (400); and a controller (424) for transmitting / receiving the routing request message accompanied by the address of the mobile node, the address of the receiving node, the random number, the certificate and the digital signature via the transmitting / receiving unit, according to an ad hoc network protocol.

Owner:GOOGLE LLC

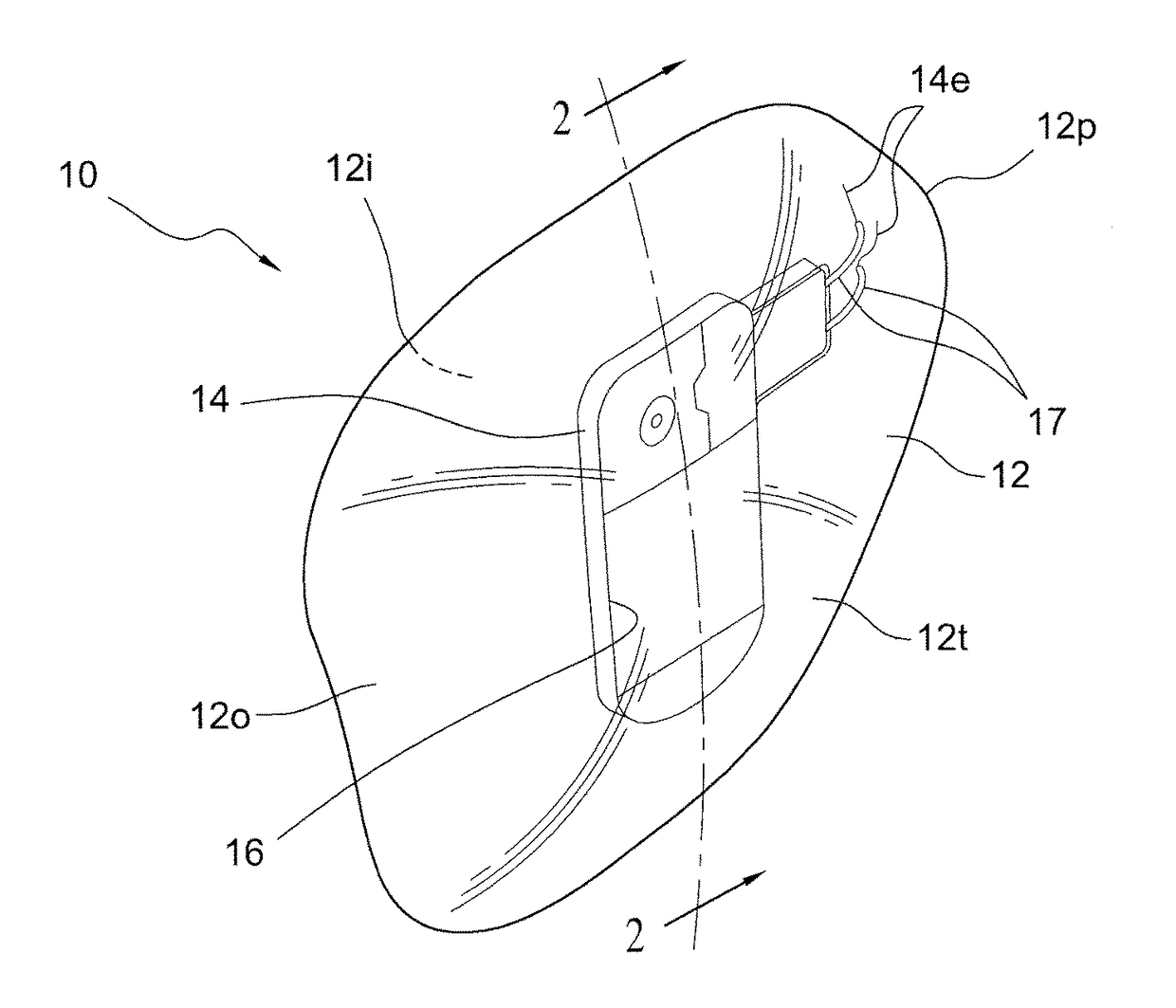

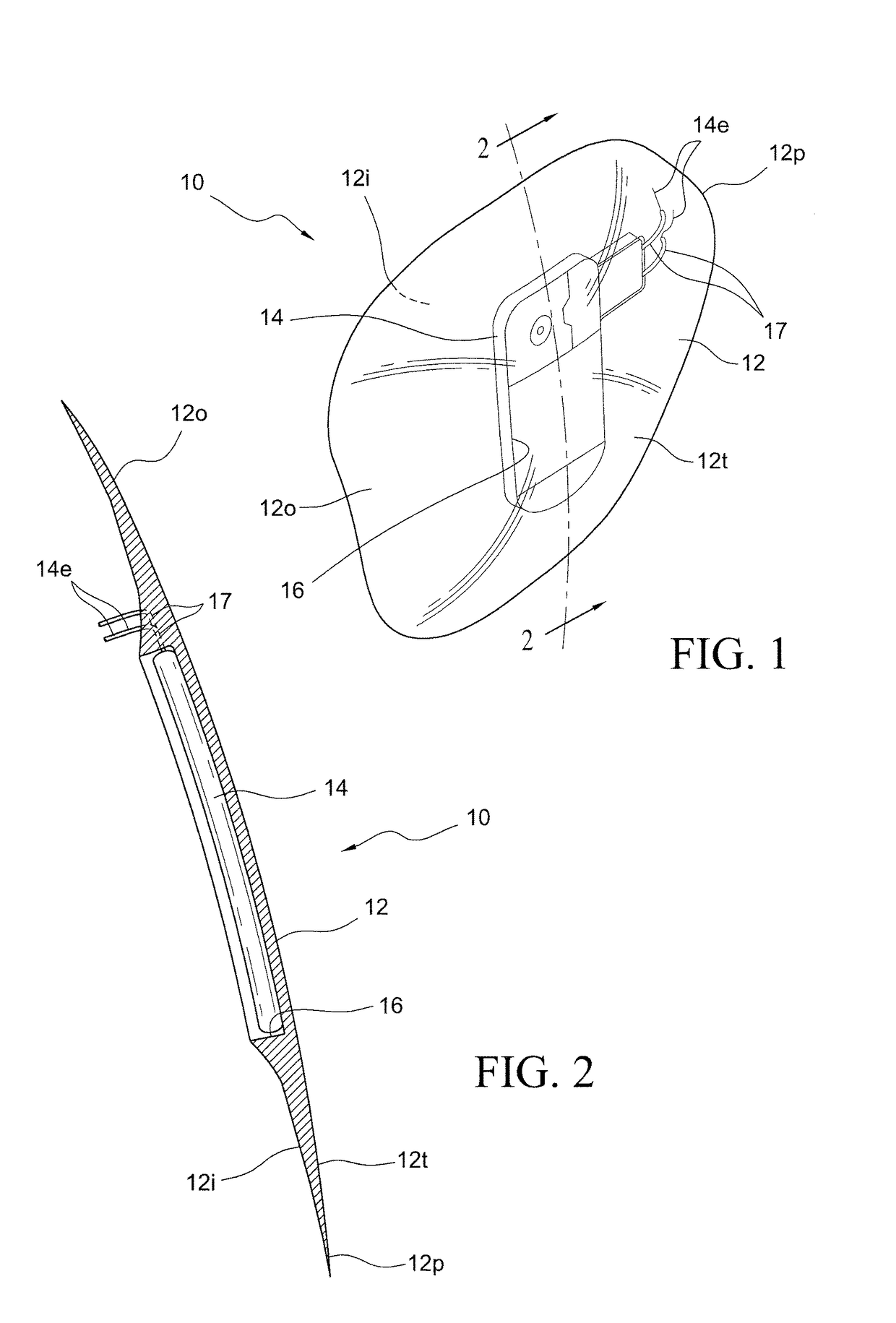

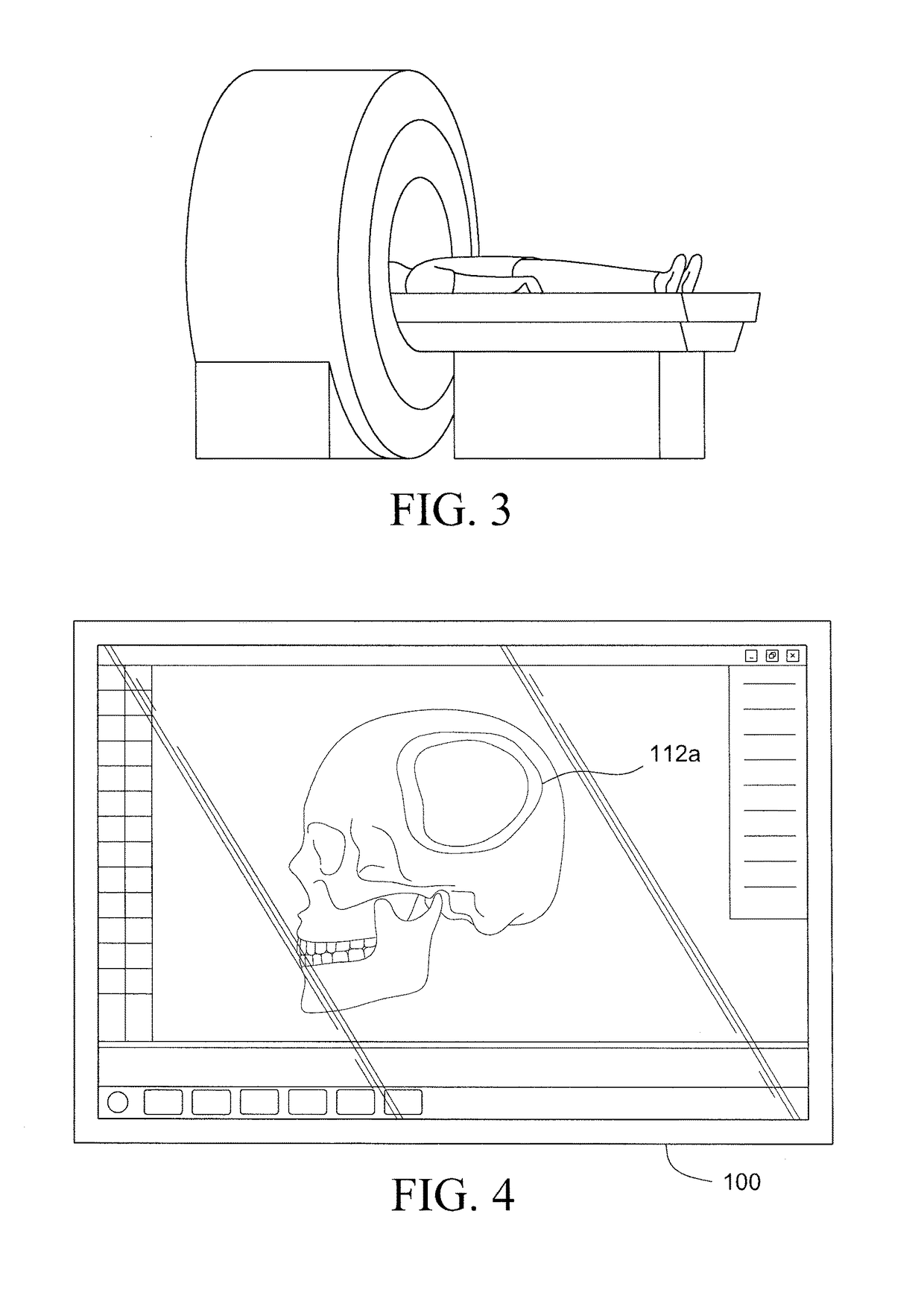

Method for manufacturing a low-profile intercranial device and the low-profile intercranial device manufactured thereby

ActiveUS20180055640A1High extrusion riskAvoid irregularitiesAdditive manufacturing apparatusHead electrodesCranial implantBiomedical engineering

A low-profile intercranial device including a low-profile static cranial implant and a functional neurosurgical implant. The low-profile static cranial implant and the functional neurosurgical implant are virtually designed and interdigitated prior to physical assembly of the low-profile intercranial device.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE +1

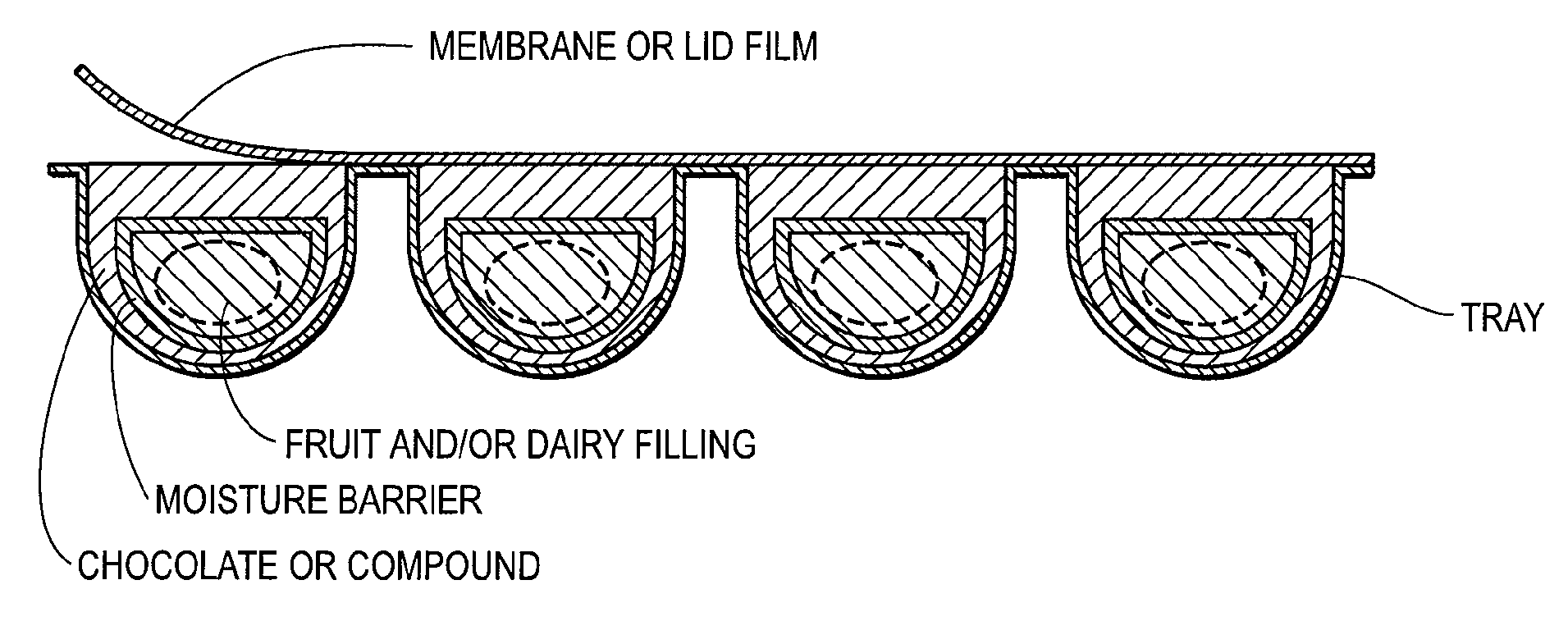

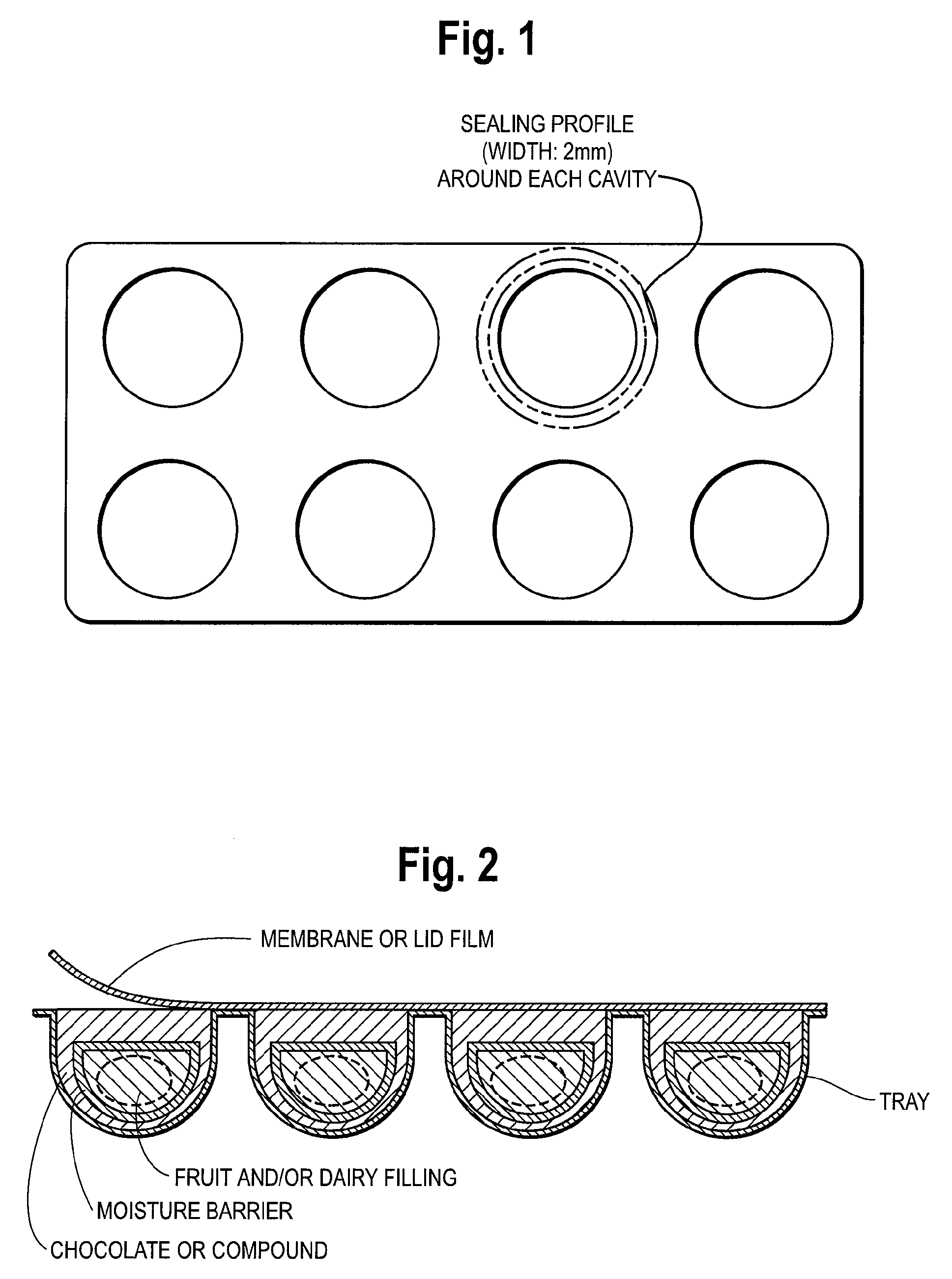

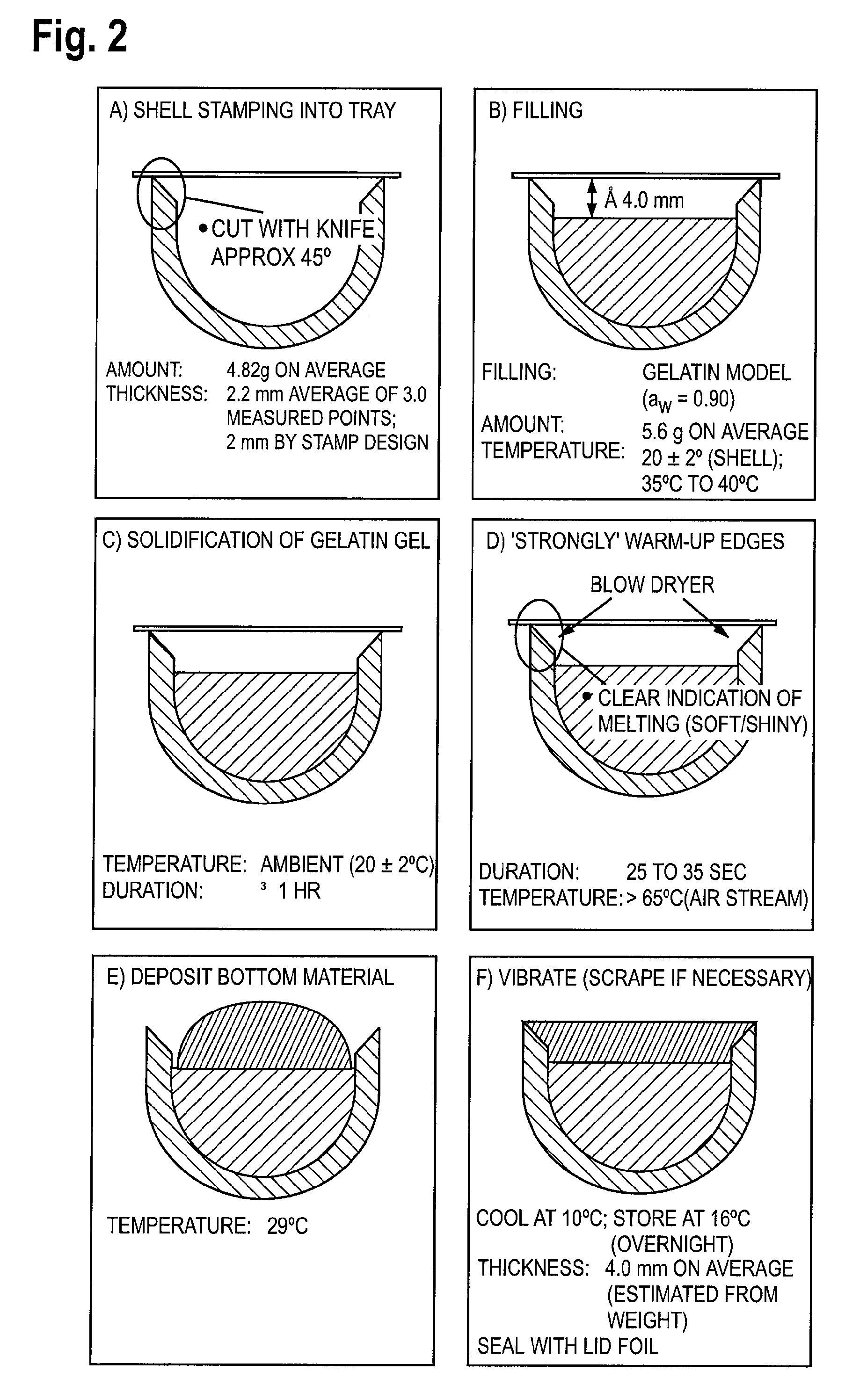

Filled confectionery products

InactiveUS20080050484A1Avoid riskAvoids microbial recontamination and contaminationConfectioneryFood preservationEngineeringWater activity

The present invention provides a process of manufacturing a filled confectionery product with extended shelf-life comprising at least one high water activity component and at least one low water activity component, which process comprises pasteurizing the confectionery product under pressure after hermetically sealing said product in its final primary package providing a hermetic seal for the product. Moreover, there are also provided filled confectionery products obtainable by this process.

