Patents

Literature

32results about How to "Rapid crushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

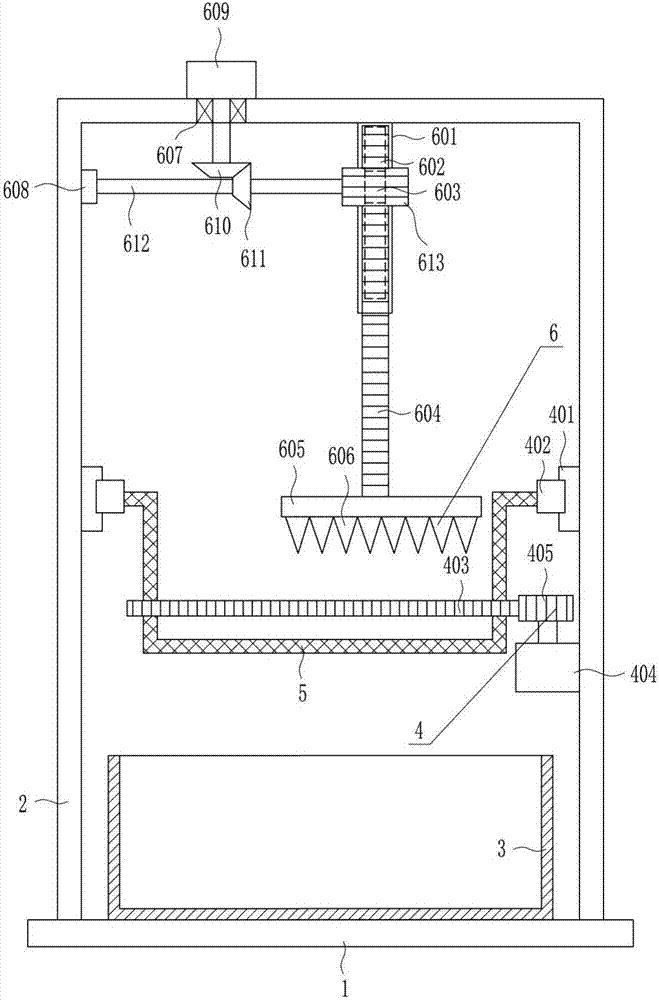

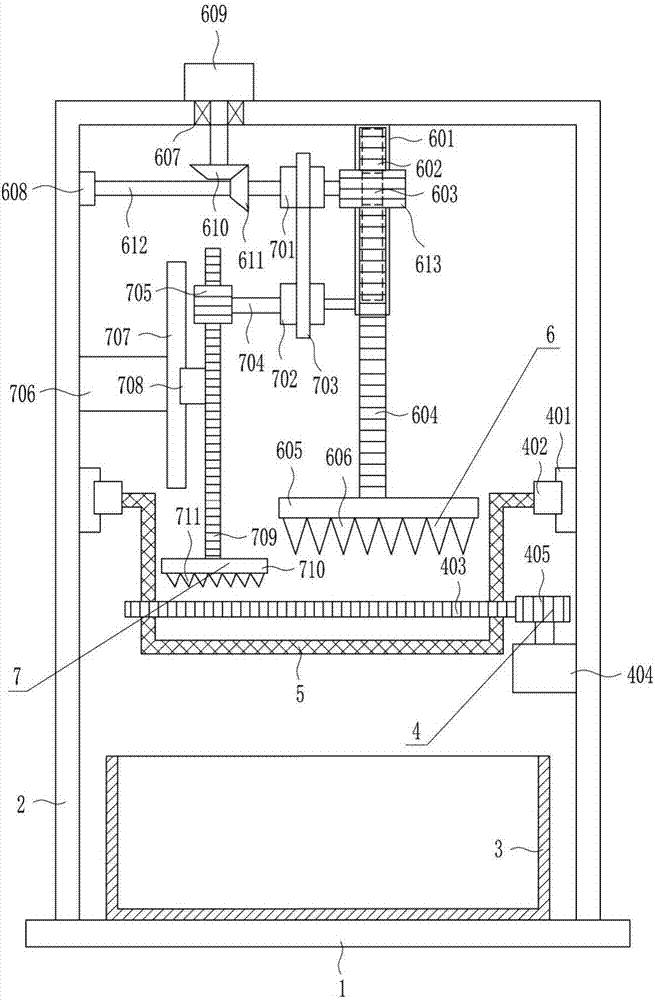

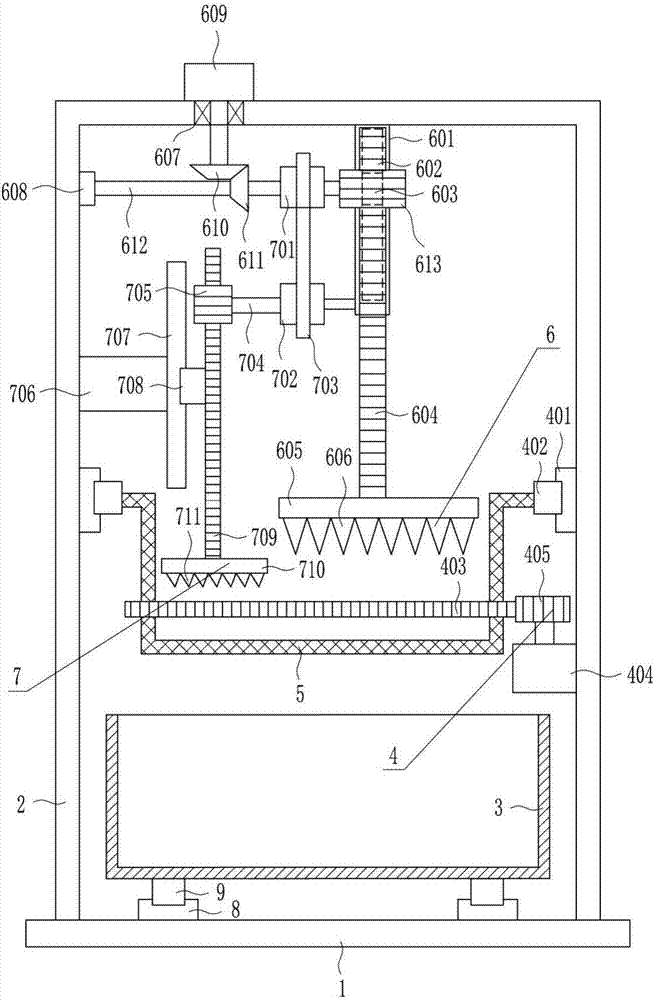

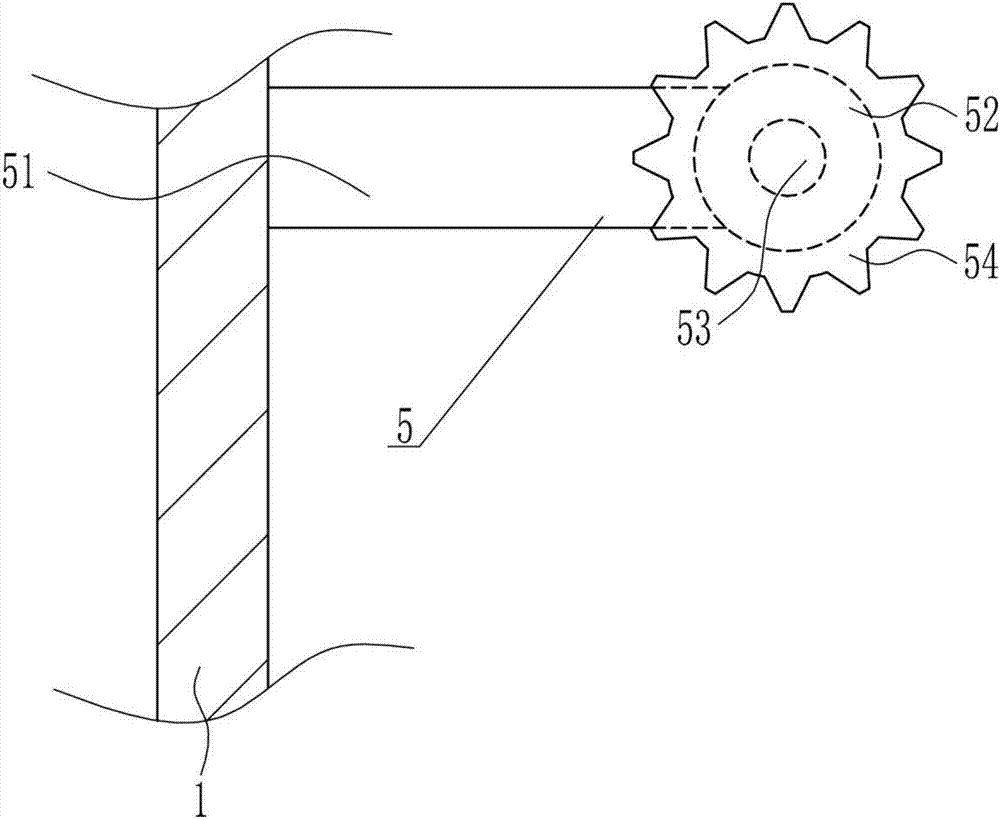

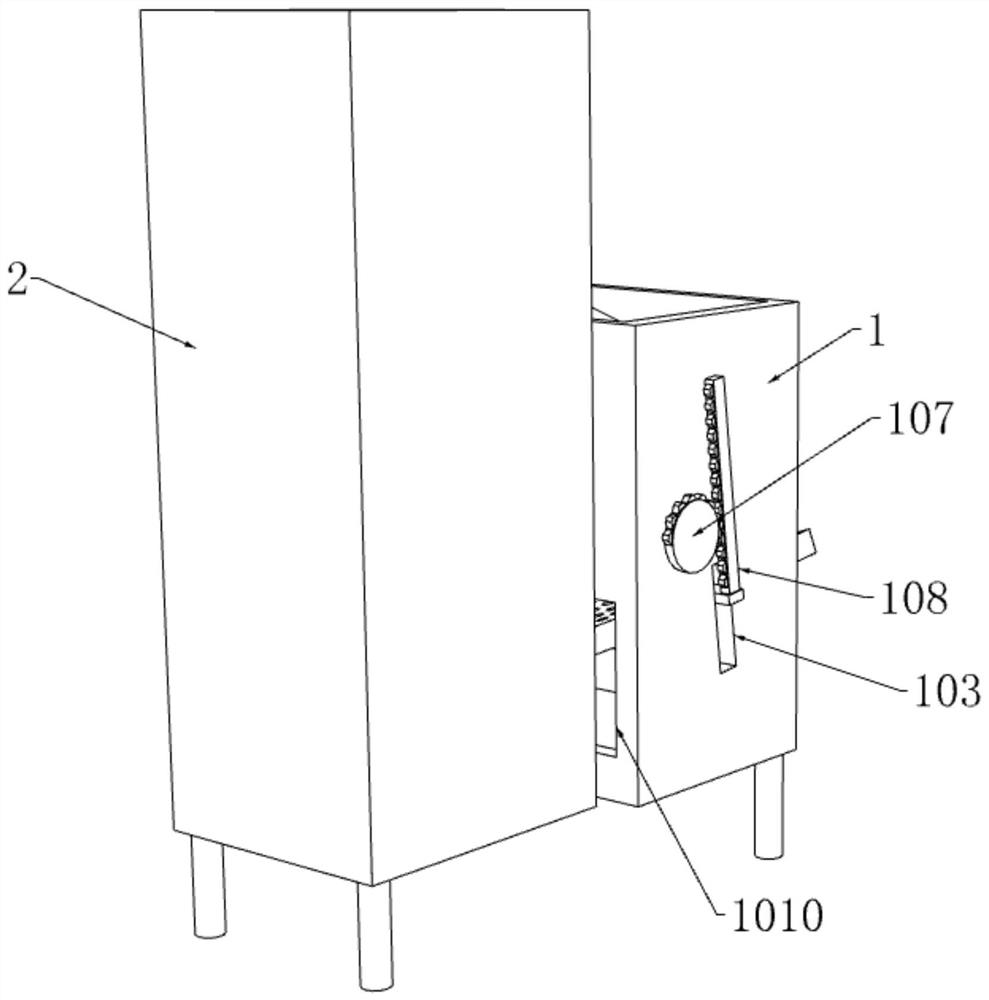

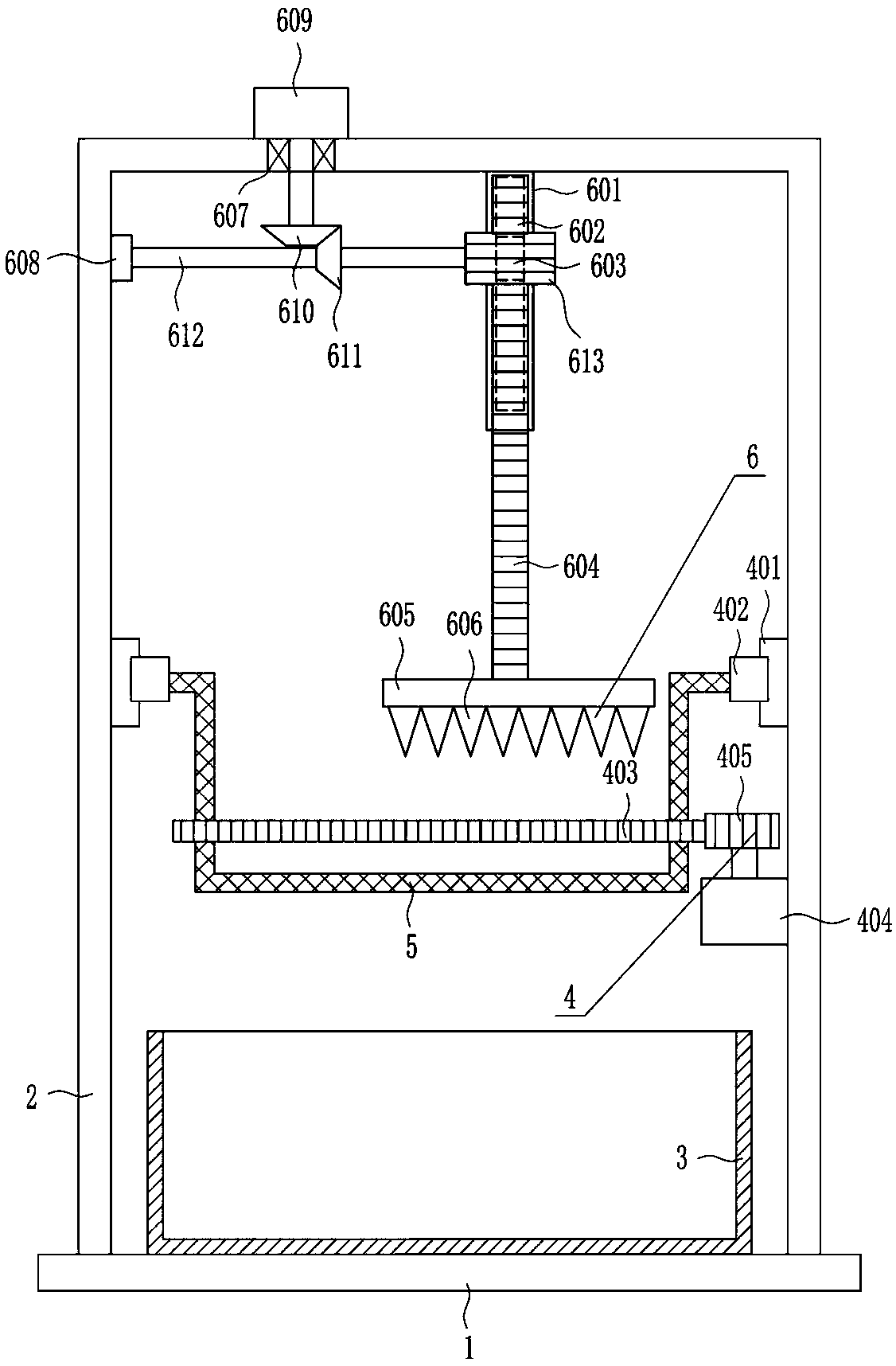

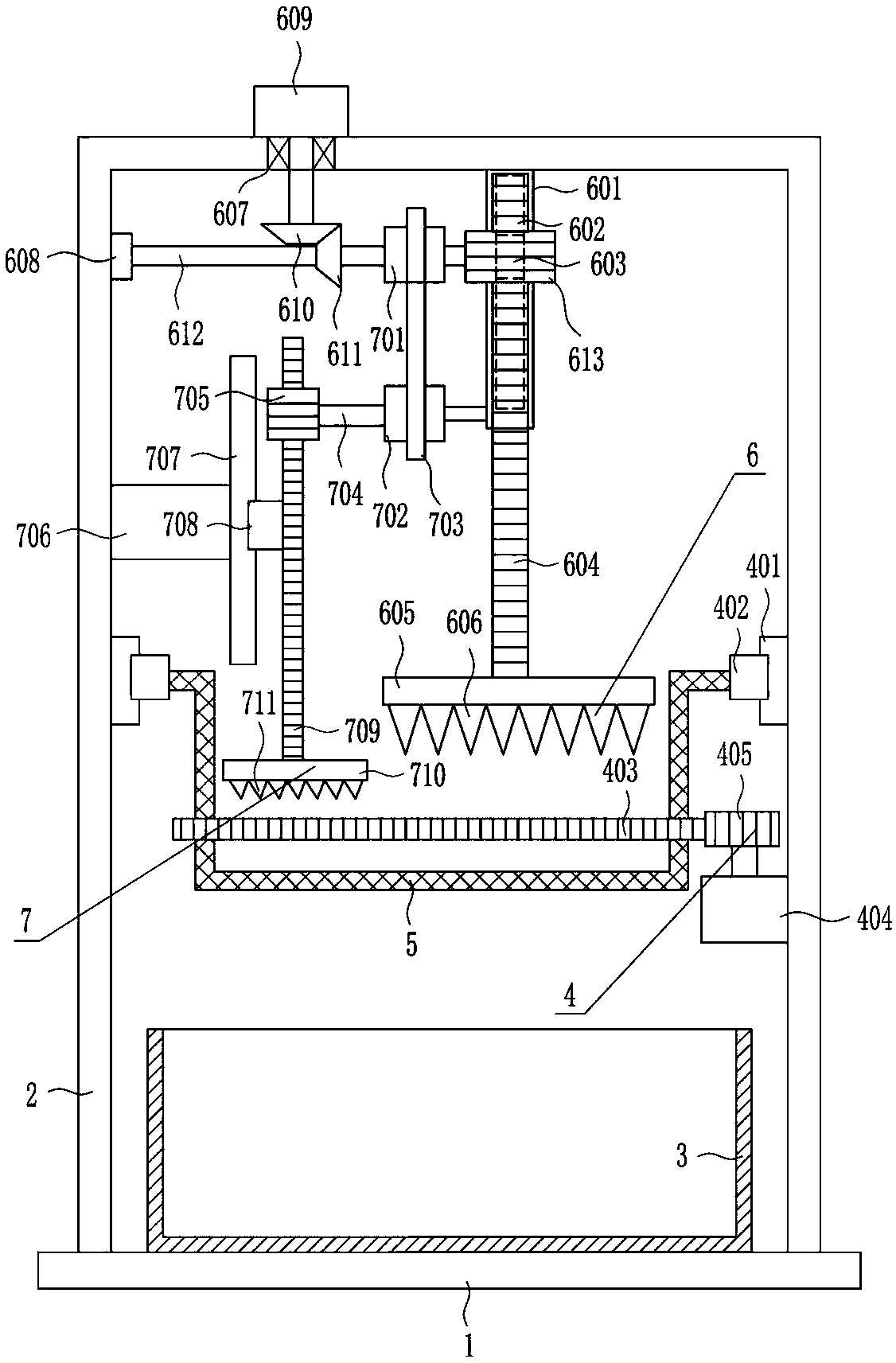

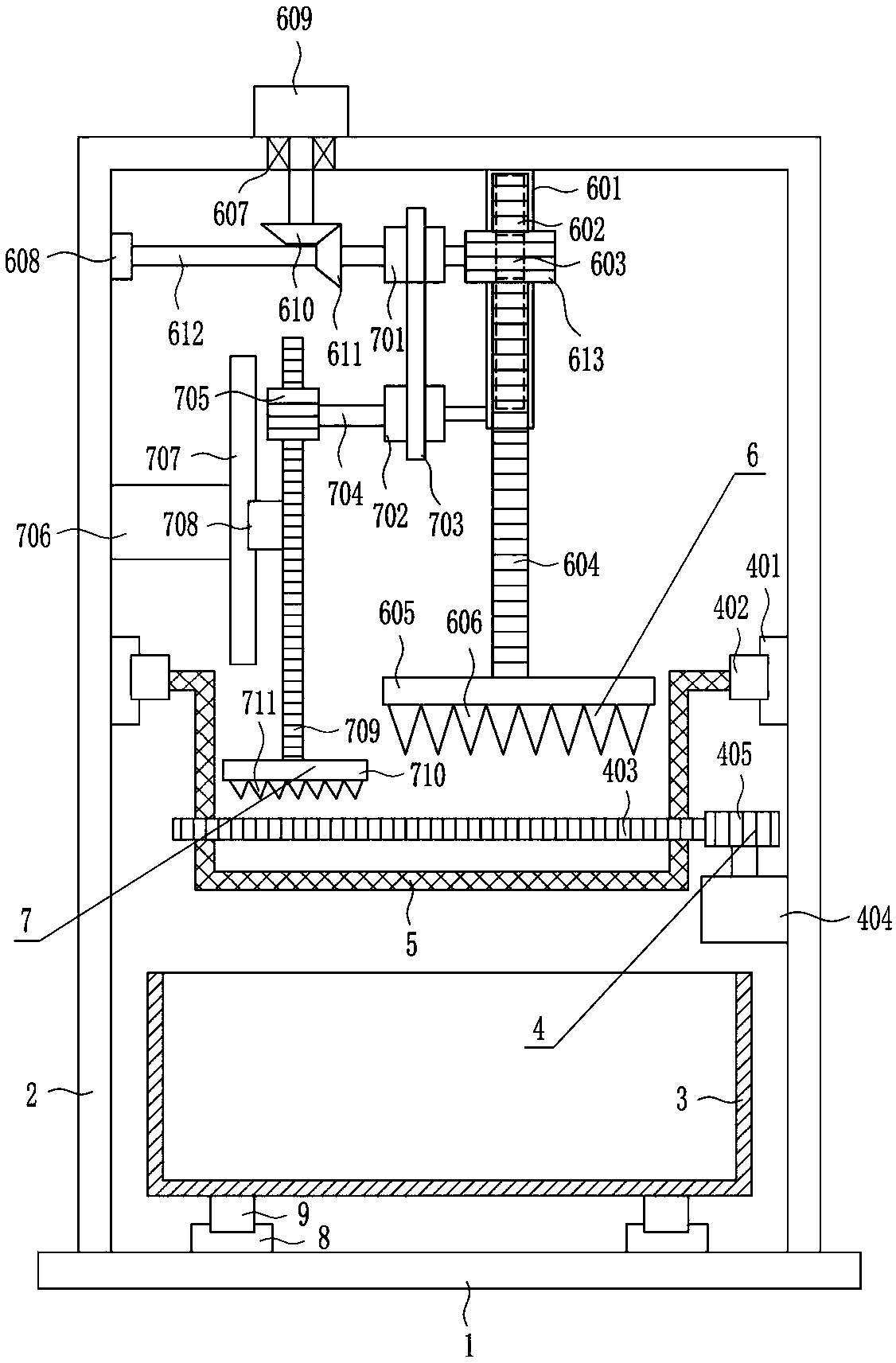

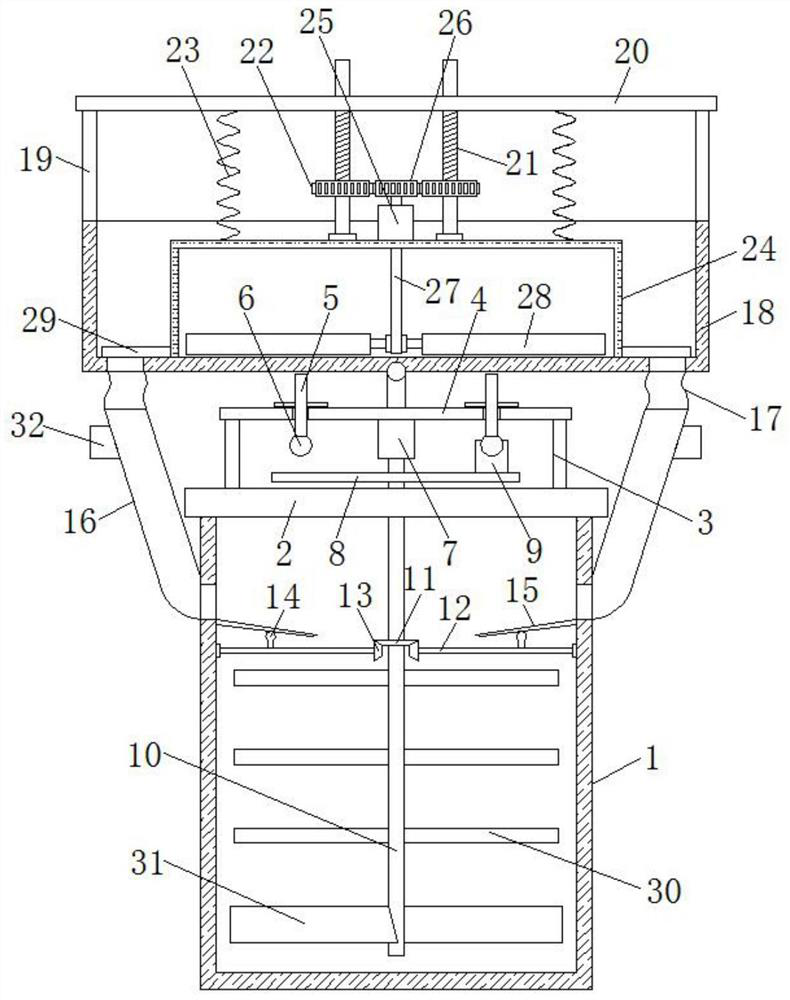

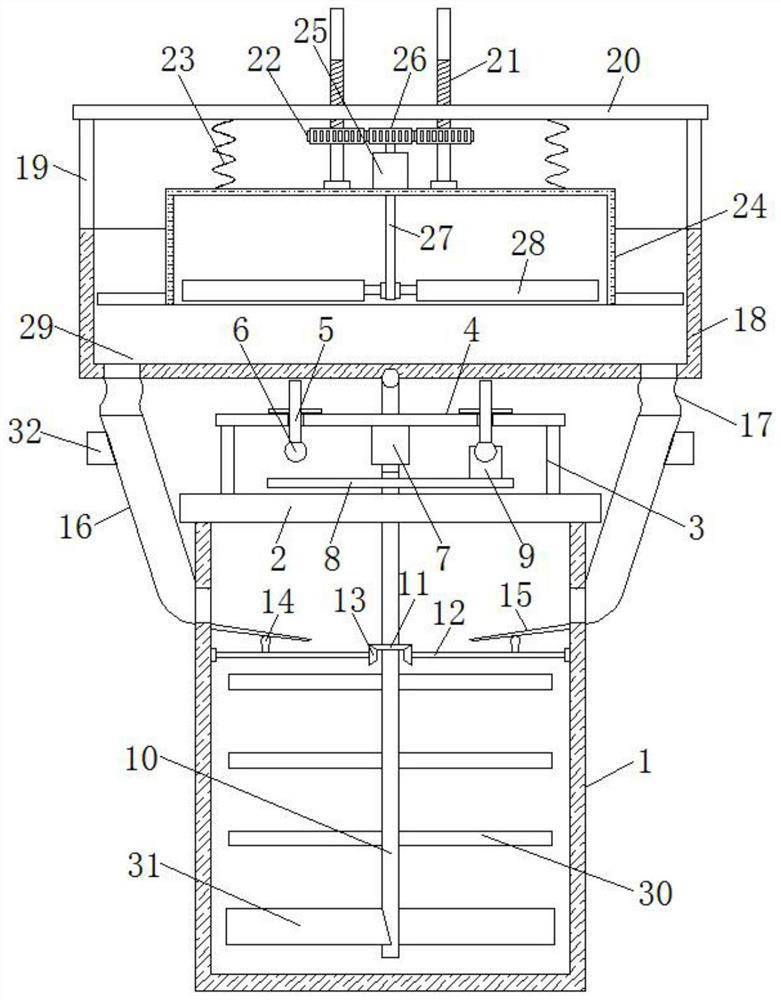

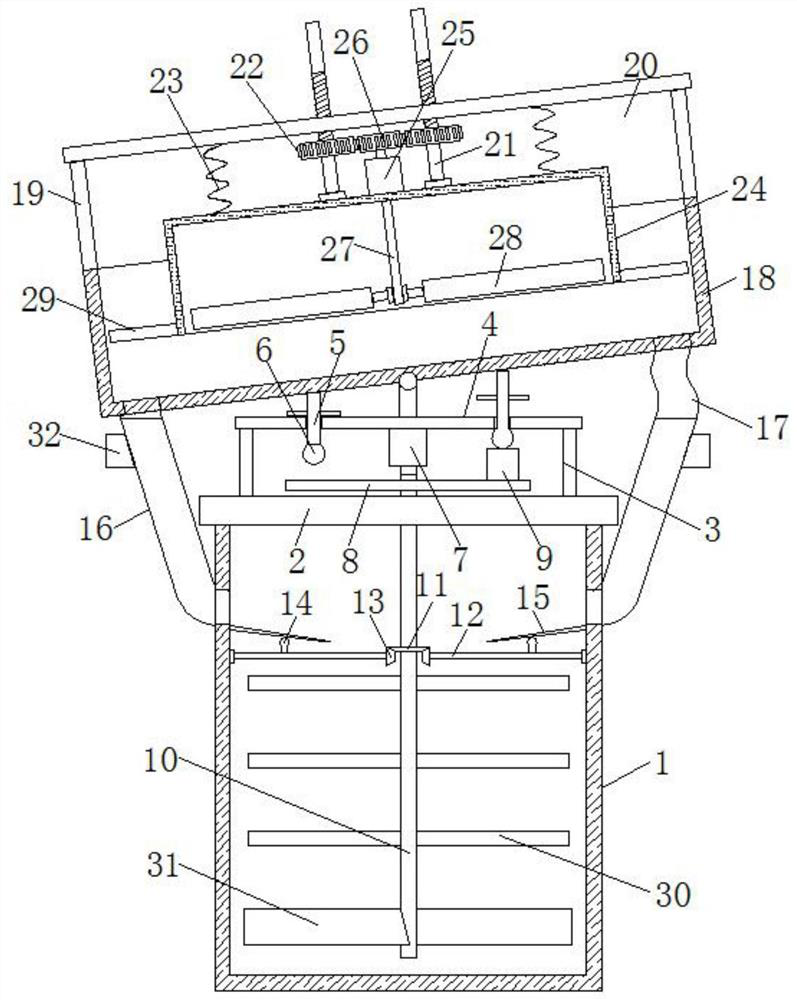

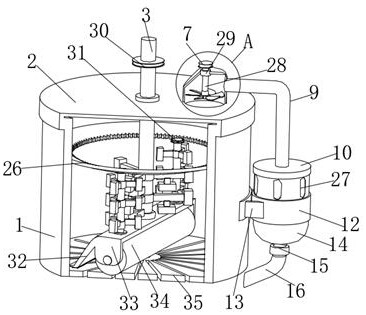

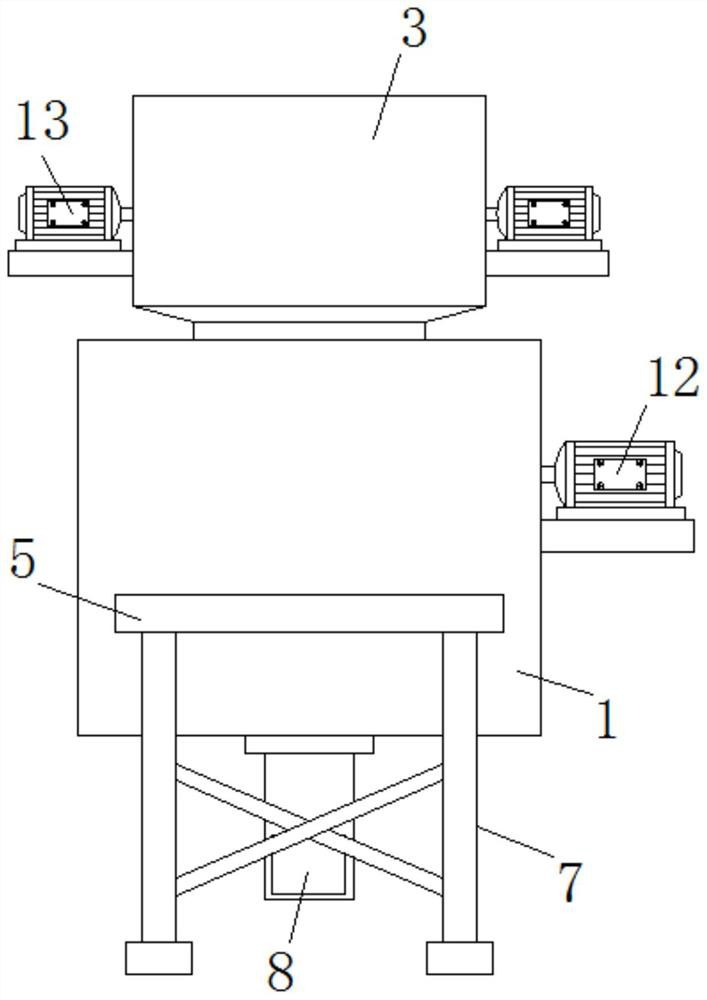

Waste material treatment device for culture media

The invention relates to a material treatment device for culture media, in particular to a waste material treatment device for culture media. The waste material treatment device for culture media achieves the technical aims that waste materials can be crushed, space usage of the waste materials can be reduced, the labor intensity of workers can be lowered and the crushing efficiency can be improved. In order to achieve the technical aims, the waste material treatment device for culture media comprises a base and other parts. The top of the base is connected with an n-shaped plate through bolts. A collecting box is connected to the inner side of the n-shaped plate through bolts and located at the top of the base. A rotating device is arranged in the middle of the inside of the n-shaped plate. The rotating device is connected with a screen frame. A first treatment device body is arranged inside the n-shaped plate and located above the screen frame. According to the waste material treatment device for culture media, the waste materials can be crushed quickly through the first treatment device body and a second treatment device body.

