Positive-circulation drilling and dedusting technique of chamber down-hole hammer and double-wall pipe

A technology of down-the-hole hammer and double-wall pipe, which is applied to drilling equipment, earthwork drilling, and driving devices for drilling in boreholes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

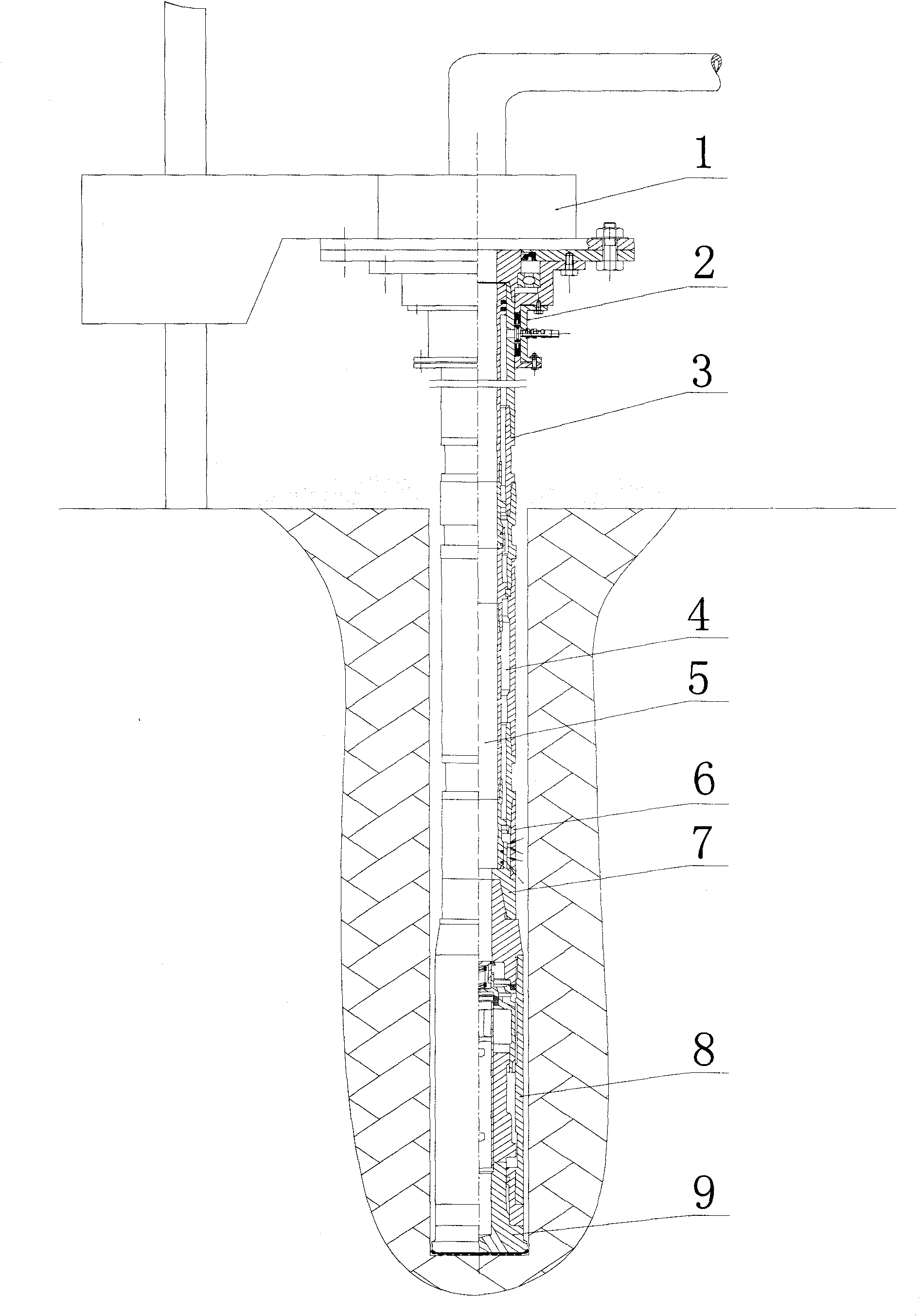

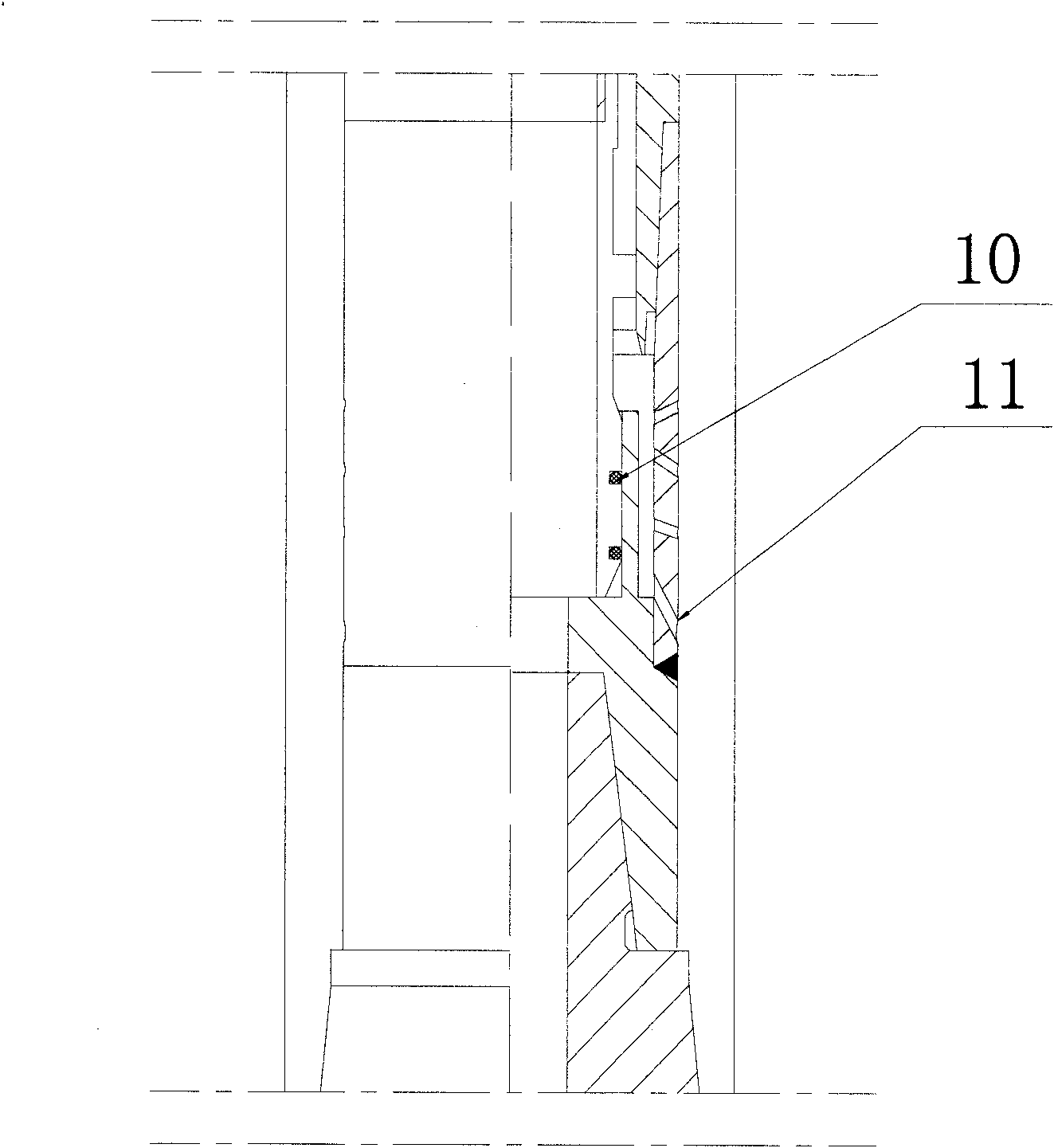

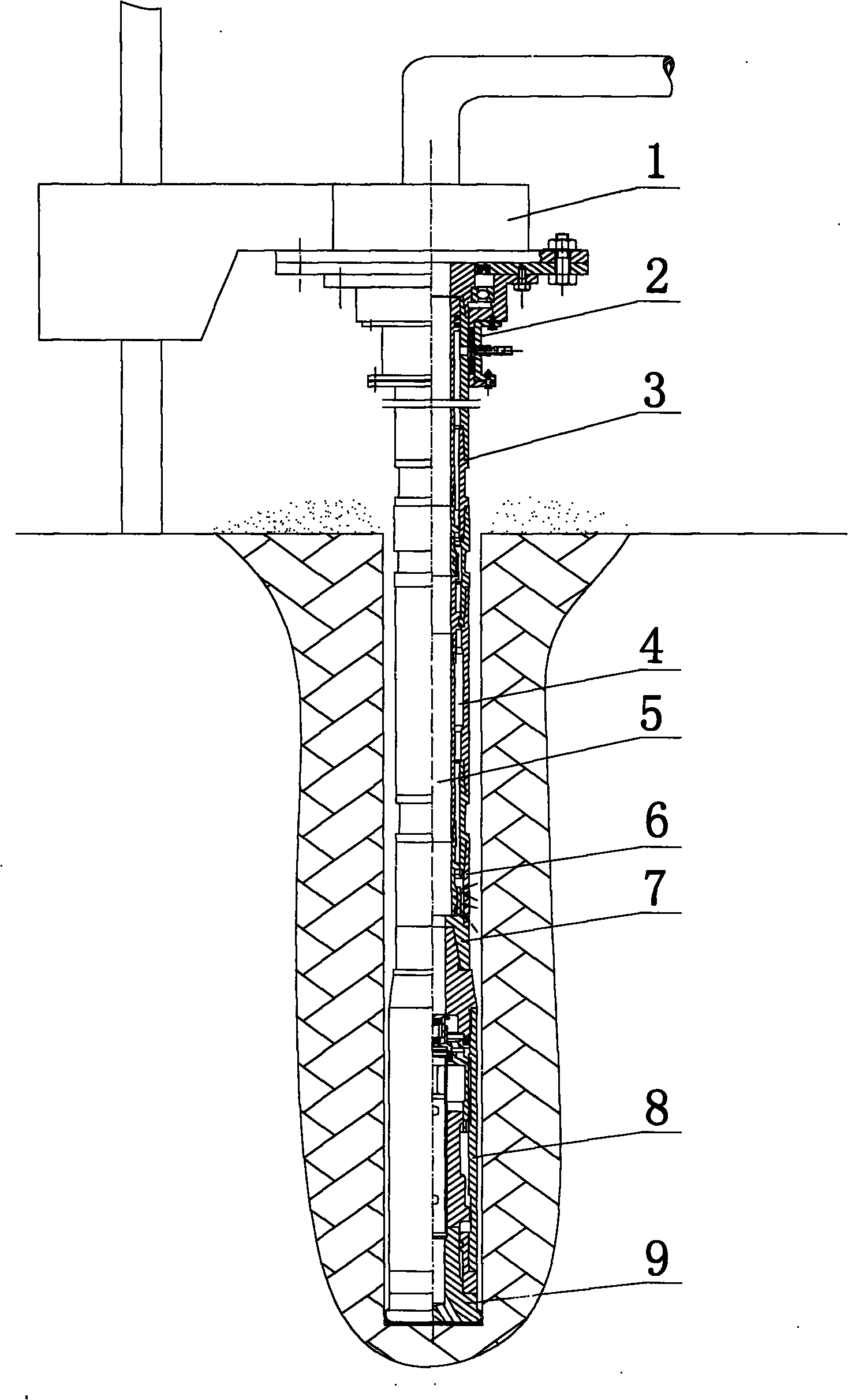

[0016] This design consists of the following parts:

[0017] Rotator 1, water supply box 2, double wall pipe 3, joint 6, joint 7, down-the-hole hammer 8, drill bit 9

[0018] When working, the compressed air is transmitted to the down-the-hole hammer (8) through the central channel (5) of the double-wall pipe, so that the gas drives the piston to reciprocate, and impacts the drill bit (9) for rock drilling; the exhaust gas is discharged through the exhaust hole of the drill bit (9) , flush the bottom of the hole, cool the drill bit (9), carry cuttings back along the gap between the hole wall and the down-the-hole hammer (8), and meet the annular gap between the water box (2) and the double-wall pipe (3) (4) In the water mist area sprayed by the conversion joint (6) (7), the exhaust gas carries the rock dust and mixes in the water mist area, and the multiphase flow of water, gas and rock slag formed runs along the double-walled pipe and the hole wall. The annular gap discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com