Owner:KRAFT FOODS R & D INC

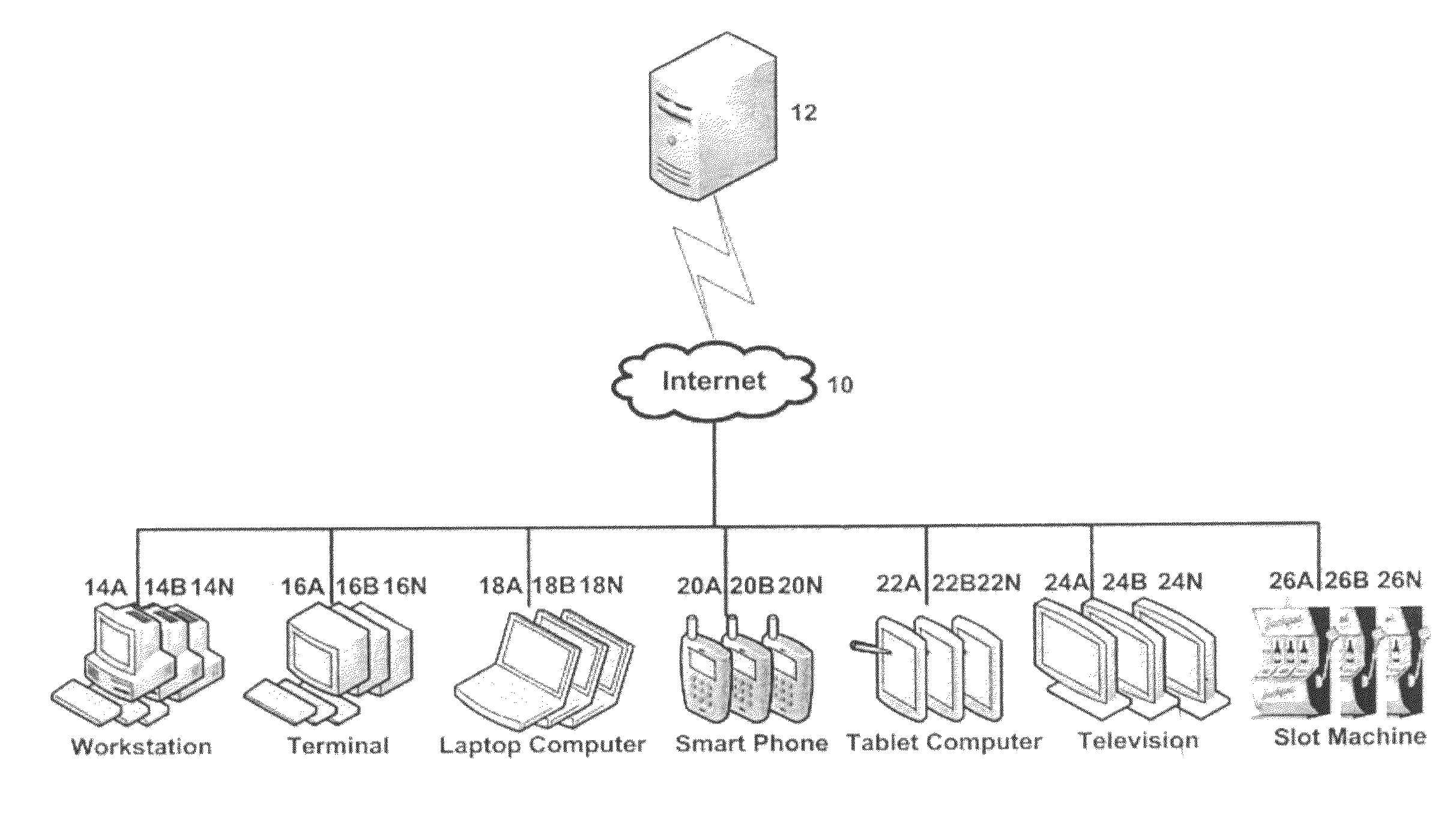

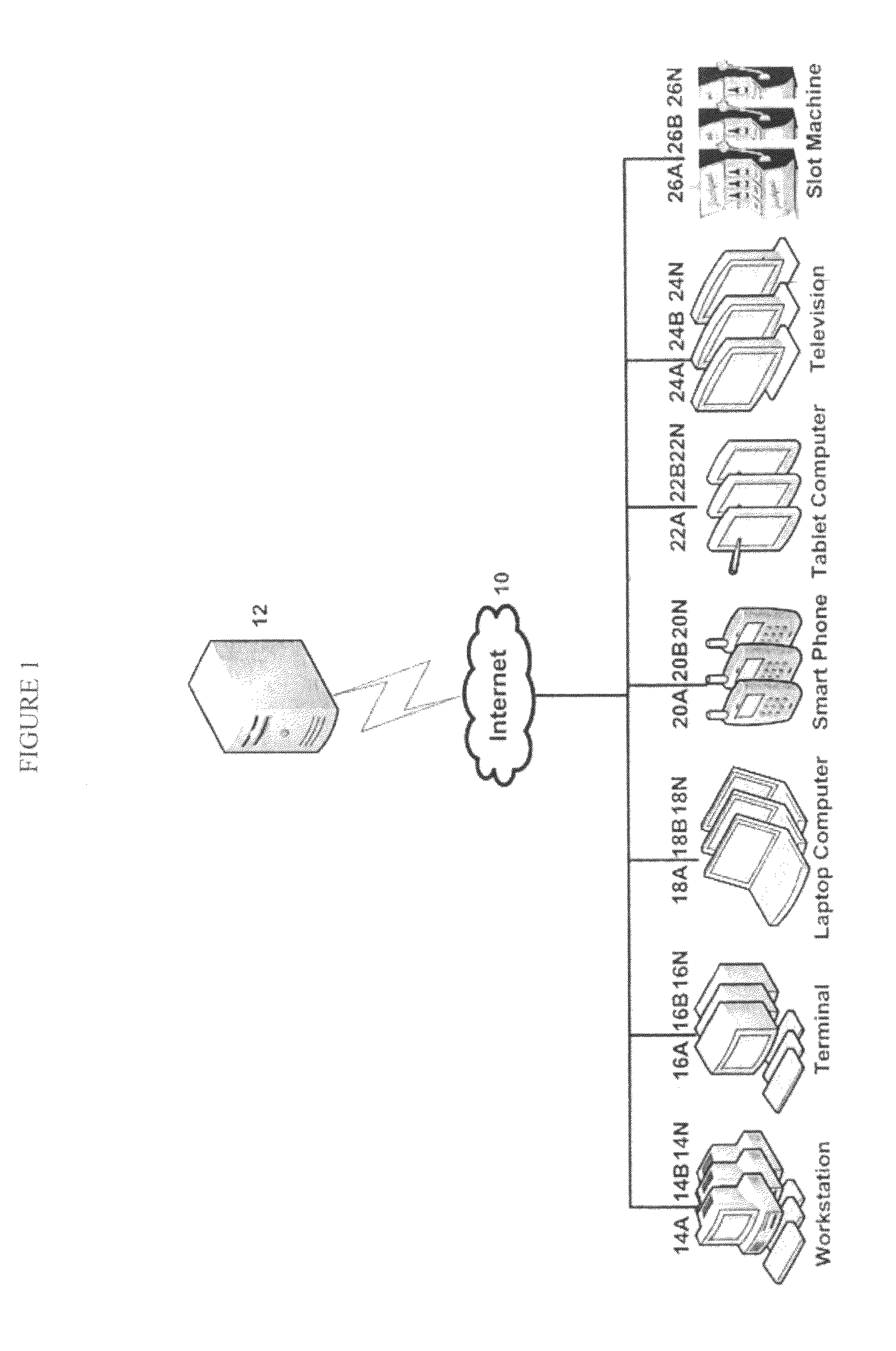

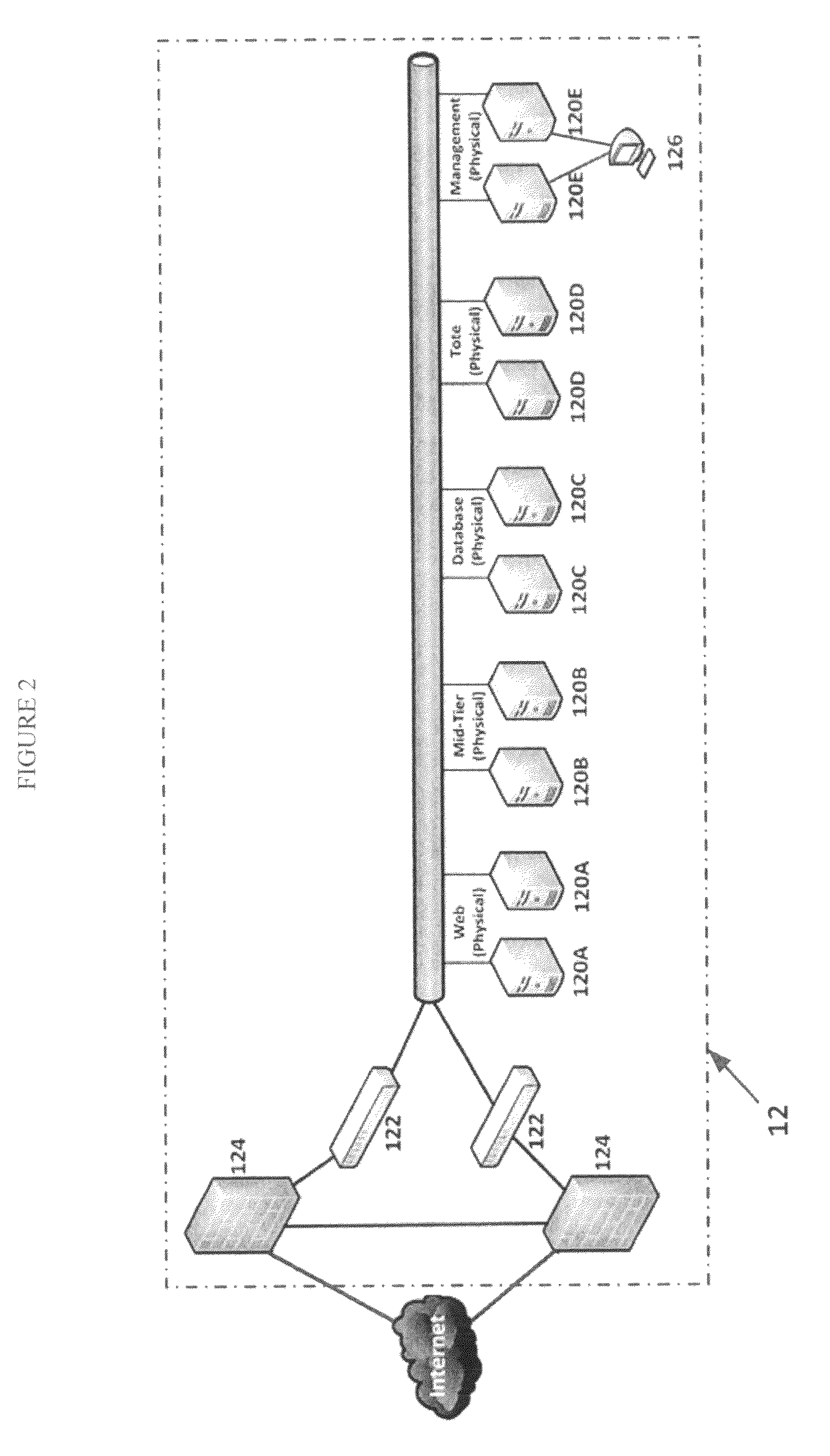

Pool wagering apparatus, methods and systems

ActiveUS8602884B1Avoid riskReduce riskCard gamesApparatus for meter-controlled dispensingData scienceOperations research

The present invention is directed to a system, method and apparatus for providing a unique pool betting product where players make selections in a number of different events which occur in sequential legs or time periods. After some and preferably most of the legs have been completed, players who have correct “win” predictions for each of the events or legs that are completed and thus remain in contention for the Jackpot Pool, and potentially those still eligible for consolations prizes, will be offered an opportunity to sell their tickets, in whole or in part, to the game operator or through the game operator.

Owner:DIOGENES

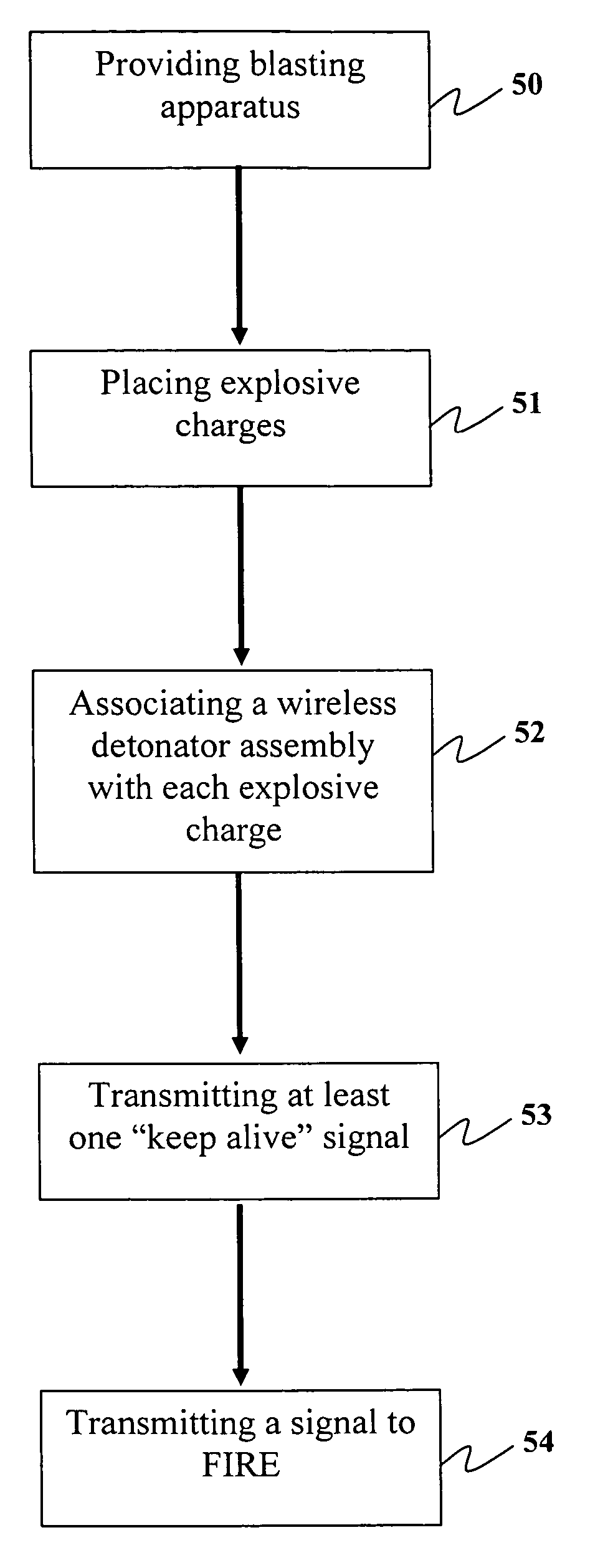

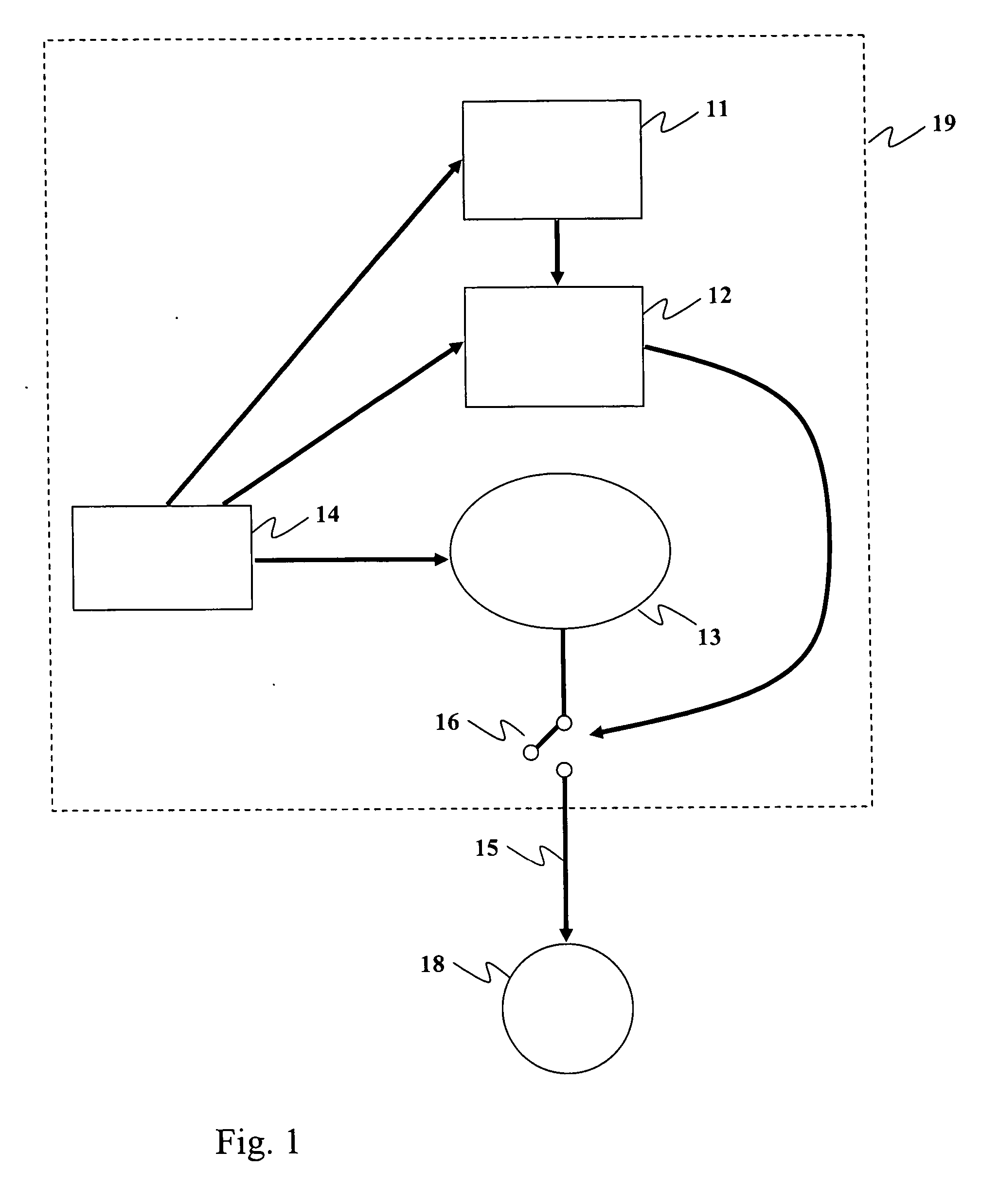

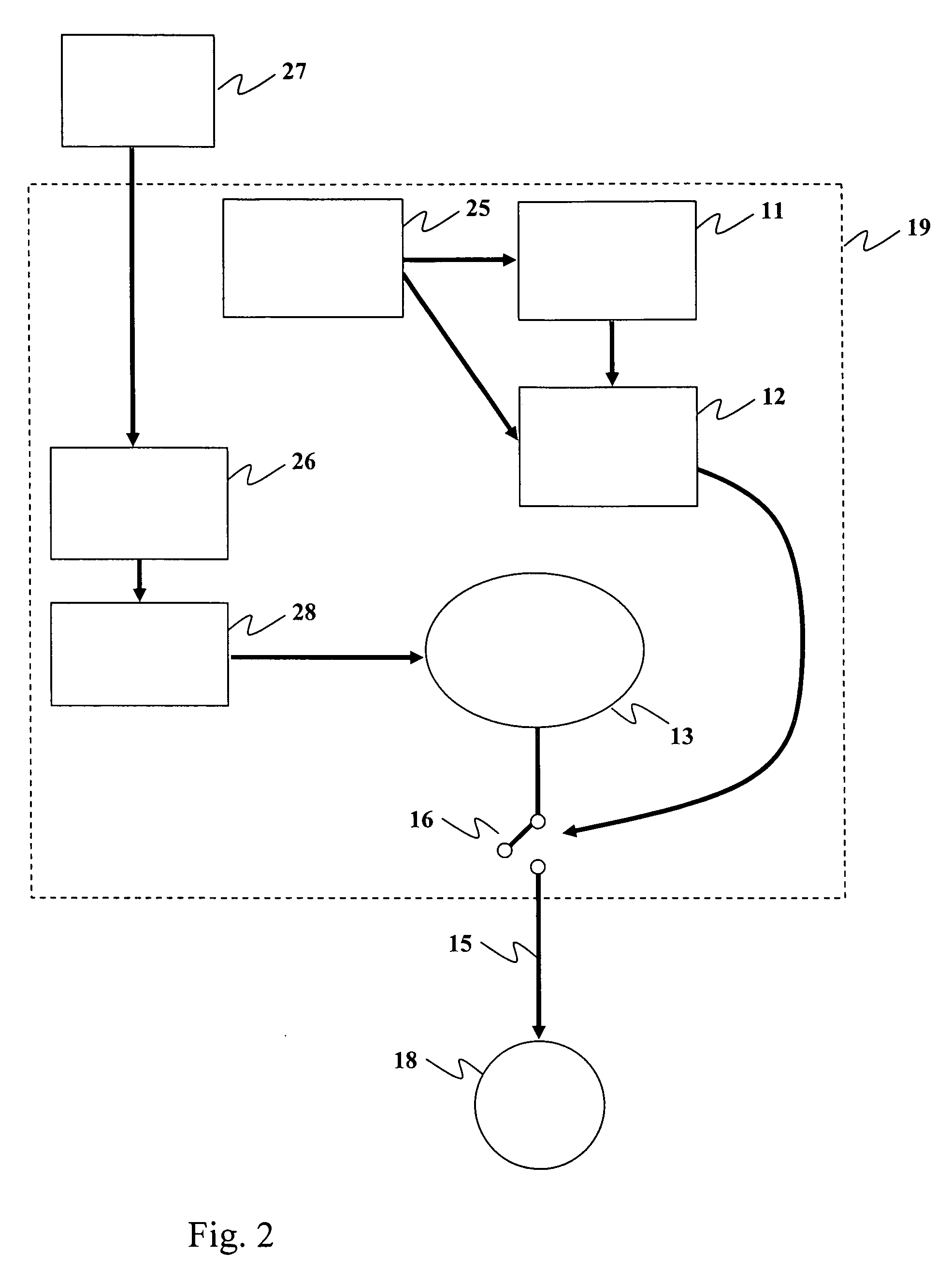

Wireless detonator assembly, and methods of blasting

ActiveUS20070044673A1Eliminate riskAvoid riskIncandescent ignitionBlasting cartridgesSpecific timeElectrical and Electronics engineering

Wireless detonators, and corresponding wireless detonator systems present opportunities for blasting arrangements that avoid the need for physical wire connections between the blasting components. The present application discloses a wireless detonator assembly, a corresponding blasting apparatus, and a method of use thereof. The wireless detonator assembly comprises a charge storage device that is capable of storing charge for discharge into a firing circuit upon receipt of an appropriate wireless command signal to FIRE, from an associated blasting machine. In preferred embodiments, the charge storage device remains or becomes charged, at least for a specific time period, if the wireless detonator assembly receives a suitable “keep alive” command signal from an associated blasting machine—otherwise the charge storage device discharges with little or no effect upon the firing circuit, such that the wireless detonator assembly retain or adopts a safe mode.