Owner:新昌县皇骐电子科技有限公司

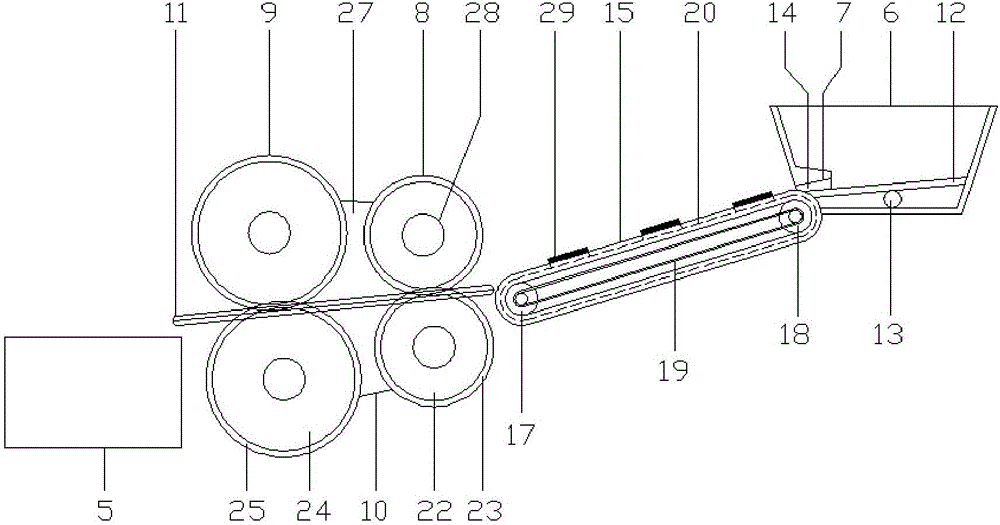

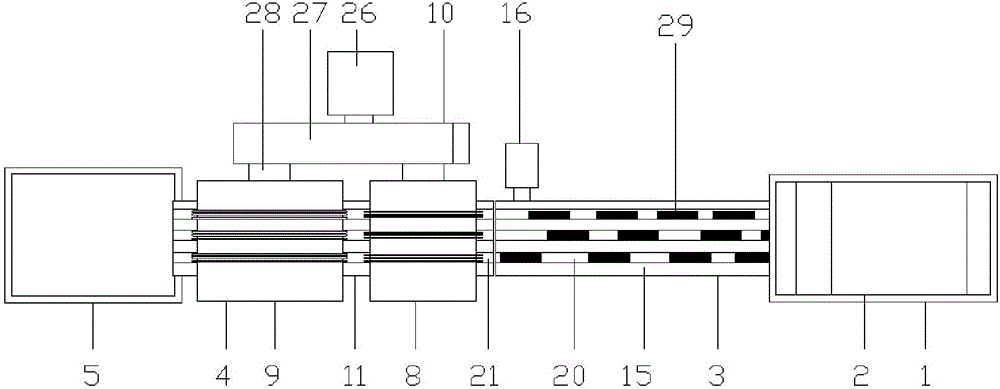

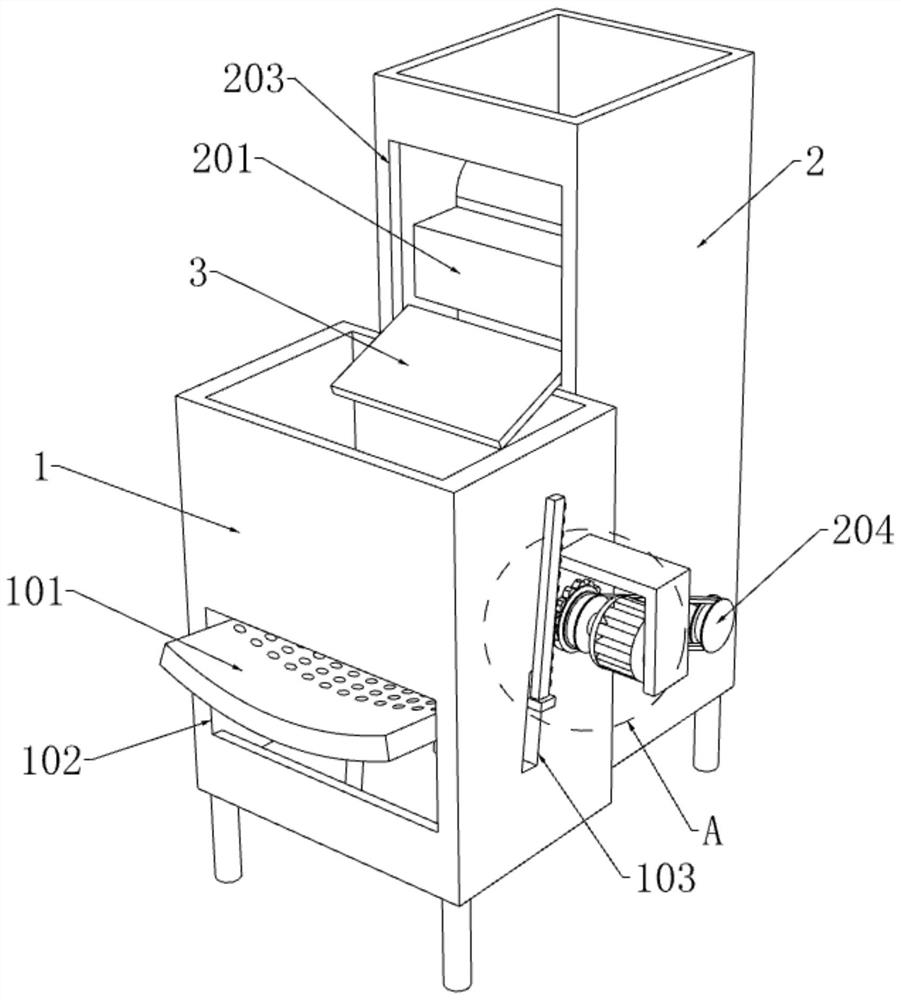

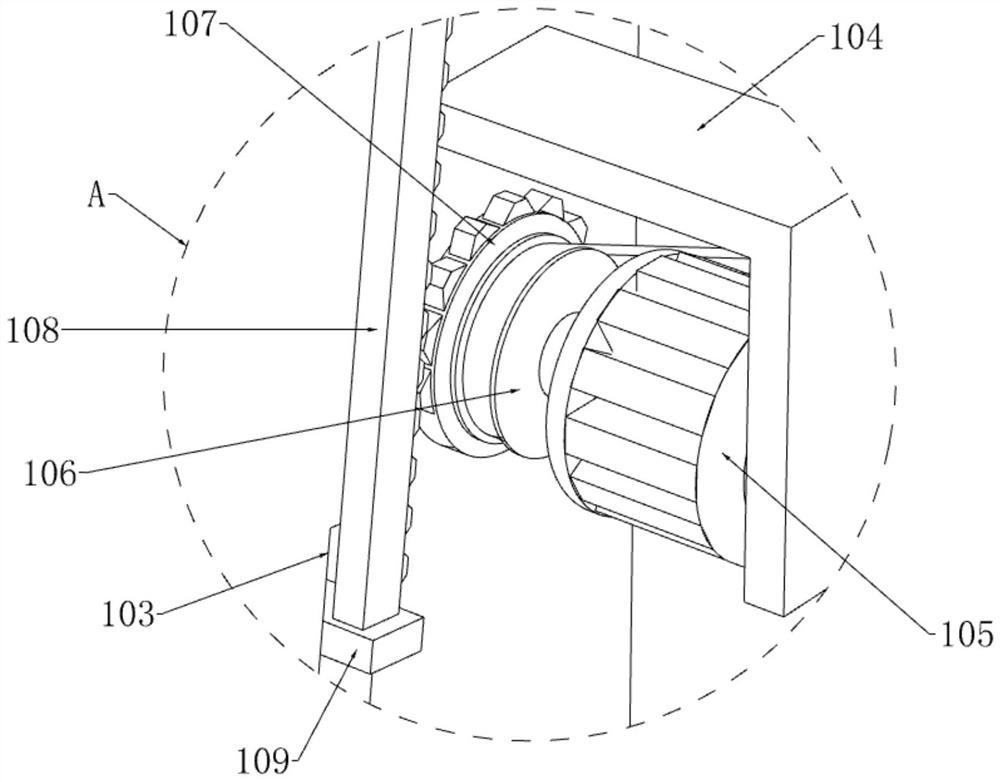

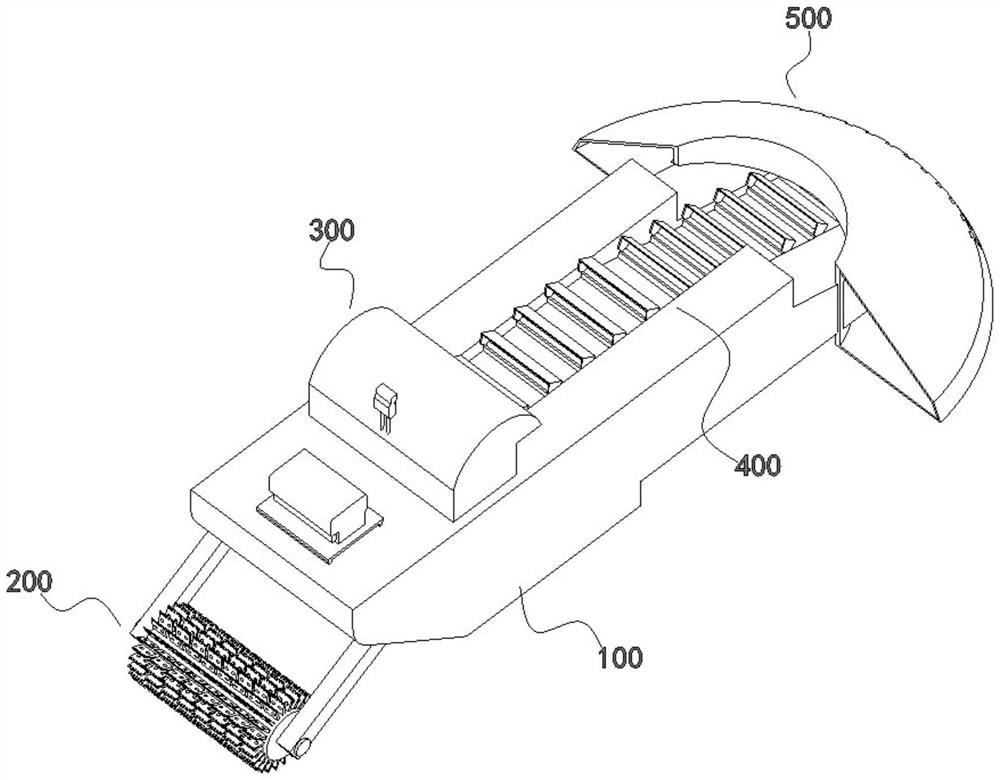

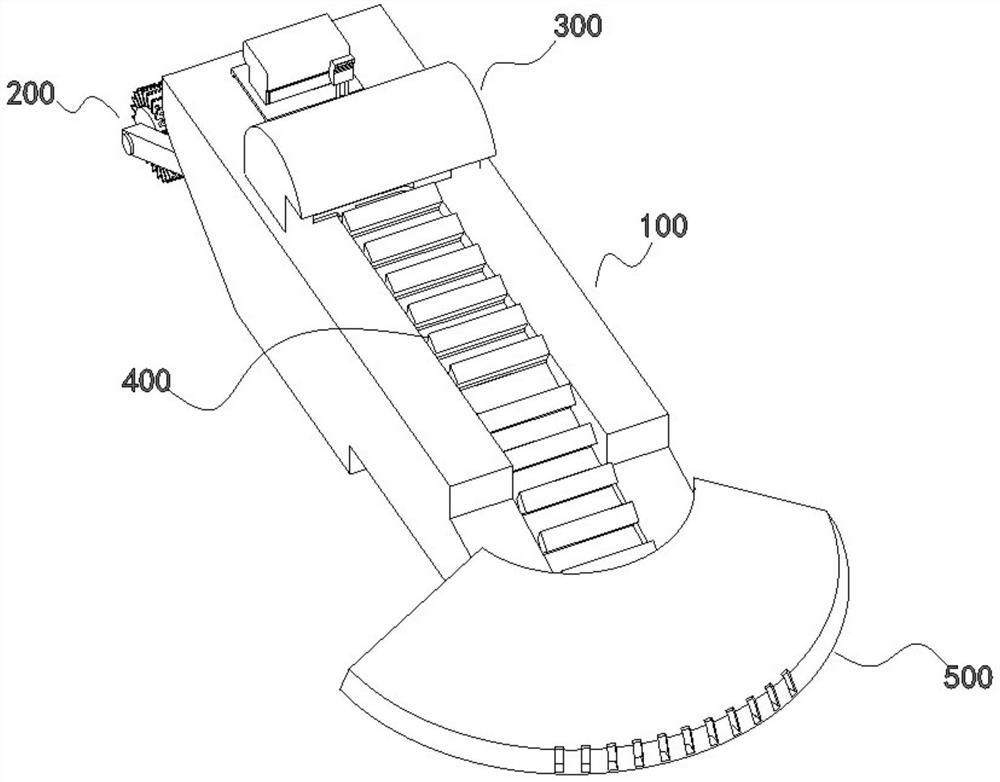

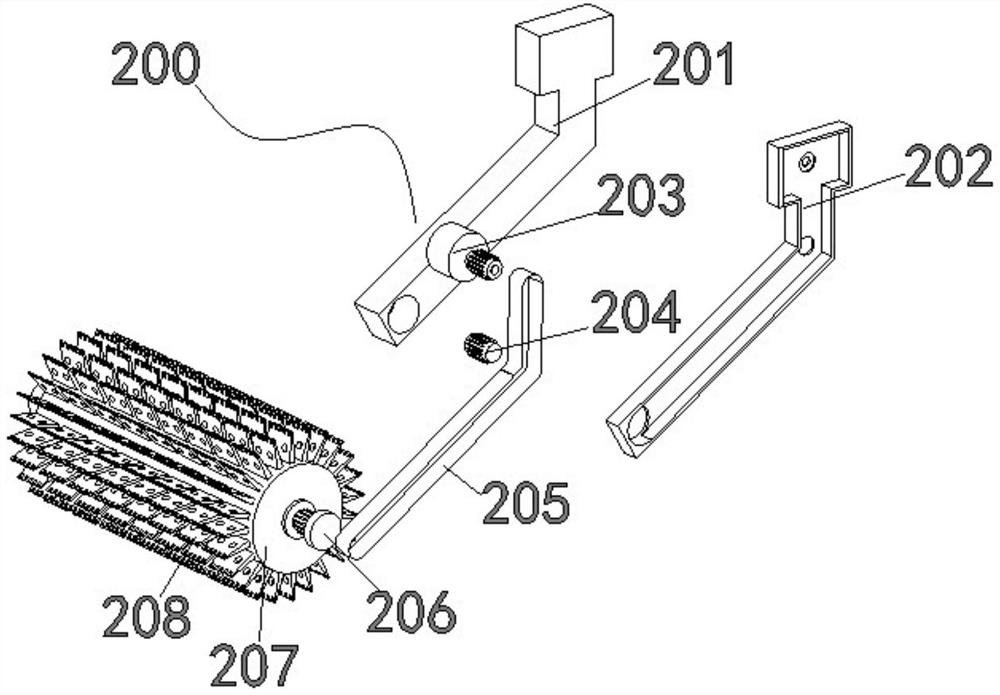

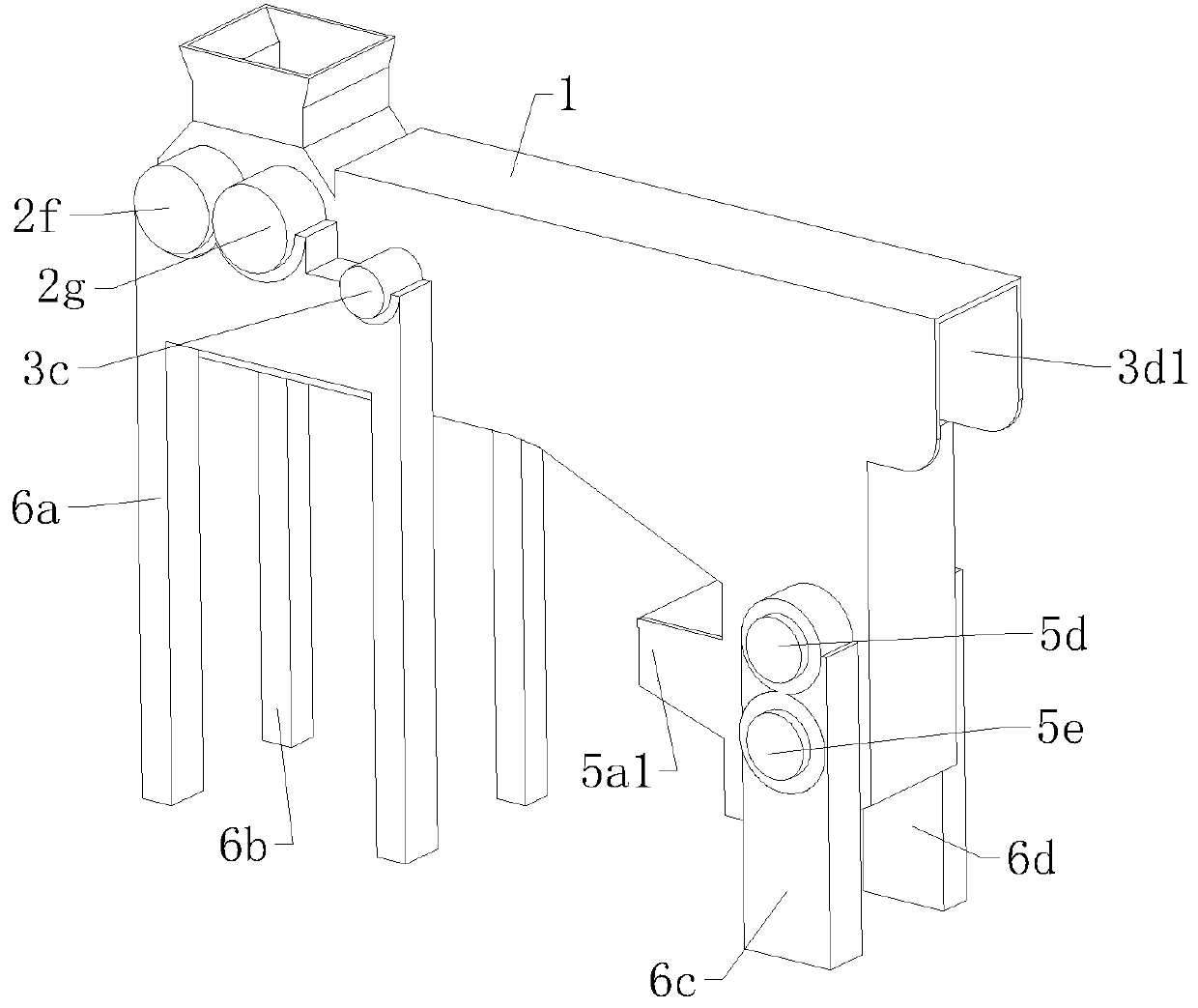

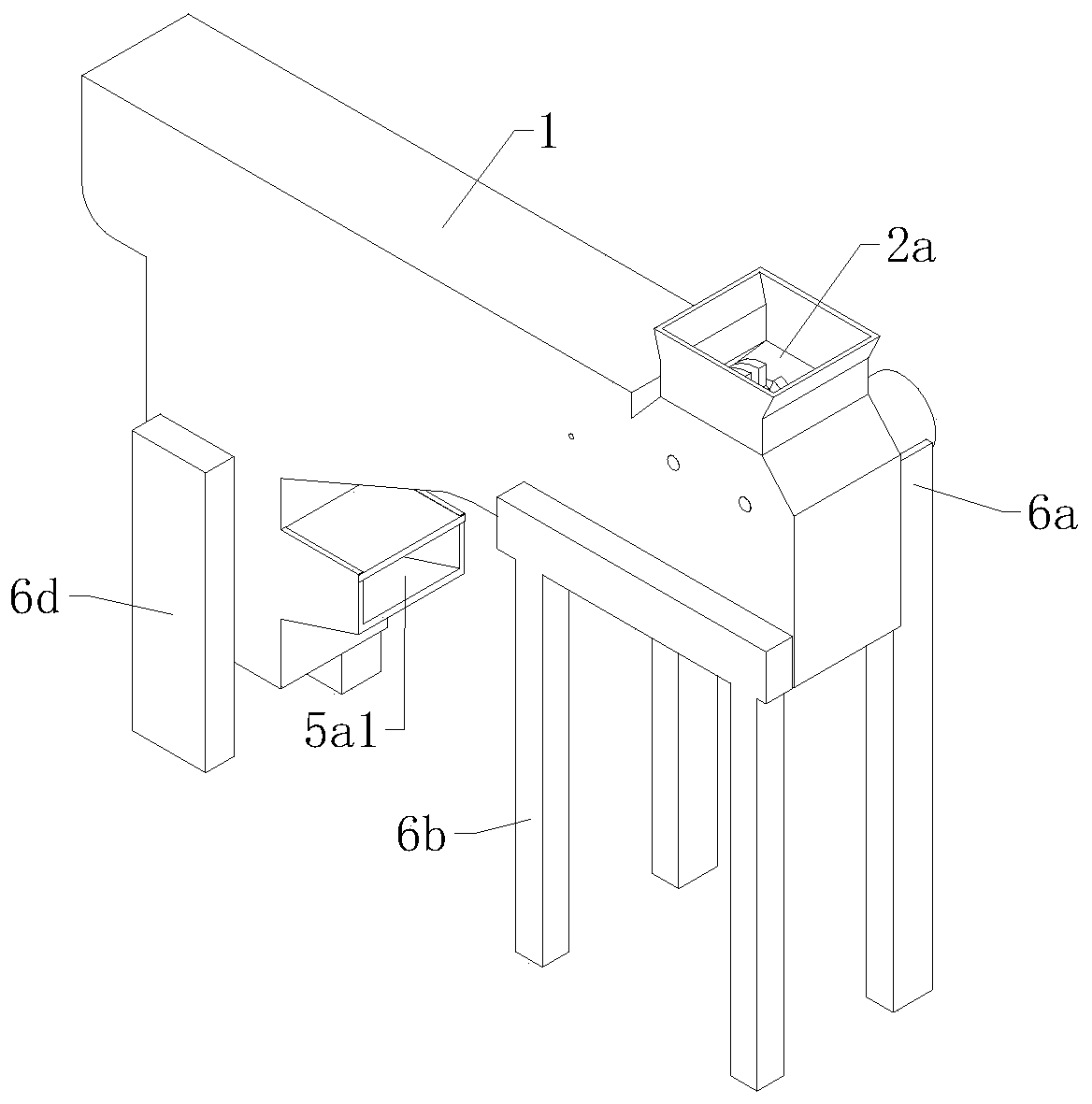

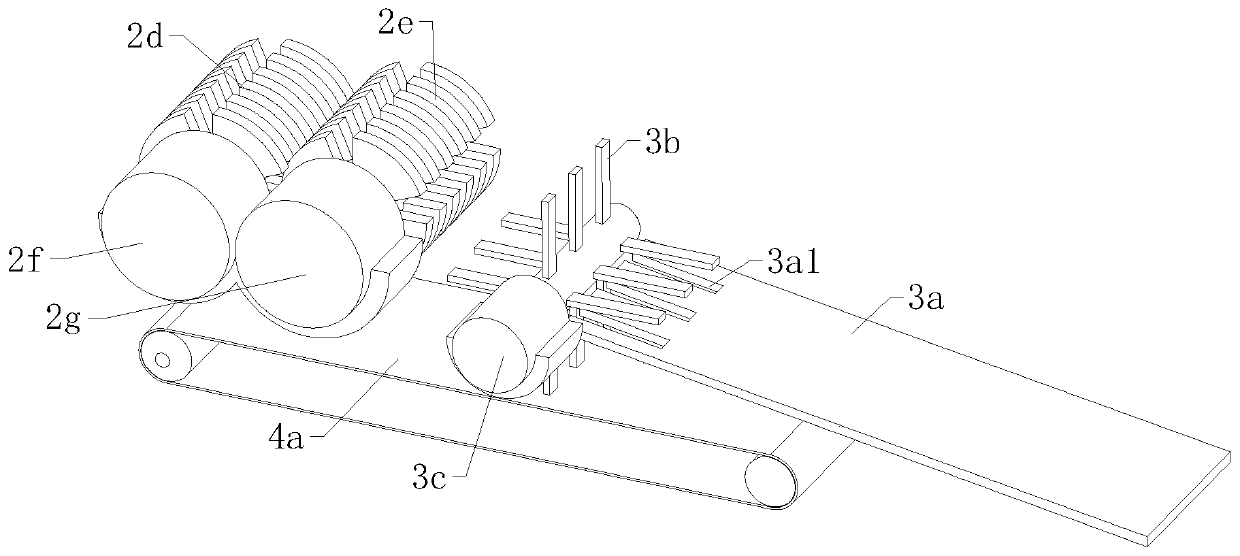

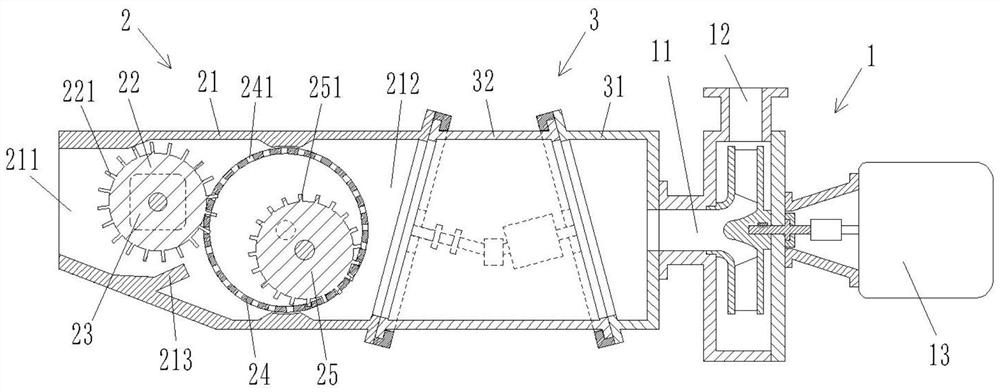

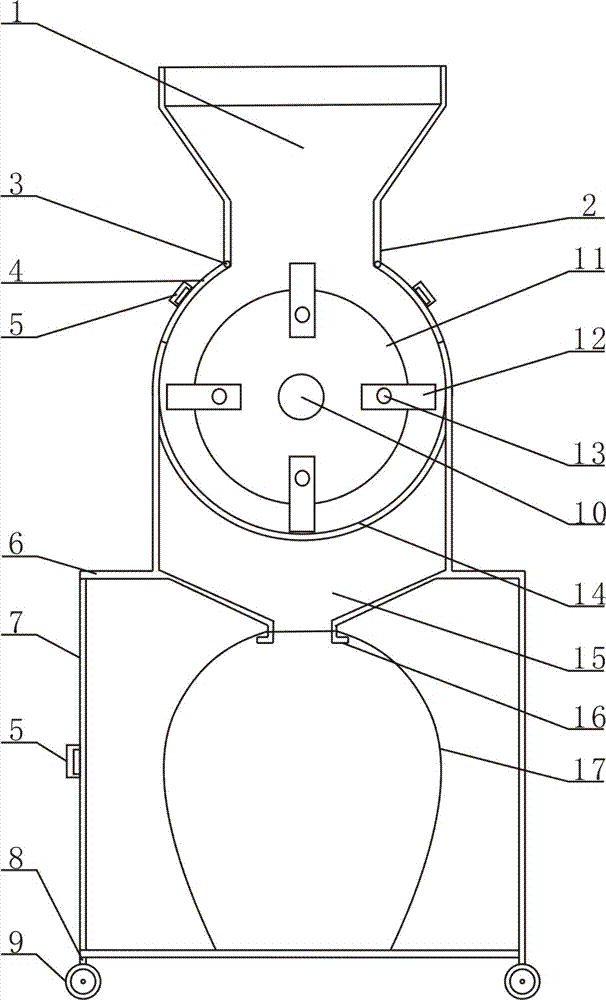

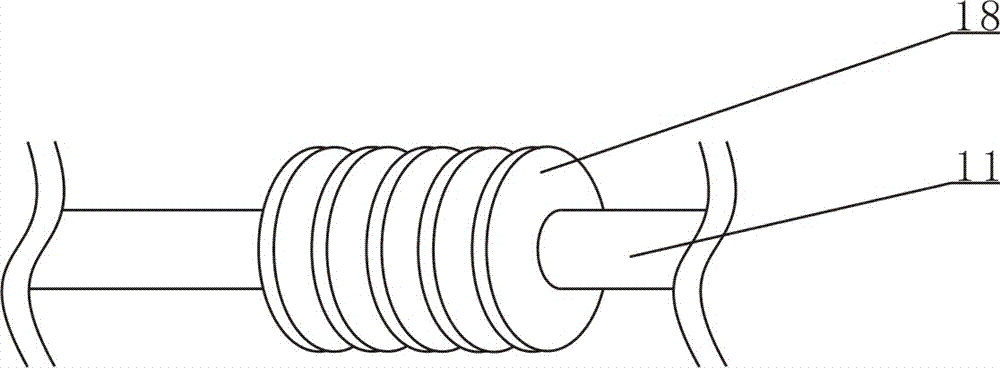

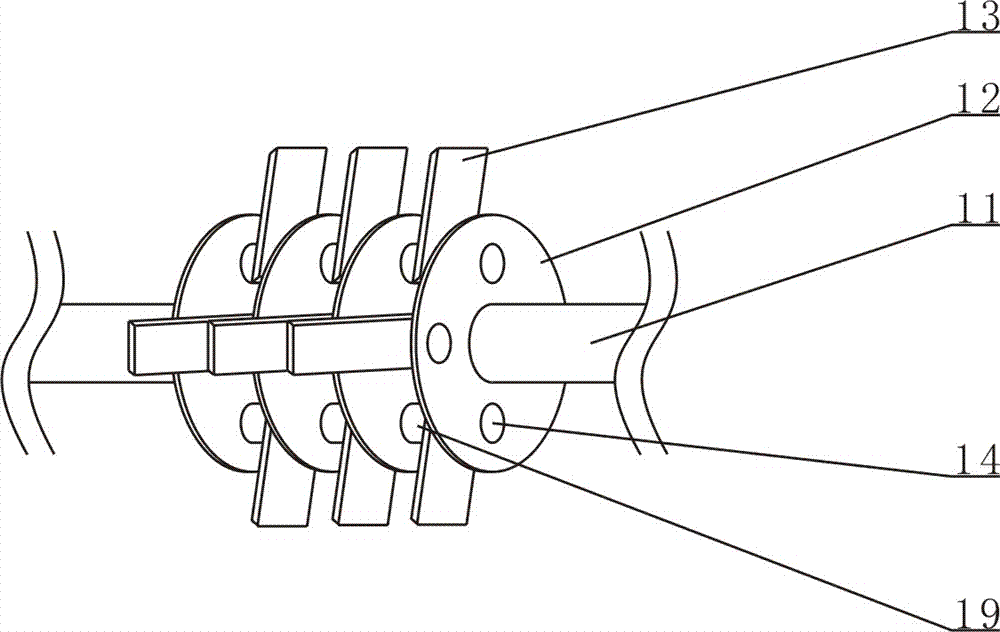

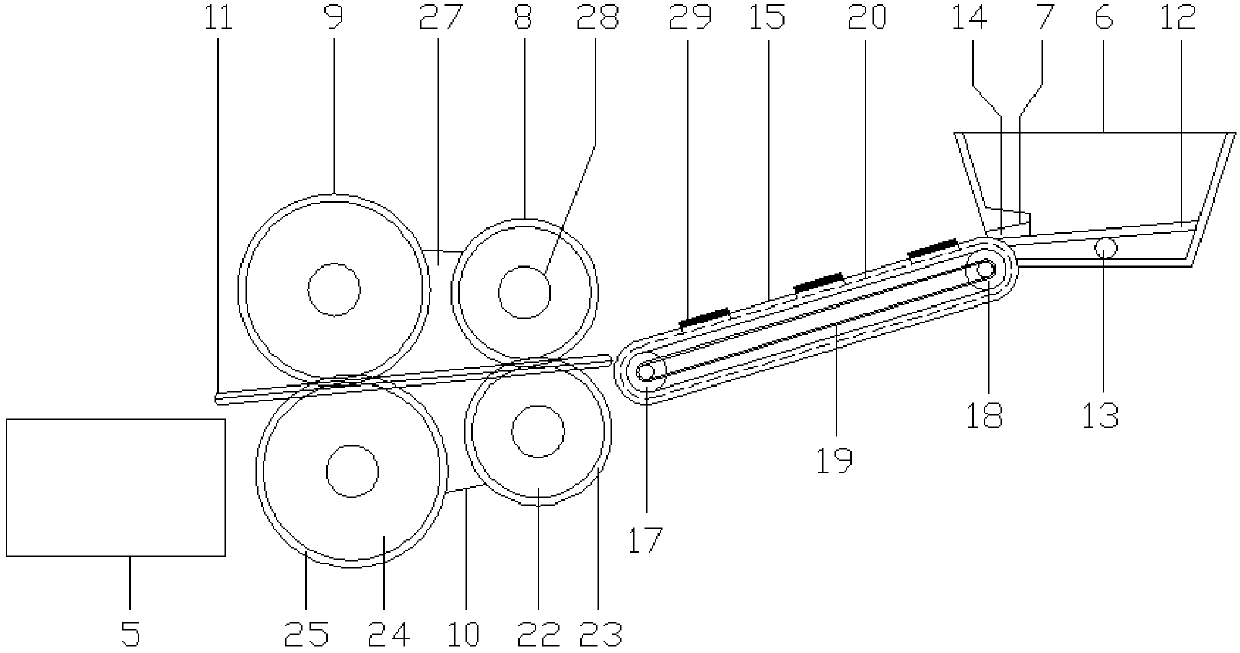

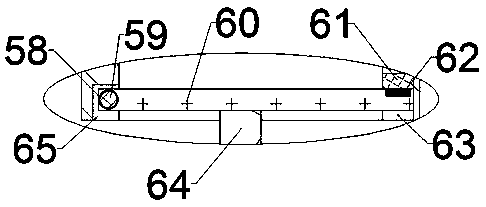

Bamboo rolling and crushing machine

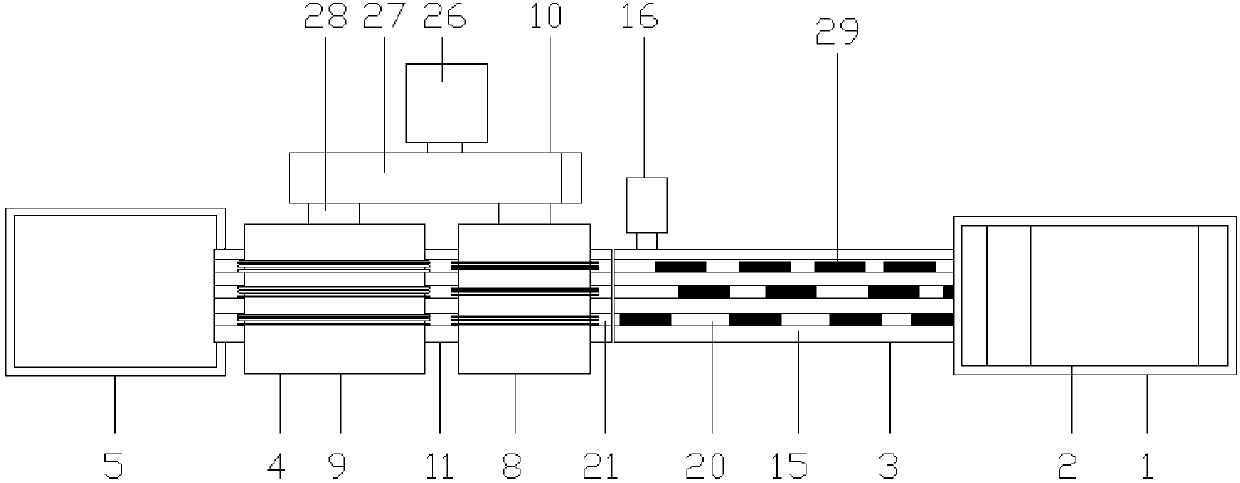

The invention discloses a bamboo rolling and crushing machine comprising a feeding hopper, a vibration device, a conveying device, a crushing device and a storage bin; the vibration device is located in the feeding hopper; a feeding hole and a discharging hole are formed in the feeding hopper; the discharging hole is connected with the conveying device; the conveying device is connected with a power source and the crushing device; the crushing device comprises a first crushing mechanism, a second crushing mechanism, a driving device and a guide table; the driving device is connected with the first crushing mechanism and the second crushing mechanism which are located on the guide table; and the guide table can be connected with the conveying device and the storage bin. The bamboo rolling and crushing machine is novel in structure, convenient to use, capable of rapidly rolling and crushing standard bamboo chips to generate a lateral pultrusion tearing effect and incapable of generating a great number of scatterable shred residues so as to be beneficial to the obtaining of overlong bamboo fibers and great reduction of loss of bamboo gadolinium in the bamboo fibers.

Owner:福建神采新材料科技有限公司

Raw material rapid treating equipment for carbon powder manufacturing

