Heat radiation fan

A technology for cooling fans and fan blades, which is applied to the components of pumping devices for elastic fluids, non-variable-capacity pumps, machines/engines, etc. Eliminate and other problems to achieve the effect of improving heat dissipation and increasing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

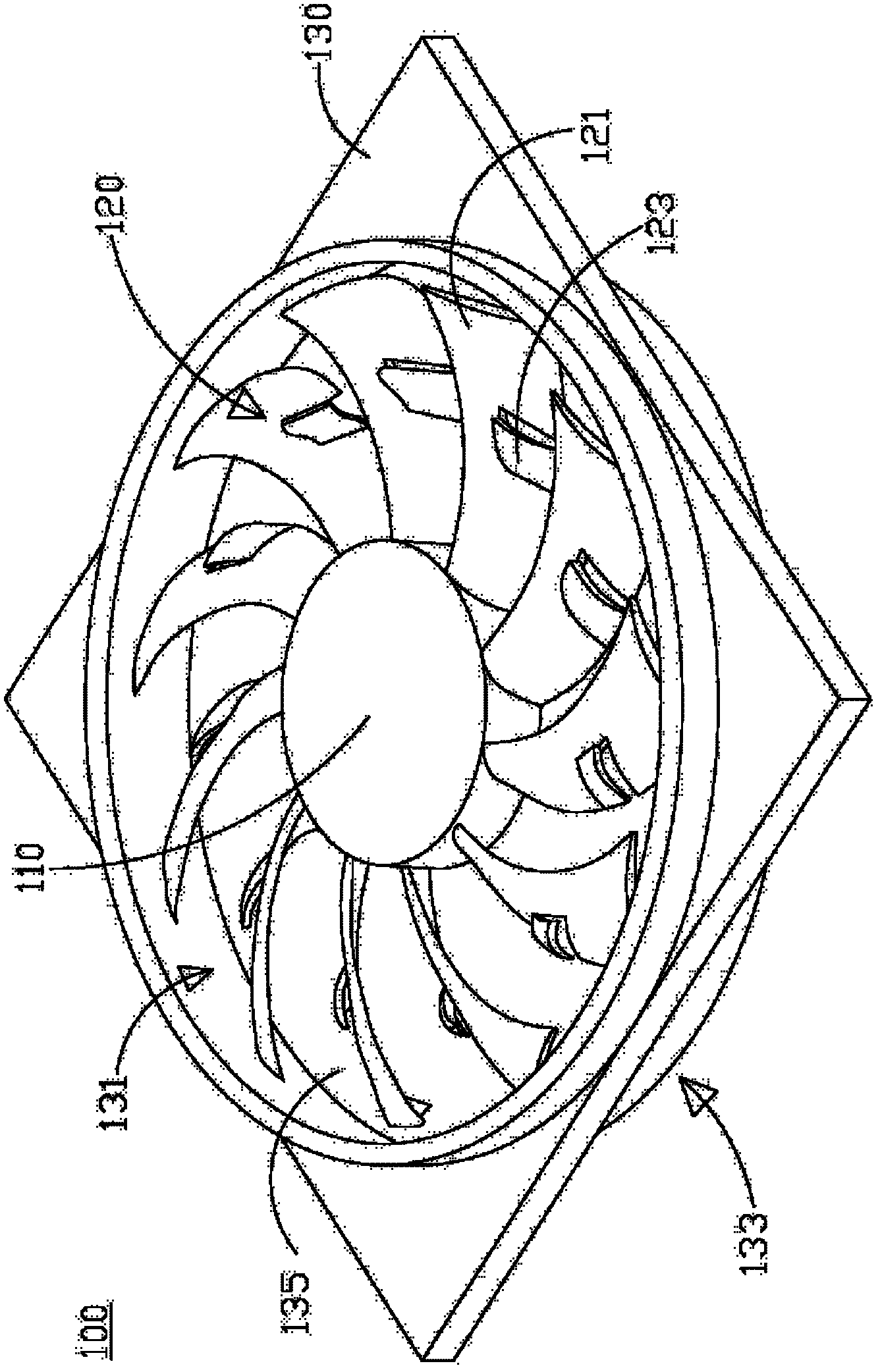

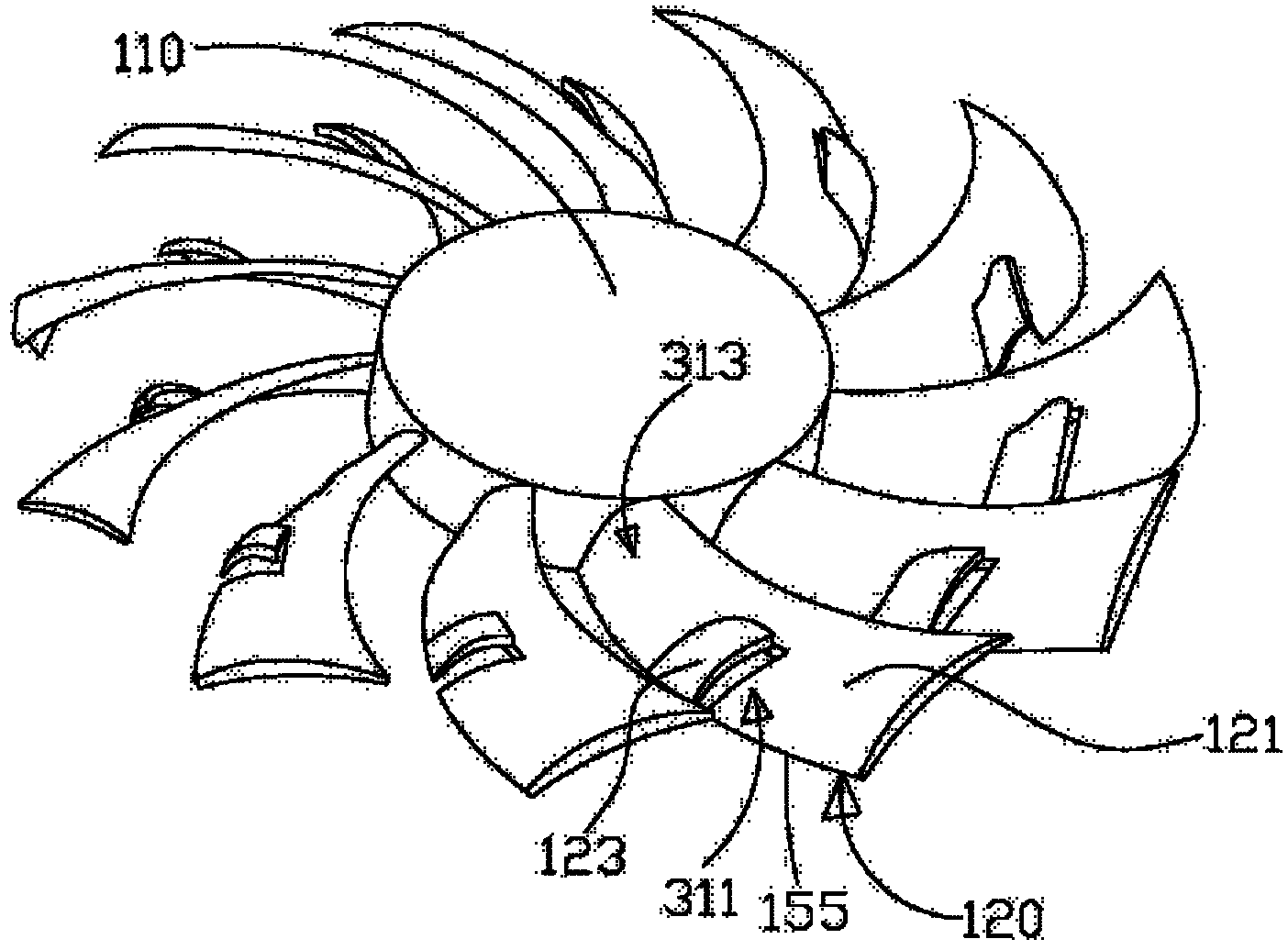

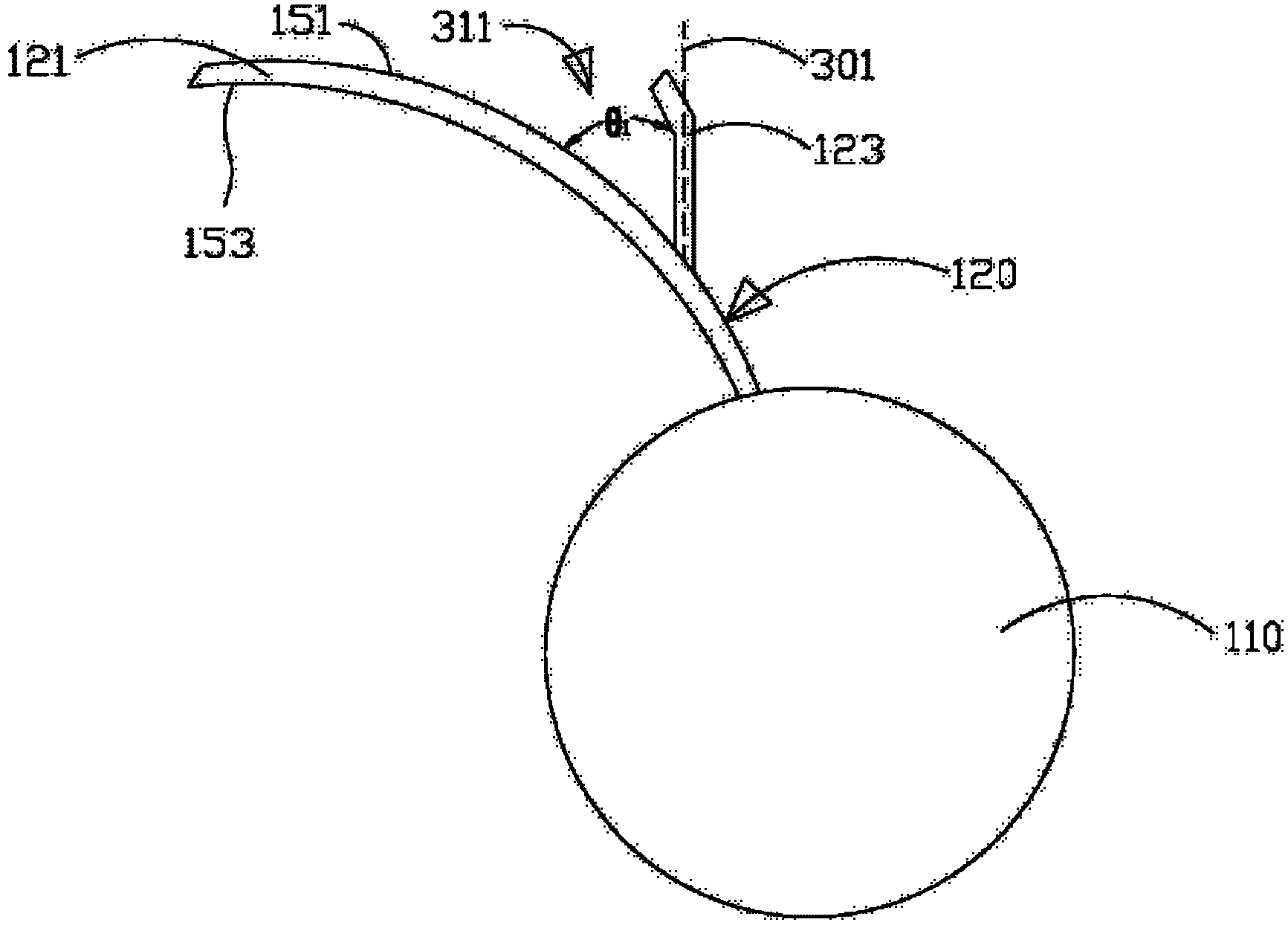

[0058] Please refer to figure 1 , a three-dimensional schematic view of the cooling fan according to the first embodiment of the present invention, wherein the cooling fan 100 of this embodiment is composed of a hub 110 , a plurality of fan blades 120 and a fan frame 130 . The fan frame 130 has an air inlet 131 and an air outlet 133 , and an accommodating space 135 is formed between the air inlet 131 and the air outlet 133 , and the hub 110 and the fan blade 120 are disposed in the accommodating space 135 .

[0059] A plurality of fan blades 120 are respectively disposed on the outer edge of the hub 110 . In this embodiment, a plurality of fan blades 120 are disposed at equiangular intervals on the outer edge of the hub 110 , but it is not limited to the embodiments disclosed in the present invention. Wherein, the fan frame 130 is electrically connected to a motor (not shown in the figure), therefore, the cooling fan 100 can drive the hub 110 to rotate through the motor, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com