Owner:ORICA EXPLOSIVES TECH PTY LTD

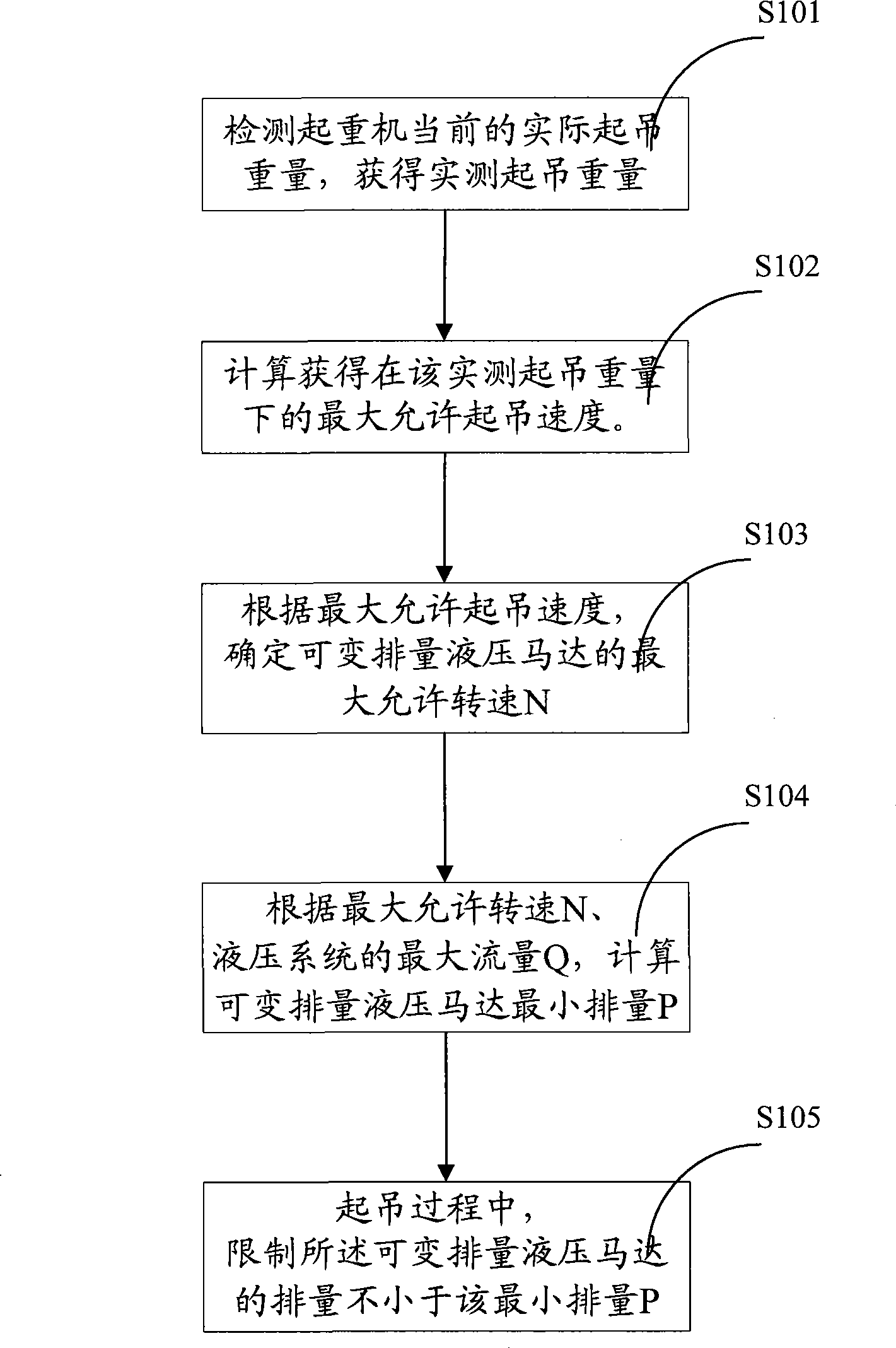

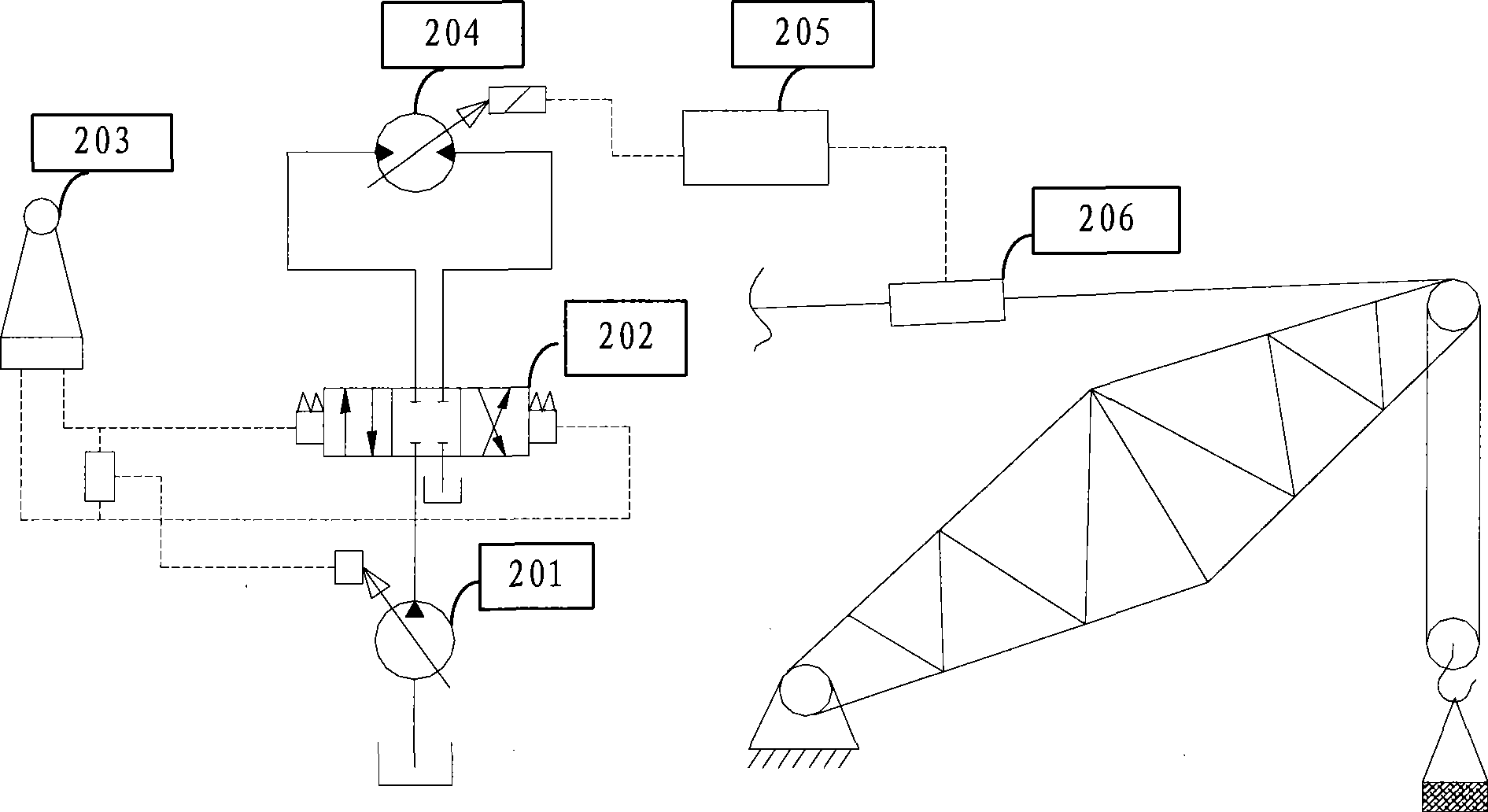

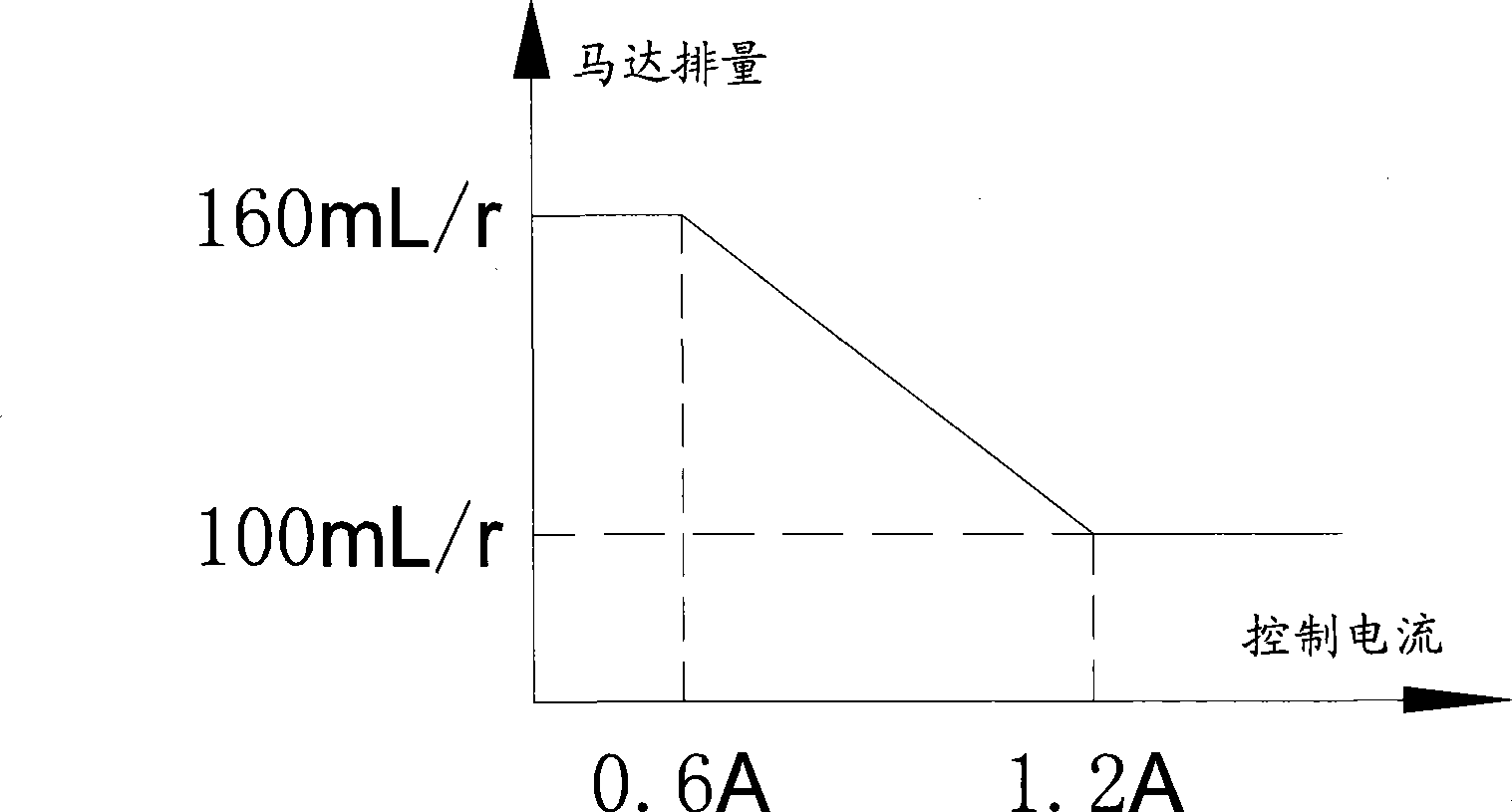

Crane lifting speed control method and device

ActiveCN101417771AAvoid riskReduce the difficulty of operationWinding mechanismsLoad-engaging elementsTraffic volumeEngineering

The invention discloses a lifting speed controlling method of cranes used in cranes adopting hydraulic motors with variable displacement and carrying out the hanging and driving by a volume-flow control method; the invention comprises that the steps of: obtaining measured lifting weight; calculating the maximum allowable lifting speed obtained under the measured lifting weight; determining the maximum allowable rotating speed N of the hydraulic motors with variable displacement driven by the implementation lifting; calculating the minimum displacement P of the hydraulic motors with variable displacement under the situation according to the maximum allowable rotating speed N and the maximum flow Q of a hydraulic system; and limiting the displacement of the hydraulic motors with variable displacement to be not less than minimum displacement P in the lifting process. Compared with the prior art, the method and the device provided by the invention can combine the crane measured lifting weight to limit the lifting speed within the allowed range, avoid the cranes from producing risks caused by a too fast lifting speed and reduce the operation difficulties of the cranes.

Owner:SANY HEAVY IND CO LTD (CN)

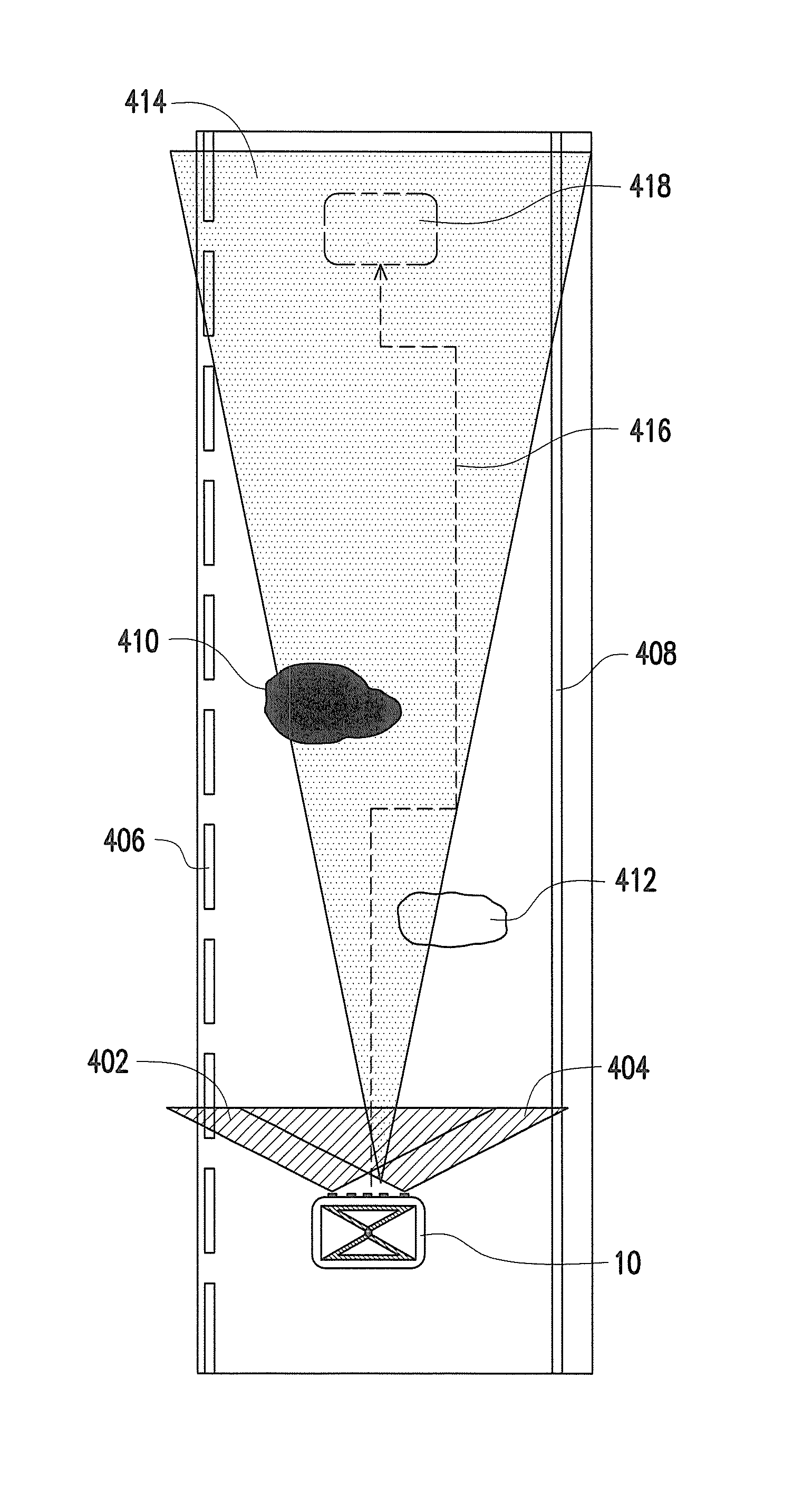

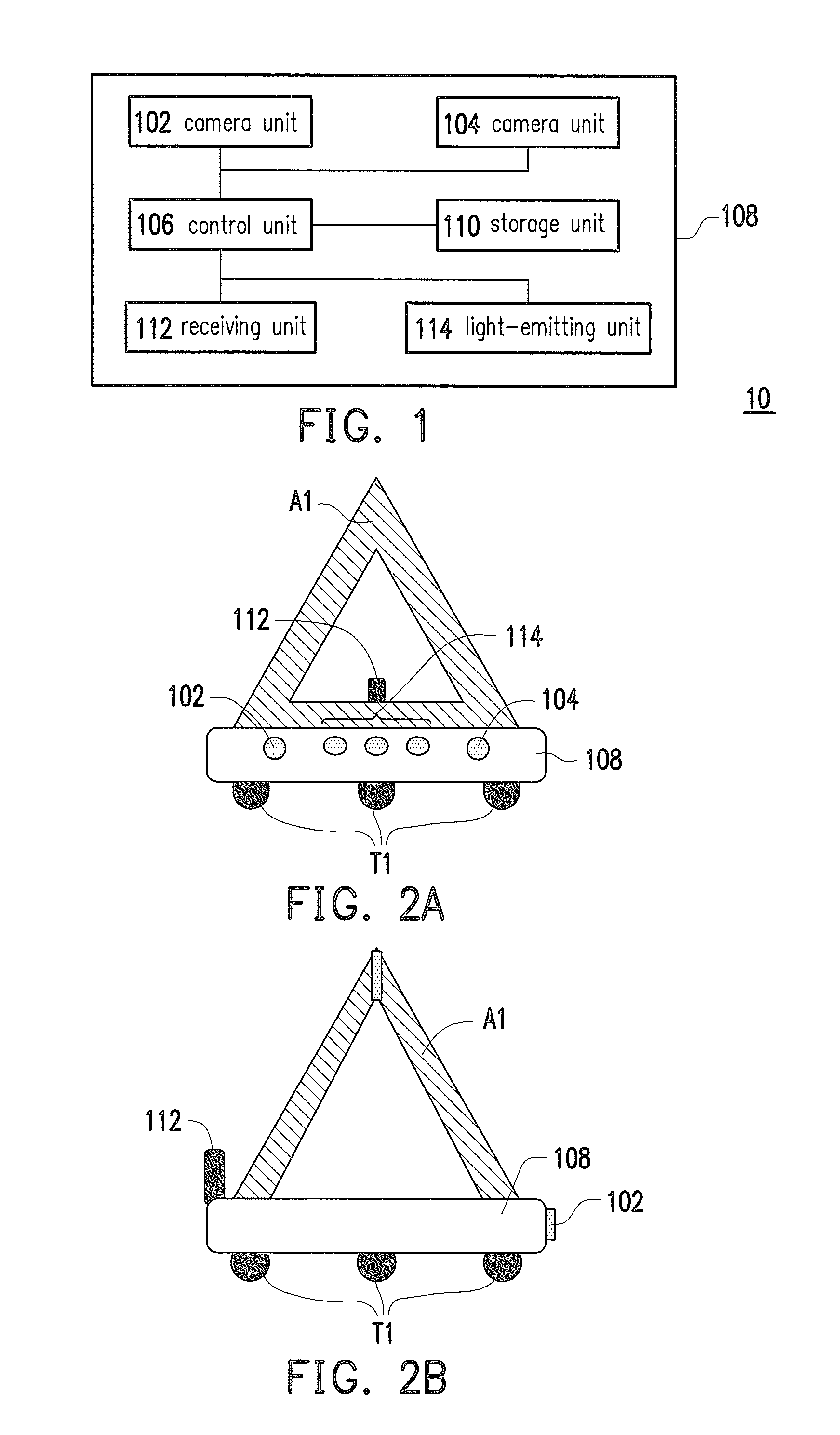

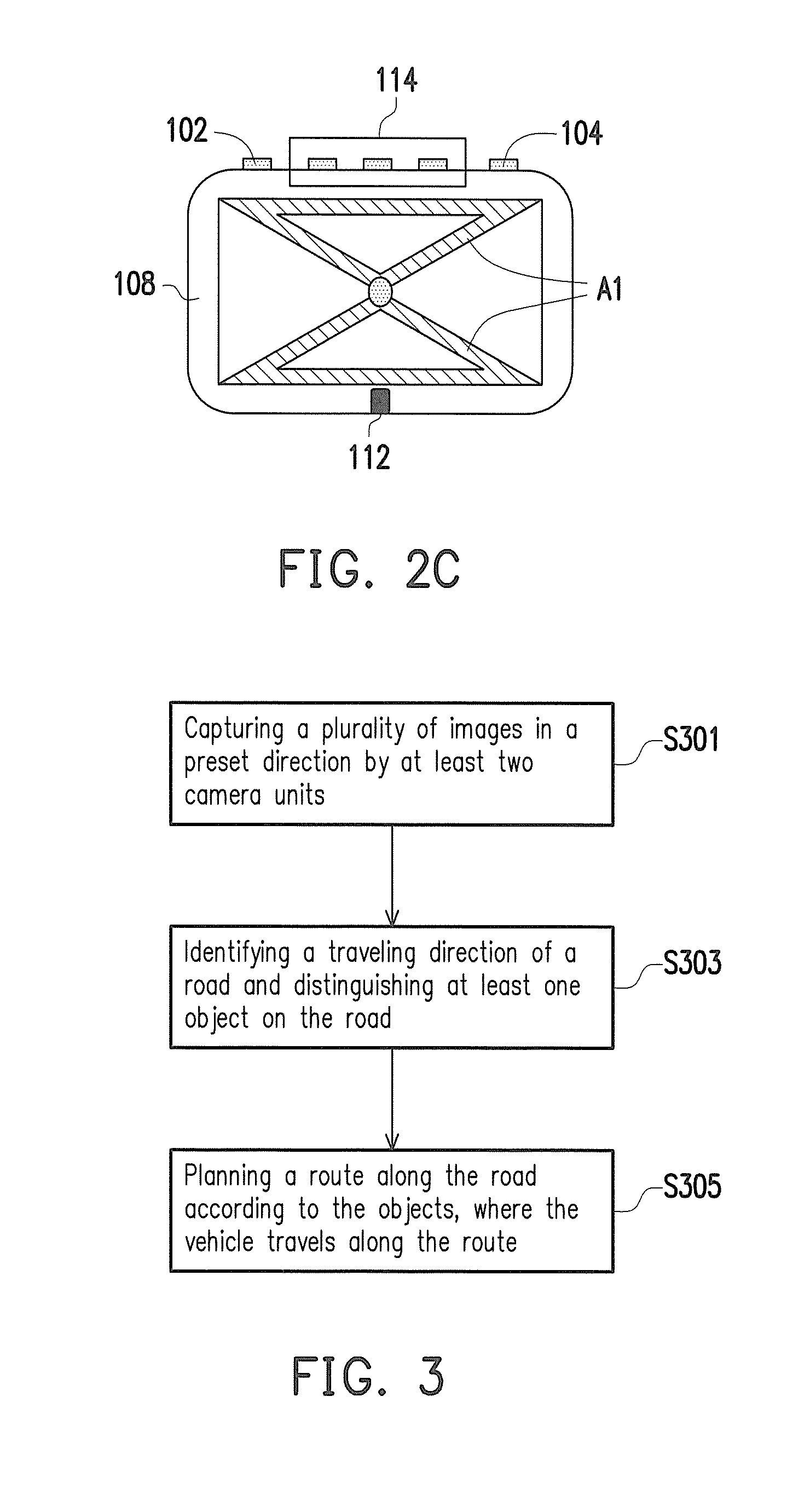

Warning sign placing apparatus and control method thereof

ActiveUS20160202077A1Avoid riskReduce riskInstruments for road network navigationScene recognitionImage basedEngineering

A warning sign placing apparatus and a control method thereof are provided. The warning sign placing apparatus includes at least two camera units, a control unit, and a vehicle. The camera unit captures a plurality of images in a preset direction. The vehicle carries at least two camera units and control unit. The control unit identifies a traveling direction of the road and distinguishes at least one object on the road based on the images, and plans a route along the road for the vehicle according to the at least one object, where the vehicle travels along the route. A warning sign is configured in the warning sign placing apparatus and is able to automatically move to a preset position with a preset distance in order to avoid the risk of dangers in a case of manually placing the warning sign.