The invention belongs to the technical field of carbon manufacturing, and particularly relates to raw material rapid treating equipment for carbon powder manufacturing. The raw material rapid treating equipment for carbon powder manufacturing aims at achieving the technical effects of saving time and labor and being good in treating effect, high in treating speed and high in working efficiency. In order to achieve the technical effects, the raw material rapid treating equipment for carbon powder manufacturing comprises a box body and the like, a baffle is hinged to the bottom of the left side face of the box body through a pin shaft, the baffle is matched with the box body, the middle inside the box body is horizontally connected with a partition plate through a bolt, the partition plate is provided with a discharge hole, the upper portion of the right side face of the box body is provided with a driving device and a treating device, and the driving device is located below the treating device. The raw material rapid treating equipment achieves the effects of saving time and labor and being good in treating effect, high in treating speed and high in working efficiency.

Owner:高佳盛

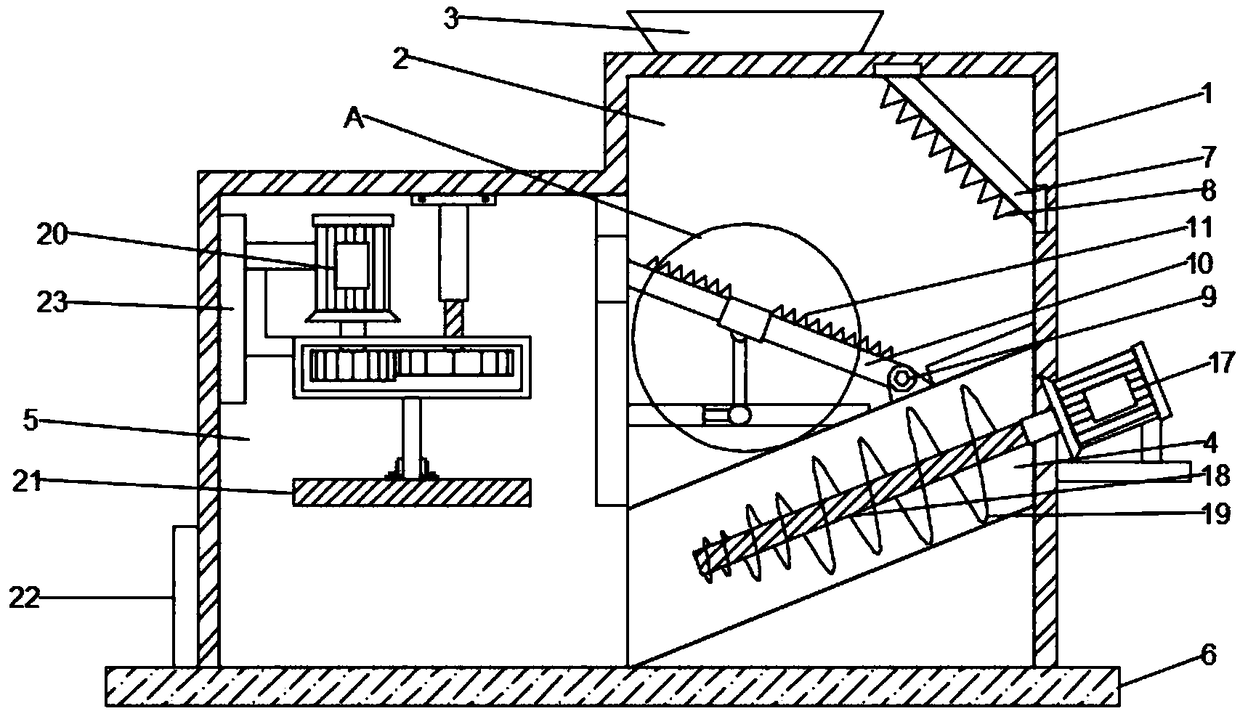

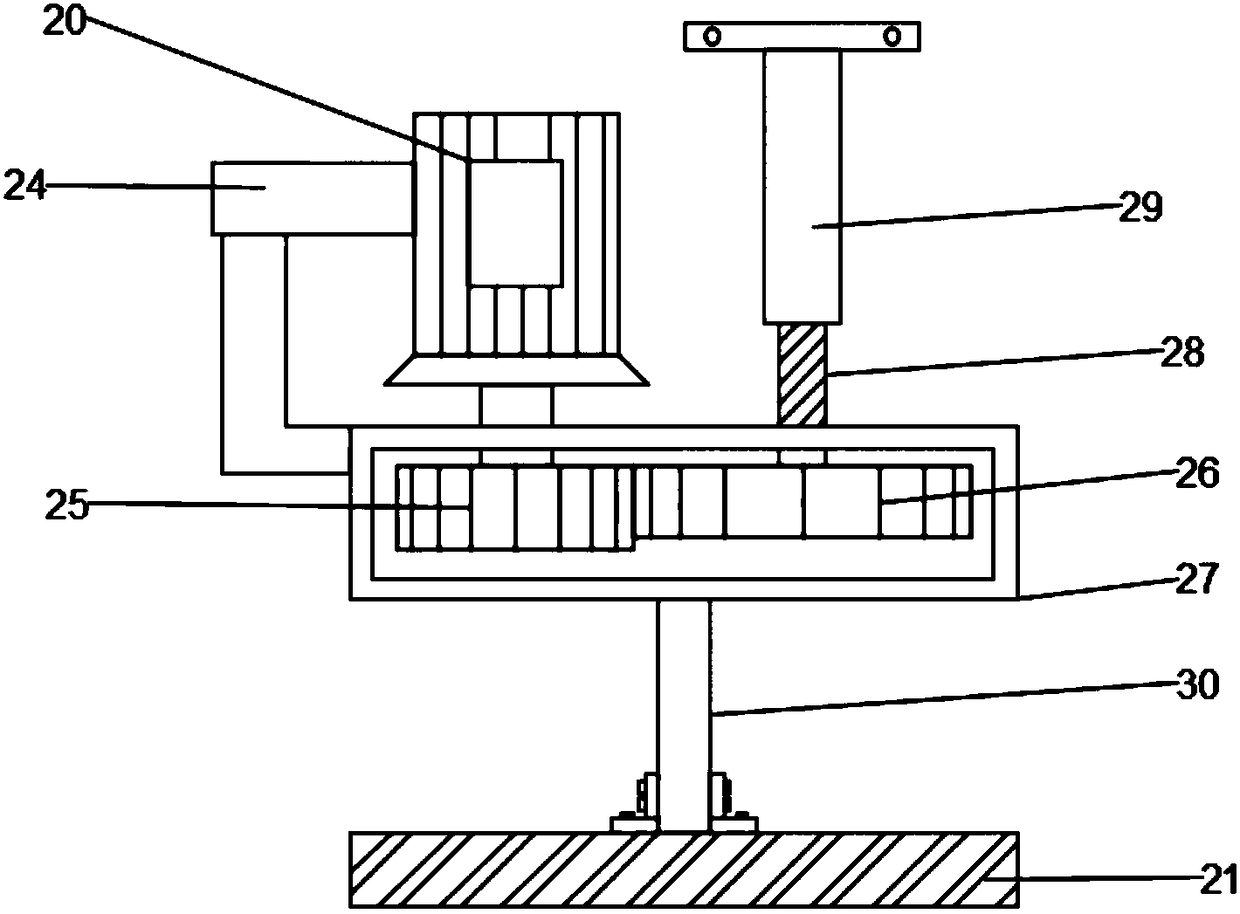

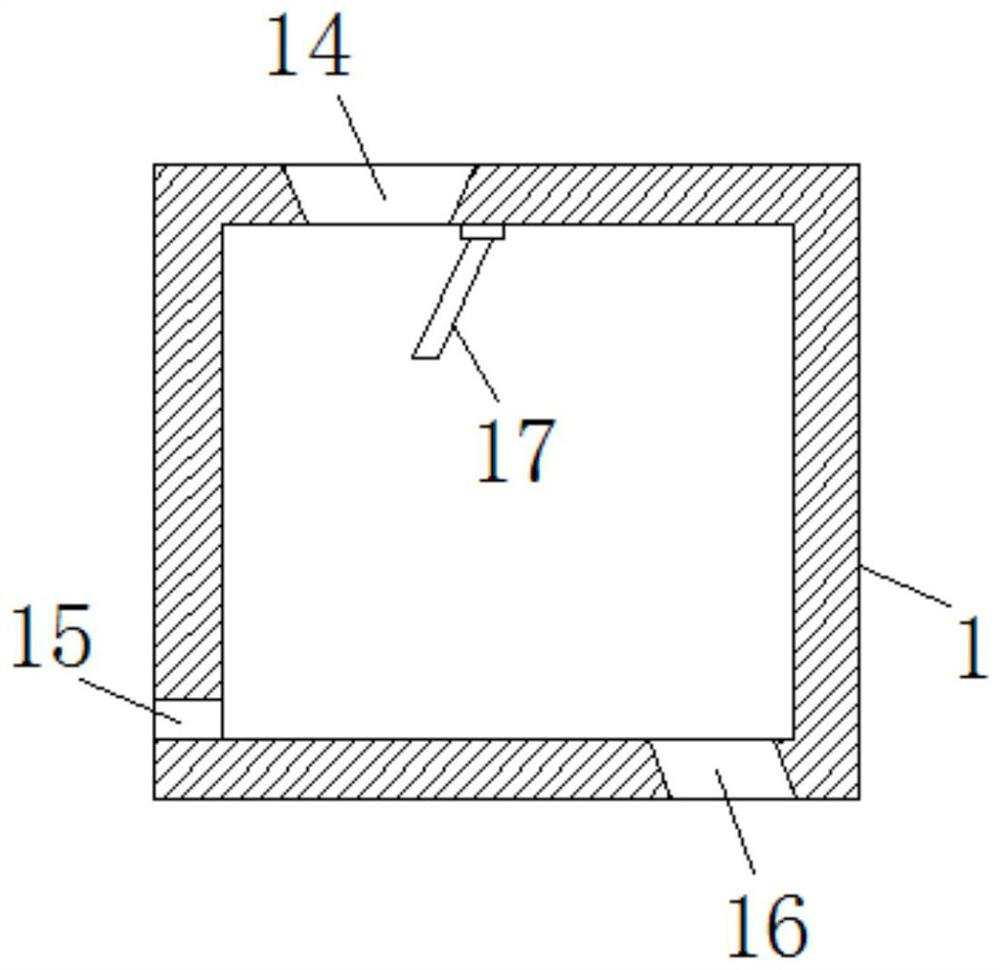

X-ray image destroying device for imaging department

InactiveCN107694715AAvoid secondary pollutionEasy to transportGrain treatmentsPressesFixed frameCoupling

The invention relates to a destroying device, in particular to an X-ray image destroying device for an imaging department. The X-ray image destroying device for the imaging department is capable of breaking waste X-ray images and achieving convenient recycling and fast treatment. To solve the technical problems, the X-ray image destroying device for the imaging department comprises a first motor,a fixing frame, a first bearing seat, a first rotary shaft, a spiral blade, a feeding hopper and the like. The first motor and a breaking groove are sequentially arranged on the lower side of the upper wall of the fixing frame from left to right. The first rotary shaft is arranged on the first motor through a coupling. According to the X-ray image destroying device for the imaging department, theX-ray image destroying device for the imaging department has the beneficial effects that the waste X-ray images can be broken, recycling is facilitated, and the treatment speed is fast; the waste X-ray images can be broken quickly by means of the equipment, the recycling efficiency can be improved, the X-ray images can be compressed after being broken, the space is saved, and the following transportation for centralized treatment is facilitated.

