Crushing device for building construction and using method thereof

A crushing device and construction technology, applied in grain processing, electrode structure, electrostatic separation, etc., can solve the problems of sufficient crushing of stones, poor crushing effect, and affecting the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

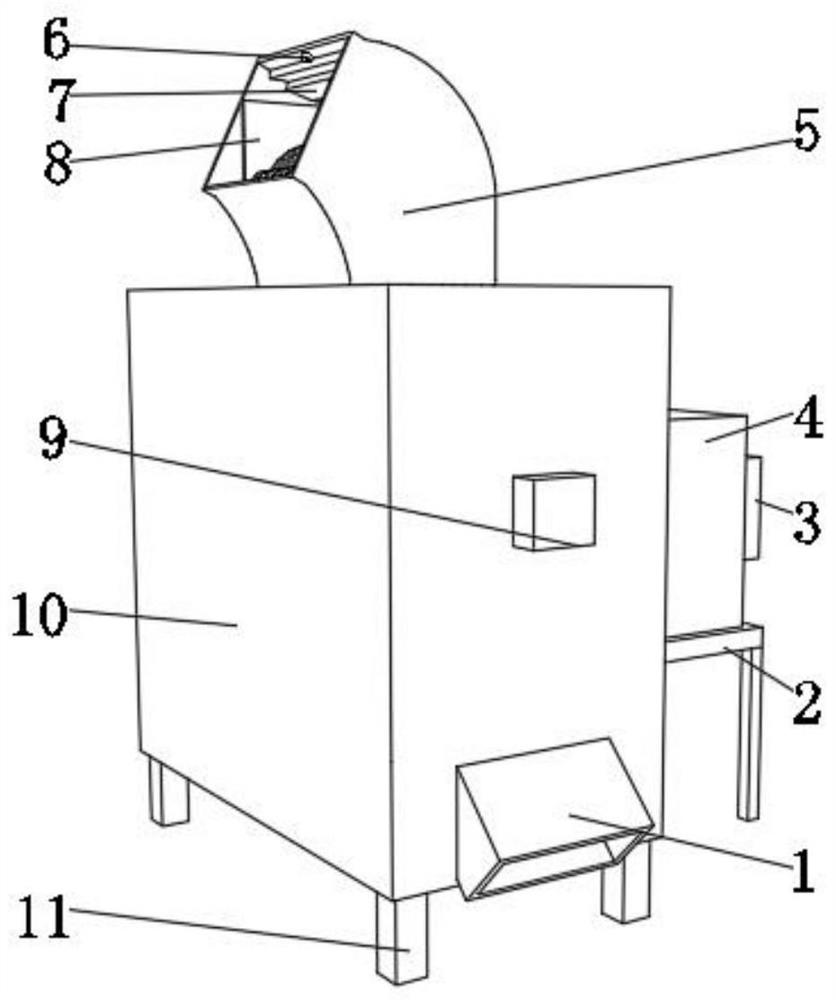

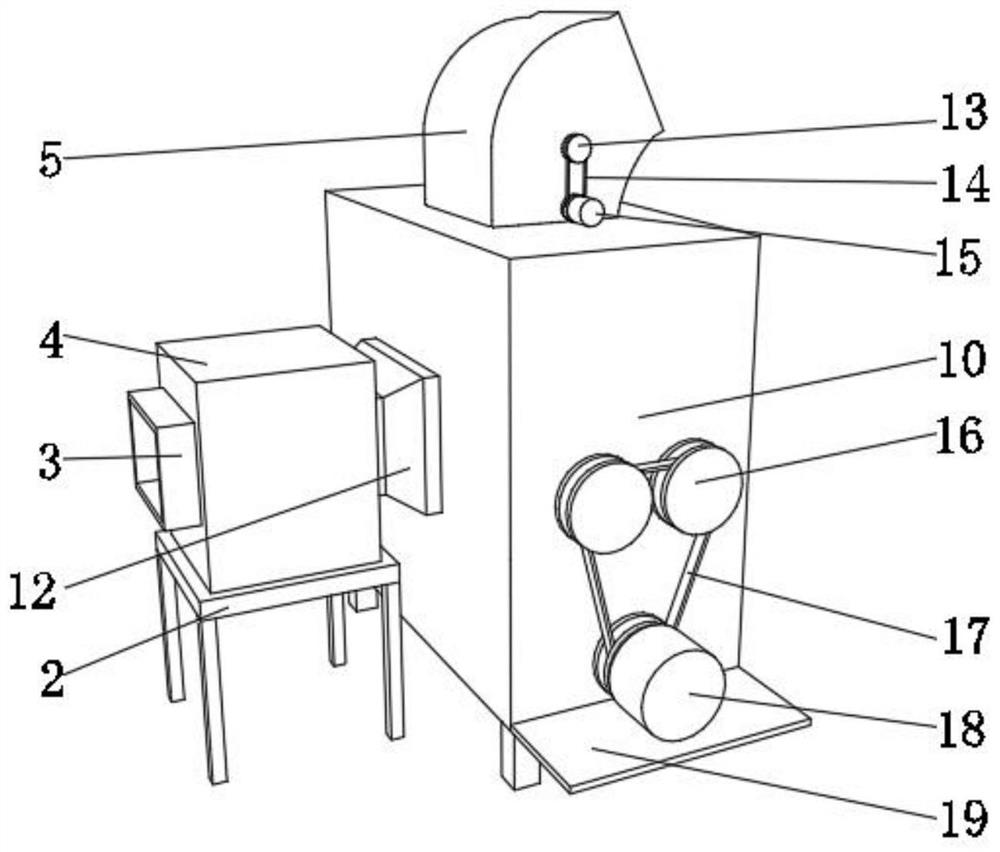

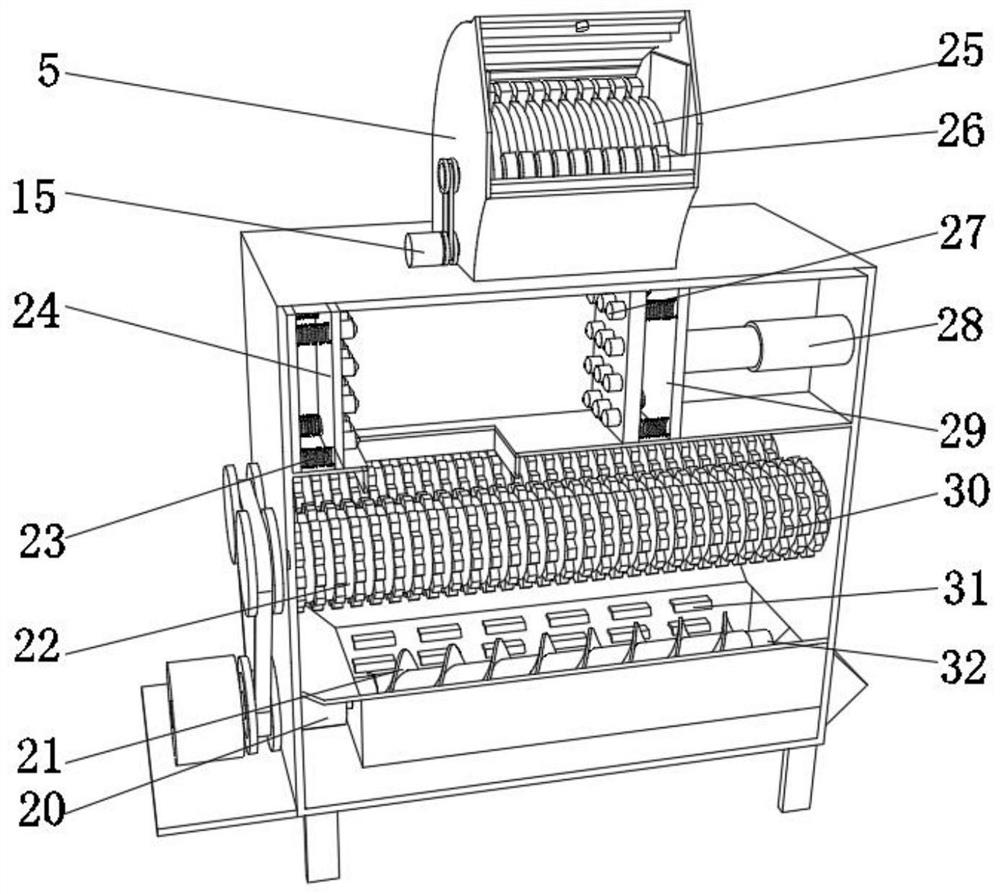

[0038] A crushing device for building construction, such as Figure 1-6 As shown, it includes a box body 10, the top of the box body 10 is fixed with a casing 5 by bolts, the outer wall of the opposite side of the casing 5 is fixed with a magnetic plate 8 by bolts, and the inner wall of the top side of the casing 5 is fixed with a metal plate by bolts. The sensor 6, the inner wall of the casing 5 is provided with a crushing mechanism, the bottom outer wall of the box body 10 is fixed with four support feet 11 by bolts, the outer wall of the bottom side of the box body 10 is fixed with a discharge pipe 1 by threads, and one part of the box body 10 The fan 9 is fixed on the outer wall of the side by bolts, the inner wall of one side of the box body 10 is fixed with a partition 33 by bolts, the outer wall of the top side of the partition 33 is provided with an extruding mechanism, and the outer wall of one side of the partition 33 is placed with a filter plate 34 One side outer w...

Embodiment 2

[0045] A crushing device for building construction, such as Figure 5 As shown, it includes a filter plate 34, the top outer wall of the filter plate 34 is fixed with more than three spikes 41 by bolts, the outer wall of the bottom side of the filter plate 34 is fixed with more than