Owner:WISTRON CORP

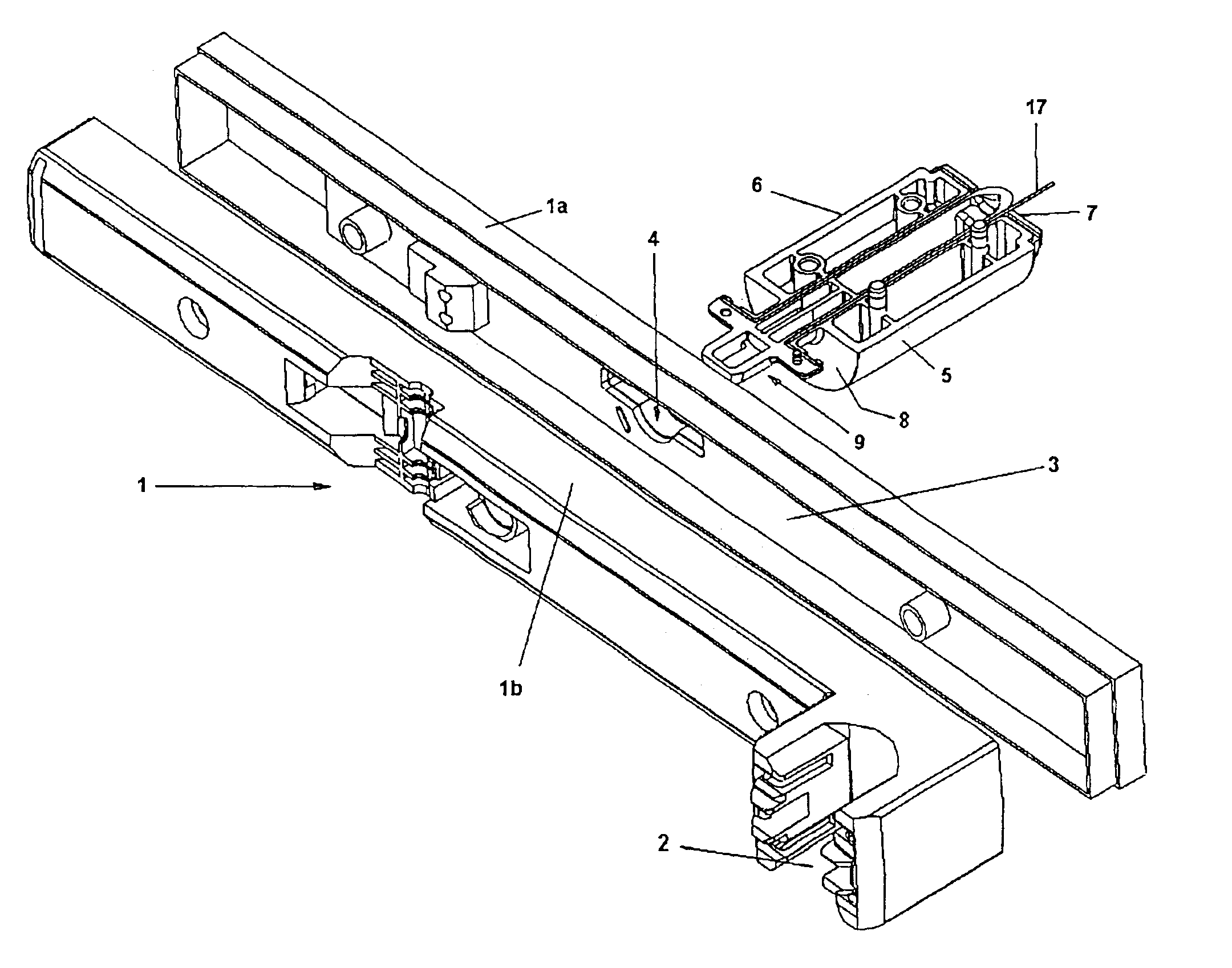

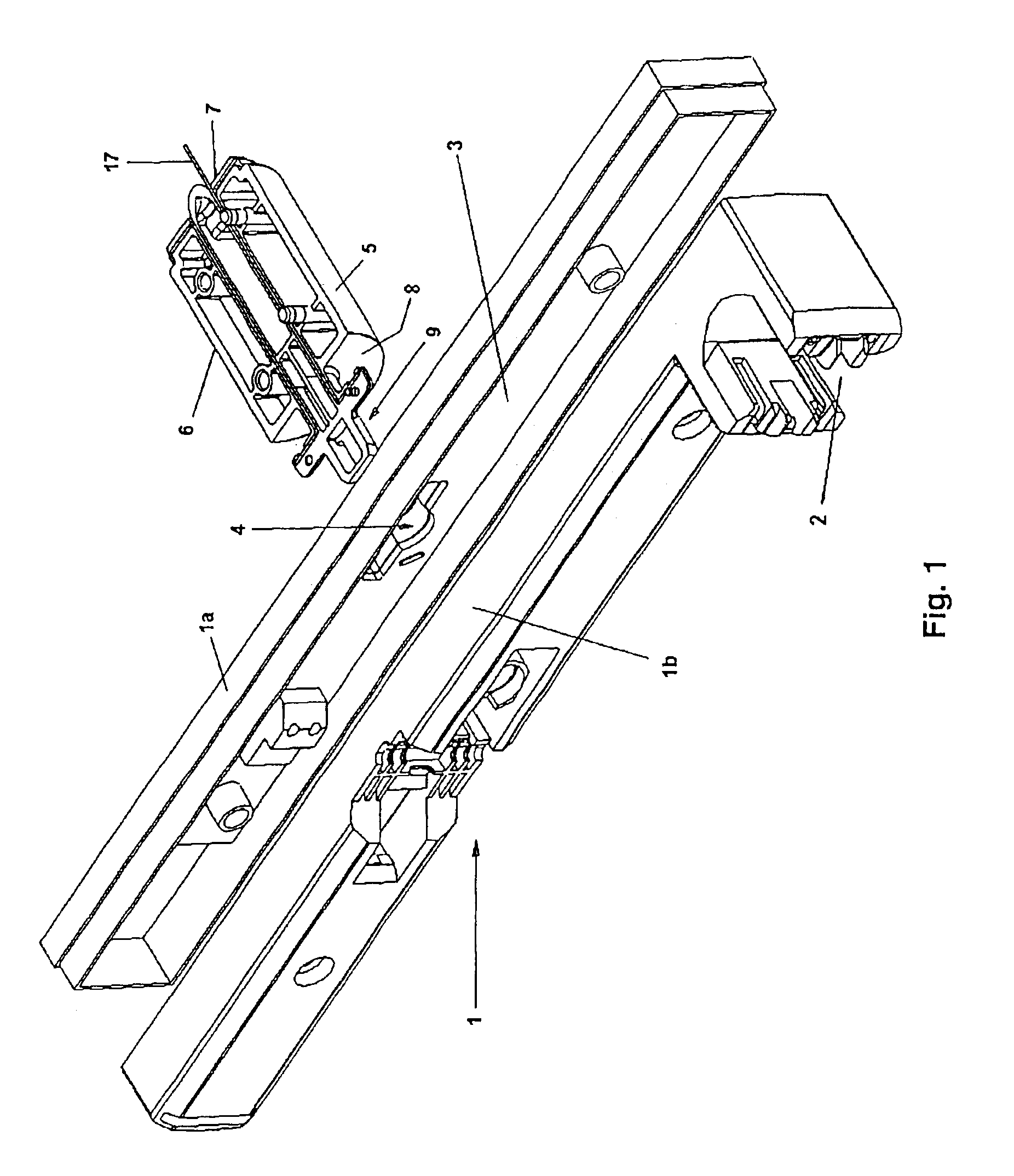

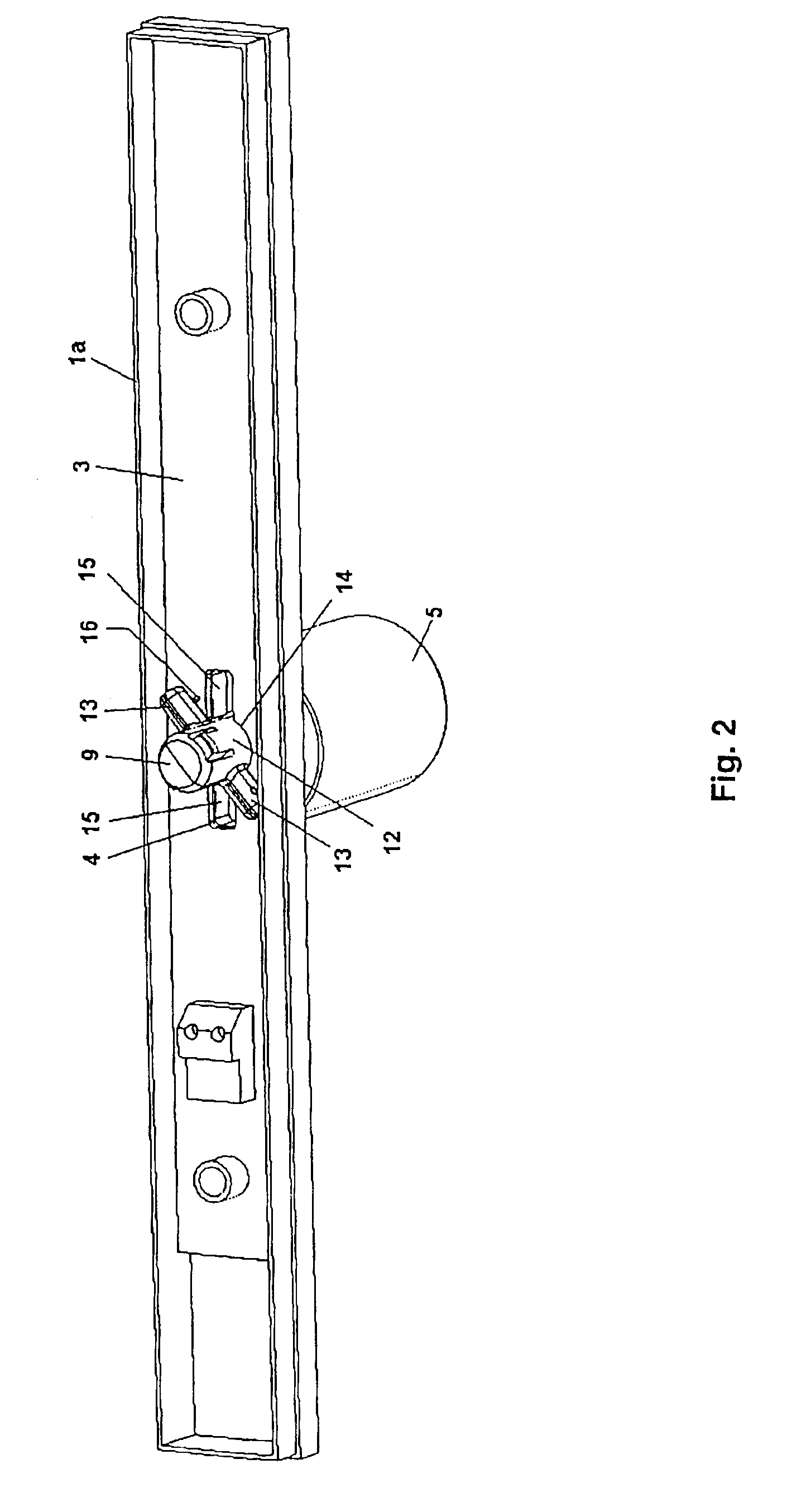

Bayonet base for lamp mount

InactiveUS6893282B2Avoid riskPrevent removalElectric discharge tubesCoupling device detailsEngineeringLight fixture

Lamp mounts for tubular fluorescent lamps with a screw base are to be configured in a more compact manner for packaging purposes. A bayonet adapter (5) which can be rotated into a lamp mount (1) is provided for this purpose. The bayonet adapter (5) has, for example, an E27-type screw base opposite the bayonet connector (9). Since the bayonet adapter (5) can be removed from the lamp mount (1), a corresponding luminaire can be packaged in a more compact manner.

Owner:PATENT TREUHAND GESELLSCHAFT FUR ELECTRIC GLUEHLAMPEN MBH

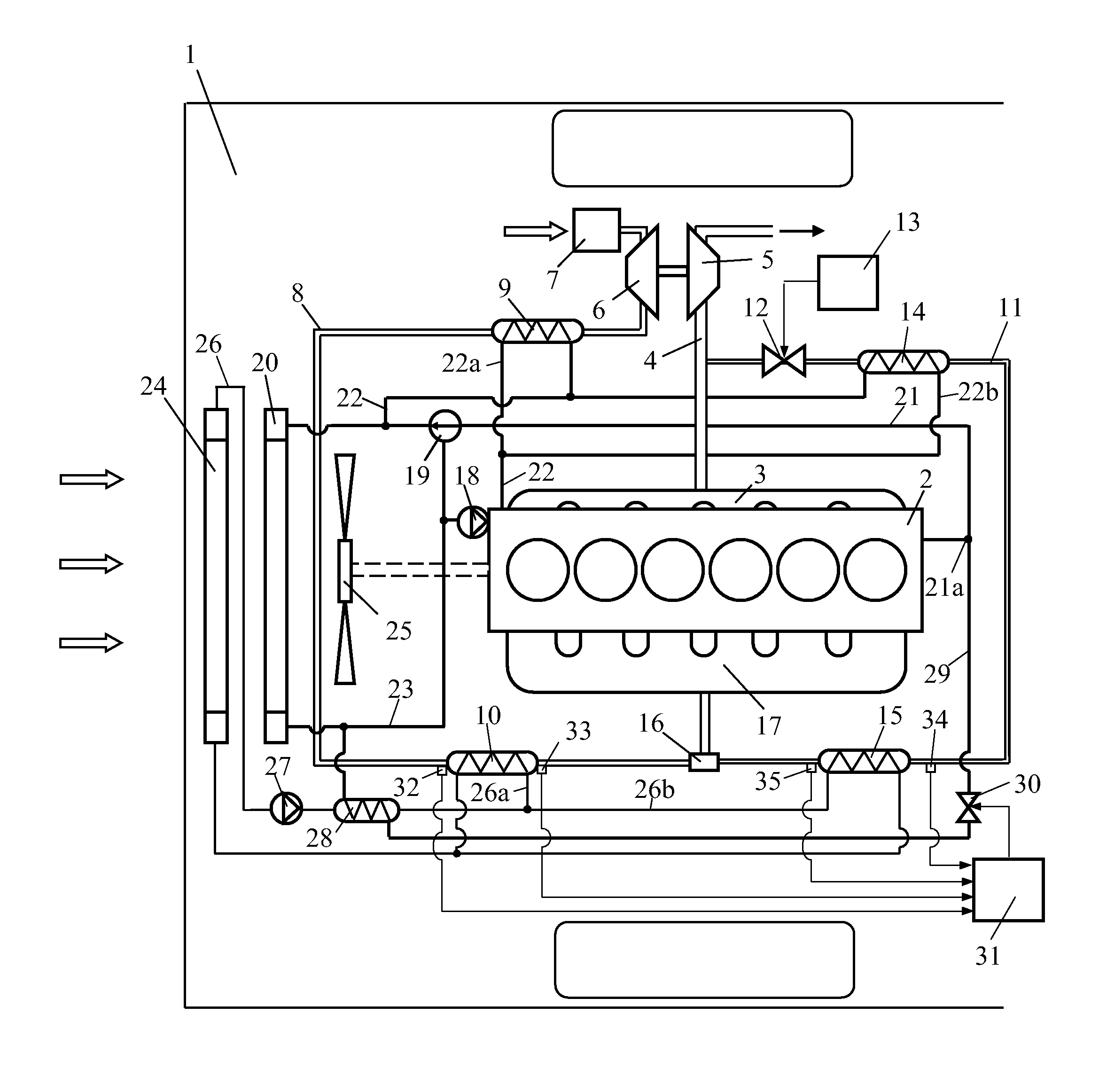

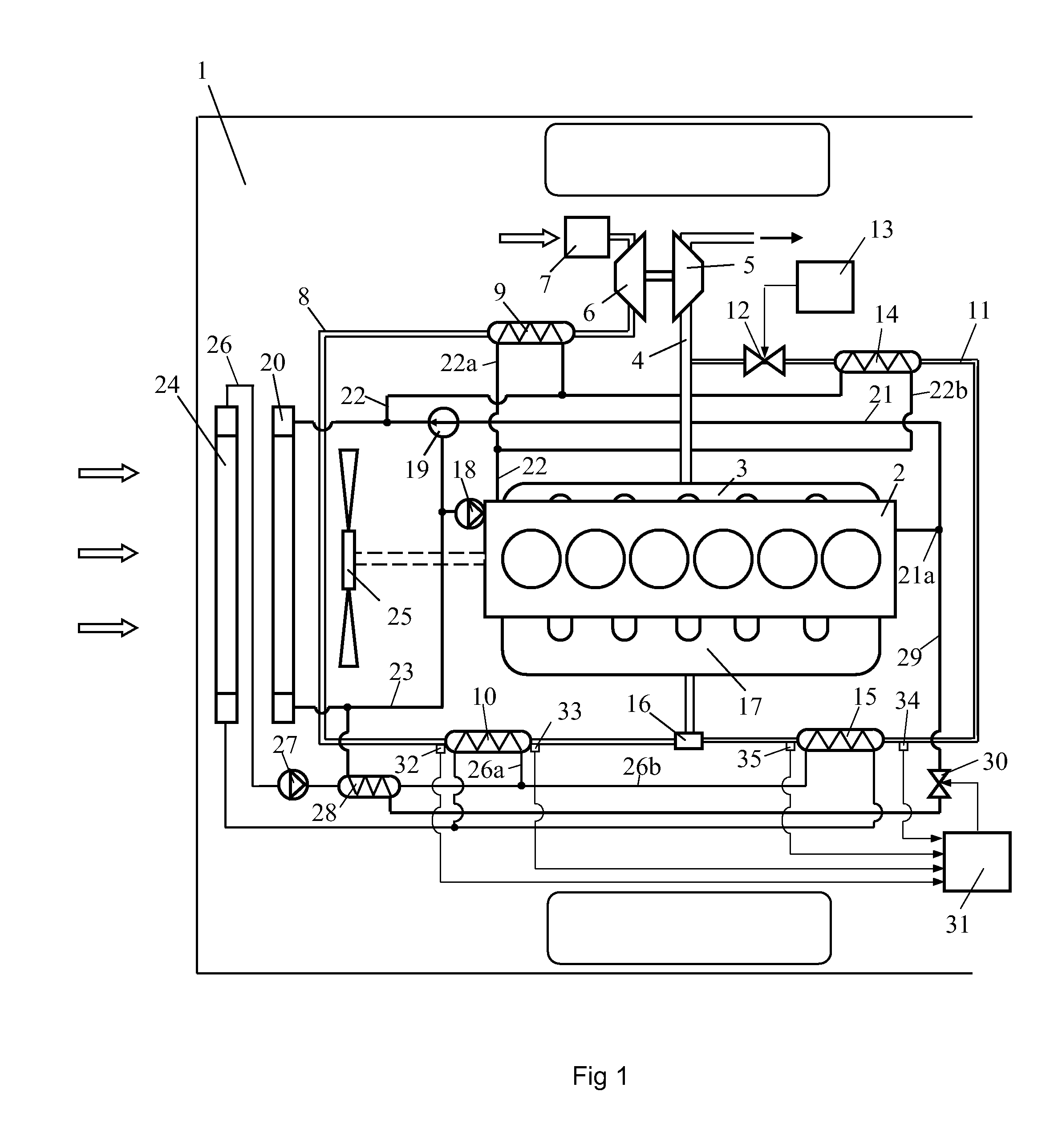

Arrangement at a supercharged internal combustion engine

InactiveUS20110000446A1Good coolingAvoid riskLiquid coolingCoolant flow controlChillerNuclear engineering

An arrangement for a supercharged combustion engine for preventing ice formation in a cooler. A first cooling system with a circulating coolant. A second cooling system with a circulating coolant which during normal operation of the combustion engine is at a lower temperature than the coolant in the first cooling system. The cooler in which a gaseous medium for the engine and which contains water vapour is intended to be cooled by the coolant in the second cooling system. A heat exchanger. A valve which can be placed in a first position wherein coolant from at least one of the cooling systems is prevented from flowing through the heat exchanger and in a second position wherein coolant from both of the cooling systems flows through the heat exchanger so that the coolant in the second cooling system is warmed by the coolant in the first cooling system.