Owner:史志成

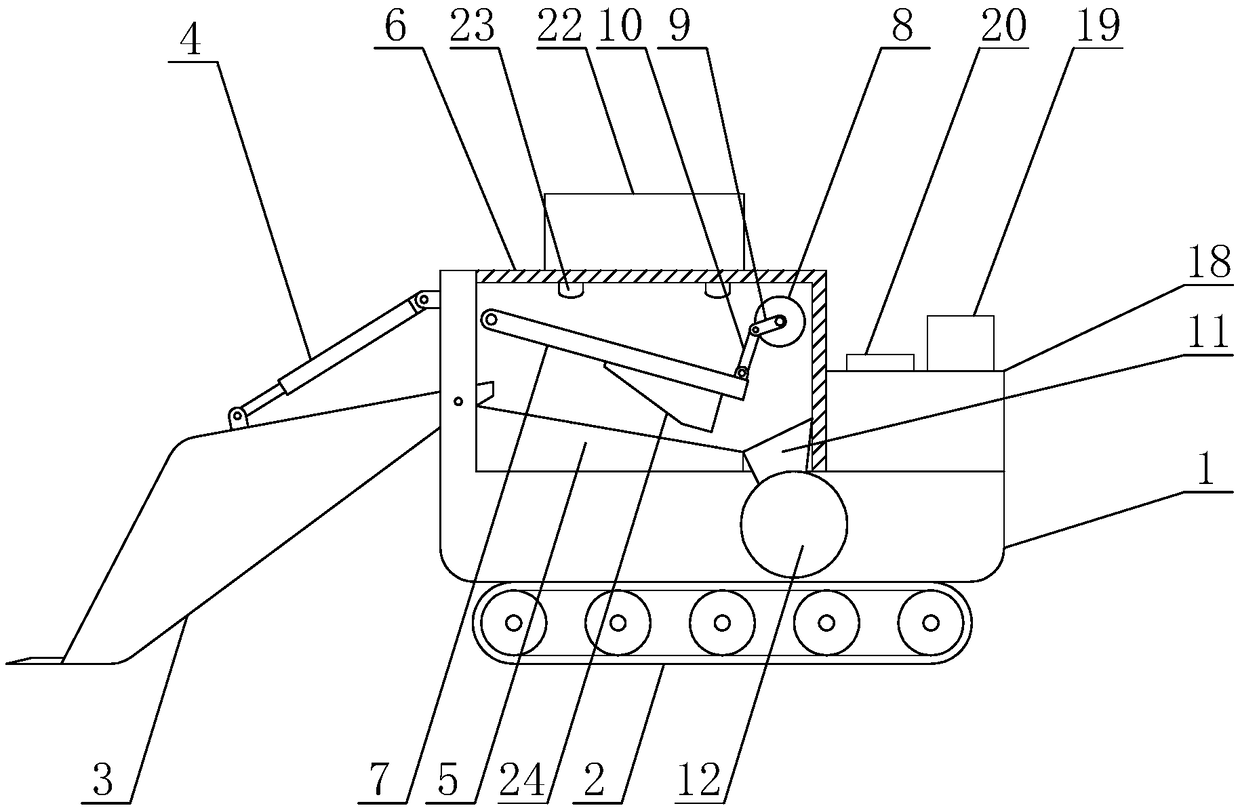

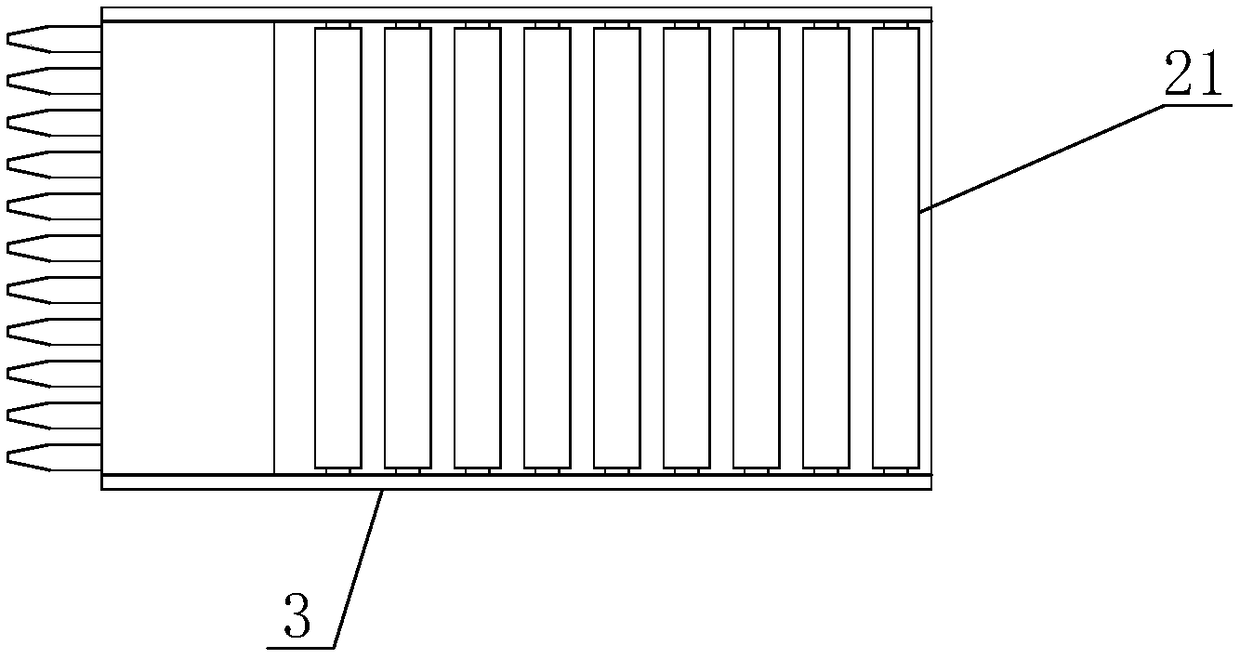

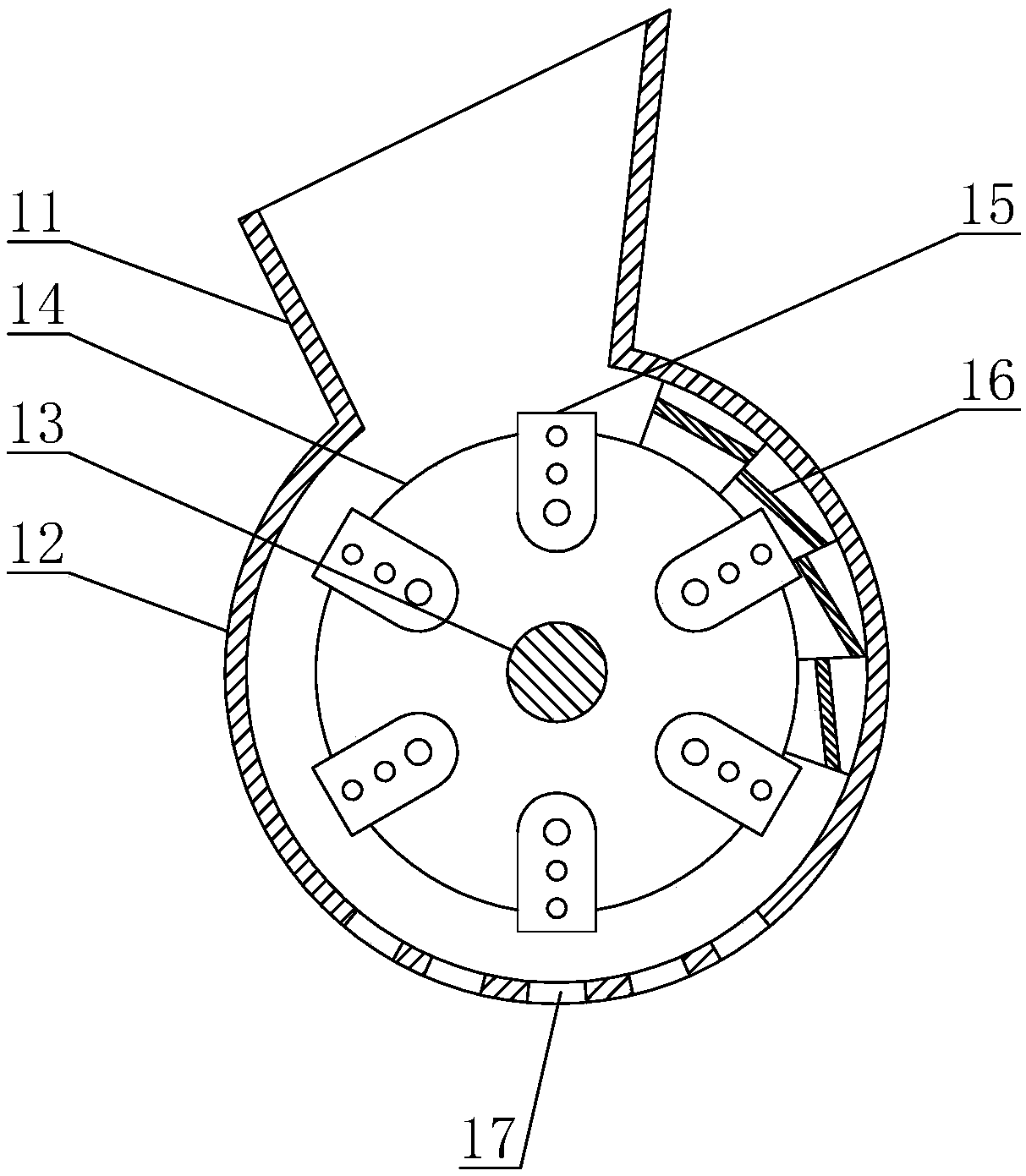

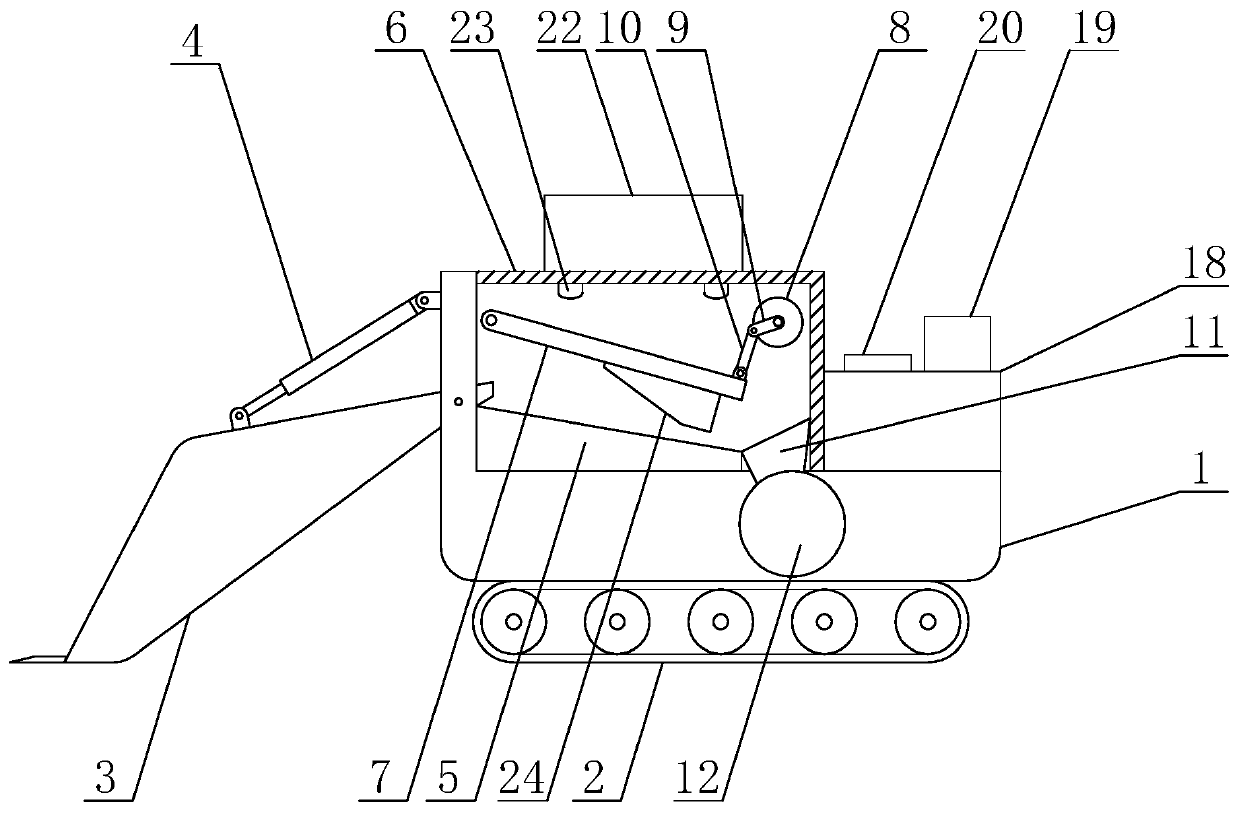

Building waste breaking device

The invention discloses a building waste breaking device which mainly relates to the field of building equipment. The building waste breaking device comprises a rack, a caterpillar drive mechanism isarranged at the bottom of the rack, a feeding bucket is arranged at one end of the rack, a fixed jaw plate is arranged on the side, close to the rack, of the feeding bucket, a protective cover matchedwith the fixed jaw plate is arranged on the rack, the upper portion in the protective cover is provided with a movable jaw plate matched with the fixed jaw plate, an inclined feeding pipe is arrangedat the end, far away from the feeding bucket, of the fixed jaw plate, a breaking shell is arranged at the bottom of the inclined feeding pipe, and an oil tank is arranged at the end, far away from the inclined feeding pipe, of the top of the rack. The building waste breaking device has the beneficial effects that the building waste can be quickly broken simply, output of the building waste is facilitated, the working load of workers can be reduced, and manpower cost is reduced.

Owner:田春玲 +2

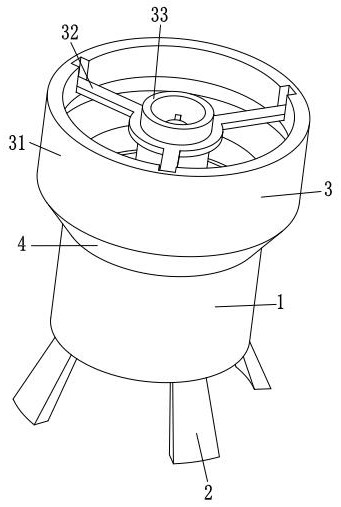

Crusher for cement production

ActiveCN112058402ARapid crushingImprove crushing efficiencySievingScreeningDrive shaftElectric machinery

The invention relates to the technical field of cement production, in particular to a crusher for cement production. The crusher comprises a crushing cylinder, wherein the top end of the crushing cylinder is fixedly sleeved with a cylinder cover, a feeding port is formed in the cylinder cover, a turning cover is mounted at the feeding port, a crushing mechanism is arranged in the crushing cylinder, the crushing mechanism comprises a motor frame fixedly mounted at the middle position of the top end of the cylinder cover, a first motor is fixedly mounted in the motor frame, a main driving shaftis vertically connected to the end of an output shaft of the first motor, the main driving shaft penetrates through the cylinder cover and extends into the crushing cylinder, a U-shaped frame is fixedly mounted at the end of the main driving shaft, and a grinding roller is rotationally mounted between the two ends of the inner side of the U-shaped frame. Compared with the prior art, the crusher has the advantages that the crushing efficiency is high, the crushing uniformity is good, a dust collection effect is achieved, the pollution of a working environment is lowered, and the waste of raw materials is relieved.

Owner:唐山兴唐建材有限公司

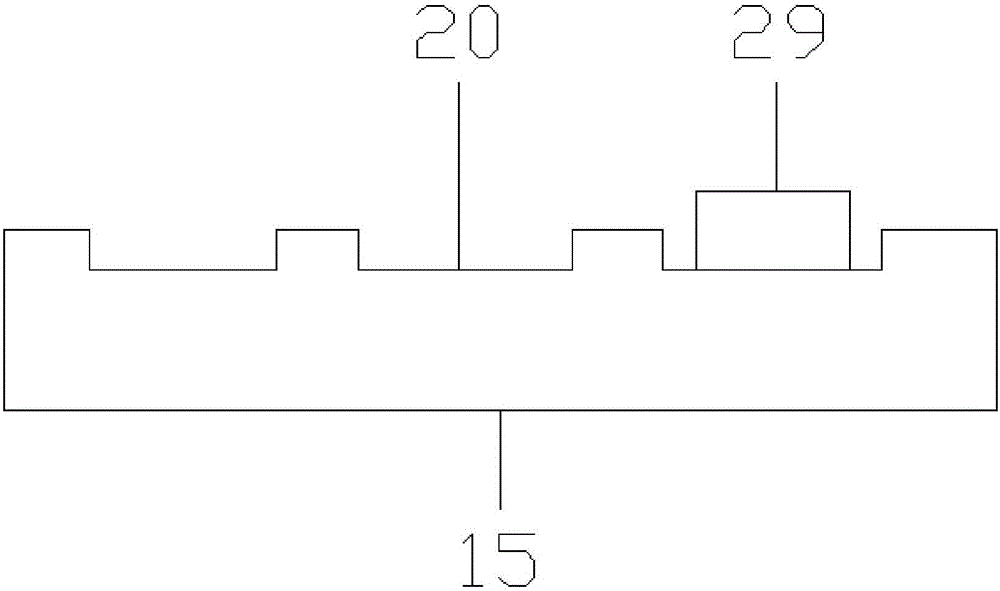

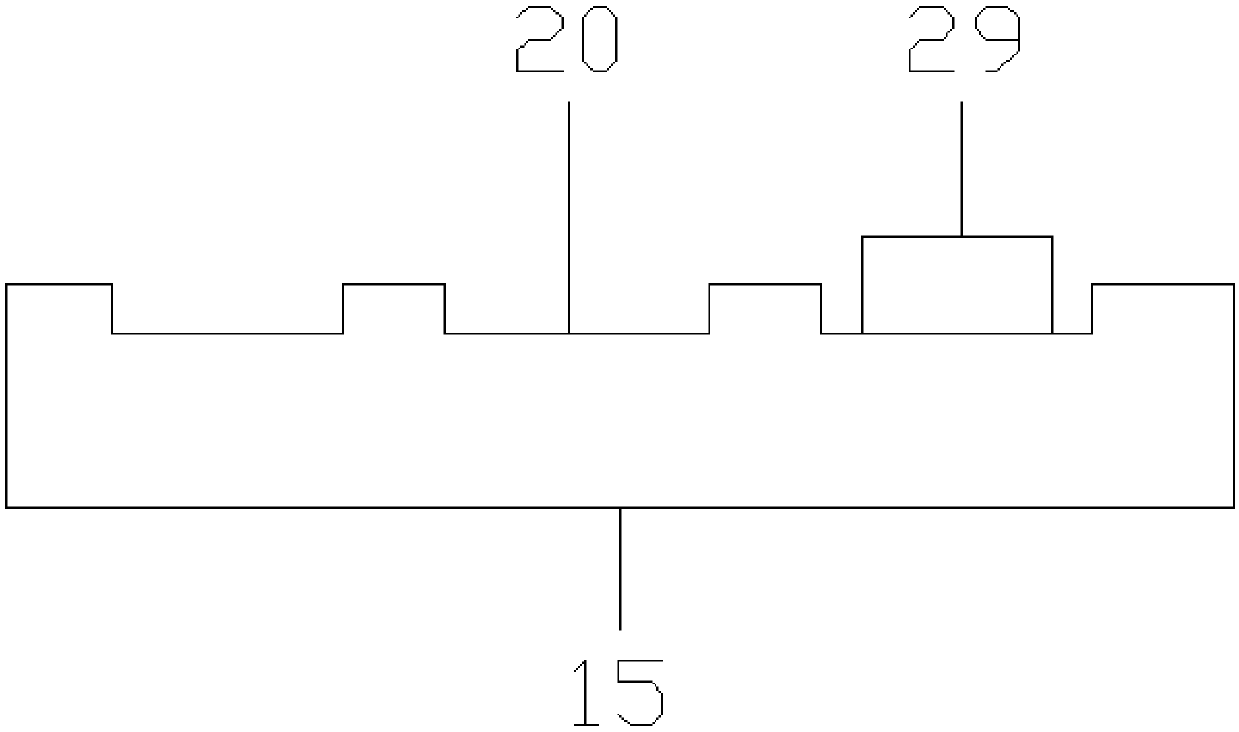

Pre-screening device for selected feed coal of coking coal

PendingCN113996387ARapid crushingEffective sieving operationSievingScreeningCoal briquetteMining engineering

The invention discloses a pre-screening device for selected feed coal of coking coal, and relates to the field of coal mining. The invention aims to overcome the problems that existing coking coal screening efficiency is low, a screen mesh is easy to block, and large-particle coal briquettes after screening cannot be subjected to secondary treatment and screening. According to a technical scheme in the invention, the pre-screening device comprises a screening box with an open top end, a limiting groove and a first discharging opening are formed in the two sides of the screening box correspondingly, a screening plate is movably installed in the screening box, the two ends of the screening plate penetrate through the limiting groove and the first discharging opening correspondingly, and a plurality of spring columns of the same structure are arranged between and fixedly connected with the bottom end of the screening plate and the inner wall of the bottom end of the screening box. According to the device, coking coal can be crushed and screened under a non-stop condition, screening holes are prevented from being blocked through vertical vibration of the screening plate, and large-particle coal briquettes which are not completely crushed can be subjected to secondary treatment, so the screening efficiency of the coking coal is effectively improved.

Owner:刘思思

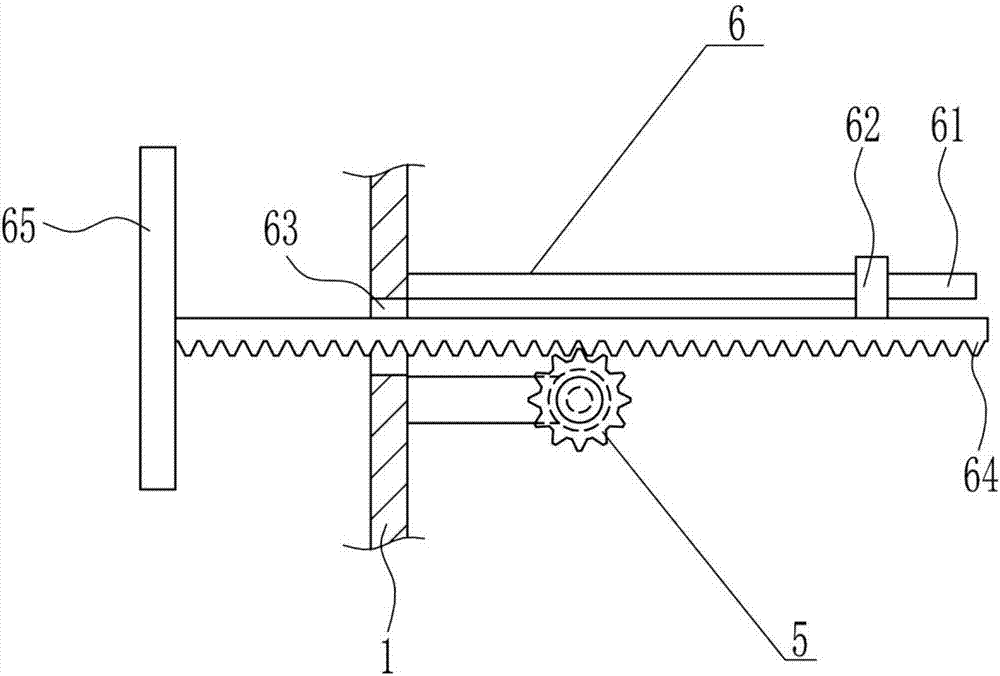

Floating type river channel sewage cleaning device and method

InactiveCN112878287ARapid crushingQuick collectionWater cleaningWaterborne vesselsRiver routingGear drive

The invention belongs to the technical field of river channel sewage cleaning, and particularly relates to a floating type river channel sewage cleaning device. The floating type river channel sewage cleaning device comprises a ship body mechanism, an icebreaking mechanism, a melting mechanism, a collecting mechanism and a gathering mechanism, the icebreaking mechanism is fixedly arranged at the outer side of the ship body mechanism and is used for breaking the whole ice layer on the river surface, and the melting mechanism used for melting dirt and garbage in floating ice is fixedly installed in an inner cavity of the ship body mechanism. A gathering groove is fixedly formed in the outer side of a ship body, a water drainage opening for reducing water pressure is formed in the outer side of the gathering groove, a component is arranged in the ship body, and meanwhile two rotating wheels outside a metal rod are driven by gears fixedly connected to the two ends of the exterior of the component, and in the process that a middle rotating shaft drives the metal rod, a crushing part for crushing floating ice is fixedly mounted outside the metal rod, so that a floating ice caking layer can be quickly crushed, and the floating ice and the dirt and garbage are moved to the position of a rectangular notch in the bottom of the inner side of the gathering groove under gathering of the gathering groove.

