High-performance pnenolic aldehyde amine hardener for epoxy resin and preparation thereof

A technology for phenalkamine curing agent and epoxy resin, which is applied in the field of high-performance phenalkamine curing agent for epoxy resin and its preparation, which can solve the problems of low strength, high brittleness of adhesive, and influence on construction and application, and achieve simple production method , avoid risks, and solve the effect of low intensity in the later stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Construction and bridge reinforcement adhesive components (percentage by weight)

[0050] CYD128 (epoxy resin) 100

[0051] EPG660 (reactive diluent) 15

[0052] Fumed silica (thickener) 1~3

[0053] This curing agent 35

[0054] Filler (silica powder, calcium carbonate, etc.) 15~30

[0055] KH-550 (coupling agent) 1

[0056] DMP-30 (accelerator) 0.5~1.5

[0057] Pigment (toner) 0.5~2.0

[0058] (2) Preparation method

[0059] Weigh CYD128, EPG660 and fumed silica according to the formula, stir well, then add filler, KH-550, stir well, finally add this curing agent, DMP-30 and pigment, stir well and proceed to construction.

Embodiment 2

[0061] (1) Sealing adhesive components (percentage by weight)

[0062] CYD128 (epoxy resin) 50

[0063] E-44 (epoxy resin) 50

[0064] EPG660 (reactive diluent) 5

[0065] Fumed silica (thickener) 1~4

[0066] This curing agent 35

[0067] Filler (silica powder, calcium carbonate, etc.) 0~50

[0068] KH-550 (coupling agent) 1

[0069] DMP-30 (accelerator) 0.5~1.5

[0070] Pigment (toner) 0~2

[0071] (2) Preparation method

[0072] Weigh CYD128, E-44, EPG660, fumed silica according to the proportion, stir evenly, then add filler, KH-550, stir evenly, finally add this curing agent, DMP-30 and pigment, stir well and carry out sealing and bonding .

[0073] 3. Effect verification

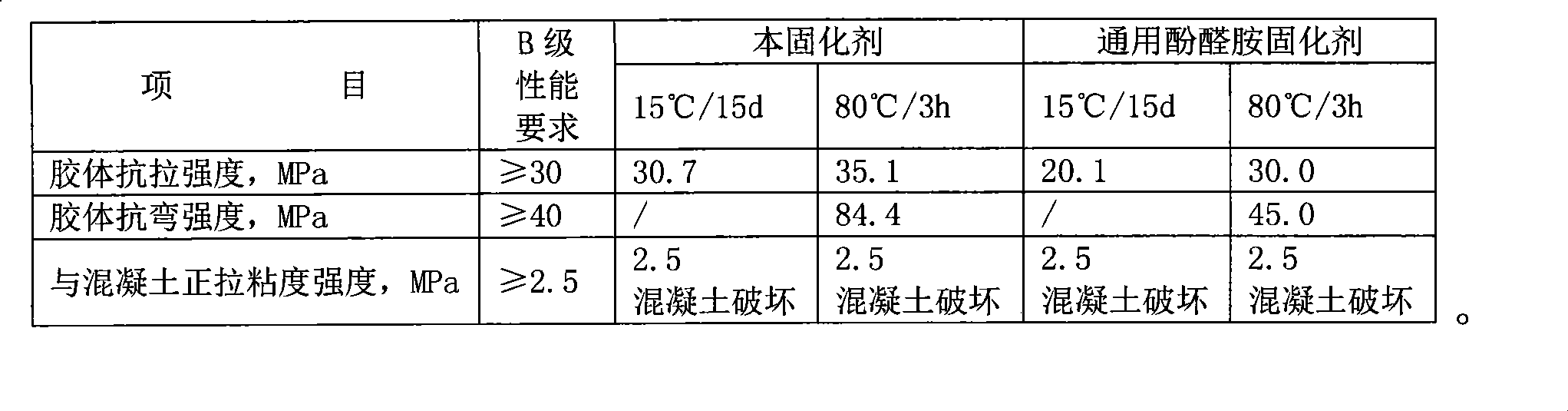

[0074] The mechanical property test (shown in table 1) of the construction and bridge reinforcement adhesive prepared according to embodiment 1

[0075] Table 1 The mechanical properties of repair glue prepared with this curing agent

[0076]Take the repair glue in GB50367-2006 Concrete Str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com