Owner:SCANIA CV AB

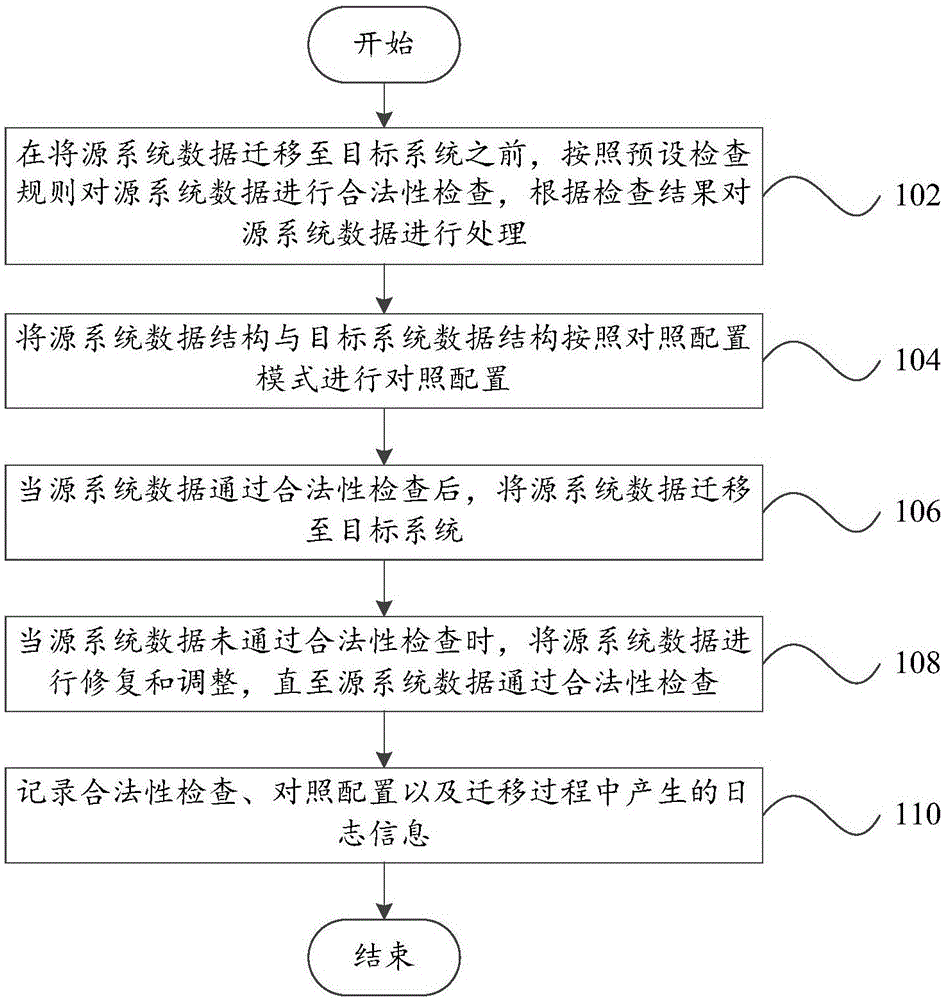

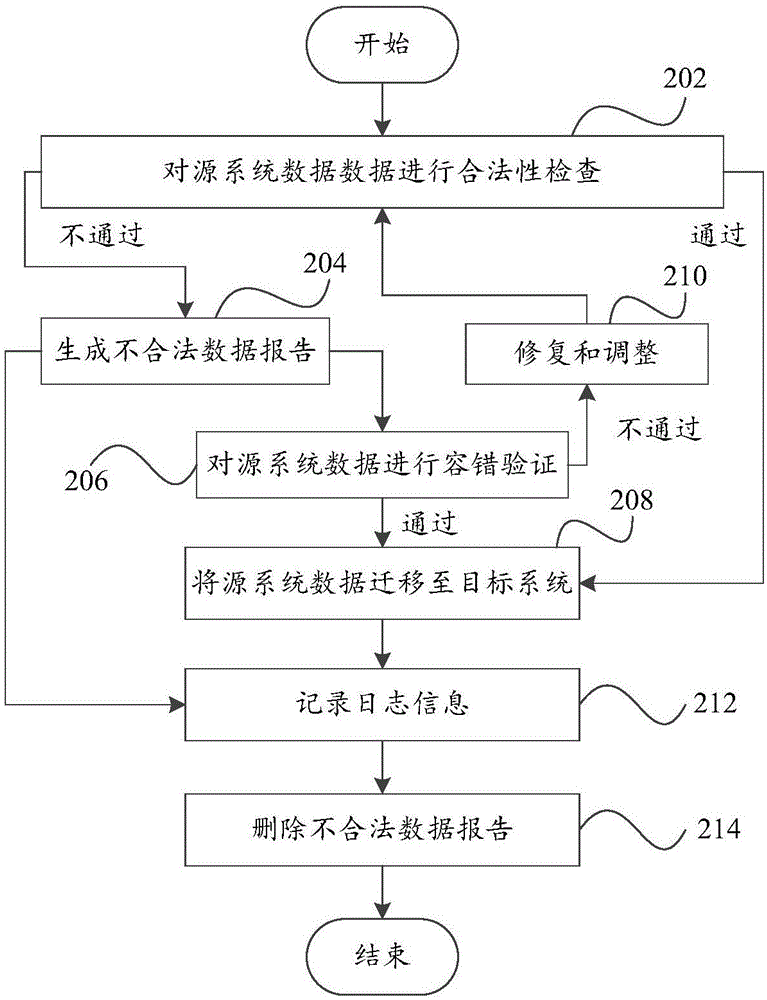

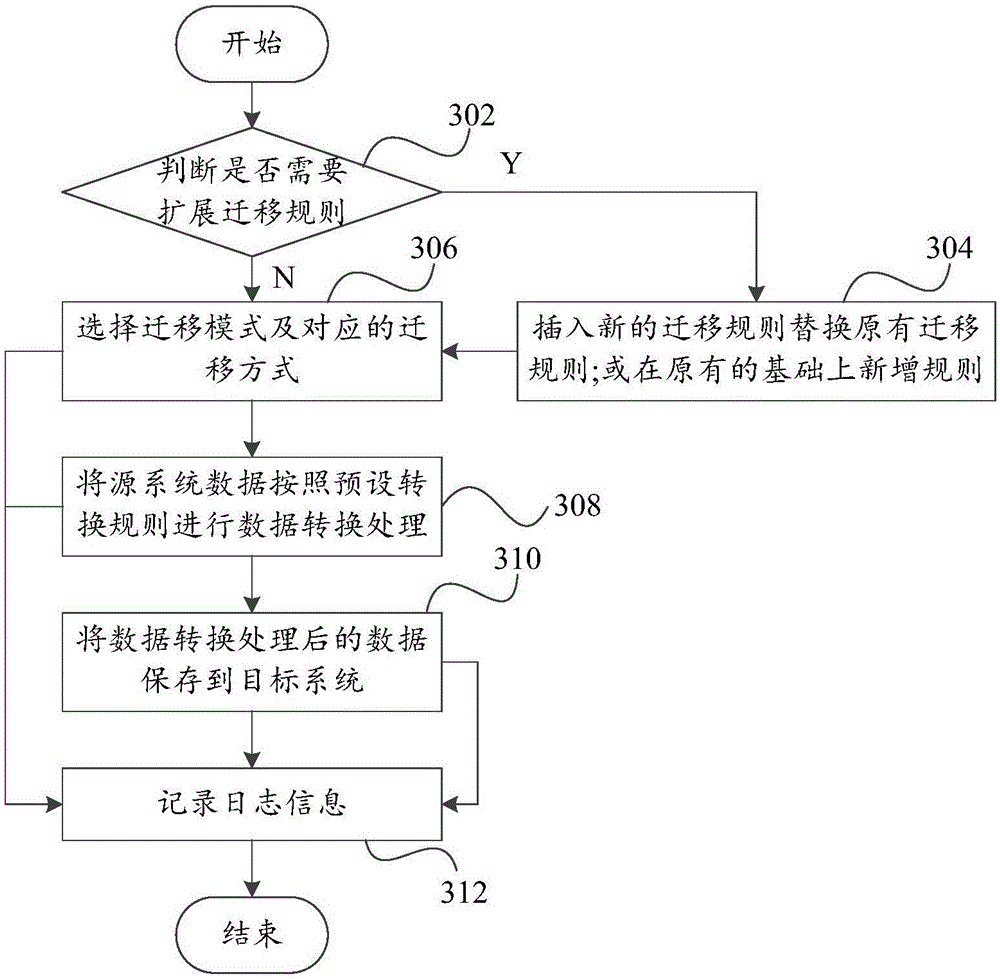

Data migration method and data migration system

InactiveCN106776876AAvoid riskImprove stabilityDatabase distribution/replicationSpecial data processing applicationsData migrationGoal system

The invention provides a data migration method and a data migration system. The data migration method comprises the following steps: before migrating source system data to a target system, performing legality checking on the source system data according to a preset checking rule, and processing the source system data according to a checking result; performing comparative configuration on a source system data structure and a target system data structure according to a comparative configuration mode; after the source system data passes legality checking, migrating the source system data to the target system; when the source system data does not pass legality checking, repairing and regulating the source system data until the source system data passes legality checking; recording log information in legality checking, comparative configuration and migration processes. According to the technical scheme, data migration logic is processed in a configurable manner, so that the data migration work is more flexible and easier, and the heterogeneous system data migration is simpler and more efficient.

Owner:YONYOU NETWORK TECH

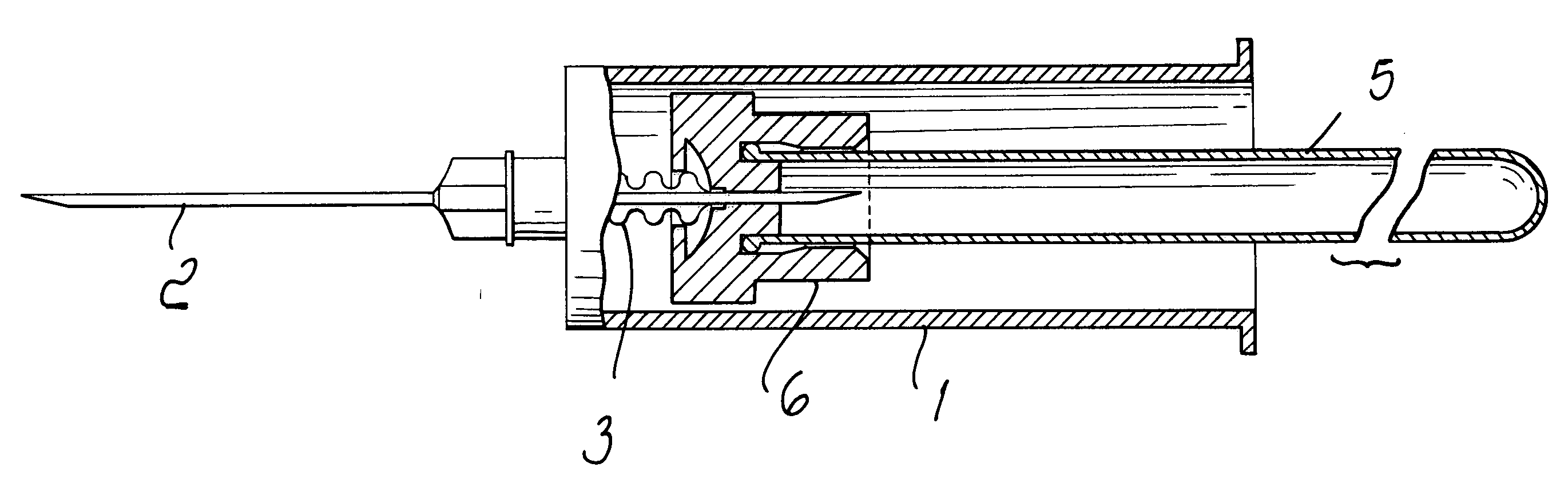

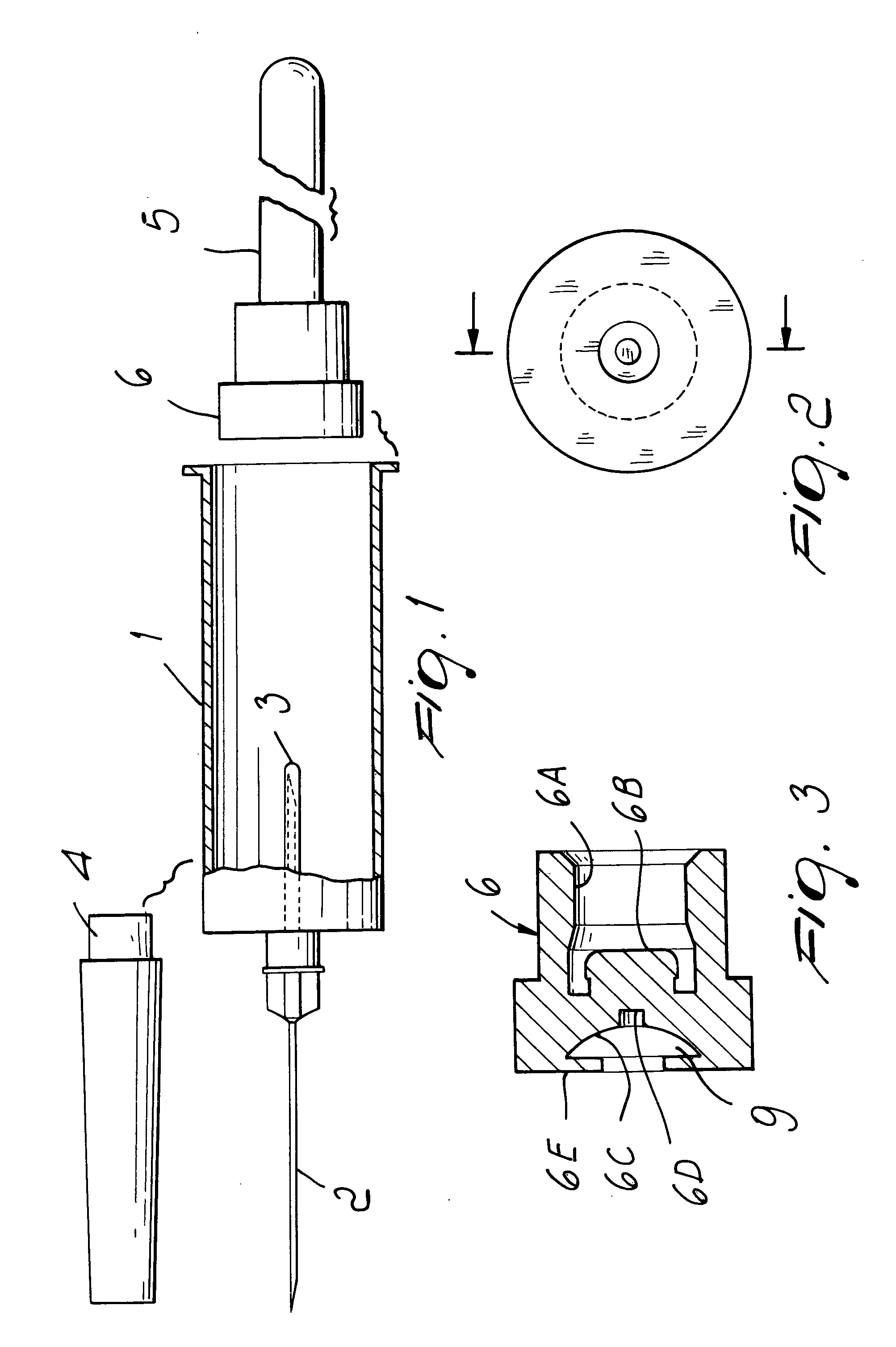

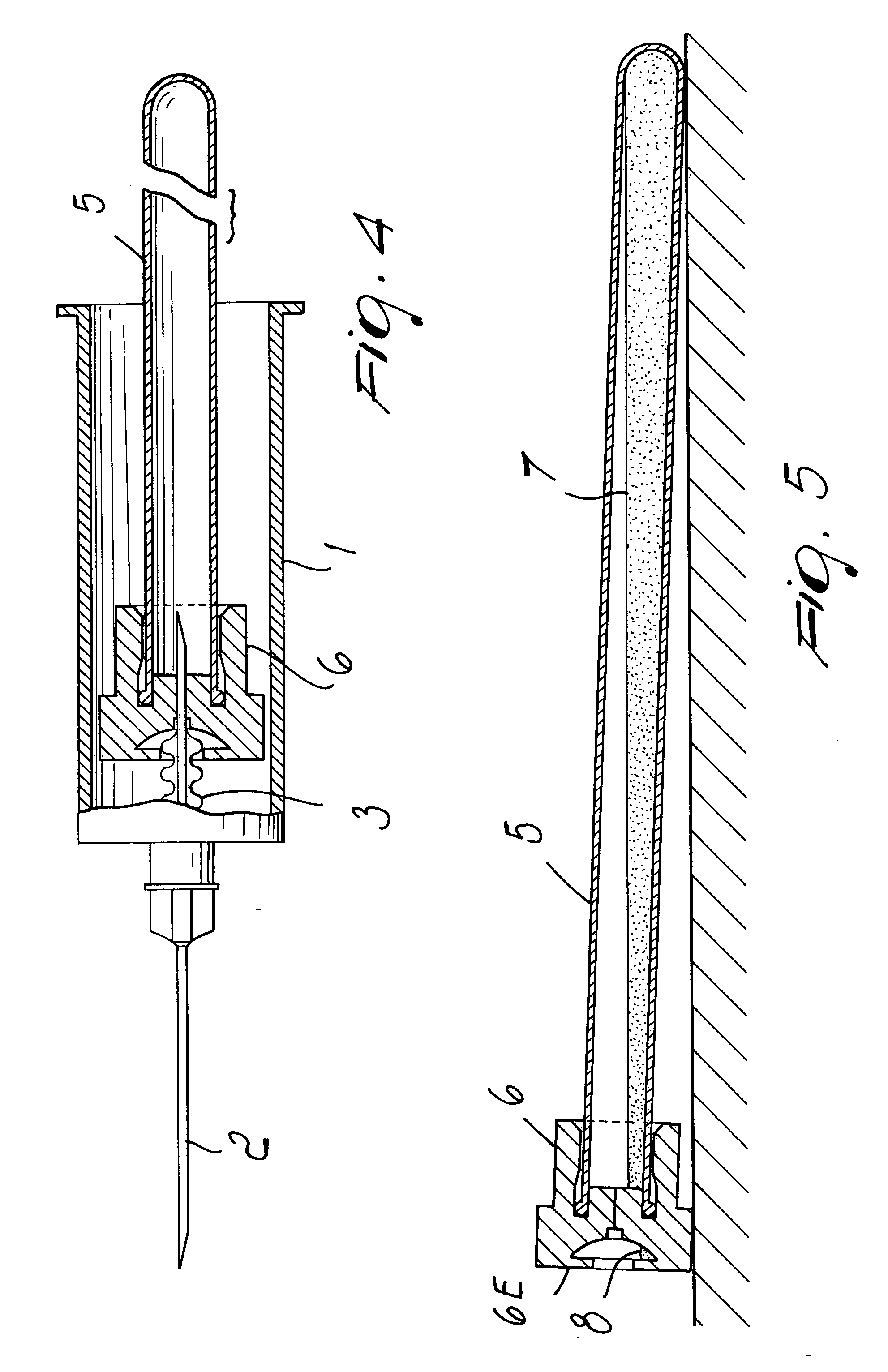

Tube for blood collecting with a vacuum method

A tube for collecting blood with a vacuum method that comprises a stopper and a blood collection needle arranged at an end of the tube for piercing insertion in the stopper. An annular lip is provided at an external region of the stopper that forms a groove surrounding the needle piercing point.

Owner:MONTANARI RENZO

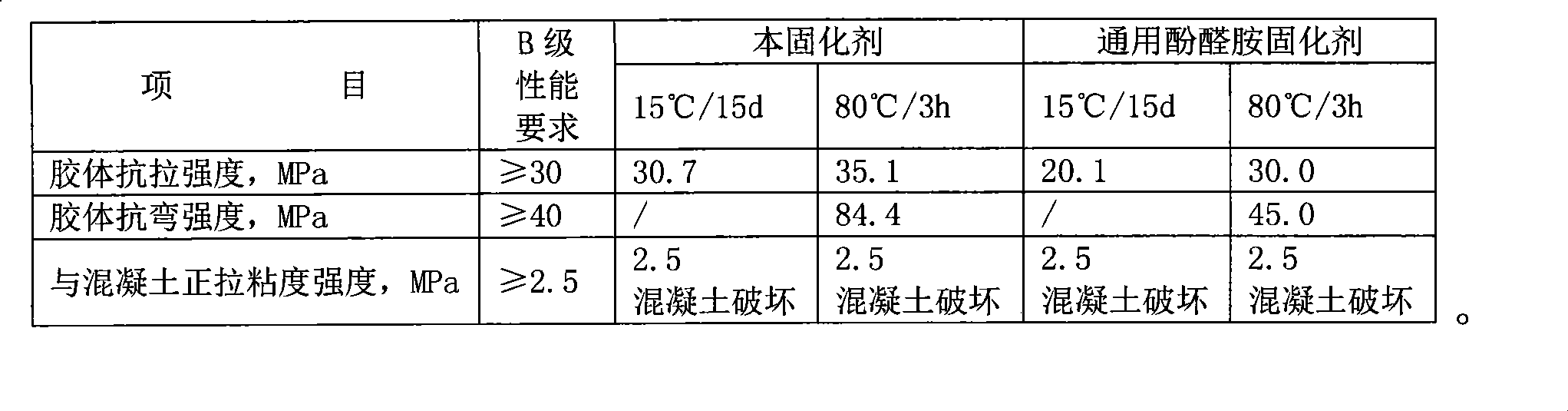

High-performance pnenolic aldehyde amine hardener for epoxy resin and preparation thereof

The invention discloses a high-performance phenol-aldehyde amine curing agent used for epoxy resin and a preparation method thereof and relates to a phenol-aldehyde amine epoxy resin curing agent which is a low-viscosity epoxy resin curing agent applicable to low-temperature damp construction. The curing agent comprises the main components with the weight percentage as follows: 36-45 percent of phenol, 5-8 percent of long-chain phenol, 18-22 percent of formaldehyde solution, 20-25 percent of ethylene polyamine, 3.5-5.5 percent of 4, 4'-diminodiphenyl-methane and 1.5-2.5 percent of polyphenyl polyamine methane. The invention uses a form of normal pressure reaction, thereby avoiding the risk of high temperature and high pressure synthesis; the production method is simple; the curing agent has high activity, low viscosity, good construction and high intensity, so the curing agent can overcome the disadvantages that the epoxy resin is cured slowly under low temperature and has low intensity later. A cured product obtained by curing the epoxy resin with the curing agent overcomes the disadvantage of the brittleness of ordinary phenol-aldehyde amine. The phenol-aldehyde amine epoxy resin curing agent is applicable to the fields of building reinforcing, bridge reinforcing, sealing bonding, water conservancy project, antiseptic paint, etc.