Owner:温州骆孚农业科技有限公司

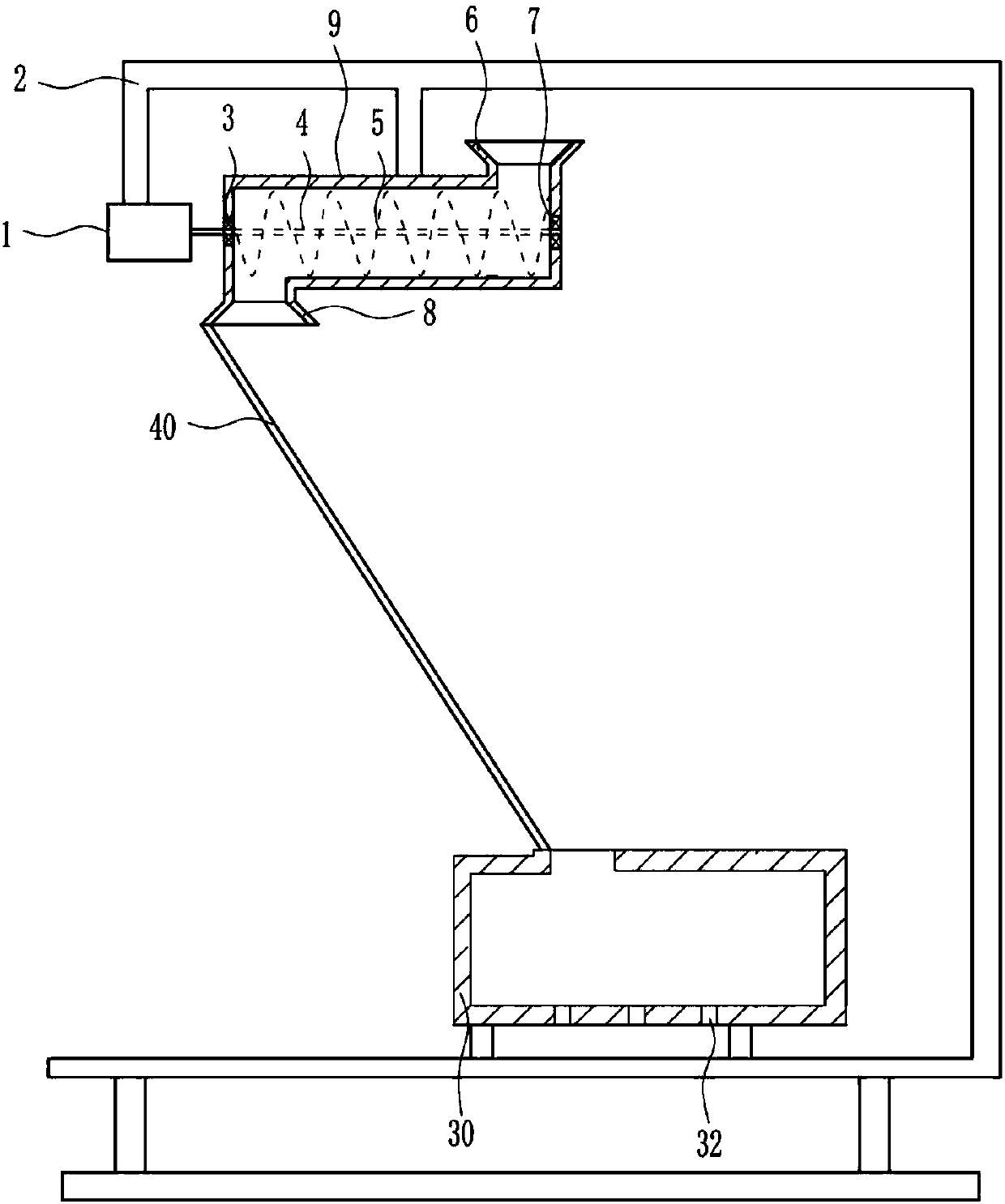

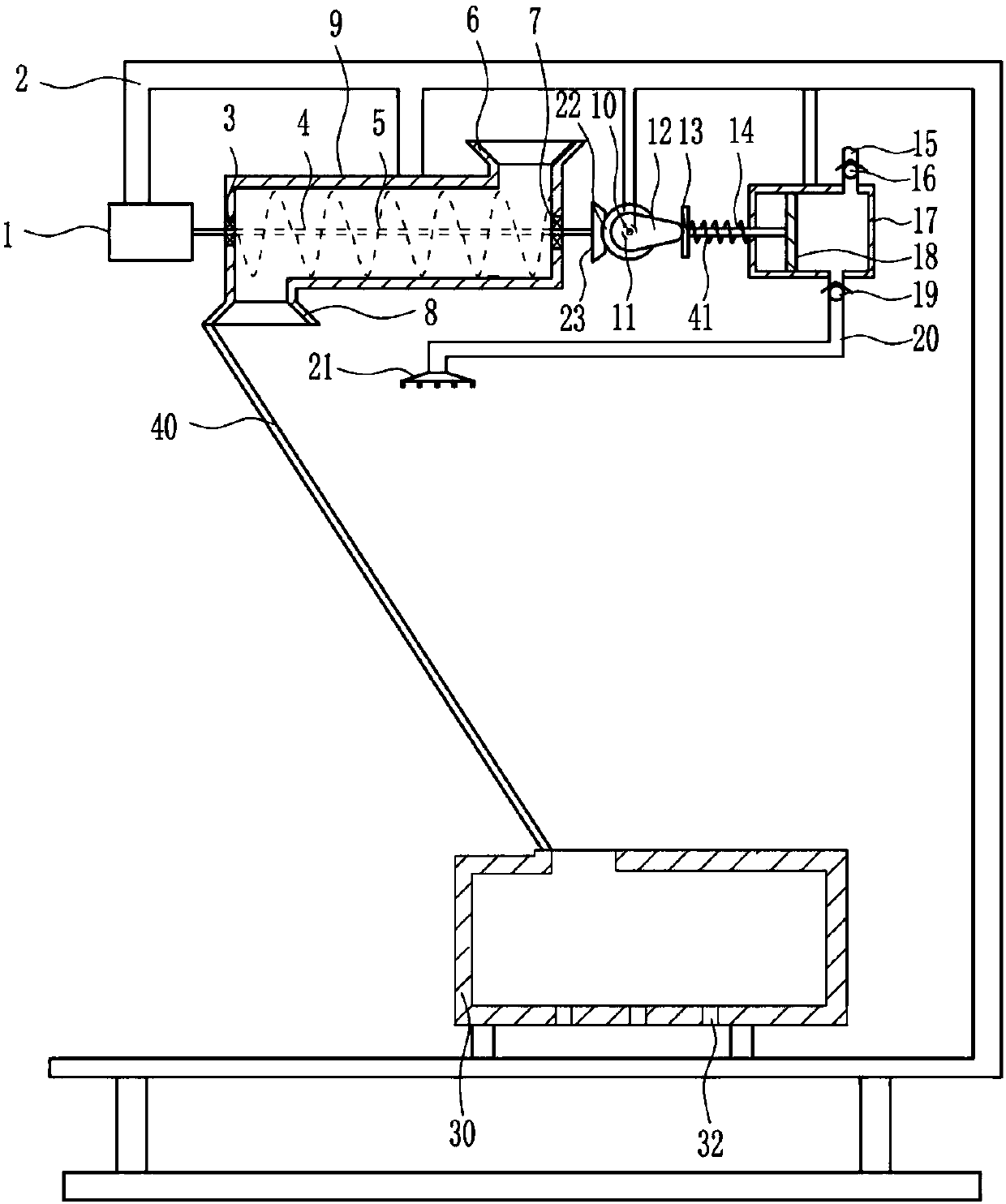

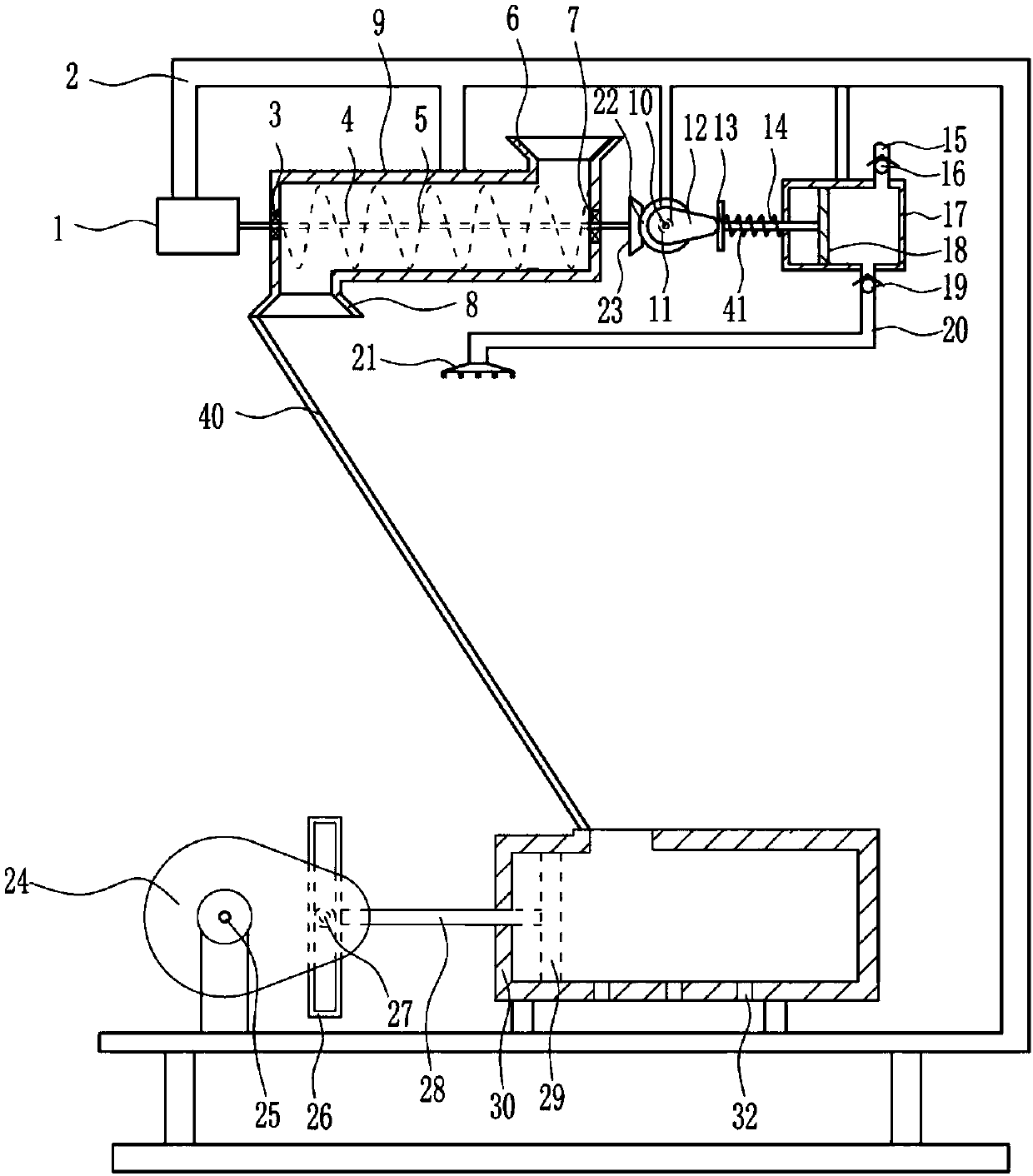

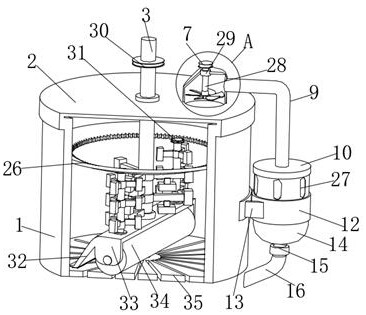

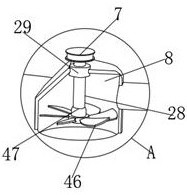

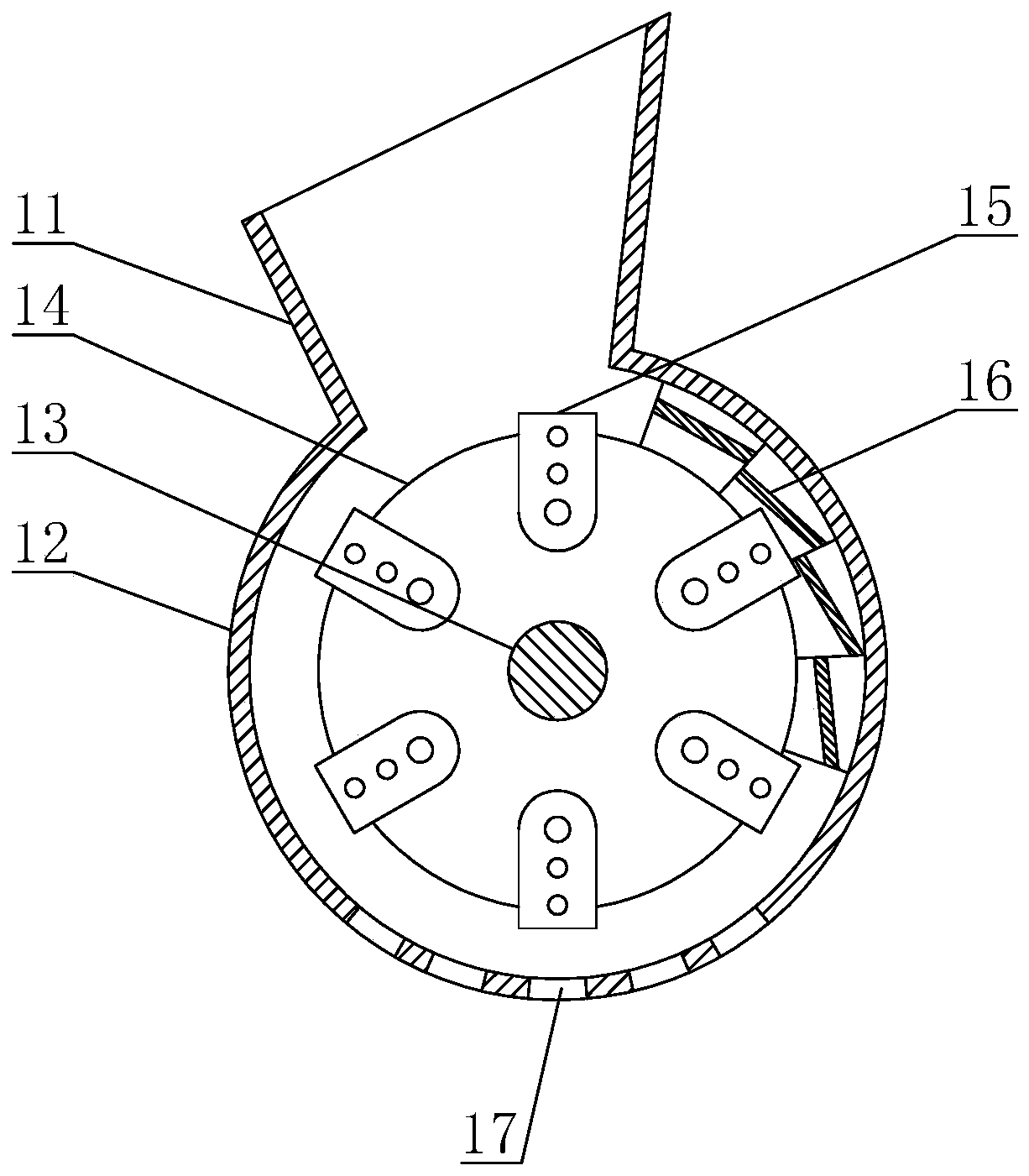

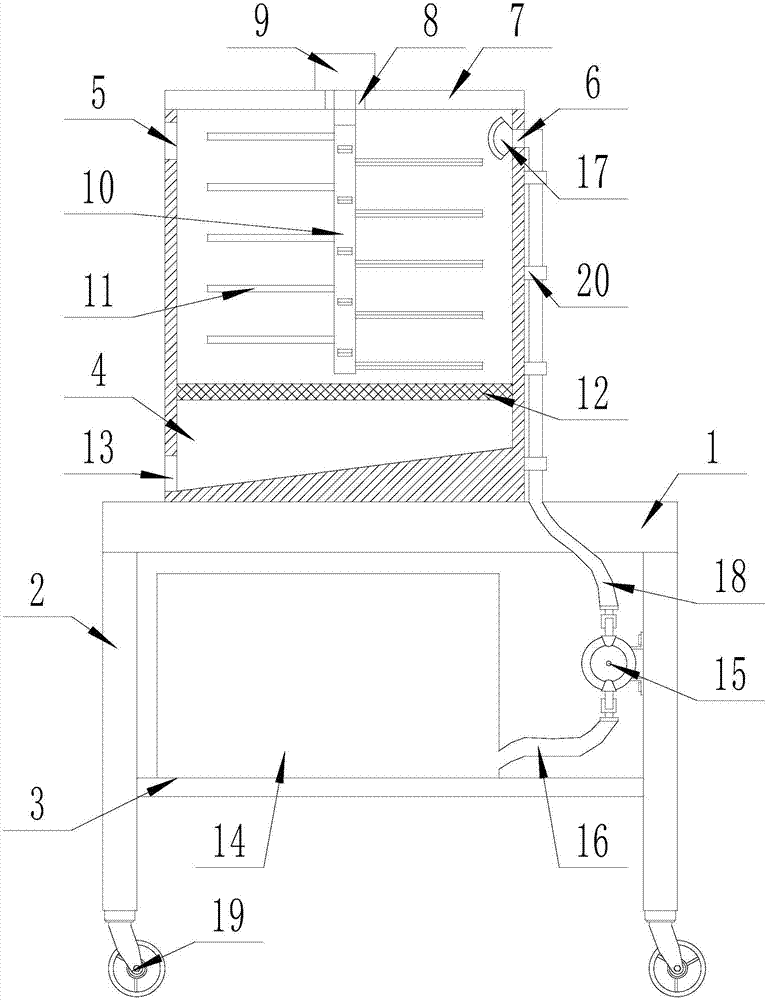

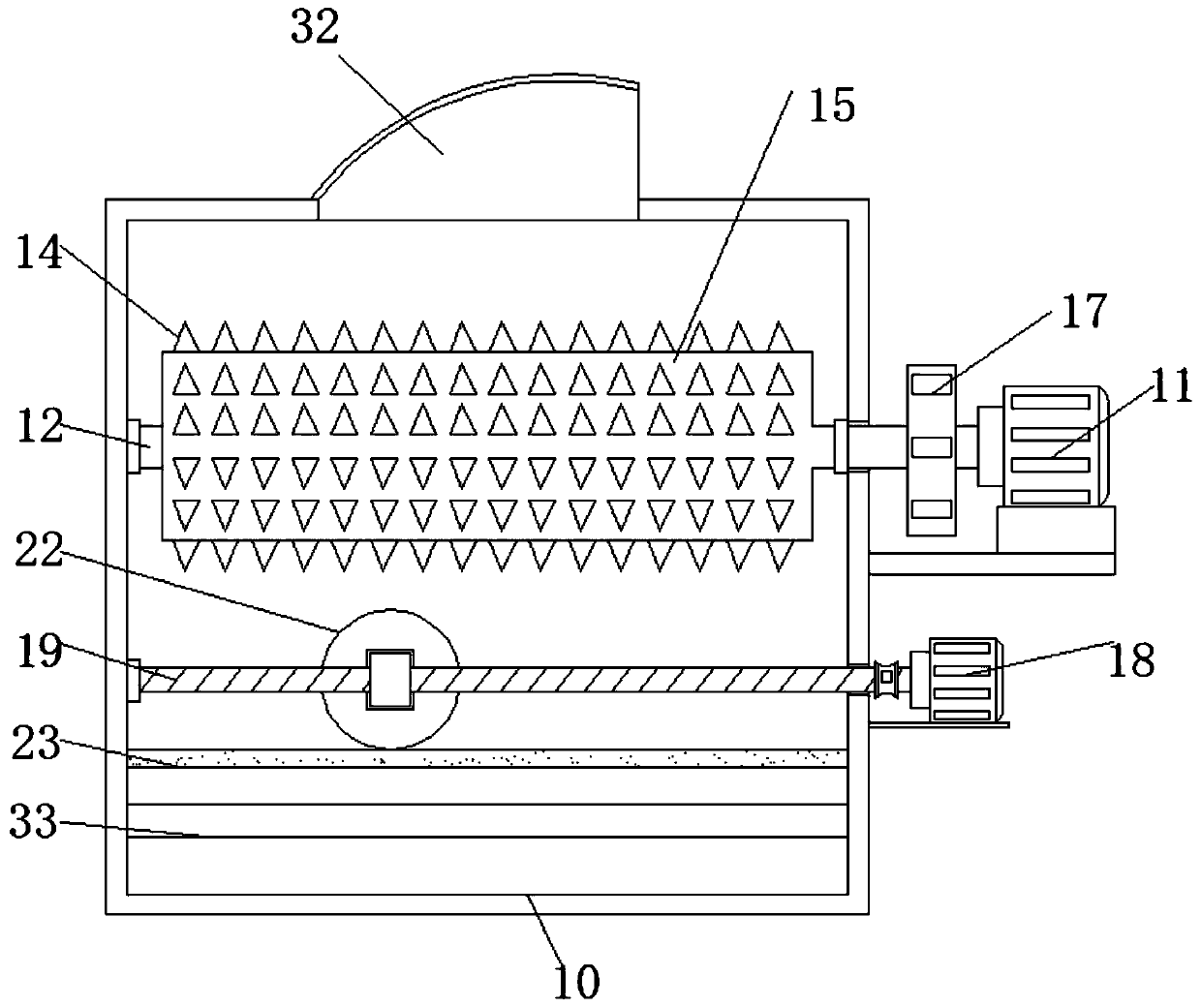

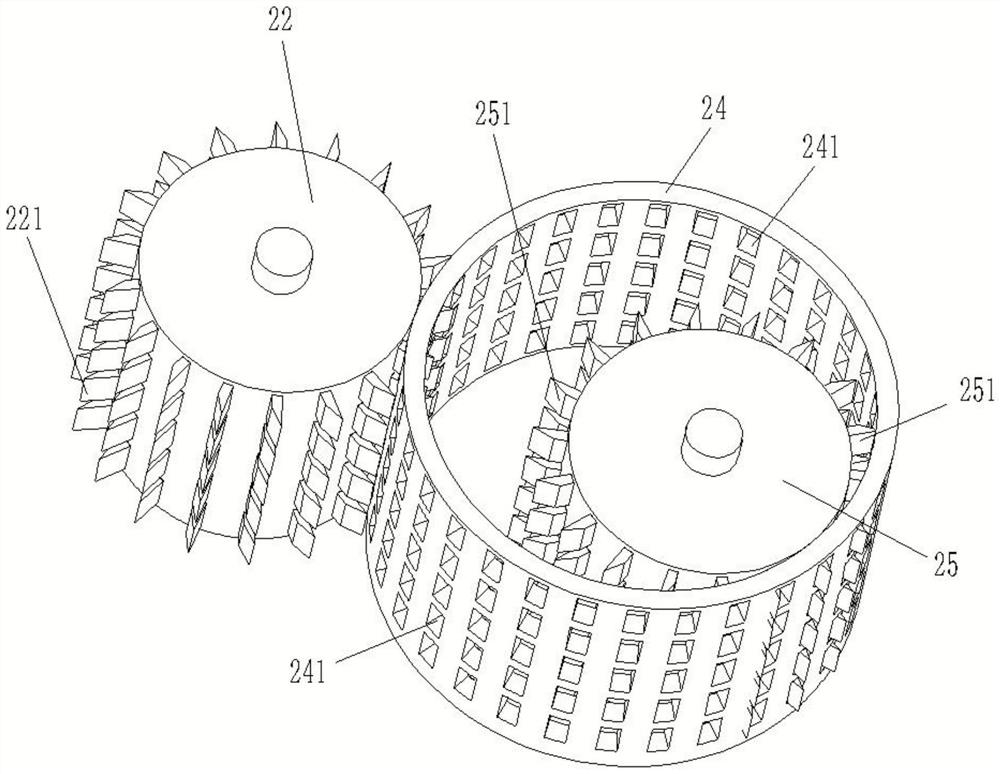

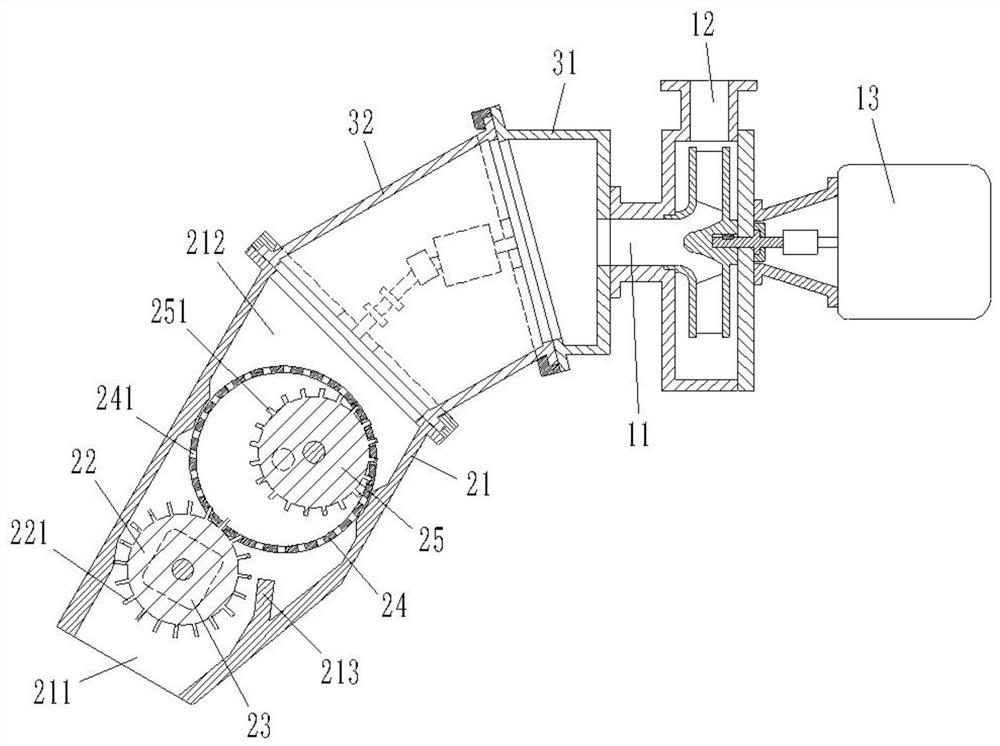

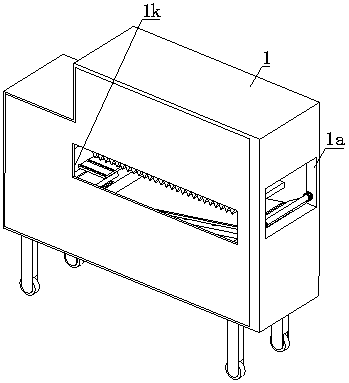

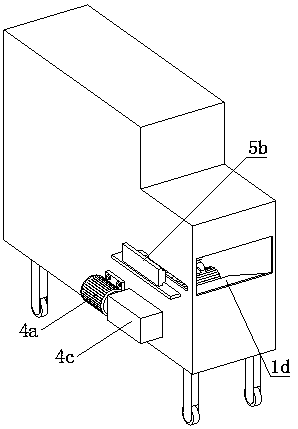

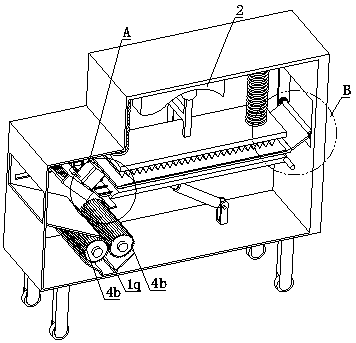

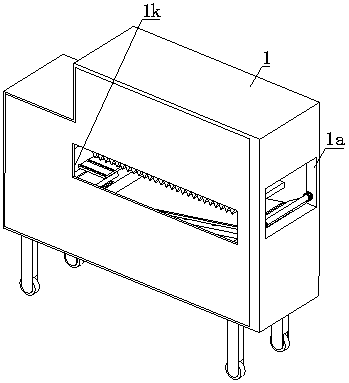

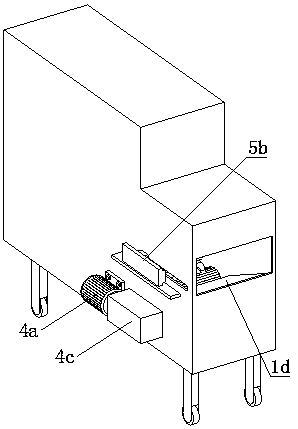

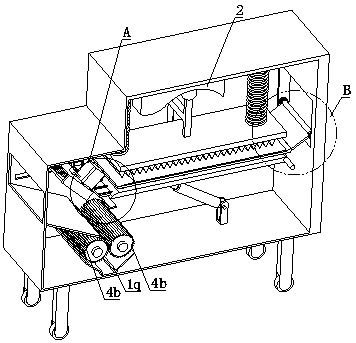

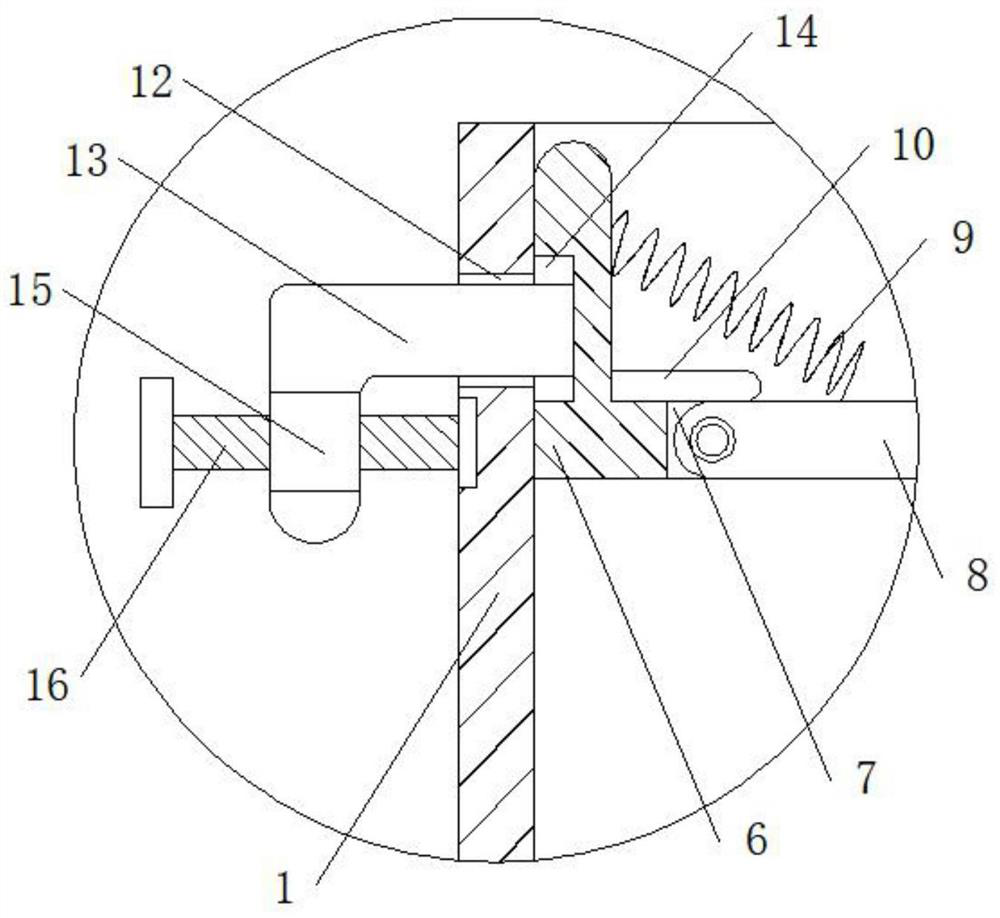

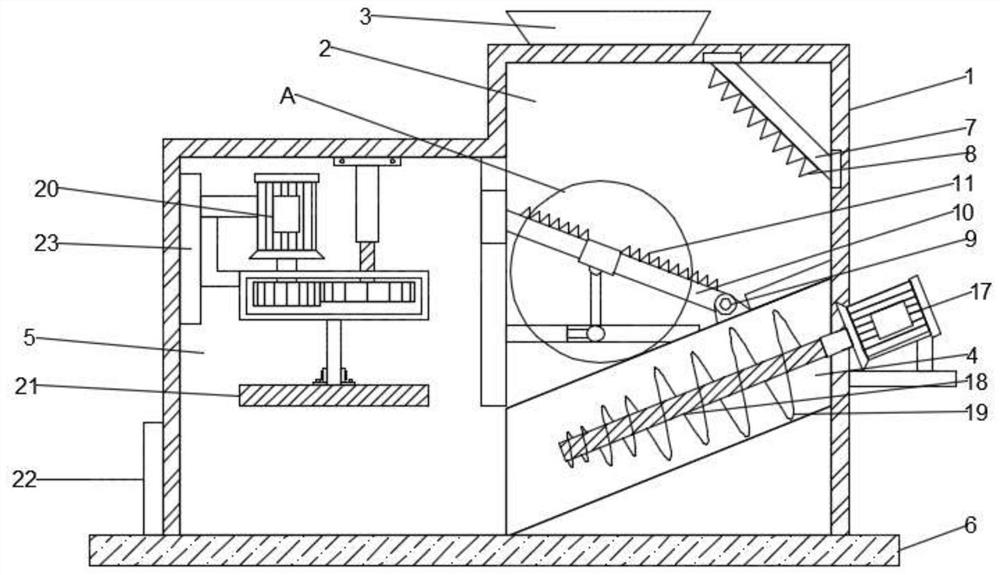

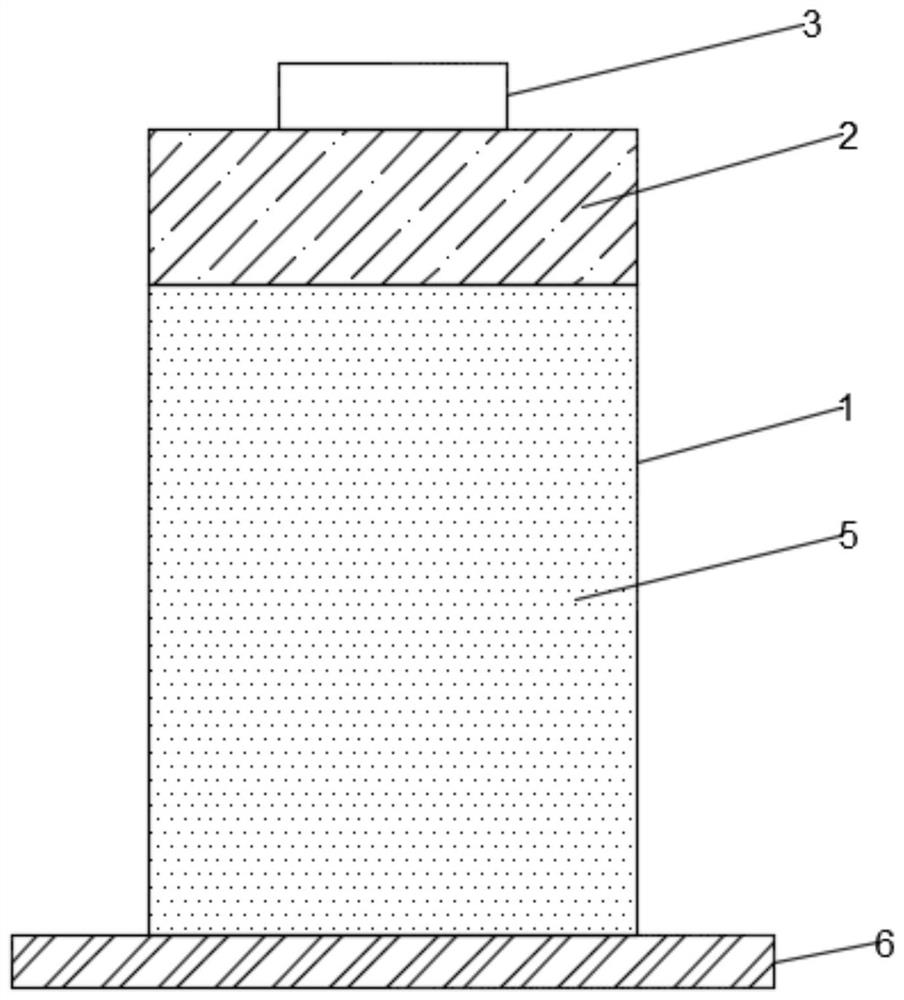

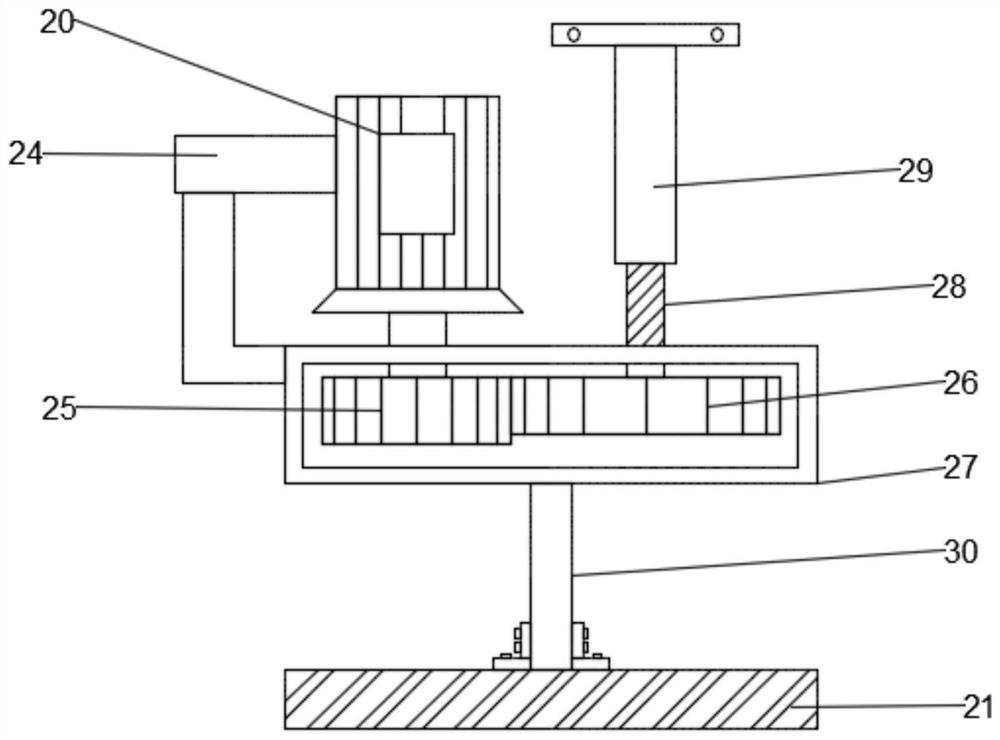

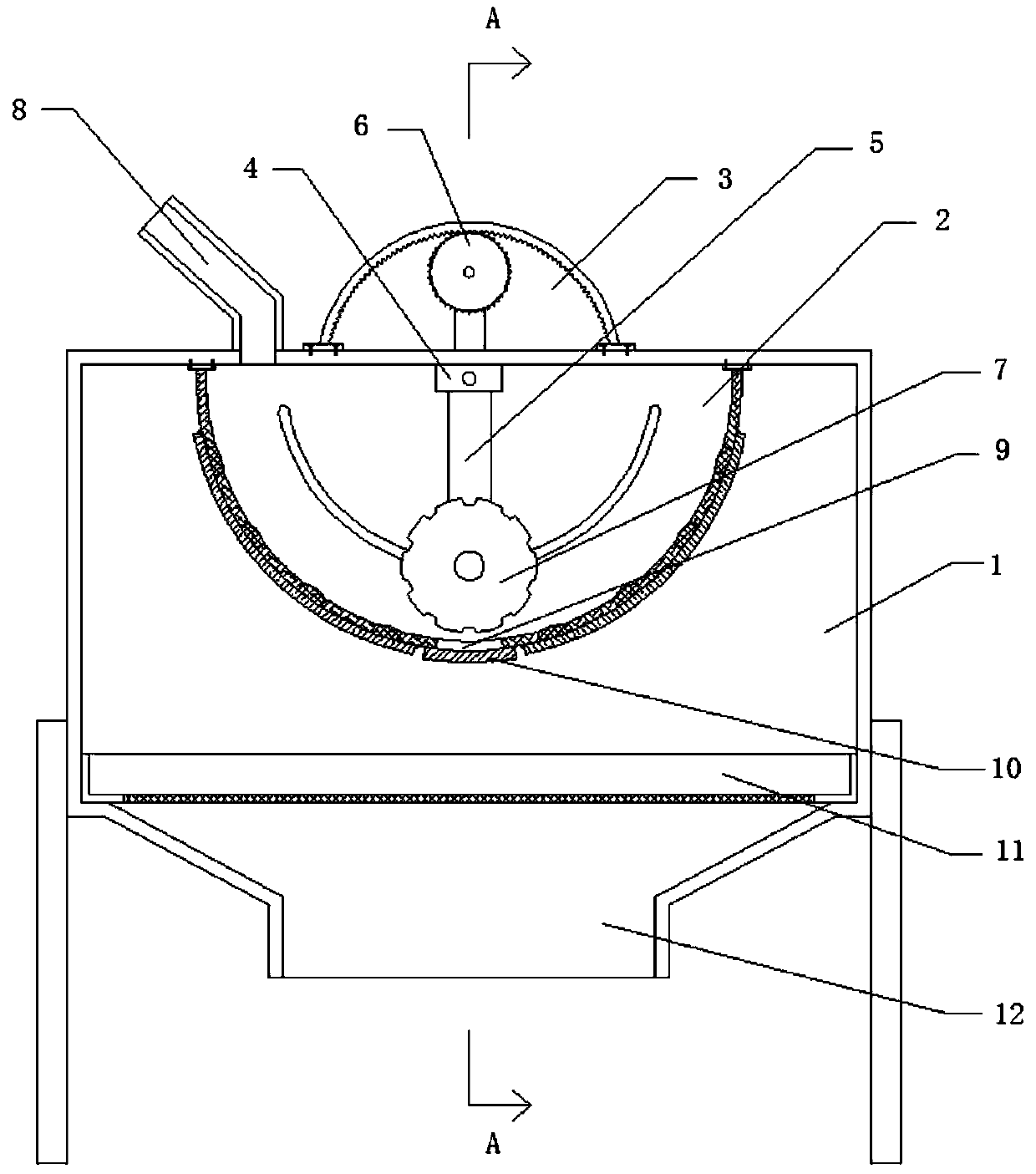

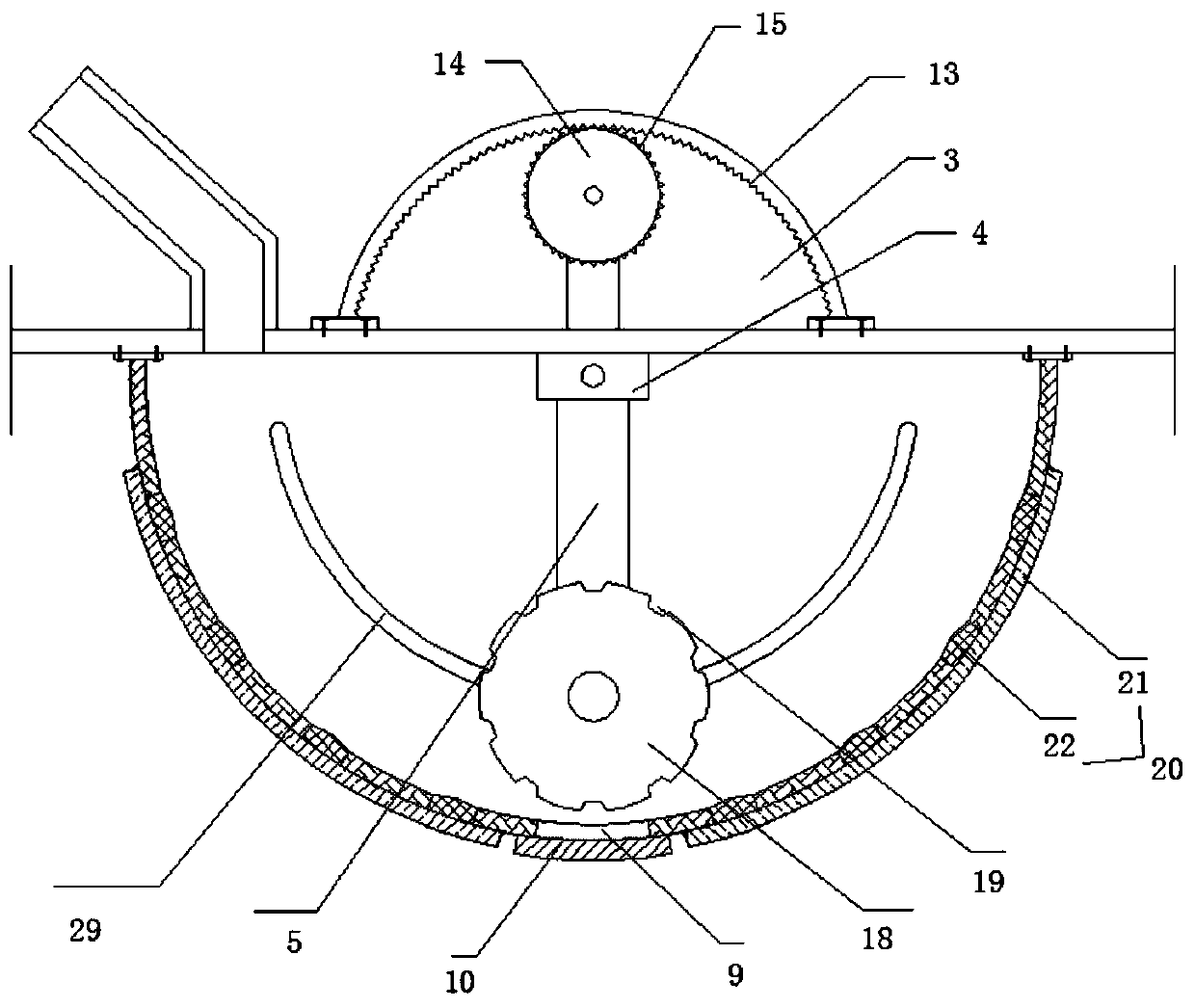

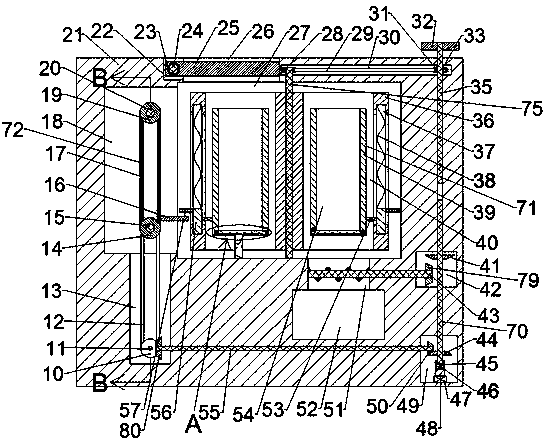

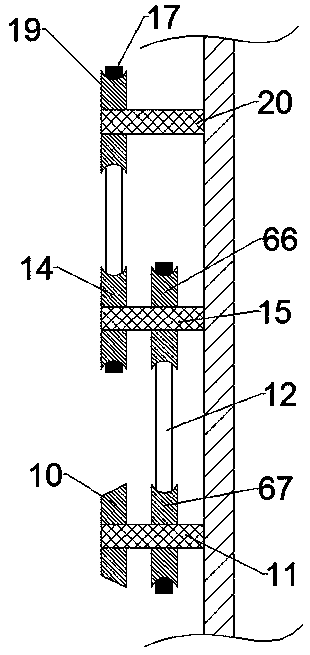

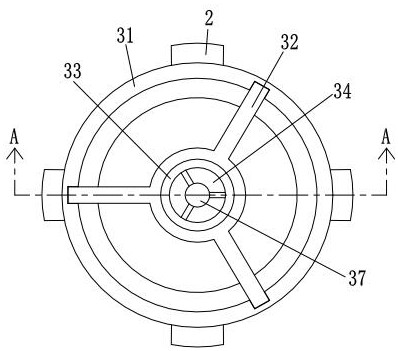

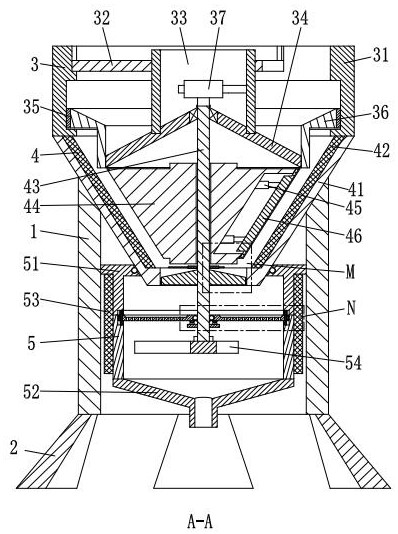

A waste material treatment device for cultural media

ActiveCN106984377BRapid crushingSmall footprintGrain treatmentsEnvironmental engineeringMaterials processing

The invention relates to a material processing device for cultural media, in particular to a waste material processing device for cultural media. The technical problem to be solved by the present invention is to provide a waste material processing device for cultural media that can crush waste materials, reduce the occupied space of waste materials, reduce labor intensity of workers, and improve crushing efficiency. In order to solve the above technical problems, the present invention provides such a waste material processing device for cultural media, including a base, etc.; the top of the base is connected with an n-shaped plate by bolts, and the top of the base inside the n-shaped plate is connected with a collection frame by bolts , the middle part of the n-shaped plate is provided with a rotating device, the rotating device is connected with a screen frame, and the n-shaped plate above the screen frame is provided with a first processing device. The present invention can rapidly crush waste materials through the first processing device and the second processing device.

Owner:新昌县皇骐电子科技有限公司

A construction waste crushing device

InactiveCN108325725BPromote fragmentationRapid crushingGrain treatmentsArchitectural engineeringConstruction waste

Owner:田春玲 +2

Macadam processing equipment for bridge engineering construction

ActiveCN108570906AAchieve brokenRealize extrusion crushingRoads maintainenceBridge engineeringCrushed stone

