Crane lifting speed control method and device

A speed control device and speed control technology, which is applied in the field of crane lifting speed control and crane lifting speed control device, can solve problems such as poor operation experience, achieve the effects of avoiding risks, improving operation experience, and reducing operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

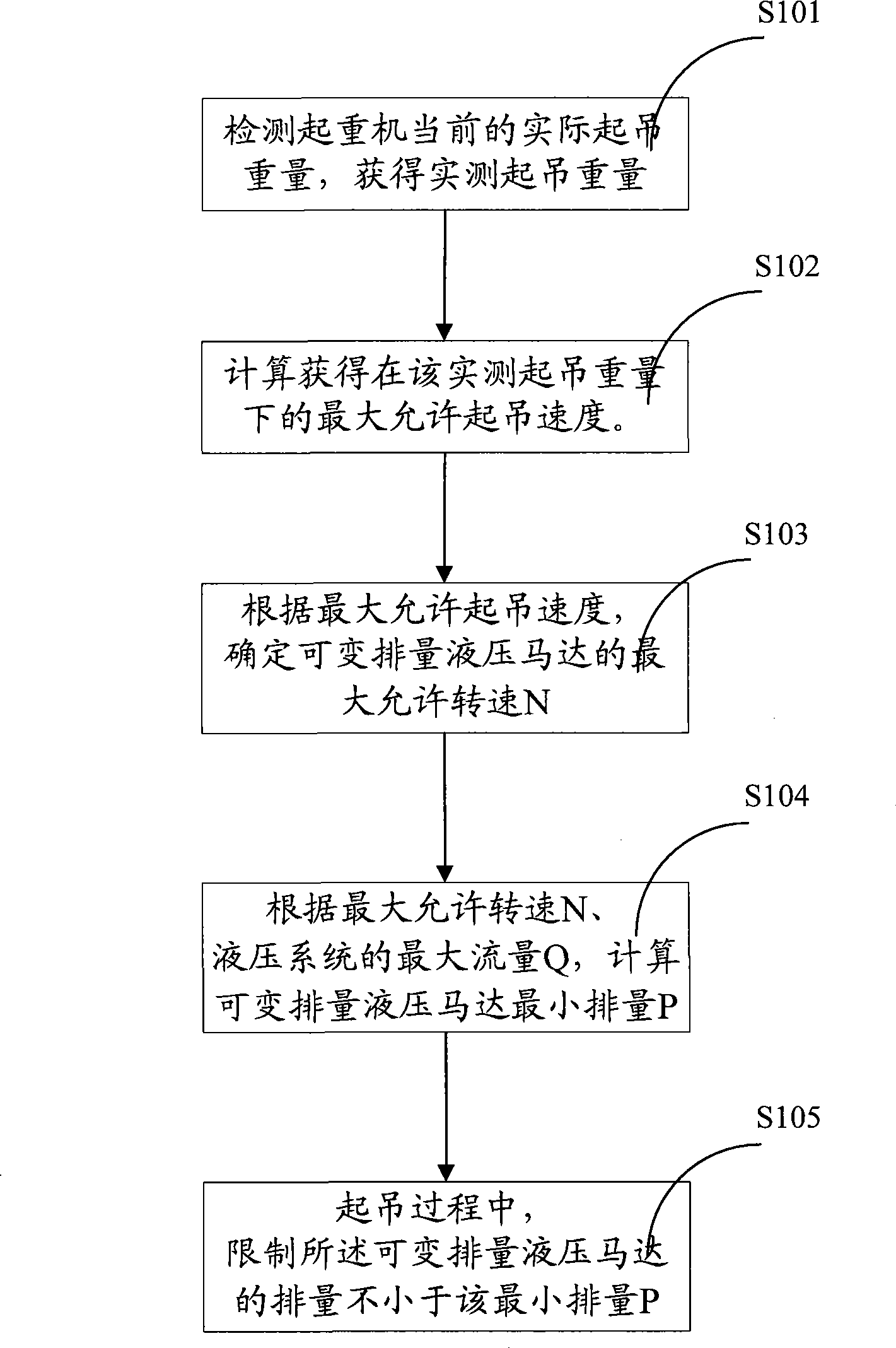

[0041] Please see figure 1 , This figure is a flow chart of the method for controlling the hoisting speed of a crane provided by the first embodiment of the present invention. The following describes the method for controlling the hoisting speed of a crane provided by the first embodiment of the present invention in conjunction with the flowchart. This method is used for cranes that use variable displacement hydraulic motors for hoisting and driving.

[0042] In step S101, the current actual hoisting weight of the crane is detected to obtain the actual hoisting weight.

[0043] Since the hoisting speed of the crane mainly depends on the real-time hoisting weight of the crane, it is necessary to obtain the actual hoisting weight of the crane in the current state through sensor detection, and use the actual hoisting weight as the basis for determining the hoisting speed. Since there is bound to be an error between the detected value and the actual value, the current lifting weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com