Owner:湖北湖大资产经营有限公司

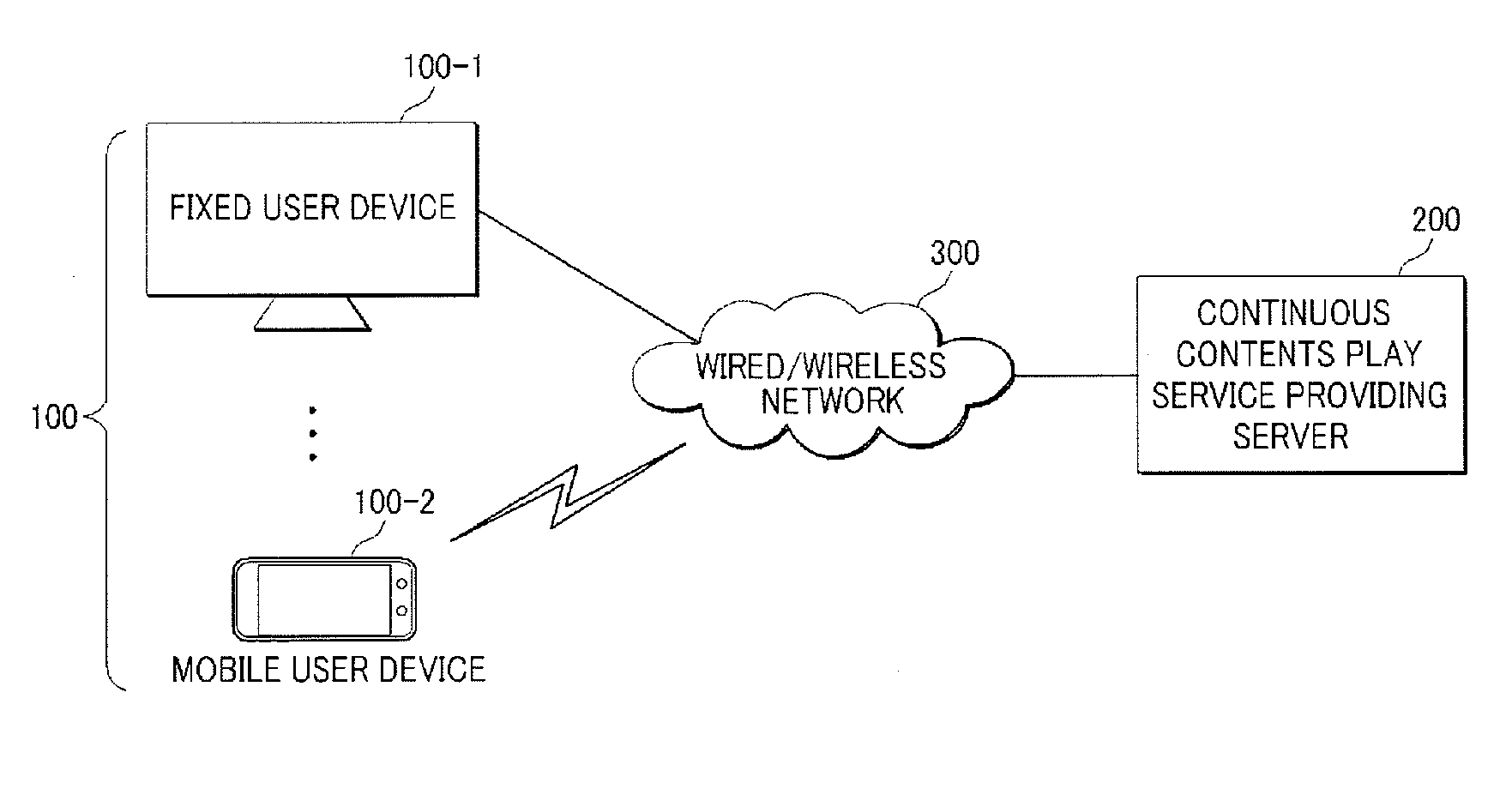

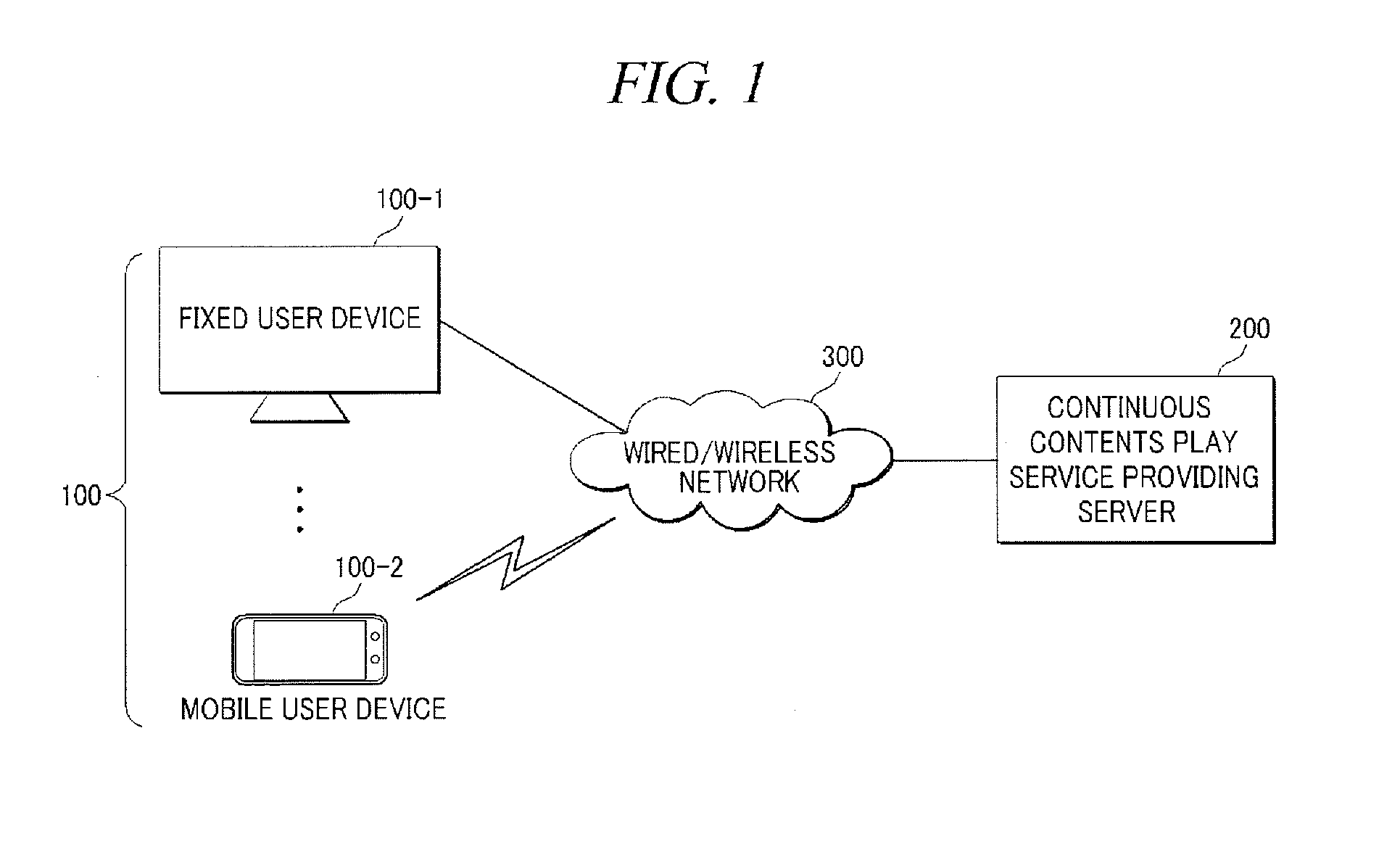

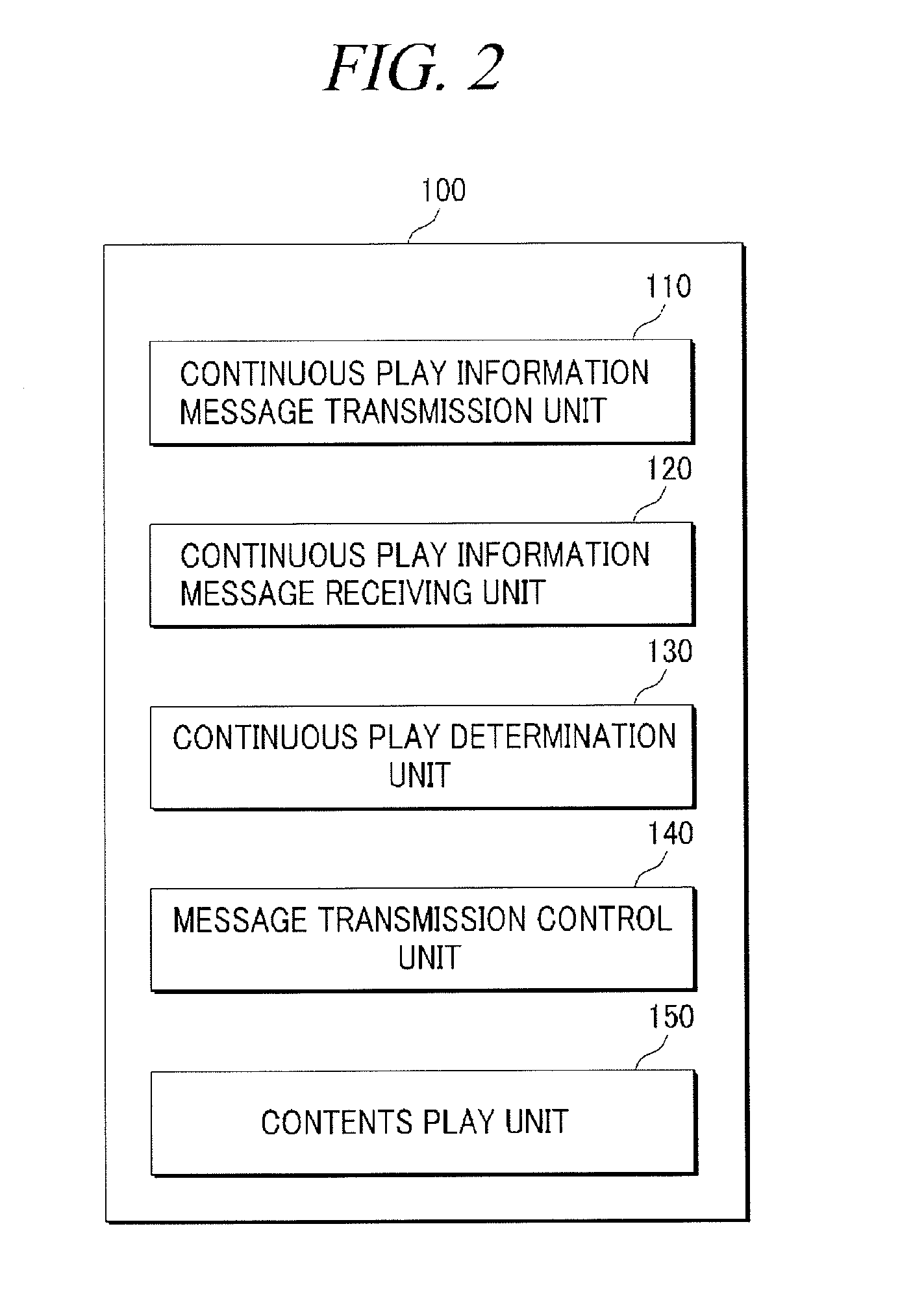

Method and server for continuously providing contents for mobile user devices based on locations thereof

ActiveUS20120066351A1Avoid riskReduce riskMultiple digital computer combinationsLocation information based serviceService provisionManagement unit

Provided are a continuous contents reproduction service providing server, a user device, and a method of providing a continuous contents reproduction service for continuously providing contents to a plurality of devices. The server may include: a device management unit to store identification information of a first device and a second device; a service interruption monitoring unit to determine whether reproducing of contents in the first device is interrupted; a continuous reproduction information message transceiving unit to generate a continuous reproduction information message when the reproducing of the contents is interrupted, and to transmit the generated continuous reproduction information message to the second device; a continuous reproduction management unit to receive a request for a continuous reproduction service and to determine whether to continuously provide the contents to the second device; and a contents providing unit to provide the contents to the second device based on the determination.

Owner:KT CORP

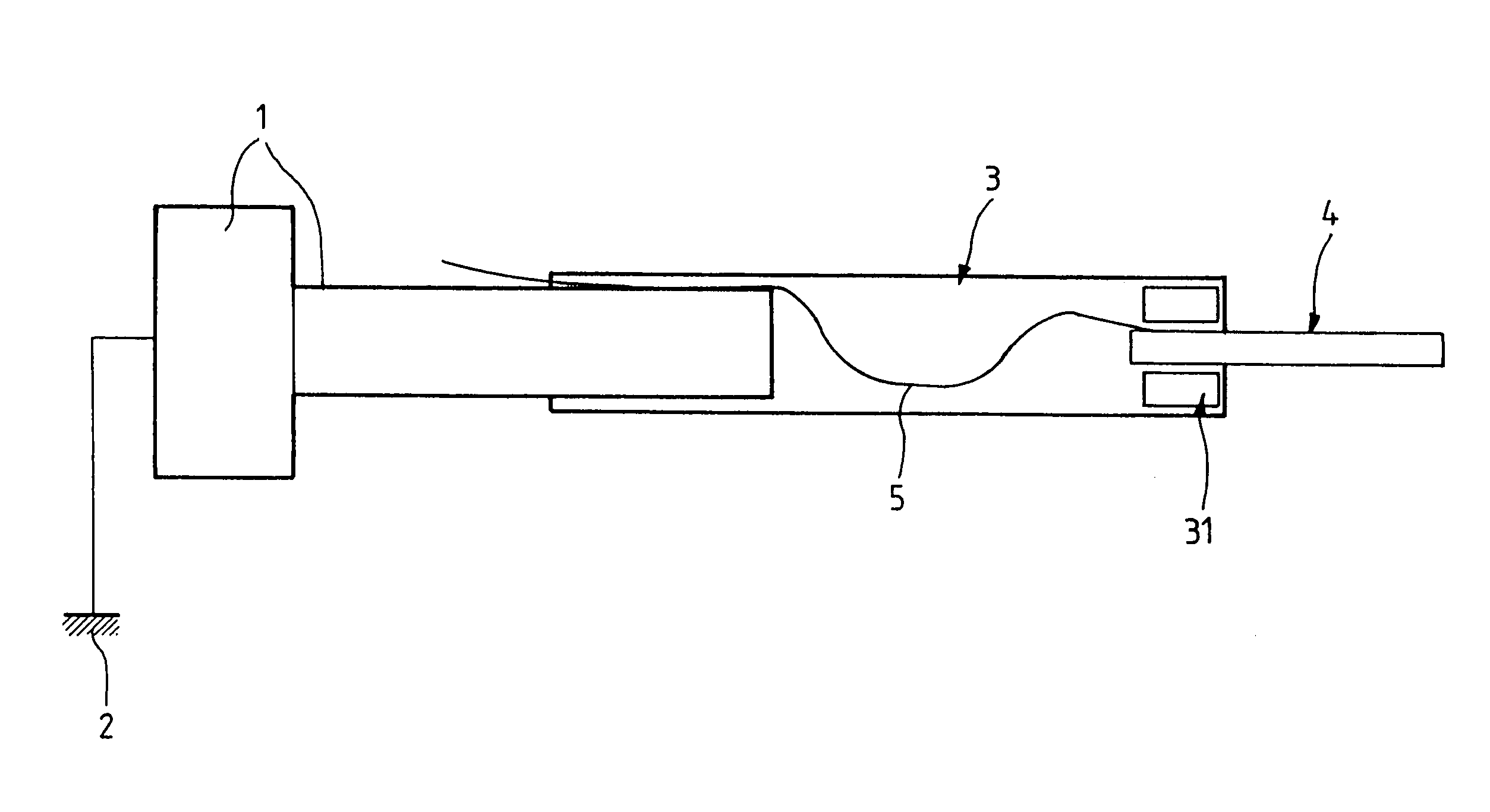

Inductive thermal plasma torch

InactiveUS7132620B2Avoid riskReduce riskGlass making apparatusElectric discharge tubesPlasma torchCapacitive discharge

The invention relates to an inductive thermal plasma torch comprising a confinement tube that comprises, longitudinally in relation to the tube, metal fingers which are insulated from each other, an ignition device that comprises an igniter (4) and an igniter support (1, 3), the purpose of the igniter (4) being to initiate a discharge in the plasma of the torch, the support having an electrically conductive end (1) which is connected to the electrical earth (2) of the plant and another, electrically insulating, end (3) which carries the igniter, the ignition device also comprising an electrically conductive connection (5) connecting the igniter (4) to the electrically conductive end (1) of the support so that the igniter is able to initiate the discharge in the plasma, the electrically conductive connection (5) having a section that is sufficiently narrow to limit the intensity of the current capable of passing through the igniter (4) in order to avoid electrical arcing by capacitive discharge between the ignition device and another part of the torch.

Owner:ALCATEL LUCENT SAS

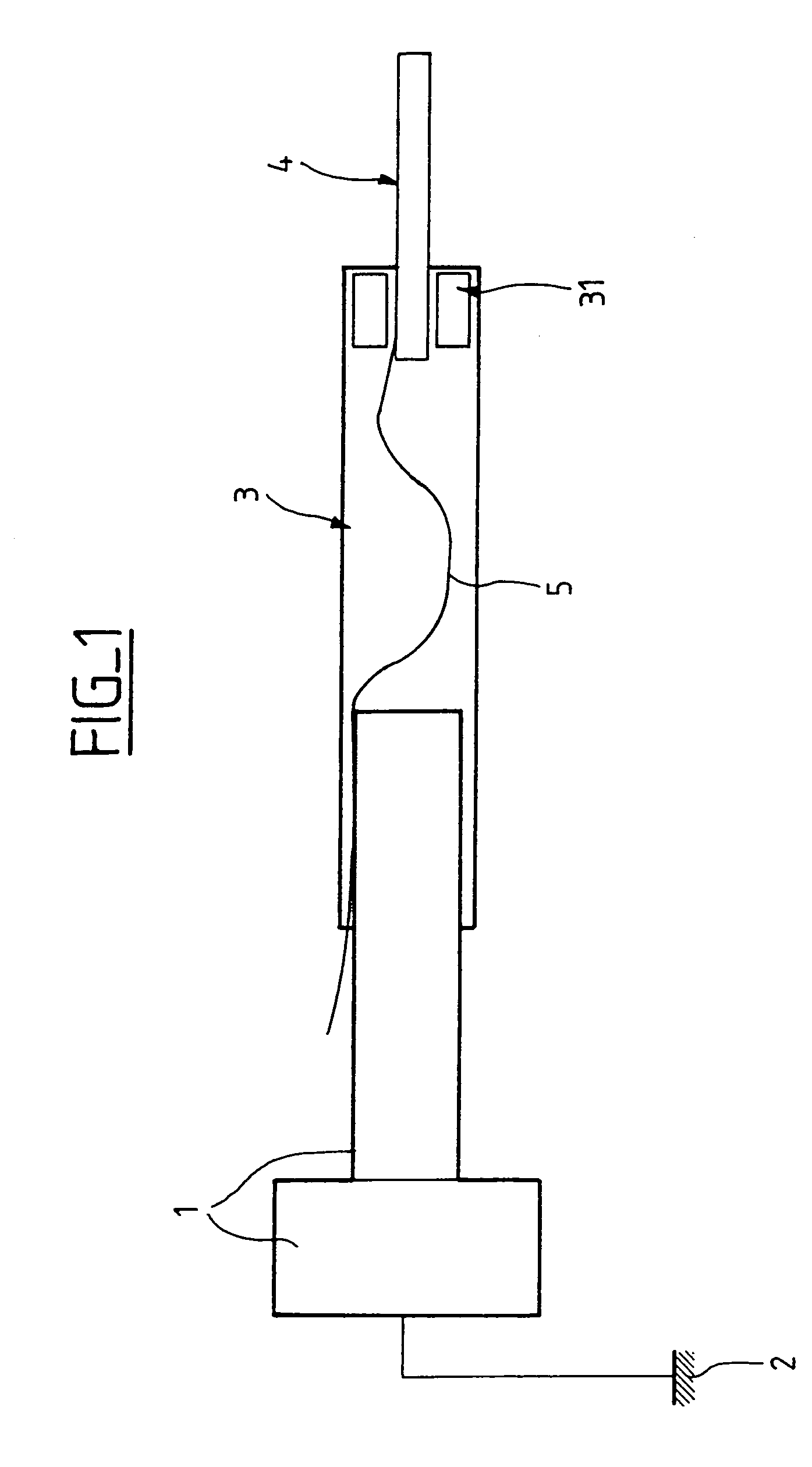

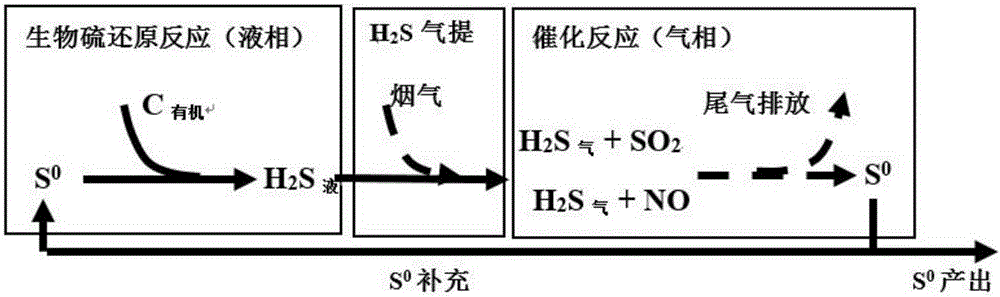

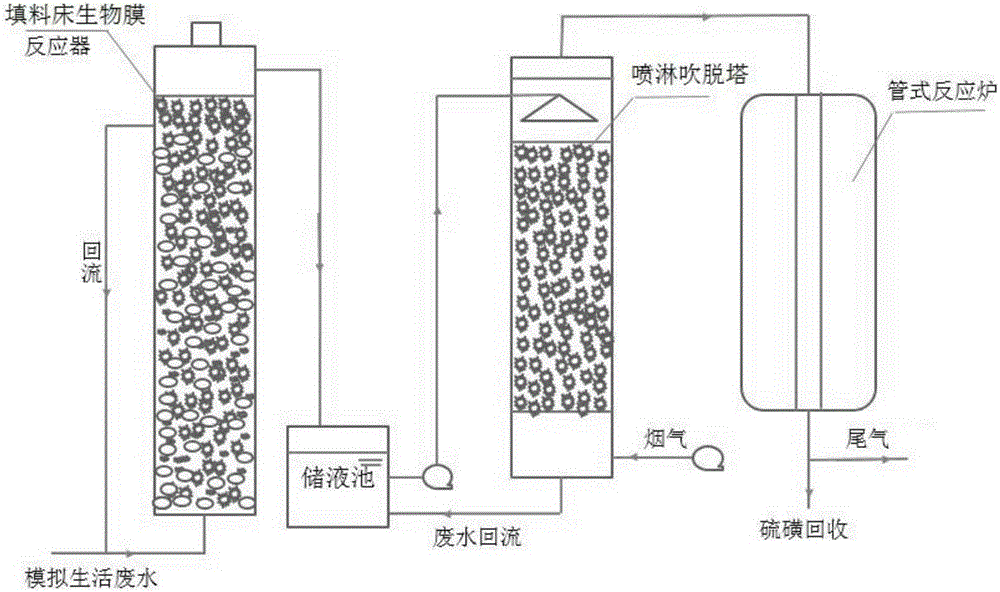

Synchronous desulfurization and denitrification technology of coal-fired flue gas by taking hydrogen sulfide as reducing agent

InactiveCN105214495ARealize integrationHigh outputUsing liquid separation agentSulfur preparation/purificationFlue gasEnvironmental engineering

The invention discloses synchronous desulfurization and denitrification technology of coal-fired flue gas by taking hydrogen sulfide as a reducing agent. The technology comprises the following steps: 1) preparation of dissolved H2S; 2) preparation of a mixed gas of H2S, NO, NO2, and SO2; and 3) synchronous desulfurization and denitrification. According to the technology, integration of a desulfurization and denitrification device is authentically realized. NO and NO2 in the coal-fired flue gas are converted into N2 and water; SO2 and H2S are converted to high-purity elemental sulfur; and organic matters in waste water are further removed, so that treatment of wastes with other wastes is realized. Elemental sulfur is recycled through the technology; one part of elemental sulfur is cycled and utilized to maintain equipment operation; and the other part of elemental sulfur is output as a product. The reducing agent of H2S in the technology is prepared from an in-situ product of elemental sulfur through reduction, can be prepared when used, and does not need to be bought outside. Therefore, cost of purchase, transportation, and storage and potential security risk are avoided. Compared with a mainstream device, the desulfurization and denitrification device is significantly lower with respect to land occupation, construction cost, operation cost, and the like.