The invention discloses macadam processing equipment for bridge engineering construction. The macadam processing equipment comprises a shell, a crushing chamber, an extrusion conveying chamber and a rolling chamber, wherein the crushing chamber is arranged at the upper right side of the shell, a feeding inlet is arranged at the left side of the top of the crushing chamber, and the crushing chamberis in communication with the feeding inlet; the extrusion conveying chamber is obliquely located at the bottom of the right side of the shell, the right side of the top of the extrusion conveying chamber is in communication with the right side at the bottom of the crushing chamber, the rolling chamber is located on the left side of the bottom of the shell, the left side of the extrusion conveyingchamber is in communication with the rolling chamber, and a second working motor is located on the top of the rolling chamber; a first connecting rod is welded on the left side of the second workingmotor, a vertical guide rail is fixedly welded at the upper part of the left side wall of the rolling chamber, and the left end of the first connecting rod extends into the vertical guide rail. The macadam processing equipment has high working efficiency, saves time and labor, and can carry out multi-stage pulverization on stones and lower the difficulty of crushing stones.

Owner:天长市富春建筑工程有限公司

Novel environment-friendly kraft paper

InactiveCN107287954ASave human resourcesReduce labor intensityPaper recyclingCellulose treatment using microorganisms/enzymesElectric machineryEngineering

The invention discloses novel environment-friendly kraft paper. The novel environment-friendly kraft paper comprises a workbench. Support legs are installed at four corners of the bottom of the workbench. The surface of the inner side of the support legs is fixedly provided with a support plate. The support plate is provided with a spraying device. The workbench is provided with a stirring and grinding device. The stirring and grinding device is formed by a stirring barrel installed on the workbench, a feeding opening installed at one side of the stirring barrel, a liquid inlet installed at the other side of the stirring barrel, a barrel cover moveably installed on the stirring barrel, a bearing installed at the center of the barrel cover, a rotation motor installed on the barrel cover and of which the rotation end is inserted in the bearing, a rotation rod installed in the stirring barrel and of which one end is fixedly connected with the rotation motor, multiple blades installed on the surface of the rotation rod side, a sieving net fixedly installed at the bottom of the inner side of the stirring barrel and positioned under the rotation rod and a discharge opening installed at one side of the bottom of the stirring barrel. The novel environment-friendly kraft paper has the beneficial effects of simple structure and strong practicability.