three springs 35 by bolts, and the other end of the spring two 35 There are two fixed plates 43 fixed by bolts, and two electric motors 42 are fixed on one side of the outer wall of one fixed plate 43 by bolts, and the output end of each electric motor 42 is fixed by a coupling so that one of the sides rotates. Axle two 37, one end of each rotating shaft two 37 is all fixed with rotating plate 38 by bolt, and the opposite side of every two rotating plates 38 is fixed with cam 36 by rotating shaft, and the top outer wall of each cam 36 is fixed with connection by rotating shaft. Rod 39, the top of connecting rod 39 is fixed with fixed block 40 by bolt, and the top outer wall of fixed block 40 is con...

Embodiment 3

[0048] A crushing device for building construction also uses a filter plate, such as Figure 5 As shown, it includes a dust collection box 4, the inner wall of the side of the dust collection box 4 near the connecting pipe 12 and the exhaust pipe 3 is fixed with an air flow distribution plate 46 by bolts, and the inner wall of the dust collecting box 4 is close to the side of the connecting pipe 12. The inner wall of one side is fixed with more than three anode plates 44 by bolts, the side of the dust collection box 4 close to the exhaust pipe 3 is fixed with more than three cathode plates 45 by bolts, and the bottom of the dust collection box 4 is fixed by bolts on the side close to the cathode plates 45 There is a rapping anvil 47, and the bottom of the dust collection box 4 is fixed with an ash discharge pipe through threads; when in use, the smoke and dust in the box body 10 enters the dust collection box 4 through the connecting pipe 12, and the smoke and dust gas is evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com