Owner:SOUTH CHINA NORMAL UNIVERSITY

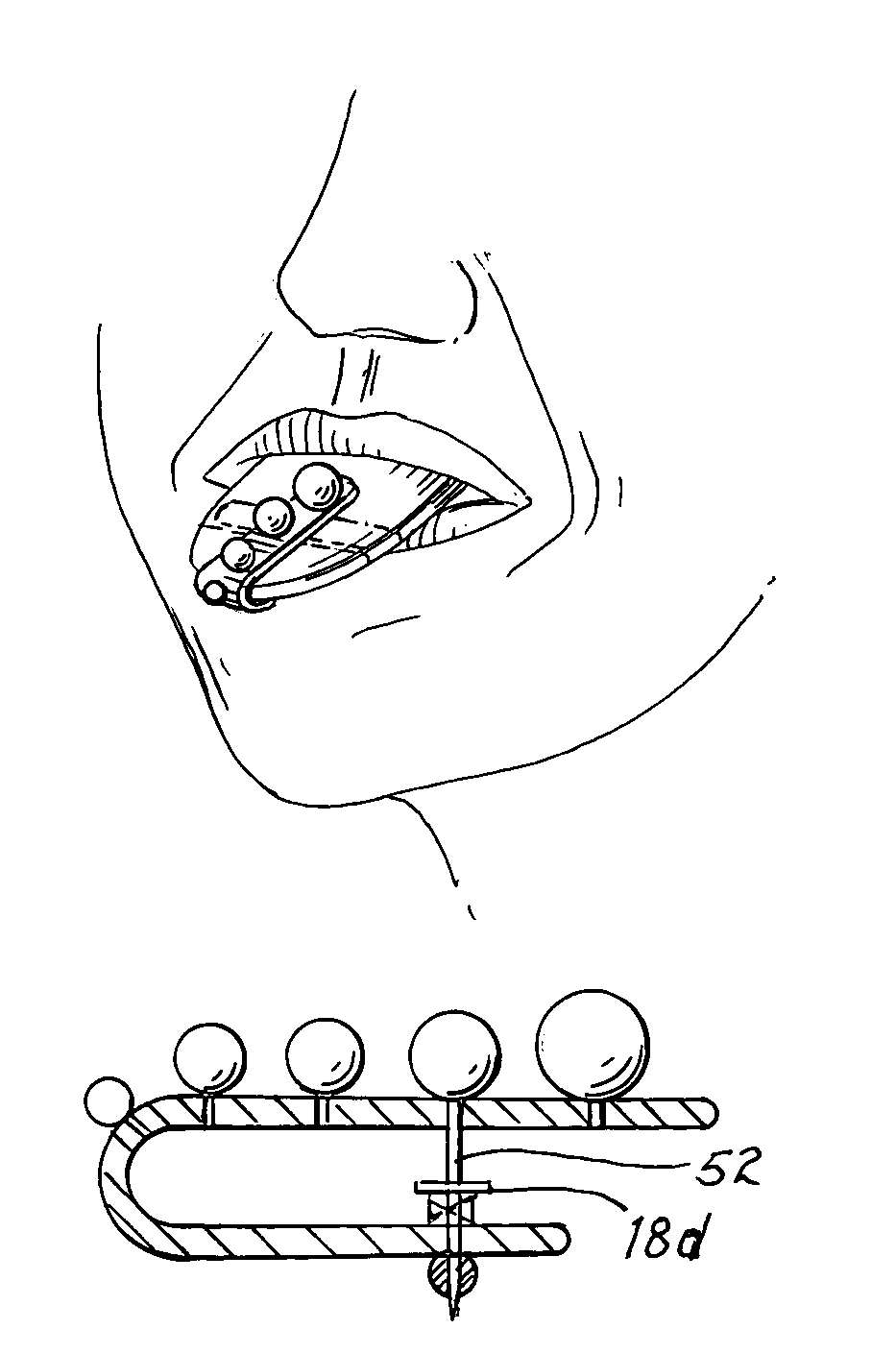

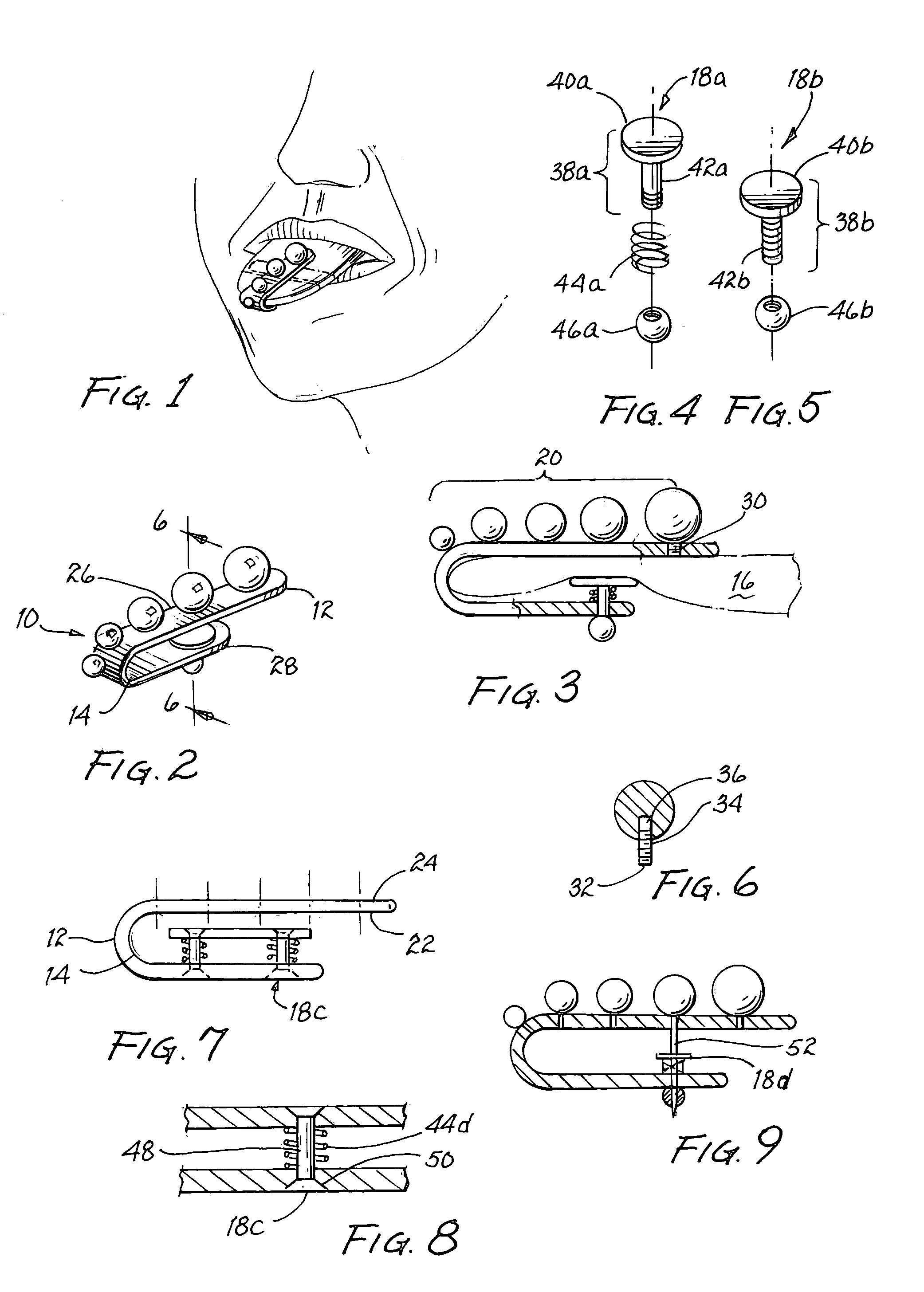

Tongue jewelry clip and method of wearing the same

A tongue jewelry clip and method for wearing the clip is provided. The tongue jewelry clip includes a substantially thin, narrow, and rigid strip of metal bent to include at least one U-shaped section for wrapping around at least one edge of the tongue. The U-shaped section may be at one or both ends of the strip or in the middle. One or more tongue ornaments may be removably mounted to a first wall of the clip and a fastening assembly through the second wall of the clip member fastens the clip member onto the tongue. The one or more tongue ornaments may be non-pierced or pierced.

Owner:UNDERWOOD MICHAEL LEE

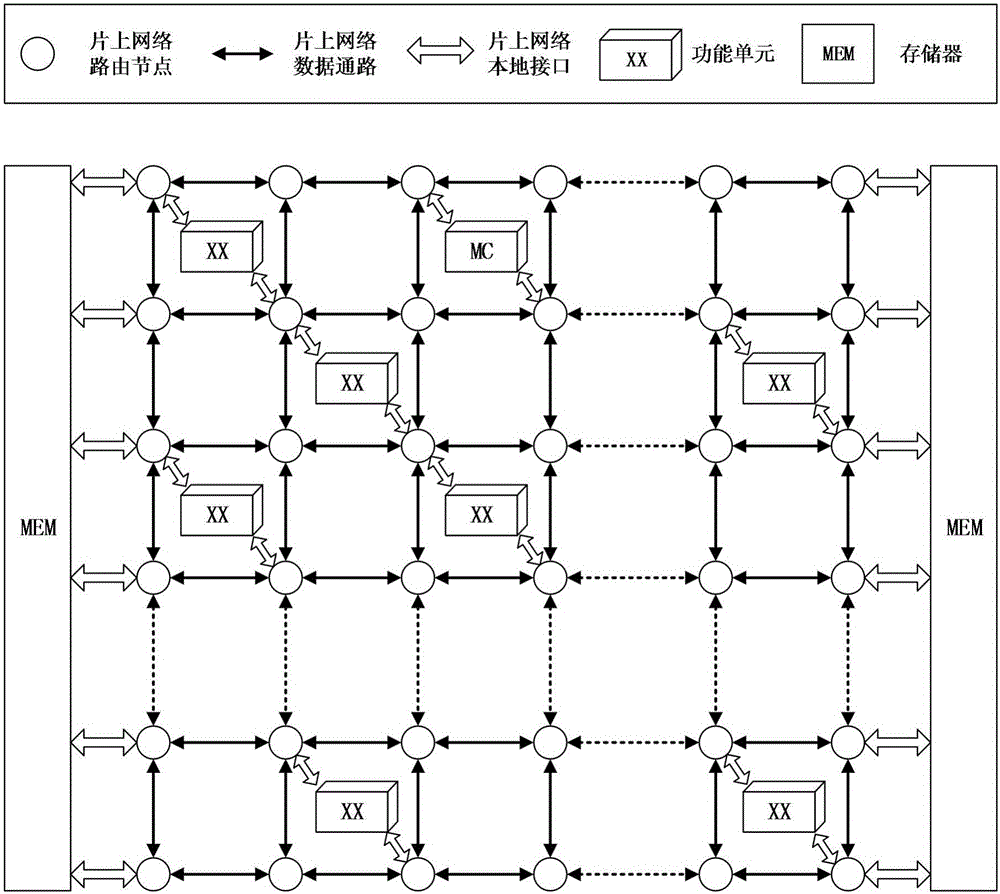

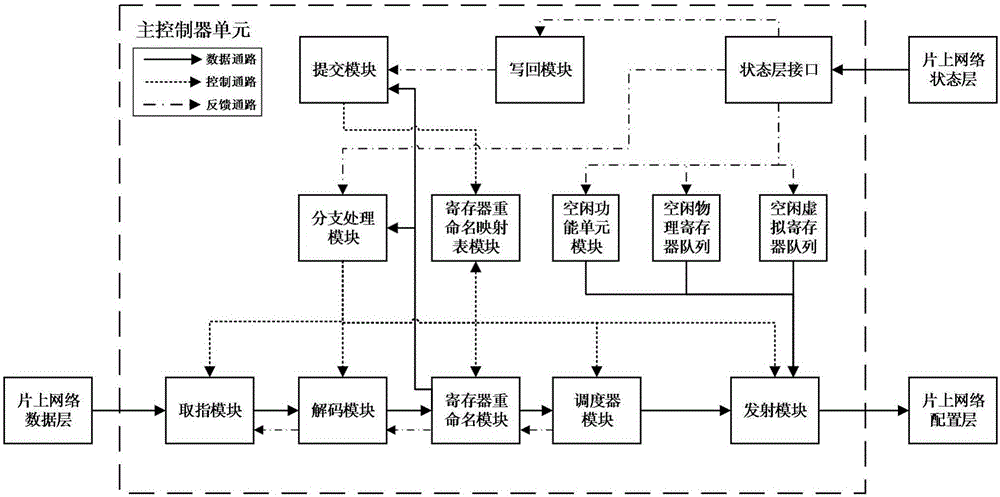

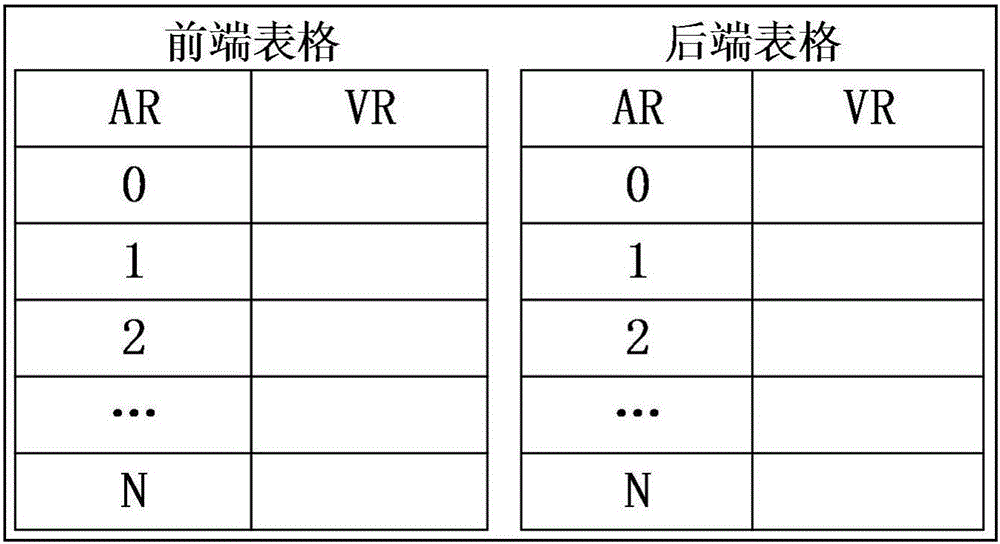

Branching processing module and mechanism for coarse grain multi-core calculating system

ActiveCN106293642AGuaranteed correctnessGuaranteed stabilityResource allocationConcurrent instruction executionSystem recoveryControl unit

The invention discloses a branching processing module and mechanism for a coarse grain multi-core calculating system. The branching processing module is characterized in that the coarse grain multi-core calculating system comprises an on-chip network, a main control unit, a memorizer unit, an interface unit and multiple function units, the main control unit can instantly start branching prediction error recovery after determining branching prediction errors and can end the execution of wrong instructions having already been transmitted in advance so as to make the system restore the normal working state, and the function units can instantly end a current calculation task, restore the idle state, release the control right and wait for the issuing of a correct task after determining the branching prediction errors. The errors can be corrected within an extremely short period of time when the branching prediction errors are found, performance loss caused by the branching prediction errors is reduced, and therefore the improvement of branching prediction on system performance is further enhanced, and the calculation system achieves higher work efficiency.

Owner:HEFEI UNIV OF TECH

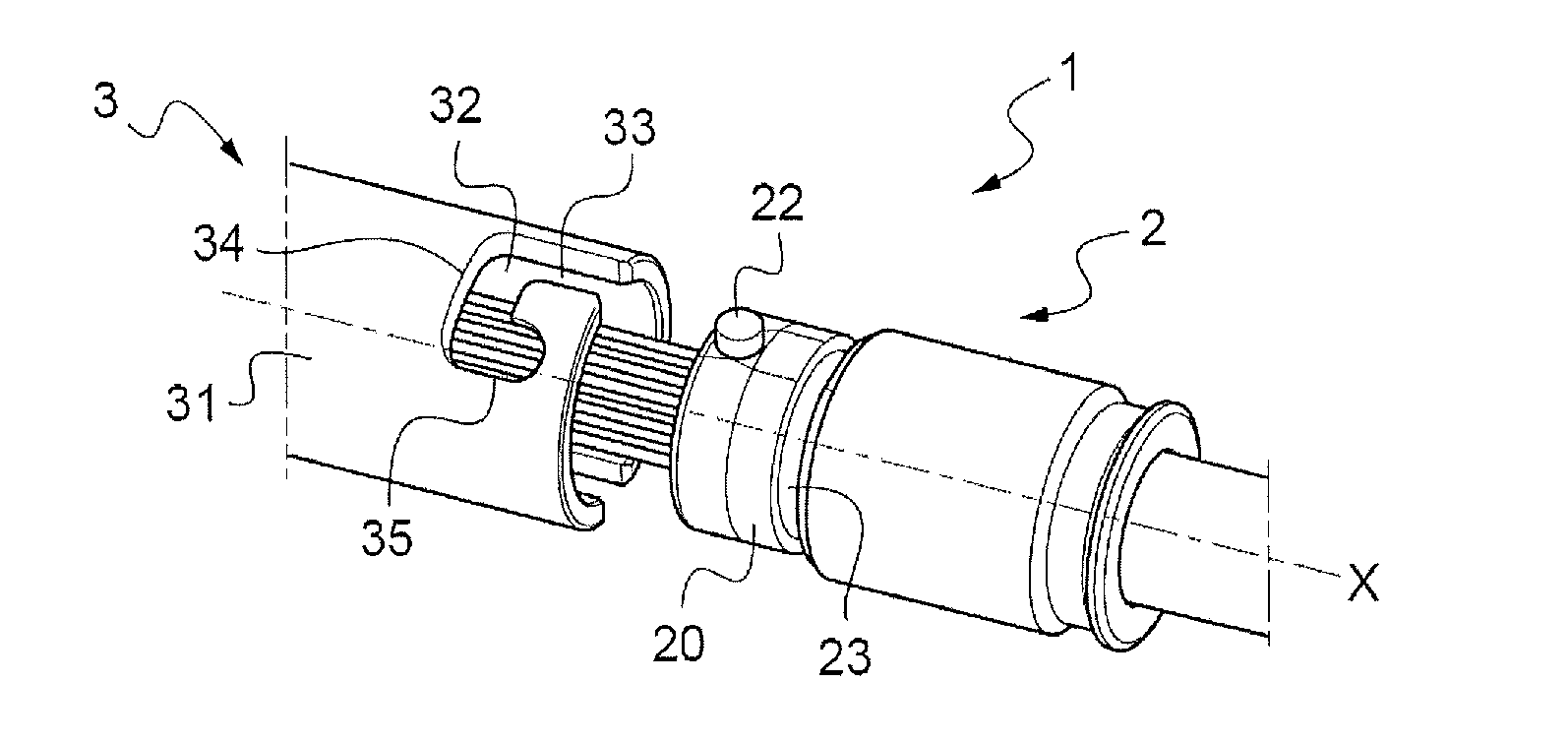

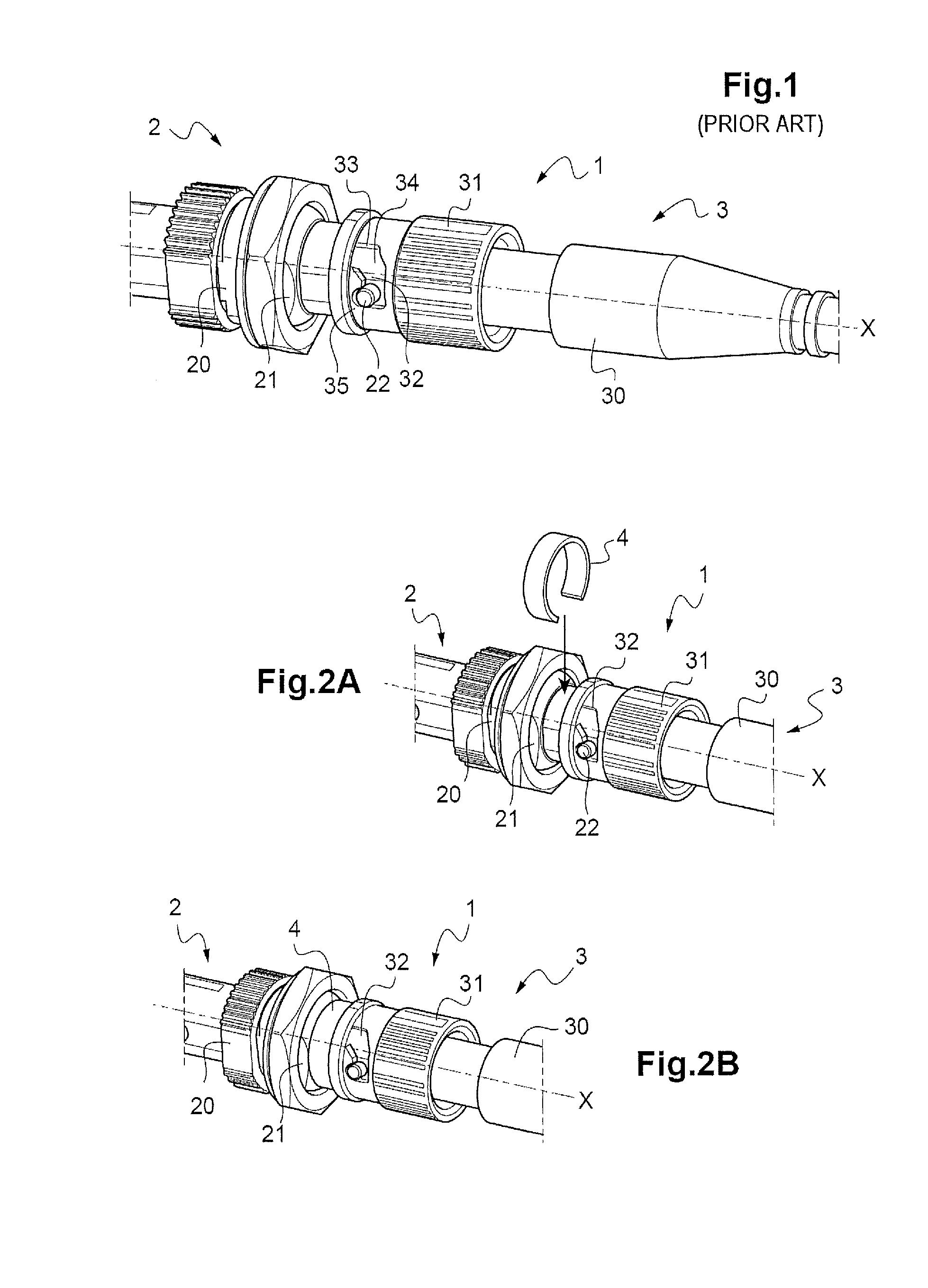

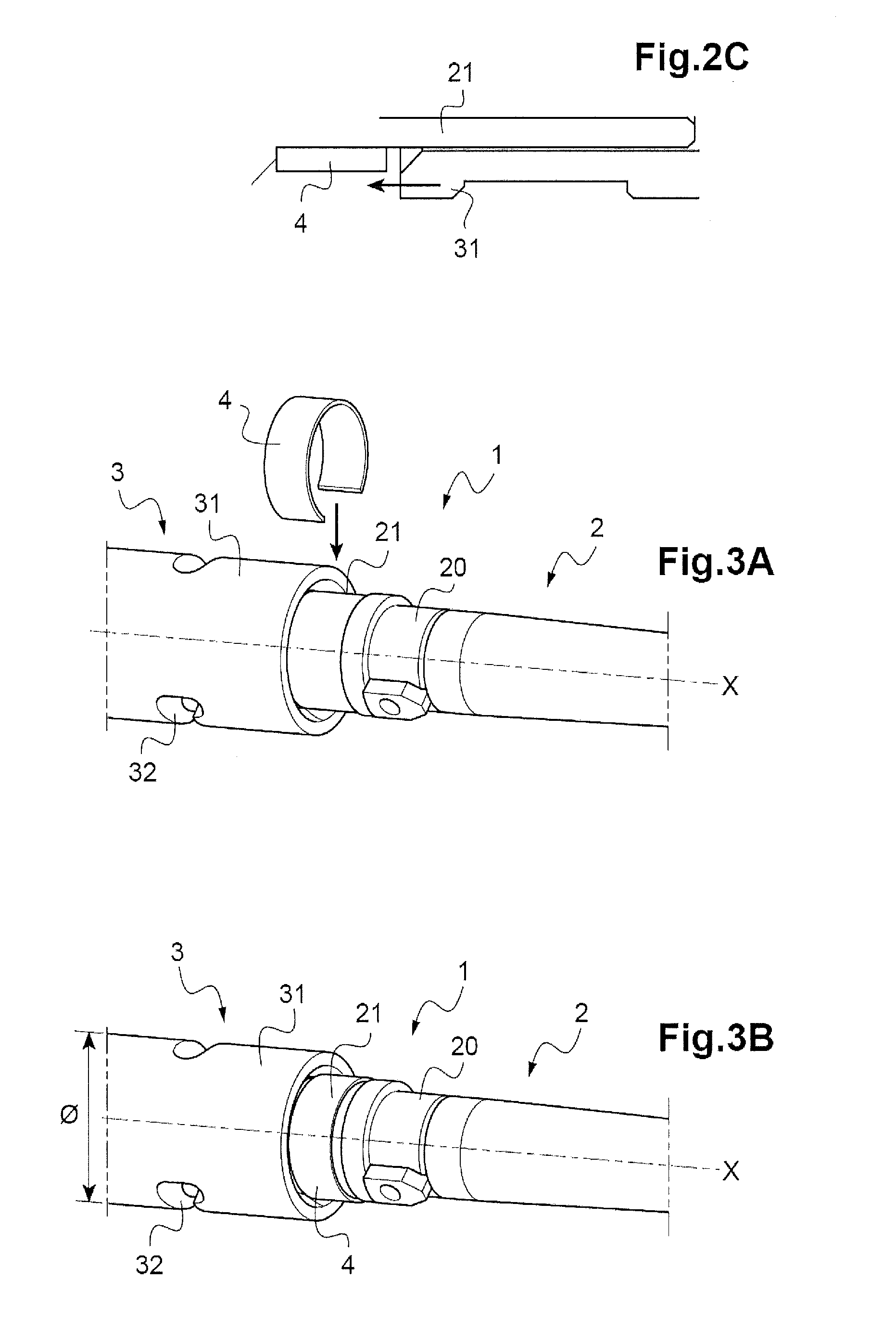

Connection assembly with bayonet locking of the connection elements

InactiveUS20160186792A1Avoid riskReduce riskCoupling device detailsRod connectionsEngineeringElectrical and Electronics engineering

A connection assembly with bayonet locking of the connection elements. In accordance with this disclosure, there is provided a part for immobilizing the locking element of the bayonet system against movement in translation in the position of mutual locking, the immobilizing part being removably placed on the body carrying the bayonet lug.