Owner:刘硕

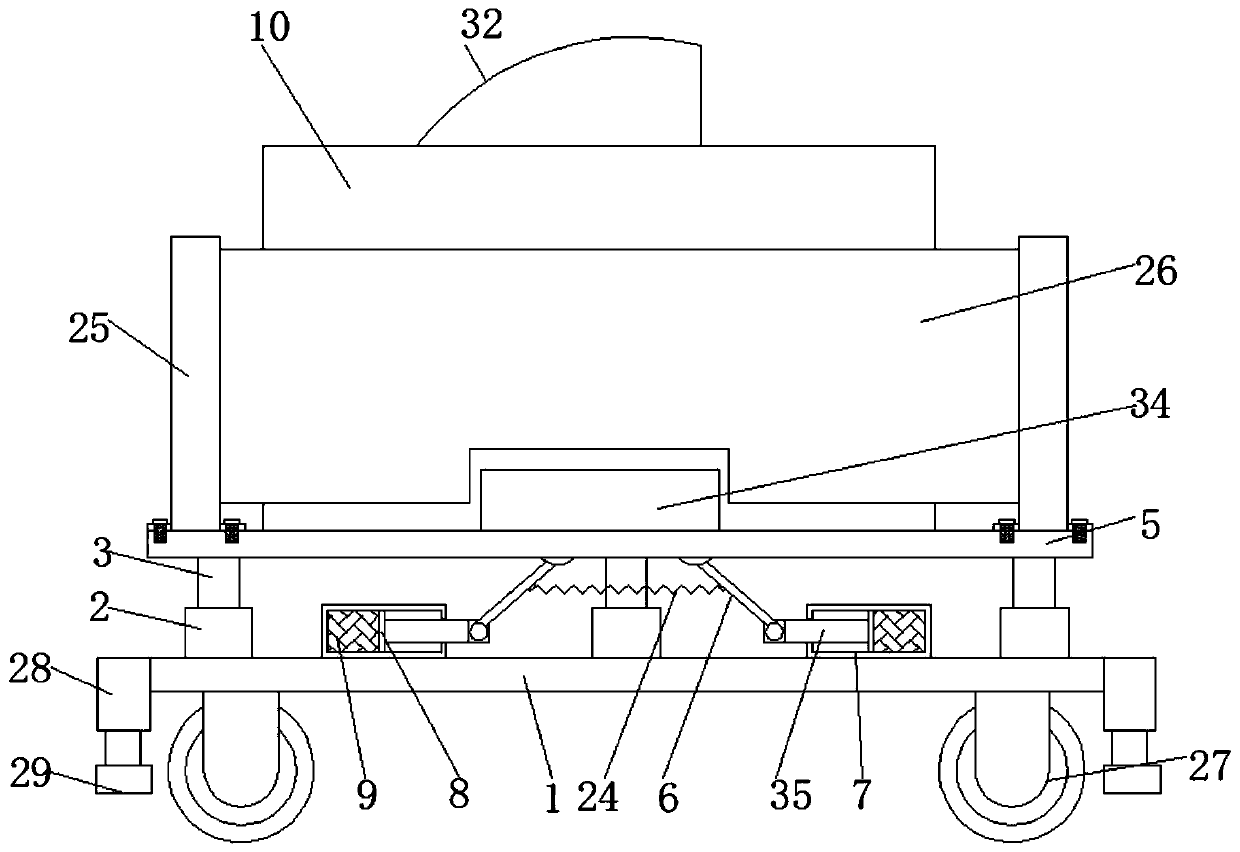

Movable crushing device

The invention relates to the technical field of crushing devices, and discloses a movable crushing device. The movable crushing device comprises a bottom plate, wherein three inner hollow sleeves arefixedly connected to the upper surface of the bottom plate, springs are arranged in the three sleeves, supporting rods are fixedly connected to the top ends of the three springs, a mounting plate is fixedly connected between the upper surfaces of the three supporting rods, and two connecting rods are hinged to the lower surface of the mounting plate. When the movable crushing device is used, crushed materials fall on a filter plate under the action of gravity, a second driving motor drives a first threaded rotating shaft to rotate, two transmission chain wheels and a transmission chain drive asecond threaded rotating shaft to rotate synchronously so that two threaded sleeves can move synchronously, then the threaded sleeves drive a grinding wheel to move so that the materials can be crushed, and finally the crushed materials are discharged through a discharging mouth under the action of a flow guide plate, and accordingly the crushing effect is further improved.

Owner:江苏华正数控机械有限公司

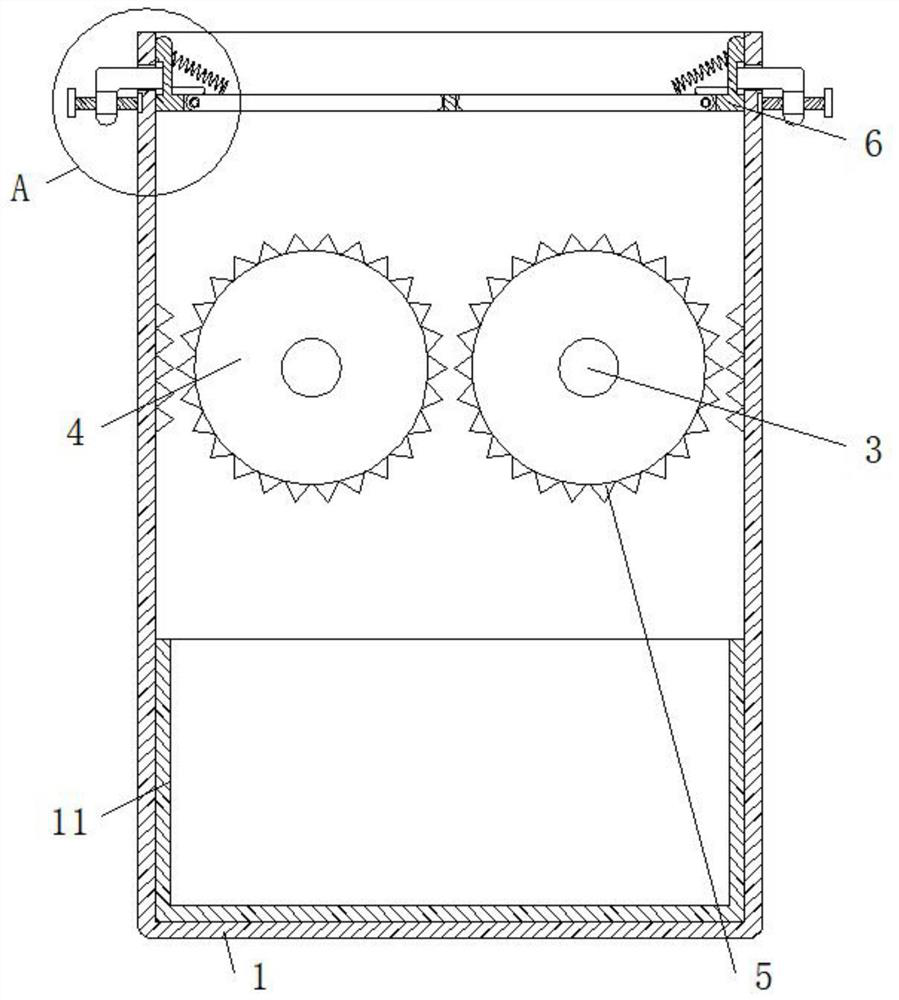

Equipment for classifying and recovering metals from construction waste

ActiveCN110433900AClear classificationRapid crushingMagnetic separationGrain treatmentsEngineeringMetal

The invention relates to the field of construction waste classification and recovery, in particular to equipment for classifying and recovering metals from construction waste. The equipment comprisesa shell, a crushing mechanism, a classification mechanism, a conveying mechanism, a separating mechanism and a supporting mechanism, wherein the conveying mechanism is horizontally arranged, the separating mechanism is vertically arranged, the supporting mechanism is vertically arranged, the crushing mechanism comprises a feeding chamber, a crushing chamber, a discharging chamber, a first crushingwheel, a second crushing wheel, a first motor, a second motor, a port, a first funnel plate and a second funnel plate, the first motor and the second motor are both horizontally arranged, and the classification mechanism comprises a first inclined plate, attracting blades and a third motor. According to the equipment for classifying and recovering the metals from the construction waste, the construction waste can be quickly crushed, the crushed construction waste is classified according to the permeability and non-permeability property, and then is classified according to the metal and non-metal property, the construction waste is classified clearly, the recovering rate is high, the operation steps are simplified, and safety and environmental protection are realized.

Owner:丽水市正明机械科技有限公司

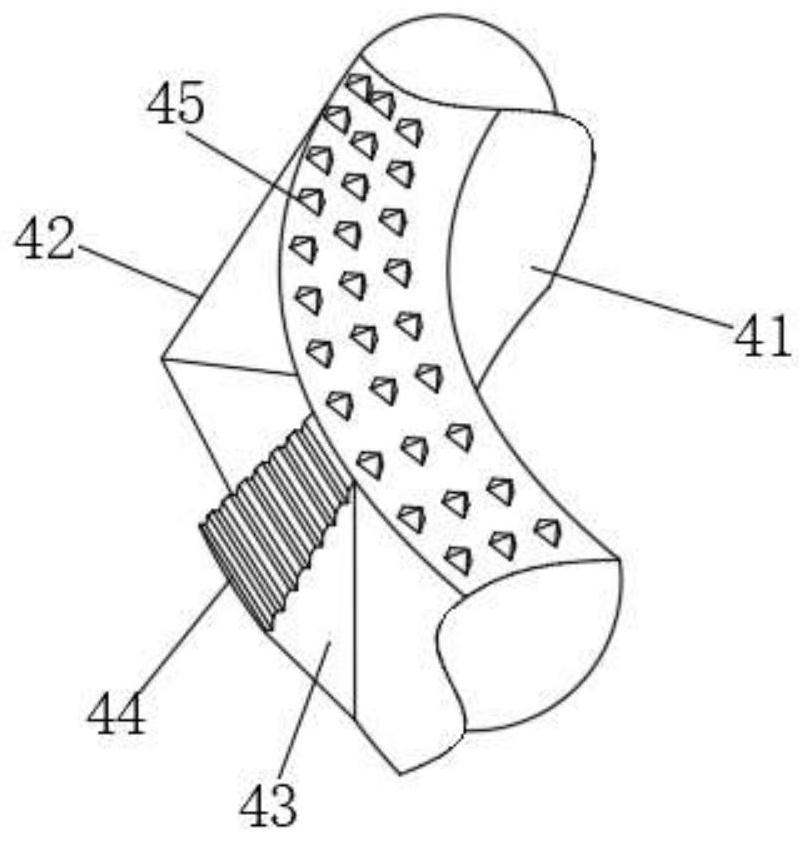

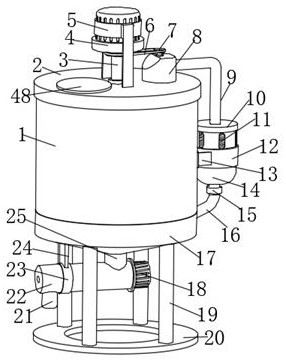

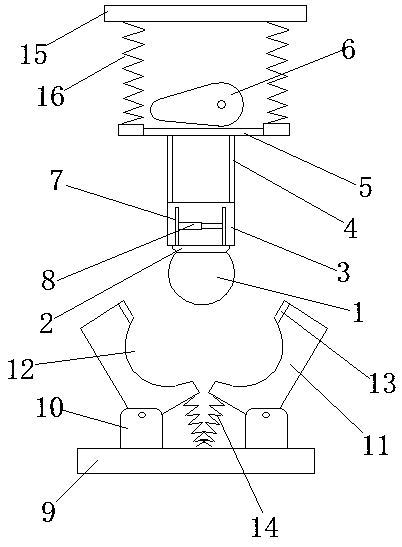

Quantitative and automatic distiller's yeast feeding mechanism for Baijiu fermentation

InactiveCN113104614ARapid crushingImprove crushing efficiencyAlcoholic beverage preparationLoading/unloadingBiotechnologyYeast

The invention discloses a quantitative automatic distiller's yeast feeding mechanism for Baijiu fermentation, relates to the technical field of Baijiu fermentation, and aims to solve the problems that during Baijiu fermentation in the prior art, distiller's yeast needs to be crushed manually, the manual feeding efficiency is low, the distiller's yeast cannot be uniformly dispersed, and uniform and rapid fermentation is not facilitated. The following scheme is proposed, and the quantitative automatic distiller's yeast feeding mechanism comprises a barrel body; a barrel cover is arranged at the top of the barrel body; first supporting rods are fixedly connected to the two sides of the top of the barrel cover; fixed plates are fixedly connected to the top ends of the first supporting rods; stirring and vibrating mechanisms are arranged at the bottoms of the fixed plates; two elastic rods are movably arranged in the fixed plates in a sleeved mode, and extrusion balls are fixedly connected to the bottoms of the elastic rods; and feeding pipes are fixedly connected to the two sides of the barrel body. According to the quantitative automatic distiller's yeast feeding mechanism for the Baijiu fermentation provided by the invention, the distiller's yeast can be conveniently and automatically crushed when needed, the crushing efficiency is improved, automatic quantitative adding is also facilitated, fermentation raw materials are stirred during adding, uniform adding of the distiller's yeast is facilitated, and therefore efficient fermentation is guaranteed.

Owner:沈卸妹

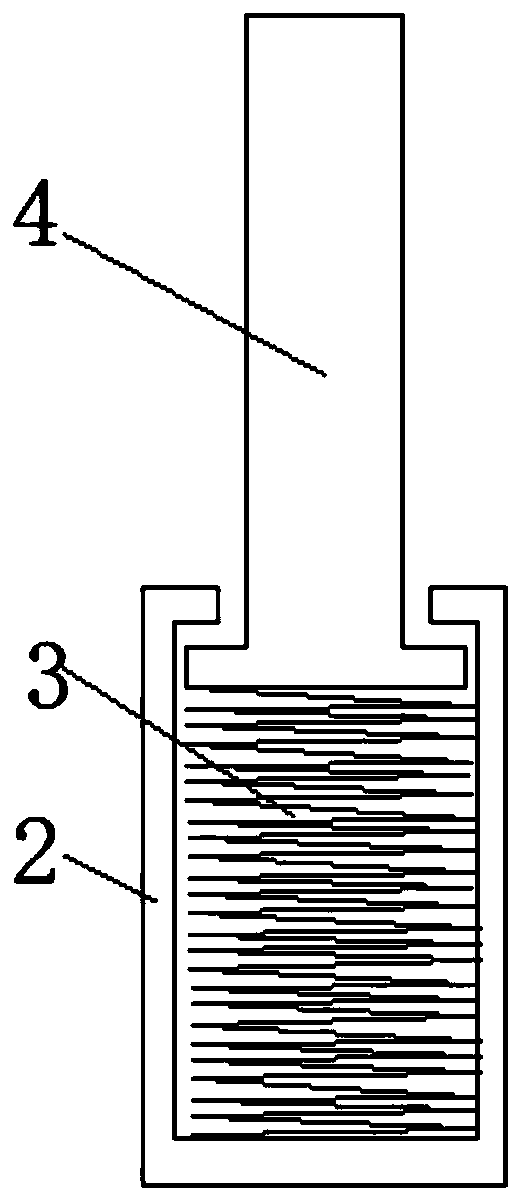

Sewage pump

InactiveCN113153757ASmall granularityExtended service lifeSpecific fluid pumpsPump componentsSewageSump pump

The invention belongs to the technical field of sewage pumps, and discloses a sewage pump. The sewage pump comprises a water pump and a crushing unit. The crushing unit is located at a water pump inlet of the water pump and used for conducting impurity crushing treatment on media flowing to the water pump inlet. The crushing unit comprises a crushing pipeline, a crushing roller and a driver. The inlet end of the crushing pipeline communicates with a to-be-conveyed medium, and the outlet end of the crushing pipeline communicates with an inlet of the water pump. The crushing roller is connected with the driver and located in the crushing pipeline, and the driver can drive the crushing roller to rotate in the crushing pipeline. Crushing blades are arranged on the outer surfaces of the crushing roller, and the ends of the crushing blades are in clearance fit with the inner wall of the crushing pipeline, so that a channel for media to penetrate through the crushing roller to flow to the downstream is formed. According to the sewage pump, impurities in sewage flowing to the water pump can be physically crushed, so that the granularity of the impurities is reduced, protection of the sewage pump is improved, and the sewage pumping efficiency of the whole sewage pump is improved.

Owner:韩景忠

Shredding equipment for construction waste

ActiveCN108906177BSmall footprintTimely processingGrain treatmentsArchitectural engineeringSmall footprint

The invention relates to the field of treatment of building garbage, in particular to a crushing device for building construction garbage. The crushing device comprises a machine body, a hammering crushing apparatus, an extrusion crushing apparatus, an auxiliary apparatus and a uniform swinging apparatus, wherein the hammering crushing apparatus is installed on the inner upper part of the machinebody, a carrier discharging plate is arranged below the hammering crushing apparatus, the extrusion crushing apparatus is arranged below a downstream of the carrier discharging plate, the auxiliary apparatus is installed on the downstream of the carrier discharging plate and comprises a load bearing plate combined with the end part of the carrier discharging plate, the bottom of the carrier discharging plate is provided with a hydraulic rod which is used for driving the downstream end to overturn downwardly, and the uniform swinging apparatus is installed above the extrusion crushing apparatus. By adopting the crushing device, various building garbage of the construction site can be effectively treated, different methods can be used for rapidly crushing the garbage according to the type ofthe garbage, the treated garbage is small in land occupation area, the construction site is not excessively crowded, and after the construction is ended, the garbage can be transported in a centralizing manner.

Owner:CHINA CONSTR FOURTH ENG DIV +1

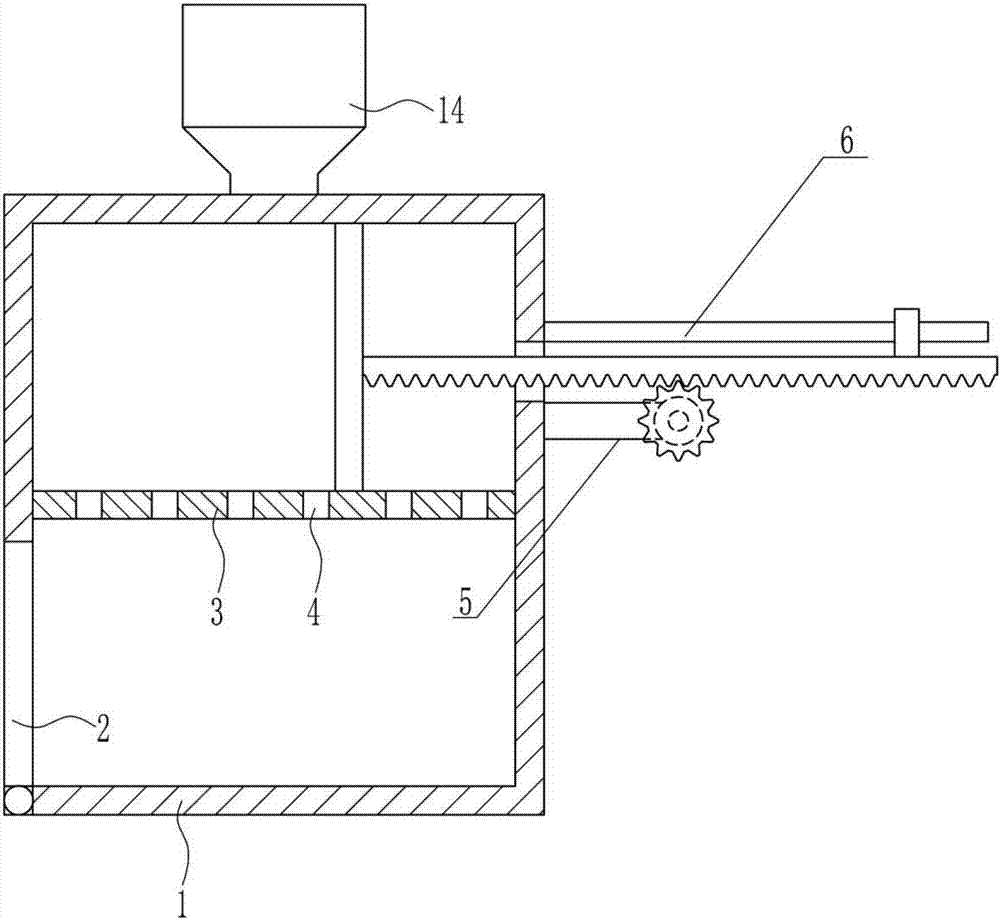

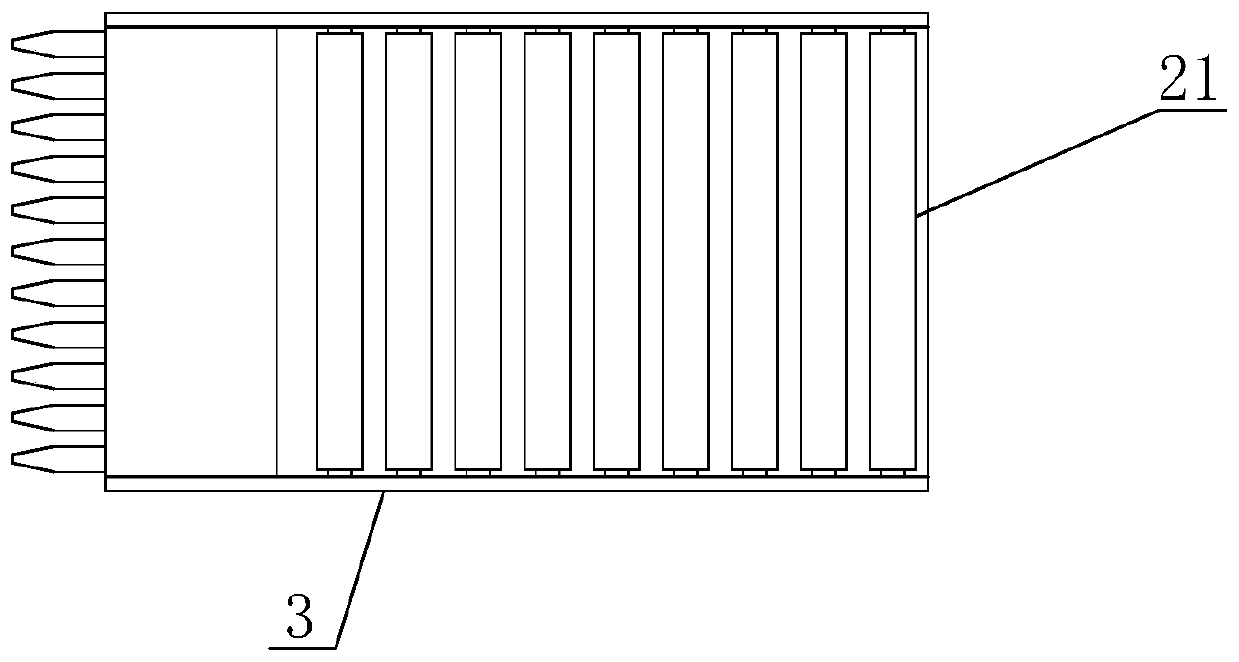

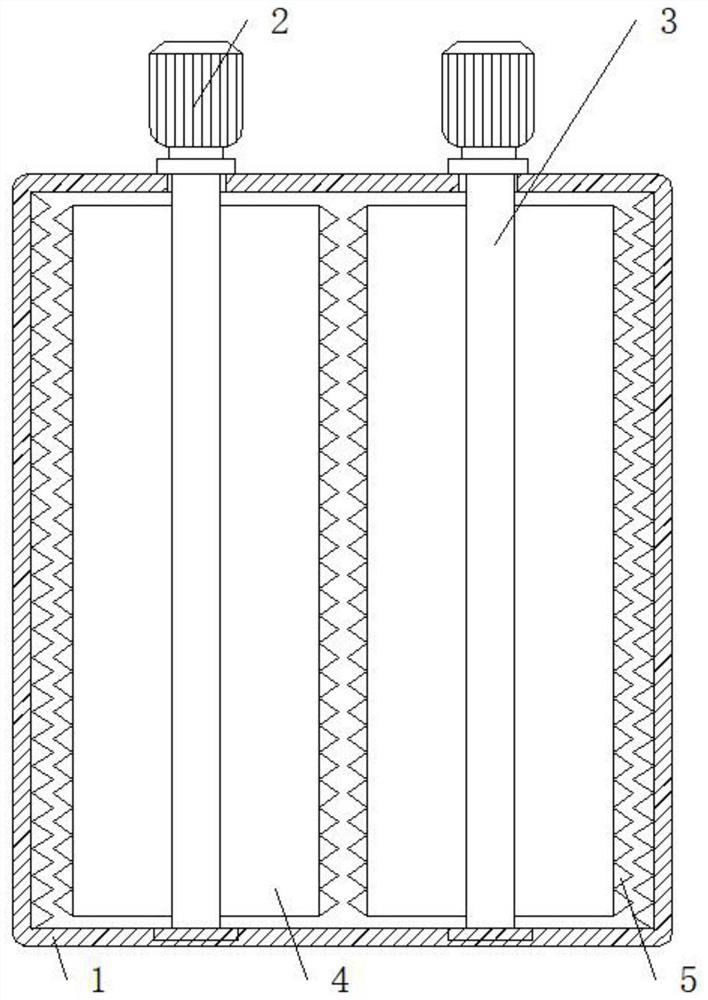

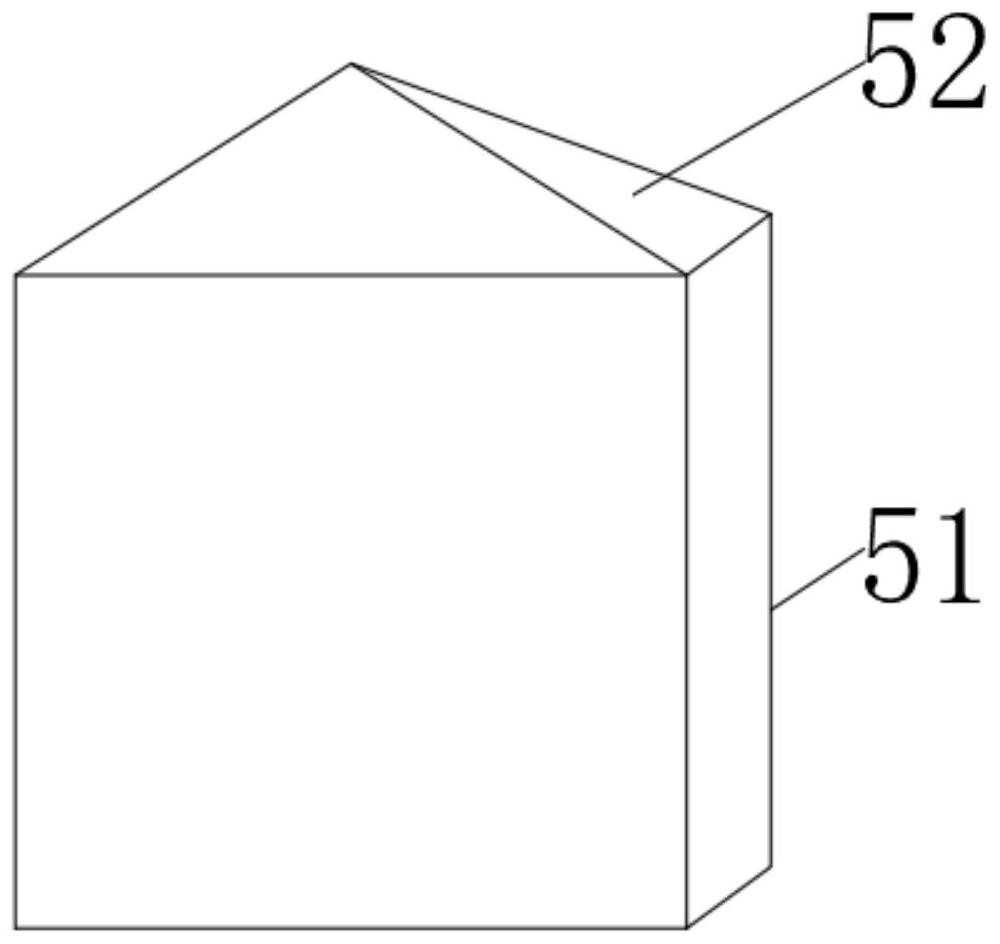

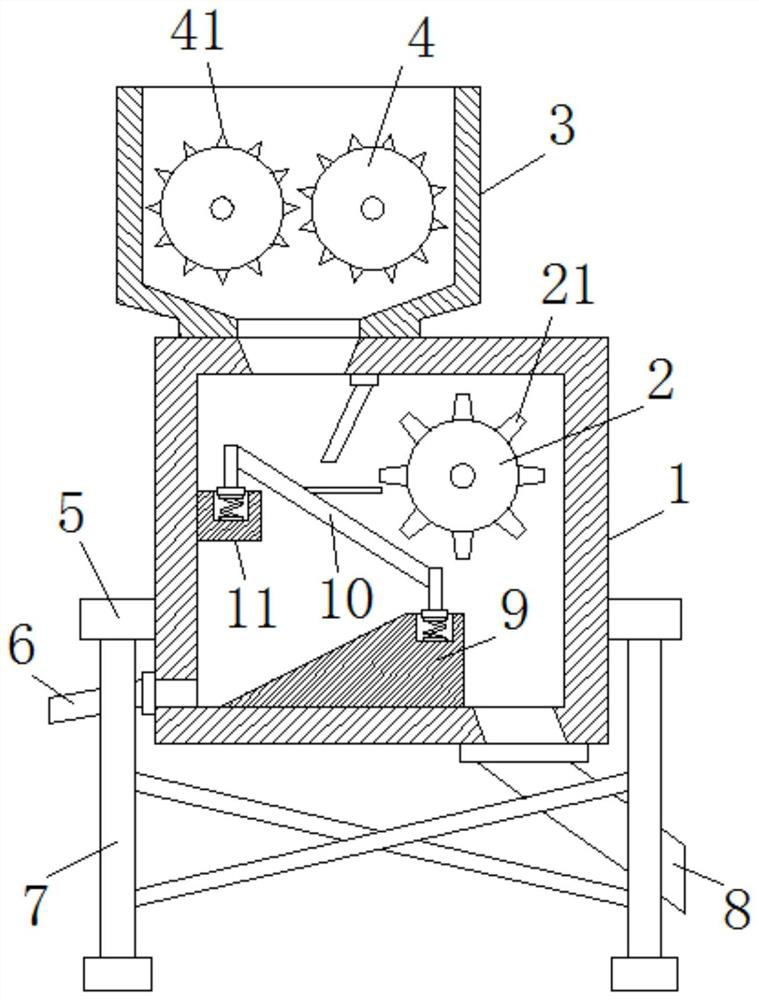

Hammer sheet type smashing device with adjustable hammer sheets

ActiveCN107159384ARapid crushingAccurate crushing and processingPlastic recyclingGrain treatmentsStructural engineeringMachining time