Owner:RADIALL SA

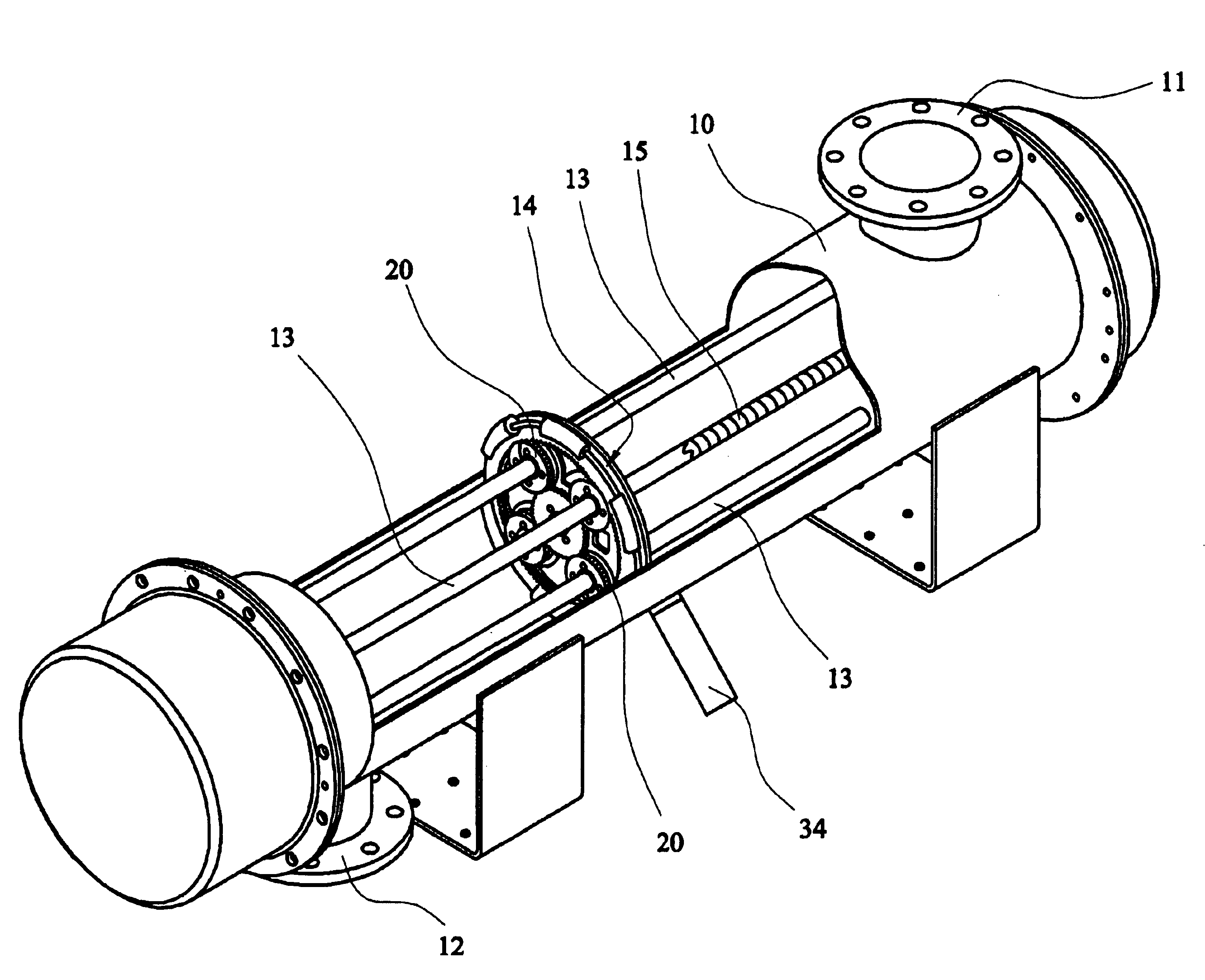

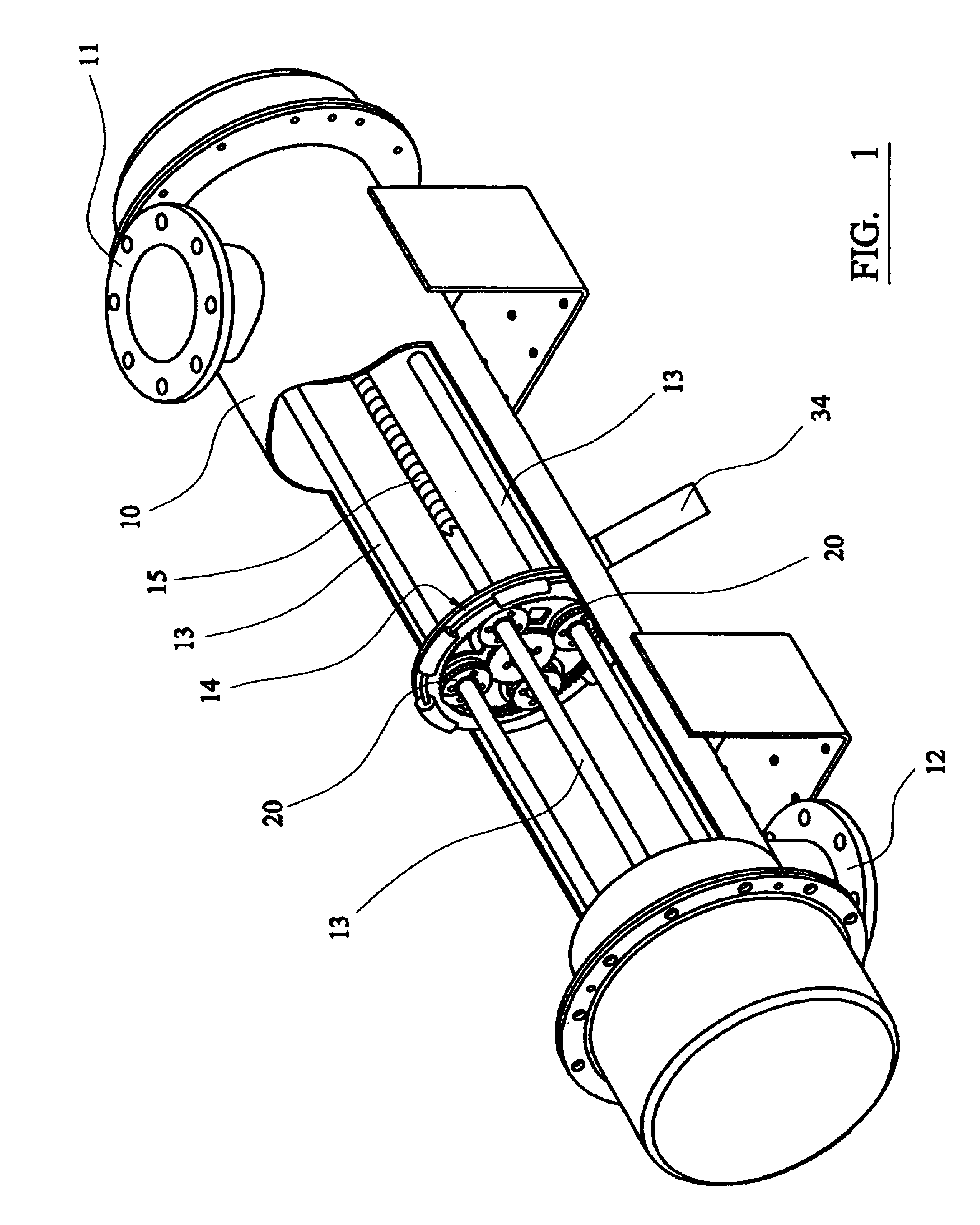

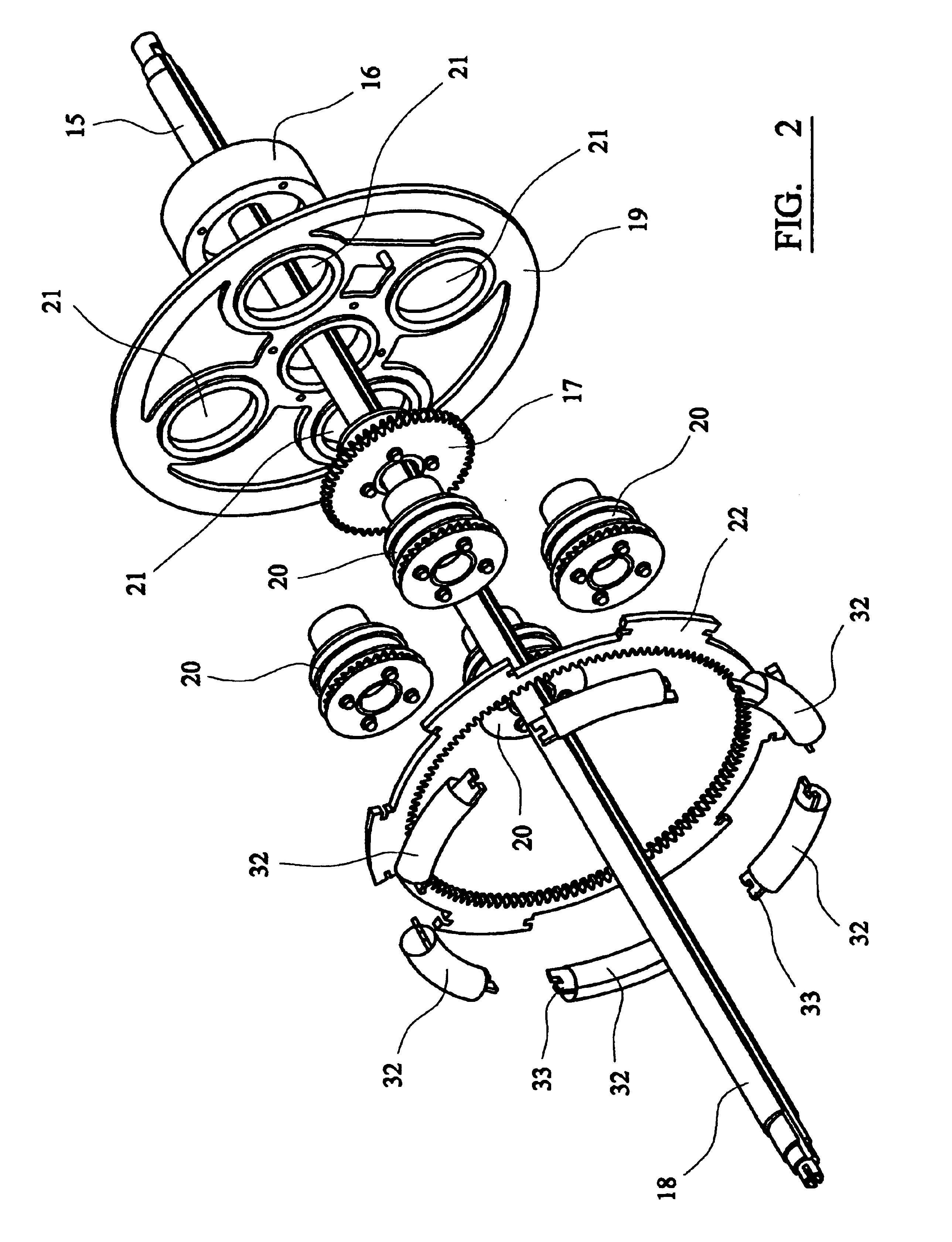

Fluid treatment apparatus

InactiveUS6911655B2Avoid riskReduce riskWater/sewage treatment by irradiationScattering properties measurementsBiomedical engineeringDioxide titanium

A fluid treatment apparatus comprises a plurality of elongate UV lamps 13 mounted in a duct 10 and a cleaning assembly 14 comprising a plurality of cleaning heads 20 which are rotated around respective lamps and are simultaneously driven longitudinally thereof to clean the lamps 13 and the internal surface of the duct 10. The cleaning heads 14 each comprise a plurality of portions 28 of titanium dioxide which are biased against the surface of the respective lamps 13 and which produce hydroxyls and oxygen free radicals in the presence of water and oxygen. Hydroxyls and oxygen free radicals are highly reactive and will break down the cells and molecules of the accumulated material on the lamps.

Owner:GB ENVIRONMENTAL

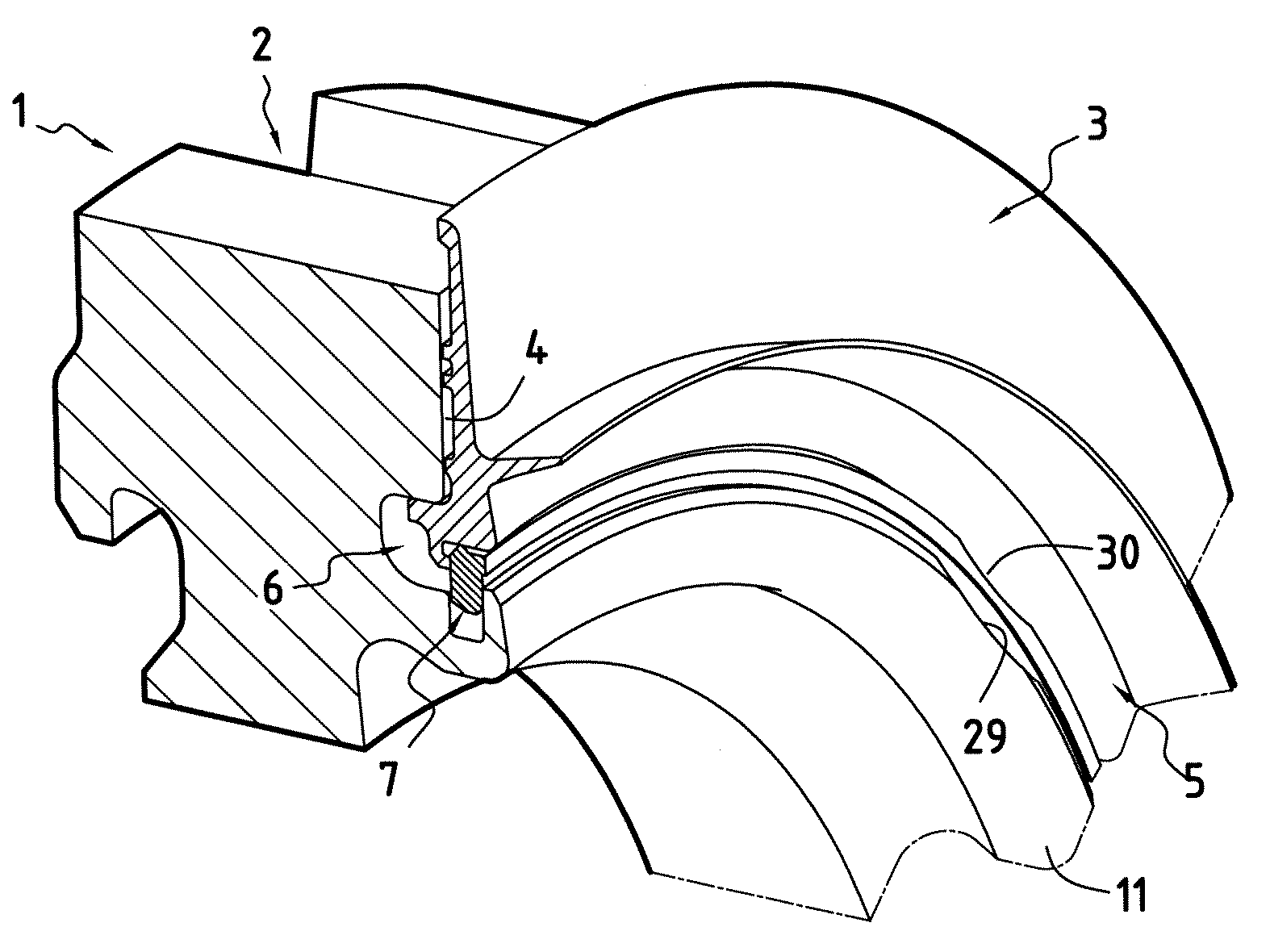

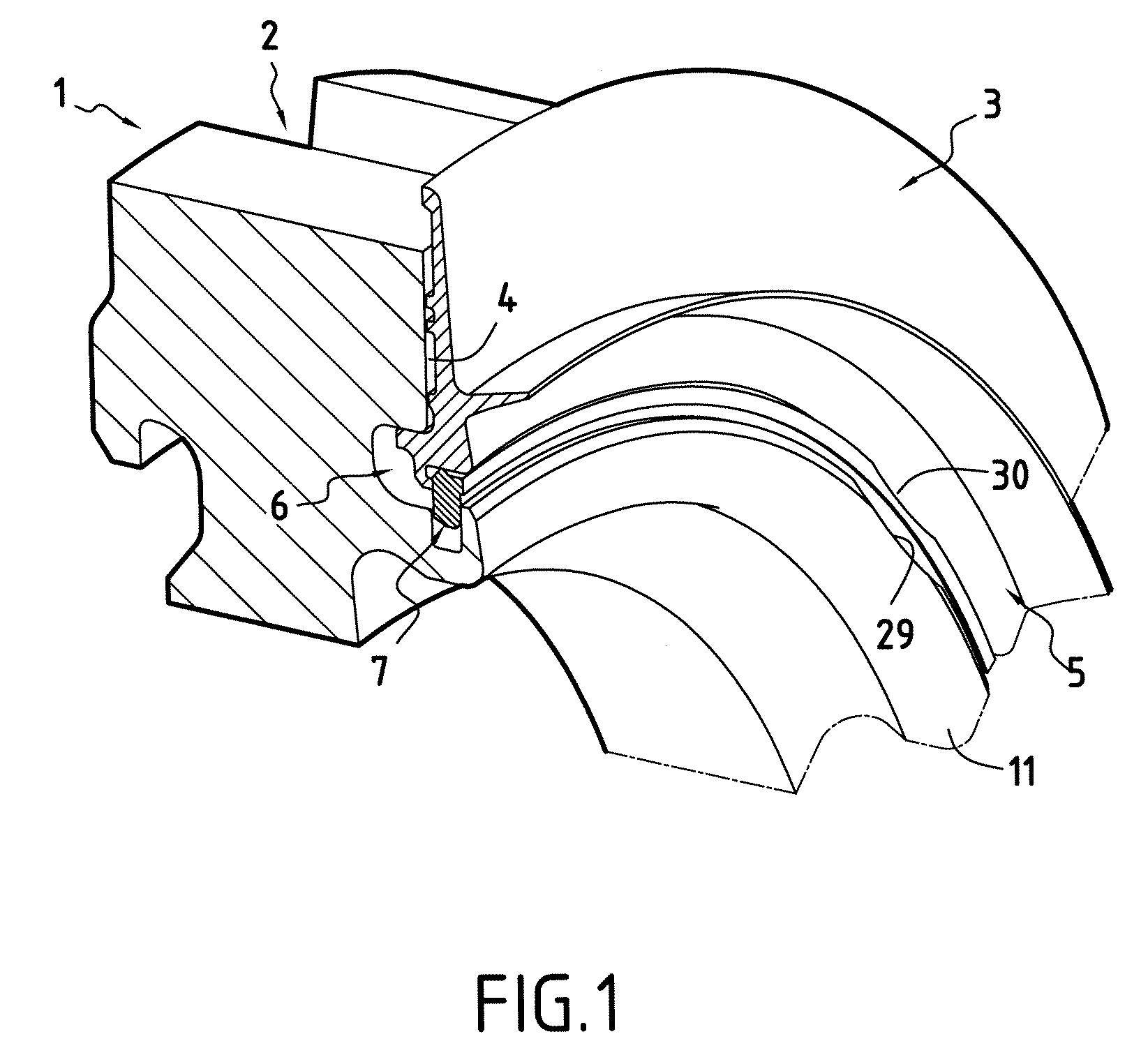

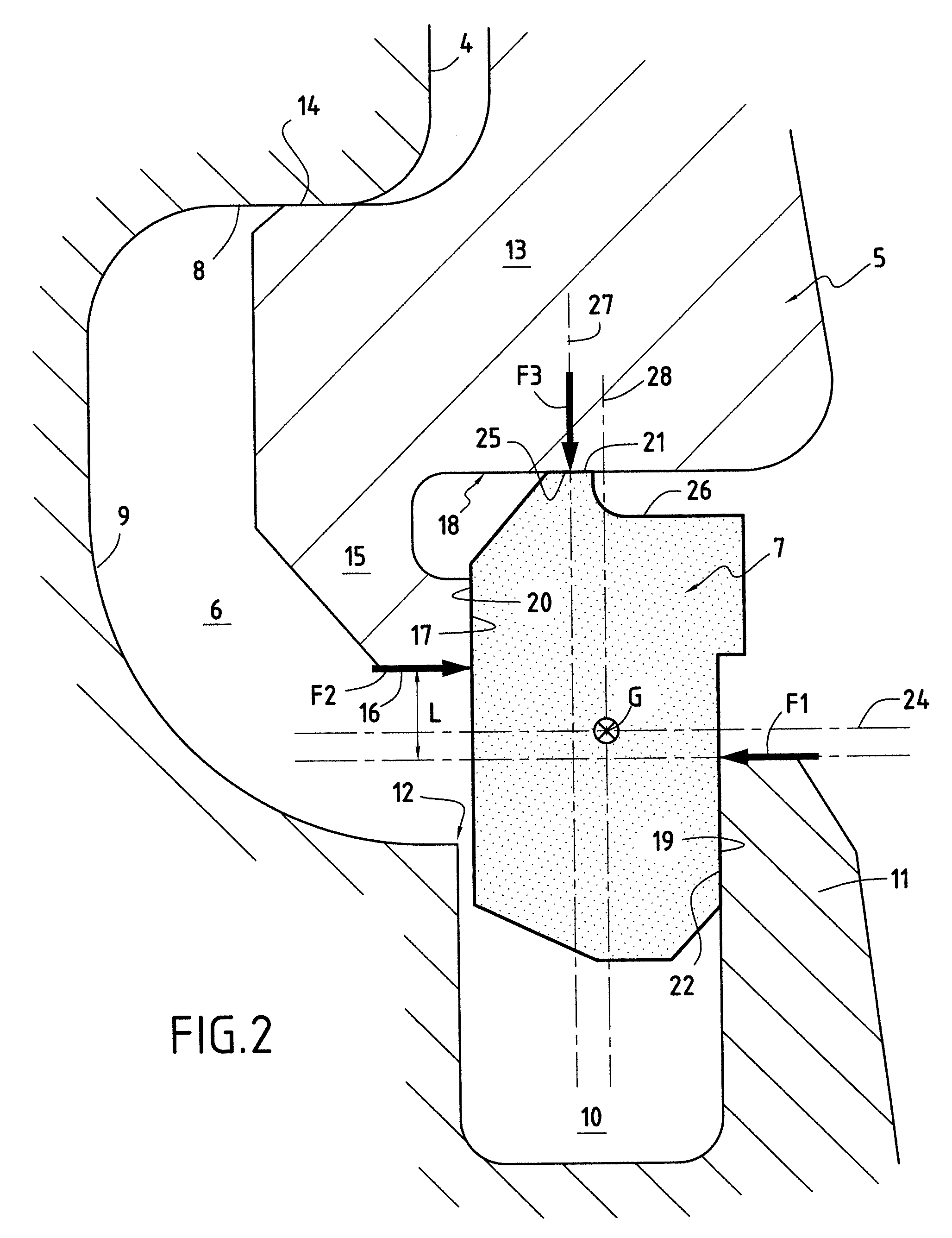

Retaining device for axially retaining a rotor disk flange in a turbomachine

ActiveUS20070237645A1Avoid riskMitigate such drawbackPropellersRotary propellersRetaining ringEngineering

The invention relates to a retention device for axially retaining a rotor disk flange, the device comprising a split annular retaining ring. The ring has an external face bearing against an internal face of the rim, thereby resulting in a first axial force, an internal face bearing against an external face of the root, thereby resulting in a second axial force, the axial forces being radially offset relative to each other, and an outer face bearing against an inner face of the base of the flange, thereby resulting in a radial force. The outer face of the ring presents an annular setback in such a manner that the radial force is situated in a plane that is offset axially relative to a radial plane passing through the center of gravity of the ring so as to obtain mechanical equilibrium between the forces acting on said ring.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com