The invention relates to the mechanical field of raw material machining, in particular to a hammer sheet type smashing device with adjustable hammer sheets. A smashing box is arranged on a collection box. The smashing box is provided with a feeding opening. The collection box is composed of a collection box body, a collection device, a box door, a handle, a support and wheels. The support is arranged on the bottom face of one end of the collection box body. The wheels are arranged on the support. The other end of the collection box is provided with the collection device. The side face of the collection box body is provided with the box door. The handle is arranged on the box door. The smashing box is composed of a smashing box body, rotating shafts, covers, handles, a screen net, a transmission device and a smashing device. The rotating shafts are arranged on the smashing box. The rotating shafts are provided with the covers. The handles are arranged on the covers. The hammer sheet type smashing device with the adjustable hammer sheets is simple in structure and convenient and rapid to operate and can rapidly and accurately smash raw materials, save the machining time and improve the machining precision. The length of the hammer sheets can be adjusted according to production needs, repeated disassembly of a machine body of the smashing device is avoided, the work time of workers is saved, and the work efficiency of the workers is improved.

Owner:洛阳蓝斯利科技有限公司

Crushing device for building construction garbage

ActiveCN108906177ASmall footprintTimely processingGrain treatmentsWaste managementBuilding construction

The invention relates to the field of treatment of building garbage, in particular to a crushing device for building construction garbage. The crushing device comprises a machine body, a hammering crushing apparatus, an extrusion crushing apparatus, an auxiliary apparatus and a uniform swinging apparatus, wherein the hammering crushing apparatus is installed on the inner upper part of the machinebody, a carrier discharging plate is arranged below the hammering crushing apparatus, the extrusion crushing apparatus is arranged below a downstream of the carrier discharging plate, the auxiliary apparatus is installed on the downstream of the carrier discharging plate and comprises a load bearing plate combined with the end part of the carrier discharging plate, the bottom of the carrier discharging plate is provided with a hydraulic rod which is used for driving the downstream end to overturn downwardly, and the uniform swinging apparatus is installed above the extrusion crushing apparatus. By adopting the crushing device, various building garbage of the construction site can be effectively treated, different methods can be used for rapidly crushing the garbage according to the type ofthe garbage, the treated garbage is small in land occupation area, the construction site is not excessively crowded, and after the construction is ended, the garbage can be transported in a centralizing manner.

Owner:CHINA CONSTR FOURTH ENG DIV +1

Cement kiln solid waste treatment device and treatment method

PendingCN113102018ARapid crushingEasy to put inIncinerator apparatusGrain treatmentsThermodynamicsProcess engineering

The invention discloses a cement kiln solid waste treatment device and a treatment method and relates to the technical field of waste treatment. Aiming at the problem that an existing cement kiln is low in solid waste treatment efficiency, the following scheme is provided; the cement kiln solid waste treatment device comprises a shell, a crushing mechanism is arranged in the shell, a stop block is connected to the interior of the shell in a sliding mode, a connecting mechanism is arranged on the shell, the stop block is connected to the interior of the shell through the connecting mechanism, the stop block is located below the crushing mechanism, and feeding grooves are formed in the two ends of the stop block. According to the cement kiln solid waste treatment device, solid waste can be quickly crushed, so that a user can conveniently throw the solid waste into a combustion furnace of a cement kiln, and therefore, the treatment efficiency of the solid waste is effectively improved; and moreover, a feeding part of the treatment device can be effectively sealed and protected, the user can conveniently take out the treated solid waste, and therefore, the treatment progress of the solid waste is effectively improved, and the working performance is high.

Owner:HWASU

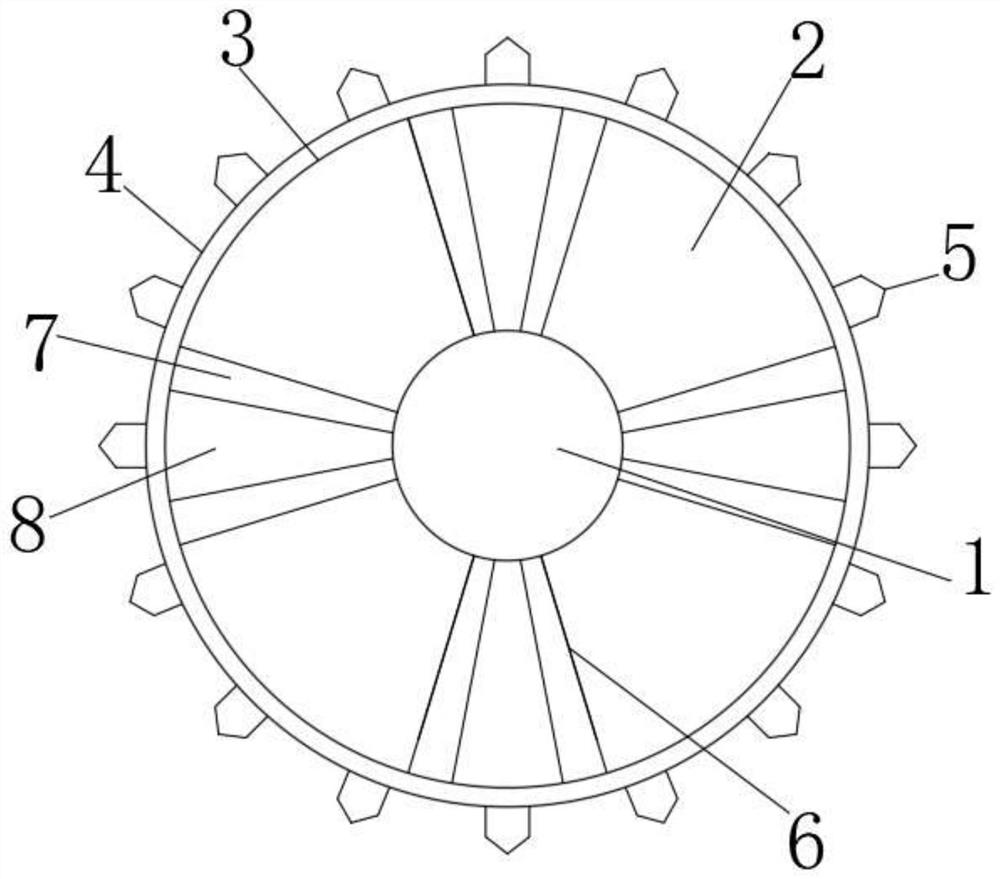

Breaking hammer for pavement patching

PendingCN114108435AAvoid causing increased problemsSmall broken areaRoads maintainenceCircular discDrive shaft

The breaking hammer for pavement patching comprises a fixed disc, a driving shaft rod is inserted into the axis of the fixed disc in a penetrating mode, breaking teeth are fixedly connected to the middle of the side surface of the fixed disc at equal intervals, and mounting grooves are formed in the two edges of the side surface of the fixed disc. During specific use, the fixed disc is driven by the crushing device to rotate, the beneficial effects of rotating crushing are that the crushing area is small, the damage degree is small, the damaged part at the joint can be quickly crushed, and when the depth of the crushed part is large, the crushing teeth downwards crush, so that the crushing effect is good. And the annular crushing mechanism can crush the two side surfaces of the crushing groove, so that the rule of a crushing surface is ensured, and the problem that the crushing surface is increased due to a traditional crushing device and the attractiveness after later repair is not facilitated is also avoided. And the fine grinding surface and the rough grinding surface can grind the crushed groove wall, so that after the crushed groove wall is repaired in the later period, the appearance is attractive, and the service life is prolonged.

Owner:安徽丰林建设工程有限公司

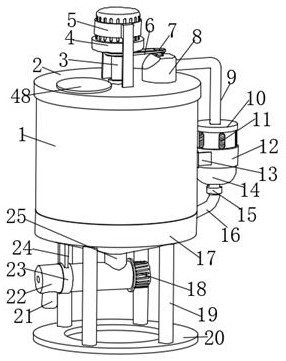

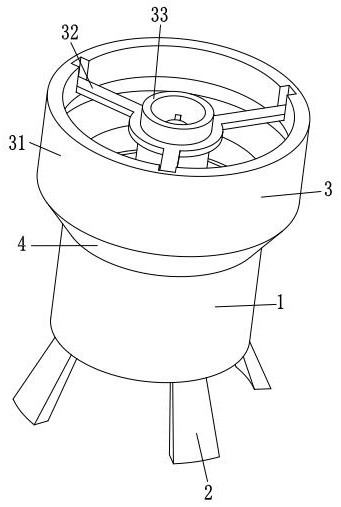

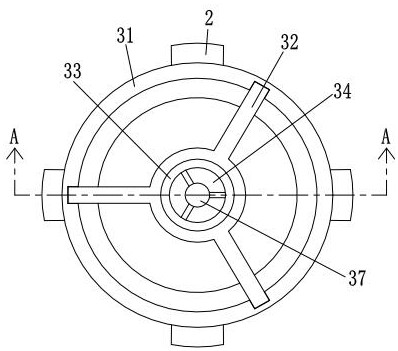

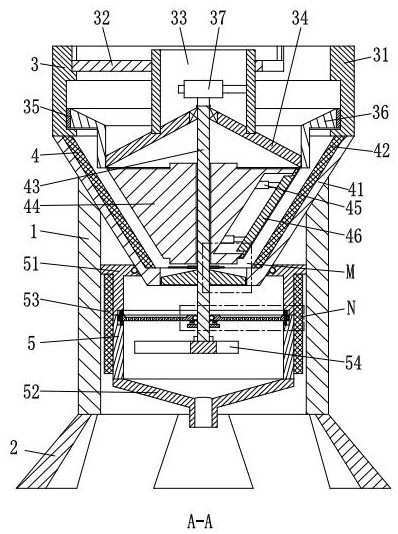

A segmented drying treatment device for organic fertilizer materials, livestock and poultry manure

ActiveCN113566550BEasy to fall intoAvoid accumulationManure dryingDrying machine combinationsBiotechnologyAgricultural science

The invention relates to the technical field of organic fertilizer production, in particular to a segmented drying treatment device for organic fertilizer materials, livestock and poultry manure, which includes a material cylinder, a foot, a feeding device, a rough drying device and a fine drying device; the lower end of the material cylinder The outer wall is evenly provided with feet, the upper end of the material cylinder is provided with a rough drying device, the upper end of the rough drying device is provided with a feeding device, and the inside of the material cylinder is provided with a fine drying device; The following problems mainly exist: in the process of drying feces each time, a large amount of feces is concentrated and dried, resulting in too much feces during the drying process, which seriously affects the drying efficiency. The condition of internal humidity; and the dried feces are easy to condense into lumps, which affects the use effect of subsequent feces; the invention ensures the drying effect of animal feces and improves the drying efficiency of animal feces.

Owner:JIANGSU HANLING FERTILIZER IND

Crushed stone processing equipment for bridge engineering construction

ActiveCN108570906BAchieve brokenRealize extrusion crushingRoads maintainenceBridge engineeringCrushed stone

The invention discloses macadam processing equipment for bridge engineering construction. The macadam processing equipment comprises a shell, a crushing chamber, an extrusion conveying chamber and a rolling chamber, wherein the crushing chamber is arranged at the upper right side of the shell, a feeding inlet is arranged at the left side of the top of the crushing chamber, and the crushing chamberis in communication with the feeding inlet; the extrusion conveying chamber is obliquely located at the bottom of the right side of the shell, the right side of the top of the extrusion conveying chamber is in communication with the right side at the bottom of the crushing chamber, the rolling chamber is located on the left side of the bottom of the shell, the left side of the extrusion conveyingchamber is in communication with the rolling chamber, and a second working motor is located on the top of the rolling chamber; a first connecting rod is welded on the left side of the second workingmotor, a vertical guide rail is fixedly welded at the upper part of the left side wall of the rolling chamber, and the left end of the first connecting rod extends into the vertical guide rail. The macadam processing equipment has high working efficiency, saves time and labor, and can carry out multi-stage pulverization on stones and lower the difficulty of crushing stones.

Owner:天长市富春建筑工程有限公司

A kind of bamboo crushing machine

The invention discloses a bamboo rolling and crushing machine comprising a feeding hopper, a vibration device, a conveying device, a crushing device and a storage bin; the vibration device is located in the feeding hopper; a feeding hole and a discharging hole are formed in the feeding hopper; the discharging hole is connected with the conveying device; the conveying device is connected with a power source and the crushing device; the crushing device comprises a first crushing mechanism, a second crushing mechanism, a driving device and a guide table; the driving device is connected with the first crushing mechanism and the second crushing mechanism which are located on the guide table; and the guide table can be connected with the conveying device and the storage bin. The bamboo rolling and crushing machine is novel in structure, convenient to use, capable of rapidly rolling and crushing standard bamboo chips to generate a lateral pultrusion tearing effect and incapable of generating a great number of scatterable shred residues so as to be beneficial to the obtaining of overlong bamboo fibers and great reduction of loss of bamboo gadolinium in the bamboo fibers.

Owner:福建神采新材料科技有限公司

cement production crusher

ActiveCN112058402BRapid crushingImprove crushing efficiencySievingScreeningDrive shaftElectric machine

The invention relates to the technical field of cement production, in particular to a crusher for cement production, which includes a crushing cylinder, the top of the crushing cylinder is fixedly sleeved with a cylinder cover, and a feeding port is opened on the cylinder cover, and the feeding port A flip cover is installed at the place, and a crushing mechanism is arranged inside the crushing cylinder, and the crushing mechanism includes a motor frame fixedly installed at the middle position of the top end of the cylinder cover, and a first motor is fixedly mounted inside the motor frame, and the first The end of the output shaft of the motor is vertically connected with the main drive shaft, the main drive shaft extends through the cylinder cover to the inside of the crushing cylinder, and a U-shaped frame is fixedly installed at the end, and the inner two ends of the U-shaped frame are rotated and installed There are rollers. Compared with the prior art, the present invention has high crushing efficiency and good crushing uniformity, and also has a dust-absorbing effect, reduces the pollution of the working environment, and reduces the waste of raw materials.

Owner:唐山兴唐建材有限公司

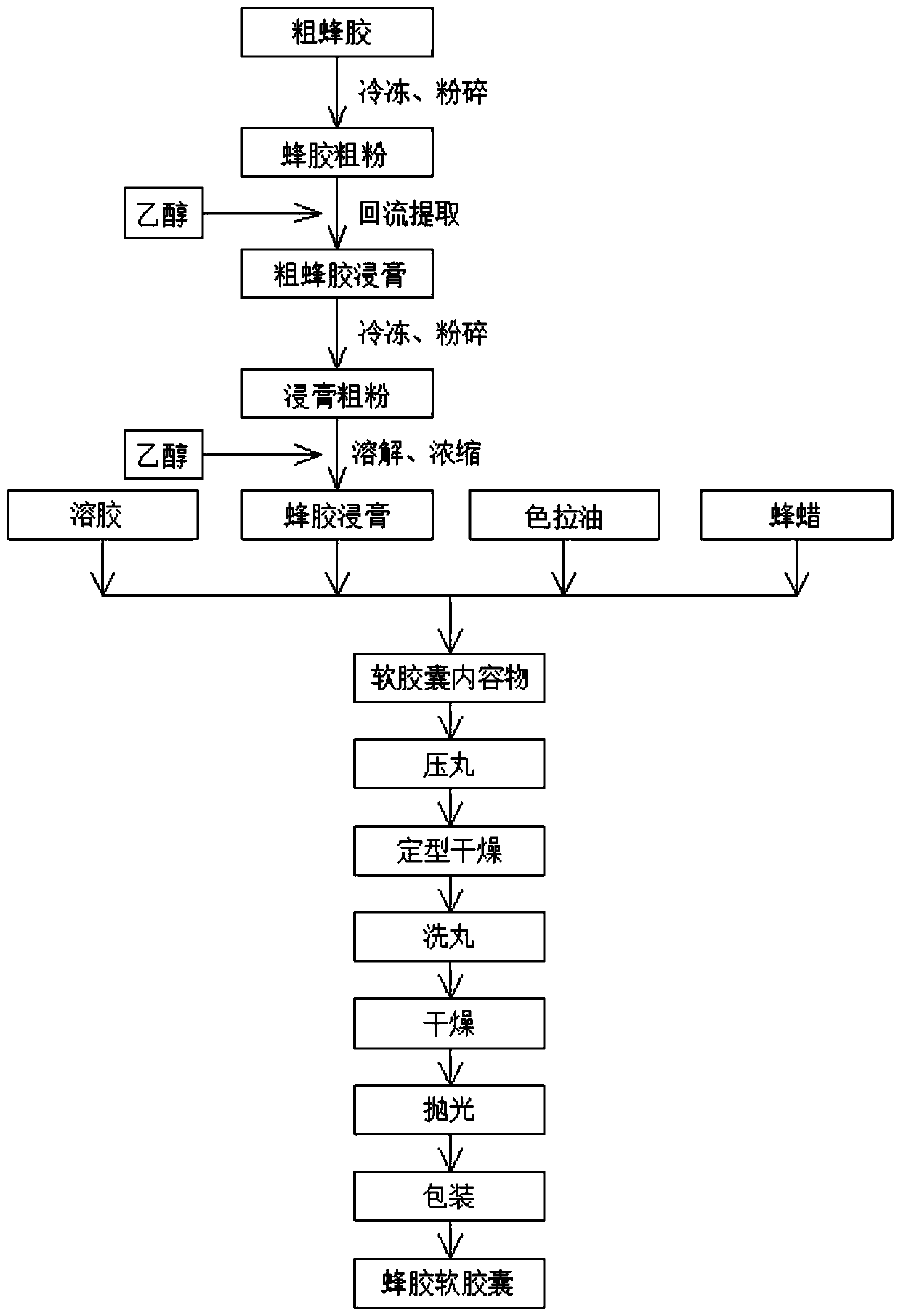

Preparation method of high-purity propolis soft capsule

PendingCN111011792AIncrease propolis contentPromote absorptionFood freezingLipidic food ingredientsBiotechnologySoftgel

The invention provides a preparation method of a high-purity propolis soft capsule. The preparation method comprises the following steps: 1) filtering crude propolis to remove impurities in the crudepropolis; 2) freezing the filtered crude propolis, and crushing the frozen crude propolis into coarse propolis powder; (3) carrying out reflux extraction on the coarse propolis powder by using ethanol, conducting filtering after extraction, and recovering ethanol from an extract under reduced pressure after filtering to obtain a crude propolis extract; 4) freezing the crude propolis extract, crushing the frozen crude propolis extract into coarse extract powder, soaking and dissolving the coarse extract powder with ethanol at normal temperature, and successively conducting filtering and concentrating to obtain a propolis extract; 5) preparing a sol; 6) keeping the sol at a temperature of 50-60 DEG C, and sequentially adding the propolis extract, salad oil and beewax until all the componentsare completely dissolved to obtain a soft capsule content; and 7) sequentially subjecting the soft capsule content to pill pressing, shaping, drying, pill washing, drying, polishing and packaging soas to obtain the propolis soft capsule. With the preparation method of the invention, the propolis content of the propolis soft capsule can be effectively increased, and the absorption of nutrients isfacilitated.

Owner:江苏鸿祺生物科技有限公司

Sealing paper storage and protection device

ActiveCN111013786AEasy to store independentlyAvoid influenceMechanical energy handlingGrain treatmentsDrive shaftElectric machinery

Owner:HUBEI XINGLONG PACKAGING MATERIAL

Feeding hopper with pretreatment function for movable crushing station

InactiveCN112318778ARapid crushingPrevent jumpingPlastic recyclingMechanical material recoveryWater filterStructural engineering

The invention discloses a feeding hopper with a pretreatment function for a movable crushing station. The feeding hopper with the pretreatment function for the movable crushing station comprises a first hopper body, a pushing roller is rotationally installed in the first hopper body, a first supporting mechanism is fixedly installed on the inner bottom wall of the first hopper body, and a second supporting mechanism is fixedly installed on the inner side wall of the first hopper body. A water filtering mechanism is commonly and fixedly installed between the second supporting mechanism and thefirst supporting mechanism, a water discharging pipe is fixedly installed on the outer side wall of the first hopper body, a discharging pipeline is fixedly installed at the bottom end of the first hopper body, a second hopper body is fixedly installed at the top end of the first hopper body, and two pressing rollers are symmetrically and rotationally installed in the second hopper body. The feeding hopper with the pretreatment function for the movable crushing station has the beneficial effects that a plastic bottle is flattened through the second hopper body, compared with a cylindrical bottle body, the flat plastic bottle is easier to cut and crush after entering a crushing station, the situation that the plastic bottle jumps between crushing rollers installed in the crushing station and cannot be sheared can be prevented, and the crushing efficiency of the plastic bottle is greatly improved.

Owner:磊蒙智能装备(湖北)有限公司

Large particle coke fragmentation and differentiation device

The invention discloses a large particle coke fragmentation and differentiation device. The large particle coke fragmentation and differentiation device comprises a pressing part and an extruding part. The pressing part comprises a horizontal type cylinder. The upper part of the cylinder is provided with an extruding platform. The extruding platform is provided with a group of opposite supportingplates. The upper part of one supporting plate is provided with two stand columns. The upper ends of the four stand columns are provided with a pressing plate. A pressing cam is arranged above the pressing plate, and the pair of supporting plates are internally provided with a pair of limiting extrusion plates. The extrusion part comprises a bottom plate. The bottom plate is provided with two hinged bases. The hinged bases are provided with extruding blocks. The opposite faces of the two extruding blocks are provided with semi-circular grooves. A hollow cylinder formed after the two extrudingblocks are combined and the cylinder are coaxial. The parts, located above the semi-circular grooves, of the extrusion blocks are extruding faces. The large particle coke fragmentation and differentiation device is used for large coke with relatively high hardness, rapid extrusion fragmentation can be carried out on site, and later blast furnace ironmaking is facilitated.

Owner:JIANGSU SURUN HIGH CARBON

Sectional type drying treatment device for organic fertilizer material livestock and poultry manure

ActiveCN113566550AEasy to fall intoAvoid accumulationManure dryingDrying machine combinationsAgricultural scienceAgricultural engineering

The invention relates to the technical field of organic fertilizer production, in particular to a sectional type drying treatment device for organic fertilizer material livestock and poultry manure. The sectional type drying treatment device comprises a material barrel, supporting legs, a feeding device, a coarse drying device and a fine drying device, wherein the supporting legs are uniformly arranged on the outer wall of the lower end of the material barrel, the coarse drying device is arranged at the upper end of the material barrel, the feeding device is arranged at the upper end of the coarse drying device, and the fine drying device is arranged inside the material barrel. The sectional type drying treatment device solves the following main problems in the process of drying the animal manure at present: most of the manure is subjected to centralized drying treatment in the process of drying the manure each time, so that the drying efficiency is seriously influenced due to the fact that the amount of the manure is too large in the drying process, and the condition that the surface of the manure is dried and the interior of the manure is wet exists; and the dried manure is prone to being condensed into blocks, so that the use effect of the subsequent manure is influenced. According to the sectional type drying treatment device, the drying effect of the animal manure is guaranteed, and the drying efficiency of the animal manure is improved.

Owner:JIANGSU HANLING FERTILIZER IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com